NISSAN LATIO 2009 Service Owners Manual

LATIO 2009

NISSAN

NISSAN

https://www.carmanualsonline.info/img/5/57359/w960_57359-0.png

NISSAN LATIO 2009 Service Owners Manual

Trending: fuel, fuse box, jump start terminals, temp gauge, TPMS, OBD port, alarm

Page 91 of 4331

.

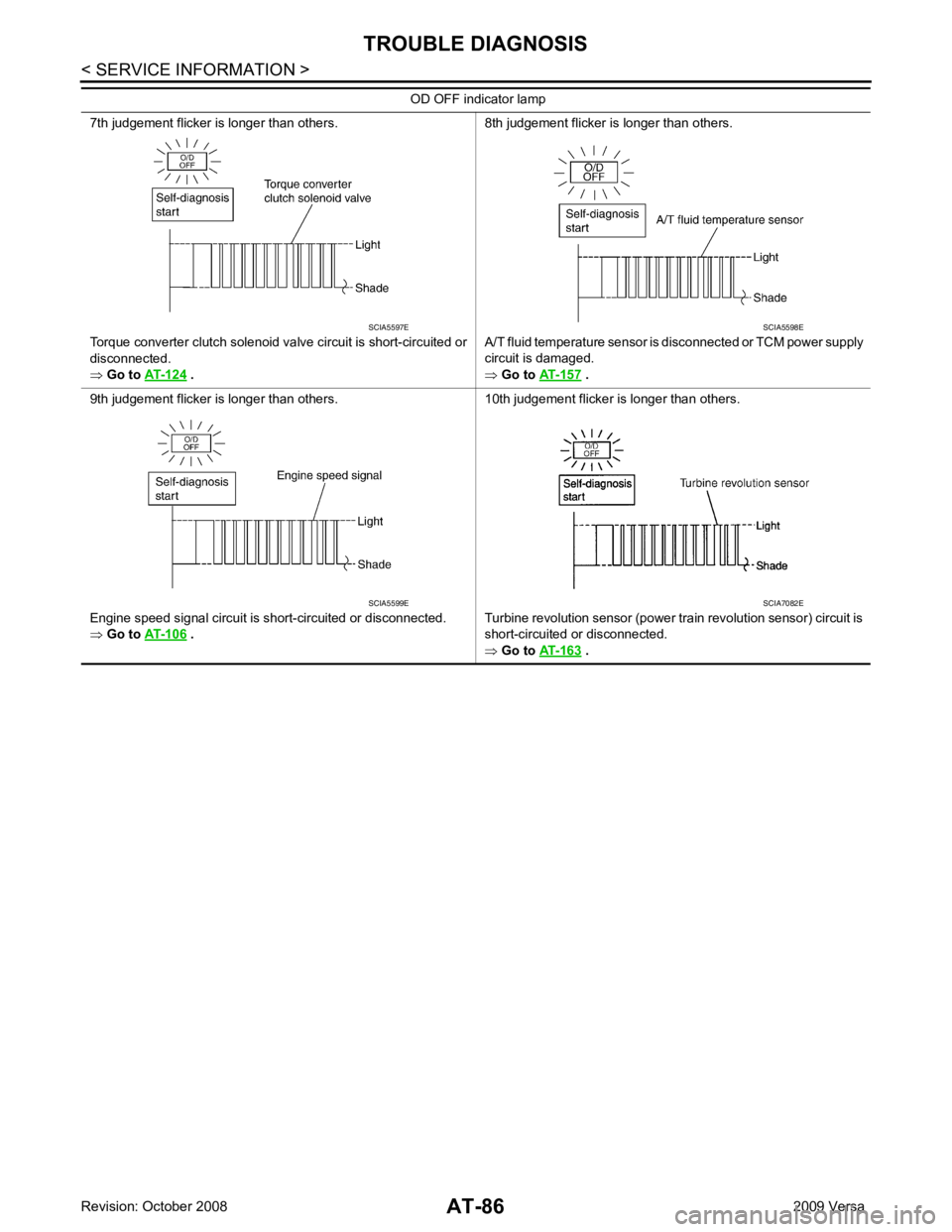

8th judgement flicker is longer than others.

A/T fluid temperature sensor is disconnected or TCM power supply

circuit is damaged.

⇒ Go to AT-157 .

9th judgement flicker is longer than others.

Engine speed signal circuit is short-circuited or disconnected.

⇒ Go to AT-106 .

10th judgement flicker is longer than others.

Turbine revolution sensor (power train revolution sensor) circuit is

short-circuited or disconnected.

⇒ Go to AT-163 .

OD OFF indicator lamp

Page 92 of 4331

AT

N

O P

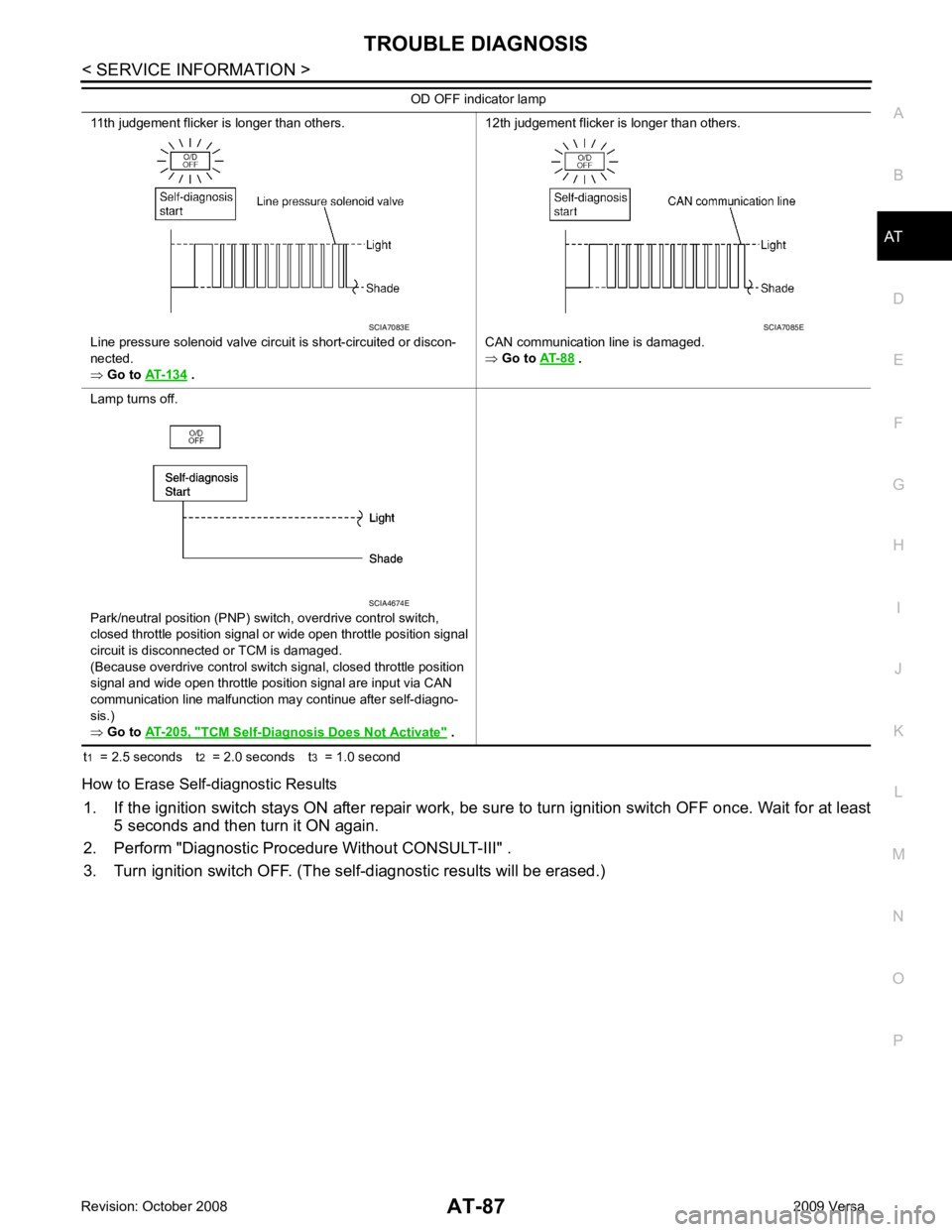

t

1 = 2.5 seconds t 2 = 2.0 seconds t 3 = 1.0 second

How to Erase Self-diagnostic Results 1. If the ignition switch stays ON after repair work, be su re to turn ignition switch OFF once. Wait for at least

5 seconds and then turn it ON again.

2. Perform "Diagnostic Procedure Without CONSULT-III" .

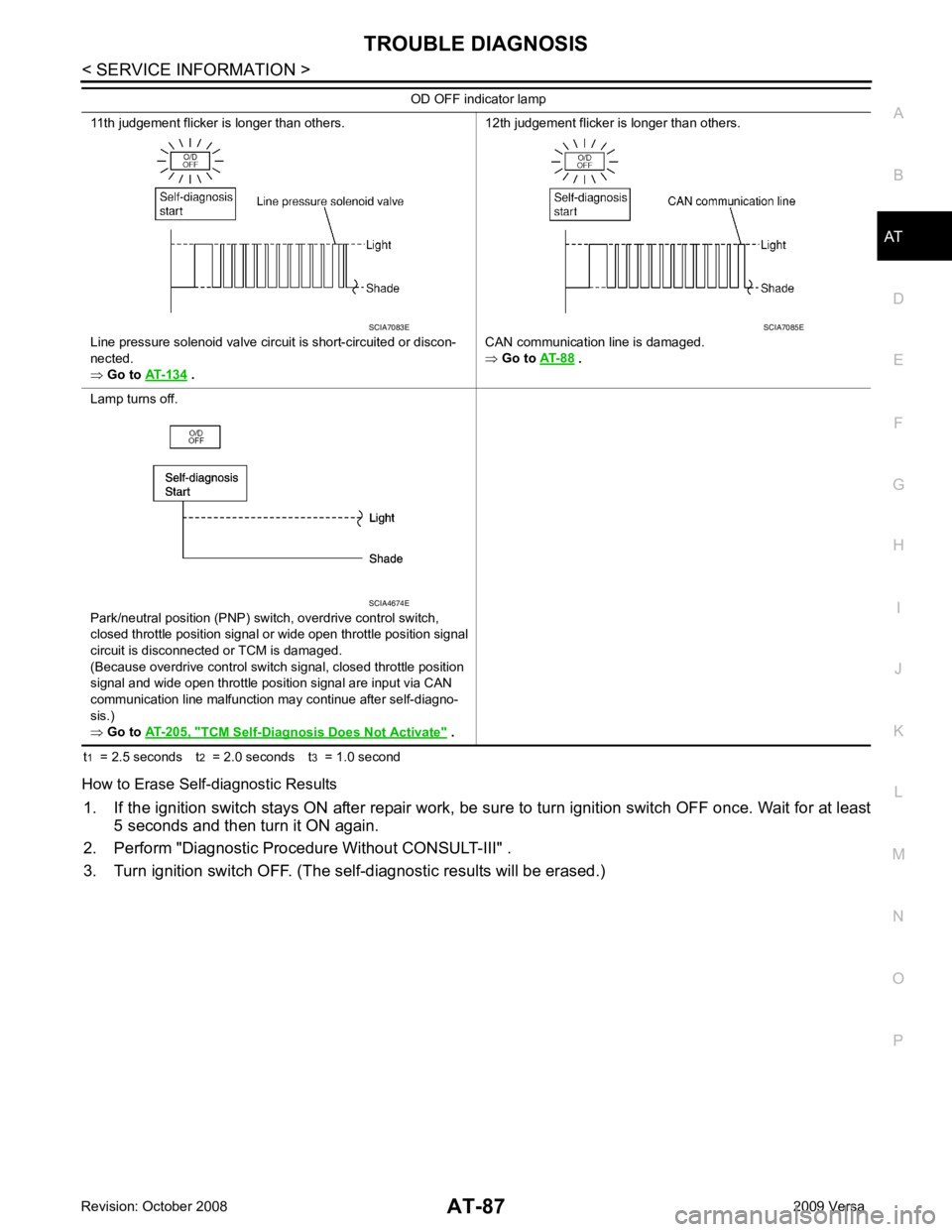

3. Turn ignition switch OFF. (The self-diagnostic results will be erased.) 11th judgement flicker is longer than others.

Line pressure solenoid valve circuit is short-circuited or discon-

nected.

⇒ Go to AT-134 .

12th judgement flicker is longer than others.

CAN communication line is damaged.

⇒ Go to AT-88 .

Lamp turns off.

Park/neutral position (PNP) switch, overdrive control switch,

closed throttle position signal or wide open throttle position signal

circuit is disconnected or TCM is damaged.

(Because overdrive control switch signal, closed throttle position

signal and wide open throttle position signal are input via CAN

communication line malfunction may continue after self-diagno-

sis.)

⇒ Go to AT-205, " TCM Self-Diagnosis

Does Not Activate " .

OD OFF indicator lamp

Page 93 of 4331

Diagnosis Procedure " .

WITH GST

Follow the procedure “WITH CONSULT-III”.

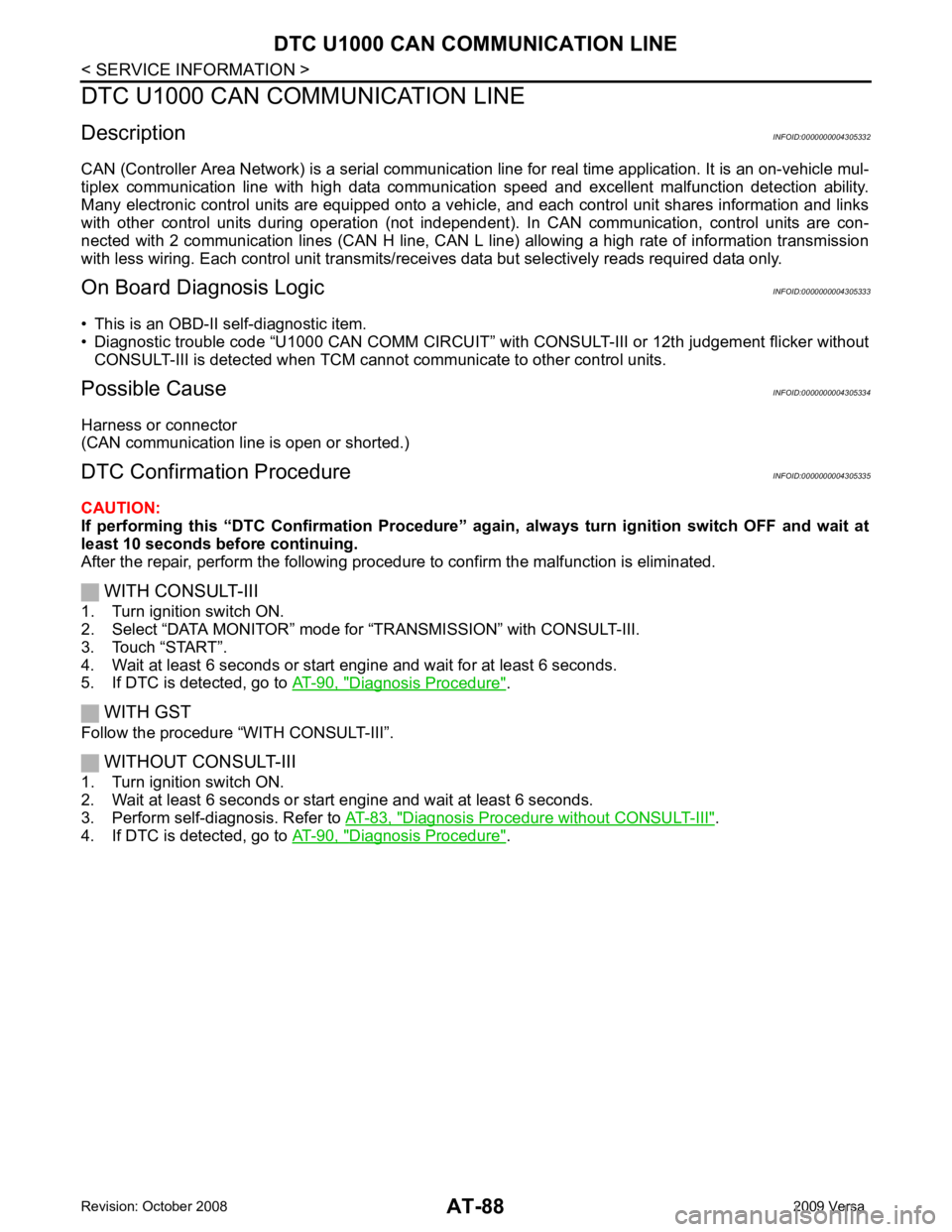

WITHOUT CONSULT-III

1. Turn ignition switch ON.

2. Wait at least 6 seconds or start engine and wait at least 6 seconds.

3. Perform self-diagnosis. Refer to AT-83, " Diagnosis Procedure without CONSULT-III " .

4. If DTC is detected, go to AT-90, " Diagnosis Procedure " .

Page 94 of 4331

AT

N

O P

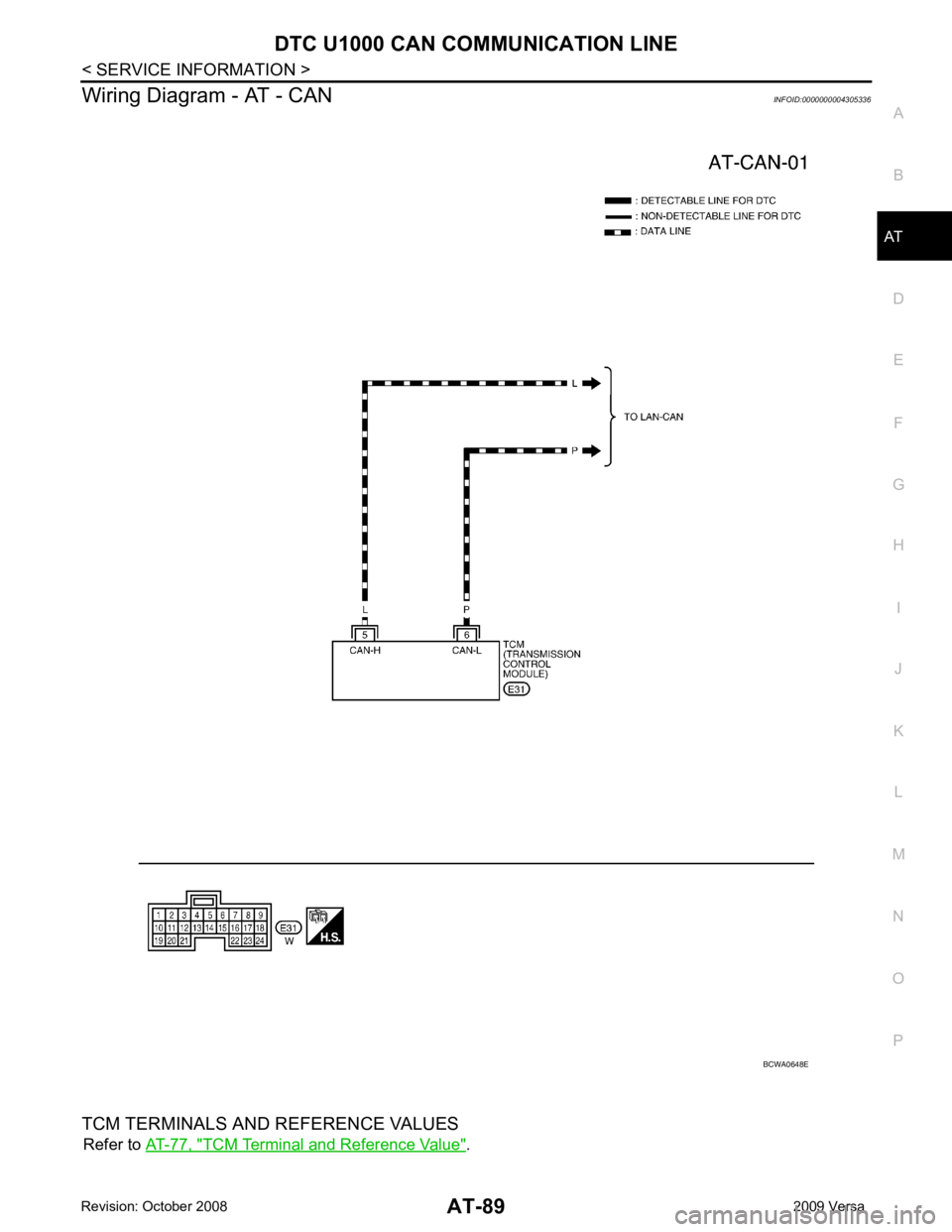

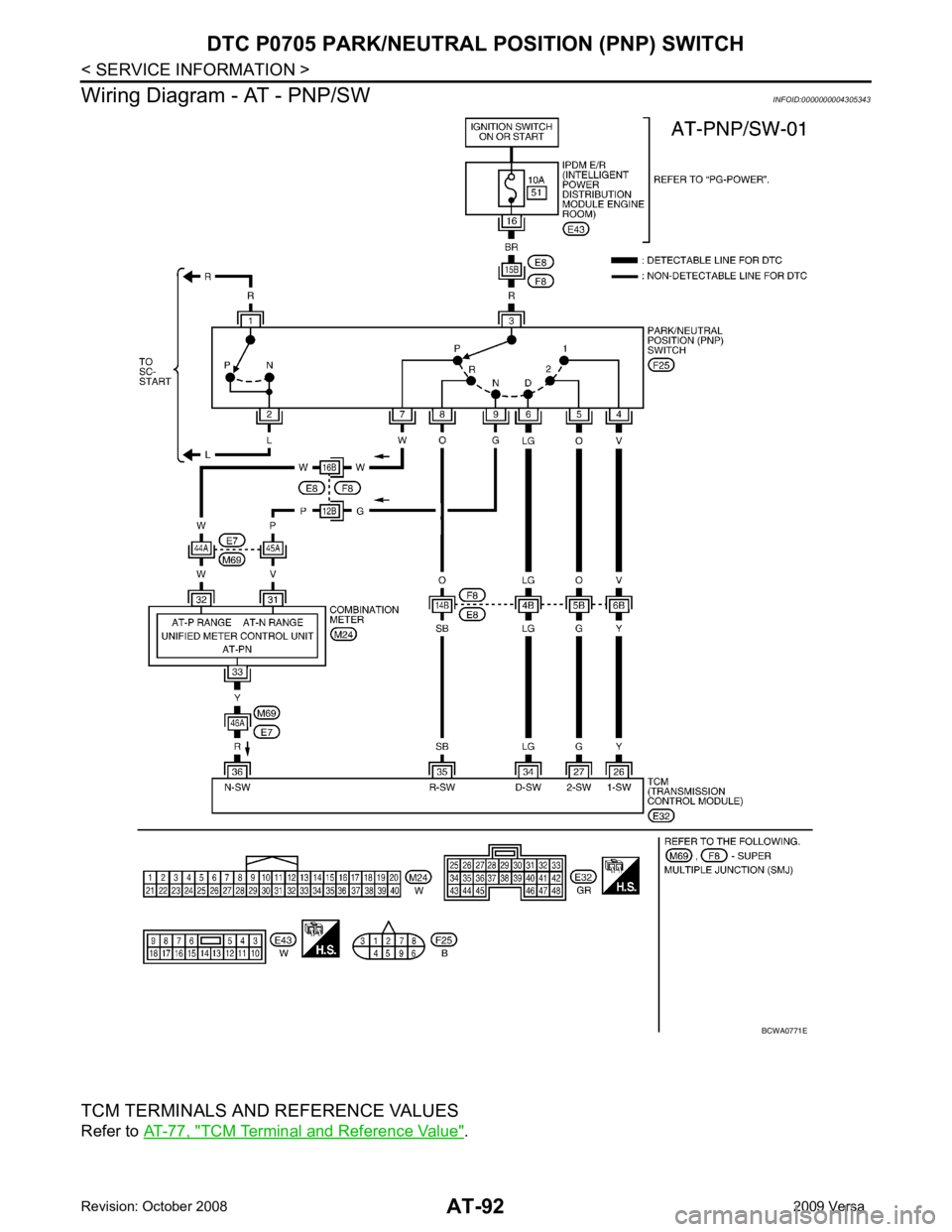

Wiring Diagram - AT - CAN

INFOID:0000000004305336

TCM TERMINALS AND REFERENCE VALUES Refer to AT-77, " TCM Terminal and Reference Value " .

Page 95 of 4331

“ U1000 CAN COMM CIRCUIT ” indicated?

YES >> Print out CONSULT-III screen, Go to LAN section. Refer to

LAN-26, " CAN System Specification

Chart " .

NO >> INSPECTION END

Page 96 of 4331

AT

N

O P

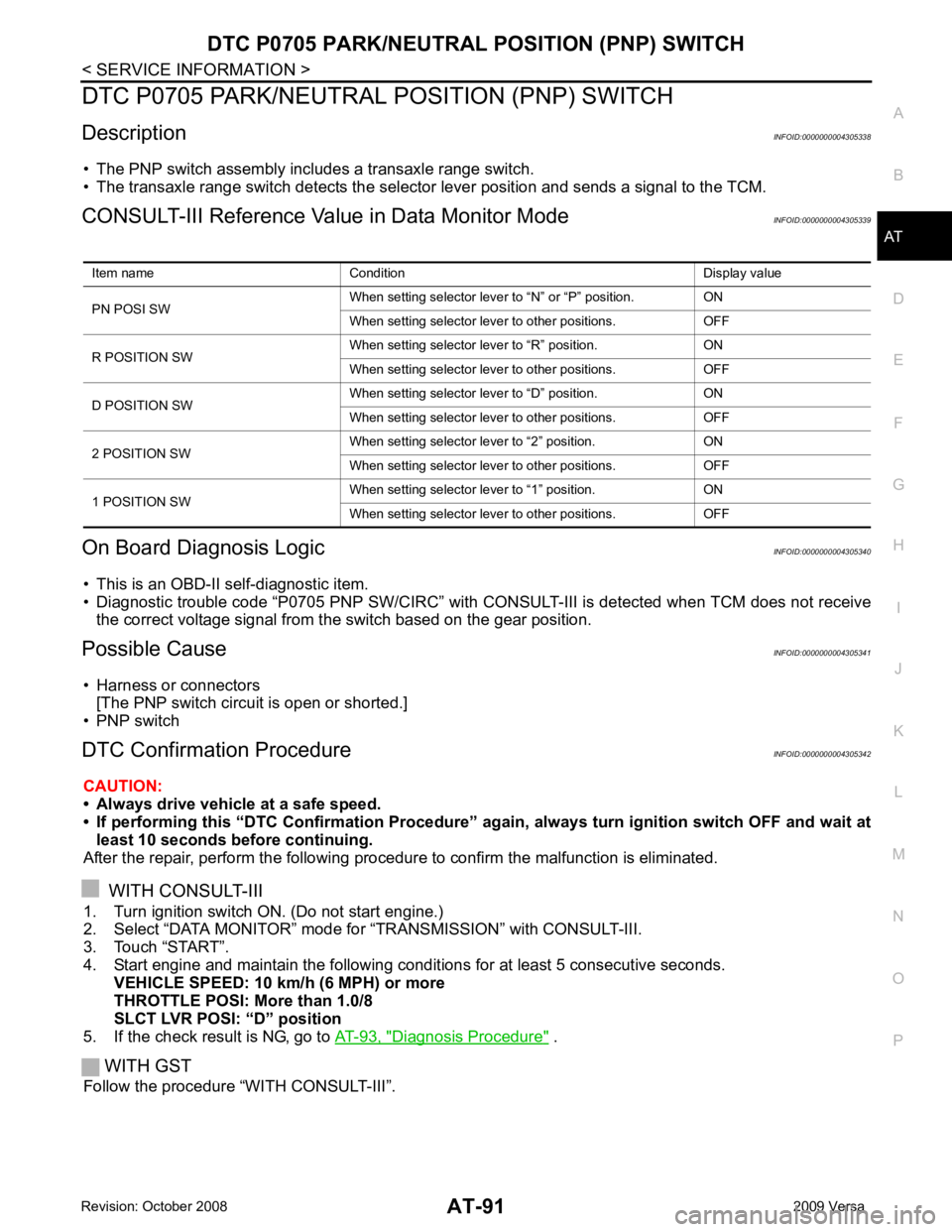

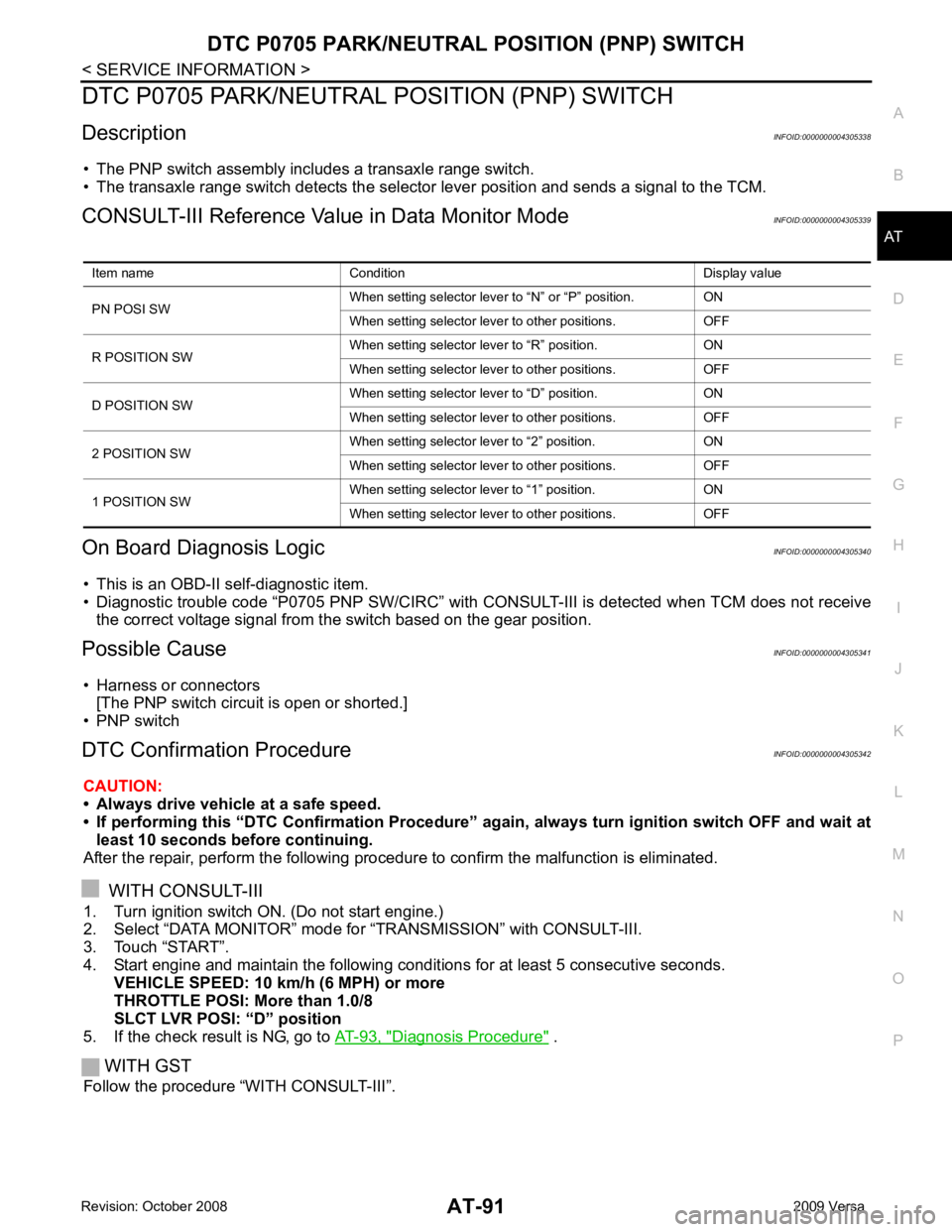

DTC P0705 PARK/NEUTRAL POSITION (PNP) SWITCH

Description INFOID:0000000004305338

• The PNP switch assembly includes a transaxle range switch.

• The transaxle range switch detects the selector lever position and sends a signal to the TCM.

CONSULT-III Reference Val ue in Data Monitor Mode INFOID:0000000004305339

On Board Diagnosis Logic INFOID:0000000004305340

• This is an OBD-II self-diagnostic item.

• Diagnostic trouble code “P0705 PNP SW/CIRC” with CONS ULT-III is detected when TCM does not receive

the correct voltage signal from the switch based on the gear position.

Possible Cause INFOID:0000000004305341

• Harness or connectors [The PNP switch circuit is open or shorted.]

• PNP switch

DTC Confirmation Procedure INFOID:0000000004305342

CAUTION:

• Always drive vehicle at a safe speed.

• If performing this “DTC Confirmation Procedure” again, always turn ignition switch OFF and wait at

least 10 seconds before continuing.

After the repair, perform the following procedure to confirm the malfunction is eliminated.

WITH CONSULT-III

1. Turn ignition switch ON. (Do not start engine.)

2. Select “DATA MONITOR” mode for “TRANSMISSION” with CONSULT-III.

3. Touch “START”.

4. Start engine and maintain the following conditions for at least 5 consecutive seconds.

VEHICLE SPEED: 10 km/h (6 MPH) or more

THROTTLE POSI: More than 1.0/8

SLCT LVR POSI: “D” position

5. If the check result is NG, go to AT-93, " Diagnosis Procedure " .

WITH GST

Follow the procedure “WITH CONSULT-III”. Item name Condition Display value

PN POSI SW When setting selector lever

to “N” or “P” position. ON

When setting selector lever to other positions. OFF

R POSITION SW When setting selector lever to “R” position. ON

When setting selector lever to other positions. OFF

D POSITION SW When setting selector lever to “D” position. ON

When setting selector lever to other positions. OFF

2 POSITION SW When setting selector lever to “2” position. ON

When setting selector lever to other positions. OFF

1 POSITION SW When setting selector lever to “1” position. ON

When setting selector lever to other positions. OFF

Page 97 of 4331

TCM Terminal and Reference Value " .

Page 98 of 4331

AT

N

O P

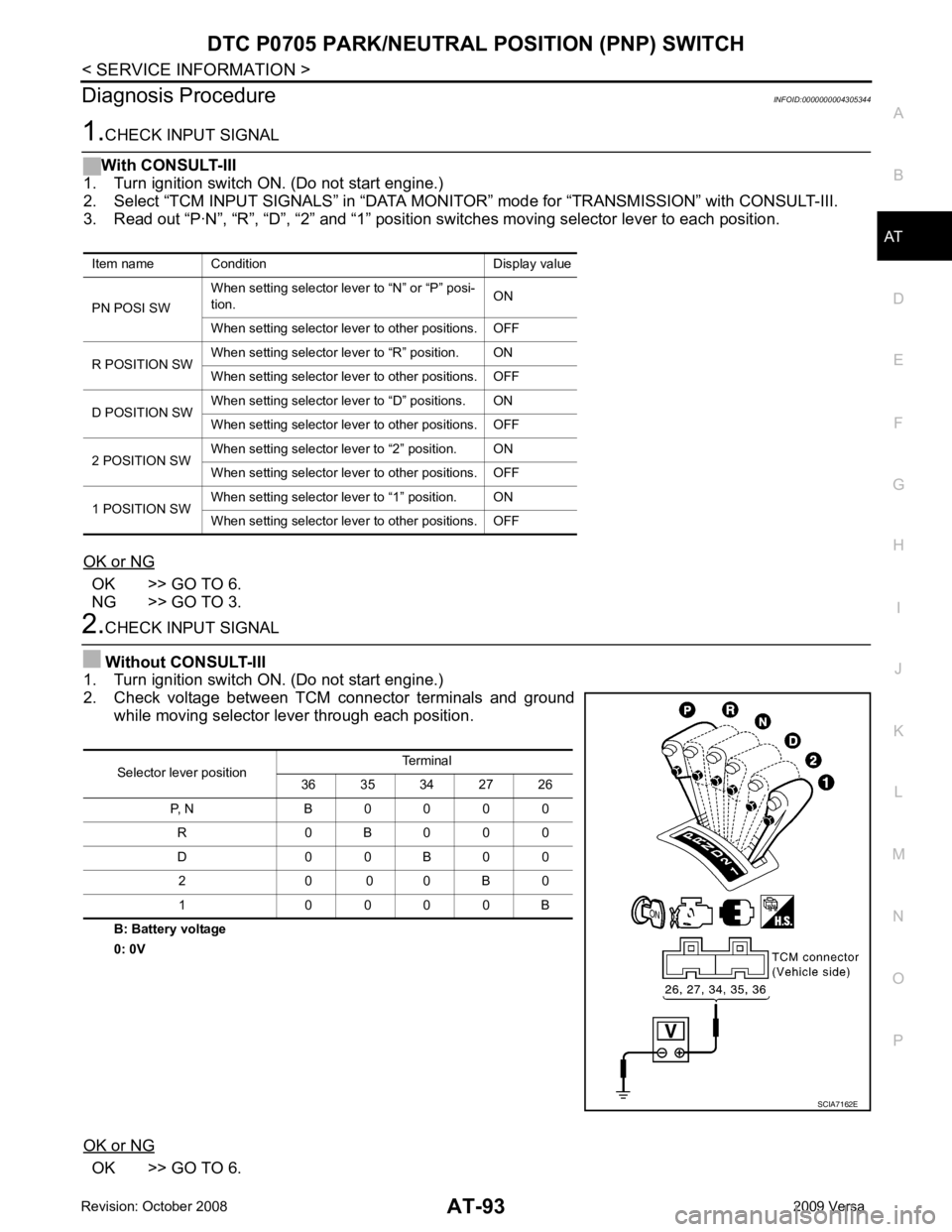

Diagnosis Procedure

INFOID:0000000004305344OK >> GO TO 6.

NG >> GO TO 3. OK >> GO TO 6.

Item name Condition Display value

PN POSI SW When setting selector le

ver to “N” or “P” posi-

tion. ON

When setting selector lever to other positions. OFF

R POSITION SW When setting selector lever to “R” position. ON

When setting selector lever to other positions. OFF

D POSITION SW When setting selector lever to “D” positions. ON

When setting selector lever to other positions. OFF

2 POSITION SW When setting selector lever to “2” position. ON

When setting selector lever to other positions. OFF

1 POSITION SW When setting selector lever to “1” position. ON

When setting selector lever to other positions. OFF Selector lever position

Terminal

36 35 34 27 26

P, N B 0 0 0 0 R 0 B 0 0 0

D 0 0 B 0 0 2 0 0 0 B 0

1 0 0 0 0 B

Page 99 of 4331

OK >> GO TO 5.

NG >> GO TO 4. OK >> Adjust control cable. Refer to

AT-216, " Adjustment of A/T Position " .

NG >> Check PNP switch (Refer to test group 1) again after adjusting PNP switch (Refer to AT-224 ).

• If OK, INSPECTION END

• If NG, repair or replace PNP switch. Refer to AT-224, " Park/Neutral Position (PNP) Switch " .

.

• Ignition switch. Refer to PG-3 .

OK or NG OK >> GO TO 6.

NG >> Repair or replace damaged parts. DTC Confirmation Procedure " .

OK or NG OK >>

INSPECTION END

NG >> GO TO 7. TCM Terminal and Reference Value " .

2. If NG, recheck TCM pin terminals for damage or loose connection with harness connector.

OK or NG OK >>

INSPECTION END

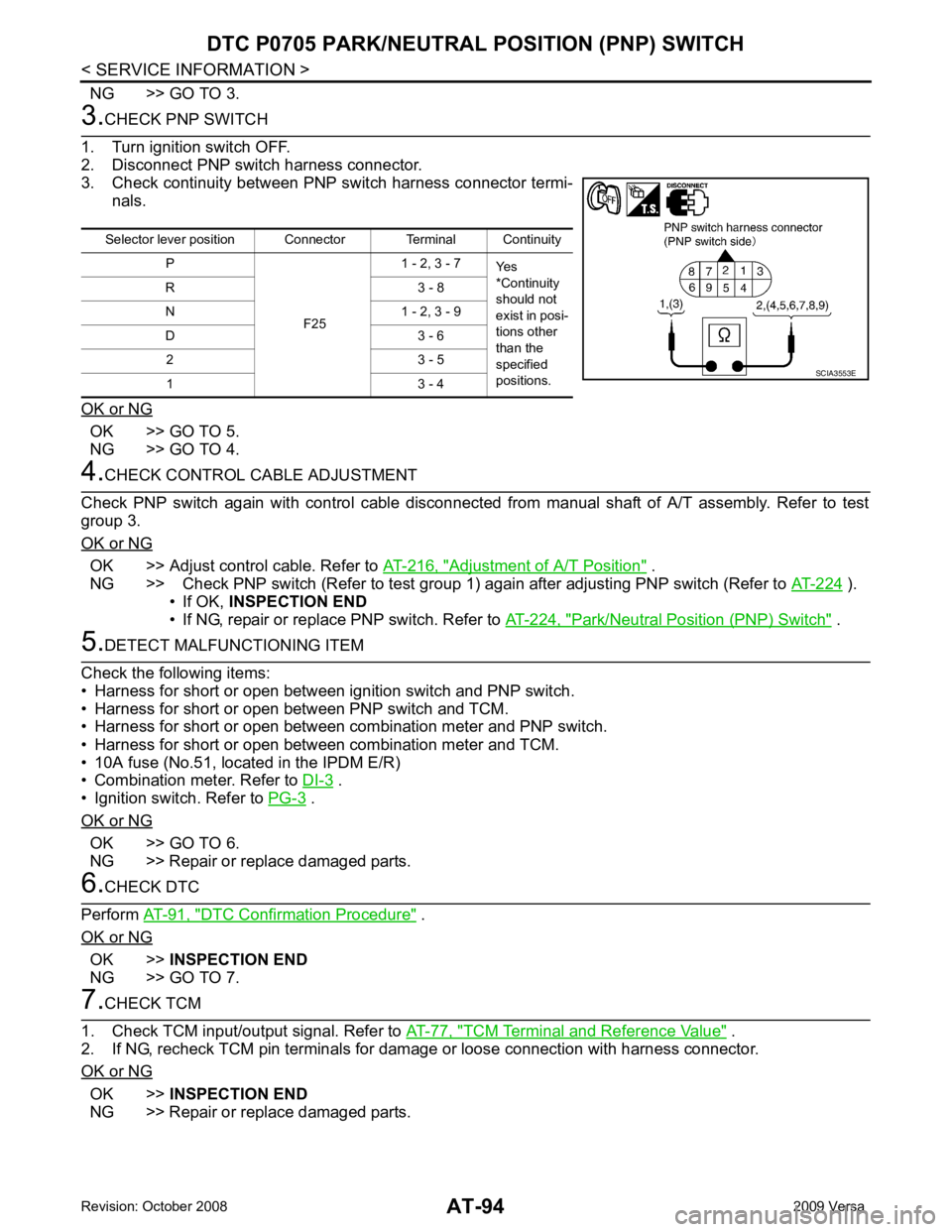

NG >> Repair or replace damaged parts. Selector lever position Connector Terminal Continuity

P

F251 - 2, 3 - 7

Yes

*Continuity

should not

exist in posi-

tions other

than the

specified

positions.

R 3 - 8

N 1 - 2, 3 - 9

D 3 - 6 2 3 - 5

1 3 - 4

Page 100 of 4331

AT

N

O P

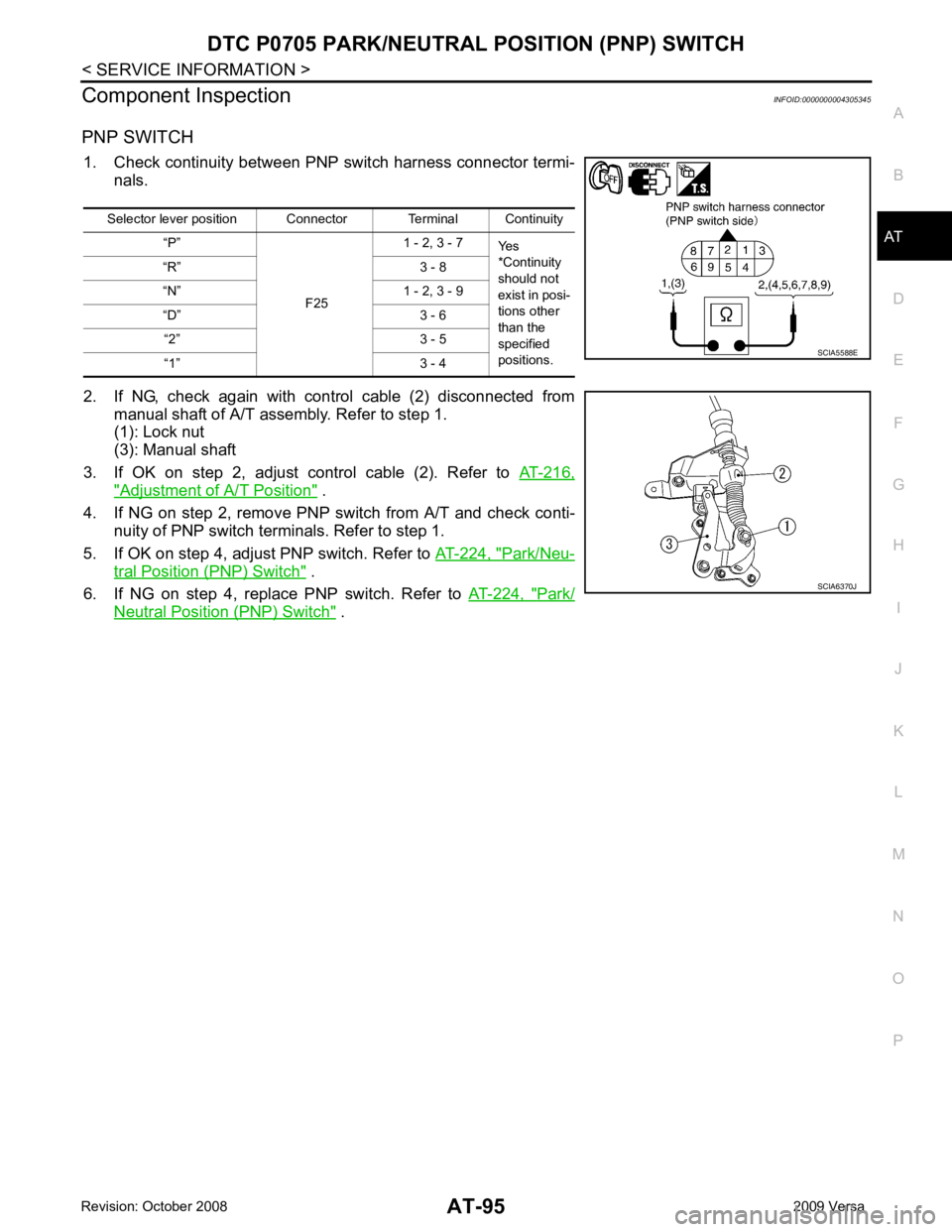

Component Inspection

INFOID:0000000004305345

PNP SWITCH 1. Check continuity between PNP switch harness connector termi- nals.

2. If NG, check again with control cable (2) disconnected from manual shaft of A/T assembly. Refer to step 1.

(1): Lock nut

(3): Manual shaft

3. If OK on step 2, adjust control cable (2). Refer to AT-216," Adjustment of A/T Position " .

4. If NG on step 2, remove PNP switch from A/T and check conti-

nuity of PNP switch terminals. Refer to step 1.

5. If OK on step 4, adjust PNP switch. Refer to AT-224, " Park/Neu-

tral Position (PNP) Switch " .

6. If NG on step 4, replace PNP switch. Refer to AT-224, " Park/

Neutral Position (PNP) Switch " .

Selector lever position Connector Terminal Continuity

“P”

F251 - 2, 3 - 7

Yes

*Continuity

should not

exist in posi-

tions other

than the

specified

positions.

“R” 3 - 8

“N” 1 - 2, 3 - 9

“D” 3 - 6 “2” 3 - 5

“1” 3 - 4

Trending: tow, warning lights, run flat, heating, steering, spark plugs, checking oil