NISSAN LATIO 2009 Service Repair Manual

Manufacturer: NISSAN, Model Year: 2009, Model line: LATIO, Model: NISSAN LATIO 2009Pages: 4331, PDF Size: 58.04 MB

Page 131 of 4331

OK >> GO TO 5.

NG >> GO TO 2. OK >> GO TO 5.

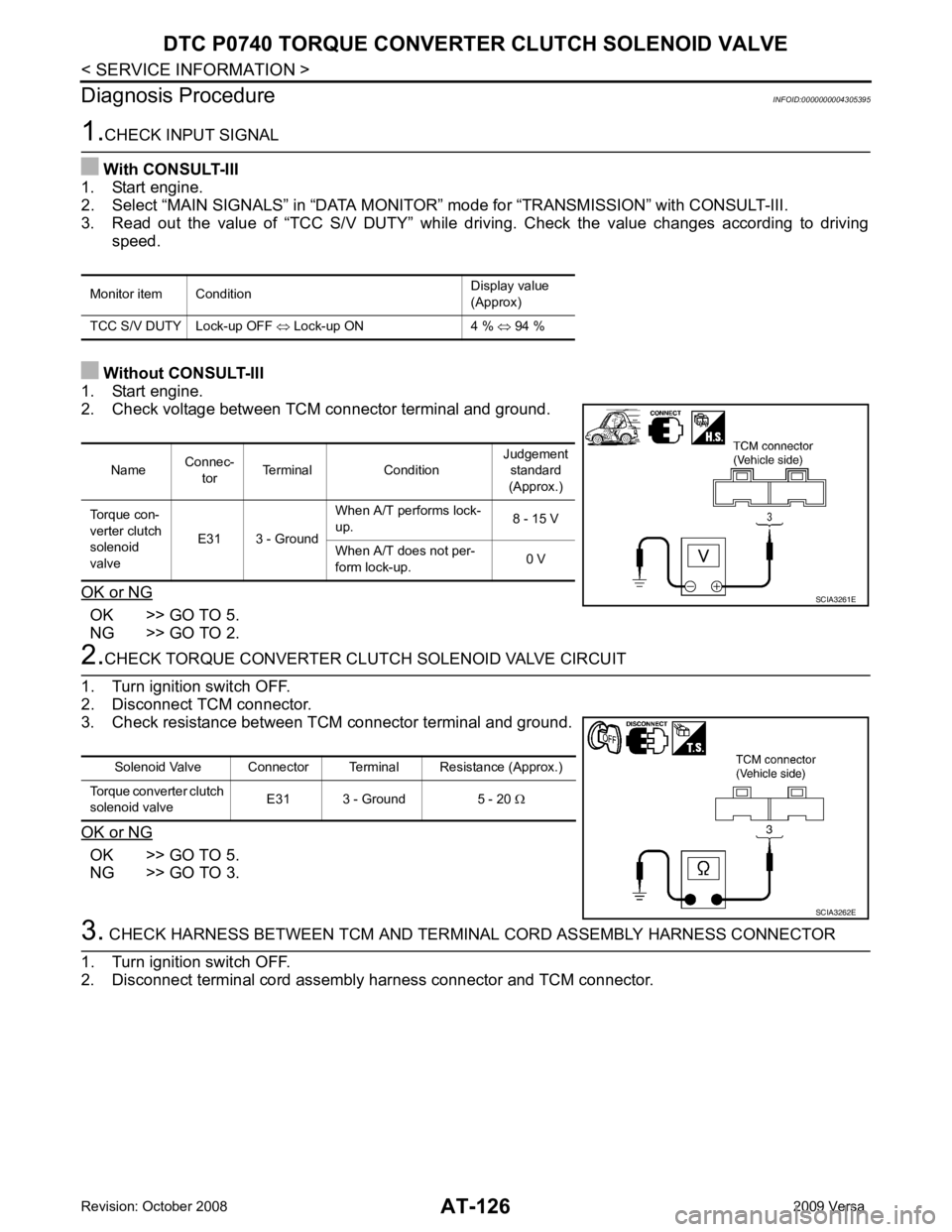

NG >> GO TO 3. Name

Connec-

tor Terminal Condition Judgement

standard

(Approx.)

Torque con-

verter clutch

solenoid

valve E31 3 - Ground When A/T performs lock-

up. 8 - 15 V

When A/T does not per-

form lock-up. 0 V

Page 132 of 4331

AT

N

O P

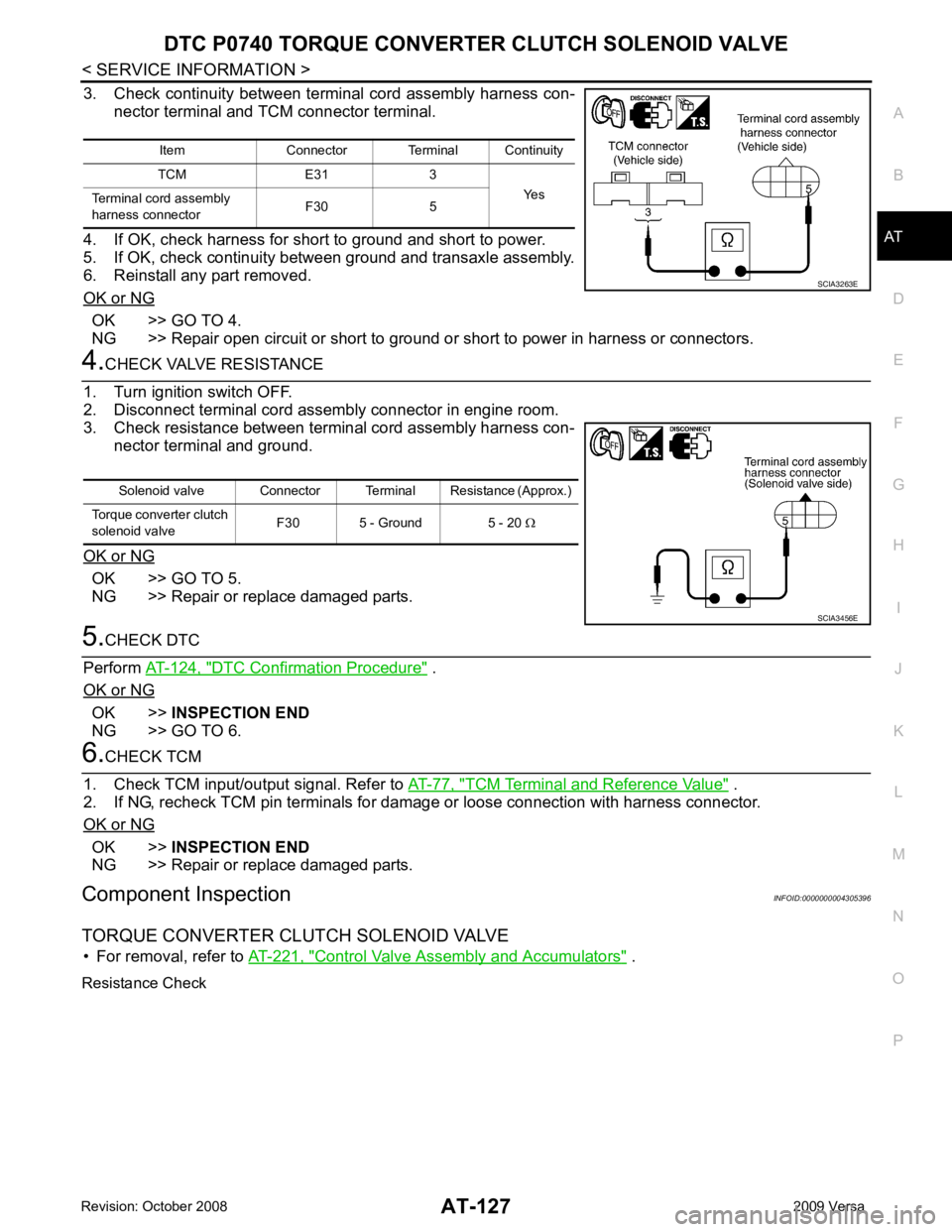

3. Check continuity between terminal cord assembly harness con-

nector terminal and TCM connector terminal.

4. If OK, check harness for short to ground and short to power.

5. If OK, check continuity between ground and transaxle assembly.

6. Reinstall any part removed.

OK or NG OK >> GO TO 4.

NG >> Repair open circuit or short to ground or short to power in harness or connectors. OK >> GO TO 5.

NG >> Repair or replace damaged parts. DTC Confirmation Procedure " .

OK or NG OK >>

INSPECTION END

NG >> GO TO 6. TCM Terminal and Reference Value " .

2. If NG, recheck TCM pin terminals for dam age or loose connection with harness connector.

OK or NG OK >>

INSPECTION END

NG >> Repair or replace damaged parts.

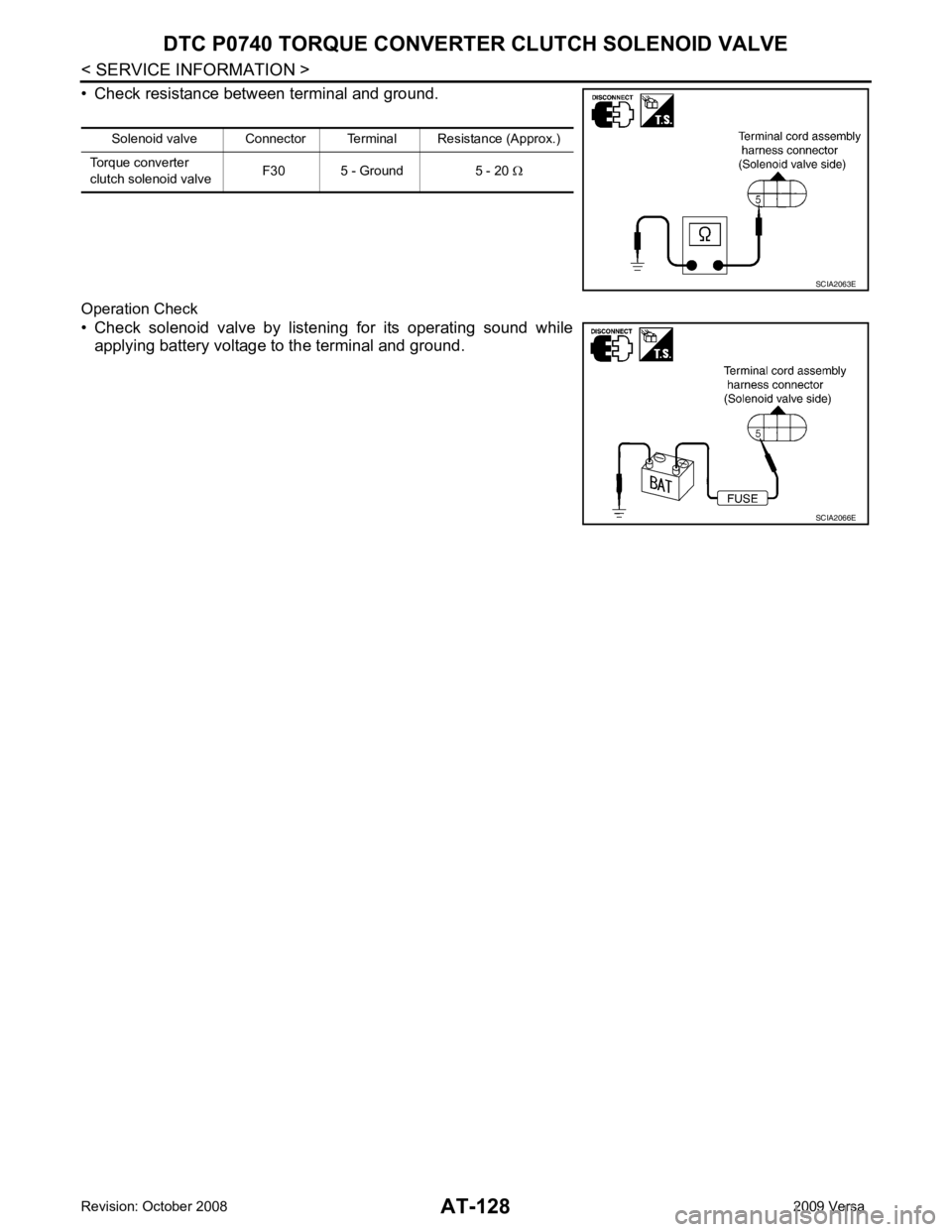

Component Inspection INFOID:0000000004305396

TORQUE CONVERTER CLUTCH SOLENOID VALVE • For removal, refer to AT-221, " Control Valve Assembly and Accumulators " .

Resistance Check Item Connector Terminal Continuity

TCM E31 3 Yes

Terminal cord assembly

harness connector F30 5

Page 133 of 4331

SCIA2066E

Page 134 of 4331

AT

N

O P

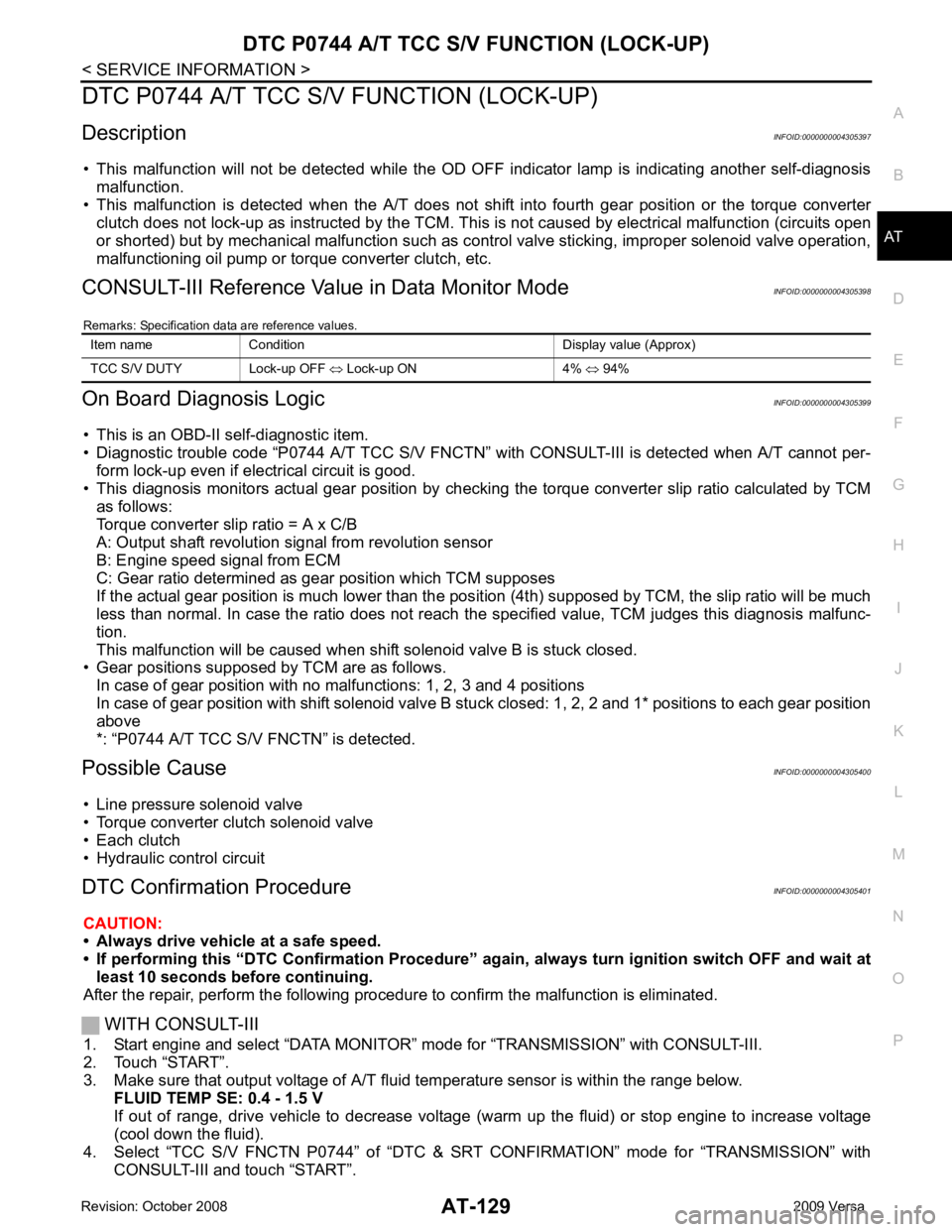

DTC P0744 A/T TCC S/V FUNCTION (LOCK-UP)

Description INFOID:0000000004305397

• This malfunction will not be detected while the OD OFF indicator lamp is indicating another self-diagnosis malfunction.

• This malfunction is detected when the A/T does not shif t into fourth gear position or the torque converter

clutch does not lock-up as instructed by the TCM. This is not caused by electrical malfunction (circuits open

or shorted) but by mechanical malfunction such as c ontrol valve sticking, improper solenoid valve operation,

malfunctioning oil pump or torque converter clutch, etc.

CONSULT-III Reference Val ue in Data Monitor Mode INFOID:0000000004305398

Remarks: Specification data are reference values.

On Board Diagnosis Logic INFOID:0000000004305399

• This is an OBD-II self-diagnostic item.

• Diagnostic trouble code “P0744 A/T TCC S/V FNCTN” wi th CONSULT-III is detected when A/T cannot per-

form lock-up even if electrical circuit is good.

• This diagnosis monitors actual gear position by checki ng the torque converter slip ratio calculated by TCM

as follows:

Torque converter slip ratio = A x C/B

A: Output shaft revolution signal from revolution sensor

B: Engine speed signal from ECM

C: Gear ratio determined as gear position which TCM supposes

If the actual gear position is much lower than the pos ition (4th) supposed by TCM, the slip ratio will be much

less than normal. In case the ratio does not reach t he specified value, TCM judges this diagnosis malfunc-

tion.

This malfunction will be caused when shift solenoid valve B is stuck closed.

• Gear positions supposed by TCM are as follows.

In case of gear position with no malfunctions: 1, 2, 3 and 4 positions

In case of gear position with shift solenoid valve B stu ck closed: 1, 2, 2 and 1* positions to each gear position

above

*: “P0744 A/T TCC S/V FNCTN” is detected.

Possible Cause INFOID:0000000004305400

• Line pressure solenoid valve

• Torque converter clutch solenoid valve

• Each clutch

• Hydraulic control circuit

DTC Confirmation Procedure INFOID:0000000004305401

CAUTION:

• Always drive vehicle at a safe speed.

• If performing this “DTC Confirmation Procedure” again, always turn ignition switch OFF and wait at

least 10 seconds before continuing.

After the repair, perform the following procedure to confirm the malfunction is eliminated.

WITH CONSULT-III

1. Start engine and select “DATA MONITOR” m ode for “TRANSMISSION” with CONSULT-III.

2. Touch “START”.

3. Make sure that output voltage of A/T fluid temperature sensor is within the range below. FLUID TEMP SE: 0.4 - 1.5 V

If out of range, drive vehicle to decrease voltage (warm up the fluid) or stop engine to increase voltage

(cool down the fluid).

4. Select “TCC S/V FNCTN P0744” of “DTC & SR T CONFIRMATION” mode for “TRANSMISSION” with

CONSULT-III and touch “START”.

Item name Condition Display value (Approx)

TCC S/V DUTY Lock-up OFF ⇔ Lock-up ON 4% ⇔ 94%

Page 135 of 4331

AT-130< SERVICE INFORMATION >

DTC P0744 A/T TCC S/V FUNCTION (LOCK-UP)

5. Accelerate vehicle to more than 80 km/h (50 MPH) and maintain the following conditions continuously until “TESTING” has turned to “COMPLETE”. (It wi ll take approximately 30 seconds after “TESTING”

shows.)

THROTTLE POSI: 1.0/8 - 2.0/8 (at all times during step 4)

SLCT LVR POSI: “D” position

TCC S/V DUTY: More than 94%

VEHICLE SPEED: Constant speed of more than 80 km/h (50 MPH)

- Make sure that “GEAR” shows “4”.

- For shift schedule, refer to AT-64, " Vehicle Speed at Which Gear Shifting Occurs " .

- If “TESTING” does not ap pear on CONSULT-III for a long ti me, select “SELF-DIAG RESULTS”. In

case a DTC other than “P0744 A/T TCC S/ V FNCTN” is shown, refer to AT-79, " CONSULT-III Func-

tion (TRANSMISSION) " .

6. Make sure that “OK” is displayed. (If “NG” is displayed, refer to “DIAGNOSTIC PROCEDURE”.)

Refer to AT-130, " Diagnosis Procedure " .

Refer to AT-64, " Vehicle Speed at Which Lock-up Occurs/Releases " .

WITH GST

Follow the procedure “WITH CONSULT-III”.

Diagnosis Procedure INFOID:00000000043054021.

CHECK SHIFT-UP (D 3 TO D 4)

During AT-58, " Cruise Test - Part 1 " .

Does A/T shift from D 3 to D 4 at the specified speed?

YES >> GO TO 11.

NO >> GO TO 2. 2.

CHECK LINE PRESSURE

Perform line pressure test. Refer to AT-51, " Inspections Before Trouble Diagnosis " .

OK or NG OK >> GO TO 3.

NG >> GO TO 6. 3.

CHECK CONTROL VALVE

1. Disassemble control valve assembly. Refer to AT-280, " Control Valve Assembly " .

2. Check to ensure that:

- Valve, sleeve and plug slide along valve bore under their own weight.

- Valve, sleeve and plug are free from burrs, dents and scratches.

- Control valve springs are free from damage, deformation and fatigue.

- Hydraulic line is free from obstacles.

OK or NG OK >> GO TO 4.

NG >> Repair control valve. 4.

CHECK SHIFT-UP (D 3 TO D 4) SCIA7190E

Page 136 of 4331

DTC P0744 A/T TCC S/

V FUNCTION (LOCK-UP)

AT-131

< SERVICE INFORMATION >

D

E

F

G H

I

J

K L

M A

B AT

N

O P

During

AT-58, " Cruise Test - Part 1 " .

Does A/T shift from D 3 to D 4 at the specified speed?

YES >> GO TO 5.

NO >> Check control valve again. Repair or replace control valve assembly. 5.

CHECK DTC

Perform AT-129, " DTC Confirmation Procedure " .

OK or NG OK >>

INSPECTION END

NG >> GO TO 11. Check for proper lock-up. 6.

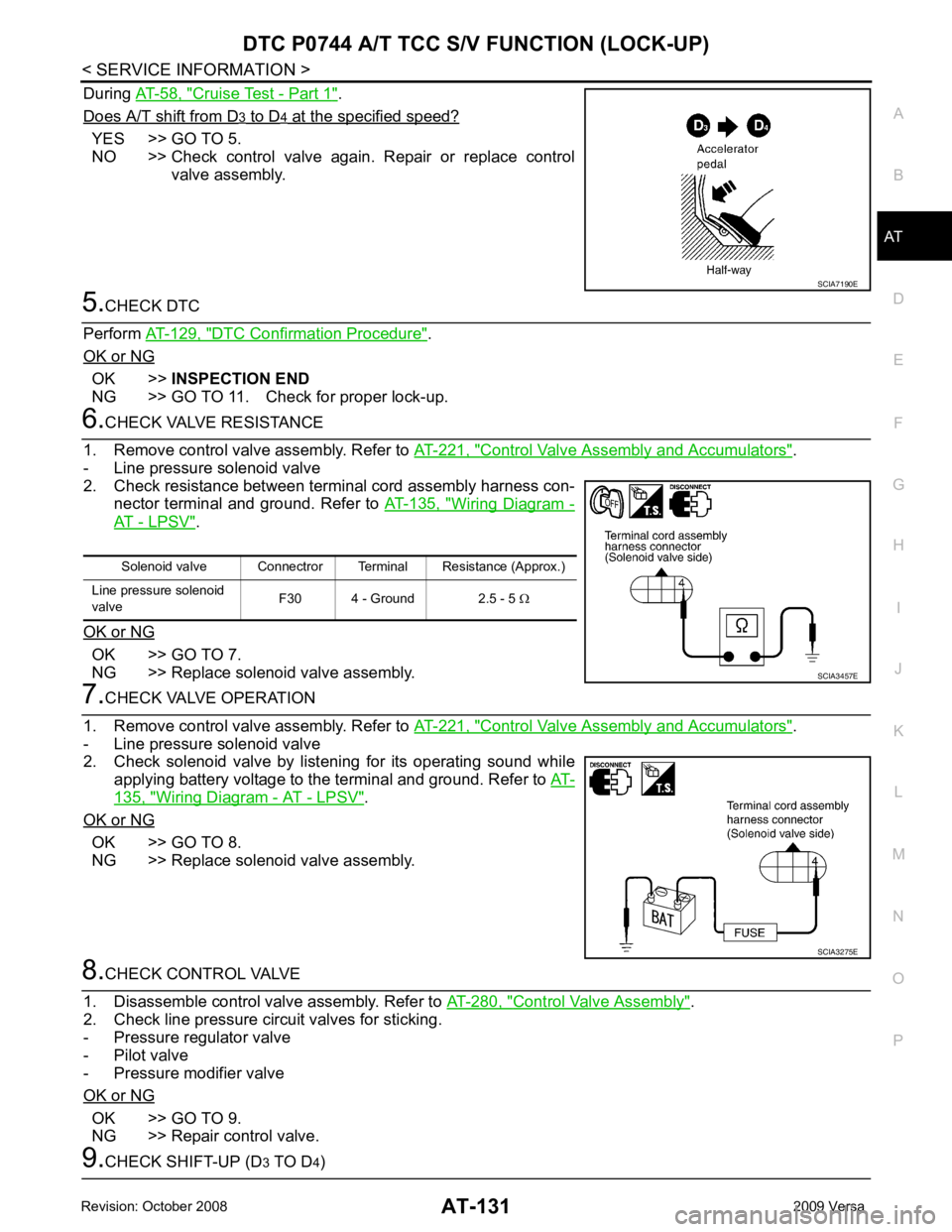

CHECK VALVE RESISTANCE

1. Remove control valve assembly. Refer to AT-221, " Control Valve Assembly and Accumulators " .

- Line pressure solenoid valve

2. Check resistance between terminal cord assembly harness con- nector terminal and ground. Refer to AT-135, " Wiring Diagram -

AT - LPSV " .

OK or NG OK >> GO TO 7.

NG >> Replace solenoid valve assembly. 7.

CHECK VALVE OPERATION

1. Remove control valve assembly. Refer to AT-221, " Control Valve Assembly and Accumulators " .

- Line pressure solenoid valve

2. Check solenoid valve by listening for its operating sound while

applying battery voltage to the terminal and ground. Refer to AT-135, " Wiring Diagram - AT - LPSV " .

OK or NG OK >> GO TO 8.

NG >> Replace solenoid valve assembly. 8.

CHECK CONTROL VALVE

1. Disassemble control valve assembly. Refer to AT-280, " Control Valve Assembly " .

2. Check line pressure circuit valves for sticking.

- Pressure regulator valve

- Pilot valve

- Pressure modifier valve

OK or NG OK >> GO TO 9.

NG >> Repair control valve. 9.

CHECK SHIFT-UP (D 3 TO D 4) SCIA7190E

Solenoid valve Connectror Terminal Resistance (Approx.)

Line pressure solenoid

valve F30 4 - Ground 2.5 - 5

Ω SCIA3457E

SCIA3275E

Page 137 of 4331

AT-132< SERVICE INFORMATION >

DTC P0744 A/T TCC S/V FUNCTION (LOCK-UP)

During AT-58, " Cruise Test - Part 1 " .

Does A/T shift from D 3 to D 4 at the specified speed?

YES >> GO TO 10.

NO >> Check control valve again. Repair or replace control valve assembly. 10.

CHECK DTC

Perform AT-129, " DTC Confirmation Procedure " .

OK or NG OK >>

INSPECTION END

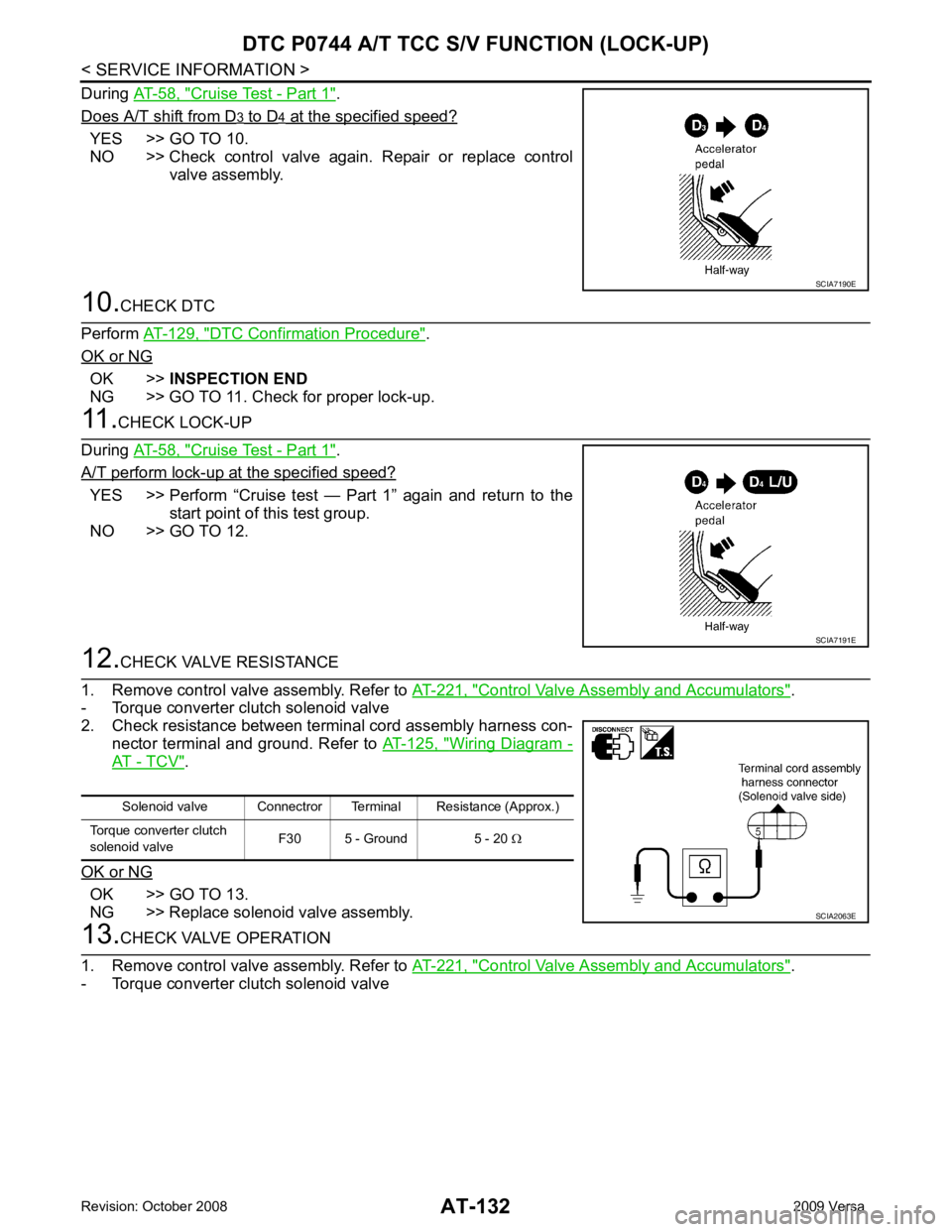

NG >> GO TO 11. Check for proper lock-up. 11.

CHECK LOCK-UP

During AT-58, " Cruise Test - Part 1 " .

A/T perform lock-up at the specified speed? YES >> Perform “Cruise test — Part 1” again and return to the

start point of this test group.

NO >> GO TO 12. 12.

CHECK VALVE RESISTANCE

1. Remove control valve assembly. Refer to AT-221, " Control Valve Assembly and Accumulators " .

- Torque converter clutch solenoid valve

2. Check resistance between terminal cord assembly harness con-

nector terminal and ground. Refer to AT-125, " Wiring Diagram -

AT - TCV " .

OK or NG OK >> GO TO 13.

NG >> Replace solenoid valve assembly. 13.

CHECK VALVE OPERATION

1. Remove control valve assembly. Refer to AT-221, " Control Valve Assembly and Accumulators " .

- Torque converter clutch solenoid valve SCIA7190E

SCIA7191E

Solenoid valve Connectror Terminal Resistance (Approx.)

Torque converter clutch

solenoid valve F30 5 - Ground 5 - 20

Ω SCIA2063E

Page 138 of 4331

DTC P0744 A/T TCC S/

V FUNCTION (LOCK-UP)

AT-133

< SERVICE INFORMATION >

D

E

F

G H

I

J

K L

M A

B AT

N

O P

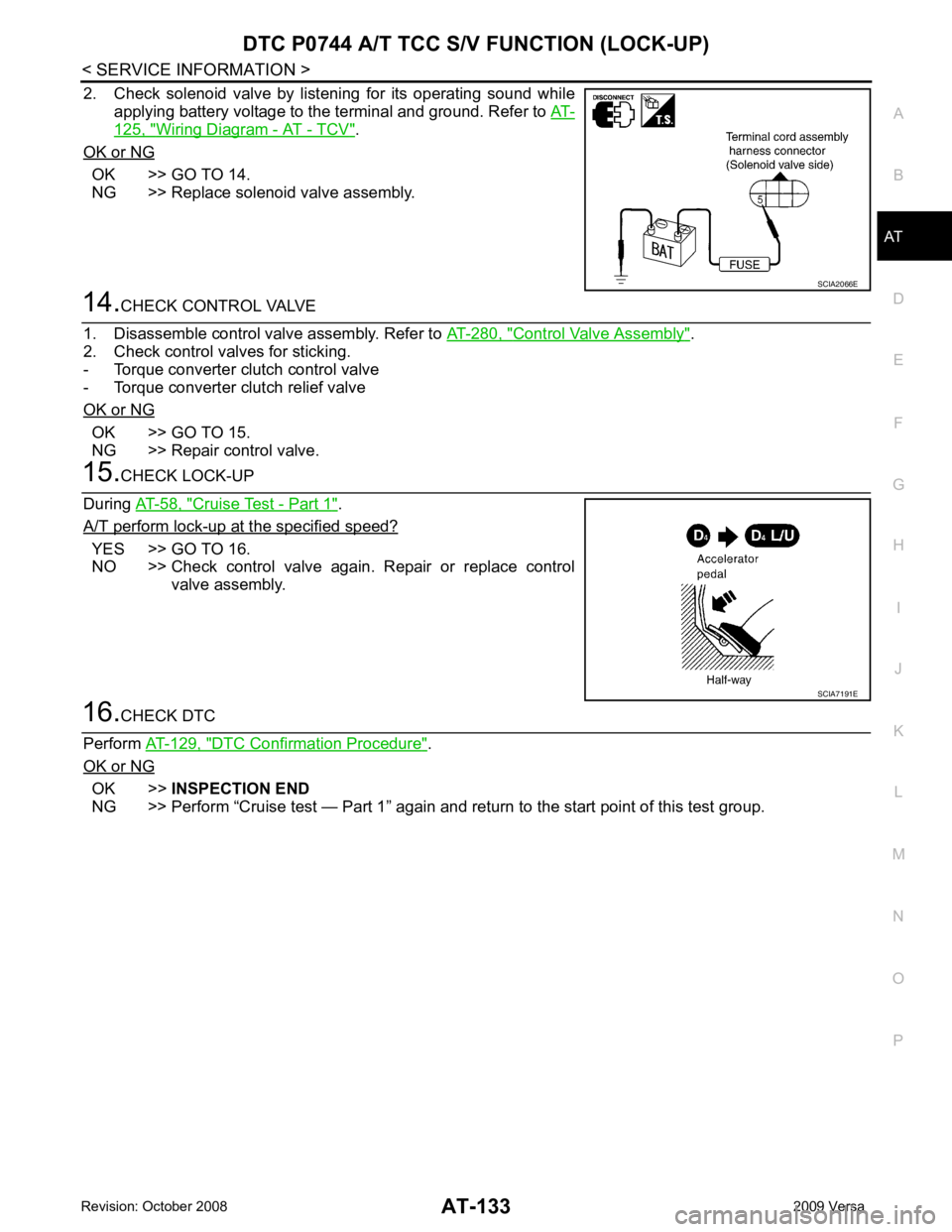

2. Check solenoid valve by listening for its operating sound while

applying battery voltage to the terminal and ground. Refer to AT-125, " Wiring Diagram - AT - TCV " .

OK or NG OK >> GO TO 14.

NG >> Replace solenoid valve assembly. 14.

CHECK CONTROL VALVE

1. Disassemble control valve assembly. Refer to AT-280, " Control Valve Assembly " .

2. Check control valves for sticking.

- Torque converter clutch control valve

- Torque converter clutch relief valve

OK or NG OK >> GO TO 15.

NG >> Repair control valve. 15.

CHECK LOCK-UP

During AT-58, " Cruise Test - Part 1 " .

A/T perform lock-up at the specified speed? YES >> GO TO 16.

NO >> Check control valve again. Repair or replace control

valve assembly. 16.

CHECK DTC

Perform AT-129, " DTC Confirmation Procedure " .

OK or NG OK >>

INSPECTION END

NG >> Perform “Cruise test — Part 1” again and re turn to the start point of this test group. SCIA2066E

SCIA7191E

Page 139 of 4331

Diagnosis Procedure " .

WITH GST

Follow the procedure “WITH CONSULT-III”.

WITHOUT CONSULT-III

1. Start engine.

2. With brake pedal depressed, shift the lever from “P” →“N” →“D” →“N” →“P” positions.

3. Perform self-diagnosis. Refer to AT-83, " Diagnosis Procedure without CONSULT-III " .

4. If the check result is NG, go to AT-136, " Diagnosis Procedure " .

Item name Condition Display value (Approx.)

LINE PRES DTY Small throttle opening (Low line pressure)

⇔ Large

throttle opening (High line pressure) 0%

⇔ 94%

Page 140 of 4331

AT

N

O P

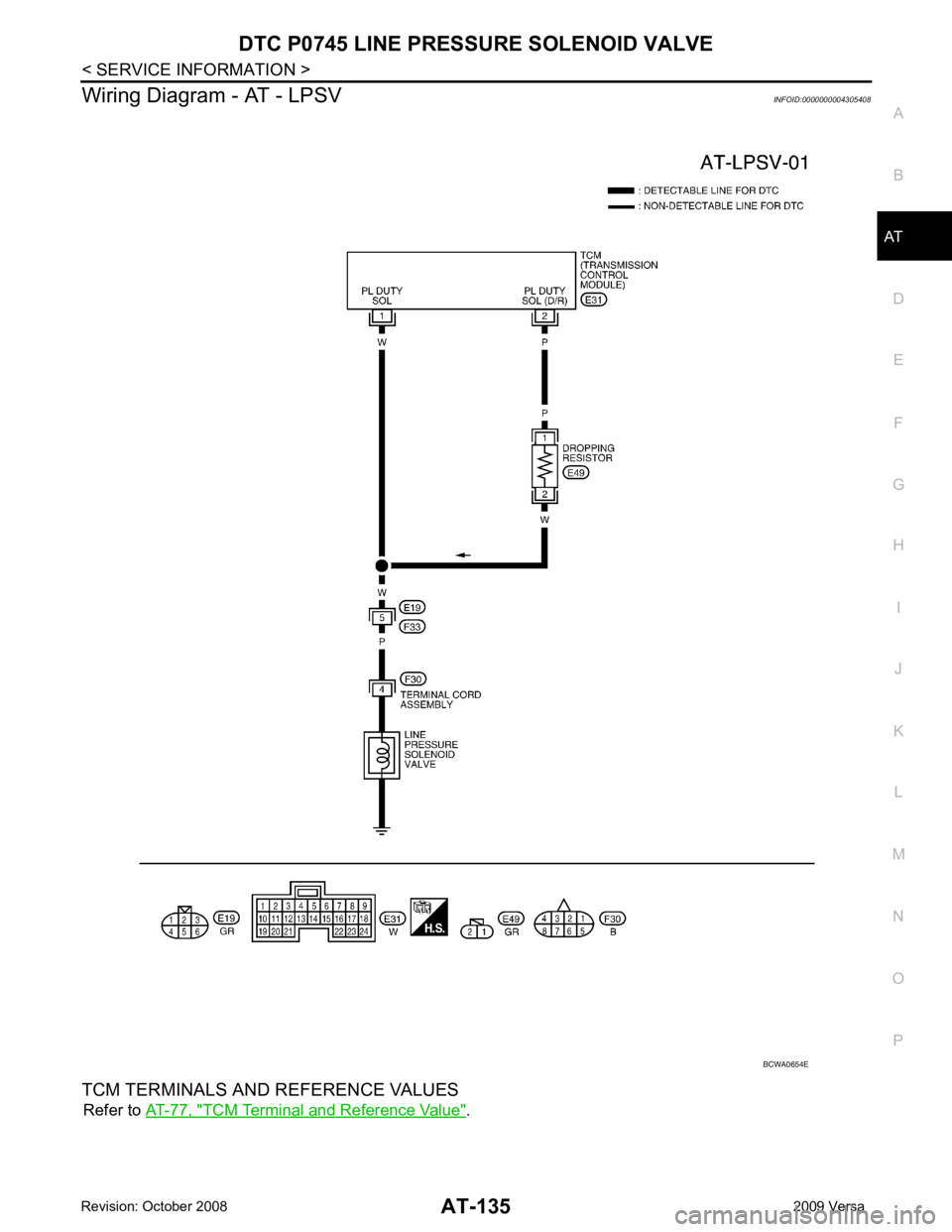

Wiring Diagram - AT - LPSV

INFOID:0000000004305408

TCM TERMINALS AND REFERENCE VALUES Refer to AT-77, " TCM Terminal and Reference Value " .