sensor NISSAN LATIO 2011 Service Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2011, Model line: LATIO, Model: NISSAN LATIO 2011Pages: 3787, PDF Size: 78.35 MB

Page 1178 of 3787

![NISSAN LATIO 2011 Service Repair Manual P1726 THROTTLE CONTROL SIGNALCVT-123

< SERVICE INFORMATION > [RE0F08B]

D

E

F

G H

I

J

K L

M A

B

CVT

N

O P

P1726 THROTTLE CONTROL SIGNAL

DescriptionINFOID:0000000005928905

Electric throttle control actu NISSAN LATIO 2011 Service Repair Manual P1726 THROTTLE CONTROL SIGNALCVT-123

< SERVICE INFORMATION > [RE0F08B]

D

E

F

G H

I

J

K L

M A

B

CVT

N

O P

P1726 THROTTLE CONTROL SIGNAL

DescriptionINFOID:0000000005928905

Electric throttle control actu](/img/5/57357/w960_57357-1177.png)

P1726 THROTTLE CONTROL SIGNALCVT-123

< SERVICE INFORMATION > [RE0F08B]

D

E

F

G H

I

J

K L

M A

B

CVT

N

O P

P1726 THROTTLE CONTROL SIGNAL

DescriptionINFOID:0000000005928905

Electric throttle control actuator consists of throttle control motor, accelerator pedal position sensor, throttle

position sensor etc. The actuator sends a signal to the ECM, and ECM sends the signal to TCM with CAN

communication.

On Board Diagnosis LogicINFOID:0000000005928906

• This is not an OBD-II self-diagnostic item.

• Diagnostic trouble code “P1726” with CONS ULT-III is detected when the electronically controlled throttle for

ECM is malfunctioning.

Possible CauseINFOID:0000000005928907

Harness or connectors

(Sensor circuit is open or shorted.)

DTC Confirmation ProcedureINFOID:0000000005928908

NOTE:

If “DTC Confirmation Procedure” has been previously performed, always turn ignition switch OFF and

wait at least 10 seconds before performing the next test.

After the repair, touch “ERASE” on “SELF-DIAG RESULTS” and then perform the following procedure to con-

firm the malfunction is eliminated.

WITH CONSULT-III

1. Turn ignition switch ON. (Do not start engine.)

2. Select “DATA MONITOR” mode for “TRANSMISSION” with CONSULT-III.

3. Start engine and let it idle for 5 second.

4. If DTC is detected, go to CVT-123, "

Diagnosis Procedure".

Diagnosis ProcedureINFOID:0000000005928909

1.CHECK DTC WITH ECM

With CONSULT-III

1. Turn ignition switch ON. (Do not start engine.)

2. Select “SELF-DIAG RESULTS” mode for “ENGINE” with CONSULT-III. Refer to EC-612, "

CONSULT-III

Function (ENGINE)".

OK or NG

OK >> GO TO 2.

NG >> Check the DTC Detected Item. Refer to EC-612, "

CONSULT-III Function (ENGINE)".

• If CAN communication line is detected, go to CVT-56

.

2.CHECK DTC

Perform CVT-123, "

DTC Confirmation Procedure".

OK or NG

OK >> INSPECTION END

NG >> GO TO 3.

3.DETECT MALFUNCTIONING ITEM

Check the following:

• The TCM pin terminals for damage or loose connection with harness connector.

OK or NG

OK >> Replace TCM. Refer to CVT-159, "Removal and Installation".

NG >> Repair or replace damaged parts.

Revision: May 2010 2011 Versa

Page 1183 of 3787

![NISSAN LATIO 2011 Service Repair Manual CVT-128

< SERVICE INFORMATION >[RE0F08B]

P1745 LINE PRESSURE CONTROL

P1745 LINE PRESSURE CONTROL

DescriptionINFOID:0000000005928918

The line pressure solenoid valve regulates the oil pump discharge pr NISSAN LATIO 2011 Service Repair Manual CVT-128

< SERVICE INFORMATION >[RE0F08B]

P1745 LINE PRESSURE CONTROL

P1745 LINE PRESSURE CONTROL

DescriptionINFOID:0000000005928918

The line pressure solenoid valve regulates the oil pump discharge pr](/img/5/57357/w960_57357-1182.png)

CVT-128

< SERVICE INFORMATION >[RE0F08B]

P1745 LINE PRESSURE CONTROL

P1745 LINE PRESSURE CONTROL

DescriptionINFOID:0000000005928918

The line pressure solenoid valve regulates the oil pump discharge pressure to suit the driving condition in

response to a signal sent from the TCM.

On Board Diagn

osis LogicINFOID:0000000005928919

• This is not an OBD-II self-diagnostic item.

• Diagnostic trouble code “P1745” with CONSULT-III is detected when TCM detects the unexpected line pres-

sure.

Possible CauseINFOID:0000000005928920

TCM

DTC Confirmation ProcedureINFOID:0000000005928921

NOTE:

If “DTC Confirmation Procedure” has been previously performed, alw ays turn ignition switch OFF and

wait at least 10 seconds before performing the next test.

After the repair, touch “ERASE” on “SELF-DIAG RESULTS” and then perform the following procedure to con-

firm the malfunction is eliminated.

WITH CONSULT-III

1. Turn ignition switch ON and select “DATA MONI TOR” mode for “TRANSMISSION” with CONSULT-III.

2. Make sure that output voltage of CVT fluid temperature sensor is within the range below.

ATF TEMP SEN: 1.0 - 2.0 V

If out of range, drive the vehicle to decrease the voltage (warm up the fluid) or stop engine to

increase the voltage (cool down the fluid)

3. If DTC is detected, go to CVT-128, "

Diagnosis Procedure" .

Diagnosis ProcedureINFOID:0000000005928922

1.CHECK DTC

1. Turn ignition switch ON. (Do not start engine.)

2. Select “SELF-DIAG RESULTS” mode fo r “TRANSMISSION” with CONSULT-III.

3. Erase self-diagnostic results. Refer to CVT-27, "

OBD-II Diagnostic Trouble Code (DTC)".

4. Turn ignition switch OFF, and wait for 10 seconds or more.

5. Start engine.

6. Confirm self-diagnostic results again. Refer to CVT-48, "

CONSULT-III Function (TRANSMISSION)" .

Is the

“P1745” displayed?

YES >> Replace TCM. Refer to CVT-159, "Removal and Installation" .

NO >> INSPECTION END

Revision: May 2010 2011 Versa

Page 1188 of 3787

![NISSAN LATIO 2011 Service Repair Manual P1778 STEP MOTORCVT-133

< SERVICE INFORMATION > [RE0F08B]

D

E

F

G H

I

J

K L

M A

B

CVT

N

O P

P1778 STEP MOTOR

DescriptionINFOID:0000000005928931

• The step motor is included in the control valve asse NISSAN LATIO 2011 Service Repair Manual P1778 STEP MOTORCVT-133

< SERVICE INFORMATION > [RE0F08B]

D

E

F

G H

I

J

K L

M A

B

CVT

N

O P

P1778 STEP MOTOR

DescriptionINFOID:0000000005928931

• The step motor is included in the control valve asse](/img/5/57357/w960_57357-1187.png)

P1778 STEP MOTORCVT-133

< SERVICE INFORMATION > [RE0F08B]

D

E

F

G H

I

J

K L

M A

B

CVT

N

O P

P1778 STEP MOTOR

DescriptionINFOID:0000000005928931

• The step motor is included in the control valve assembly.

• The step motor's 4 aspects of ON/OFF change according to the signal from TCM. As a result, the flow of line pressure to primary pulley is changed and pulley ratio is controlled.

• This diagnosis item is detected when electrical system is OK, but mechanical system is NG.

• This diagnosis item is detected when the state of the changing the speed mechanism in unit does not oper- ate normally.

CONSULT-III Reference Val ue in Data Monitor ModeINFOID:0000000005928932

Remarks: Specification data are reference values.

On Board Diagnosis LogicINFOID:0000000005928933

• This is an OBD-II self-diagnostic item.

• Diagnostic trouble code “P1778” with CONSULT-III is detected under the following conditions.

- When not changing the pulley ratio according to the instruction of TCM.

Possible CauseINFOID:0000000005928934

Step motor

DTC Confirmation ProcedureINFOID:0000000005928935

CAUTION:

• Always drive vehicle at a safe speed.

• Before starting “DTC Confirmation Procedure”, confirm “Hi” or “Mid” or “Low” fixation by “PRI

SPEED” and “VEHICLE SPEED” on “DATA MONITOR MODE”.

• If hi-geared fixation occurred, go to CVT-134, "

Diagnosis Procedure".

NOTE:

If “DTC Confirmation Procedure” has been previously performed, always turn ignition switch OFF and

wait at least 10 seconds before performing the next test.

After the repair, touch “ERASE” on “SELF-DIAG RESULTS” and then perform the following procedure to con-

firm the malfunction is eliminated.

WITH CONSULT-III

1. Turn ignition switch ON and select “DATA MO NITOR” mode for “TRANSMISSION” with CONSULT-III.

2. Make sure that output voltage of CVT fluid temperature sensor is within the range below.

ATF TEMP SEN: 1.0 - 2.0 V

If out of range, drive the vehicle to decrease the voltage (warm up the fluid) or stop engine to

increase the voltage (c ool down the fluid)

3. Select “DATA MONITOR” mode for “TRANSMISSION” with CONSULT-III.

4. Start engine and maintain the following conditions for at least 30 consecutive seconds. TEST START FROM 0 km/h (0 MPH)

CONSTANT ACCELERATION: Keep 30 sec or more

VEHICLE SPEED: 10 km/h (6 MPH) or more

ACC PEDAL OPEN: More than 1.0/8

RANGE: “D” position

ENG SPEED: 450 rpm or more

5. If DTC is detected, go to CVT-134, "

Diagnosis Procedure".

WITH GST

Follow the procedure “WITH CONSULT-III”.

Item name Condition Display value (Approx.)

STM STEP During driving(−

20) - (+180) step

GEAR RATIO 2.56 - 0.43

Revision: May 2010 2011 Versa

Page 1224 of 3787

![NISSAN LATIO 2011 Service Repair Manual PRIMARY SPEED SENSORCVT-169

< SERVICE INFORMATION > [RE0F08B]

D

E

F

G H

I

J

K L

M A

B

CVT

N

O P

PRIMARY SPEED SENSOR

Exploded ViewINFOID:0000000005928968

Removal and InstallationINFOID:000000000592896 NISSAN LATIO 2011 Service Repair Manual PRIMARY SPEED SENSORCVT-169

< SERVICE INFORMATION > [RE0F08B]

D

E

F

G H

I

J

K L

M A

B

CVT

N

O P

PRIMARY SPEED SENSOR

Exploded ViewINFOID:0000000005928968

Removal and InstallationINFOID:000000000592896](/img/5/57357/w960_57357-1223.png)

PRIMARY SPEED SENSORCVT-169

< SERVICE INFORMATION > [RE0F08B]

D

E

F

G H

I

J

K L

M A

B

CVT

N

O P

PRIMARY SPEED SENSOR

Exploded ViewINFOID:0000000005928968

Removal and InstallationINFOID:0000000005928969

REMOVAL

1. Disconnect the battery cabl e from the negative terminal.

2. Remove air duct (inlet) and air cleaner case. Refer to EM-135, "

Component".

3. Disconnect primary speed sensor connector.

4. Remove primary speed sensor.

5. Remove O-ring from primary speed sensor.

INSTALLATION

Note the following, and install in the reverse order of removal.

CAUTION:

• Never reuse O-ring.

• Apply CVT fluid to O-ring.

InspectionINFOID:0000000005928970

INSPECTION AFTER INSTALLATION

Check for CVT fluid leakage and check CVT fluid level. Refer to CVT-14, "Checking CVT Fluid".

1. Primary speed sensor2. O-ring3. Transaxle assembly

: Apply CVT Fluid NS-2.

JSDIA0750GB

Revision: May 2010 2011 Versa

Page 1225 of 3787

![NISSAN LATIO 2011 Service Repair Manual CVT-170

< SERVICE INFORMATION >[RE0F08B]

SECONDARY SPEED SENSOR

SECONDARY SPEED SENSOR

Exploded ViewINFOID:0000000005928971

Removal and InstallationINFOID:0000000005928972

REMOVAL

1. Disconnect the ba NISSAN LATIO 2011 Service Repair Manual CVT-170

< SERVICE INFORMATION >[RE0F08B]

SECONDARY SPEED SENSOR

SECONDARY SPEED SENSOR

Exploded ViewINFOID:0000000005928971

Removal and InstallationINFOID:0000000005928972

REMOVAL

1. Disconnect the ba](/img/5/57357/w960_57357-1224.png)

CVT-170

< SERVICE INFORMATION >[RE0F08B]

SECONDARY SPEED SENSOR

SECONDARY SPEED SENSOR

Exploded ViewINFOID:0000000005928971

Removal and InstallationINFOID:0000000005928972

REMOVAL

1. Disconnect the battery cable from the negative terminal.

2. Remove air duct (inlet) and air cleaner case. Refer to

EM-135, "

Component".

3. Disconnect secondary speed sensor connector.

4. Remove secondary speed sensor.

5. Remove O-ring from secondary speed sensor.

INSTALLATION

Note the following, and install in the reverse order of removal.

CAUTION:

• Never reuse O-ring.

• Apply CVT fluid to O-ring.

InspectionINFOID:0000000005928973

INSPECTION AFTER INSTALLATION

Check for CVT fluid leakage and check CVT fluid level. Refer to CVT-14, "Checking CVT Fluid".

1. Secondary speed sensor2. O-ring3. Transaxle assembly

: Apply CVT Fluid NS-2.

JSDIA0751GB

Revision: May 2010 2011 Versa

Page 1236 of 3787

![NISSAN LATIO 2011 Service Repair Manual TRANSAXLE ASSEMBLYCVT-181

< SERVICE INFORMATION > [RE0F08B]

D

E

F

G H

I

J

K L

M A

B

CVT

N

O P

2. Disconnect the primary speed sensor (A) and the secondary

speed sensor connector (B) and CVT unit conn NISSAN LATIO 2011 Service Repair Manual TRANSAXLE ASSEMBLYCVT-181

< SERVICE INFORMATION > [RE0F08B]

D

E

F

G H

I

J

K L

M A

B

CVT

N

O P

2. Disconnect the primary speed sensor (A) and the secondary

speed sensor connector (B) and CVT unit conn](/img/5/57357/w960_57357-1235.png)

TRANSAXLE ASSEMBLYCVT-181

< SERVICE INFORMATION > [RE0F08B]

D

E

F

G H

I

J

K L

M A

B

CVT

N

O P

2. Disconnect the primary speed sensor (A) and the secondary

speed sensor connector (B) and CVT unit connector (C). Refer

to CVT-9, "

Removal and Installation Procedure for CVT Unit

Connector".

3. Remove the harness from the transaxle.

4. Remove the four drive plate to torque converter nuts. NOTE:

Rotate the crankshaft clockwise as viewed from front of engine

for access to drive plate to torque converter nuts.

5. Put matching marks on the drive plate and torque converter alignment stud. CAUTION:

For matching marks, use paint. Never dama ge the drive plate or torque converter.

6. Remove the transaxle to engine and engine to transaxle bolts.

7. Separate the transaxle from the engine.

8. If necessary, remove the following from the transaxle: • CVT fluid charging pipe

• Engine mounting bracket (LH)

• Fluid cooler tubes

• Air breather hose

• Any necessary brackets

INSTALLATION

Installation is in the reverse order of removal.

CAUTION:

• When replacing an engine or transmission you must make sure any dowels are installed correctlyduring re-assembly.

• Improper alignment caused by missing dowels may cause vibration, oil leaks or breakage of drive train components.

• Do not reuse O-rings and copper washers.

• When turning crankshaft, turn it clockwise as viewed from the front of the engine.

• When tightening the nuts for the torque converter while securing the crankshaft pulley bolt, be sure

to confirm the tightening torque of the crankshaft pulley bolt. Refer to EM-159

.

• After converter is installed to drive plate, ro tate crankshaft several turns to check that transaxle

rotates freely without binding.

AWDIA0661GB

WCIA0616E

Revision: May 2010 2011 Versa

Page 1239 of 3787

![NISSAN LATIO 2011 Service Repair Manual CVT-184

< SERVICE INFORMATION >[RE0F08B]

SERVICE DATA AND SPECIFICATIONS (SDS)

Solenoid Valves

INFOID:0000000005928981

CVT Fluid Temperature SensorINFOID:0000000005928982

Primary Speed SensorINFOID:00 NISSAN LATIO 2011 Service Repair Manual CVT-184

< SERVICE INFORMATION >[RE0F08B]

SERVICE DATA AND SPECIFICATIONS (SDS)

Solenoid Valves

INFOID:0000000005928981

CVT Fluid Temperature SensorINFOID:0000000005928982

Primary Speed SensorINFOID:00](/img/5/57357/w960_57357-1238.png)

CVT-184

< SERVICE INFORMATION >[RE0F08B]

SERVICE DATA AND SPECIFICATIONS (SDS)

Solenoid Valves

INFOID:0000000005928981

CVT Fluid Temperature SensorINFOID:0000000005928982

Primary Speed SensorINFOID:0000000005928983

Secondary Speed SensorINFOID:0000000005928984

Removal and InstallationINFOID:0000000005928985

Name Resistance (Approx.) Terminal

secondary pressure solenoid valve 3 - 9 Ω3

Line pressure solenoid valve 2

Torque converter clutch solenoid valve 12

Lock-up select solenoid valve 6 - 19Ω 13

NameCondition CONSULT-III “DATA MONI TOR” (Approx.) Resistance (Approx.)

ATF TEMP SEN 20

°C (68 °F) 2.0 V 6.5 kΩ

80 °C (176 °F) 1.0 V 0.9 kΩ

Name ConditionData (Approx.)

Primary speed sensor When driving [“L” position, 20 km/h (12 MPH)]. 1250 Hz

NameConditionData (Approx.)

Secondary speed sensor When driving [“D” position, 20 km/h (12 MPH)]. 570 Hz

Distance between end of converter housing and torque converter 14.4 mm (0.57 in)

Revision: May 2010 2011 Versa

Page 1240 of 3787

DI-1

ELECTRICAL

C

DE

F

G H

I

J

L

M

SECTION DI

A

B

DI

N

O P

CONTENTS

DRIVER INFORMATION SYSTEM

SERVICE INFORMATION .. ..........................2

PRECAUTION ................................................ .....2

Precaution for Supplemental Restraint System

(SRS) "AIR BAG" and "SEAT BELT PRE-TEN-

SIONER" ............................................................. ......

2

Precaution Necessary for Steering Wheel Rota-

tion After Battery Disconnect ............................... ......

2

COMBINATION METERS ...................................4

Component Parts and Harness Connector Loca-

tion ...................................................................... ......

4

System Description ...................................................4

Arrangement of Combination Meter ..........................6

Internal Circuit ...........................................................7

Wiring Diagram - METER - .......................................8

Combination Meter Harness Connector Terminal

Layout .....................................................................

10

Terminal and Reference Value for Combination

Meter .......................................................................

10

Self-Diagnosis Mode of Combination Meter ........ ....11

CONSULT-III Function (METER/M&A) ............... ....13

Trouble Diagnosis ...................................................14

Symptom Chart .......................................................15

Power Supply and Ground Circuit Inspection .........15

Vehicle Speed Signal Inspection .............................16

Engine Speed Signal Inspection .............................17

Fuel Level Sensor Signal Inspection .......................17

Fuel Gauge Fluctuates, Indicates Wrong Value, or

Varies ......................................................................

19

Fuel Gauge Does Not Move to Full-position ...........19

DTC [U1000] CAN Communication Circuit ......... ....19

Electrical Component Inspection .............................20

Removal and Installation .........................................20

WARNING LAMPS ......................................... ....21

Schematic ........................................................... ....21

Wiring Diagram - WARN - ................................... ....22

Oil Pressure Warning Lamp Stays Off (Ignition

Switch ON) .......................................................... ....

30

Oil Pressure Warning Lamp Does Not Turn Off

(Oil Pressure Is Normal) ...................................... ....

32

Component Inspection .............................................32

A/T INDICATOR ................................................34

System Description ..................................................34

Wiring Diagram - AT/IND - .......................................35

A/T Indicator Does Not Illuminate ............................36

CVT INDICATOR ...............................................38

System Description ..................................................38

Schematic ................................................................38

Wiring Diagram - CVTIND - .....................................39

CVT Indicator Does Not Illuminate ..........................41

WARNING CHIME .............................................43

Component Parts and Harness Connector Loca-

tion ....................................................................... ....

43

System Description ..................................................43

Wiring Diagram - CHIME - .......................................46

Terminal and Reference Value for BCM ..................47

CONSULT-III Function (B CM) .................................47

Trouble Diagnosis ................................................ ....48

Combination Meter Buzzer Circuit Inspection .........49

Front Door Switch LH Signal Inspection .............. ....50

Key Switch Signal Inspection (Without Intelligent

Key) ..................................................................... ....

51

Key Switch and Ignition Knob Switch Signal In-

spection (With Intelligent Key, When Mechanical

Key Is Used) ........................................................ ....

52

Lighting Switch Signal Inspection ............................54

Parking Brake Switch Signal Inspection ..................54

Electrical Component Inspection .............................55

Revision: May 2010 2011 Versa

Page 1241 of 3787

DI-2

< SERVICE INFORMATION >

PRECAUTION

SERVICE INFORMATION

PRECAUTION

Precaution for Supplemental Restraint System (SRS) "AIR BAG" and "SEAT BELT

PRE-TENSIONER"

INFOID:0000000006412029

The Supplemental Restraint System such as “A IR BAG” and “SEAT BELT PRE-TENSIONER”, used along

with a front seat belt, helps to reduce the risk or severity of injury to the driver and front passenger for certain

types of collision. This system includes seat belt switch inputs and dual stage front air bag modules. The SRS

system uses the seat belt switches to determine the front air bag deployment, and may only deploy one front

air bag, depending on the severity of a collision and w hether the front occupants are belted or unbelted.

Information necessary to service the system safely is included in the SRS and SB section of this Service Man-

ual.

WARNING:

• To avoid rendering the SRS inopera tive, which could increase the risk of personal injury or death in

the event of a collision which would result in air bag inflation, all maintenance must be performed by

an authorized NISSAN/INFINITI dealer.

• Improper maintenance, including in correct removal and installation of the SRS, can lead to personal

injury caused by unintent ional activation of the system. For re moval of Spiral Cable and Air Bag

Module, see the SRS section.

• Do not use electrical test equipmen t on any circuit related to the SRS unless instructed to in this

Service Manual. SRS wiring harn esses can be identified by yellow and/or orange harnesses or har-

ness connectors.

PRECAUTIONS WHEN USING POWER TOOLS (AIR OR ELECTRIC) AND HAMMERS

WARNING:

• When working near the Airbag Diagnosis Sensor Unit or other Airbag System sensors with the Igni-

tion ON or engine running, DO NOT use air or electri c power tools or strike near the sensor(s) with a

hammer. Heavy vibration could activate the sensor( s) and deploy the air bag(s), possibly causing

serious injury.

• When using air or electric power tools or hammers , always switch the Ignition OFF, disconnect the

battery, and wait at least 3 minu tes before performing any service.

Precaution Necessary for Steering W heel Rotation After Battery Disconnect

INFOID:0000000006412030

NOTE:

• This Procedure is applied only to models with Intelligent Key system and NATS (NISSAN ANTI-THEFT SYS-

TEM).

• Remove and install all control units after disconnecting both battery cables with the ignition knob in the

″LOCK ″ position.

• Always use CONSULT-III to perform self-diagnosis as a part of each function inspection after finishing work.

If DTC is detected, perform trouble diagnosis according to self-diagnostic results.

For models equipped with the Intelligent Key system and NATS, an electrically controlled steering lock mech-

anism is adopted on the key cylinder.

For this reason, if the battery is disconnected or if the battery is discharged, the steering wheel will lock and

steering wheel rotation will become impossible.

If steering wheel rotation is required when battery pow er is interrupted, follow the procedure below before

starting the repair operation.

OPERATION PROCEDURE

1. Connect both battery cables. NOTE:

Supply power using jumper cables if battery is discharged.

2. Use the Intelligent Key or mechanical key to turn the ignition switch to the ″ACC ″ position. At this time, the

steering lock will be released.

3. Disconnect both battery cables. The steering lock will remain released and the steering wheel can be rotated.

4. Perform the necessary repair operation.

Revision: May 2010 2011 Versa

Page 1243 of 3787

DI-4

< SERVICE INFORMATION >

COMBINATION METERS

COMBINATION METERS

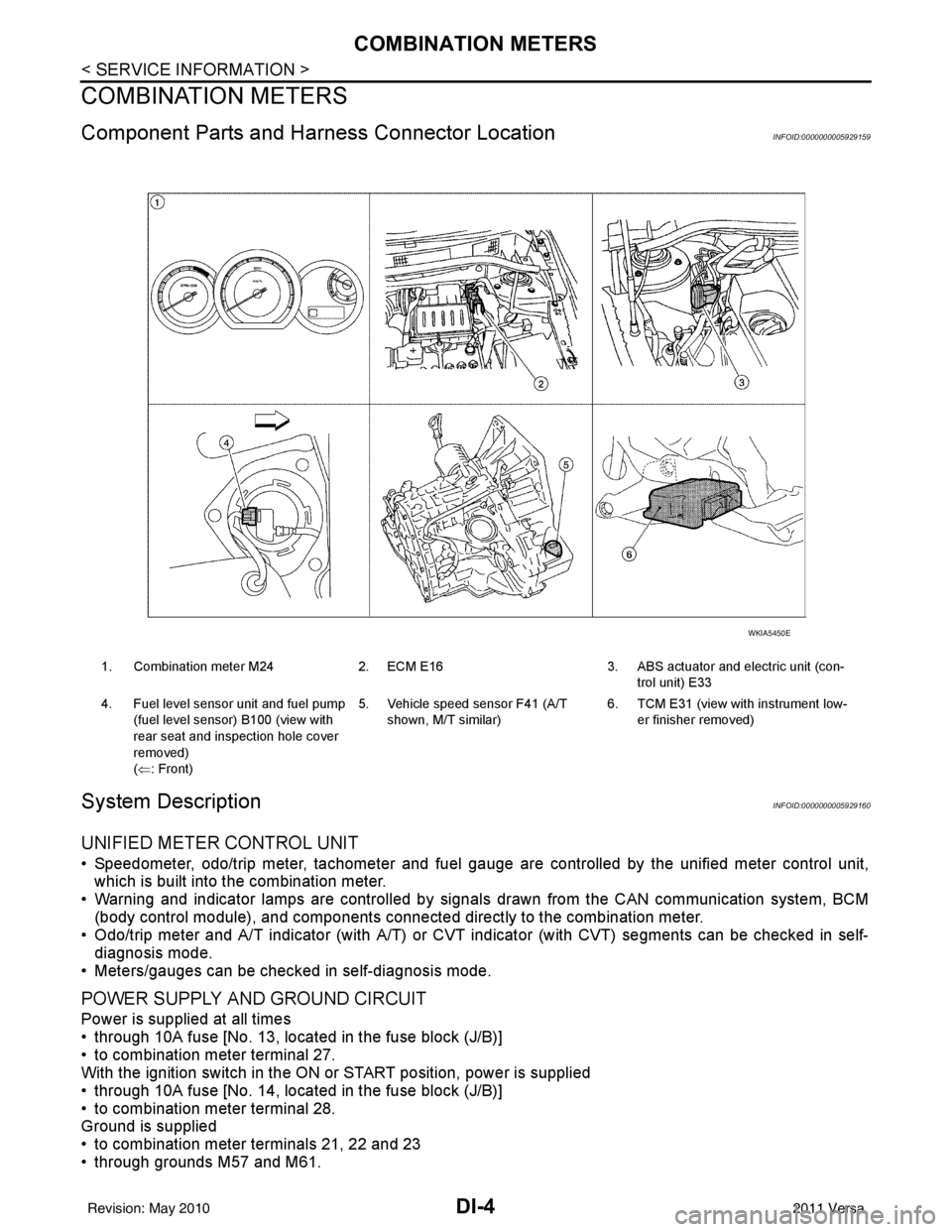

Component Parts and Harness Connector LocationINFOID:0000000005929159

System DescriptionINFOID:0000000005929160

UNIFIED METER CONTROL UNIT

• Speedometer, odo/trip meter, tachometer and fuel gauge are controlled by the unified meter control unit,

which is built into the combination meter.

• Warning and indicator lamps are controlled by signals drawn from the CAN communication system, BCM

(body control module), and components connected directly to the combination meter.

• Odo/trip meter and A/T indicator (with A/T) or CVT i ndicator (with CVT) segments can be checked in self-

diagnosis mode.

• Meters/gauges can be checked in self-diagnosis mode.

POWER SUPPLY AND GROUND CIRCUIT

Power is supplied at all times

• through 10A fuse [No. 13, located in the fuse block (J/B)]

• to combination meter terminal 27.

With the ignition switch in the ON or START position, power is supplied

• through 10A fuse [No. 14, located in the fuse block (J/B)]

• to combination meter terminal 28.

Ground is supplied

• to combination meter terminals 21, 22 and 23

• through grounds M57 and M61.

1. Combination meter M24 2. ECM E16 3. ABS actuator and electric unit (con-

trol unit) E33

4. Fuel level sensor unit and fuel pump (fuel level sensor) B100 (view with

rear seat and inspection hole cover

removed)

(⇐: Front) 5. Vehicle speed sensor F41 (A/T

shown, M/T similar) 6. TCM E31 (view with

instrument low-

er finisher removed)

WKIA5450E

Revision: May 2010 2011 Versa