ignition NISSAN LATIO 2011 Service Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2011, Model line: LATIO, Model: NISSAN LATIO 2011Pages: 3787, PDF Size: 78.35 MB

Page 3736 of 3787

WT-18

< SERVICE INFORMATION >

TROUBLE DIAGNOSES

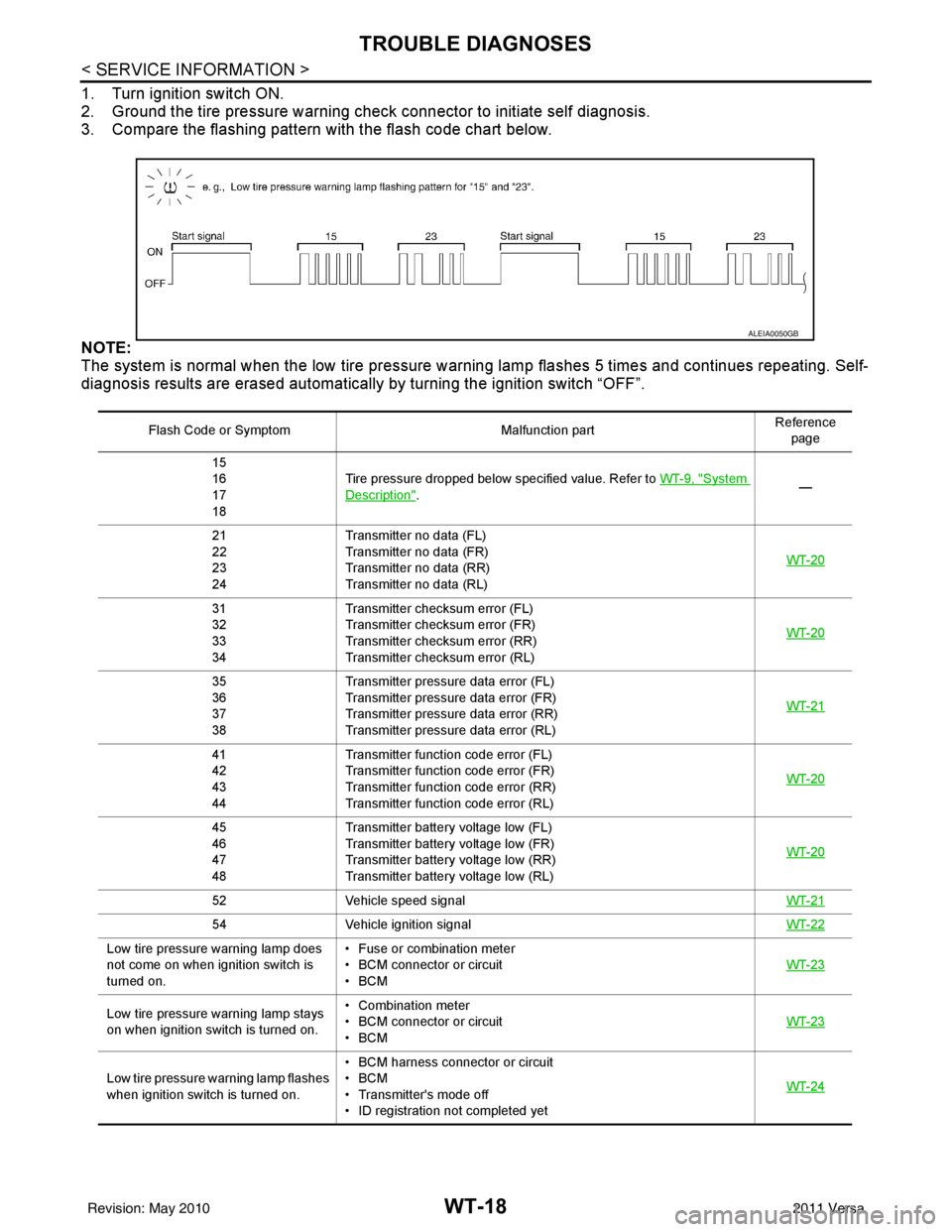

1. Turn ignition switch ON.

2. Ground the tire pressure warning check connector to initiate self diagnosis.

3. Compare the flashing pattern with the flash code chart below.

NOTE:

The system is normal when the low tire pressure warning lamp flashes 5 times and continues repeating. Self-

diagnosis results are erased automatically by turning the ignition switch “OFF”.

Flash Code or Symptom Malfunction partReference

page

15

16

17

18 Tire pressure dropped below specified value. Refer to

WT-9, "

System

Description". —

21

22

23

24 Transmitter no data (FL)

Transmitter no data (FR)

Transmitter no data (RR)

Transmitter no data (RL)

WT-20

31

32

33

34Transmitter chec

ksum error (FL)

Transmitter chec ksum error (FR)

Transmitter chec ksum error (RR)

Transmitter chec ksum error (RL) WT-20

35

36

37

38Transmitter pressure

data error (FL)

Transmitter pressure data error (FR)

Transmitter pressure data error (RR)

Transmitter pressure data error (RL) WT-21

41

42

43

44Transmitter function

code error (FL)

Transmitter function code error (FR)

Transmitter function code error (RR)

Transmitter function code error (RL) WT-20

45

46

47

48Transmitter battery voltage low (FL)

Transmitter battery voltage low (FR)

Transmitter battery voltage low (RR)

Transmitter battery voltage low (RL)

WT-20

52

Vehicle speed signal WT-21

54Vehicle ignition signal WT-22

Low tire pressure warning lamp does

not come on when ignition switch is

turned on.• Fuse or combination meter

• BCM connector or circuit

•BCM

WT-23

Low tire pressure

warning lamp stays

on when ignition switch is turned on. • Combination meter

• BCM connector or circuit

•BCM

WT-23

Low tire pressure wa

rning lamp flashes

when ignition switch is turned on. • BCM harness connector or circuit

•BCM

• Transmitter's mode off

• ID registration not completed yet

WT-24

ALEIA0050GB

Revision: May 2010

2011 Versa

Page 3740 of 3787

WT-22

< SERVICE INFORMATION >

TROUBLE DIAGNOSIS FOR SELF-DIAGNOSTIC ITEMS

Vehicle Ignition Signal

INFOID:0000000005931116

MALFUNCTION CODE NO. 54 (DTC C1735)

1.CAN IGNITION SIGNAL

Check BCM IGN RLY signal with CONSULT-III. Refer to BCS-12, "

Terminal and Reference Value for BCM".

Are the inspection results normal with the ignition switch ON?

YES >> GO TO 2.

NO >> Check CAN system. Refer to LAN-17, "

Trouble Diagnosis Flow Chart".

2.BCM POWER SUPPLY

Check BCM power supply (ignition ON). Refer to BCS-16, "

BCM Power Supply and Ground Circuit Inspec-

tion".

Is the power supply with the ignition switch ON normal?

YES >> GO TO 3.

NO >> Repair power supply as necessary.

3.DRIVE VEHICLE

Clear DTC and then test drive the vehicle and check the low tire pressure warning lamp.

Does the vehicle operate without any low tire pressure warning lamp?

YES >> Inspection End.

NO >> Replace BCM. Refer to BCS-19, "

Removal and Installation of BCM".

Revision: May 2010 2011 Versa

Page 3741 of 3787

TROUBLE DIAGNOSIS FOR SYMPTOMSWT-23

< SERVICE INFORMATION >

C

DF

G H

I

J

K L

M A

B

WT

N

O P

TROUBLE DIAGNOSIS FOR SYMPTOMS

Low Tire Pressure Warning Lamp Does Not Come On When Ignition Switch Is Turned

On

INFOID:0000000005931117

DIAGNOSTIC PROCEDURE

1.SELF-DIAGNOSTIC RESULT CHECK

Using CONSULT-III, check display contents in self-diagnostic results.

Is "CAN COMM CIRCUIT" displayed in the self-diagnosis display items?

YES >> Malfunction in CAN communication system. GO TO LAN-13, "CAN Diagnosis with CONSULT-

III".

NO >> GO TO 2.

2.CHECK COMBINATION METER

Check combination meter operation. Refer to DI-11, "

Self-Diagnosis Mode of Combination Meter".

Inspection results OK?

OK >> GO TO 3.

NG >> Replace combination meter. Refer to IP-12, "

Removal and Installation".

3.CHECK LOW TIRE PRE SSURE WARNING LAMP

Disconnect BCM harness connector.

Does the low tire pressure warning lamp activate?

YES >> Replace BCM. Refer to BCS-19, "Removal and Installation of BCM".

NO >> Check combination meter operation. Refer to DI-11, "

Self-Diagnosis Mode of Combination

Meter".

Low Tire Pressure Warning Lamp Stays On When Ignition Switch Is Turned On

INFOID:0000000005931118

DIAGNOSTIC PROCEDURE

1.CHECK BCM CONNECTORS

1. Turn ignition switch OFF.

2. Disconnect BCM harness connectors M18 and M20.

3. Check terminals for damage or loose connections.

Inspection results OK?

OK >> GO TO 2.

NG >> Repair or replace damaged parts.

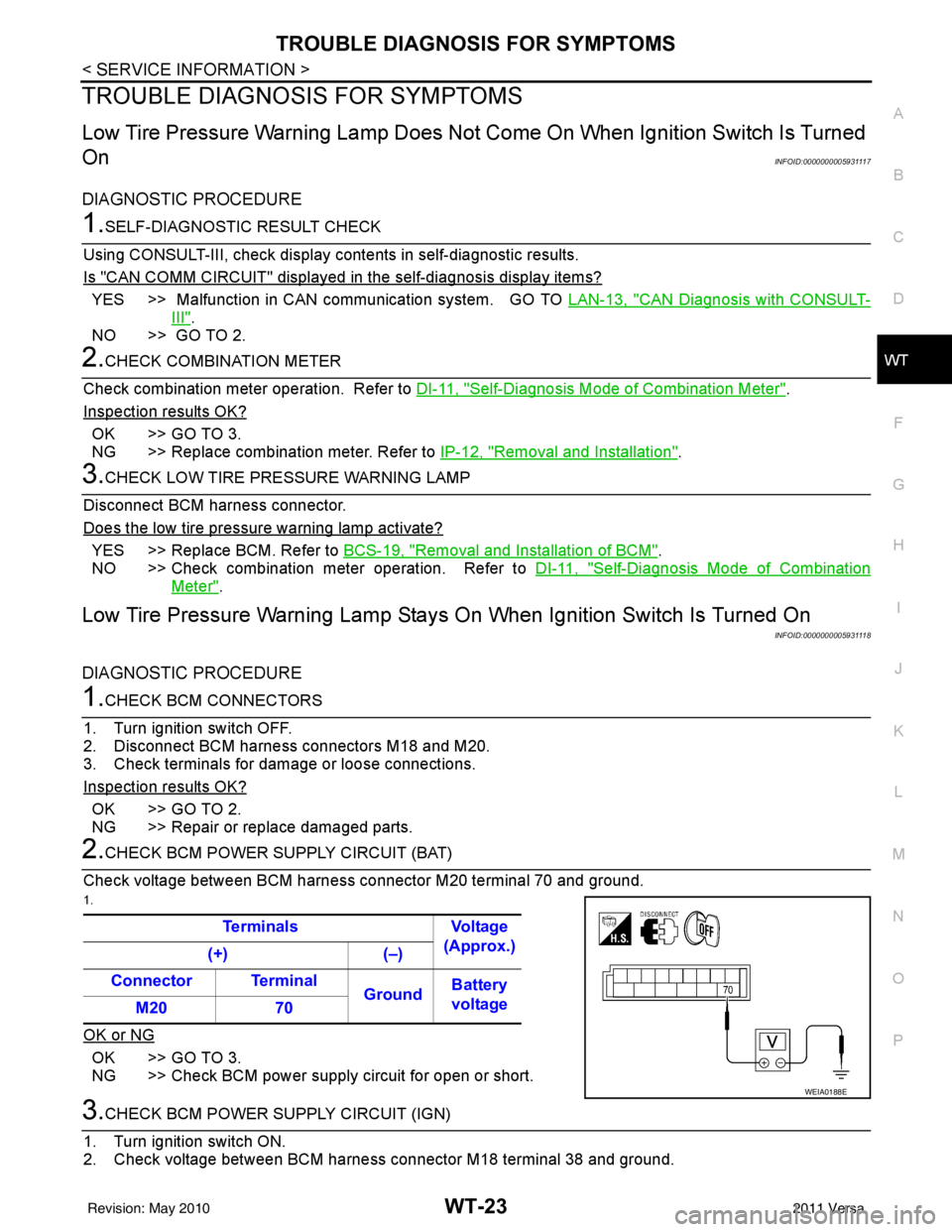

2.CHECK BCM POWER SUPPLY CIRCUIT (BAT)

Check voltage between BCM harness connector M20 terminal 70 and ground.

1.

OK or NG

OK >> GO TO 3.

NG >> Check BCM power supply circuit for open or short.

3.CHECK BCM POWER SUPPLY CIRCUIT (IGN)

1. Turn ignition switch ON.

2. Check voltage between BCM harness connector M18 terminal 38 and ground. Terminals Voltage

(Approx.)

(+) (–)

Connector Terminal GroundBattery

voltage

M20 70

WEIA0188E

Revision: May 2010 2011 Versa

Page 3742 of 3787

WT-24

< SERVICE INFORMATION >

TROUBLE DIAGNOSIS FOR SYMPTOMS

OK or NG

OK >> GO TO 4.

NG >> Check BCM power supply circuit for open or short.

4.CHECK BCM GROUND CIRCUIT

1. Turn ignition switch OFF.

2. Check continuity between BCM harnes s connector M20 terminal 67 and ground.

OK or NG

OK >> Replace BCM. Refer to BCS-19, "Removal and Installa-

tion of BCM".

NG >> Repair BCM ground circuit.

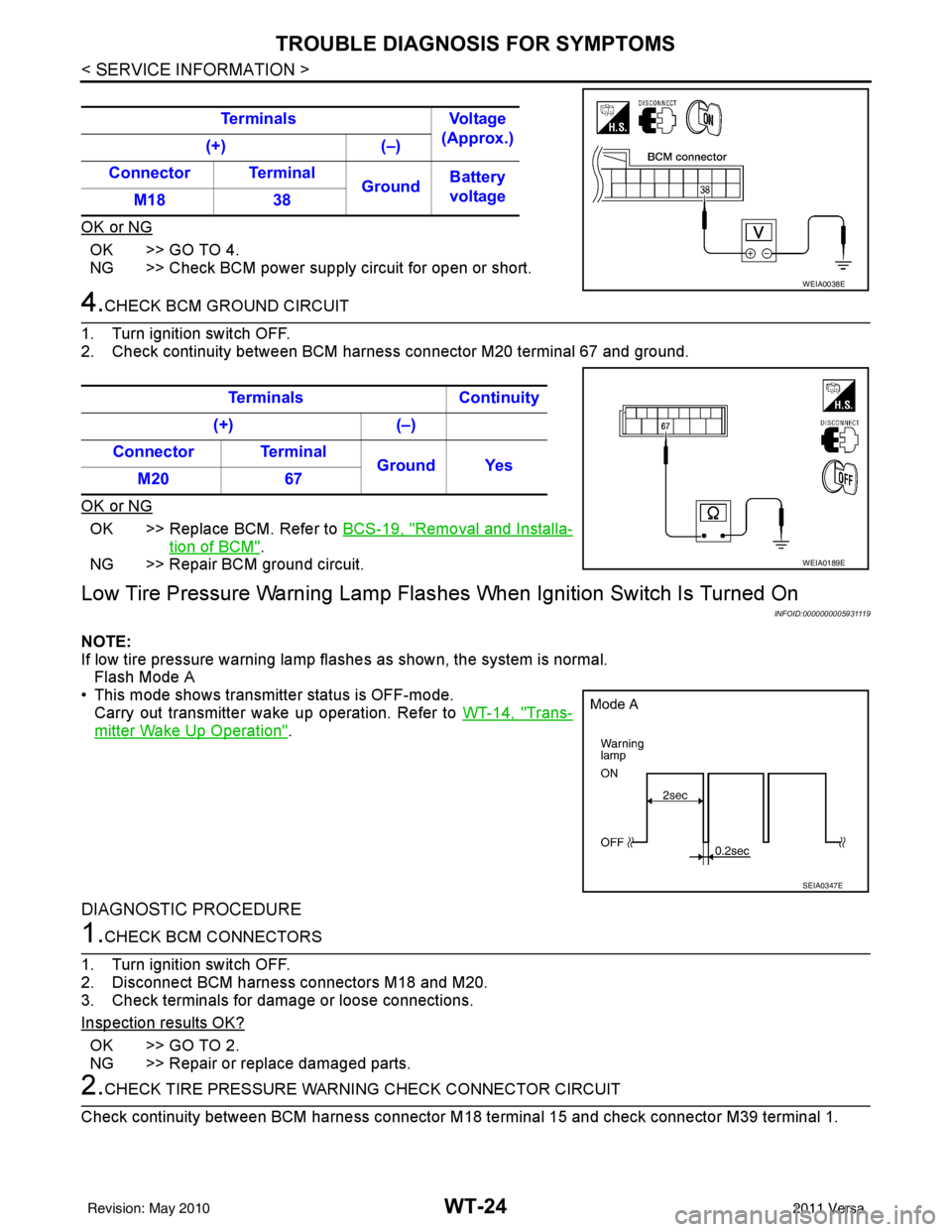

Low Tire Pressure Warning Lamp Flashes When Ignition Switch Is Turned On

INFOID:0000000005931119

NOTE:

If low tire pressure warning lamp flashes as shown, the system is normal. Flash Mode A

• This mode shows transmitter status is OFF-mode. Carry out transmitter wake up operation. Refer to WT-14, "

Trans-

mitter Wake Up Operation".

DIAGNOSTIC PROCEDURE

1.CHECK BCM CONNECTORS

1. Turn ignition switch OFF.

2. Disconnect BCM harness connectors M18 and M20.

3. Check terminals for damage or loose connections.

Inspection results OK?

OK >> GO TO 2.

NG >> Repair or replace damaged parts.

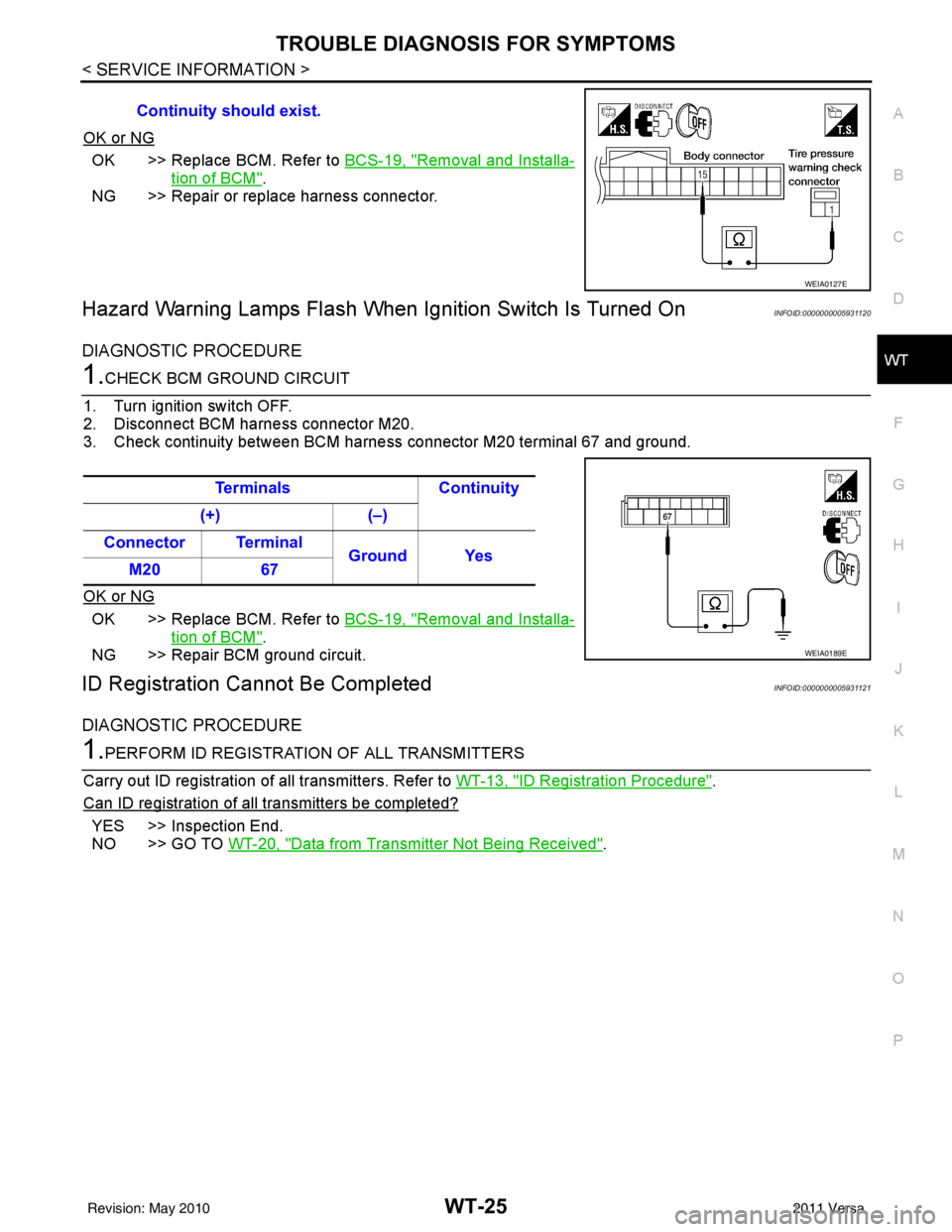

2.CHECK TIRE PRESSURE WARNING CHECK CONNECTOR CIRCUIT

Check continuity between BCM harness connector M 18 terminal 15 and check connector M39 terminal 1.

Terminals

Voltage

(Approx.)

(+) (–)

Connector Terminal GroundBattery

voltage

M18 38

WEIA0038E

Terminals Continuity

(+) (–)

Connector Terminal Ground Yes

M20 67

WEIA0189E

SEIA0347E

Revision: May 2010 2011 Versa

Page 3743 of 3787

TROUBLE DIAGNOSIS FOR SYMPTOMSWT-25

< SERVICE INFORMATION >

C

DF

G H

I

J

K L

M A

B

WT

N

O P

OK or NG

OK >> Replace BCM. Refer to BCS-19, "Removal and Installa-

tion of BCM".

NG >> Repair or replace harness connector.

Hazard Warning Lamps Flash When Ignition Switch Is Turned OnINFOID:0000000005931120

DIAGNOSTIC PROCEDURE

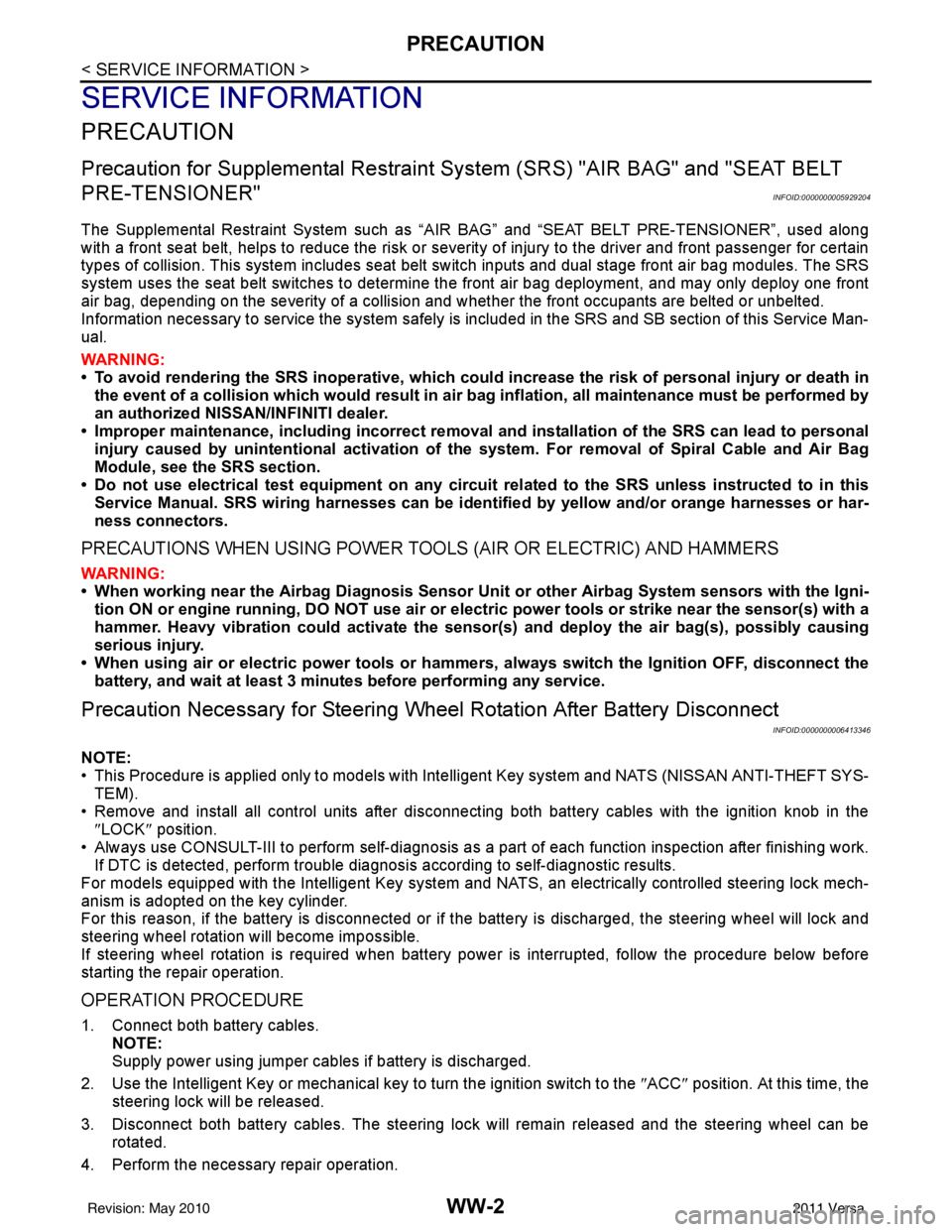

1.CHECK BCM GROUND CIRCUIT

1. Turn ignition switch OFF.

2. Disconnect BCM harness connector M20.

3. Check continuity between BCM harness connector M20 terminal 67 and ground.

OK or NG

OK >> Replace BCM. Refer to BCS-19, "Removal and Installa-

tion of BCM".

NG >> Repair BCM ground circuit.

ID Registration Cannot Be CompletedINFOID:0000000005931121

DIAGNOSTIC PROCEDURE

1.PERFORM ID REGISTRATION OF ALL TRANSMITTERS

Carry out ID registration of all transmitters. Refer to WT-13, "

ID Registration Procedure".

Can ID registration of all transmitters be completed?

YES >> Inspection End.

NO >> GO TO WT-20, "

Data from Transmitter Not Being Received".

Continuity should exist.

WEIA0127E

Terminals

Continuity

(+) (–)

Connector Terminal Ground Yes

M20 67

WEIA0189E

Revision: May 2010 2011 Versa

Page 3748 of 3787

WW-2

< SERVICE INFORMATION >

PRECAUTION

SERVICE INFORMATION

PRECAUTION

Precaution for Supplemental Restraint System (SRS) "AIR BAG" and "SEAT BELT

PRE-TENSIONER"

INFOID:0000000005929204

The Supplemental Restraint System such as “A IR BAG” and “SEAT BELT PRE-TENSIONER”, used along

with a front seat belt, helps to reduce the risk or severity of injury to the driver and front passenger for certain

types of collision. This system includes seat belt switch inputs and dual stage front air bag modules. The SRS

system uses the seat belt switches to determine the front air bag deployment, and may only deploy one front

air bag, depending on the severity of a collision and w hether the front occupants are belted or unbelted.

Information necessary to service the system safely is included in the SRS and SB section of this Service Man-

ual.

WARNING:

• To avoid rendering the SRS inopera tive, which could increase the risk of personal injury or death in

the event of a collision which would result in air bag inflation, all maintenance must be performed by

an authorized NISSAN/INFINITI dealer.

• Improper maintenance, including incorrect removal and installation of the SRS can lead to personal

injury caused by unintent ional activation of the system. For re moval of Spiral Cable and Air Bag

Module, see the SRS section.

• Do not use electrical test equipmen t on any circuit related to the SRS unless instructed to in this

Service Manual. SRS wiring harn esses can be identified by yellow and/or orange harnesses or har-

ness connectors.

PRECAUTIONS WHEN USING POWER TOOLS (AIR OR ELECTRIC) AND HAMMERS

WARNING:

• When working near the Airbag Diagnosis Sensor Unit or other Airbag System sensors with the Igni-

tion ON or engine running, DO NOT use air or electri c power tools or strike near the sensor(s) with a

hammer. Heavy vibration could activate the sensor( s) and deploy the air bag(s), possibly causing

serious injury.

• When using air or electric power tools or hammers , always switch the Ignition OFF, disconnect the

battery, and wait at least 3 minu tes before performing any service.

Precaution Necessary for Steering W heel Rotation After Battery Disconnect

INFOID:0000000006413346

NOTE:

• This Procedure is applied only to models with Intelligent Key system and NATS (NISSAN ANTI-THEFT SYS-

TEM).

• Remove and install all control units after disconnecting both battery cables with the ignition knob in the

″LOCK ″ position.

• Always use CONSULT-III to perform self-diagnosis as a part of each function inspection after finishing work.

If DTC is detected, perform trouble diagnosis according to self-diagnostic results.

For models equipped with the Intelligent Key system and NATS, an electrically controlled steering lock mech-

anism is adopted on the key cylinder.

For this reason, if the battery is disconnected or if the battery is discharged, the steering wheel will lock and

steering wheel rotation will become impossible.

If steering wheel rotation is required when battery pow er is interrupted, follow the procedure below before

starting the repair operation.

OPERATION PROCEDURE

1. Connect both battery cables. NOTE:

Supply power using jumper cables if battery is discharged.

2. Use the Intelligent Key or mechanical key to turn the ignition switch to the ″ACC ″ position. At this time, the

steering lock will be released.

3. Disconnect both battery cables. The steering lock will remain released and the steering wheel can be rotated.

4. Perform the necessary repair operation.

Revision: May 2010 2011 Versa

Page 3749 of 3787

PRECAUTIONWW-3

< SERVICE INFORMATION >

C

DE

F

G H

I

J

L

M A

B

WW

N

O P

5. When the repair work is completed, return the ignition switch to the ″LOCK ″ position before connecting

the battery cables. (At this time, the steering lock mechanism will engage.)

6. Perform a self-diagnosis check of al l control units using CONSULT-III.

Precaution for Procedure without Cowl Top CoverINFOID:0000000005929205

When performing the procedure after removing cowl top cover, cover

the lower end of windshield with urethane, etc.

PIIB3706J

Revision: May 2010 2011 Versa

Page 3751 of 3787

FRONT WIPER AND WASHER SYSTEMWW-5

< SERVICE INFORMATION >

C

DE

F

G H

I

J

L

M A

B

WW

N

O P

FRONT WIPER AND WASHER SYSTEM

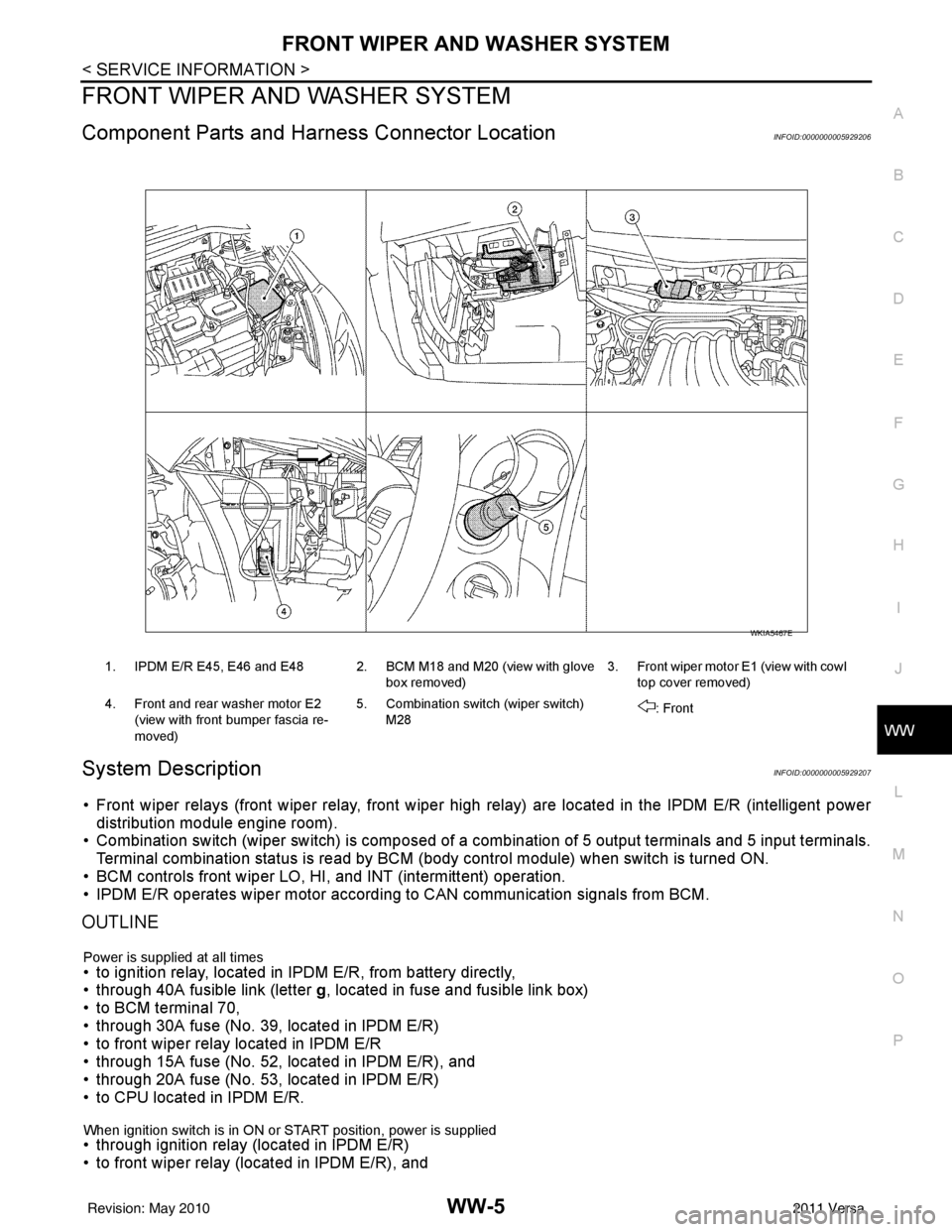

Component Parts and Har ness Connector LocationINFOID:0000000005929206

System DescriptionINFOID:0000000005929207

• Front wiper relays (front wiper relay, front wiper high relay) are located in the IPDM E/R (intelligent power

distribution module engine room).

• Combination switch (wiper switch) is composed of a combination of 5 output terminals and 5 input terminals.

Terminal combination status is read by BCM (body control module) when switch is turned ON.

• BCM controls front wiper LO, HI, and INT (intermittent) operation.

• IPDM E/R operates wiper motor accordi ng to CAN communication signals from BCM.

OUTLINE

Power is supplied at all times• to ignition relay, located in IPDM E/R, from battery directly,

• through 40A fusible link (letter g, located in fuse and fusible link box)

• to BCM terminal 70,

• through 30A fuse (No. 39, located in IPDM E/R)

• to front wiper relay located in IPDM E/R

• through 15A fuse (No. 52, located in IPDM E/R), and

• through 20A fuse (No. 53, located in IPDM E/R)

• to CPU located in IPDM E/R.

When ignition switch is in ON or START position, power is supplied • through ignition relay (located in IPDM E/R)

• to front wiper relay (located in IPDM E/R), and

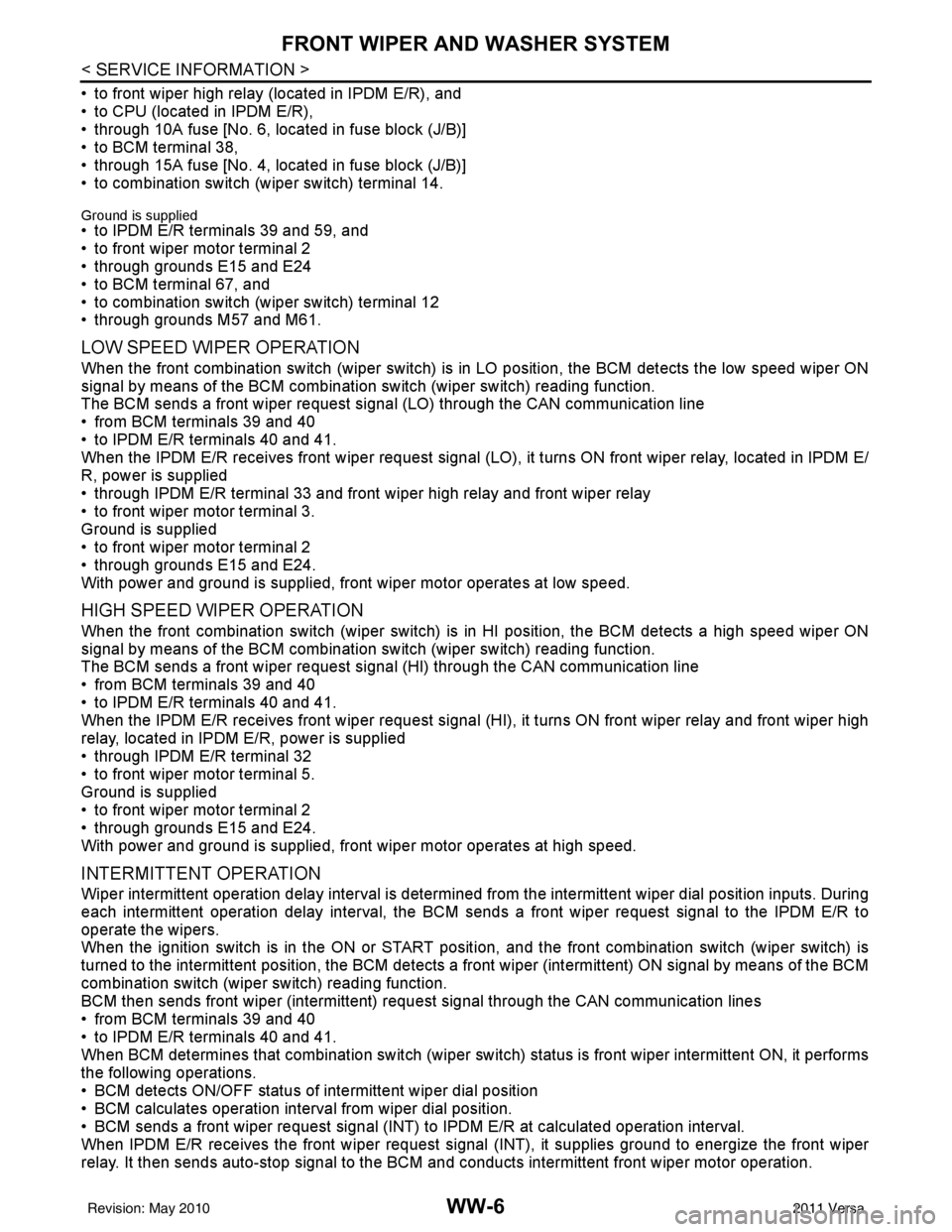

1. IPDM E/R E45, E46 and E48 2. BCM M18 and M20 (view with glove

box removed)3. Front wiper motor E1

(view with cowl

top cover removed)

4. Front and rear washer motor E2 (view with front bumper fascia re-

moved) 5. Combination switch (wiper switch)

M28 : Front

WKIA5467E

Revision: May 2010

2011 Versa

Page 3752 of 3787

WW-6

< SERVICE INFORMATION >

FRONT WIPER AND WASHER SYSTEM

• to front wiper high relay (located in IPDM E/R), and

• to CPU (located in IPDM E/R),

• through 10A fuse [No. 6, located in fuse block (J/B)]

• to BCM terminal 38,

• through 15A fuse [No. 4, located in fuse block (J/B)]

• to combination switch (wiper switch) terminal 14.

Ground is supplied

• to IPDM E/R terminals 39 and 59, and

• to front wiper motor terminal 2

• through grounds E15 and E24

• to BCM terminal 67, and

• to combination switch (wiper switch) terminal 12

• through grounds M57 and M61.

LOW SPEED WIPER OPERATION

When the front combination switch (wiper switch) is in LO position, the BCM detects the low speed wiper ON

signal by means of the BCM combination switch (wiper switch) reading function.

The BCM sends a front wiper request signal (LO) through the CAN communication line

• from BCM terminals 39 and 40

• to IPDM E/R terminals 40 and 41.

When the IPDM E/R receives front wiper request signal (LO) , it turns ON front wiper relay, located in IPDM E/

R, power is supplied

• through IPDM E/R terminal 33 and front wiper high relay and front wiper relay

• to front wiper motor terminal 3.

Ground is supplied

• to front wiper motor terminal 2

• through grounds E15 and E24.

With power and ground is supplied, front wiper motor operates at low speed.

HIGH SPEED WIPER OPERATION

When the front combination switch (wiper switch) is in HI position, the BCM detects a high speed wiper ON

signal by means of the BCM combination switch (wiper switch) reading function.

The BCM sends a front wiper request signal (HI) through the CAN communication line

• from BCM terminals 39 and 40

• to IPDM E/R terminals 40 and 41.

When the IPDM E/R receives front wiper request signal (HI), it turns ON front wiper relay and front wiper high

relay, located in IPDM E/R, power is supplied

• through IPDM E/R terminal 32

• to front wiper motor terminal 5.

Ground is supplied

• to front wiper motor terminal 2

• through grounds E15 and E24.

With power and ground is supplied, front wiper motor operates at high speed.

INTERMITTENT OPERATION

Wiper intermittent operation delay interval is determined from the intermittent wiper dial position inputs. During

each intermittent operation delay interval, the BCM s ends a front wiper request signal to the IPDM E/R to

operate the wipers.

When the ignition switch is in the ON or START positi on, and the front combination switch (wiper switch) is

turned to the intermittent position, the BCM detects a fr ont wiper (intermittent) ON signal by means of the BCM

combination switch (wiper switch) reading function.

BCM then sends front wiper (intermittent) request signal through the CAN communication lines

• from BCM terminals 39 and 40

• to IPDM E/R terminals 40 and 41.

When BCM determines that combination switch (wiper swit ch) status is front wiper intermittent ON, it performs

the following operations.

• BCM detects ON/OFF status of intermittent wiper dial position

• BCM calculates operation interval from wiper dial position.

• BCM sends a front wiper request signal (INT) to IPDM E/R at calculated operation interval.

When IPDM E/R receives the front wiper request signal (INT), it supplies ground to energize the front wiper

relay. It then sends auto-stop signal to the BCM and conducts intermittent front wiper motor operation.

Revision: May 2010 2011 Versa

Page 3753 of 3787

FRONT WIPER AND WASHER SYSTEMWW-7

< SERVICE INFORMATION >

C

DE

F

G H

I

J

L

M A

B

WW

N

O P

AUTO STOP OPERATION

With combination switch (wiper switch) turned OFF, wi per motor will continue to operate until wiper arms reach

windshield base.

When the wiper arms are not located at base of windshield with combination switch (wiper switch) OFF,

ground is supplied

• from IPDM E/R terminal 33

• to front wiper motor terminal 3, in order to continue wiper motor operation at low speed.

When the wiper arms reach base of windshield, front wiper motor terminals 4 and 2 are connected, and

ground is supplied

• to IPDM E/R terminal 38

• through front wiper motor terminals 4 and 2, and

• through grounds E15 and E24.

Then the IPDM E/R sends auto stop operation signal to BCM with CAN communication line.

When the BCM receives auto-stop operation signal, BCM sends wiper stop signal to IPDM E/R with CAN com-

munication line.

IPDM E/R stops wiper motor. Wiper motor wi ll then stop wiper arms at the STOP position.

WASHER OPERATION

When the combination switch (wiper switch) is in front wiper washer position, BCM detect front wiper washer

signal by BCM combination switch (wiper switch) reading function. Refer to BCS-4, "

System Description" .

Combination switch (wiper switch) power is supplied

• through combination switch (wiper switch) terminal 14

• to washer motor terminal 1.

Ground is supplied

• to front washer motor terminal 2

• through combination switch (wiper switch) terminal 11, and

• through combination switch (wiper switch) terminal 12

• through grounds M57 and M61.

With ground supplied, front washer motor is operated.

When the BCM detects that front washer motor has operated for 0.4 seconds or longer, BCM operates front

wiper motor for low speed.

When the BCM detects washer switch is OFF, low speed operation cycles approximately 2 times and stops.

MIST OPERATION

When the combination switch (wiper switch) is turned to the mist position, wiper low speed operation cycles

once and then stops.

For additional information about wiper operation under th is condition, refer to "LOW SPEED WIPER OPERA-

TION" .

If switch is held in mist posit ion, low speed operation continues.

FAIL-SAFE FUNCTION

If an abnormality occurs in CAN communications, IPDM E/ R holds the condition just before fail-safe status is

initiated until ignition switch is turned OFF. (If wipers we re operating in LO just before the initiation of fail-safe

status, they continue to operate in LO until ignition switch is turned OFF.)

COMBINATION SWITCH (WIPER SWITCH) READING FUNCTION

Refer to BCS-4, "System Description" .

CAN Communication System DescriptionINFOID:0000000005929208

Refer to LAN-7, "System Description".

Revision: May 2010 2011 Versa