roof rack NISSAN LATIO 2011 Service User Guide

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2011, Model line: LATIO, Model: NISSAN LATIO 2011Pages: 3787, PDF Size: 78.35 MB

Page 3547 of 3787

RF-24

< ON-VEHICLE REPAIR >

SUNROOF

SUNROOF UNIT ASSEMBLY

Removal

1. Tilt glass lid up, then remove. Follow the GLASS LID procedure.

2. Position sunroof unit assembly to the fully closed position.

3. Remove the headlining. Refer to EI-50, "

Component".

4. Disconnect drain hoses.

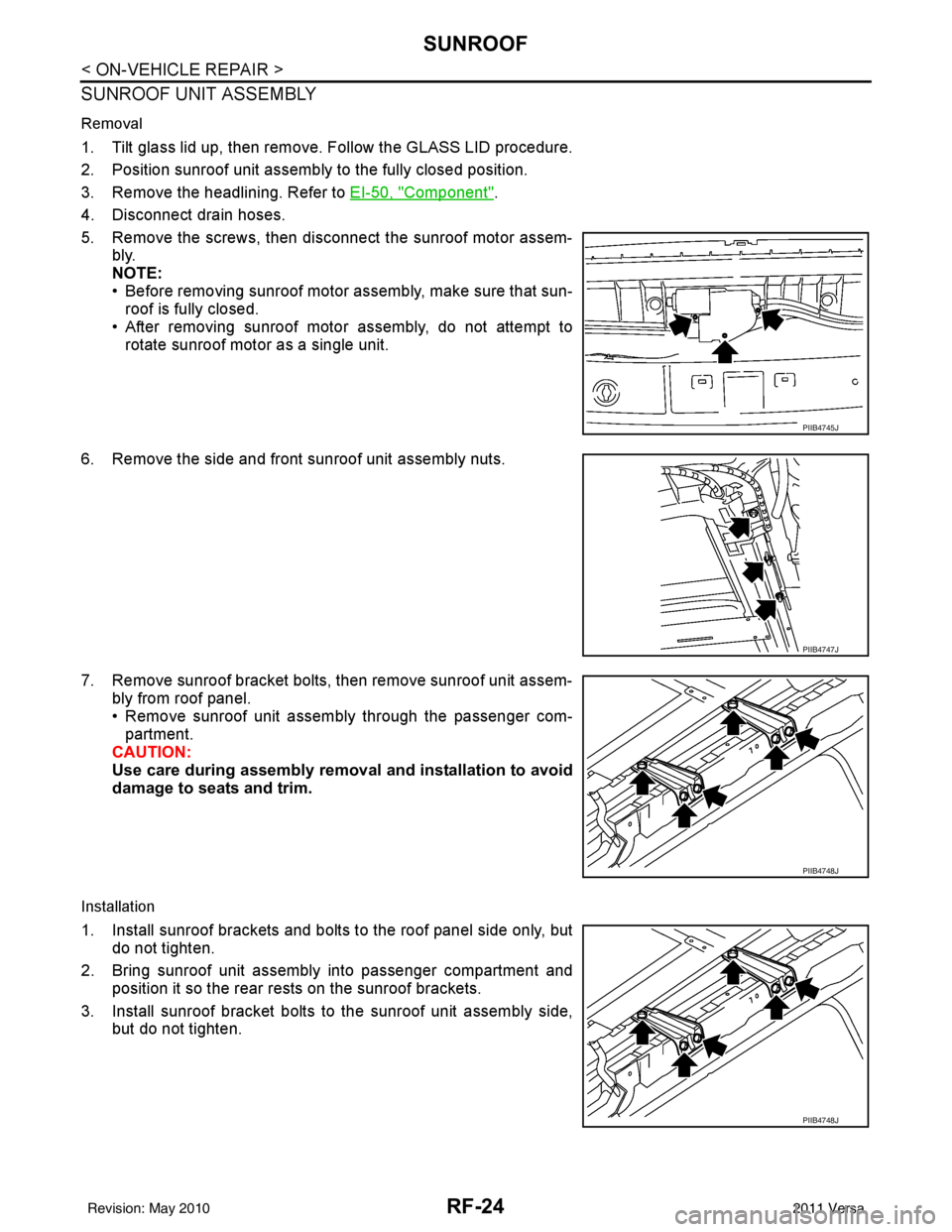

5. Remove the screws, then disconnect the sunroof motor assem- bly.

NOTE:

• Before removing sunroof motor assembly, make sure that sun-roof is fully closed.

• After removing sunroof motor assembly, do not attempt to rotate sunroof motor as a single unit.

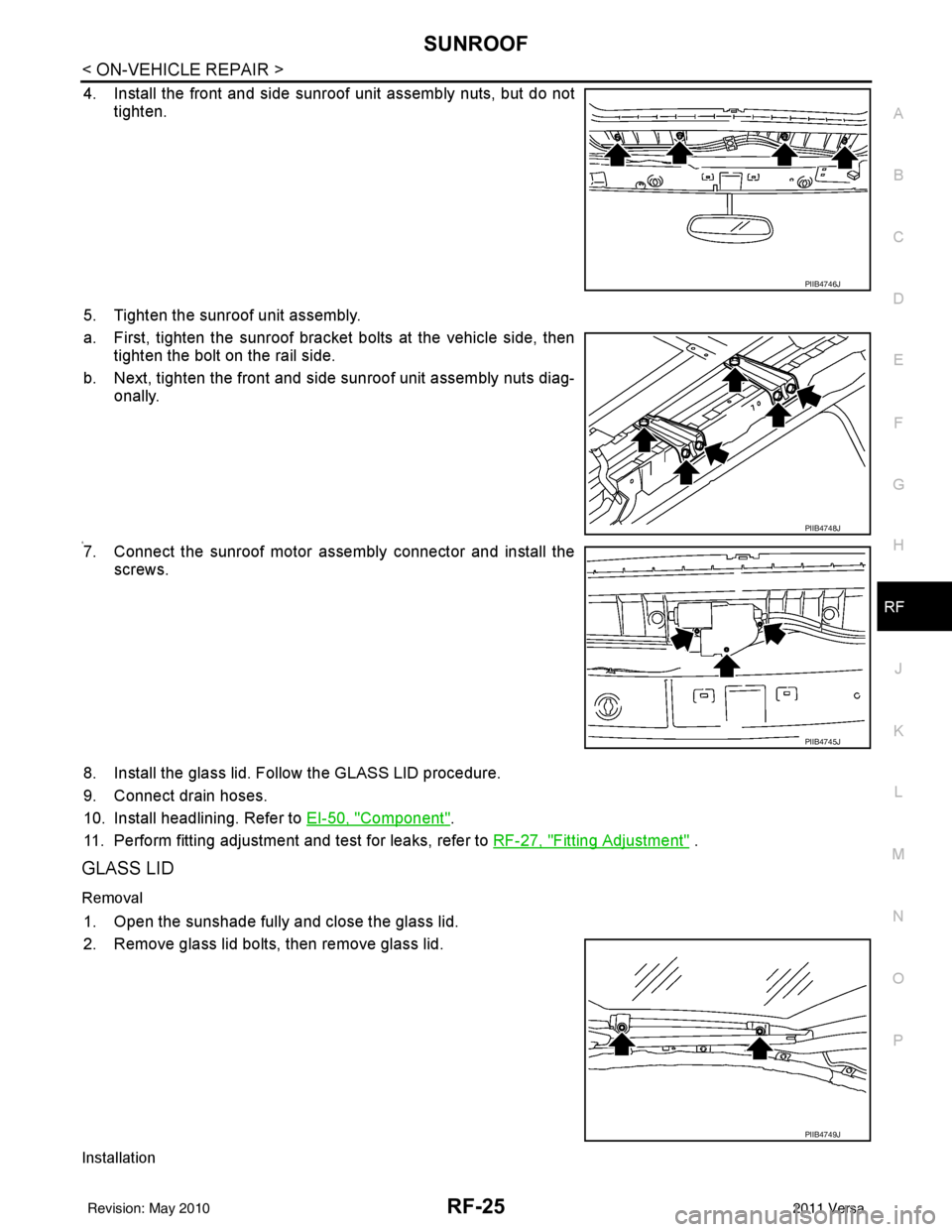

6. Remove the side and front sunroof unit assembly nuts.

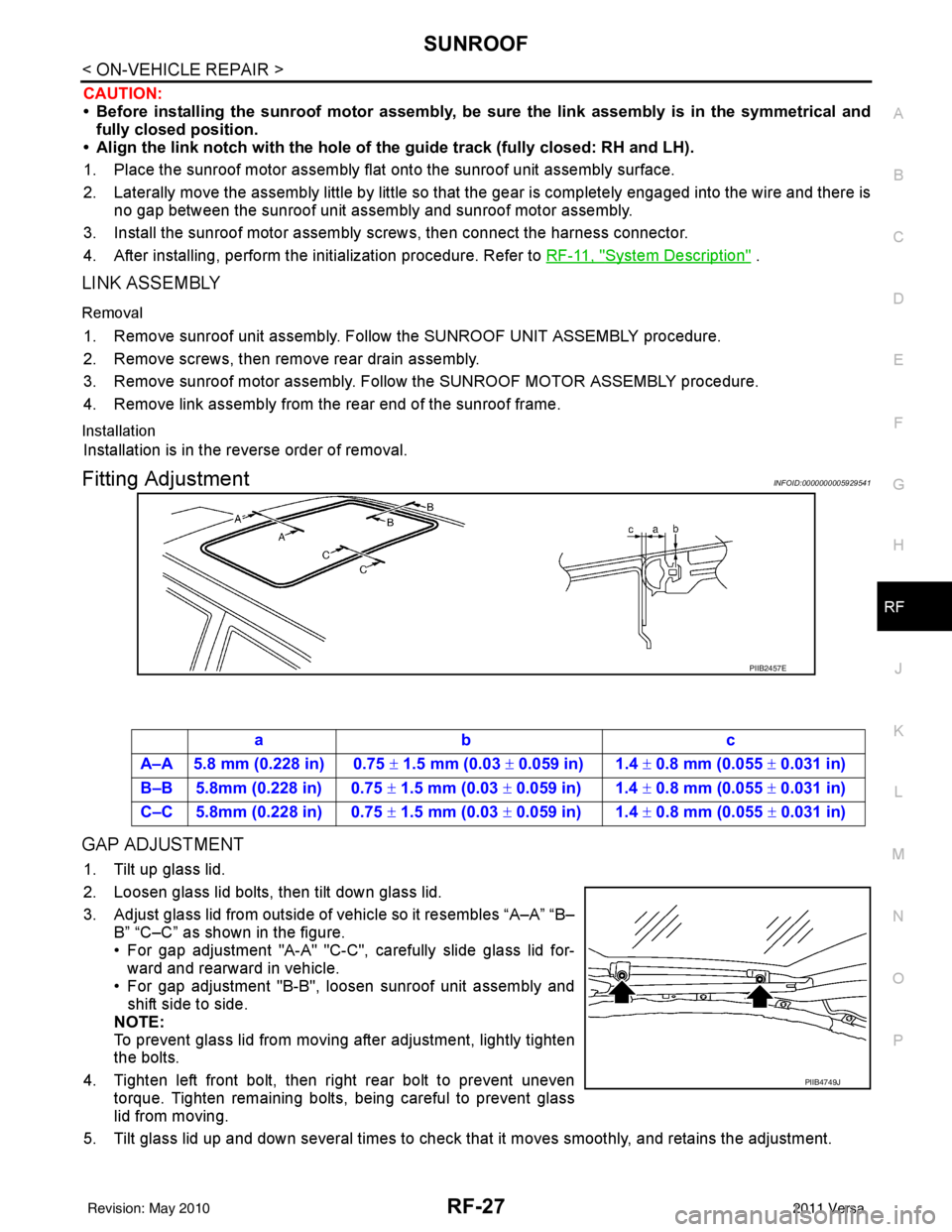

7. Remove sunroof bracket bolts, then remove sunroof unit assem- bly from roof panel.

• Remove sunroof unit assembly through the passenger com-

partment.

CAUTION:

Use care during assembly removal and installation to avoid

damage to seats and trim.

Installation

1. Install sunroof brackets and bolts to the roof panel side only, but do not tighten.

2. Bring sunroof unit assembly into passenger compartment and position it so the rear rests on the sunroof brackets.

3. Install sunroof bracket bolts to the sunroof unit assembly side, but do not tighten.

PIIB4745J

PIIB4747J

PIIB4748J

PIIB4748J

Revision: May 2010 2011 Versa

Page 3548 of 3787

SUNROOFRF-25

< ON-VEHICLE REPAIR >

C

DE

F

G H

J

K L

M A

B

RF

N

O P

4. Install the front and side sunroof unit assembly nuts, but do not tighten.

5. Tighten the sunroof unit assembly.

a. First, tighten the sunroof bracket bolts at the vehicle side, then tighten the bolt on the rail side.

b. Next, tighten the front and side sunroof unit assembly nuts diag- onally.

6.7. Connect the sunroof motor assembly connector and install thescrews.

8. Install the glass lid. Follow the GLASS LID procedure.

9. Connect drain hoses.

10. Install headlining. Refer to EI-50, "

Component".

11. Perform fitting adjustment and test for leaks, refer to RF-27, "

Fitting Adjustment" .

GLASS LID

Removal

1. Open the sunshade fully and close the glass lid.

2. Remove glass lid bolts, then remove glass lid.

Installation

PIIB4746J

PIIB4748J

PIIB4745J

PIIB4749J

Revision: May 2010 2011 Versa

Page 3550 of 3787

SUNROOFRF-27

< ON-VEHICLE REPAIR >

C

DE

F

G H

J

K L

M A

B

RF

N

O P

CAUTION:

• Before installing the sunroof motor assembly, be su re the link assembly is in the symmetrical and

fully closed position.

• Align the link notch with the hole of the guide track (fully closed: RH and LH).

1. Place the sunroof motor assembly flat onto the sunroof unit assembly surface.

2. Laterally move the assembly little by little so that the gear is completely engaged into the wire and there is no gap between the sunroof unit assembly and sunroof motor assembly.

3. Install the sunroof motor assembly screws, then connect the harness connector.

4. After installing, perform the initialization procedure. Refer to RF-11, "

System Description" .

LINK ASSEMBLY

Removal

1. Remove sunroof unit assembly. Follow the SUNROOF UNIT ASSEMBLY procedure.

2. Remove screws, then remove rear drain assembly.

3. Remove sunroof motor assembly. Follow the SUNROOF MOTOR ASSEMBLY procedure.

4. Remove link assembly from the rear end of the sunroof frame.

Installation

Installation is in the reverse order of removal.

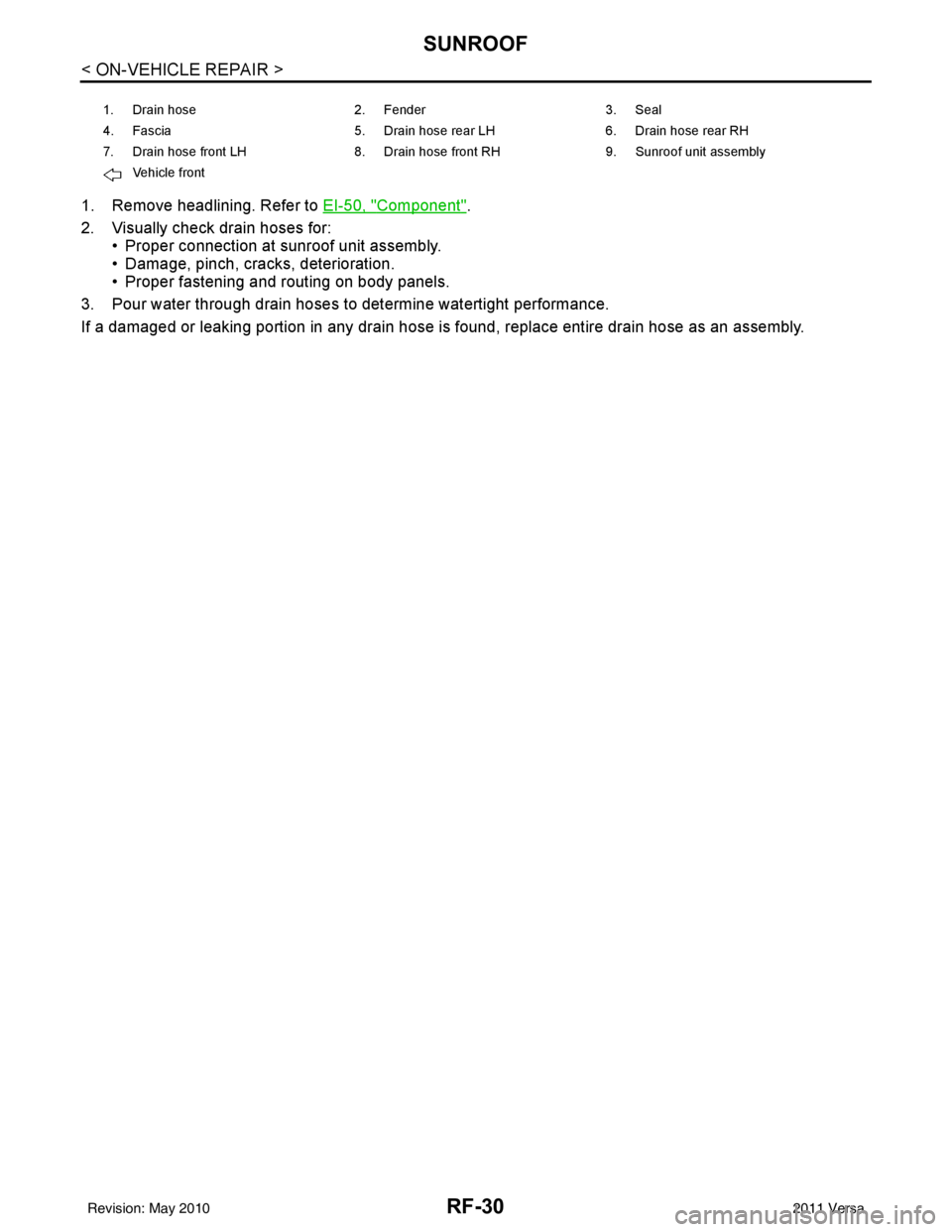

Fitting AdjustmentINFOID:0000000005929541

GAP ADJUSTMENT

1. Tilt up glass lid.

2. Loosen glass lid bolts, then tilt down glass lid.

3. Adjust glass lid from outside of vehicle so it resembles “A–A” “B–

B” “C–C” as shown in the figure.

• For gap adjustment "A-A" "C-C", carefully slide glass lid for-

ward and rearward in vehicle.

• For gap adjustment "B-B", loosen sunroof unit assembly and

shift side to side.

NOTE:

To prevent glass lid from moving after adjustment, lightly tighten

the bolts.

4. Tighten left front bolt, then right rear bolt to prevent uneven torque. Tighten remaining bolts, being careful to prevent glass

lid from moving.

5. Tilt glass lid up and down several times to check that it moves smoothly, and retains the adjustment.

PIIB2457E

ab c

A–A 5.8 mm (0.228 in) 0.75 ± 1.5 mm (0.03 ± 0.059 in) 1.4 ± 0.8 mm (0.055 ± 0.031 in)

B–B 5.8mm (0.228 in) 0.75 ± 1.5 mm (0.03 ± 0.059 in) 1.4 ± 0.8 mm (0.055 ± 0.031 in)

C–C 5.8mm (0.228 in) 0.75 ± 1.5 mm (0.03 ± 0.059 in) 1.4 ± 0.8 mm (0.055 ± 0.031 in)

PIIB4749J

Revision: May 2010 2011 Versa

Page 3553 of 3787

RF-30

< ON-VEHICLE REPAIR >

SUNROOF

1. Remove headlining. Refer to EI-50, "Component".

2. Visually check drain hoses for: • Proper connection at sunroof unit assembly.

• Damage, pinch, cracks, deterioration.

• Proper fastening and routing on body panels.

3. Pour water through drain hoses to determine watertight performance.

If a damaged or leaking portion in any drain hose is found, replace entire drain hose as an assembly.

1. Drain hose2. Fender 3. Seal

4. Fascia 5. Drain hose rear LH6. Drain hose rear RH

7. Drain hose front LH 8. Drain hose front RH 9. Sunroof unit assembly

Vehicle front

Revision: May 2010 2011 Versa

Page 3586 of 3787

SC-8

< SERVICE INFORMATION >

BATTERY

INSTALLATION (All except MR18DE with CVT)

Installation is in the reverse order of removal.

CAUTION:

When connecting, connect the battery positive terminal first.

Reset electronic systems as necessary. Refer to SC-8, "

Required Procedure After Battery Disconnection".

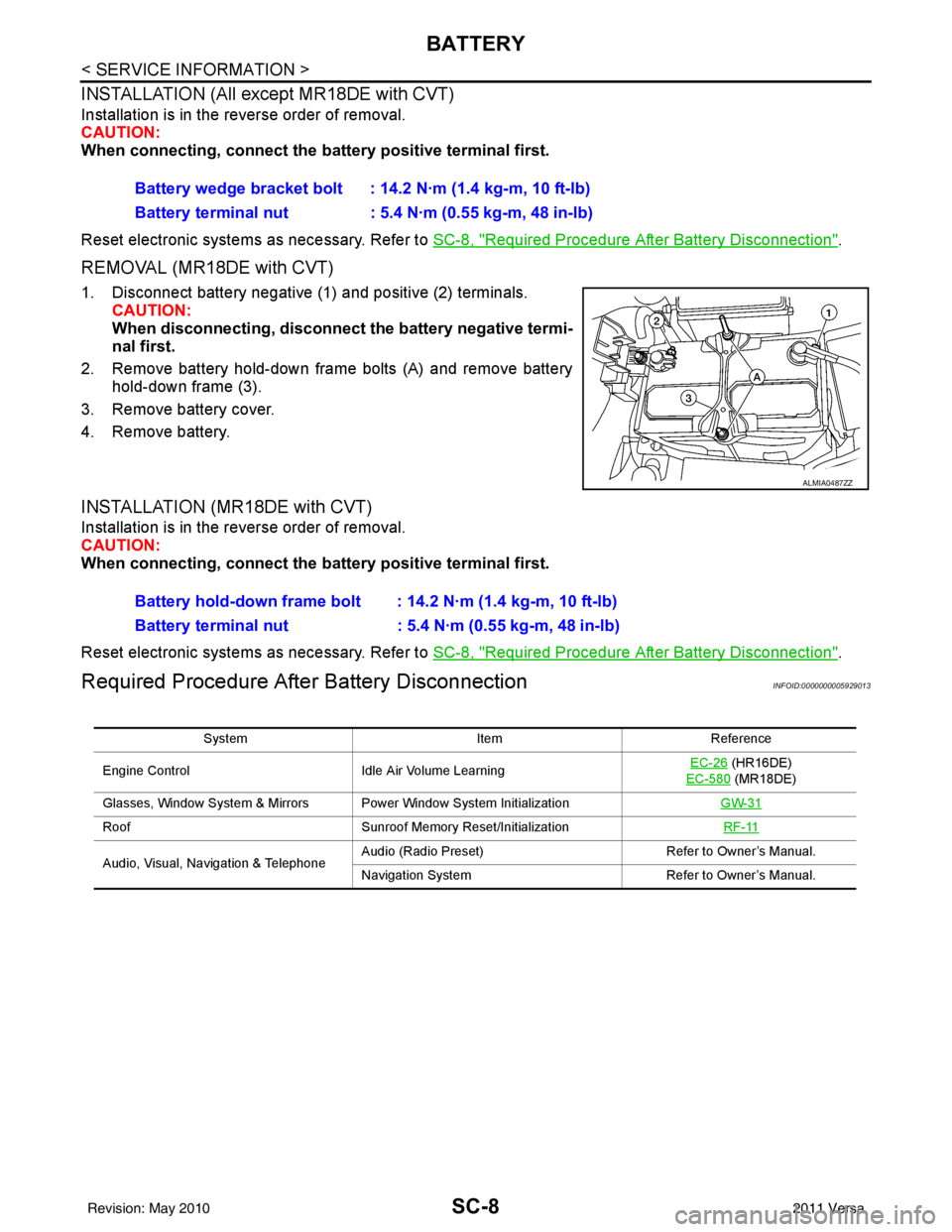

REMOVAL (MR18DE with CVT)

1. Disconnect battery negative (1) and positive (2) terminals.

CAUTION:

When disconnecting, disconnect the battery negative termi-

nal first.

2. Remove battery hold-down frame bolts (A) and remove battery hold-down frame (3).

3. Remove battery cover.

4. Remove battery.

INSTALLATION (MR18DE with CVT)

Installation is in the reverse order of removal.

CAUTION:

When connecting, connect the battery positive terminal first.

Reset electronic systems as necessary. Refer to SC-8, "

Required Procedure After Battery Disconnection".

Required Procedure After Battery DisconnectionINFOID:0000000005929013

Battery wedge bracket bolt : 14.2 N·m (1.4 kg-m, 10 ft-lb)

Battery terminal nut : 5.4 N·m (0.55 kg-m, 48 in-lb)

ALMIA0487ZZ

Battery hold-down frame bolt : 14.2 N·m (1.4 kg-m, 10 ft-lb)

Battery terminal nut : 5.4 N·m (0.55 kg-m, 48 in-lb)

System ItemReference

Engine Control Idle Air Volume Learning EC-26

(HR16DE)

EC-580

(MR18DE)

Glasses, Window System & Mirrors Power Window System Initialization GW-31

RoofSunroof Memory Reset/Initialization RF-11

Audio, Visual, Navigation & TelephoneAudio (Radio Preset)

Refer to Owner’s Manual.

Navigation System Refer to Owner’s Manual.

Revision: May 2010 2011 Versa

Page 3613 of 3787

SE-8

< SERVICE INFORMATION >

SQUEAK AND RATTLE TROUBLE DIAGNOSES

Most of these incidents can be repaired by adjusting, securing or insulating the item(s) or component(s) caus-

ing the noise.

SUNROOF/HEADLINING

Noises in the sunroof/headlining area c an often be traced to one of the following:

1. Sunroof lid, rail, linkage or seals making a rattle or light knocking noise

2. Sun visor shaft shaking in the holder

3. Front or rear windshield touching headliner and squeaking

Again, pressing on the components to stop the noise while duplicating the conditions can isolate most of these

incidents. Repairs usually consist of insulating with felt cloth tape.

OVERHEAD CONSOLE (FRONT AND REAR)

Overhead console noises are often caused by the c onsole panel clips not being engaged correctly. Most of

these incidents are repaired by pushing up on the c onsole at the clip locations until the clips engage.

In addition look for:

1. Loose harness or harness connectors.

2. Front console map/reading lamp lense loose.

3. Loose screws at console attachment points.

SEATS

When isolating seat noise it's important to note the pos ition the seat is in and the load placed on the seat when

the noise is present. These conditions should be duplicated when verifying and isolating the cause of the

noise.

Cause of seat noise include:

1. Headrest rods and holder

2. A squeak between the seat pad cushion and frame

3. The rear seatback lock and bracket

These noises can be isolated by moving or pressing on the suspected components while duplicating the con-

ditions under which the noise occurs. Most of thes e incidents can be repaired by repositioning the component

or applying urethane tape to the contact area.

UNDERHOOD

Some interior noise may be caused by components under the hood or on the engine wall. The noise is then

transmitted into the passenger compartment.

Causes of transmitted underhood noise include:

1. Any component mounted to the engine wall

2. Components that pass through the engine wall

3. Engine wall mounts and connectors

4. Loose radiator mounting pins

5. Hood bumpers out of adjustment

6. Hood striker out of adjustment

These noises can be difficult to isolate since they cannot be reached from the interior of the vehicle. The best

method is to secure, move or insulate one component at a time and test drive the \

vehicle. Also, engine RPM

or load can be changed to isolate the noise. Repairs can usually be made by moving, adjusting, securing, or

insulating the component causing the noise.

Revision: May 2010 2011 Versa