NISSAN LATIO 2010 Service Repair Manual

Manufacturer: NISSAN, Model Year: 2010, Model line: LATIO, Model: NISSAN LATIO 2010Pages: 3745, PDF Size: 73.67 MB

Page 2681 of 3745

HOW TO USE THIS MANUALGI-15

< SERVICE INFORMATION >

C

DE

F

G H

I

J

K L

M B

GI

N

O P

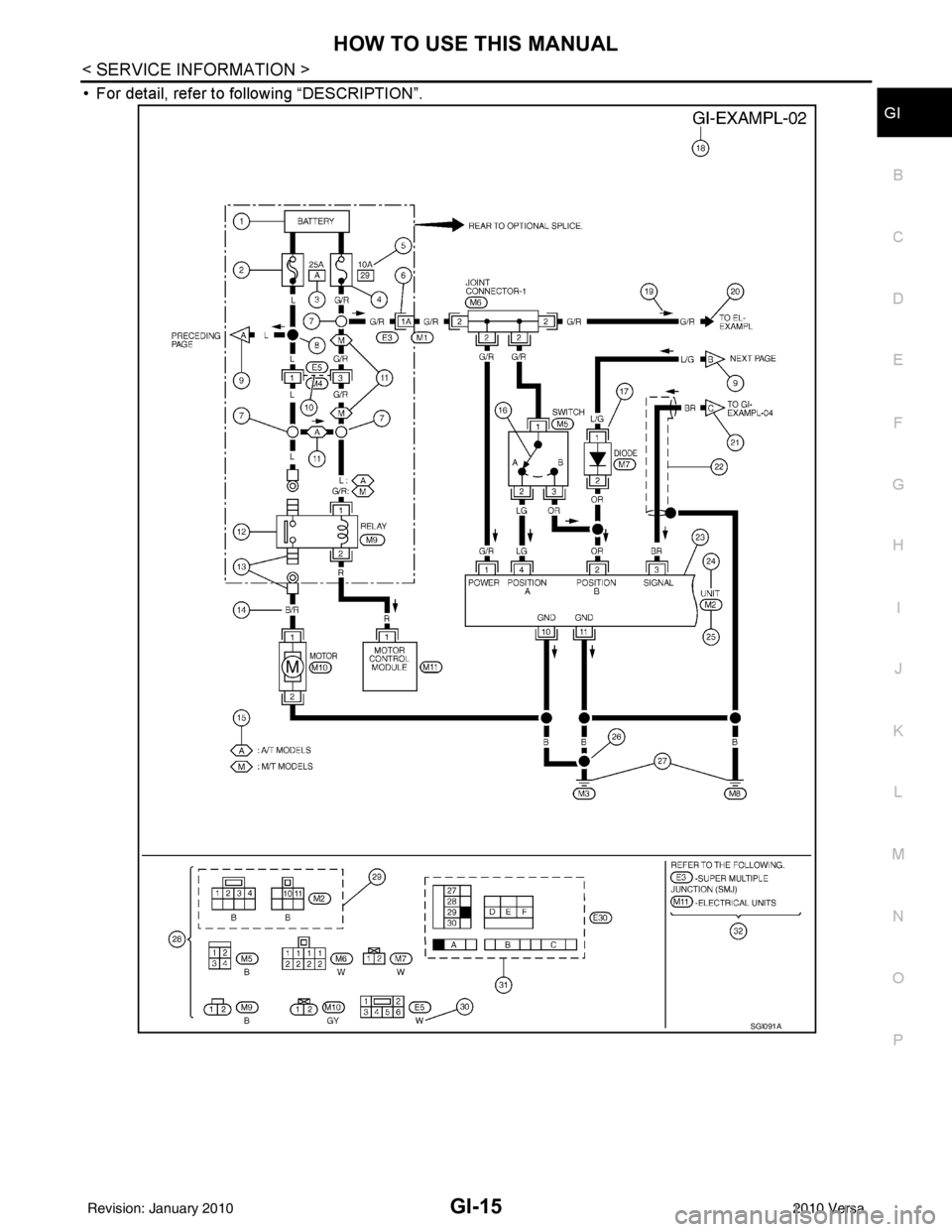

• For detail, refer to following “DESCRIPTION”.

SGI091A

Revision: January 20102010 Versa

Page 2682 of 3745

GI-16

< SERVICE INFORMATION >

HOW TO USE THIS MANUAL

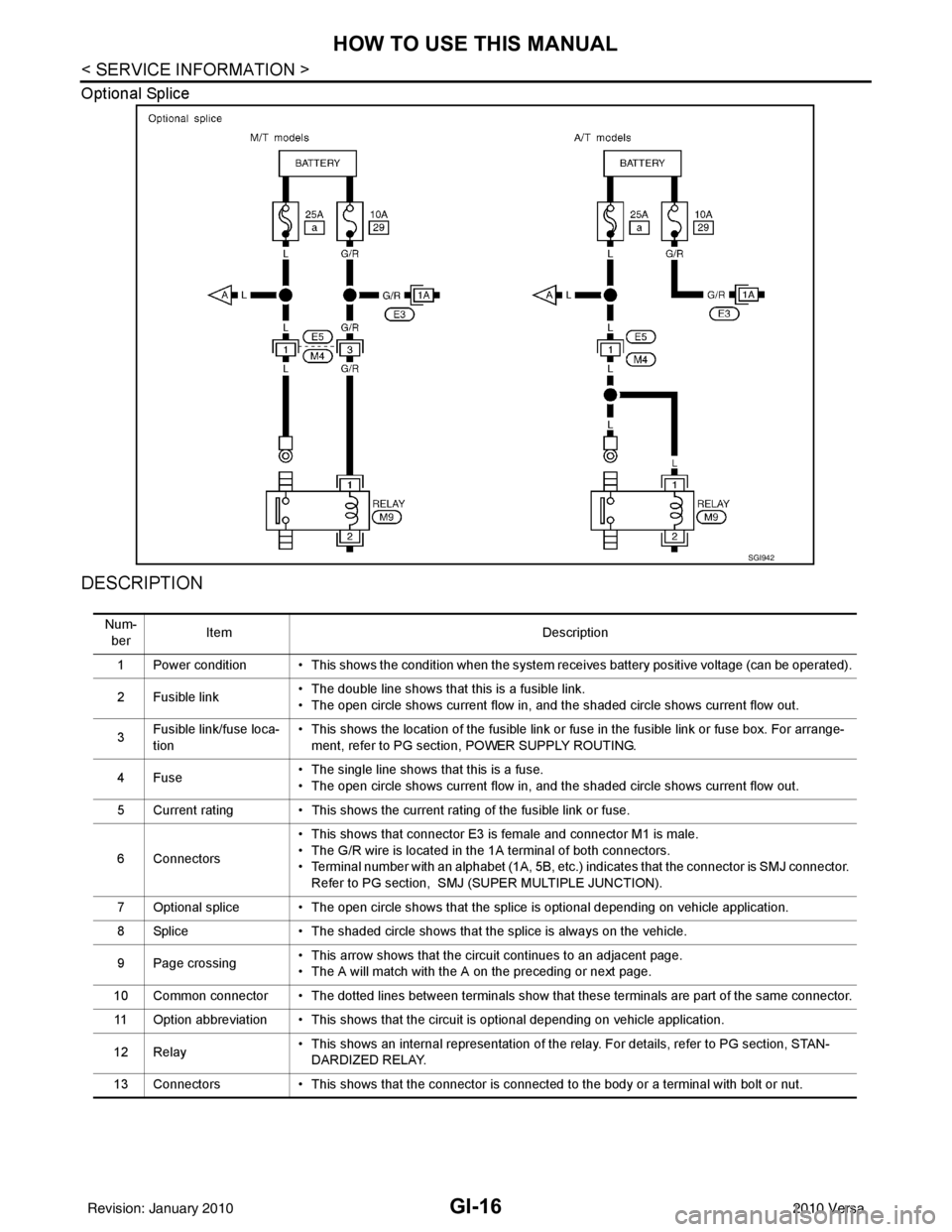

Optional Splice

DESCRIPTION

SGI942

Num-ber Item

Description

1 Power condition • This shows the condition when the system receives battery positive voltage (can be operated).

2 Fusible link • The double line shows that this is a fusible link.

• The open circle shows current flow in, and the shaded circle shows current flow out.

3 Fusible link/fuse loca-

tion • This shows the location of the fusible link or fuse in the fusible link or fuse box. For arrange-

ment, refer to PG section, POWER SUPPLY ROUTING.

4Fuse • The single line shows that this is a fuse.

• The open circle shows current flow in, and the shaded circle shows current flow out.

5 Current rating • This shows the current rating of the fusible link or fuse.

6 Connectors • This shows that connector E3 is female and connector M1 is male.

• The G/R wire is located in the 1A terminal of both connectors.

• Terminal number with an alphabet (1A, 5B, etc.) indicates that the connector is SMJ connector.

Refer to PG section, SMJ (SUPER MULTIPLE JUNCTION).

7 Optional splice • The open circle shows that the splice is optional depending on vehicle application.

8 Splice • The shaded circle shows that the splice is always on the vehicle.

9 Page crossing • This arrow shows that the circuit continues to an adjacent page.

• The A will match with the A on the preceding or next page.

10 Common connector • The dotted lines between terminals show that these terminals are part of the same connector. 11 Option abbreviation • This shows that the circuit is optional depending on vehicle application.

12 Relay • This shows an internal representation of the relay. For details, refer to PG section, STAN-

DARDIZED RELAY.

13 Connectors • This shows that the connector is connected to the body or a terminal with bolt or nut.

Revision: January 20102010 Versa

Page 2683 of 3745

HOW TO USE THIS MANUALGI-17

< SERVICE INFORMATION >

C

DE

F

G H

I

J

K L

M B

GI

N

O P

Harness Indication

14 Wire color • This shows a code for the color of the wire.

B = Black

W = White

R = Red

G = Green

L = Blue

Y = Yellow

LG = Light Green BR = Brown

OR or O = Orange

P = Pink

PU or V (Violet) = Purple

GY or GR = Gray

SB = Sky Blue

CH = Dark Brown

DG = Dark Green

When the wire color is striped, the base color is given first, followed by the stripe color as shown

below:

Example: L/W = Blue with White Stripe

15 Option description • This shows a description of the option abbreviation used on the page.

16 Switch • This shows that continuity exists between terminals 1 and 2 when the switch is in the A posi-

tion. Continuity exists between terminals 1 and 3 when the switch is in the B position.

17 Assembly parts • Connector terminal in component shows that it is a harness incorporated assembly.

18 Cell code • This identifies each page of the wiring diagram by section, system and wiring diagram page

number.

19 Current flow arrow • Arrow indicates electric current flow, especially where the direction of standard flow (vertically

downward or horizontally from left to right) is difficult to follow.

• A double arrow “ ” shows that current can flow in either direction depending on circuit operation.

20 System branch • This shows that the system branches to another system identified by cell code (section and

system).

21 Page crossing • This arrow shows that the circuit continues to another page identified by cell code.

• The C will match with the C on another page within the system other than the next or preceding

pages.

22 Shielded line • The line enclosed by broken line circle shows shield wire.

23 Component box in

wave line • This shows that another part of the component is also shown on another page (indicated by

wave line) within the system.

24 Component name • This shows the name of a component.

25 Connector number • This shows the connector number.

• The letter shows which harness the connector is located in.

•Example:

M: main harness. For detail and to locate the connector, refer to PG section "Main

Harness", “Harness Layout”. A coordinate grid is included for complex harnesses to aid in lo-

cating connectors.

26 Ground (GND) • The line spliced and grounded under wire color shows that ground line is spliced at the ground-

ed connector.

27 Ground (GND) • This shows the ground connection. For detailed ground distribution information, refer to

"Ground Distribution" in PG section.

28 Connector views • This area shows the connector faces of the components in the wiring diagram on the page.

29 Common component • Connectors enclosed in broken line show that these connectors belong to the same compo-

nent.

30 Connector color • This shows a code for the color of the connector. For code meaning, refer to wire color codes,

Number 14 of this chart.

31 Fusible link and fuse

box • This shows the arrangement of fusible link(s) and fuse(s), used for connector views of "POW-

ER SUPPLY ROUTING" in PG section.

The open square shows current flow in, and the shaded square shows current flow out.

32 Reference area • This shows that more information on the Super Multiple Junction (SMJ) and Joint Connectors

(J/C) exists on the PG section. Refer to "Reference Area" for details.

Num-

ber Item

Description

Revision: January 20102010 Versa

Page 2684 of 3745

GI-18

< SERVICE INFORMATION >

HOW TO USE THIS MANUAL

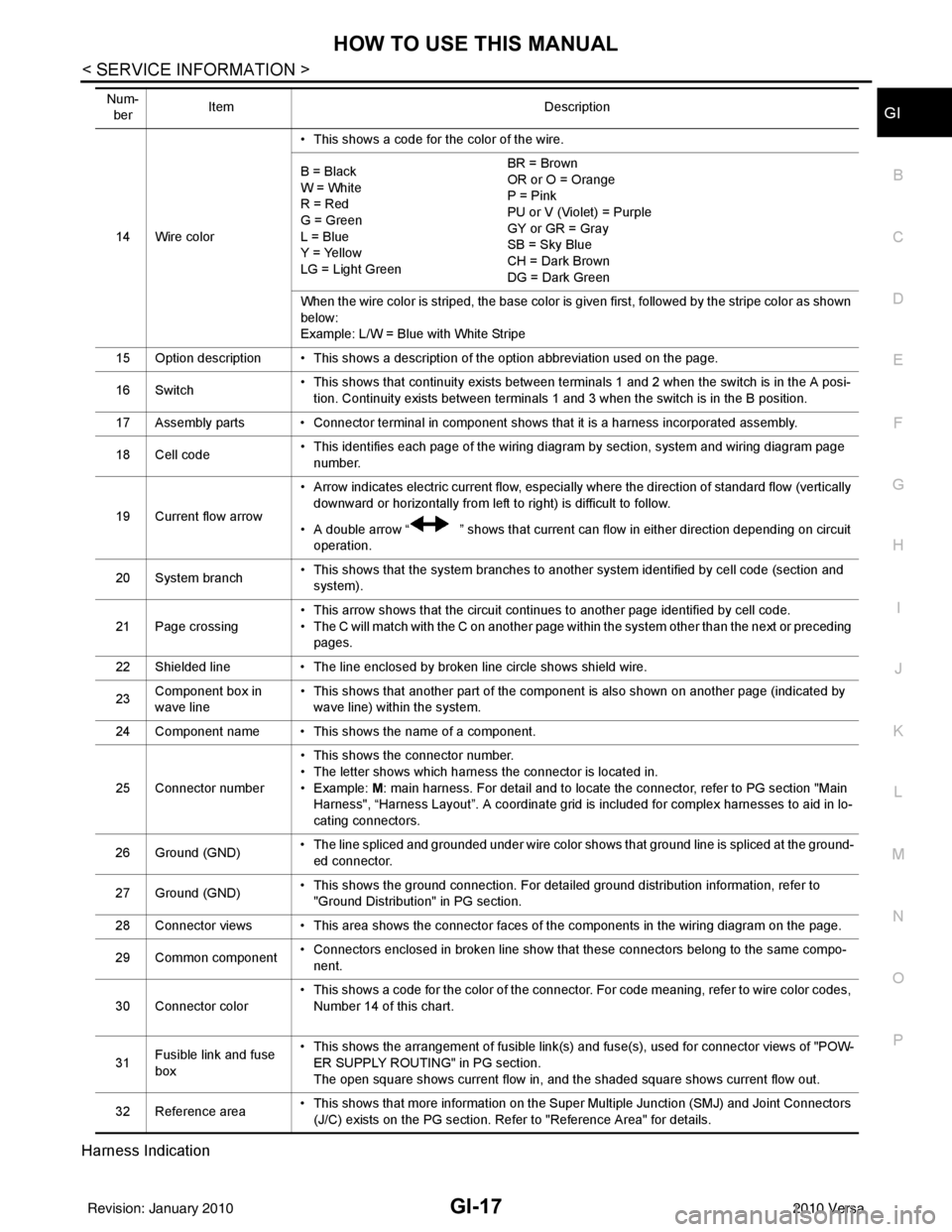

• Letter designations next to test meter probe indicate harness (con-nector) wire color.

• Connector numbers in a single circle M33 indicate harness con-

nectors.

Component Indication

Connector numbers in a double circle F211 indicate component connectors.

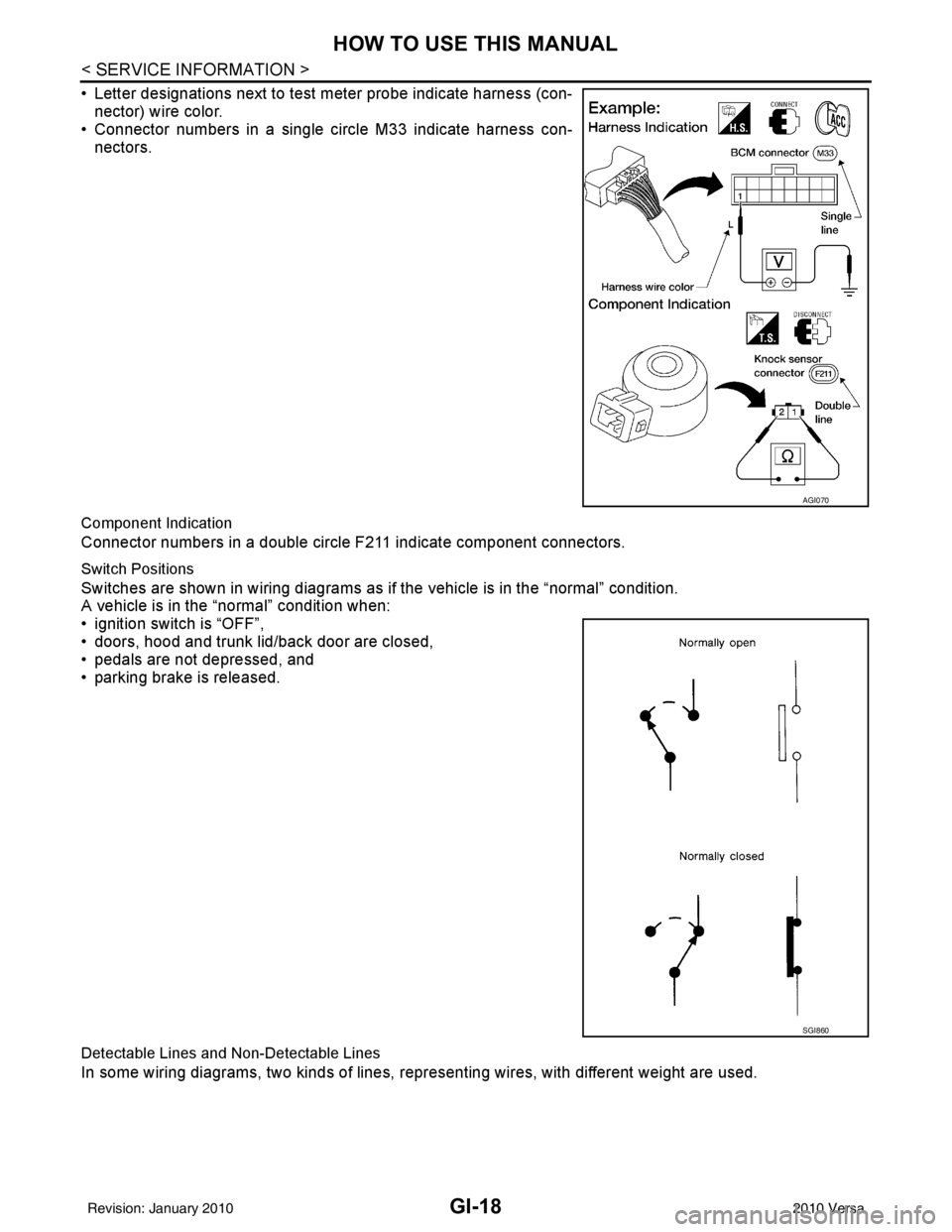

Switch Positions

Switches are shown in wiring diagrams as if the vehicle is in the “normal” condition.

A vehicle is in the “normal” condition when:

• ignition switch is “OFF”,

• doors, hood and trunk lid/back door are closed,

• pedals are not depressed, and

• parking brake is released.

Detectable Lines and Non-Detectable Lines

In some wiring diagrams, two kinds of lines, r epresenting wires, with different weight are used.

AGI070

SGI860

Revision: January 20102010 Versa

Page 2685 of 3745

HOW TO USE THIS MANUALGI-19

< SERVICE INFORMATION >

C

DE

F

G H

I

J

K L

M B

GI

N

O P

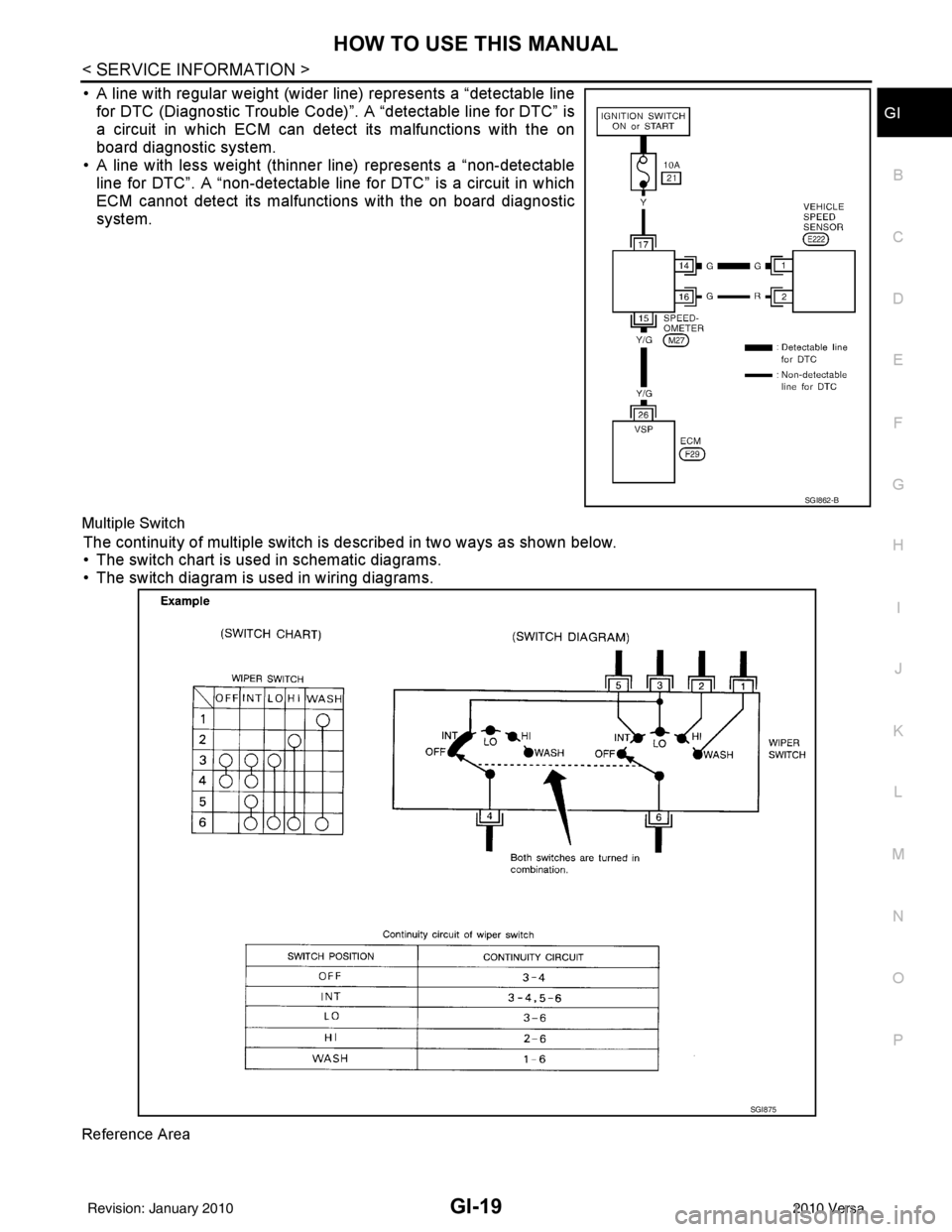

• A line with regular weight (wider line) represents a “detectable line for DTC (Diagnostic Trouble Code)”. A “detectable line for DTC” is

a circuit in which ECM can detect its malfunctions with the on

board diagnostic system.

• A line with less weight (thinner line) represents a “non-detectable line for DTC”. A “non-detectable line for DTC” is a circuit in which

ECM cannot detect its malfunctions with the on board diagnostic

system.

Multiple Switch

The continuity of multiple switch is described in two ways as shown below.

• The switch chart is used in schematic diagrams.

• The switch diagram is used in wiring diagrams.

Reference Area

SGI862-B

SGI875

Revision: January 20102010 Versa

Page 2686 of 3745

GI-20

< SERVICE INFORMATION >

HOW TO USE THIS MANUAL

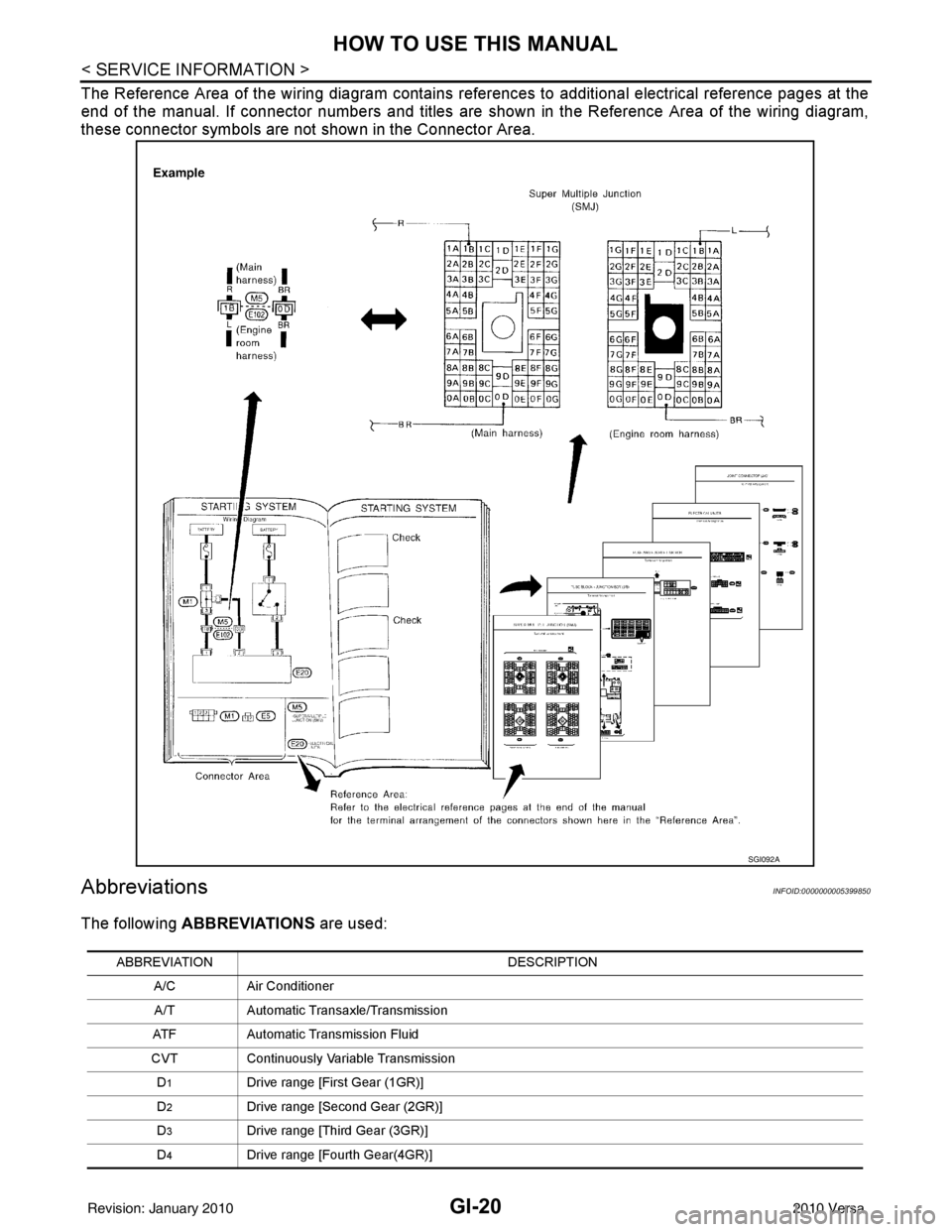

The Reference Area of the wiring diagram contains references to additional electrical reference pages at the

end of the manual. If connector numbers and titles are shown in the Reference Area of the wiring diagram,

these connector symbols are not shown in the Connector Area.

AbbreviationsINFOID:0000000005399850

The following ABBREVIATIONS are used:

SGI092A

ABBREVIATION DESCRIPTION

A/C Air Conditioner

A/T Automatic Transaxle/Transmission

ATF Automatic Transmission Fluid

CVT Continuously Variable Transmission

D

1Drive range [First Gear (1GR)]

D

2Drive range [Second Gear (2GR)]

D

3Drive range [Third Gear (3GR)]

D

4Drive range [Fourth Gear(4GR)]

Revision: January 20102010 Versa

Page 2687 of 3745

HOW TO USE THIS MANUALGI-21

< SERVICE INFORMATION >

C

DE

F

G H

I

J

K L

M B

GI

N

O PFR, RR Front, RearLH, RH Left-Hand, Right-Hand M/T Manual Transaxle/Transmission

OD Overdrive

P/S Power Steering

SAE Society of Automotive Engineers, Inc.

SDS Service Data and Specifications

SST Special Service Tools

2WD 2-Wheel Drive

2

22nd range Second [Gear (2GR)]

2

12nd range First [Gear (1GR)]

1

21st range Second [Gear (2GR)]

1

11st range First [Gear (1GR)]

ABBREVIATION

DESCRIPTION

Revision: January 20102010 Versa

Page 2688 of 3745

GI-22

< SERVICE INFORMATION >

SERVICE INFORMATION FOR ELECTRICAL INCIDENT

SERVICE INFORMATION FOR ELECTRICAL INCIDENT

How to Check TerminalINFOID:0000000005399851

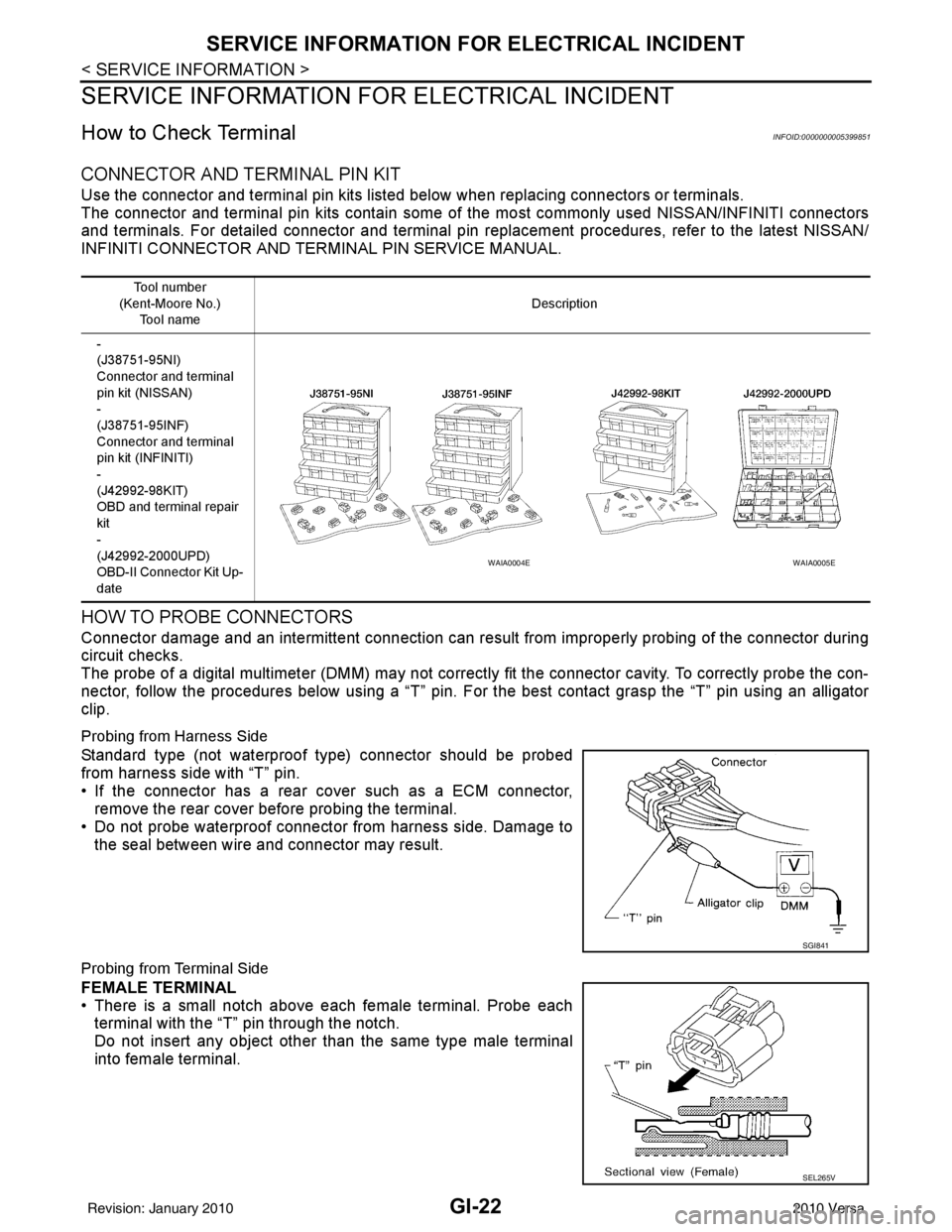

CONNECTOR AND TERMINAL PIN KIT

Use the connector and terminal pin kits listed below when replacing connectors or terminals.

The connector and terminal pin kits contain some of the most commonly used NISSAN/INFINITI connectors

and terminals. For detailed connector and terminal pin repl acement procedures, refer to the latest NISSAN/

INFINITI CONNECTOR AND TERMINAL PIN SERVICE MANUAL.

HOW TO PROBE CONNECTORS

Connector damage and an intermittent connection can result from improperly probing of the connector during

circuit checks.

The probe of a digital multimeter (DMM) may not correct ly fit the connector cavity. To correctly probe the con-

nector, follow the procedures below using a “T” pin. For the best contact grasp the “T” pin using an alligator

clip.

Probing from Harness Side

Standard type (not waterproof type) connector should be probed

from harness side with “T” pin.

• If the connector has a rear cover such as a ECM connector, remove the rear cover before probing the terminal.

• Do not probe waterproof connector from harness side. Damage to

the seal between wire and connector may result.

Probing from Terminal Side

FEMALE TERMINAL

• There is a small notch above each female terminal. Probe eachterminal with the “T” pin through the notch.

Do not insert any object other than the same type male terminal

into female terminal.

Tool number

(Kent-Moore No.) Tool name Description

-

(J38751-95NI)

Connector and terminal

pin kit (NISSAN)

-

(J38751-95INF)

Connector and terminal

pin kit (INFINITI)

-

(J42992-98KIT)

OBD and terminal repair

kit

-

(J42992-2000UPD)

OBD-II Connector Kit Up-

date

WAIA0004EWAIA0005E

SGI841

SEL265V

Revision: January 20102010 Versa

Page 2689 of 3745

SERVICE INFORMATION FOR ELECTRICAL INCIDENTGI-23

< SERVICE INFORMATION >

C

DE

F

G H

I

J

K L

M B

GI

N

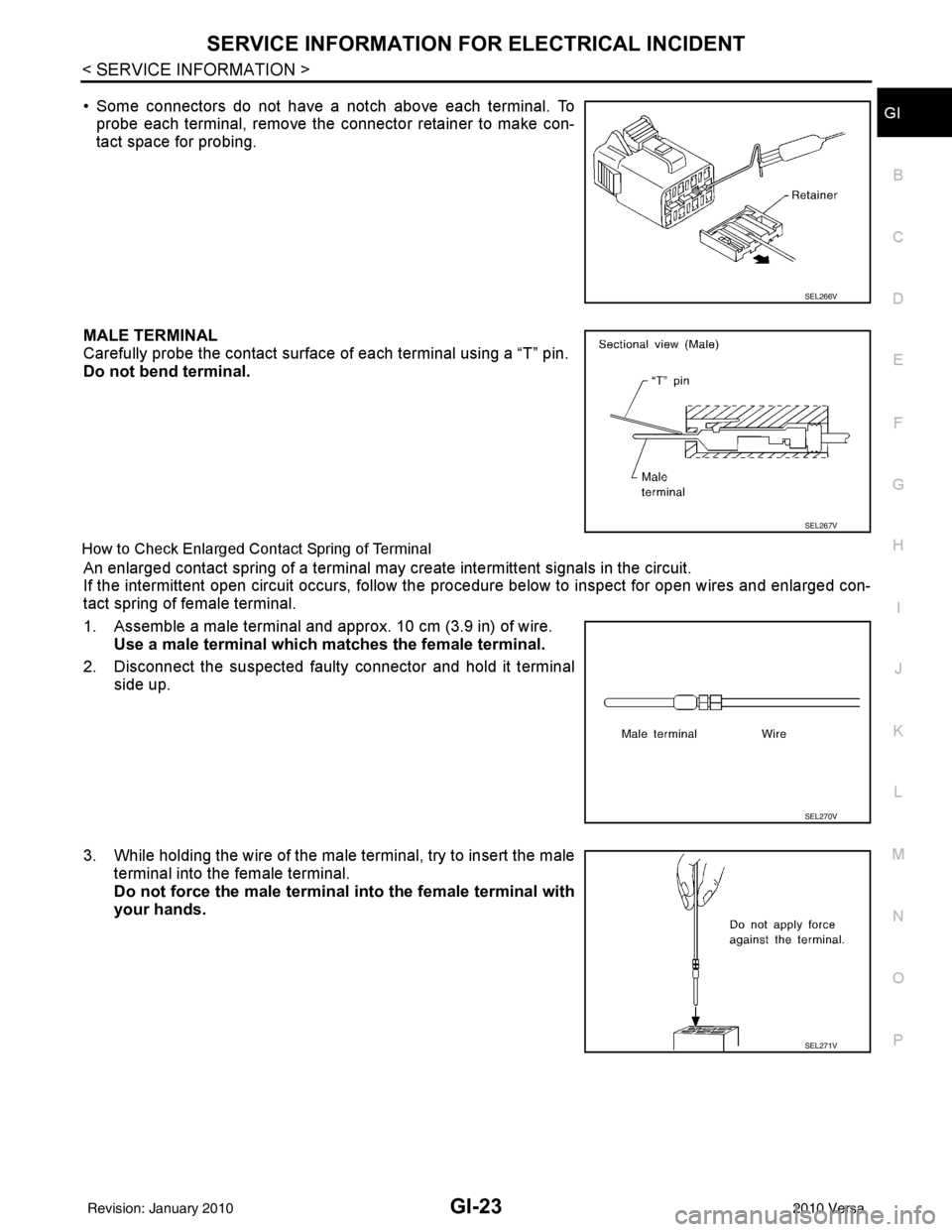

O P• Some connectors do not have a notch above each terminal. To probe each terminal, remove the connector retainer to make con-

tact space for probing.

MALE TERMINAL

Carefully probe the contact surface of each terminal using a “T” pin.

Do not bend terminal.

How to Check Enlarged Cont act Spring of Terminal

An enlarged contact spring of a terminal may create intermittent signals in the circuit.

If the intermittent open circuit occurs, follow the procedure below to inspect for open wires and enlarged con-

tact spring of female terminal.

1. Assemble a male terminal and approx. 10 cm (3.9 in) of wire. Use a male terminal which matches the female terminal.

2. Disconnect the suspected faulty connector and hold it terminal side up.

3. While holding the wire of the male terminal, try to insert the male terminal into the female terminal.

Do not force the male terminal into the female terminal with

your hands.

SEL266V

SEL267V

SEL270V

SEL271V

Revision: January 20102010 Versa

Page 2690 of 3745

GI-24

< SERVICE INFORMATION >

SERVICE INFORMATION FOR ELECTRICAL INCIDENT

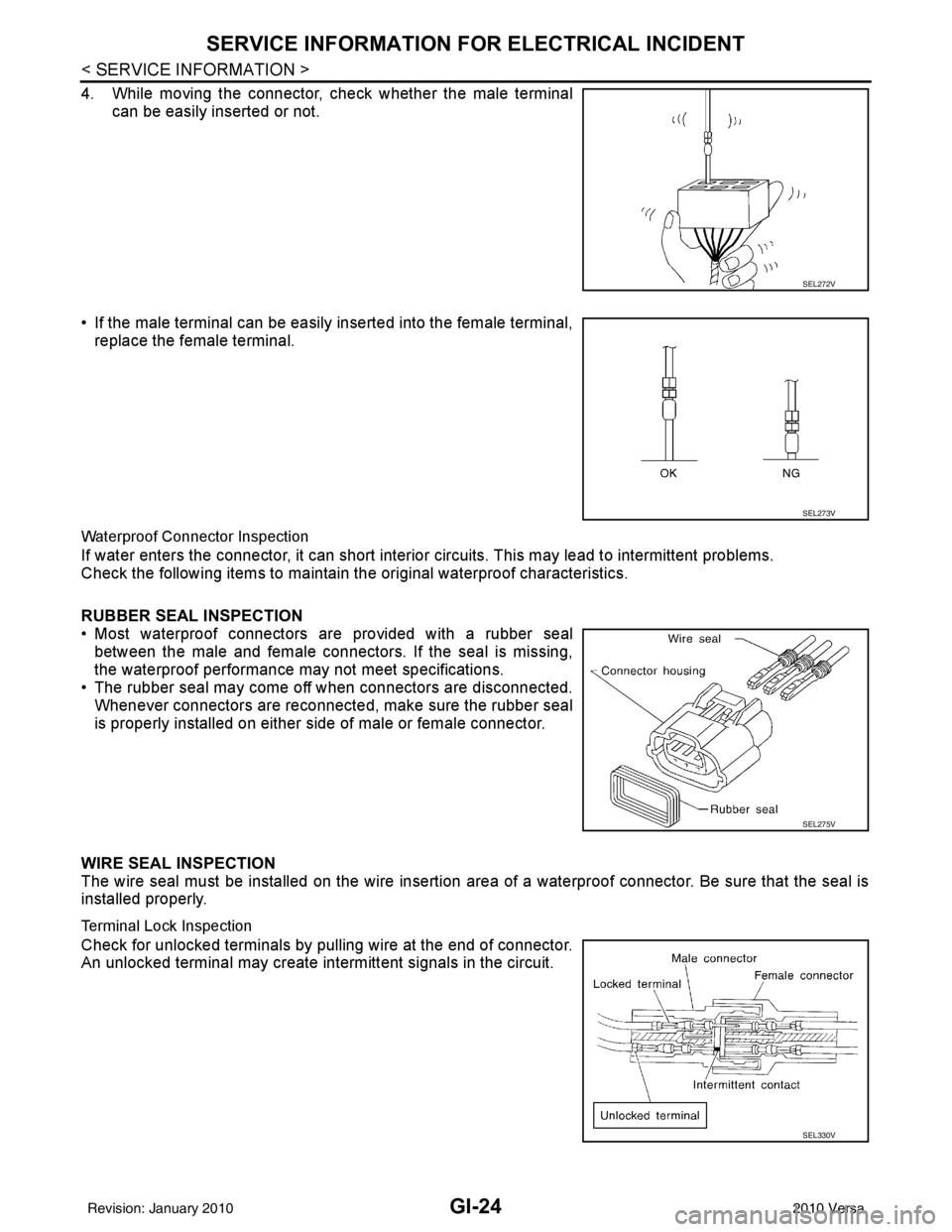

4. While moving the connector, check whether the male terminalcan be easily inserted or not.

• If the male terminal can be easily inserted into the female terminal, replace the female terminal.

Waterproof Connector Inspection

If water enters the connector, it can short interior circuits. This may lead to intermittent problems.

Check the following items to maintain the original waterproof characteristics.

RUBBER SEAL INSPECTION

• Most waterproof connectors are provided with a rubber seal between the male and female connectors. If the seal is missing,

the waterproof performance may not meet specifications.

• The rubber seal may come off when connectors are disconnected. Whenever connectors are reconnected, make sure the rubber seal

is properly installed on either side of male or female connector.

WIRE SEAL INSPECTION

The wire seal must be installed on the wire insertion area of a waterproof connector. Be sure that the seal is

installed properly.

Terminal Lock Inspection

Check for unlocked terminals by pulling wire at the end of connector.

An unlocked terminal may create intermittent signals in the circuit.

SEL272V

SEL273V

SEL275V

SEL330V

Revision: January 20102010 Versa