O2 sensor NISSAN LATIO 2010 Service Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2010, Model line: LATIO, Model: NISSAN LATIO 2010Pages: 3745, PDF Size: 73.67 MB

Page 1030 of 3745

![NISSAN LATIO 2010 Service Repair Manual CO-48

< SERVICE INFORMATION >[MR18DE]

WATER OUTLET AND WATER CONTROL VALVE

WATER OUTLET AND WATER CONTROL VALVE

ComponentINFOID:0000000005398226

Removal and InstallationINFOID:0000000005398227

REMOVAL NISSAN LATIO 2010 Service Repair Manual CO-48

< SERVICE INFORMATION >[MR18DE]

WATER OUTLET AND WATER CONTROL VALVE

WATER OUTLET AND WATER CONTROL VALVE

ComponentINFOID:0000000005398226

Removal and InstallationINFOID:0000000005398227

REMOVAL](/img/5/57358/w960_57358-1029.png)

CO-48

< SERVICE INFORMATION >[MR18DE]

WATER OUTLET AND WATER CONTROL VALVE

WATER OUTLET AND WATER CONTROL VALVE

ComponentINFOID:0000000005398226

Removal and InstallationINFOID:0000000005398227

REMOVAL

1. Drain engine coolant from radiator. Refer to

CO-36, "Changing Engine Coolant".

CAUTION:

• Perform this step when engine is cold.

• Never spill engine coolant on drive belt.

2. Remove battery and battery tray. Refer to SC-7, "

Removal and Installation".

3. Remove air cleaner and air duct. Refer to EM-135, "

Component".

4. Remove radiator hose (lower) from engine. Refer to CO-40, "

Component".

5. Remove heater hoses and water hoses.

6. Remove water outlet.

7. Remove water control valve.

8. Remove engine coolant temperature sensor from the water outlet, if necessary.

CAUTION:

• Handle carefully to avoid any shock to engine coolant temperature sensor.

• Replace the gasket with a new one.

INSPECTION AFTER REMOVAL

1. Engine coolant temperature sensor 2. Rubber ring 3. Water control valve

4. Gasket 5. Water hose 6. Gasket

7. Water hose 8. Water outlet 9. Heater hose

10. Heater hose 11. Radiator hose (upper) Front

A. To heater B. To electric throttle control actuator C. To radiator

PBIC4699E

Revision: January 20102010 Versa

Page 1035 of 3745

CVT-2

P0703 BRAKE SWITCH B ............................. ...60

Description ........................................................... ...60

CONSULT-III Reference Value in Data Monitor

Mode .................................................................... ...

60

On Board Diagnosis Logic ......................................60

Possible Cause .......................................................60

DTC Confirmation Procedure .................................60

Diagnosis Procedure ..............................................60

P0705 TRANSMISSION RANGE SWITCH A ....62

Description ..............................................................62

CONSULT-III Reference Value in Data Monitor

Mode .................................................................... ...

62

On Board Diagnosis Logic ......................................62

Possible Cause .......................................................62

DTC Confirmation Procedure .................................62

Wiring Diagram - CVT - TR/SW ..............................63

Diagnosis Procedure ..............................................64

Component Inspection ............................................65

P0710 TRANSMISSION FLUID TEMPERA-

TURE SENSOR A ..............................................

67

Description ........................................................... ...67

CONSULT-III Reference Value in Data Monitor

Mode .................................................................... ...

67

On Board Diagnosis Logic ......................................67

Possible Cause .......................................................67

DTC Confirmation Procedure .................................67

Wiring Diagram - CVT - FTS ...................................68

Diagnosis Procedure ..............................................69

Component Inspection ............................................70

P0715 INPUT SPEED SENSOR A ....................72

Description ........................................................... ...72

CONSULT-III Reference Value in Data Monitor

Mode .................................................................... ...

72

On Board Diagnosis Logic ......................................72

Possible Cause .......................................................72

DTC Confirmation Procedure .................................72

Wiring Diagram - CVT - PRSCVT ...........................73

Diagnosis Procedure ..............................................74

P0720 OUTPUT SPEED SENSOR ....................76

Description ........................................................... ...76

CONSULT-III Reference Value in Data Monitor

Mode .................................................................... ...

76

On Board Diagnosis Logic ......................................76

Possible Cause .......................................................76

DTC Confirmation Procedure .................................76

Wiring Diagram - CVT - SESCVT ...........................77

Diagnosis Procedure ........................................... ...78

P0725 ENGINE SPEED .....................................81

Description ........................................................... ...81

CONSULT-III Reference Value in Data Monitor

Mode .................................................................... ...

81

On Board Diagnosis Logic ......................................81

Possible Cause .......................................................81

DTC Confirmation Procedure .................................81

Diagnosis Procedure ..............................................81

P0730 INCORRECT GEAR RATIO ...................83

Description ........................................................... ...83

CONSULT-III Reference Value in Data Monitor

Mode .................................................................... ...

83

On Board Diagnosis Logic ......................................83

Possible Cause .......................................................83

DTC Confirmation Procedure ..................................83

Diagnosis Procedure ...............................................83

P0740 TORQUE CONVERTER .........................84

Description ........................................................... ...84

CONSULT-III Reference Value in Data Monitor

Mode .................................................................... ...

84

On Board Diagnosis Logic ......................................84

Possible Cause .......................................................84

DTC Confirmation Procedure ..................................84

Wiring Diagram - CVT - TCV ..................................85

Diagnosis Procedure ...............................................86

Component Inspection ............................................87

P0744 TORQUE CONVERTER .........................89

Description ........................................................... ...89

CONSULT-III Reference Value in Data Monitor

Mode .................................................................... ...

89

On Board Diagnosis Logic ......................................89

Possible Cause .......................................................89

DTC Confirmation Procedure ..................................89

Diagnosis Procedure ...............................................89

P0745 PRESSURE CONTROL SOLENOID A ...91

Description ........................................................... ...91

CONSULT-III Reference Value in Data Monitor

Mode .................................................................... ...

91

On Board Diagnosis Logic ......................................91

Possible Cause .......................................................91

DTC Confirmation Procedure ..................................91

Wiring Diagram - CVT - LPSV ................................92

Diagnosis Procedure ............................................ ...93

Component Inspection ............................................94

P0746 PRESSURE CONTROL SOLENOID A ...96

Description ........................................................... ...96

CONSULT-III Reference Value in Data Monitor

Mode .................................................................... ...

96

On Board Diagnosis Logic ......................................96

Possible Cause .......................................................96

DTC Confirmation Procedure ..................................96

Diagnosis Procedure ...............................................96

P0776 PRESSURE CONTROL SOLENOID B ...98

Description ........................................................... ...98

CONSULT-III Reference Value in Data Monitor

Mode .................................................................... ...

98

On Board Diagnosis Logic ......................................98

Possible Cause .......................................................98

DTC Confirmation Procedure ..................................98

Diagnosis Procedure ...............................................98

P0778 PRESSURE CONTROL SOLENOID B ..100

Description ........................................................... .100

Revision: January 20102010 Versa

Page 1036 of 3745

CVT-3

DE

F

G H

I

J

K L

M A

B

CVT

N

O

P

N

CONSULT-III Refe

rence Value in Data Monitor

Mode ................................................................... ..

100

On Board Diagnosis Logic ....................................100

Possible Cause .....................................................100

DTC Confirmation Procedure ................................100

Wiring Diagram - CVT - SECPSV ....................... ..101

Diagnosis Procedure ........................................... ..102

Component Inspection ..........................................103

P0840 TRANSMISSION FLUID PRESSURE

SEN/SW A ........................................................

105

Description ............................................................105

CONSULT-III Reference Value in Data Monitor

Mode ................................................................... ..

105

On Board Diagnosis Logic ....................................105

Possible Cause .....................................................105

DTC Confirmation Procedure ................................105

Wiring Diagram - CVT - SECPS ............................106

Diagnosis Procedure .............................................107

P0841 TRANSMISSION FLUID PRESSURE

SEN/SW A ........................................................

109

Description ............................................................109

CONSULT-III Reference Value in Data Monitor

Mode ................................................................... ..

109

On Board Diagnosis Logic ....................................109

Possible Cause .....................................................109

DTC Confirmation Procedure ................................109

Diagnosis Procedure .............................................109

P0868 TRANSMISSION FLUID PRESSURE ...111

Description .......................................................... ..111

CONSULT-III Reference Value in Data Monitor

Mode ................................................................... ..

111

On Board Diagnosis Logic ....................................111

Possible Cause .....................................................111

DTC Confirmation Procedure ................................111

Diagnosis Procedure .............................................111

P1701 TCM .......................................................113

Description .......................................................... ..113

On Board Diagnosis Logic ....................................113

Possible Cause .....................................................113

DTC Confirmation Procedure ................................113

Wiring Diagram - CVT - POWER ..........................114

Diagnosis Procedure .............................................115

P1705 TP SENSOR ..........................................117

Description .......................................................... ..117

CONSULT-III Reference Value in Data Monitor

Mode ................................................................... ..

117

On Board Diagnosis Logic ....................................117

Possible Cause .....................................................117

DTC Confirmation Procedure ................................117

Diagnosis Procedure .............................................117

P1722 VEHICLE SPEED ..................................119

Description ............................................................119

CONSULT-III Reference Value in Data Monitor

Mode ................................................................... ..

119

On Board Diagnosis Logic ................................... ..119

Possible Cause ......................................................119

DTC Confirmation Procedure ................................119

Diagnosis Procedure .............................................119

P1723 SPEED SENSOR .................................121

Description .............................................................121

On Board Diagnosis Logic .....................................121

Possible Cause ......................................................121

DTC Confirmation Procedure ................................121

Diagnosis Procedure .............................................121

P1726 THROTTLE CONTROL SIGNAL .........123

Description .............................................................123

On Board Diagnosis Logic .....................................123

Possible Cause ......................................................123

DTC Confirmation Procedure ................................123

Diagnosis Procedure .............................................123

P1740 SELECT SOLENOID ...........................124

Description .............................................................124

CONSULT-III Reference Value in Data Monitor

Mode .................................................................... ..

124

On Board Diagnosis Logic .....................................124

Possible Cause ......................................................124

DTC Confirmation Procedure ................................124

Wiring Diagram - CVT - L/USSV ...........................125

Diagnosis Procedure .............................................126

Component Inspection ...........................................127

P1745 LINE PRESSURE CONTROL ..............128

Description .............................................................128

On Board Diagnosis Logic .....................................128

Possible Cause ......................................................128

DTC Confirmation Procedure ................................128

Diagnosis Procedure .............................................128

P1777 STEP MOTOR ......................................129

Description .............................................................129

CONSULT-III Reference Value in Data Monitor

Mode .................................................................... ..

129

On Board Diagnosis Logic .....................................129

Possible Cause ......................................................129

DTC Confirmation Procedure ................................129

Wiring Diagram - CVT - STM .................................130

Diagnosis Procedure .............................................131

Component Inspection ...........................................132

P1778 STEP MOTOR ......................................133

Description .............................................................133

CONSULT-III Reference Value in Data Monitor

Mode .................................................................... ..

133

On Board Diagnosis Logic .....................................133

Possible Cause ......................................................133

DTC Confirmation Procedure ................................133

Diagnosis Procedure .............................................134

OVERDRIVE CONTROL SWITCH ..................135

Description .............................................................135

Revision: January 20102010 Versa

Page 1037 of 3745

CVT-4

CONSULT-III Reference Value in Data Monitor

Mode .................................................................... ..

135

Wiring Diagram - CVT - ODSW .............................136

Diagnosis Procedure .............................................136

Component Inspection ...........................................138

SHIFT POSITION INDICATOR CIRCUIT ........140

Description ........................................................... ..140

CONSULT-III Reference Value in Data Monitor

Mode .................................................................... ..

140

Diagnosis Procedure .............................................140

TROUBLE DIAGNOSIS FOR SYMPTOMS .....141

Wiring Diagram - CVT - NONDTC ....................... ..141

O/D OFF Indicator Lamp Does Not Come On .......143

Engine Cannot Be Started in "P" and "N" Position ..145

In "P" Position, Vehicle Moves Forward or Back-

ward When Pushed ...............................................

145

In "N" Position, Vehicle Moves ............................ ..146

Large Shock "N" → "R" Position .......................... ..146

Vehicle Does Not Creep Backward in "R" Position ..147

Vehicle Does Not Creep Forward in "D" or "L" Po-

sition ......................................................................

148

Vehicle Speed Does Not Change in "L" Position ...149

Vehicle Speed Does Not Change in overdrive-off

mode ......................................................................

150

Vehicle Speed Does Not Change in "D" Position ..151

Vehicle Does Not Decelerate by Engine Brake .....151

CVT SHIFT LOCK SYSTEM ........................... .153

Description ........................................................... ..153

Shift Lock System Electrical Parts Location ..........154

Wiring Diagram - CVT - SHIFT ..............................155

Diagnosis Procedure .............................................155

TCM ..................................................................159

Removal and Installation ..................................... ..159

SHIFT CONTROL SYSTEM ............................160

Removal and Installation .......................................160

CVT Shift Selector Disa ssembly and Assembly .. .163

Shift Lever Handle Removal and Installation ....... .163

Adjustment of CVT Position ................................. .164

Checking of CVT Position .....................................164

KEY INTERLOCK CABLE ...............................166

Removal and Installation .......................................166

PRIMARY SPEED SENSOR .......................... ..169

Exploded View ..................................................... .169

Removal and Installation .......................................169

Inspection ............................................................. .169

SECONDARY SPEED SENSOR ......................170

Exploded View ..................................................... .170

Removal and Installation .......................................170

Inspection ............................................................. .170

AIR BREATHER HOSE ....................................171

Removal and Installation .......................................171

DIFFERENTIAL SIDE OIL SEAL .....................172

Removal and Installation .......................................172

TRANSAXLE ASSEMBLY ............................. ..173

Removal and Installation .......................................173

SERVICE DATA AND SPECIFICATIONS

(SDS) .............................................................. ..

176

General Specification ........................................... .176

Vehicle Speed When Shifting Gears .....................176

Stall Speed ............................................................176

Line Pressure ........................................................176

Solenoid Valves ....................................................177

CVT Fluid Temperature Sensor ............................177

Primary Speed Sensor ..........................................177

Secondary Speed Sensor .................................... .177

Removal and Installation .......................................177

Revision: January 20102010 Versa

Page 1038 of 3745

![NISSAN LATIO 2010 Service Repair Manual INDEX FOR DTCCVT-5

< SERVICE INFORMATION > [RE0F08B]

D

E

F

G H

I

J

K L

M A

B

CVT

N

O P

SERVICE INFORMATION

INDEX FOR DTC

Alphabetical IndexINFOID:0000000005397756

NOTE:

If DTC “U1000” is displayed NISSAN LATIO 2010 Service Repair Manual INDEX FOR DTCCVT-5

< SERVICE INFORMATION > [RE0F08B]

D

E

F

G H

I

J

K L

M A

B

CVT

N

O P

SERVICE INFORMATION

INDEX FOR DTC

Alphabetical IndexINFOID:0000000005397756

NOTE:

If DTC “U1000” is displayed](/img/5/57358/w960_57358-1037.png)

INDEX FOR DTCCVT-5

< SERVICE INFORMATION > [RE0F08B]

D

E

F

G H

I

J

K L

M A

B

CVT

N

O P

SERVICE INFORMATION

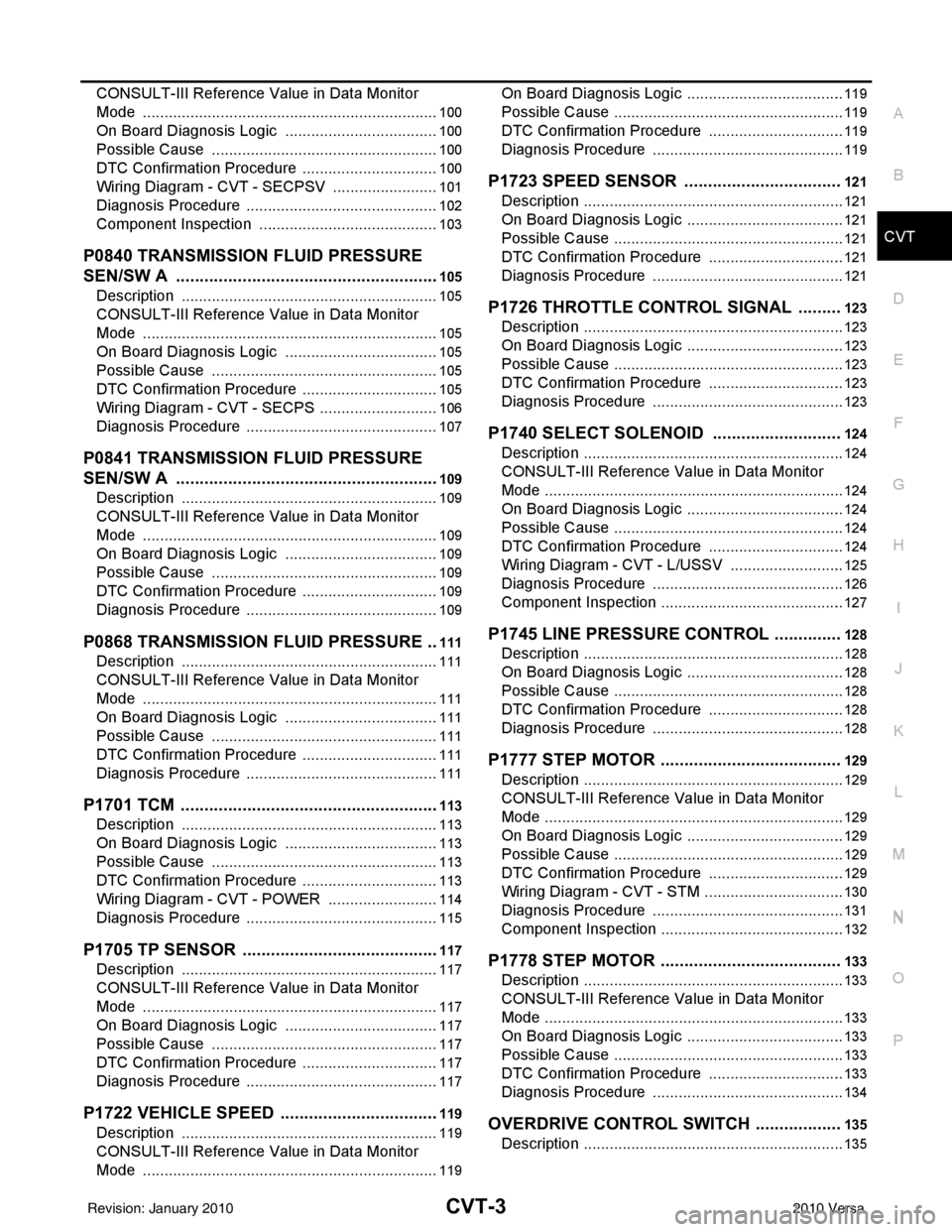

INDEX FOR DTC

Alphabetical IndexINFOID:0000000005397756

NOTE:

If DTC “U1000” is displayed with other DTCs, fi rst perform the trouble diagnosis for DTC “U1000”.

Refer to CVT-56

.

*1: These numbers are prescribed by SAE J2012.

*2: Models without ABS does not indicate.

DTC No. IndexINFOID:0000000005397757

NOTE:

If DTC “U1000” is displayed with other DTCs, fi rst perform the trouble diagnosis for DTC “U1000”.

Refer to CVT-56

.

Items

(CONSULT-III screen terms) DTC

Reference page

OBD-II

Except OBD-II

CONSULT-III GST*

1 CONSULT-III only

“TRANSMISSION”

BRAKE SWITCH B —P0703 CVT-60

CAN COMM CIRCUIT U1000 U1000 CVT-56

CONTROL UNIT (CAN)—U1010 CVT-59

ENGINE SPEED —P0725 CVT-81

FLUID PRESS LOW —P0868C V T- 111

FLUID PRESS SEN/SW A P0840P0840CVT-105

FLUID PRESS SEN/SW A —P0841CVT-109

FLUID TEMP SENSOR A P0710P0710CVT-67

INCORRECT GR RATIO —P0730 CVT-83

INPUT SPEED SENSOR A P0715P0715CVT-72

LINE PRESS CONTROL —P1745CVT-128

OUTPUT SPEED SENSOR P0720P0720CVT-76

PC SOLENOID A P0745P0745CVT-91

PC SOLENOID A P0746P0746CVT-96

PC SOLENOID B P0776P0776CVT-98

PC SOLENOID B P0778P0778CVT-100

SLCT SOLENOID P1740P1740CVT-124

SPEED SENSOR —P1723CVT-121

STEP MOTOR P1777P1777CVT-129

STEP MOTOR P1778P1778CVT-133

TCM —P1701CVT-113

THROTTLE CONTROL SIG —P1726CVT-123

T/M RANGE SENSOR A P0705P0705CVT-62

TORQUE CONVERTER P0740P0740CVT-84

TORQUE CONVERTER P0744 P0744 CVT-89

TP SENSOR —P1705CVT-117

VEHICLE SPEED*2— P1722CVT-119

Revision: January 20102010 Versa

Page 1039 of 3745

![NISSAN LATIO 2010 Service Repair Manual CVT-6

< SERVICE INFORMATION >[RE0F08B]

INDEX FOR DTC

*1: These numbers are pr

escribed by SAE J2012.

*2: Models without ABS does not indicate.

DTC

Items

(CONSULT-III screen terms) Reference page

OBD-I NISSAN LATIO 2010 Service Repair Manual CVT-6

< SERVICE INFORMATION >[RE0F08B]

INDEX FOR DTC

*1: These numbers are pr

escribed by SAE J2012.

*2: Models without ABS does not indicate.

DTC

Items

(CONSULT-III screen terms) Reference page

OBD-I](/img/5/57358/w960_57358-1038.png)

CVT-6

< SERVICE INFORMATION >[RE0F08B]

INDEX FOR DTC

*1: These numbers are pr

escribed by SAE J2012.

*2: Models without ABS does not indicate.

DTC

Items

(CONSULT-III screen terms) Reference page

OBD-II

Except OBD-II

CONSULT-III GST*

1CONSULT-III only

“TRANSMISSION”

— P0703 BRAKE SWITCH B CVT-60

P0705P0705 T/M RANGE SENSOR A CVT-62

P0710P0710 FLUID TEMP SENSOR A CVT-67

P0715P0715 INPUT SPEED SENSOR A CVT-72

P0720P0720 OUTPUT SPEED SENSOR CVT-76

—P0725 ENGINE SPEED CVT-81

—P0730 INCORRECT GR RATIO CVT-83

P0740P0740 TORQUE CONVERTER CVT-84

P0744 P0744 TORQUE CONVERTER CVT-89

P0745P0745 PC SOLENOID A CVT-91

P0746P0746 PC SOLENOID A CVT-96

P0776P0776 PC SOLENOID B CVT-98

P0778P0778 PC SOLENOID B CVT-100

P0840P0840 FLUID PRESS SEN/SW A CVT-105

—P0841 FLUID PRESS SEN/SW A CVT-109

—P0868 FLUID PRESS LOW C V T- 111

—P1701 TCM CVT-113

—P1705 TP SENSOR CVT-117

—P1722

VEHICLE SPEED*2CVT-119

— P1723 SPEED SENSOR CVT-121

—P1726 THROTTLE CONTROL SIG CVT-123

P1740P1740 SLCT SOLENOID CVT-124

—P1745 LINE PRESS CONTROL CVT-128

P1777P1777 STEP MOTOR CVT-129

P1778P1778 STEP MOTOR CVT-133

U1000U1000 CAN COMM CIRCUIT CVT-56

—U1010 CONTROL UNIT(CAN) CVT-59

Revision: January 20102010 Versa

Page 1040 of 3745

![NISSAN LATIO 2010 Service Repair Manual PRECAUTIONSCVT-7

< SERVICE INFORMATION > [RE0F08B]

D

E

F

G H

I

J

K L

M A

B

CVT

N

O P

PRECAUTIONS

Precaution for Supplemental Restraint System (SRS) "AIR BAG" and "SEAT BELT

PRE-TENSIONER"

INFOID:000 NISSAN LATIO 2010 Service Repair Manual PRECAUTIONSCVT-7

< SERVICE INFORMATION > [RE0F08B]

D

E

F

G H

I

J

K L

M A

B

CVT

N

O P

PRECAUTIONS

Precaution for Supplemental Restraint System (SRS) "AIR BAG" and "SEAT BELT

PRE-TENSIONER"

INFOID:000](/img/5/57358/w960_57358-1039.png)

PRECAUTIONSCVT-7

< SERVICE INFORMATION > [RE0F08B]

D

E

F

G H

I

J

K L

M A

B

CVT

N

O P

PRECAUTIONS

Precaution for Supplemental Restraint System (SRS) "AIR BAG" and "SEAT BELT

PRE-TENSIONER"

INFOID:0000000006046365

The Supplemental Restraint System such as “AIR BAG” and “SEAT BELT PRE-TENSIONER”, used along

with a front seat belt, helps to reduce the risk or severi ty of injury to the driver and front passenger for certain

types of collision. This system includes seat belt switch inputs and dual stage front air bag modules. The SRS

system uses the seat belt switches to determine the front air bag deployment, and may only deploy one front

air bag, depending on the severity of a collision and w hether the front occupants are belted or unbelted.

Information necessary to service the system safely is included in the SRS and SB section of this Service Man-

ual.

WARNING:

• To avoid rendering the SRS inoper ative, which could increase the risk of personal injury or death in

the event of a collision which would result in air bag inflation, all maintenance must be performed by

an authorized NISSAN/INFINITI dealer.

• Improper maintenance, including in correct removal and installation of the SRS can lead to personal

injury caused by unintentional act ivation of the system. For removal of Spiral Cable and Air Bag

Module, see the SRS section.

• Do not use electrical test equipm ent on any circuit related to the SRS unless instructed to in this

Service Manual. SRS wiring harnesses can be identi fied by yellow and/or orange harnesses or har-

ness connectors.

PRECAUTIONS WHEN USING POWER TOOLS (AIR OR ELECTRIC) AND HAMMERS

WARNING:

• When working near the Airbag Diagnosis Sensor Un it or other Airbag System sensors with the Igni-

tion ON or engine running, DO NOT use air or el ectric power tools or strike near the sensor(s) with a

hammer. Heavy vibration could activate the sensor( s) and deploy the air bag(s), possibly causing

serious injury.

• When using air or electric power tools or hammers, always switch the Ignition OFF, disconnect the battery, and wait at least 3 minutes before performing any service.

Precaution Necessary for Steering Wheel Rotation After Battery Disconnect

INFOID:0000000005397759

NOTE:

• This Procedure is applied only to models with Intelligent Key system and NVIS /IVIS (NISSAN/INFINITI

VEHICLE IMMOBILIZER SYSTEM - NATS).

• Remove and install all control units after disconnecti ng both battery cables with the ignition knob in the

″ LOCK ″ position.

• Always use CONSULT-III to perform self-diagnosis as a part of each function inspection after finishing work.

If DTC is detected, perform trouble diagnosis according to self-diagnostic results.

For models equipped with the Intelligent Key system and NVIS/IVIS, an electrically controlled steering lock

mechanism is adopted on the key cylinder.

For this reason, if the battery is disconnected or if the battery is discharged, the steering wheel will lock and

steering wheel rotation will become impossible.

If steering wheel rotation is required when battery power is interrupted, follow the procedure below before

starting the repair operation.

OPERATION PROCEDURE

1. Connect both battery cables. NOTE:

Supply power using jumper cables if battery is discharged.

2. Use the Intelligent Key or mechanical key to turn the ignition switch to the ″ACC ″ position. At this time, the

steering lock will be released.

3. Disconnect both battery cables. The steering lock will remain released and the steering wheel can be

rotated.

4. Perform the necessary repair operation.

5. When the repair work is completed, return the ignition switch to the ″LOCK ″ position before connecting

the battery cables. (At this time, the steering lock mechanism will engage.)

Revision: January 20102010 Versa

Page 1041 of 3745

![NISSAN LATIO 2010 Service Repair Manual CVT-8

< SERVICE INFORMATION >[RE0F08B]

PRECAUTIONS

6. Perform a self-diagnosis check of a

ll control units using CONSULT-III.

Precaution for On Board Diagnosis (OBD) System of CVT and EngineINFOID:00 NISSAN LATIO 2010 Service Repair Manual CVT-8

< SERVICE INFORMATION >[RE0F08B]

PRECAUTIONS

6. Perform a self-diagnosis check of a

ll control units using CONSULT-III.

Precaution for On Board Diagnosis (OBD) System of CVT and EngineINFOID:00](/img/5/57358/w960_57358-1040.png)

CVT-8

< SERVICE INFORMATION >[RE0F08B]

PRECAUTIONS

6. Perform a self-diagnosis check of a

ll control units using CONSULT-III.

Precaution for On Board Diagnosis (OBD) System of CVT and EngineINFOID:0000000005397760

The ECM has an on board diagnostic system. It will light up the malfunction indicator lamp (MIL) to warn the

driver of a malfunction causing emission deterioration.

CAUTION:

• Be sure to turn the ignition switch OFF and disconnect the battery cable from the negative terminal

before any repair or inspection work. The open/sho rt circuit of related switches, sensors, solenoid

valves, etc. will cause the MIL to light up.

• Be sure to connect and lock the connectors secure ly after work. A loose (unlocked) connector will

cause the MIL to light up due to an open circuit. (Be sure the connector is free from water, grease,

dirt, bent terminals, etc.)

• Be sure to route and secure th e harnesses properly after work. Interference of the harness with a

bracket, etc. may cause the MIL to light up due to a short circuit.

• Be sure to connect rubber tubes properly afte r work. A misconnected or disconnected rubber tube

may cause the MIL to light up due to a malfunction of the EVAP system or fuel injection system, etc.

• Be sure to erase the unnecessary malfunction informa tion (repairs completed) from the TCM and

ECM before returning the vehicle to the customer.

Service After Replacing TCM and Transaxle AssemblyINFOID:0000000005525365

SERVICE AFTER REPLACING TCM AND TRANSAXLE ASSEMBLY

Perform the applicable service according to the following table when replacing TCM or transaxle assembly.

CAUTION:

• Never start the engine unti l the service is completed.

• “DTC P1701” may be indicated soon after replaci ng TCM or transaxle assembly (after erasing the

memory in the pattern B). Restart the self-diagnos is after erasing the self-diagnosis result using

CONSULT-III. Check that no error is detected.

NOTE:

Old unit means that the unit has been already used for another vehicle.

PATTERN A

1. Shift the selector lever to “P” position after replacing TCM.

2. Turn ignition switch ON.

3. Check that the shift position indicator in the combination meter turns ON (It indicates approximately 1 or 2 seconds after turning ignition switch ON.)

• Check the following items if shift position indicator does not turn ON. Repair or replace accordingly as

necessary.

- The harness between TCM and ROM ASSY in tr ansaxle assembly is open or shorted.

- Terminals disconnected, loose, or bent from connector housing.

PATTERN B

1. Turn ignition switch ON after replacing each part.

2. Connect the vehicle with CONSULT-III.

3. Start engine.

CAUTION:

Never start driving.

4. Select “Data monitor” in “TRANSMISSION”.

5. Warm up transaxle assembly until “ATFTEMP COUNT” indicates 47 [approximately 20° C (68°F)] or more,

and then turn ignition switch OFF.

TCM Transaxle assembly Service pattern

Replaced with new unit Not replaced the unit “PATTERN A”

Not replaced the unit Replaced with new or old unit

“PATTERN B”

Replaced with old unit Not replaced the unit

Replaced with new or old unit

Replaced with new unit Replaced with new or old unit “PATTERN C”

Revision: January 20102010 Versa

Page 1054 of 3745

![NISSAN LATIO 2010 Service Repair Manual CVT SYSTEMCVT-21

< SERVICE INFORMATION > [RE0F08B]

D

E

F

G H

I

J

K L

M A

B

CVT

N

O P

Hydraulic Control SystemINFOID:0000000005397772

TCM FunctionINFOID:0000000005397773

The function of the TCM is to:

NISSAN LATIO 2010 Service Repair Manual CVT SYSTEMCVT-21

< SERVICE INFORMATION > [RE0F08B]

D

E

F

G H

I

J

K L

M A

B

CVT

N

O P

Hydraulic Control SystemINFOID:0000000005397772

TCM FunctionINFOID:0000000005397773

The function of the TCM is to:](/img/5/57358/w960_57358-1053.png)

CVT SYSTEMCVT-21

< SERVICE INFORMATION > [RE0F08B]

D

E

F

G H

I

J

K L

M A

B

CVT

N

O P

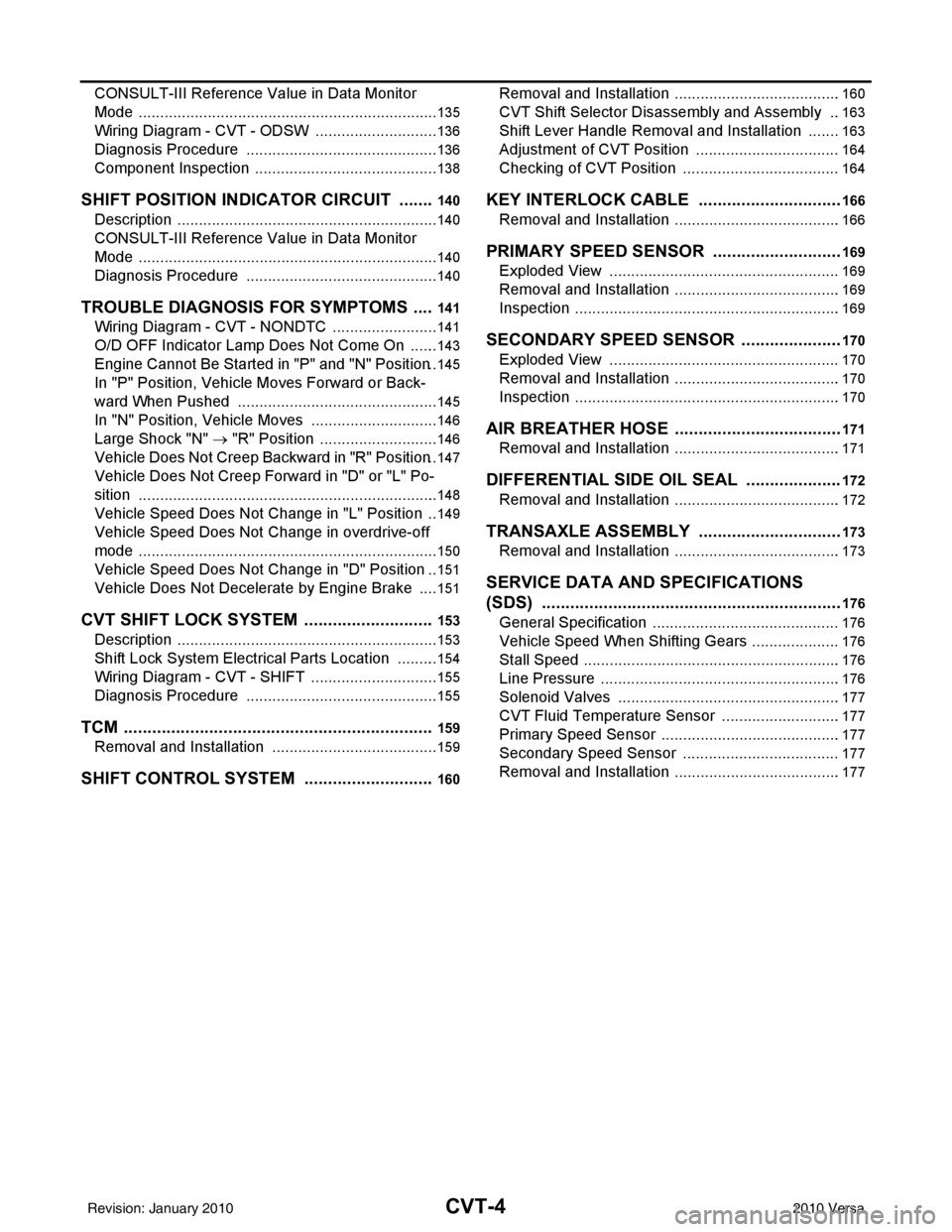

Hydraulic Control SystemINFOID:0000000005397772

TCM FunctionINFOID:0000000005397773

The function of the TCM is to:

• Receive input signals sent from various switches and sensors.

• Determine required line pressure, shifting point, and lock-up operation.

• Send required output signals to the step motor and the respective solenoids.

CONTROL SYSTEM OUTLINE

The CVT senses vehicle operating conditions through various sensors. It always controls the optimum shift

position and reduces shifting and lock-up shocks.

AWDIA0768GB

SENSORS (or SIGNAL)

⇒TCM

⇒ACTUATORS

Transmission range switch

Accelerator pedal position signal

Closed throttle position signal

Engine speed signal

CVT fluid temperature sensor

Vehicle speed signal

Overdrive control signal

Stop lamp switch signal

Primary speed sensor

Secondary speed sensor

Secondary pressure sensor Shift control

Line pressure control

Primary pressure control

Secondary pressure control

Lock-up control

Engine brake control

Vehicle speed control

Fail-safe control

Self-diagnosis

CONSULT-III co

mmunication

line

Duet-EA control

CAN system

On board diagnosis Step motor

Torque converter clutch solenoid

valve

Lock-up select solenoid valve

Line pressure solenoid valve

Secondary pressure solenoid

valve

Shift position indicator

O/D OFF indicator lamp

Starter relay

Revision: January 20102010 Versa

Page 1055 of 3745

![NISSAN LATIO 2010 Service Repair Manual CVT-22

< SERVICE INFORMATION >[RE0F08B]

CVT SYSTEM

CONTROL SYSTEM DIAGRAM

CAN CommunicationINFOID:0000000005397774

SYSTEM DESCRIPTION

CAN (Controller Area Network) is a serial communication line for NISSAN LATIO 2010 Service Repair Manual CVT-22

< SERVICE INFORMATION >[RE0F08B]

CVT SYSTEM

CONTROL SYSTEM DIAGRAM

CAN CommunicationINFOID:0000000005397774

SYSTEM DESCRIPTION

CAN (Controller Area Network) is a serial communication line for](/img/5/57358/w960_57358-1054.png)

CVT-22

< SERVICE INFORMATION >[RE0F08B]

CVT SYSTEM

CONTROL SYSTEM DIAGRAM

CAN CommunicationINFOID:0000000005397774

SYSTEM DESCRIPTION

CAN (Controller Area Network) is a serial communication line for real time application. It is an on-vehicle mul-

tiplex communication line with high data communication s

peed and excellent error detection ability. Many elec-

tronic control units are equipped onto a vehicle, and each control unit shares information and links with other

control units during operation (not independent). In CA N communication, control units are connected with 2

communication lines (CAN-H line, CAN-L line) allowing a high rate of information transmission with less wiring.

Each control unit transmits/receives data but selectively reads required data only. For details, refer to LAN-7,

"System Description".

Input/Output Signal of TCMINFOID:0000000005397775

AWDIA0769GB

Control itemFluid

pressure control Select con-

trol Shift control Lock-up

control CAN com-

munication control Fail-safe

function (*3)

Input T

ra n sm is sio n r ang e s wit c h XXXXXX

Accelerator pedal position signal

(*1)XXXXXX

Closed throttle position signal

(*1)X XXX

Engine speed signal

(*1)XX XXX

CVT fluid temperature sensor XX XX X

Stop lamp switch signal

(*1)X XXX

Overdrive control signal

(*1)XX

Primary speed sensor X XXXX

Secondary speed sensor XXXXXX

Secondary pressure sensor XX X

T C M pow er s upp ly v olt a ge s ig n al XXXXXX

Revision: January 20102010 Versa