relay NISSAN LATIO 2011 Service Owners Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2011, Model line: LATIO, Model: NISSAN LATIO 2011Pages: 3787, PDF Size: 78.35 MB

Page 2733 of 3787

SERVICE INFORMATION FOR ELECTRICAL INCIDENTGI-29

< SERVICE INFORMATION >

C

DE

F

G H

I

J

K L

M B

GI

N

O P

• Close the relay and probe at the solenoid. voltage; open is further down the circuit than the solenoid.

no voltage; open is between relay and solenoid (point C).

Any powered circuit can be diagnosed using the approach in the previous example.

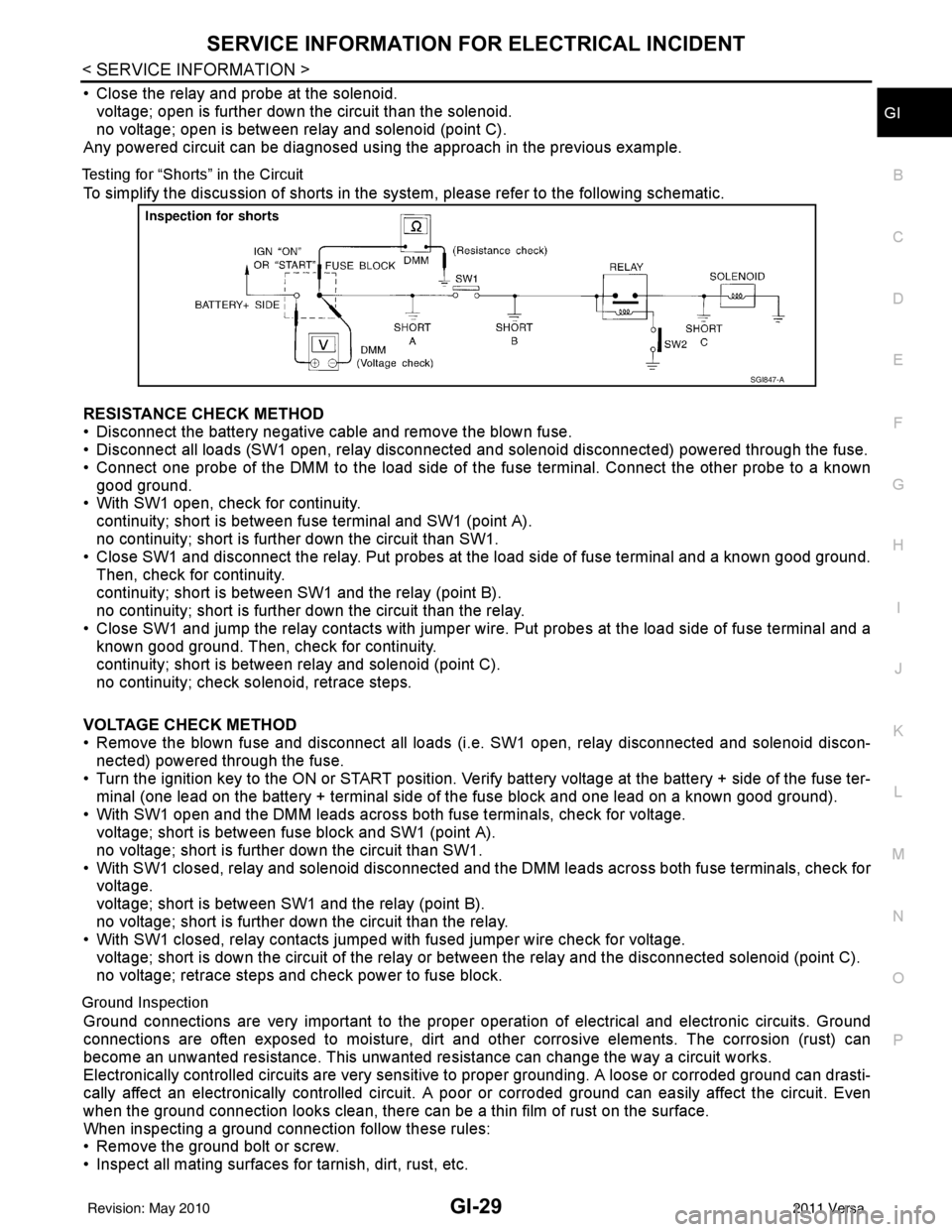

Testing for “Shorts” in the Circuit

To simplify the discussion of shorts in the system, please refer to the following schematic.

RESISTANCE CHECK METHOD

• Disconnect the battery negative cable and remove the blown fuse.

• Disconnect all loads (SW1 open, relay disconnected and solenoid disconnected) powered through the fuse.

• Connect one probe of the DMM to the load side of the fuse terminal. Connect the other probe to a known

good ground.

• With SW1 open, check for continuity.

continuity; short is between fuse terminal and SW1 (point A).

no continuity; short is further down the circuit than SW1.

• Close SW1 and disconnect the relay. Put probes at the load side of fuse terminal and a known good ground.

Then, check for continuity.

continuity; short is between SW1 and the relay (point B).

no continuity; short is further down the circuit than the relay.

• Close SW1 and jump the relay contacts with jumper wir e. Put probes at the load side of fuse terminal and a

known good ground. Then, check for continuity.

continuity; short is between relay and solenoid (point C).

no continuity; check solenoid, retrace steps.

VOLTAGE CHECK METHOD

• Remove the blown fuse and disconnect all loads (i .e. SW1 open, relay disconnected and solenoid discon-

nected) powered through the fuse.

• Turn the ignition key to the ON or START position. Veri fy battery voltage at the battery + side of the fuse ter-

minal (one lead on the battery + terminal side of the fuse block and one lead on a known good ground).

• With SW1 open and the DMM leads across both fuse terminals, check for voltage.

voltage; short is between fuse block and SW1 (point A).

no voltage; short is further down the circuit than SW1.

• With SW1 closed, relay and solenoid disconnected and the DMM leads across both fuse terminals, check for voltage.

voltage; short is between SW1 and the relay (point B).

no voltage; short is further down the circuit than the relay.

• With SW1 closed, relay contacts jumped with fused jumper wire check for voltage.

voltage; short is down the circuit of the relay or between the relay and the disconnected solenoid (point C).

no voltage; retrace steps and check power to fuse block.

Ground Inspection

Ground connections are very important to the proper oper ation of electrical and electronic circuits. Ground

connections are often exposed to moisture, dirt and other corrosive elements. The corrosion (rust) can

become an unwanted resistance. This unwanted resistance can change the way a circuit works.

Electronically controlled circuits are very sensitive to proper grounding. A loose or corroded ground can drasti-

cally affect an electronically controlled circuit. A poor or corroded ground can easily affect the circuit. Even

when the ground connection looks clean, there can be a thin film of rust on the surface.

When inspecting a ground connection follow these rules:

• Remove the ground bolt or screw.

• Inspect all mating surfaces for tarnish, dirt, rust, etc.

SGI847-A

Revision: May 2010 2011 Versa

Page 2805 of 3787

REAR WINDOW DEFOGGERGW-51

< SERVICE INFORMATION >

C

DE

F

G H

J

K L

M A

B

GW

N

O P

REAR WINDOW DEFOGGER

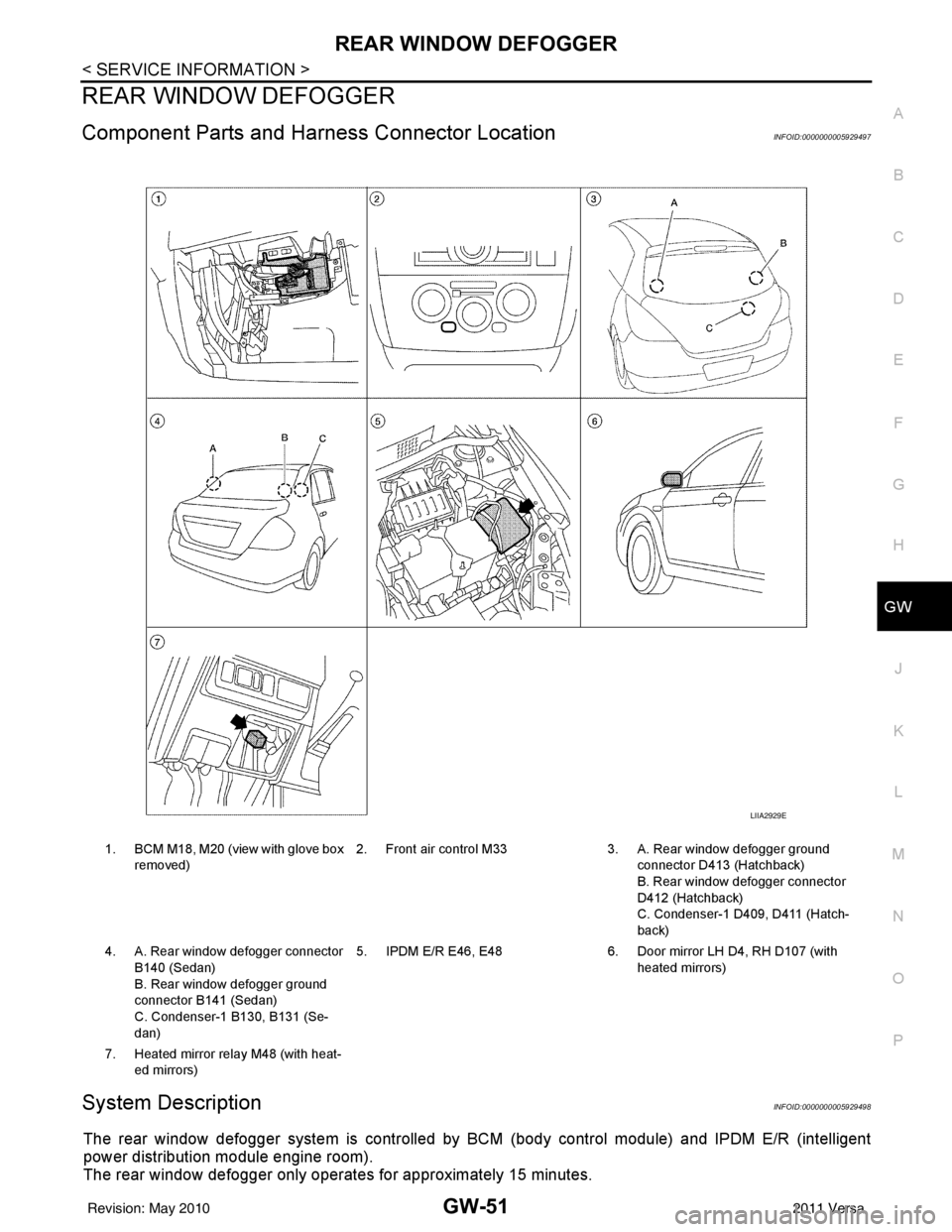

Component Parts and Har ness Connector LocationINFOID:0000000005929497

System DescriptionINFOID:0000000005929498

The rear window defogger system is controlled by BCM (body control module) and IPDM E/R (intelligent

power distribution module engine room).

The rear window defogger only operates for approximately 15 minutes.

1. BCM M18, M20 (view with glove box

removed) 2. Front air control M33 3. A. Rear window defogger ground

connector D413 (Hatchback)

B. Rear window defogger connector

D412 (Hatchback)

C. Condenser-1 D409, D411 (Hatch-

back)

4. A. Rear window defogger connector B140 (Sedan)

B. Rear window defogger ground

connector B141 (Sedan)

C. Condenser-1 B130, B131 (Se-

dan) 5. IPDM E/R E46, E48

6. Door mirror LH D4, RH D107 (with

heated mirrors)

7. Heated mirror relay M48 (with heat- ed mirrors)

LIIA2929E

Revision: May 2010 2011 Versa

Page 2806 of 3787

GW-52

< SERVICE INFORMATION >

REAR WINDOW DEFOGGER

Power is supplied at all times

• through 15A fuses (No. 46 and 47, located in the IPDM E/R)

• to rear window defogger relay

• through 10A fuse [No. 5 (with heated mirrors), located in the fuse block (J/B)]

• to heated mirror relay terminal 3

• through 40A fusible link (letter g , located in the fuse and fusible link box)

• to BCM terminal 70.

With the ignition switch turned to ON or START position, power is supplied

• through ignition relay

• to rear window defogger relay (located in the IPDM E/R)

• through 10A fuse [No. 6, located in the fuse block (J/B)]

• to BCM terminal 38.

Ground is supplied

• to BCM terminal 67 and

• to front air control terminal 8

• through body grounds M57 and M61

• to IPDM E/R terminals 39 and 59

• through body grounds E15 and E24.

When front air control (rear window defogger switch) is turned to ON, ground is supplied

• to BCM terminal 9

• through front air control terminal 3

• through front air control terminal 8

• through body grounds M57 and M61.

Then rear window defogger switch is illuminated.

Then BCM recognizes that rear window defogger switch is turned to ON.

Then it sends rear window defogger switch signals to IPDM E/R via CAN communication (CAN-H, CAN-L).

When IPDM E/R receives rear window defogger switch signals, ground is supplied

• to rear window defogger relay (located in the IPDM E/R)

• through IPDM E/R terminals 39 and 59

• through body grounds E15 and E24

Then rear window defogger relay is energized.

With power and ground supplied, rear window def ogger filaments heat and defog the rear window.

When rear window defogger relay is turned to ON (with heated mirrors), power is supplied

• through heated mirror relay terminal 5

• to door mirror (LH and RH) terminal 1.

Door mirror (LH and RH) is grounded through body grounds M57 and M61.

With power and ground supplied, rear window defogger filaments heat and defog the rear window and door

mirror filaments heat and defog the mirrors.

CAN Communication System DescriptionINFOID:0000000005929499

Refer to LAN-7, "System Description".

Revision: May 2010 2011 Versa

Page 2813 of 3787

REAR WINDOW DEFOGGERGW-59

< SERVICE INFORMATION >

C

DE

F

G H

J

K L

M A

B

GW

N

O P

OK or NG

OK >> GO TO 5.

NG >> Repair or replace harness.

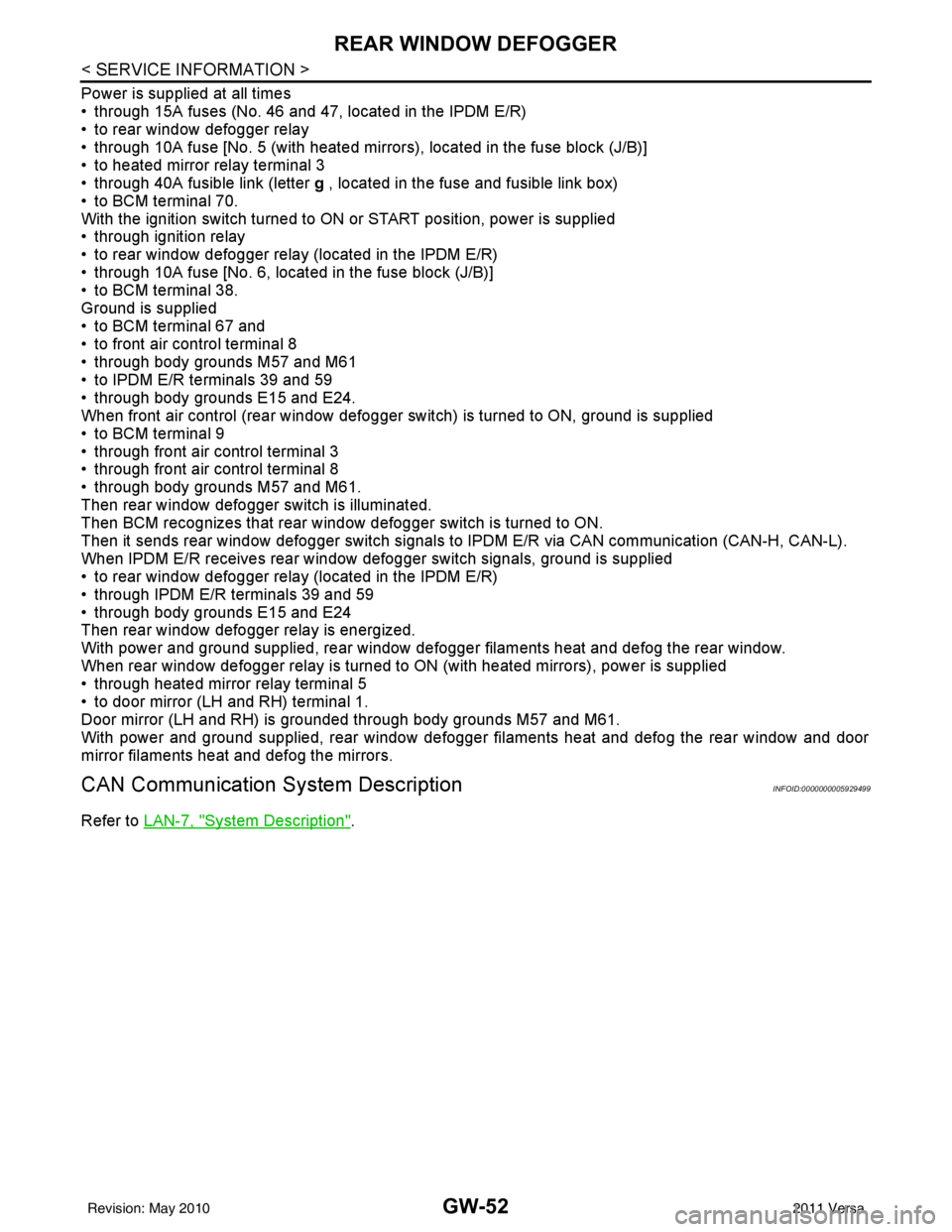

5.CHECK CONDENSER-1

Check continuity between condenser-1 terminals.

OK or NG

OK >> GO TO 6.

NG >> Replace condenser-1.

6.CHECK CONDENSER-1 HARNESS CONTINUITY

1. Disconnect IPDM E/R.

2. Check continuity between condenser-1 connector and IPDM E/ R connector.

3. Check continuity between condenser-1 connector and ground.

OK or NG

OK >> GO TO 7.

NG >> Repair or replace harness.

7.CHECK REAR WINDOW DEFOGGER RELAY OUTPUT SIGNAL

1. Connect IPDM E/R.

2. Turn ignition switch ON.

3. Check voltage between IPDM E/R connector and ground.

A

GroundContinuity

Connector Terminal

D412 (Hatchback) B140 (Sedan) 1N

o

AB

Continuity

Te r m i n a l Te r m i n a l

12Y es

PIIB6487E

AB

Continuity

Connector Terminal Connector Terminal

D409 (Hatchback) B130 (Sedan) 1

E48 60 Yes

A GroundContinuity

Condenser-1

connector Te r m i n a l

D409 (Hatch- back)

B130 (Sedan) 1N

o

LIIA2644E

ConnectorTe r m i n a l s

ConditionVoltage (V)

(Approx.)

(+) (-)

E48 60 Ground Rear window defogger

switch ON

Battery voltage

Rear window defogger

switch OFF 0

LIIA2190E

Revision: May 2010

2011 Versa

Page 2814 of 3787

GW-60

< SERVICE INFORMATION >

REAR WINDOW DEFOGGER

OK or NG

OK >> Check condition of harness and connector.

NG >> Replace IPDM E/R. Refer to PG-28, "

Removal and Installation of IPDM E/R" .

Door Mirror Defogger Circuit InspectionINFOID:0000000005929509

1.CHECK FUSE

Check if the following fuse in the fuse block (J/B) is blown.

OK or NG

OK >> GO TO 2.

NG >> If fuse is blown, be sure to eliminate cause of malfunction before installing new fuse.

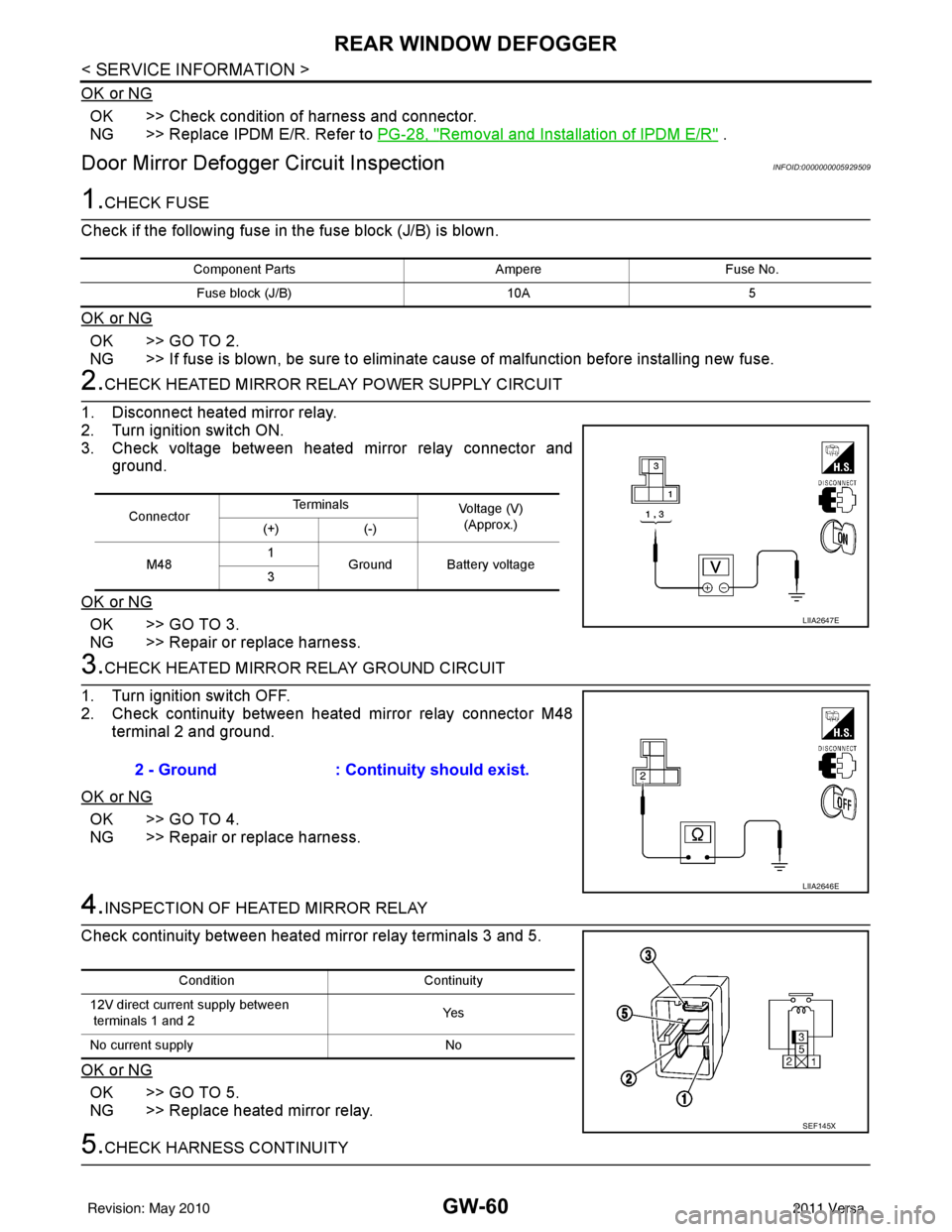

2.CHECK HEATED MIRROR RELAY POWER SUPPLY CIRCUIT

1. Disconnect heated mirror relay.

2. Turn ignition switch ON.

3. Check voltage between heated mirror relay connector and ground.

OK or NG

OK >> GO TO 3.

NG >> Repair or replace harness.

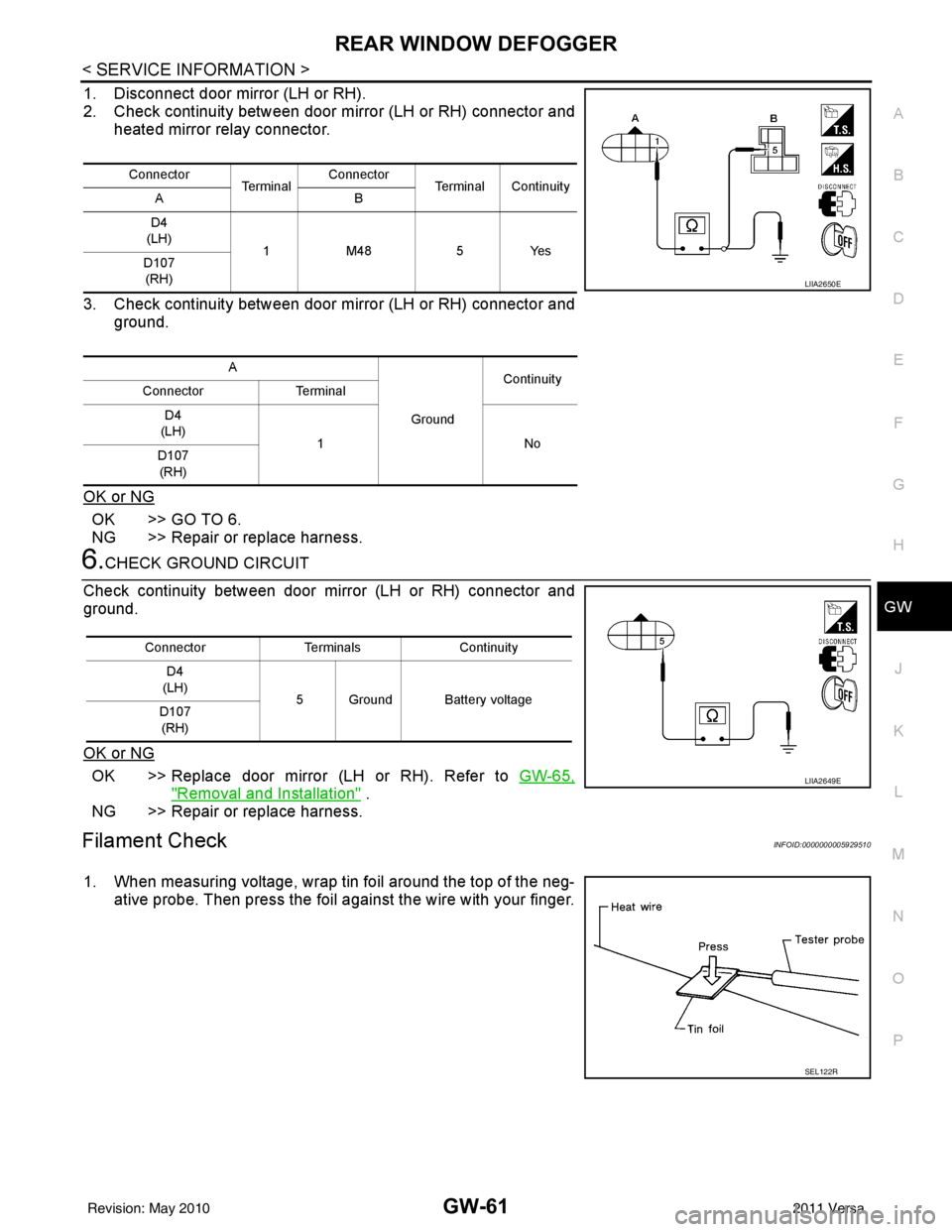

3.CHECK HEATED MIRROR RELAY GROUND CIRCUIT

1. Turn ignition switch OFF.

2. Check continuity between heated mirror relay connector M48 terminal 2 and ground.

OK or NG

OK >> GO TO 4.

NG >> Repair or replace harness.

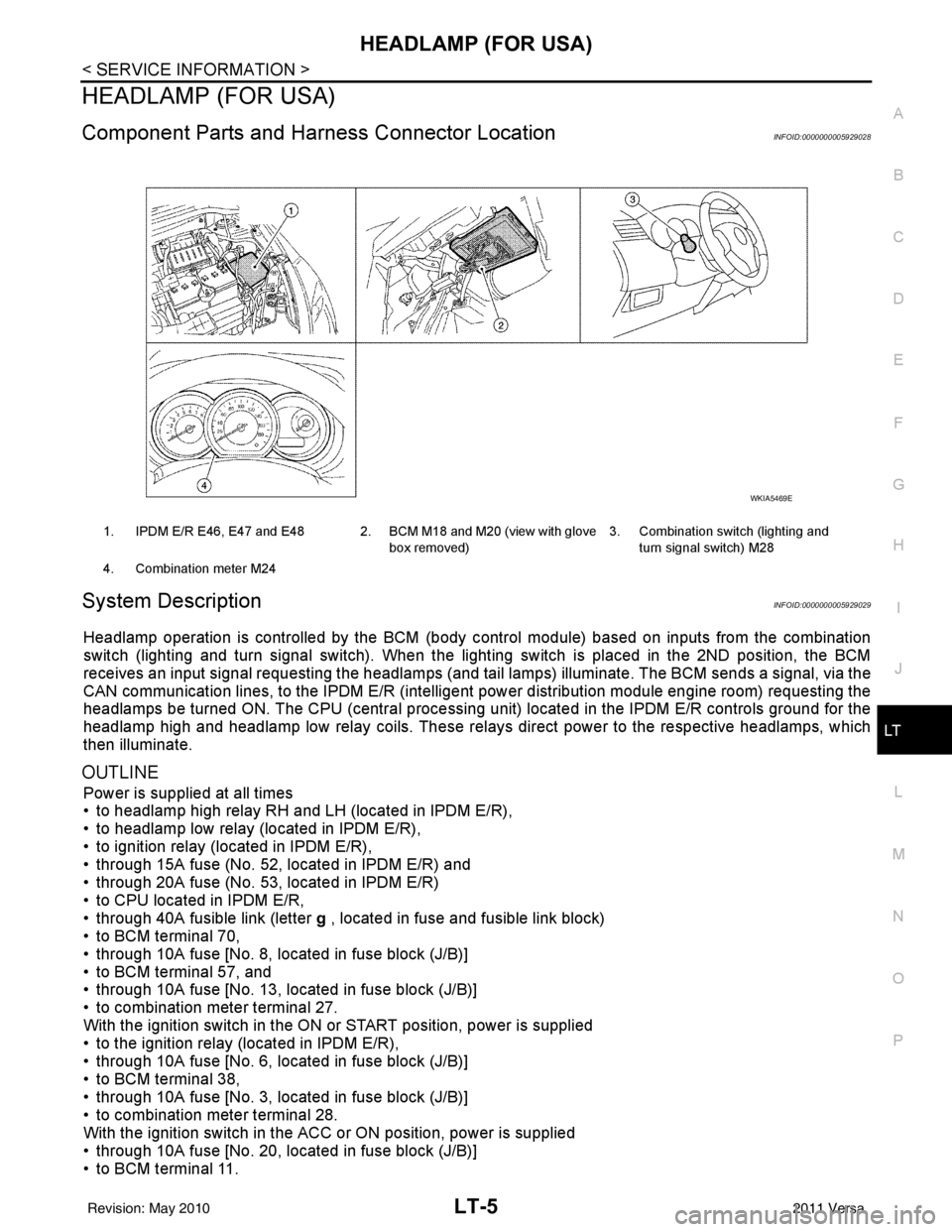

4.INSPECTION OF HEATED MIRROR RELAY

Check continuity between heated mirror relay terminals 3 and 5.

OK or NG

OK >> GO TO 5.

NG >> Replace heated mirror relay.

5.CHECK HARNESS CONTINUITY

Component Parts AmpereFuse No.

Fuse block (J/B) 10A5

ConnectorTe r m i n a l s

Voltage (V)

(Approx.)

(+) (-)

M48 1

Ground Battery voltage

3

LIIA2647E

2 - Ground : Continuity should exist.

LIIA2646E

Condition Continuity

12V direct current supply between

terminals 1 and 2 Ye s

No current supply No

SEF145X

Revision: May 2010 2011 Versa

Page 2815 of 3787

REAR WINDOW DEFOGGERGW-61

< SERVICE INFORMATION >

C

DE

F

G H

J

K L

M A

B

GW

N

O P

1. Disconnect door mirror (LH or RH).

2. Check continuity between door mirror (LH or RH) connector and heated mirror relay connector.

3. Check continuity between door mirror (LH or RH) connector and ground.

OK or NG

OK >> GO TO 6.

NG >> Repair or replace harness.

6.CHECK GROUND CIRCUIT

Check continuity between door mirror (LH or RH) connector and

ground.

OK or NG

OK >> Replace door mirror (LH or RH). Refer to GW-65,

"Removal and Installation" .

NG >> Repair or replace harness.

Filament CheckINFOID:0000000005929510

1. When measuring voltage, wrap tin foil around the top of the neg- ative probe. Then press the foil against the wire with your finger.

Connector Te r m i n a lConnector

Terminal Continuity

AB

D4

(LH) 1M48 5Yes

D107

(RH)

A GroundContinuity

Connector Terminal

D4

(LH) 1N o

D107

(RH)

LIIA2650E

Connector TerminalsContinuity

D4

(LH) 5 Ground Battery voltage

D107

(RH)

LIIA2649E

SEL122R

Revision: May 2010 2011 Versa

Page 3037 of 3787

HEADLAMP (FOR USA)LT-5

< SERVICE INFORMATION >

C

DE

F

G H

I

J

L

M A

B

LT

N

O P

HEADLAMP (FOR USA)

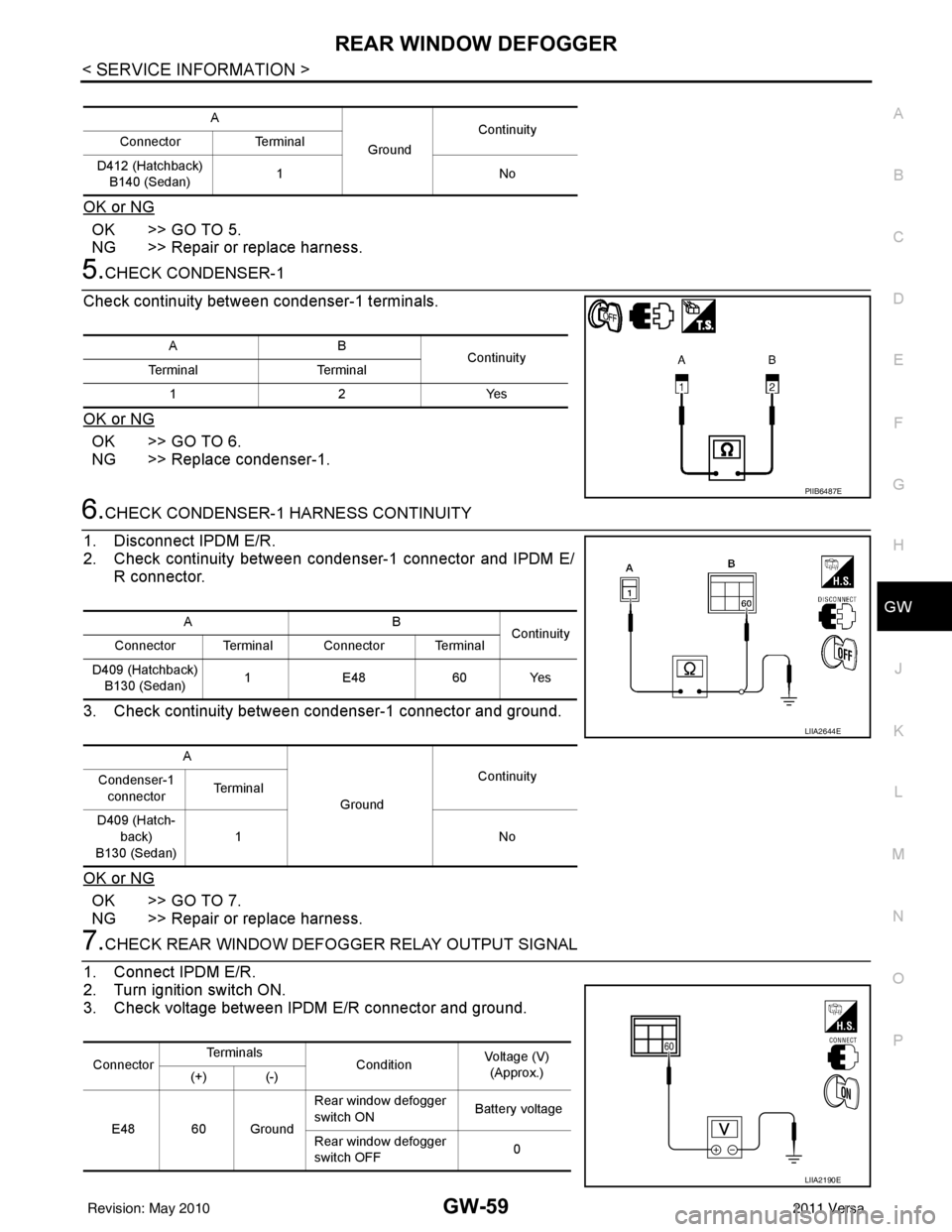

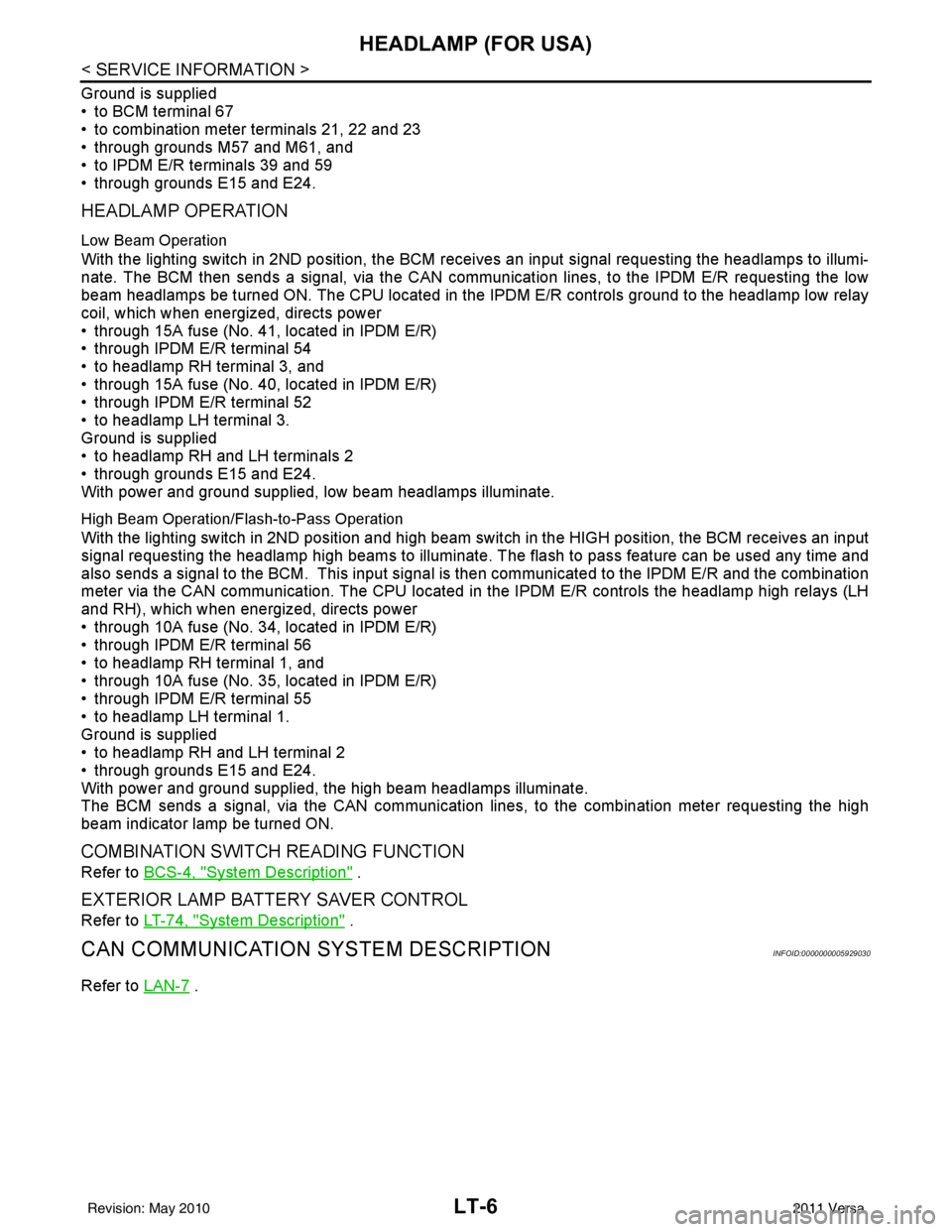

Component Parts and Har ness Connector LocationINFOID:0000000005929028

System DescriptionINFOID:0000000005929029

Headlamp operation is controlled by the BCM (body c ontrol module) based on inputs from the combination

switch (lighting and turn signal switch). When the light ing switch is placed in the 2ND position, the BCM

receives an input signal requesting the headlamps (and tail lamps) illuminate. The BCM sends a signal, via the

CAN communication lines, to the IPDM E/R (intelligent power distribution module engine room) requesting the

headlamps be turned ON. The CPU (centra l processing unit) located in the IPDM E/R controls ground for the

headlamp high and headlamp low relay coils. These relays direct power to the respective headlamps, which

then illuminate.

OUTLINE

Power is supplied at all times

• to headlamp high relay RH and LH (located in IPDM E/R),

• to headlamp low relay (located in IPDM E/R),

• to ignition relay (located in IPDM E/R),

• through 15A fuse (No. 52, located in IPDM E/R) and

• through 20A fuse (No. 53, located in IPDM E/R)

• to CPU located in IPDM E/R,

• through 40A fusible link (letter g , located in fuse and fusible link block)

• to BCM terminal 70,

• through 10A fuse [No. 8, located in fuse block (J/B)]

• to BCM terminal 57, and

• through 10A fuse [No. 13, located in fuse block (J/B)]

• to combination meter terminal 27.

With the ignition switch in the ON or START position, power is supplied

• to the ignition relay (located in IPDM E/R),

• through 10A fuse [No. 6, located in fuse block (J/B)]

• to BCM terminal 38,

• through 10A fuse [No. 3, located in fuse block (J/B)]

• to combination meter terminal 28.

With the ignition switch in the ACC or ON position, power is supplied

• through 10A fuse [No. 20, located in fuse block (J/B)]

• to BCM terminal 11.

1. IPDM E/R E46, E47 and E48 2. BCM M18 and M20 (view with glove

box removed)3. Combination switch (lighting and

turn signal switch) M28

4. Combination meter M24

WKIA5469E

Revision: May 2010 2011 Versa

Page 3038 of 3787

LT-6

< SERVICE INFORMATION >

HEADLAMP (FOR USA)

Ground is supplied

• to BCM terminal 67

• to combination meter terminals 21, 22 and 23

• through grounds M57 and M61, and

• to IPDM E/R terminals 39 and 59

• through grounds E15 and E24.

HEADLAMP OPERATION

Low Beam Operation

With the lighting switch in 2ND position, the BCM receives an input signal requesting the headlamps to illumi-

nate. The BCM then sends a signal, via the CAN comm unication lines, to the IPDM E/R requesting the low

beam headlamps be turned ON. The CPU located in the IPDM E/R controls ground to the headlamp low relay

coil, which when energized, directs power

• through 15A fuse (No. 41, located in IPDM E/R)

• through IPDM E/R terminal 54

• to headlamp RH terminal 3, and

• through 15A fuse (No. 40, located in IPDM E/R)

• through IPDM E/R terminal 52

• to headlamp LH terminal 3.

Ground is supplied

• to headlamp RH and LH terminals 2

• through grounds E15 and E24.

With power and ground supplied, low beam headlamps illuminate.

High Beam Operation/Flash-to-Pass Operation

With the lighting switch in 2ND position and high beam swit ch in the HIGH position, the BCM receives an input

signal requesting the headlamp high beams to illuminate. T he flash to pass feature can be used any time and

also sends a signal to the BCM. This input signal is then communicated to the IPDM E/R and the combination

meter via the CAN communication. The CPU located in the IPDM E/R controls the headlamp high relays (LH

and RH), which when energized, directs power

• through 10A fuse (No. 34, located in IPDM E/R)

• through IPDM E/R terminal 56

• to headlamp RH terminal 1, and

• through 10A fuse (No. 35, located in IPDM E/R)

• through IPDM E/R terminal 55

• to headlamp LH terminal 1.

Ground is supplied

• to headlamp RH and LH terminal 2

• through grounds E15 and E24.

With power and ground supplied, the high beam headlamps illuminate.

The BCM sends a signal, via the CAN communication lines, to the combination meter requesting the high

beam indicator lamp be turned ON.

COMBINATION SWITCH READING FUNCTION

Refer to BCS-4, "System Description" .

EXTERIOR LAMP BATTERY SAVER CONTROL

Refer to LT-74, "System Description" .

CAN COMMUNICATION SYSTEM DESCRIPTIONINFOID:0000000005929030

Refer to LAN-7 .

Revision: May 2010 2011 Versa

Page 3046 of 3787

LT-14

< SERVICE INFORMATION >

HEADLAMP (FOR USA)

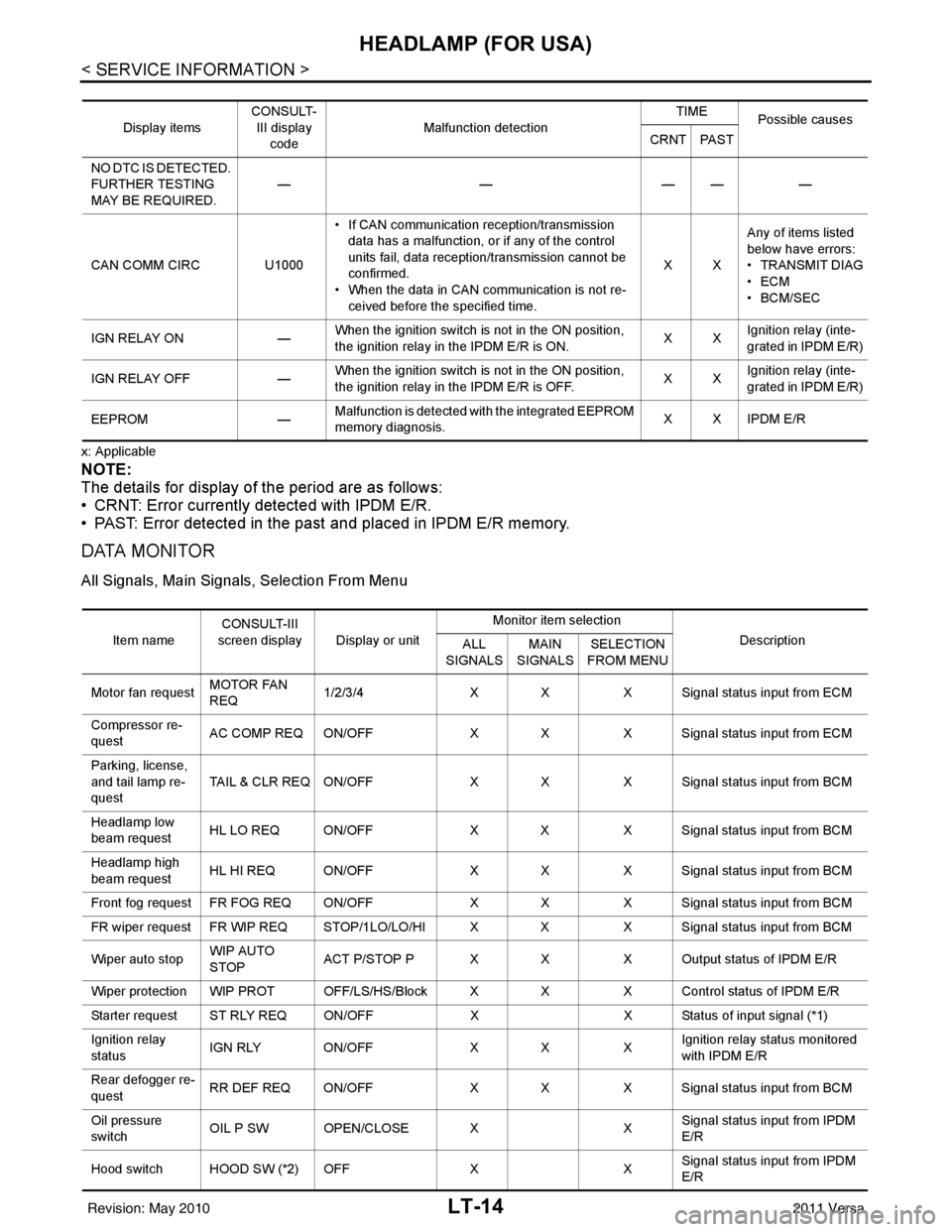

x: Applicable

NOTE:

The details for display of the period are as follows:

• CRNT: Error currently detected with IPDM E/R.

• PAST: Error detected in the past and placed in IPDM E/R memory.

DATA MONITOR

All Signals, Main Signals, Selection From Menu

Display itemsCONSULT-

III display code Malfunction detection TIME

Possible causes

CRNT PAST

NO DTC IS DETECTED.

FURTHER TESTING

MAY BE REQUIRED. —————

CAN COMM CIRC U1000 • If CAN communication reception/transmission

data has a malfunction, or if any of the control

units fail, data reception/transmission cannot be

confirmed.

• When the data in CAN communication is not re-

ceived before the specified time. XX

Any of items listed

below have errors:

• TRANSMIT DIAG

•ECM

• BCM/SEC

IGN RELAY ON —When the ignition switch is not in the ON position,

the ignition relay in the IPDM E/R is ON. XX

Ignition relay (inte-

grated in IPDM E/R)

IGN RELAY OFF —When the ignition switch is not in the ON position,

the ignition relay in the IPDM E/R is OFF. XXIgnition relay (inte-

grated in IPDM E/R)

EEPROM —Malfunction is de

tected with the integrated EEPROM

memory diagnosis. X X IPDM E/R

Item nameCONSULT-III

screen display Display or unit Monitor item selection

Description

ALL

SIGNALS MAIN

SIGNALS SELECTION

FROM MENU

Motor fan request MOTOR FAN

REQ1/2/3/4

X X X Signal status input from ECM

Compressor re-

quest AC COMP REQ ON/OFF

X XX Signal status input from ECM

Parking, license,

and tail lamp re-

quest TAIL & CLR REQ ON/OFF

X XX Signal status input from BCM

Headlamp low

beam request HL LO REQ ON/OFF

X XX Signal status input from BCM

Headlamp high

beam request HL HI REQ ON/OFF

X XX Signal status input from BCM

Front fog request FR FOG REQ ON/OFF X XX Signal status input from BCM

FR wiper request FR WIP REQ STOP/1LO/LO/HI X X X Signal status input from BCM

Wiper auto stop WIP AUTO

STOPACT P/STOP P X X

X Output status of IPDM E/R

Wiper protection WIP PROT OFF/LS/HS/Block X X X Control status of IPDM E/R

Starter request ST RLY REQ ON/OFF XX Status of input signal (*1)

Ignition relay

status IGN RLY ON/OFF

X XXIgnition relay status monitored

with IPDM E/R

Rear defogger re-

quest RR DEF REQ ON/OFF

X XX Signal status input from BCM

Oil pressure

switch OIL P SW OPEN/CLOSE X

XSignal status input from IPDM

E/R

Hood switch HOOD SW (*2) OFF XXSignal status input from IPDM

E/R

Revision: May 2010

2011 Versa

Page 3047 of 3787

HEADLAMP (FOR USA)LT-15

< SERVICE INFORMATION >

C

DE

F

G H

I

J

L

M A

B

LT

N

O P

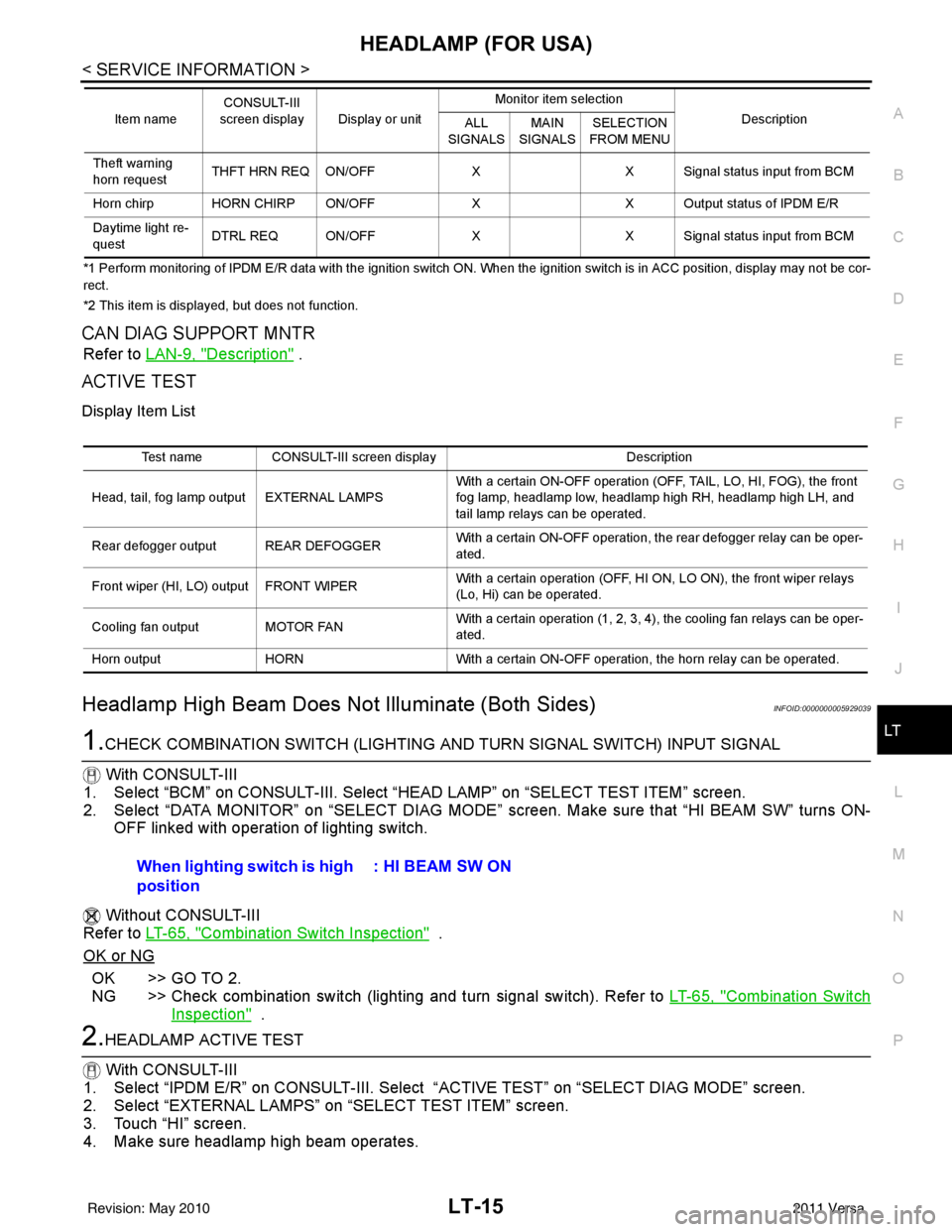

*1 Perform monitoring of IPDM E/R data with the ignition switch ON. When the ignition switch is in ACC position, display may no t be cor-

rect.

*2 This item is displayed, but does not function.

CAN DIAG SUPPORT MNTR

Refer to LAN-9, "Description" .

ACTIVE TEST

Display Item List

Headlamp High Beam Does No t Illuminate (Both Sides)INFOID:0000000005929039

1.CHECK COMBINATION SWITCH (LIGHTING AND TURN SIGNAL SWITCH) INPUT SIGNAL

With CONSULT-III

1. Select “BCM” on CONSULT-III. Select “HEAD LAMP” on “SELECT TEST ITEM” screen.

2. Select “DATA MONITOR” on “SELECT DIAG MODE” sc reen. Make sure that “HI BEAM SW” turns ON-

OFF linked with operation of lighting switch.

Without CONSULT-III

Refer to LT-65, "

Combination Switch Inspection" .

OK or NG

OK >> GO TO 2.

NG >> Check combination switch (lighting and turn signal switch). Refer to LT-65, "

Combination Switch

Inspection" .

2.HEADLAMP ACTIVE TEST

With CONSULT-III

1. Select “IPDM E/R” on CONSUL T-III. Select “ACTIVE TEST” on “SELECT DIAG MODE” screen.

2. Select “EXTERNAL LAMPS” on “SELECT TEST ITEM” screen.

3. Touch “HI” screen.

4. Make sure headlamp high beam operates.

Theft warning

horn request THFT HRN REQ ON/OFF

XX Signal status input from BCM

Horn chirp HORN CHIRP ON/OFF XX Output status of IPDM E/R

Daytime light re-

quest DTRL REQ ON/OFF

XX Signal status input from BCM

Item name

CONSULT-III

screen display Display or unit Monitor item selection

Description

ALL

SIGNALS MAIN

SIGNALS SELECTION

FROM MENU

Test name CONSULT-III screen display Description

Head, tail, fog lamp output EXTERNAL LAMPS With a certain ON-OFF operation (OFF, TAIL, LO, HI, FOG), the front

fog lamp, headlamp low, headlamp high RH, headlamp high LH, and

tail lamp relays can be operated.

Rear defogger output REAR DEFOGGER With a certain ON-OFF operation, the rear defogger relay can be oper-

ated.

Front wiper (HI, LO) output FRONT WIPER With a certain operation (OFF, HI ON, LO ON), the front wiper relays

(Lo, Hi) can be operated.

Cooling fan output MOTOR FAN With a certain operation (1, 2, 3, 4), the cooling fan relays can be oper-

ated.

Horn output HORN With a certain ON-OFF operation, the horn relay can be operated.

When lighting switch is high

position : HI BEAM SW ON

Revision: May 2010

2011 Versa