NISSAN LATIO 2009 Service Repair Manual

Manufacturer: NISSAN, Model Year: 2009, Model line: LATIO, Model: NISSAN LATIO 2009Pages: 4331, PDF Size: 58.04 MB

Page 3731 of 4331

Drain and refill

With oil filter change Approximately 3.0 (3 1/8, 2 5/8)

Without oil filter change Approximately 2.8 (3, 2 1/2)

Dry engine (engine overhaul) Approximately 3.5 (3 3/4, 3 1/8) Engine speed rpm

Approximate discharge pressure* [kPa (bar, kg/cm 2

, psi)]

Idle speed More than 60 (0.60, 0.61, 9) 2,000 More than 270 (2.7, 2.8, 39)

Page 3732 of 4331

LU

NP

O

SERVICE INFORMATION

PRECAUTIONS

Precaution for Supplemental Restraint System (SRS) "AIR BAG" and "SEAT BELT

PRE-TENSIONER" INFOID:0000000004784384

The Supplemental Restraint System such as “A IR BAG” and “SEAT BELT PRE-TENSIONER”, used along

with a front seat belt, helps to reduce the risk or severi ty of injury to the driver and front passenger for certain

types of collision. This system includes seat belt switch inputs and dual stage front air bag modules. The SRS

system uses the seat belt switches to determine the front air bag deployment, and may only deploy one front

air bag, depending on the severity of a collision and w hether the front occupants are belted or unbelted.

Information necessary to service the system safely is included in the SRS and SB section of this Service Man-

ual.

WARNING:

• To avoid rendering the SRS inoper ative, which could increase the risk of personal injury or death in

the event of a collision which would result in air bag inflation, all maintenance must be performed by

an authorized NISSAN/INFINITI dealer.

• Improper maintenance, including in correct removal and installation of the SRS can lead to personal

injury caused by unintentional act ivation of the system. For removal of Spiral Cable and Air Bag

Module, see the SRS section.

• Do not use electrical test equipm ent on any circuit related to the SRS unless instructed to in this

Service Manual. SRS wiring harnesses can be identi fied by yellow and/or orange harnesses or har-

ness connectors.

• When working near the Airbag Diagnosis Sensor Un it or other Airbag System sensors with the Igni-

tion ON or engine running, DO NOT use air or el ectric power tools or strike near the sensor(s) with a

hammer. Heavy vibration could activate the sensor( s) and deploy the air bag(s), possibly causing

serious injury.

• When using air or electric power tools or hammers , always switch the Ignition OFF, disconnect the

battery, and wait at least 3 minutes before performing any service.

Precaution Necessary for Steering Wh eel Rotation After Battery Disconnect

INFOID:0000000004673030

NOTE:

• This Procedure is applied only to models with Inte lligent Key system and NATS (NISSAN ANTI-THEFT SYS-

TEM).

• Remove and install all control units after disconnecti ng both battery cables with the ignition knob in the

″ LOCK ″ position.

• Always use CONSULT-III to perform self-diagnosis as a part of each function inspection after finishing work.

If DTC is detected, perform trouble diagnosis according to self-diagnostic results.

For models equipped with the Intelligent Key system and NATS , an electrically controlled steering lock mech-

anism is adopted on the key cylinder.

For this reason, if the battery is disconnected or if the battery is discharged, the steering wheel will lock and

steering wheel rotation will become impossible.

If steering wheel rotation is required when battery pow er is interrupted, follow the procedure below before

starting the repair operation.

OPERATION PROCEDURE 1. Connect both battery cables. NOTE:

Supply power using jumper cables if battery is discharged.

2. Use the Intelligent Key or mechanical key to turn the ignition switch to the ″ACC ″ position. At this time, the

steering lock will be released.

3. Disconnect both battery cables. The steering lock will remain released and the steering wheel can be

rotated.

4. Perform the necessary repair operation.

5. When the repair work is completed, return the ignition switch to the ″LOCK ″ position before connecting

the battery cables. (At this time, the steering lock mechanism will engage.)

6. Perform a self-diagnosis check of al l control units using CONSULT-III.

Page 3733 of 4331

![NISSAN LATIO 2009 Service Repair Manual LU-12< SERVICE INFORMATION >

[MR18DE]

PRECAUTIONS

Precaution for Liquid Gasket INFOID:0000000004788557

REMOVAL OF LIQUID GASKET SEALING

• After removing nuts and bolts, separate the mating surface, NISSAN LATIO 2009 Service Repair Manual LU-12< SERVICE INFORMATION >

[MR18DE]

PRECAUTIONS

Precaution for Liquid Gasket INFOID:0000000004788557

REMOVAL OF LIQUID GASKET SEALING

• After removing nuts and bolts, separate the mating surface,](/img/5/57359/w960_57359-3732.png)

LU-12< SERVICE INFORMATION >

[MR18DE]

PRECAUTIONS

Precaution for Liquid Gasket INFOID:0000000004788557

REMOVAL OF LIQUID GASKET SEALING

• After removing nuts and bolts, separate the mating surface, using Tool and remove old liquid gasket sealing.

CAUTION:

Be careful not to damage the mating surfaces.

• Tap Tool to insert it (1), and then slide it by tapping on the side (2) as shown.

• In areas where Tool is difficult to use, use plastic hammer to lightly tap the parts, to remove it.

CAUTION:

If for some unavoidable reason suitable tool such as screw-

driver is used, be careful no t to damage the mating surfaces.

LIQUID GASKET APPLICATION PROCEDURE

1. Remove old liquid gasket adhering to the liquid gasket applica- tion surface and the mating surface, using scraper.

• Remove liquid gasket completely from the groove of the liquid

gasket application surface, bolts, and bolt holes.

2. Thoroughly clean the mating surfaces and remove adhering moisture, grease and foreign materials.

3. Attach liquid gasket tube to Tool.

Use Genuine RTV Silicone Seal ant or equivalent. Refer to GI-42, " Recommended Chemical Prod-

uct and Sealant " .

4. Apply liquid gasket without breaks to the specif ied location with the specified dimensions.

• If there is a groove for the liquid gasket application, apply liquid gasket to the groove.

• As for the bolt holes, normally apply liquid gasket inside the holes. Occasionally, it should be applied outside the holes.

Make sure to read the text of service manual.

• Within five minutes of liquid gasket application, install the mat- ing component.

• If liquid gasket protrudes, wipe it off immediately.

• Do not retighten nuts or bolts after the installation.

• After 30 minutes or more have passed from the installation, fill engine oil and engine coolant.

CAUTION:

If there are specific instructions in this manual, observe them.

Tool number : KV10111100 (J-37228)

WBIA0566E

Tool number : WS39930000 ( — )

PBIC0003E

WBIA0567E

SEM159F

Page 3734 of 4331

![NISSAN LATIO 2009 Service Repair Manual PREPARATION

LU-13

< SERVICE INFORMATION >

[MR18DE] C

D E

F

G H

I

J

K L

M A LU

NP

O

PREPARATION

Special Service Tool INFOID:0000000004307165

The actual shapes of Kent-Moore tools may differ fr om those NISSAN LATIO 2009 Service Repair Manual PREPARATION

LU-13

< SERVICE INFORMATION >

[MR18DE] C

D E

F

G H

I

J

K L

M A LU

NP

O

PREPARATION

Special Service Tool INFOID:0000000004307165

The actual shapes of Kent-Moore tools may differ fr om those](/img/5/57359/w960_57359-3733.png)

PREPARATION

LU-13

< SERVICE INFORMATION >

[MR18DE] C

D E

F

G H

I

J

K L

M A LU

NP

O

PREPARATION

Special Service Tool INFOID:0000000004307165

The actual shapes of Kent-Moore tools may differ fr om those of special service tools illustrated here.

Commercial Service Tool INFOID:0000000004307166

Tool number

(Kent-Moore No.)

Tool name Description

ST25051001

(J-25695-1)

Oil pressure gauge Measuring oil pressure

Maximum measuring range: 2,452 kPa (25

kg/cm 2

, 356 psi)

ST25052000

(J-25695-2)

Hose Adapting oil pressure gauge to oil pan (upper)

KV10115801

(J-38956)

Oil filter wrench Removing oil filter

a: 64.3 mm (2.531 in)

WS39930000

( — )

Tube presser Pressing the tube of liquid gasket NT050

S-NT559

S-NT375

NT052

Page 3735 of 4331

![NISSAN LATIO 2009 Service Repair Manual LU-14< SERVICE INFORMATION >

[MR18DE]

PREPARATION

Tool name Description

Power tool Loosening nuts and bolts

Deep socket Removing and installing oil pressure switch

a: 26 mm (1.02 in) PBIC0190E

PBIC207 NISSAN LATIO 2009 Service Repair Manual LU-14< SERVICE INFORMATION >

[MR18DE]

PREPARATION

Tool name Description

Power tool Loosening nuts and bolts

Deep socket Removing and installing oil pressure switch

a: 26 mm (1.02 in) PBIC0190E

PBIC207](/img/5/57359/w960_57359-3734.png)

LU-14< SERVICE INFORMATION >

[MR18DE]

PREPARATION

Tool name Description

Power tool Loosening nuts and bolts

Deep socket Removing and installing oil pressure switch

a: 26 mm (1.02 in) PBIC0190E

PBIC2072E

Page 3736 of 4331

LU

NP

O

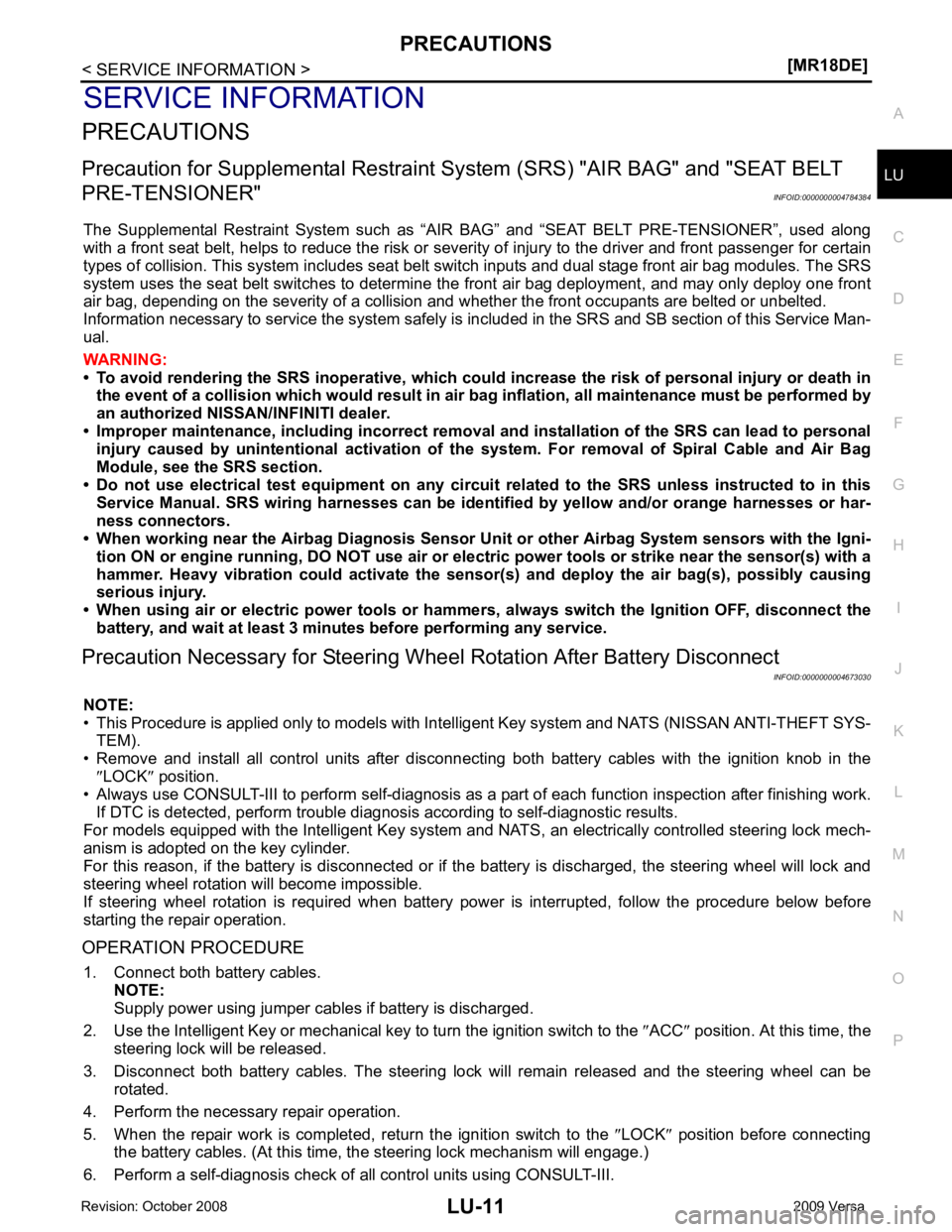

LUBRICATION SYSTEM

Lubrication Circuit INFOID:0000000004307167

Page 3737 of 4331

PBIC3310E

Page 3738 of 4331

![NISSAN LATIO 2009 Service Repair Manual ENGINE OIL

LU-17

< SERVICE INFORMATION >

[MR18DE] C

D E

F

G H

I

J

K L

M A LU

NP

O

4. Install oil pressure gauge and hose.

5. Start engine and warm it up to normal operating temperature.

6. Check oil p NISSAN LATIO 2009 Service Repair Manual ENGINE OIL

LU-17

< SERVICE INFORMATION >

[MR18DE] C

D E

F

G H

I

J

K L

M A LU

NP

O

4. Install oil pressure gauge and hose.

5. Start engine and warm it up to normal operating temperature.

6. Check oil p](/img/5/57359/w960_57359-3737.png)

ENGINE OIL

LU-17

< SERVICE INFORMATION >

[MR18DE] C

D E

F

G H

I

J

K L

M A LU

NP

O

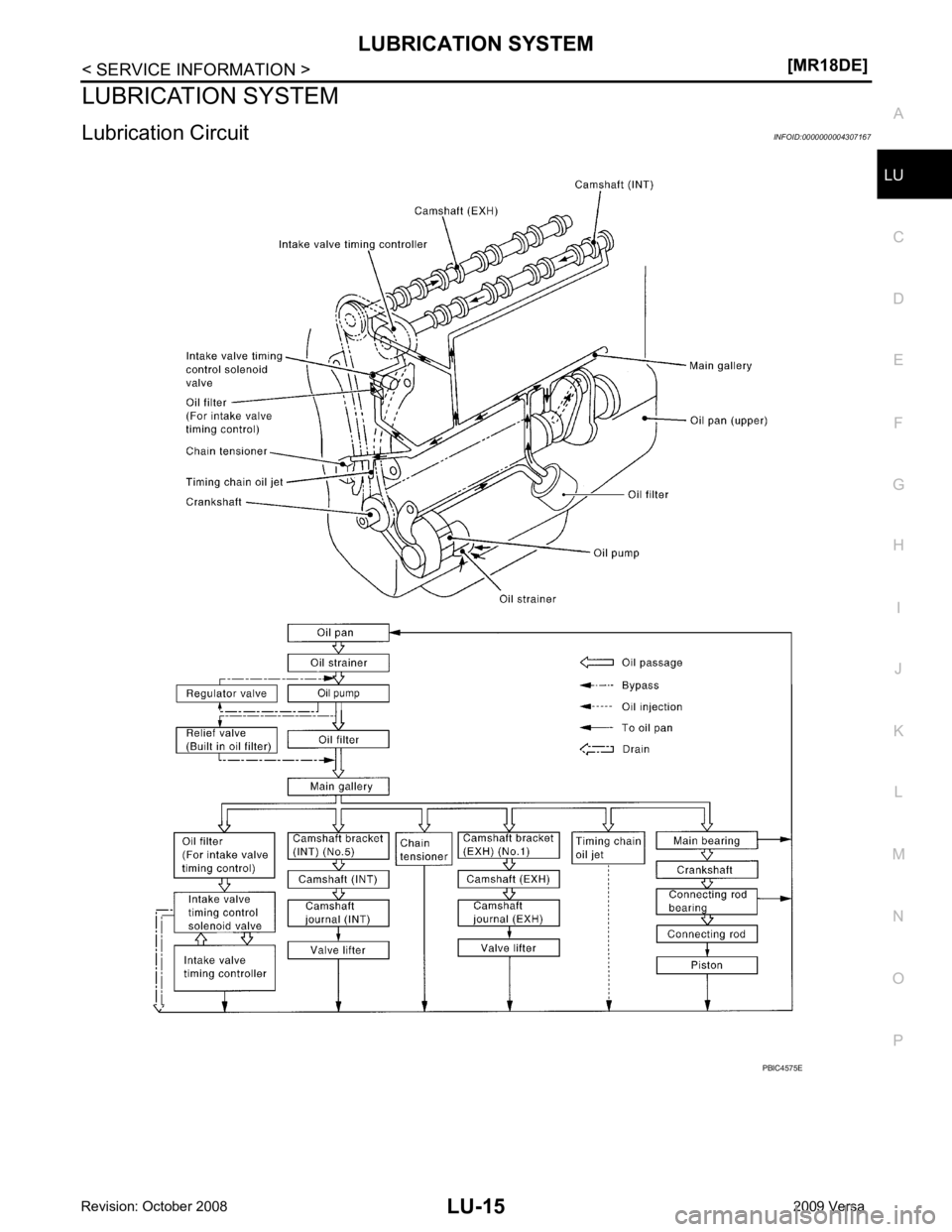

4. Install oil pressure gauge and hose.

5. Start engine and warm it up to normal operating temperature.

6. Check oil pressure with engine running under no-load. Refer to LU-22, " Standard and Limit " .

If difference is extreme, check oi l passage and oil pump for oil leaks.

NOTE:

When engine oil temperature is low, engine oil pressure becomes high.

7. After the inspections, install oil pressure switch as follows:

a. Remove old liquid gasket adhering to oil pressure switch and engine.

b. Apply liquid gasket and tighten oil pressure switch to specification. Use Genuine Silicone RT V Sealant or equivalent. Refer to GI-42, " Recommended Chemical Product

and Sealant " .

c. Check engine oil level.

d. After warming up engine, make sure there are no leaks of engine oil with running engine.

Changing Engine Oil INFOID:0000000004307169

WARNING:

• Be careful not to burn yoursel f, as engine oil may be hot.

• Prolonged and repeated contact with used engine oil may cause skin cancer. Try to avoid direct skin

contact with used engine oil. If skin contact is made, wash thorough ly with soap or hand cleaner as

soon as possible.

1. Warm up the engine, park vehicle on a level surf ace and check for engine oil leakage from engine compo-

nents. Refer to LU-16, " Inspection " .

2. Stop the engine and wait for 10 minutes. Tool number : ST25051001 (J-25695-1)

: ST25052000 (J-25695-2) WBIA0571E

Oil pressure switch : 14.7 N·

m (1.5 kg-m, 11 ft-lb)

Page 3739 of 4331

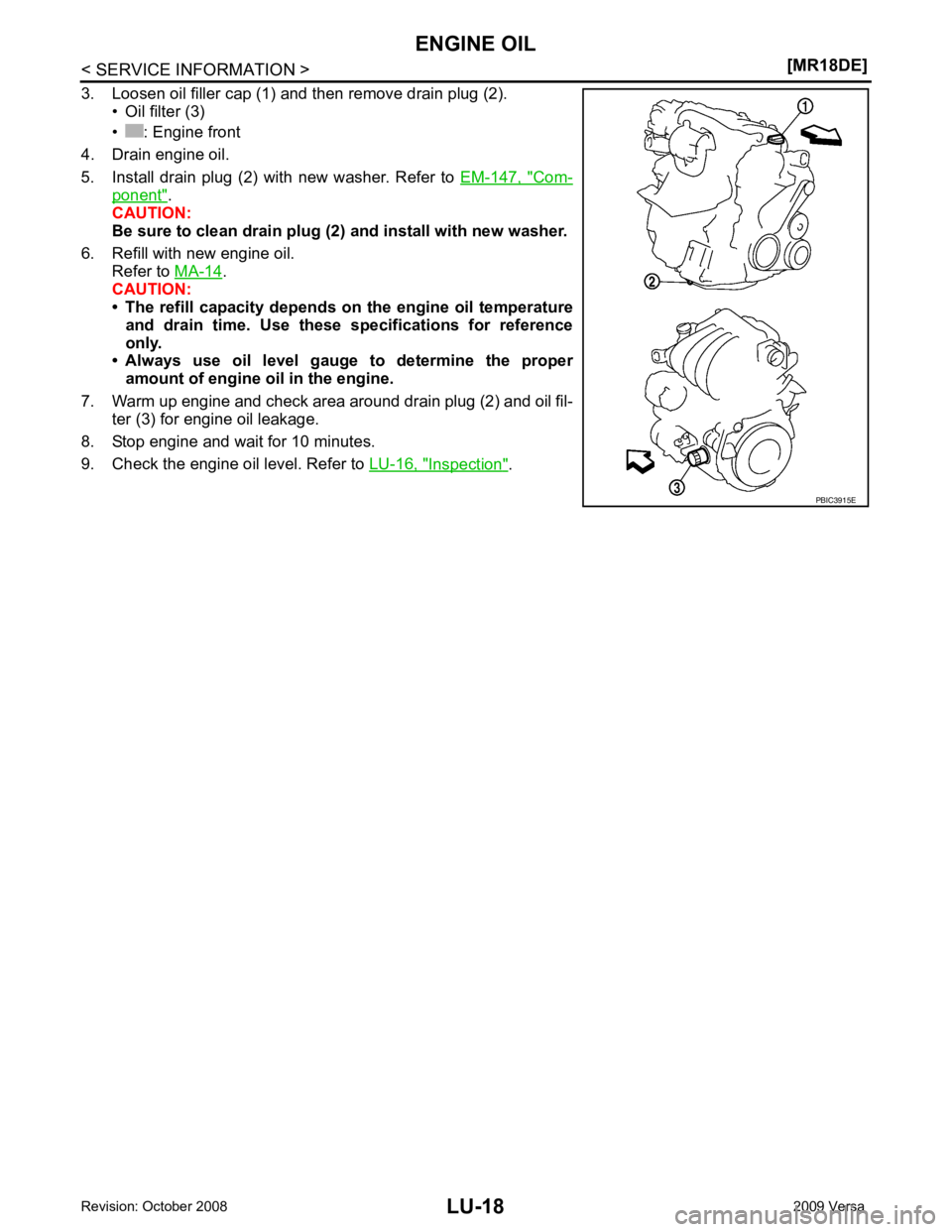

Com-

ponent " .

CAUTION:

Be sure to clean drain plug (2 ) and install with new washer.

6. Refill with new engine oil. Refer to MA-14 .

CAUTION:

• The refill capacity depends on the engine oil temperature

and drain time. Use these specifications for reference

only.

• Always use oil level gauge to determine the proper amount of engine oil in the engine.

7. Warm up engine and check area around drain plug (2) and oil fil- ter (3) for engine oil leakage.

8. Stop engine and wait for 10 minutes.

9. Check the engine oil level. Refer to LU-16, " Inspection " .

Page 3740 of 4331

![NISSAN LATIO 2009 Service Repair Manual OIL FILTER

LU-19

< SERVICE INFORMATION >

[MR18DE] C

D E

F

G H

I

J

K L

M A LU

NP

O

OIL FILTER

Removal and Installation INFOID:0000000004307170

REMOVAL 1. Remove oil filter using Tool (A). • : Front

W NISSAN LATIO 2009 Service Repair Manual OIL FILTER

LU-19

< SERVICE INFORMATION >

[MR18DE] C

D E

F

G H

I

J

K L

M A LU

NP

O

OIL FILTER

Removal and Installation INFOID:0000000004307170

REMOVAL 1. Remove oil filter using Tool (A). • : Front

W](/img/5/57359/w960_57359-3739.png)

OIL FILTER

LU-19

< SERVICE INFORMATION >

[MR18DE] C

D E

F

G H

I

J

K L

M A LU

NP

O

OIL FILTER

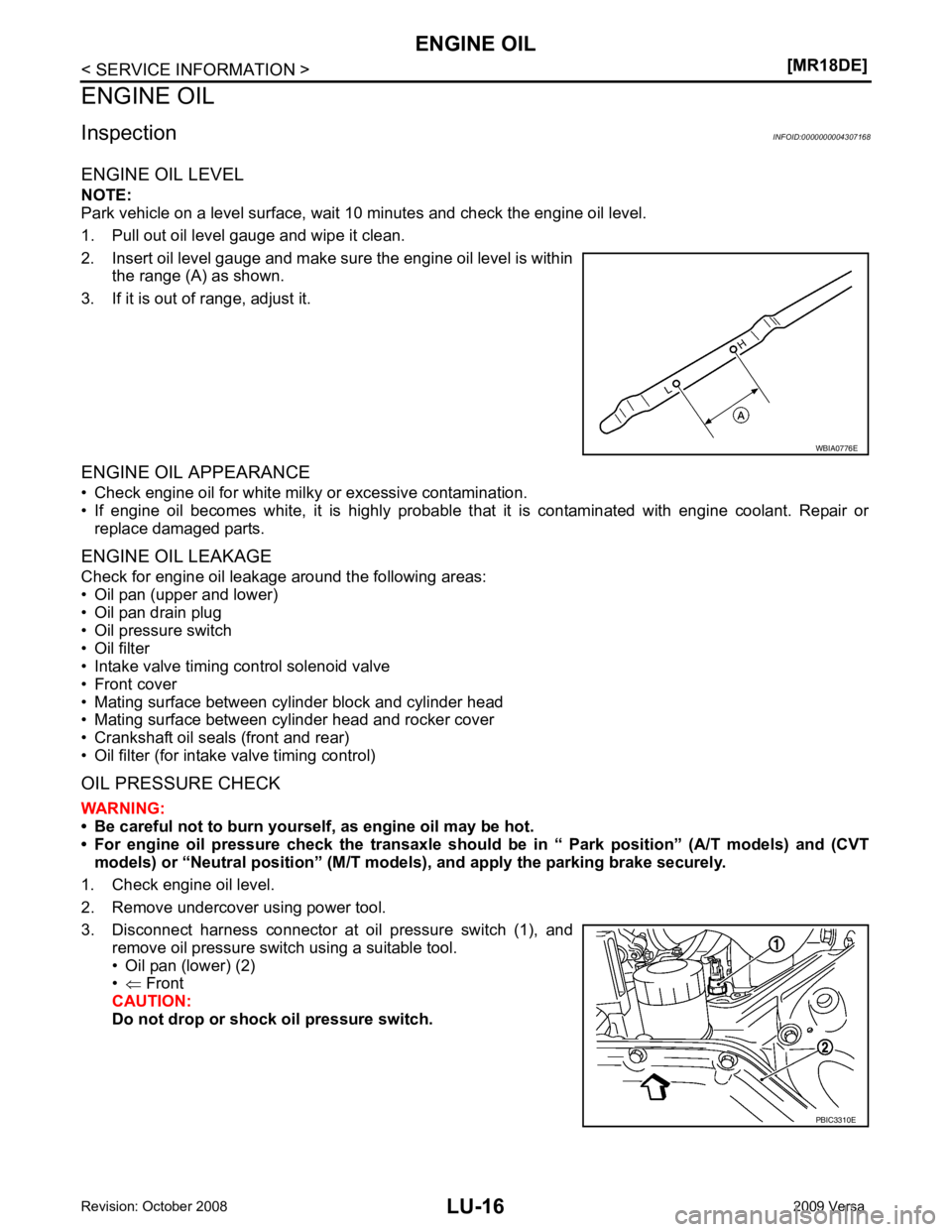

Removal and Installation INFOID:0000000004307170

REMOVAL 1. Remove oil filter using Tool (A). • : Front

WARNING:

• Be careful not to get burned when engine and engine oil

may be hot.

CAUTION:

• Oil filter is provided with relief valve. Use Genuine

NISSAN Oil Filter or equivalent.

• When removing, prepare a s hop cloth to absorb any

engine oil leakage or spillage.

• Do not spill engine oil on drive belt.

• Completely wipe off any engine oil that spills on engine and vehicle.

INSTALLATION 1. Remove foreign materials adhering to the oil filter installation surface.

2. Apply new engine oil to the oil seal contact surface of new oil fil- ter.

3. Screw oil filter manually until it touches the installation surface,

then tighten it by 2/3 turn. Or tighten to specification.

INSPECTION AFTER INSTALLATION 1. Check the engine oil level. Refer to LU-16, " Inspection " .

2. Start engine, and make sure there are no leaks of engine oil.

3. Stop engine and wait for 10 minutes.

4. Check the engine oil level and adjust as necessary. Refer to LU-16, " Inspection " .

Tool number : KV10115801 (J-38956) PBIC3818E

SMA010

Oil filter: : 17.7 N·m (1.8 kg-m, 13 ft-lb)

SMA229B