fuel type NISSAN LATIO 2011 Service Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2011, Model line: LATIO, Model: NISSAN LATIO 2011Pages: 3787, PDF Size: 78.35 MB

Page 11 of 3787

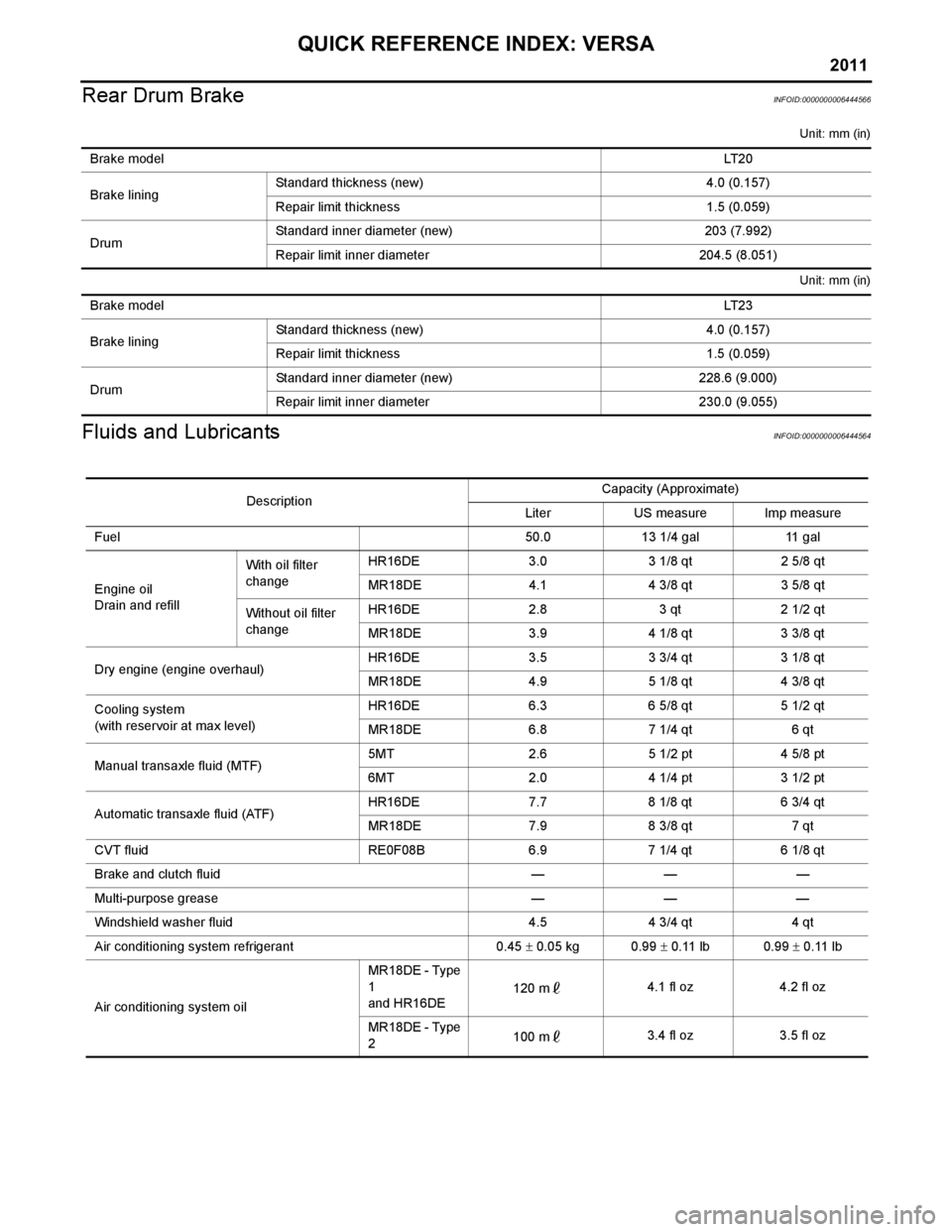

QUICK REFERENCE INDEX: VERSA

2011

Rear Drum BrakeINFOID:0000000006444566

Unit: mm (in)

Unit: mm (in)

Fluids and LubricantsINFOID:0000000006444564

Brake modelLT 2 0

Brake lining Standard thickness (new)

4.0 (0.157)

Repair limit thickness 1.5 (0.059)

Drum Standard inner diameter (new)

203 (7.992)

Repair limit inner diameter 204.5 (8.051)

Brake model LT 2 3

Brake lining Standard thickness

(new) 4.0 (0.157)

Repair limit thickness 1.5 (0.059)

Drum Standard inner diameter (new)

228.6 (9.000)

Repair limit inner diameter 230.0 (9.055)

DescriptionCapacity (Approximate)

Liter US measure Imp measure

Fuel 50.013 1/4 gal 11 gal

Engine oil

Drain and refill With oil filter

change

HR16DE

3.03 1/8 qt 2 5/8 qt

MR18DE 4.14 3/8 qt 3 5/8 qt

Without oil filter

change HR16DE

2.83 qt2 1/2 qt

MR18DE 3.94 1/8 qt 3 3/8 qt

Dry engine (engine overhaul) HR16DE

3.53 3/4 qt 3 1/8 qt

MR18DE 4.95 1/8 qt 4 3/8 qt

Cooling system

(with reservoir at max level) HR16DE

6.36 5/8 qt 5 1/2 qt

MR18DE 6.87 1/4 qt 6 qt

Manual transaxle fluid (MTF) 5MT

2.65 1/2 pt 4 5/8 pt

6MT 2.04 1/4 pt 3 1/2 pt

Automatic transaxle fluid (ATF) HR16DE

7.78 1/8 qt 6 3/4 qt

MR18DE 7.98 3/8 qt 7 qt

CVT fluid RE0F08B6.97 1/4 qt 6 1/8 qt

Brake and clutch fluid —— —

Multi-purpose grease —— —

Windshield washer fluid 4.54 3/4 qt 4 qt

Air conditioning system refrigerant 0.45 ± 0.05 kg 0.99 ± 0.11 lb 0.99 ± 0.11 lb

Air conditioning system oil MR18DE - Type

1

and HR16DE

120 m

4.1 fl oz

4.2 fl oz

MR18DE - Type

2 100 m

3.4 fl oz

3.5 fl oz

Page 1343 of 3787

![NISSAN LATIO 2011 Service Repair Manual MULTIPORT FUEL INJECTION SYSTEMEC-49

< FUNCTION DIAGNOSIS > [HR16DE]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

designed. Both manufacturing differences (i.e., mass air

flow sensor hot wire) and characteristic NISSAN LATIO 2011 Service Repair Manual MULTIPORT FUEL INJECTION SYSTEMEC-49

< FUNCTION DIAGNOSIS > [HR16DE]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

designed. Both manufacturing differences (i.e., mass air

flow sensor hot wire) and characteristic](/img/5/57357/w960_57357-1342.png)

MULTIPORT FUEL INJECTION SYSTEMEC-49

< FUNCTION DIAGNOSIS > [HR16DE]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

designed. Both manufacturing differences (i.e., mass air

flow sensor hot wire) and characteristic changes dur-

ing operation (i.e., fuel injector clogging) directly affect mixture ratio.

Accordingly, the difference between the basic and theoretical mixture ratios is monitored in this system. This is

then computed in terms of “injection pulse duration” to automatically compensate for the difference between

the two ratios.

“Fuel trim” refers to the feedback compensation value co mpared against the basic injection duration. Fuel trim

includes short-term fuel trim and long-term fuel trim.

“Short-term fuel trim” is the short-term fuel compensati on used to maintain the mixture ratio at its theoretical

value. The signal from A/F sensor 1 indicates whether the mixture ratio is RICH or LEAN compared to the the-

oretical value. The signal then triggers a reduction in fuel volume if the mixture ratio is rich, and an increase in

fuel volume if it is lean.

“Long-term fuel trim” is overall fuel compensation carried out over time to compensate for continual deviation

of the short-term fuel trim from the central value. Continual deviation will occur due to individual engine differ-

ences, wear over time and changes in the usage environment.

FUEL INJECTION TIMING

Two types of systems are used.

• Sequential Multiport Fuel Injection System Fuel is injected into each cylinder during each engine cycle according to the ignition order. This system is

used when the engine is running.

• Simultaneous Multiport Fuel Injection System Fuel is injected simultaneously into all four cylinders twice each engine cycle. In other words, pulse signals

of the same width are simultaneously transmitted from the ECM.

The four injectors will then receive the signals two times for each engine cycle.

This system is used when the engine is being started and/or if the fail-safe system (CPU) is operating.

FUEL SHUT-OFF

Fuel to each cylinder is cut off during deceleration, operation of the engine at excessively high speeds or oper-

ation of the vehicle at excessively high speeds.

SEF337W

Revision: May 2010 2011 Versa

Page 1554 of 3787

![NISSAN LATIO 2011 Service Repair Manual EC-260

< COMPONENT DIAGNOSIS >[HR16DE]

P0300, P0301,

P0302, P0303, P0304 MISFIRE

7.CHECK SPARK PLUG

Check the initial spark plug for fouling, etc.

Is the inspection result normal?

YES >> Replace spar NISSAN LATIO 2011 Service Repair Manual EC-260

< COMPONENT DIAGNOSIS >[HR16DE]

P0300, P0301,

P0302, P0303, P0304 MISFIRE

7.CHECK SPARK PLUG

Check the initial spark plug for fouling, etc.

Is the inspection result normal?

YES >> Replace spar](/img/5/57357/w960_57357-1553.png)

EC-260

< COMPONENT DIAGNOSIS >[HR16DE]

P0300, P0301,

P0302, P0303, P0304 MISFIRE

7.CHECK SPARK PLUG

Check the initial spark plug for fouling, etc.

Is the inspection result normal?

YES >> Replace spark plug(s) with standard type one(s). For spark plug type, refer to EM-112, "

Spark Plug".

NO >> Repair or clean spark plug. Then GO TO 8.

8.CHECK FUNCTION OF IGNITION COIL-III

1. Reconnect the initial spark plugs.

2. Crank engine for about 3 seconds, and recheck whether spark is generated between the spark plug and the grounded portion.

Is the inspection result normal?

YES >> INSPECTION END

NO >> Replace spark plug(s) with standard type one(s). For spark plug type, refer to EM-112, "

Spark

Plug".

9.CHECK COMPRESSION PRESSURE

Check compression pressure. Refer to EM-22, "

Inspection".

Is the inspection result normal?

YES >> GO TO 10.

NO >> Check pistons, piston rings, valves, valve seats and cylinder head gaskets.

10.CHECK FUEL PRESSURE

1. Install all removed parts.

2. Check fuel pressure. Refer to EC-499, "

Inspection".

Is the inspection result normal?

YES >> GO TO 12.

NO >> GO TO 11.

11 .DETECT MALFUNCTIONING PART

Check fuel hoses and fuel tubes for clogging.

Is the inspection result normal?

YES >> Replace “fuel level sensor unit, fuel filter and fuel pump assembly”. Refer to FL-6, "Component".

NO >> Repair or replace.

12.CHECK IGNITION TIMING

Check the following items. Refer to EC-20, "

BASIC INSPECTION : Special Repair Requirement".

For specification, refer to EC-503, "

Ignition Timing".

Is the inspection result normal?

YES >> GO TO 13.

NO >> Follow the EC-20, "

BASIC INSPECTION : Special Repair Requirement".

13.CHECK A/F SENSOR 1 INPUT SIGNAL CIRCUIT

1. Turn ignition switch OFF.

2. Disconnect corresponding A/F sensor 1 harness connector.

3. Disconnect ECM harness connector.

4. Check the continuity between A/F sensor 1 harness connector and ECM harness connector.

SEF156I

Spark should be generated.

Revision: May 2010 2011 Versa

Page 1574 of 3787

![NISSAN LATIO 2011 Service Repair Manual EC-280

< COMPONENT DIAGNOSIS >[HR16DE]

P0420 THREE WAY CATALYST FUNCTION

Do the following procedure in the place where ventilation is good without the combustible.

1. Turn ignition switch OFF.

2. Remo NISSAN LATIO 2011 Service Repair Manual EC-280

< COMPONENT DIAGNOSIS >[HR16DE]

P0420 THREE WAY CATALYST FUNCTION

Do the following procedure in the place where ventilation is good without the combustible.

1. Turn ignition switch OFF.

2. Remo](/img/5/57357/w960_57357-1573.png)

EC-280

< COMPONENT DIAGNOSIS >[HR16DE]

P0420 THREE WAY CATALYST FUNCTION

Do the following procedure in the place where ventilation is good without the combustible.

1. Turn ignition switch OFF.

2. Remove fuel pump fuse in IPDM E/R to release fuel pressure.

NOTE:

Do not use CONSULT-III to release fuel pressure, or fuel pressure applies again during the following pro-

cedure.

3. Start engine.

4. After engine stalls, crank it two or three times to release all fuel pressure.

5. Turn ignition switch OFF.

6. Remove all ignition coil harness connectors to avoi d the electrical discharge from the ignition coils.

7. Remove ignition coil and spark plug of the cylinder to be checked.

8. Crank engine for 5 seconds or more to remove combustion gas in the cylinder.

9. Connect spark plug and harness connector to ignition coil.

10. Fix ignition coil using a rope etc. with gap of 13 - 17 mm (0.52 - 0.66 in) between the edge of the spark plug and grounded metal

portion as shown in the figure.

11. Crank engine for about 3 seconds, and check whether spark is generated between the spark plug and the grounded metal por-

tion.

CAUTION:

• During the operation, always stay 0.5 m (19.7 in) awayfrom the spark plug and the ignition coil. Be careful not to

get an electrical shock wh ile checking, because the elec-

trical discharge voltage becomes 20 kV or more.

• It might cause to damage the igni tion coil if the gap of more than 17 mm (0.66 in) is taken.

NOTE:

When the gap is less than 13 mm (0.52 in), the sp ark might be generated even if the coil is mal-

functioning.

Is the inspection result normal?

YES >> GO TO 10.

NO >> GO TO 7.

7.CHECK FUNCTION OF IGNITION COIL-II

1. Turn ignition switch OFF.

2. Disconnect spark plug and connect a known-good spark plug.

3. Crank engine for about 3 seconds, and recheck whether spark is generated between the spark plug and the grounded metal portion.

Is the inspection result normal?

YES >> GO TO 8.

NO >> Check ignition coil, power transistor and their circuits. Refer to EC-444, "

Diagnosis Procedure".

8.CHECK SPARK PLUG

Check the initial spark plug for fouling, etc.

Is the inspection result normal?

YES >> Replace spark plug(s) with standard type one(s). For spark plug type, refer to EM-112, "

Spark Plug".

NO >> Repair or clean spark plug. Then GO TO 9.

9.CHECK FUNCTION OF IGNITION COIL-III Spark should be generated.

JMBIA0066GB

Spark should be generated.

SEF156I

Revision: May 2010

2011 Versa

Page 1575 of 3787

![NISSAN LATIO 2011 Service Repair Manual P0420 THREE WAY CATALYST FUNCTIONEC-281

< COMPONENT DIAGNOSIS > [HR16DE]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

1. Reconnect the initial spark plugs.

2. Crank engine for about three seconds, and recheck whet NISSAN LATIO 2011 Service Repair Manual P0420 THREE WAY CATALYST FUNCTIONEC-281

< COMPONENT DIAGNOSIS > [HR16DE]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

1. Reconnect the initial spark plugs.

2. Crank engine for about three seconds, and recheck whet](/img/5/57357/w960_57357-1574.png)

P0420 THREE WAY CATALYST FUNCTIONEC-281

< COMPONENT DIAGNOSIS > [HR16DE]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

1. Reconnect the initial spark plugs.

2. Crank engine for about three seconds, and recheck whether spark is generated between the spark plug

and the grounded portion.

Is the inspection result normal?

YES >> INSPECTION END

NO >> Replace spark plug(s) with standard type one(s). For spark plug type, refer to EM-112, "

Spar k

Plug".

10.CHECK FUEL INJECTOR

1. Turn ignition switch OFF. Refer to EM-33, "

Removal and Installation".

2. Remove fuel injector assembly. Keep fuel hose and all fuel injectors connected to fuel tube.

3. Disconnect all ignition coil harness connectors.

4. Reconnect all fuel injector harness connectors disconnected.

5. Turn ignition switch ON.

Does fuel drip from fuel injector?

YES >> GO TO 11.

NO >> Replace the fuel injector(s) from which fuel is dripping. Refer to EM-33, "

Exploded View".

11 .CHECK INTERMITTENT INCIDENT

Refer to EC-122, "

Diagnosis Procedure".

Is the inspection result normal?

YES >> Replace three way catalyst assembly. Refer to EM-30, "Exploded View".

NO >> Repair or replace harness or connector Spark should be generated.

Revision: May 2010

2011 Versa

Page 1791 of 3787

![NISSAN LATIO 2011 Service Repair Manual PREPARATIONEC-497

< PREPARATION > [HR16DE]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

PREPARATION

PREPARATION

Special Service ToolsINFOID:0000000005930164

NOTE:

The actual shapes of Kent-Moore tools may differ f NISSAN LATIO 2011 Service Repair Manual PREPARATIONEC-497

< PREPARATION > [HR16DE]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

PREPARATION

PREPARATION

Special Service ToolsINFOID:0000000005930164

NOTE:

The actual shapes of Kent-Moore tools may differ f](/img/5/57357/w960_57357-1790.png)

PREPARATIONEC-497

< PREPARATION > [HR16DE]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

PREPARATION

PREPARATION

Special Service ToolsINFOID:0000000005930164

NOTE:

The actual shapes of Kent-Moore tools may differ from those of special service tools illustrated here.

Commercial Service ToolsINFOID:0000000005930165

Tool number

(Kent-Moore No.)

Tool name

Description

(J-44321)

Fuel pressure gauge

kit Checks fuel pressure

(J-44321-6)

Fuel pressure adapter Connects fuel pressure gauge to quick connector

type fuel lines.

KV10118400

Fuel tube adapter Measures fuel pressure

LEC642

LBIA0376E

PBIB3043E

Tool name

(Kent-Moore No.)

Description

Leak detector

i.e.: (J-41416) Locates the EVAP leak

EVAP service port

adapter

i.e.: (J-41413-OBD) Applies positive pressure through EVAP service

port

S-NT703

S-NT704

Revision: May 2010

2011 Versa

Page 1805 of 3787

![NISSAN LATIO 2011 Service Repair Manual PRECAUTIONSEC-511

< SERVICE INFORMATION > [MR18DE]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

6. Perform a self-diagnosis check of al

l control units using CONSULT-III.

Precaution for Procedure without Cowl Top NISSAN LATIO 2011 Service Repair Manual PRECAUTIONSEC-511

< SERVICE INFORMATION > [MR18DE]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

6. Perform a self-diagnosis check of al

l control units using CONSULT-III.

Precaution for Procedure without Cowl Top](/img/5/57357/w960_57357-1804.png)

PRECAUTIONSEC-511

< SERVICE INFORMATION > [MR18DE]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

6. Perform a self-diagnosis check of al

l control units using CONSULT-III.

Precaution for Procedure without Cowl Top CoverINFOID:0000000006341692

When performing the procedure after removing cowl top cover, cover

the lower end of windshield with urethane, etc.

On Board Diagnosis (OBD) Syst em of Engine and A/T, CVTINFOID:0000000006341693

The ECM has an on board diagnostic system . It will light up the malfunction indicator lamp (MIL) to warn the

driver of a malfunction causing emission deterioration.

CAUTION:

• Be sure to turn the ignition sw itch OFF and disconnect the battery ground cable before any repair or

inspection work. The open/short circuit of relate d switches, sensors, solenoid valves, etc. will cause

the MIL to light up.

• Be sure to connect and lock the connectors secure ly after work. A loose (unlocked) connector will

cause the MIL to light up due to the open circuit. (Be sure the connector is free from water, grease,

dirt, bent terminals, etc.)

• Certain systems and components, especially those related to OBD, may use a new style slide-lock-

ing type harness connector. For description and how to disconnect, refer to PG-65

.

• Be sure to route and secure the harnesses properly after work. The interference of the harness with

a bracket, etc. may cause the MIL to li ght up due to the short circuit.

• Be sure to connect rubber tubes properly afte r work. A misconnected or disconnected rubber tube

may cause the MIL to light up due to the malfunction of the fuel injection system, etc.

• Be sure to erase the unnecessary malfunction information (repairs completed) from the ECM and TCM (Transmission control module) before returning the vehicle to the customer.

PrecautionINFOID:0000000006341694

•Always use a 12 volt battery as power source.

• Do not attempt to disconnect battery cables while engine is

running.

• Before connecting or disc onnecting the ECM harness con-

nector, turn ignition switch OFF and disconnect negative bat-

tery cable. Failure to do so may damage the ECM because

battery voltage is applied to ECM even if ignition switch is

turned OFF.

• Before removing parts, turn ig nition switch OFF and then dis-

connect negative battery cable.

• Do not disassemble ECM.

• If battery cable is disconnected, the memory will return to the

initial ECM values.

The ECM will now start to self-c ontrol at its initial values.

Engine operation can vary slightly in this case. However, this

is not an indication of a malf unction. Do not replace parts

because of a slight variation.

• If the battery is disconnected, the following emission-related

diagnostic information will be lost within 24 hours.

- Diagnostic trouble codes

- 1st trip diagnostic trouble codes

PIIB3706J

SEF289H

PBIA9222J

Revision: May 2010 2011 Versa

Page 1809 of 3787

![NISSAN LATIO 2011 Service Repair Manual PREPARATIONEC-515

< SERVICE INFORMATION > [MR18DE]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

PREPARATION

Special Service ToolINFOID:0000000006341695

The actual shapes of Kent-Moore tools may differ from those o NISSAN LATIO 2011 Service Repair Manual PREPARATIONEC-515

< SERVICE INFORMATION > [MR18DE]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

PREPARATION

Special Service ToolINFOID:0000000006341695

The actual shapes of Kent-Moore tools may differ from those o](/img/5/57357/w960_57357-1808.png)

PREPARATIONEC-515

< SERVICE INFORMATION > [MR18DE]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

PREPARATION

Special Service ToolINFOID:0000000006341695

The actual shapes of Kent-Moore tools may differ from those of special service tools illustrated here.

Commercial Service ToolINFOID:0000000006341696

Tool number

(Kent-Moore No.)

Tool name

Description

(J-44321)

Fuel pressure gauge

Kit Checking fuel pressure

(J-44321-6)

Fuel pressure adapter Connecting fuel pressure gauge to quick connec-

tor type fuel lines.

KV10118400

Fuel tube adapter Measuring fuel pressure

LEC642

LBIA0376E

PBIB3043E

Tool number

(Kent-Moore No.)

Tool name Description

Leak detector

i.e.: (J-41416) Locating the EVAP leak

EVAP service port

adapter

i.e.: (J-41413-OBD) Applying positive pressure through EVAP service

port

S-NT703

S-NT704

Revision: May 2010

2011 Versa

Page 1813 of 3787

![NISSAN LATIO 2011 Service Repair Manual ENGINE CONTROL SYSTEMEC-519

< SERVICE INFORMATION > [MR18DE]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

The mixture ratio feedback system provides the best air/

fuel mixture ratio for drivability and emission co NISSAN LATIO 2011 Service Repair Manual ENGINE CONTROL SYSTEMEC-519

< SERVICE INFORMATION > [MR18DE]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

The mixture ratio feedback system provides the best air/

fuel mixture ratio for drivability and emission co](/img/5/57357/w960_57357-1812.png)

ENGINE CONTROL SYSTEMEC-519

< SERVICE INFORMATION > [MR18DE]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

The mixture ratio feedback system provides the best air/

fuel mixture ratio for drivability and emission control.

The three way catalyst (manifold) can then better r educe CO, HC and NOx emissions. This system uses air

fuel ratio (A/F) sensor 1 in the exhaust manifold to monitor whether the engine operation is rich or lean. The

ECM adjusts the injection pulse width according to the sensor voltage signal. For more information about air

fuel ratio (A/F) sensor 1, refer to EC-704

. This maintains the mixture ratio within the range of stoichiometric

(ideal air/fuel mixture).

This stage is referred to as the closed loop control condition.

Heated oxygen sensor 2 is located downstream of the th ree way catalyst (manifold). Even if the switching

characteristics of air fuel ratio (A/F) sensor 1 shift, the air/fuel ratio is controlled to stoichiometric by the signal

from heated oxygen sensor 2.

Open Loop Control

The open loop system condition refers to when the ECM detects any of the following conditions. Feedback

control stops in order to maintain stabilized fuel combustion.

• Deceleration and acceleration

• High-load, high-speed operation

• Malfunction of air fuel ratio (A/F) sensor 1 or its circuit

• Insufficient activation of air fuel ratio (A /F) sensor 1 at low engine coolant temperature

• High engine coolant temperature

• During warm-up

• After shifting from N to D (A/T and CVT models)

• When starting the engine

MIXTURE RATIO SELF-LEARNING CONTROL

The mixture ratio feedback control system monitors the mixture ratio signal tr ansmitted from air fuel ratio (A/F)

sensor 1. This feedback signal is then sent to the ECM. The ECM controls the basic mixture ratio as close to

the theoretical mixture ratio as possible. However, the bas ic mixture ratio is not necessarily controlled as orig-

inally designed. Both manufacturing differences (i.e., mass air flow sensor hot wire) and characteristic

changes during operation (i.e., fuel injector clogging) directly affect mixture ratio.

Accordingly, the difference between the basic and theoretical mixture ratios is monitored in this system. This is

then computed in terms of “injection pulse duration” to automatically compensate for the difference between

the two ratios.

“Fuel trim” refers to the feedback compensation value co mpared against the basic injection duration. Fuel trim

includes short term fuel trim and long term fuel trim.

“Short term fuel trim” is the short-term fuel compensati on used to maintain the mixture ratio at its theoretical

value. The signal from air fuel ratio (A/F) sensor 1 i ndicates whether the mixture ratio is RICH or LEAN com-

pared to the theoretical value. The signal then triggers a reduction in fuel volume if the mixture ratio is rich, and

an increase in fuel volume if it is lean.

“Long term fuel trim” is overall fuel compensation ca rried out long-term to compensate for continual deviation

of the short term fuel trim from the central value. Such deviation will occur due to individual engine differences,

wear over time and changes in the usage environment.

FUEL INJECTION TIMING

Two types of systems are used.

Sequential Multiport Fuel Injection System

Fuel is injected into each cylinder during each engine cycl e according to the firing order. This system is used

when the engine is running.

Simultaneous Multiport Fuel Injection System

Fuel is injected simultaneously into all four cylinders twice each engine cycle. In other words, pulse signals of

the same width are simultaneously transmitted from the ECM.

The four fuel injectors will then receive the signals two times for each engine cycle.

SEF337W

Revision: May 2010 2011 Versa

Page 2080 of 3787

![NISSAN LATIO 2011 Service Repair Manual EC-786

< SERVICE INFORMATION >[MR18DE]

DTC P0300 - P0304 MULTIPLE CYLINDER

MISFIRE, NO. 1 - 4 CYLINDER MIS-

FIRE

3. Crank engine for about 3 seconds, and recheck whether spark is generated between th NISSAN LATIO 2011 Service Repair Manual EC-786

< SERVICE INFORMATION >[MR18DE]

DTC P0300 - P0304 MULTIPLE CYLINDER

MISFIRE, NO. 1 - 4 CYLINDER MIS-

FIRE

3. Crank engine for about 3 seconds, and recheck whether spark is generated between th](/img/5/57357/w960_57357-2079.png)

EC-786

< SERVICE INFORMATION >[MR18DE]

DTC P0300 - P0304 MULTIPLE CYLINDER

MISFIRE, NO. 1 - 4 CYLINDER MIS-

FIRE

3. Crank engine for about 3 seconds, and recheck whether spark is generated between the spark plug and

the grounded metal portion.

OK or NG

OK >> GO TO 7.

NG >> Check ignition coil, power transistor and their circuits. Refer to EC-1019

.

7.CHECK SPARK PLUG

Check the initial spark plug for fouling, etc.

OK or NG

OK >> Replace spark plug(s) with standard type one(s). For spark plug type, refer to EM-230, "

Standard and Limit".

NG >> 1. Repair or clean spark plug. 2. GO TO 8.

8.CHECK FUNCTION OF IGNITION COIL-III

1. Reconnect the initial spark plugs.

2. Crank engine for about three seconds, and recheck whether spark is generated between the spark plug

and the grounded portion.

OK or NG

OK >> INSPECTION END

NG >> Replace spark plug(s) with standard type one(s). For spark plug type, refer to EM-230, "

Standard

and Limit".

9.CHECK COMPRESSION PRESSURE

Check compression pressure. Refer to EM-186, "

On-Vehicle Service".

OK or NG

OK >> GO TO 10.

NG >> Check pistons, piston rings, valves, valve seats and cylinder head gaskets.

10.CHECK FUEL PRESSURE

1. Install all removed parts.

2. Release fuel pressure to zero. Refer to EC-582, "

Fuel Pressure Check".

3. Install fuel pressure gauge and check fuel pressure. Refer to EC-582, "

Fuel Pressure Check".

OK or NG

OK >> GO TO 12.

NG >> GO TO 11.

11 .DETECT MALFUNCTIONING PART

Check the following.

• Fuel pump and circuit (Refer to EC-1014

.)

• Fuel pressure regulator (Refer to EC-582, "

Fuel Pressure Check".)

• Fuel lines (Refer to FL-5, "

Checking Fuel Line".)

• Fuel filter for clogging

>> Repair or replace.

Spark should be generated.

SEF156I

Spark should be generated.

At idling: Approximately 350 kPa (3.57 kg/cm

2, 51 psi)

Revision: May 2010

2011 Versa