low oil pressure NISSAN LATIO 2011 Service User Guide

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2011, Model line: LATIO, Model: NISSAN LATIO 2011Pages: 3787, PDF Size: 78.35 MB

Page 203 of 3787

AT-186

< SERVICE INFORMATION >

TROUBLE DIAGNOSIS FOR SYMPTOMS

1. Disassemble A/T. Refer to AT-257, "Disassembly" .

2. Check the following items:

- Low & reverse brake assembly. Refer to AT-314, "

Low & Reverse Brake" .

- Reverse clutch assembly. Refer to AT-297, "

Reverse Clutch" .

OK or NG

OK >> GO TO 6.

NG >> Repair or replace damaged parts.

6.CHECK A/T FLUID CONDITION

1. Remove oil pan. Refer to AT-237, "

Component" .

2. Check A/T fluid condition. Refer to AT-51, "

Inspections Before Trouble Diagnosis" .

OK or NG

OK >> GO TO 8.

NG >> GO TO 7.

7.DETECT MALFUNCTIONING ITEM

1. Disassemble A/T. Refer to AT-257, "

Disassembly" .

2. Check the following items:

- Reverse clutch assembly. Refer to AT-297, "

Reverse Clutch" .

- High clutch assembly. Refer to AT-302, "

High Clutch" .

- Low & reverse brake assembly. Refer to AT-314, "

Low & Reverse Brake" .

- Forward clutch assembly. Refer to AT-307, "

Forward and Overrun Clutches" .

- Overrun clutch assembly. Refer to AT-307, "

Forward and Overrun Clutches" .

OK or NG

OK >> GO TO 8.

NG >> Repair or replace damaged parts.

8.CHECK SYMPTOM

Check again. Refer to AT-56, "

Check at Idle" .

OK or NG

OK >> INSPECTION END

NG >> GO TO 9.

9.CHECK TCM

1. Check TCM input/output signals. Refer to AT-75, "

TCM Terminal and Reference Value" .

2. If NG, recheck TCM pin terminals for damage or loose connection with harness connector.

OK or NG

OK >> INSPECTION END

NG >> Repair or replace damaged parts.

Vehicle Does Not Creep Forward in "D", "2" or "1" PositionINFOID:0000000005928253

SYMPTOM:

Vehicle does not creep forward when selecting “D”, “2” or “1” position.

DIAGNOSTIC PROCEDURE

1.CHECK A/T FLUID LEVEL

Check A/T fluid level. Refer to AT-17, "

Checking A/T Fluid" .

OK or NG

OK >> GO TO 2.

NG >> Refill ATF.

2.CHECK LINE PRESSURE

Check line pressure at idle with selector lever in “D” position. Refer to AT-51, "

Inspections Before Trouble

Diagnosis" .

OK or NG

OK >> GO TO 4.

Revision: May 2010 2011 Versa

Page 204 of 3787

TROUBLE DIAGNOSIS FOR SYMPTOMSAT-187

< SERVICE INFORMATION >

DE

F

G H

I

J

K L

M A

B

AT

N

O P

NG >> GO TO 3.

3.DETECT MALFUNCTIONING ITEM

1. Remove control valve assembly. Refer to AT-222, "

Control Valve Assembly and Accumulators" .

2. Check the following items:

- Valves to control line pressure (Pressure regulator valv e, pressure modifier valve, pilot valve and pilot fil-

ter)

- Line pressure solenoid valve

3. Disassemble A/T. Refer to AT-257, "

Disassembly" .

4. Check the following item:

- Oil pump assembly. Refer to AT-278, "

Oil Pump" .

OK or NG

OK >> GO TO 4.

NG >> Repair or replace damaged parts.

4.CHECK STALL REVOLUTION

Check stall revolution with selector lever in “D” position. Refer to AT-51, "

Inspections Before Trouble Diagno-

sis" .

OK or NG

OK >> GO TO 6.

NG >> GO TO 5.

5.DETECT MALFUNCTIONING ITEM

1. Disassemble A/T. Refer to AT-257, "

Disassembly" .

2. Check the following items:

- Oil pump assembly. Refer to AT-278, "

Oil Pump" .

- Forward clutch assembly. Refer to AT-307, "

Forward and Overrun Clutches" .

- Forward one-way clutch. Refer to AT-318, "

Rear Internal Gear and Forward Clutch Hub" .

- Low one-way clutch. Refer to AT-257, "

Disassembly" .

- Torque converter. Refer to AT-257, "

Disassembly" .

OK or NG

OK >> GO TO 7.

NG >> Repair or replace damaged parts.

6.CHECK A/T FLUID CONDITION

1. Remove oil pan. Refer to AT-237, "

Component" .

2. Check A/T fluid condition. Refer to AT-51, "

Inspections Before Trouble Diagnosis" .

OK or NG

OK >> GO TO 7.

NG >> GO TO 5.

7.CHECK SYMPTOM

Check again. Refer to AT-56, "

Check at Idle" .

OK or NG

OK >> INSPECTION END

NG >> GO TO 8.

8.CHECK TCM

1. Check TCM input/output signals. Refer to AT-75, "

TCM Terminal and Reference Value" .

2. If NG, recheck TCM pin terminals for dam age or loose connection with harness connector.

OK or NG

OK >> INSPECTION END

NG >> Repair or replace damaged parts.

Vehicle Cannot Be Started from D1INFOID:0000000005928254

SYMPTOM:

Vehicle cannot be started from D1 on “Cruise Test — Part 1”.

Revision: May 2010 2011 Versa

Page 205 of 3787

AT-188

< SERVICE INFORMATION >

TROUBLE DIAGNOSIS FOR SYMPTOMS

DIAGNOSTIC PROCEDURE

1.CHECK SYMPTOM

Check symptom. Refer to AT-56, "

Check at Idle" .

Is

“Vehicle Dose Not Creep Backward in “R” Position” OK?

OK >> GO TO 2.

NG >> Go to AT-185, "

Vehicle Does Not Creep Backward in "R" Position" .

2.CHECK SELF-DIAGNOSTIC RESULTS

Perform self-diagnosis. Refer to AT-77, "

CONSULT-III Function (TRANSMISSION)" or AT-82, "Diagnosis Pro-

cedure without CONSULT-III" .

Is any malfunction detected by self-diagnostic results?

YES >> Check the malfunctioning system. Refer to AT-77, "CONSULT-III Function (TRANSMISSION)" or

AT-82, "

Diagnosis Procedure without CONSULT-III" .

NO >> GO TO 3.

3.CHECK ACCELERATOR PEDAL POSITION SENSOR

Check accelerator pedal position sensor. Refer to EC-415, "

Description" (HR16DE), EC-982, "Component

Description" (MR18DE).

OK or NG

OK >> GO TO 4.

NG >> Repair or replace accelerator pedal position sensor.

4.CHECK LINE PRESSURE

Check line pressure at stall point with selector lever in “D” position. Refer to AT-51, "

Inspections Before Trou-

ble Diagnosis" .

OK or NG

OK >> GO TO 6.

NG >> GO TO 5.

5.DETECT MALFUNCTIONING ITEM

1. Remove control valve assembly. Refer to AT-222, "

Control Valve Assembly and Accumulators" .

2. Check the following items:

- Shift valve A

- Shift valve B

- Shift solenoid valve A

- Shift solenoid valve B

- Pilot valve

- Pilot filter

3. Disassemble A/T. Refer to AT-257, "

Disassembly" .

4. Check the following items:

- Forward clutch assembly. Refer to AT-307, "

Forward and Overrun Clutches" .

- Low one-way clutch. Refer to AT-257, "

Disassembly" .

- Forward one-way clutch. Refer to AT-318, "

Rear Internal Gear and Forward Clutch Hub" .

- High clutch assembly. Refer to AT-302, "

High Clutch" .

- Torque converter. Refer to AT-257, "

Disassembly" .

- Oil pump assembly. Refer to AT-278, "

Oil Pump" .

OK or NG

OK >> GO TO 8.

NG >> Repair or replace damaged parts.

6.CHECK A/T FLUID CONDITION

1. Remove oil pan. Refer to AT-237, "

Component" .

2. Check A/T fluid condition. Refer to AT-51, "

Inspections Before Trouble Diagnosis" .

OK or NG

OK >> GO TO 7.

NG >> GO TO 5.

Revision: May 2010 2011 Versa

Page 276 of 3787

DISASSEMBLYAT-259

< SERVICE INFORMATION >

DE

F

G H

I

J

K L

M A

B

AT

N

O P

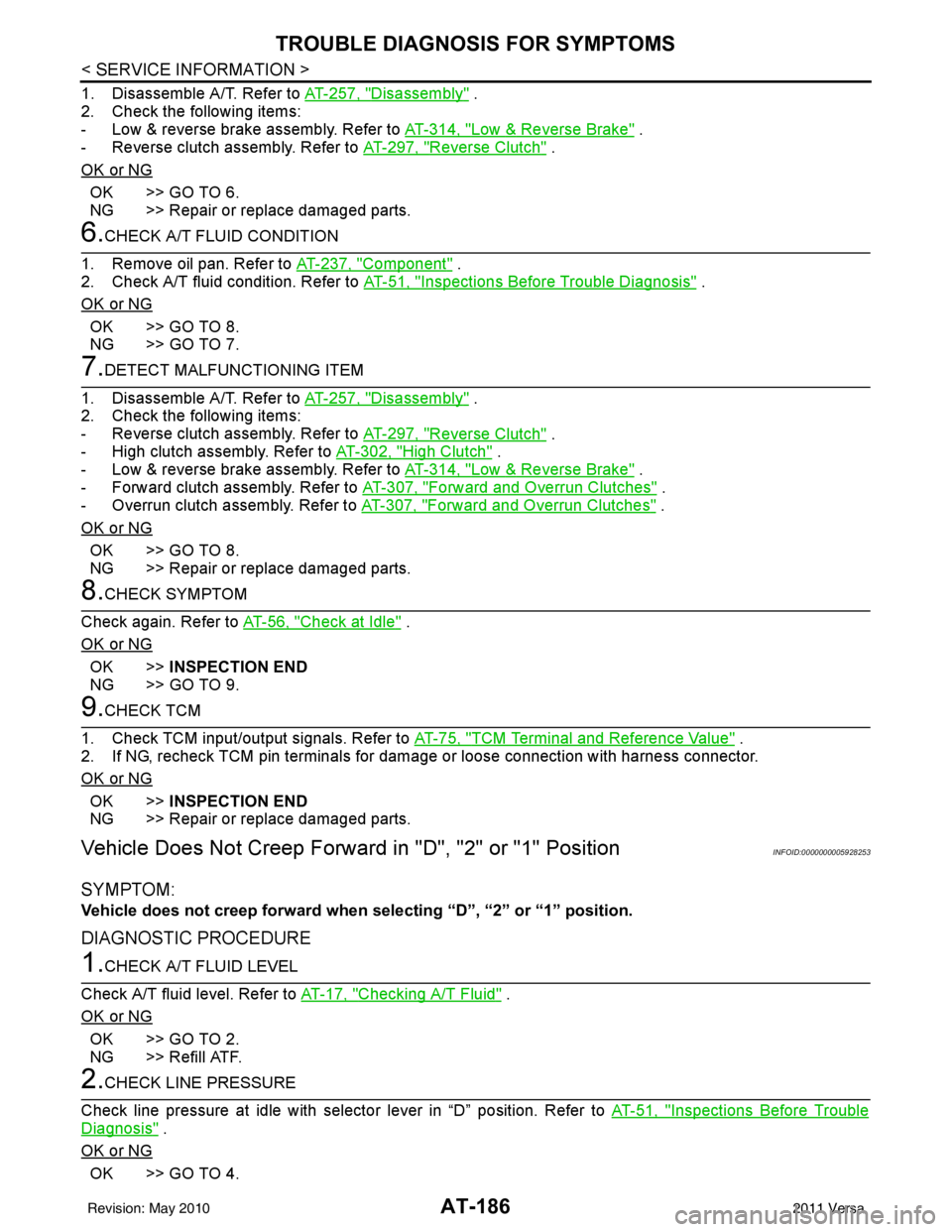

9. Set manual shaft (1) in “P” position.

10. Remove transmission range switch (2) from transaxle case. : Bolt

11. Remove oil pan bolts.

12. Remove oil pan and oil pan gasket.

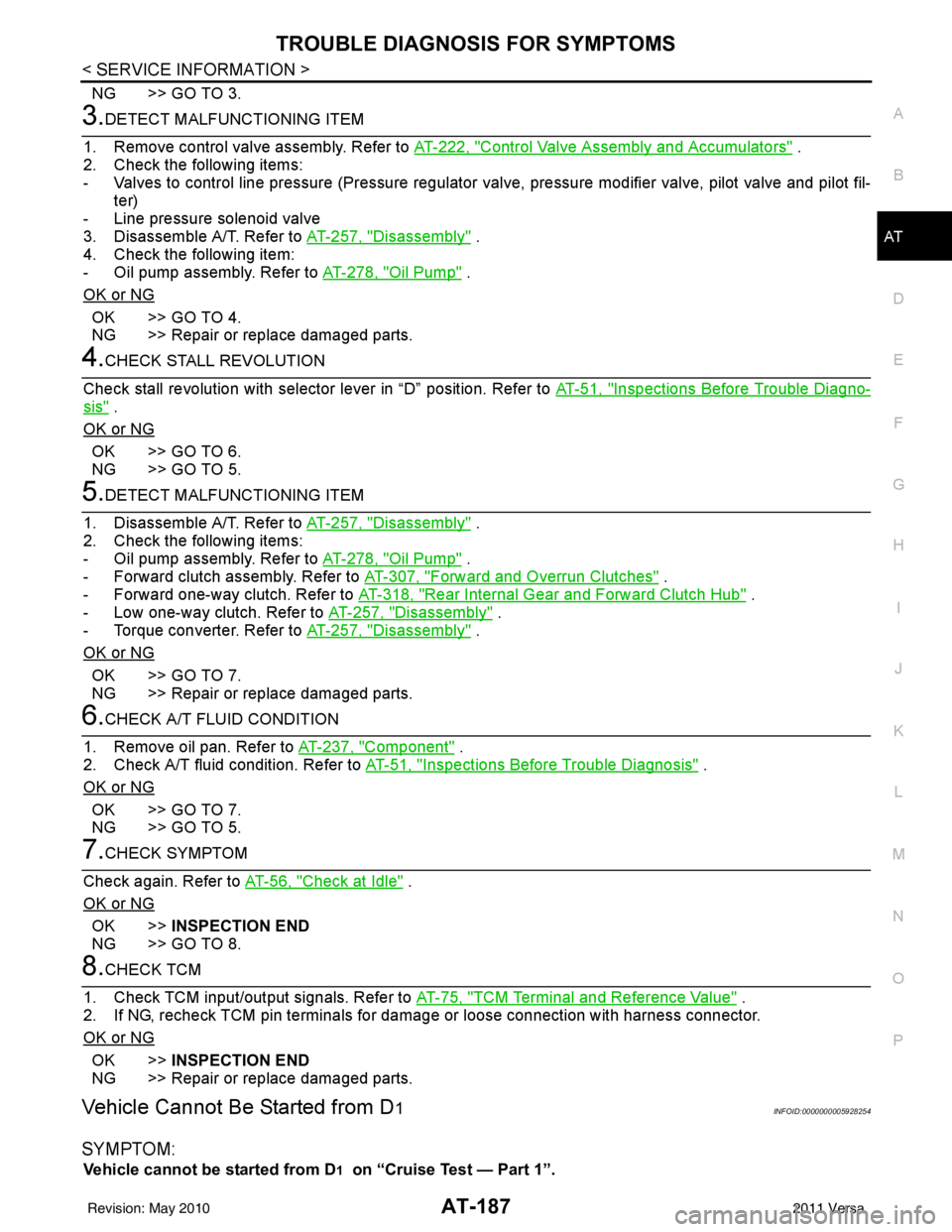

13. Check foreign materials in oil pan to help determine causes of malfunction. If the ATF is very dark, smells burned, or contains

foreign particles, frictional material (clutches, band) may need

replacement. A tacky film that will not wipe clean indicates var-

nish build up. Varnish can cause valves, servo, and clutches to

stick and can inhibit pump pressure.

•If frictional material is detected, replace radiator after

repair of A/T. Refer to CO-40

.

14. Remove magnets from oil pan.

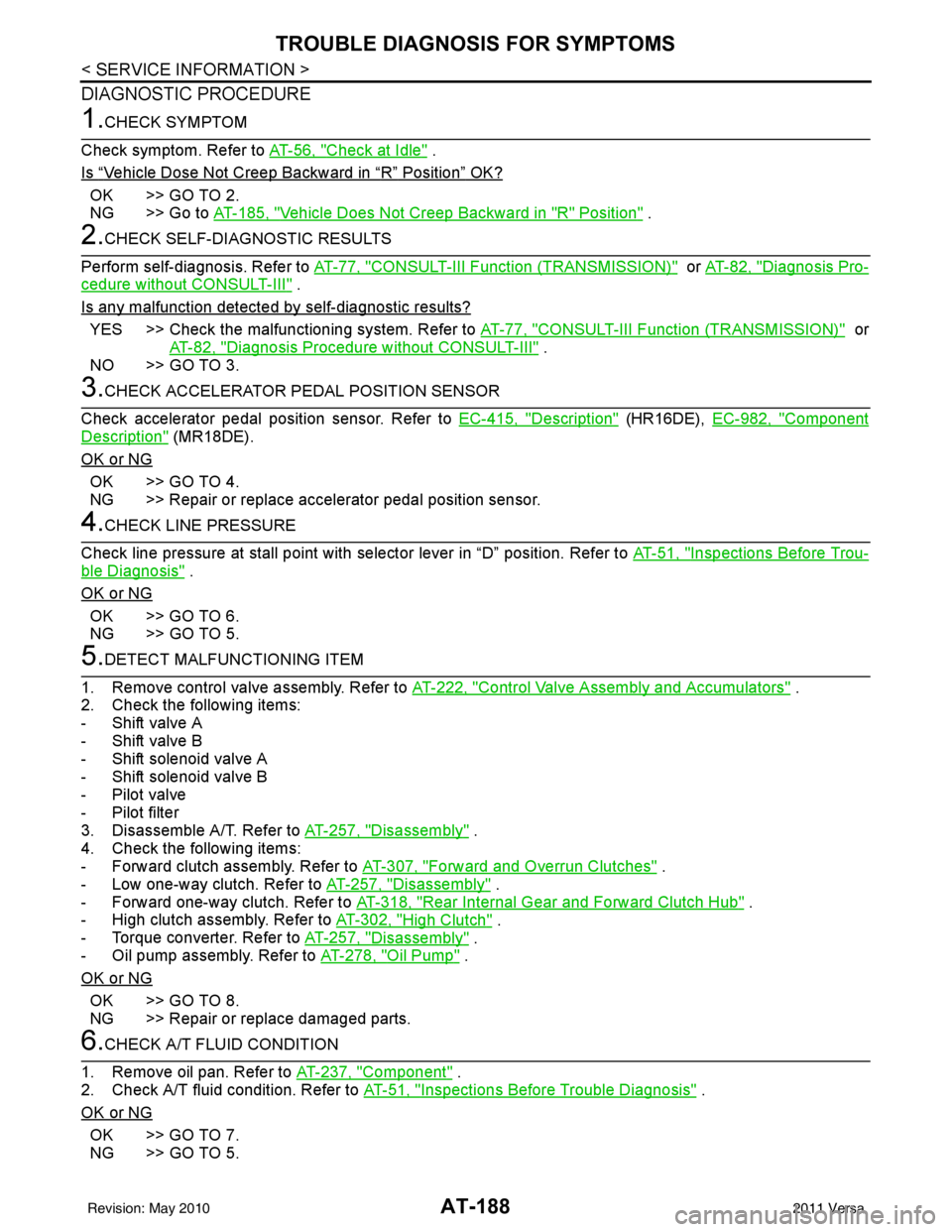

15. Remove control valve assembly according to the following procedures.

a. Remove snap ring (1) from terminal body (2). CAUTION:

Do not expand snap ring (1) excessively.

b. Push terminal body (2) into transaxle case.

c. Remove control valve assembly fitting bolts (A), (B) and ( C).

Bolt length, number and location:

d. Remove control valve assembly from transaxle case.

CAUTION:

Be careful not to drop manual valve.

SCIA5904J

SCIA8025E

SCIA6030J

Bolt symbol ABC

Bolt length “ ” [mm (in)] 40.0 mm

(1.575 in) 33.0 mm

(1.299 in) 43.5 mm

(1.713 in)

Number of bolts 562

SCIA5911J

Revision: May 2010 2011 Versa

Page 299 of 3787

AT-282

< SERVICE INFORMATION >

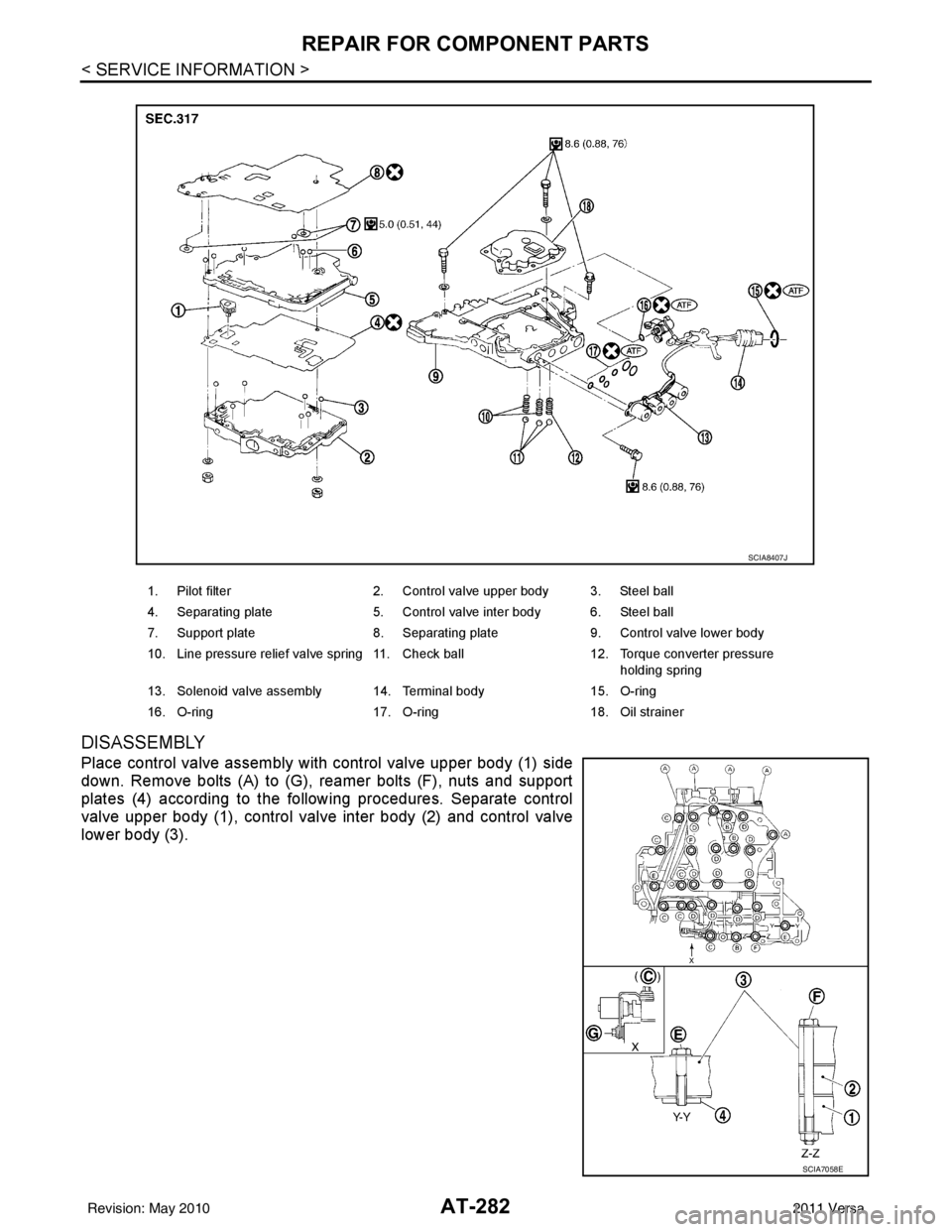

REPAIR FOR COMPONENT PARTS

DISASSEMBLY

Place control valve assembly with control valve upper body (1) side

down. Remove bolts (A) to (G), reamer bolts (F), nuts and support

plates (4) according to the following procedures. Separate control

valve upper body (1), control valve inter body (2) and control valve

lower body (3).

1. Pilot filter2. Control valve upper body 3. Steel ball

4. Separating plate 5. Control valve inter body 6. Steel ball

7. Support plate 8. Separating plate9. Control valve lower body

10. Line pressure relief valve spring 11. Check ball 12. Torque converter pressure

holding spring

13. Solenoid valve assembly 14. Terminal body 15. O-ring

16. O-ring 17. O-ring18. Oil strainer

SCIA8407J

SCIA7058E

Revision: May 2010 2011 Versa

Page 332 of 3787

REPAIR FOR COMPONENT PARTSAT-315

< SERVICE INFORMATION >

DE

F

G H

I

J

K L

M A

B

AT

N

O P

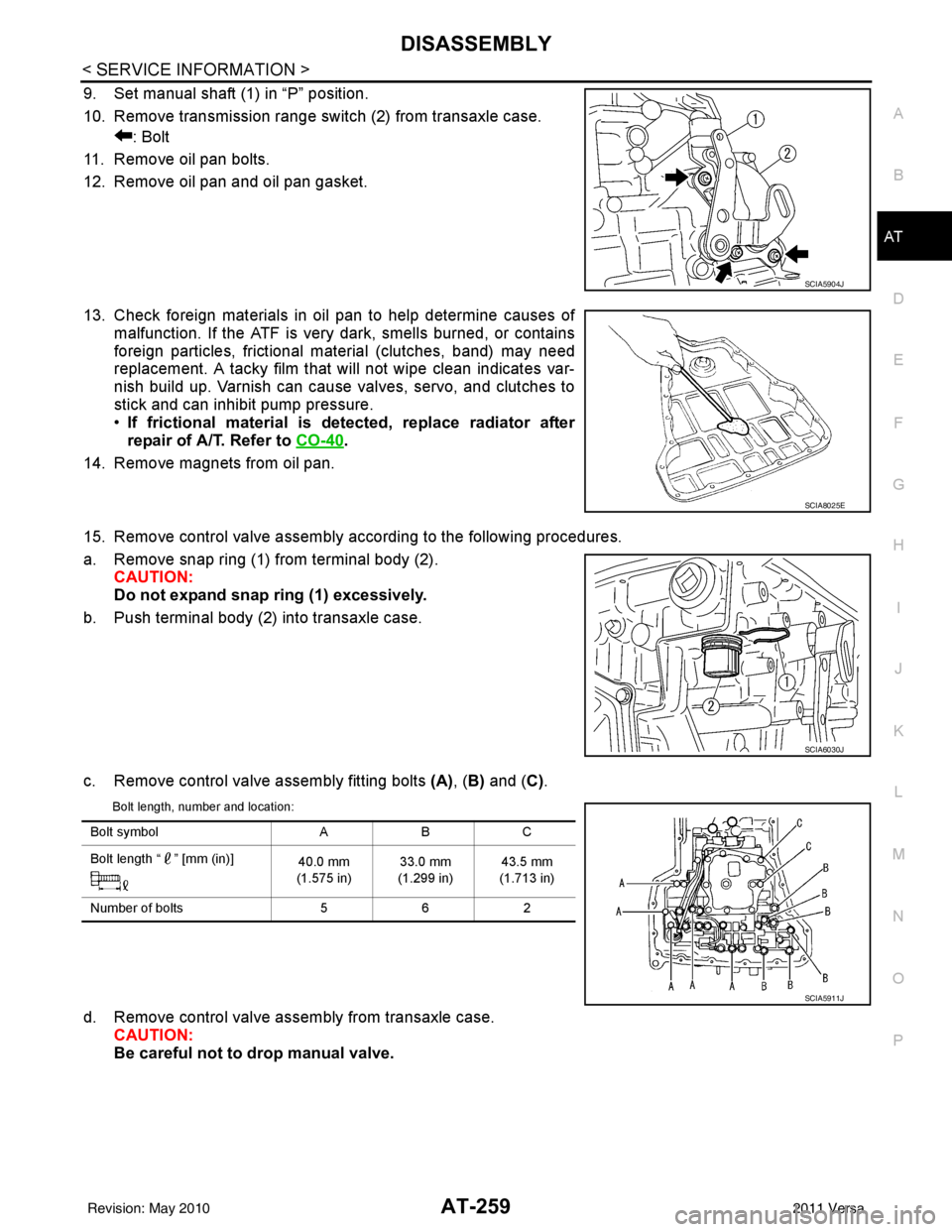

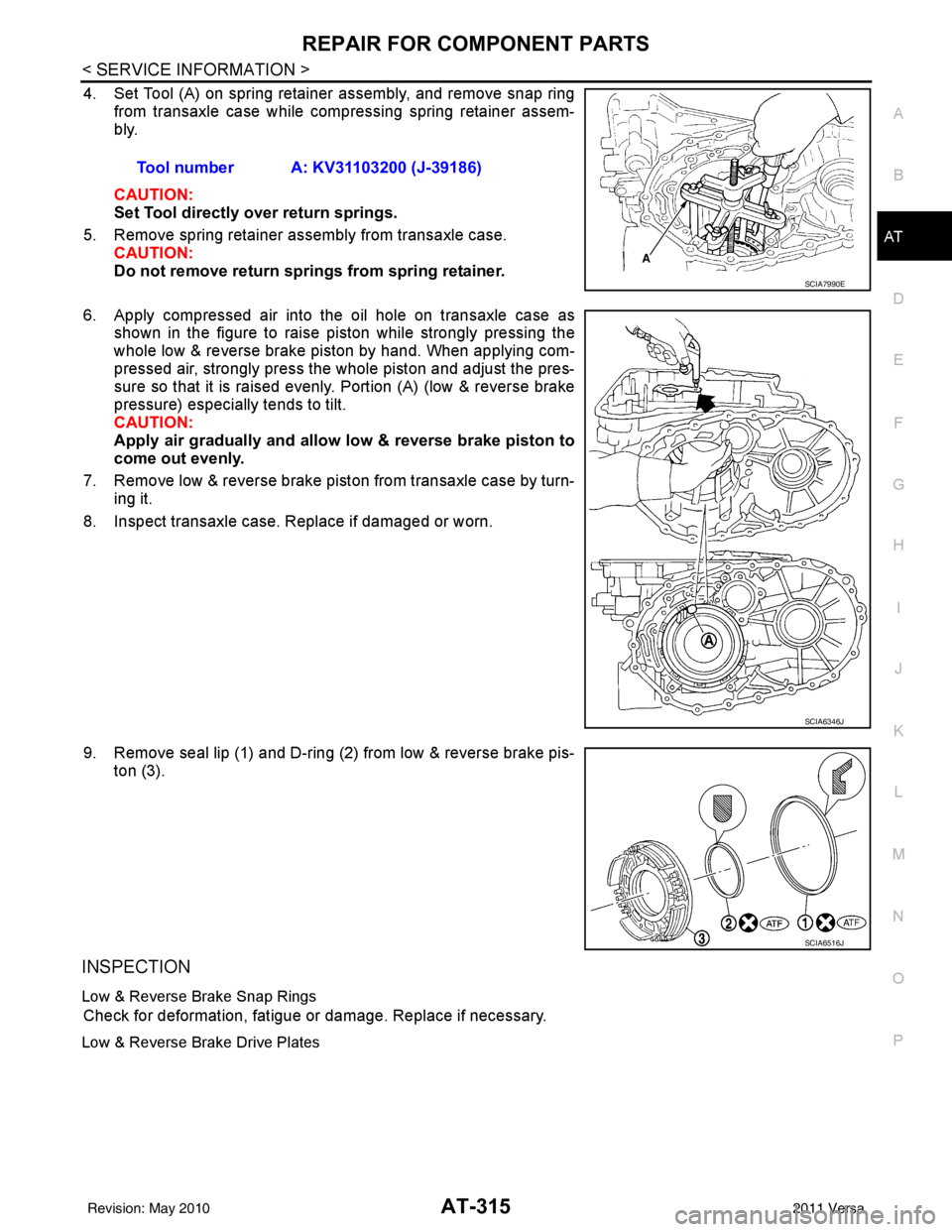

4. Set Tool (A) on spring retainer assembly, and remove snap ring from transaxle case while compressing spring retainer assem-

bly.

CAUTION:

Set Tool directly over return springs.

5. Remove spring retainer assembly from transaxle case. CAUTION:

Do not remove return springs from spring retainer.

6. Apply compressed air into the oil hole on transaxle case as shown in the figure to raise piston while strongly pressing the

whole low & reverse brake piston by hand. When applying com-

pressed air, strongly press the whole piston and adjust the pres-

sure so that it is raised evenly. Portion (A) (low & reverse brake

pressure) especially tends to tilt.

CAUTION:

Apply air gradually and allow low & reverse brake piston to

come out evenly.

7. Remove low & reverse brake piston from transaxle case by turn- ing it.

8. Inspect transaxle case. Replace if damaged or worn.

9. Remove seal lip (1) and D-ring (2) from low & reverse brake pis- ton (3).

INSPECTION

Low & Reverse Brake Snap Rings

Check for deformation, fatigue or damage. Replace if necessary.

Low & Reverse Brake Drive Plates

Tool number A: KV31103200 (J-39186)

SCIA7990E

SCIA6346J

SCIA6516J

Revision: May 2010 2011 Versa

Page 508 of 3787

BCS-18

< SERVICE INFORMATION >

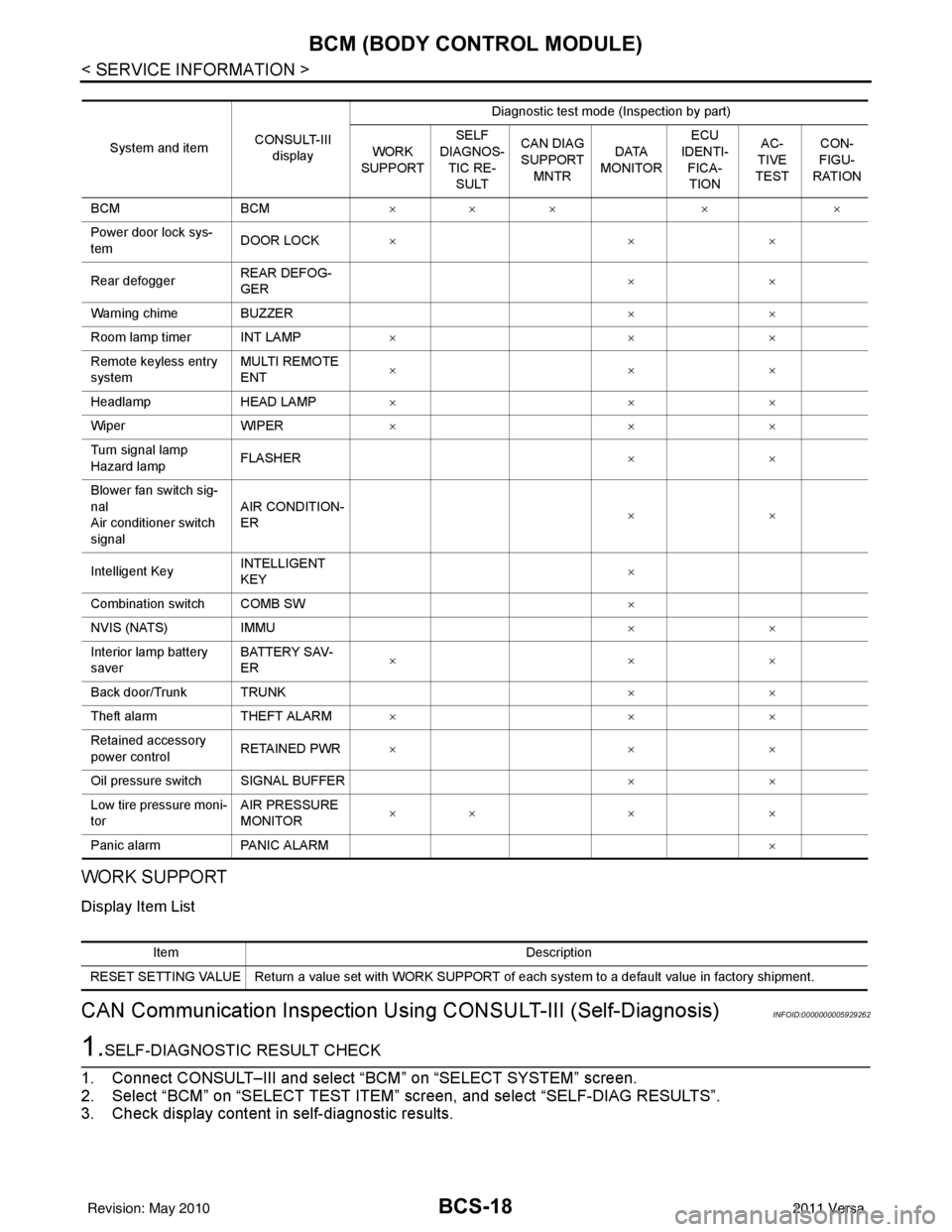

BCM (BODY CONTROL MODULE)

WORK SUPPORT

Display Item List

CAN Communication Inspection Using CONSULT-III (Self-Diagnosis)INFOID:0000000005929262

1.SELF-DIAGNOSTIC RESULT CHECK

1. Connect CONSULT–III and select “BCM” on “SELECT SYSTEM” screen.

2. Select “BCM” on “SELECT TEST ITEM” screen, and select “SELF-DIAG RESULTS”.

3. Check display content in self-diagnostic results.

System and item CONSULT-III

display Diagnostic test mode (Inspection by part)

WORK

SUPPORT SELF

DIAGNOS- TIC RE-

SULT CAN DIAG

SUPPORT MNTR DATA

MONITOR ECU

IDENTI- FICA-

TION AC-

TIVE

TEST CON-

FIGU-

RATION

BCM BCM×× × × ×

Power door lock sys-

tem DOOR LOCK

×× ×

Rear defogger REAR DEFOG-

GER ××

Warning chime BUZZER ××

Room lamp timer INT LAMP ×× ×

Remote keyless entry

system MULTI REMOTE

ENT

××

×

Headlamp HEAD LAMP×× ×

Wiper WIPER×× ×

Turn signal lamp

Hazard lamp FLASHER

××

Blower fan switch sig-

nal

Air conditioner switch

signal AIR CONDITION-

ER

××

Intelligent Key INTELLIGENT

KEY ×

Combination switch COMB SW ×

NVIS (NATS) IMMU ××

Interior lamp battery

saver BATTERY SAV-

ER

××

×

Back door/Trunk TRUNK ××

Theft alarm THEFT ALARM×× ×

Retained accessory

power control RETAINED PWR

×× ×

Oil pressure swit ch SIGNAL BUFFER ××

Low tire pressure moni-

tor AIR PRESSURE

MONITOR

××

× ×

Panic alarm PANIC ALARM ×

ItemDescription

RESET SETTING VALUE Return a value set with WORK SUPPORT of each system to a default value in factory shipment.

Revision: May 2010 2011 Versa

Page 986 of 3787

NOISE, VIBRATION AND HARSHNESS (NVH) TROUBLESHOOTINGCL-5

< SERVICE INFORMATION >

DE

F

G H

I

J

K L

M A

B

CL

N

O P

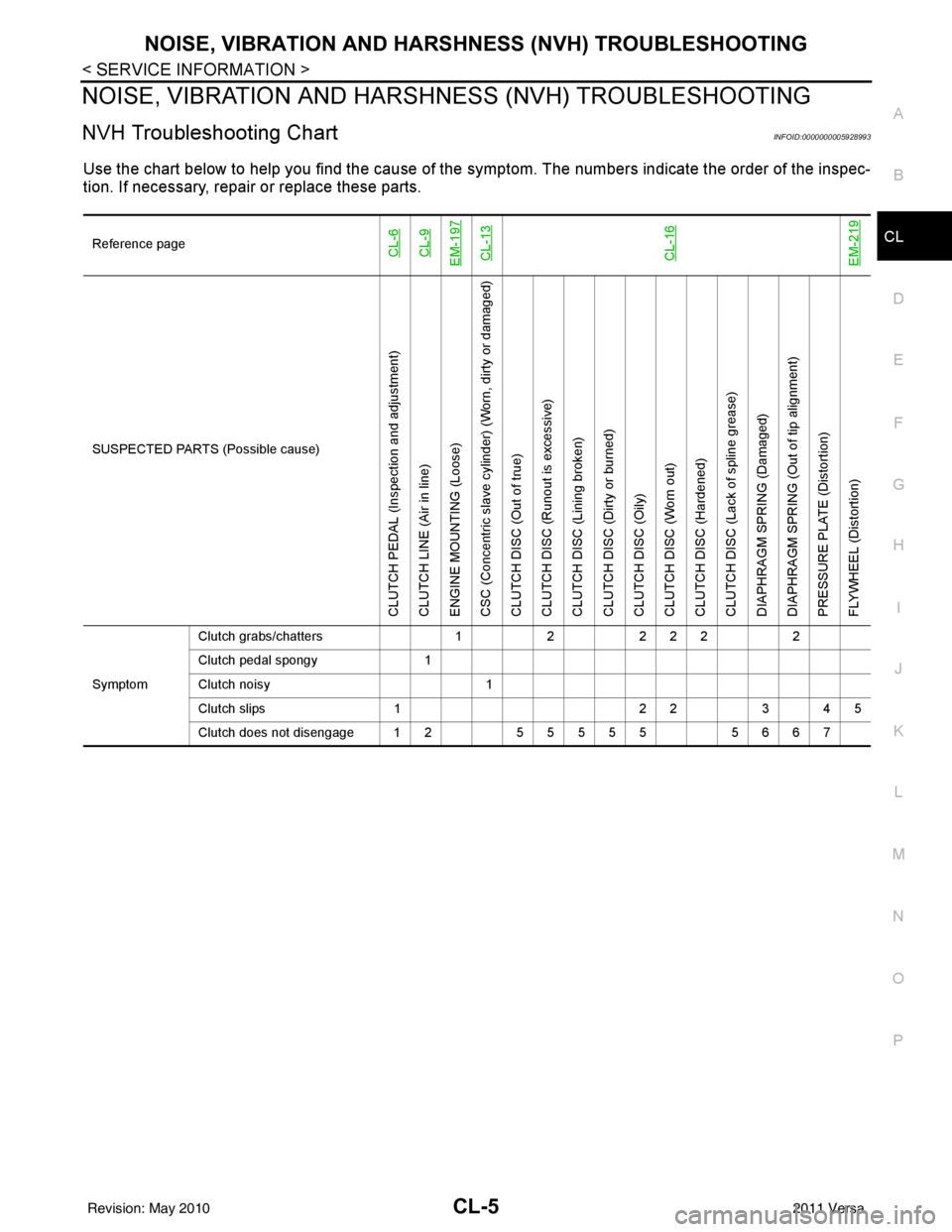

NOISE, VIBRATION AND HARSHN ESS (NVH) TROUBLESHOOTING

NVH Troubleshooting ChartINFOID:0000000005928993

Use the chart below to help you find the cause of the symptom. The numbers indicate the order of the inspec-

tion. If necessary, repair or replace these parts.

Reference pageCL-6CL-9EM-197CL-13CL-16EM-219

SUSPECTED PARTS (Possible cause)

CLUTCH PEDAL (Inspection and adjustment)

CLUTCH LINE (Air in line)

ENGINE MOUNTING (Loose)

CSC (Concentric slave cylinder) (Worn, dirty or damaged)

CLUTCH DISC (Out of true)

CLUTCH DISC (Runou t is excessive)

CLUTCH DISC (Lining broken)

CLUTCH DISC (Dirty or burned)

CLUTCH DISC (Oily)

CLUTCH DISC (Worn out)

CLUTCH DISC (Hardened)

CLUTCH DISC (Lack of spline grease)

DIAPHRAGM SPRING (Damaged)

DIAPHRAGM SPRING (Out of tip alignment)

PRESSURE PLATE (Distortion)

FLYWHEEL (Distortion)

Symptom Clutch grabs/chatters

122 2 2 2

Clutch pedal spongy 1

Clutch noisy 1

Clutch slips 1 2 23 4 5

Clutch does not disengage 12 55555 5667

Revision: May 2010 2011 Versa

Page 1014 of 3787

![NISSAN LATIO 2011 Service User Guide CO-14

< ON-VEHICLE MAINTENANCE >[HR16DE]

RADIATOR

RADIATOR

Checking Radiator CapINFOID:0000000005930779

• Check valve seat of radiator cap.

- Check if valve seat is swollen to the extent that the e NISSAN LATIO 2011 Service User Guide CO-14

< ON-VEHICLE MAINTENANCE >[HR16DE]

RADIATOR

RADIATOR

Checking Radiator CapINFOID:0000000005930779

• Check valve seat of radiator cap.

- Check if valve seat is swollen to the extent that the e](/img/5/57357/w960_57357-1013.png)

CO-14

< ON-VEHICLE MAINTENANCE >[HR16DE]

RADIATOR

RADIATOR

Checking Radiator CapINFOID:0000000005930779

• Check valve seat of radiator cap.

- Check if valve seat is swollen to the extent that the edge of the

plunger cannot be seen when watching it vertically from the top.

- Check if valve seat has no soil and damage.

• Pull negative-pressure valve to open it, and make sure that it is completely closed when released.

- Make sure that there is no dirt or damage on the valve seat of radi-

ator cap negative-pressure valve.

- Make sure that the valve operates properly in the opening and closing conditions.

• Check radiator cap relief pressure using suitable tool and Tool.

- When connecting the radiator cap to the tester, apply water or coolant to the cap seal surface.

- Replace the radiator cap if ther e is an abnormality in the negative-

pressure valve, or if the open-valve pr essure is outside of the standard values.

• Replace radiator cap if there it does not comply to specifications to the above three checks.

CAUTION:

When installing radiator cap, thoroughly wipe out the radiator filler neck to remove any waxy residue

or foreign material.

Checking RadiatorINFOID:0000000005930780

Check radiator for mud or clogging. If necessary, clean radiator as follows.

• Be careful not to bend or damage radiator fins.

• When radiator is cleaned without removal, remove all surrounding parts such as cooling fan, radiator shroud and horns. Then tape harness and connectors to prevent water from entering.

1. Apply water by hose to the back side of the radiator core vertically downward.

2. Apply water again to all radiator core surface once per minute.

3. Stop washing if any stains no longer flow out from radiator.

4. Blow air into the back side of radiator core vertically downward.

PBIC2816E

SMA967B

Tool number : EG17650301 (J-33984-A)

Standard: 78 – 98 kPa (0.78 - 0.98 bar, 0.8 – 1.0 kg/cm

2, 11

– 14 psi)

Limit: 59 kPa (0.59 bar, 0.6 kg/cm

2, 9 psi)

WBIA0570E

Revision: May 2010 2011 Versa

Page 1039 of 3787

![NISSAN LATIO 2011 Service User Guide RADIATORCO-39

< SERVICE INFORMATION > [MR18DE]

C

D

E

F

G H

I

J

K L

M A

CO

NP

O

RADIATOR

Checking Radiator CapINFOID:0000000005930808

• Check valve seat of radiator cap.

- Check if valve seat is swo NISSAN LATIO 2011 Service User Guide RADIATORCO-39

< SERVICE INFORMATION > [MR18DE]

C

D

E

F

G H

I

J

K L

M A

CO

NP

O

RADIATOR

Checking Radiator CapINFOID:0000000005930808

• Check valve seat of radiator cap.

- Check if valve seat is swo](/img/5/57357/w960_57357-1038.png)

RADIATORCO-39

< SERVICE INFORMATION > [MR18DE]

C

D

E

F

G H

I

J

K L

M A

CO

NP

O

RADIATOR

Checking Radiator CapINFOID:0000000005930808

• Check valve seat of radiator cap.

- Check if valve seat is swollen to the extent that the edge of the

plunger cannot be seen when watching it vertically from the top.

- Check if valve seat has no soil and damage.

• Pull negative-pressure valve to open it, and make sure that it is completely closed when released.

- Make sure that there is no dirt or damage on the valve seat of radi-

ator cap negative-pressure valve.

- Make sure that the valve operates properly in the opening and closing conditions.

• Check radiator cap relief pressure using suitable tool and Tool.

- When connecting the radiator cap to the tester, apply water or coolant to the cap seal surface.

- Replace the radiator cap if there is an abnormality in the negative- pressure valve, or if the open-valve pressure is outside of the standard values.

• Replace radiator cap if there it does not comply to specifications to the above three checks.

CAUTION:

When installing radiator cap, thor oughly wipe out the radiator filler neck to remove any waxy residue

or foreign material.

Checking RadiatorINFOID:0000000005930809

Check radiator for mud or clogging. If necessary, clean radiator as follows.

• Be careful not to bend or damage radiator fins.

• When radiator is cleaned without removal, remove all surrounding parts such as cooling fan, radiator shroud and horns. Then tape harness and connectors to prevent water from entering.

1. Apply water by hose to the back side of the radiator core vertically downward.

2. Apply water again to all radiator core surface once per minute.

3. Stop washing if any stains no longer flow out from radiator.

4. Blow air into the back side of radiator core vertically downward.

PBIC2816E

SMA967B

Tool number : EG17650301 (J-33984-A)

Standard: 78 – 98 kPa (0.78 - 0.98 bar, 0.8 – 1.0 kg/cm

2, 11

– 14 psi)

Limit: 59 kPa (0.59 bar, 0.6 kg/cm

2, 9 psi)

WBIA0570E

Revision: May 2010 2011 Versa