differential NISSAN LATIO 2011 Service Owner's Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2011, Model line: LATIO, Model: NISSAN LATIO 2011Pages: 3787, PDF Size: 78.35 MB

Page 279 of 3787

AT-262

< SERVICE INFORMATION >

DISASSEMBLY

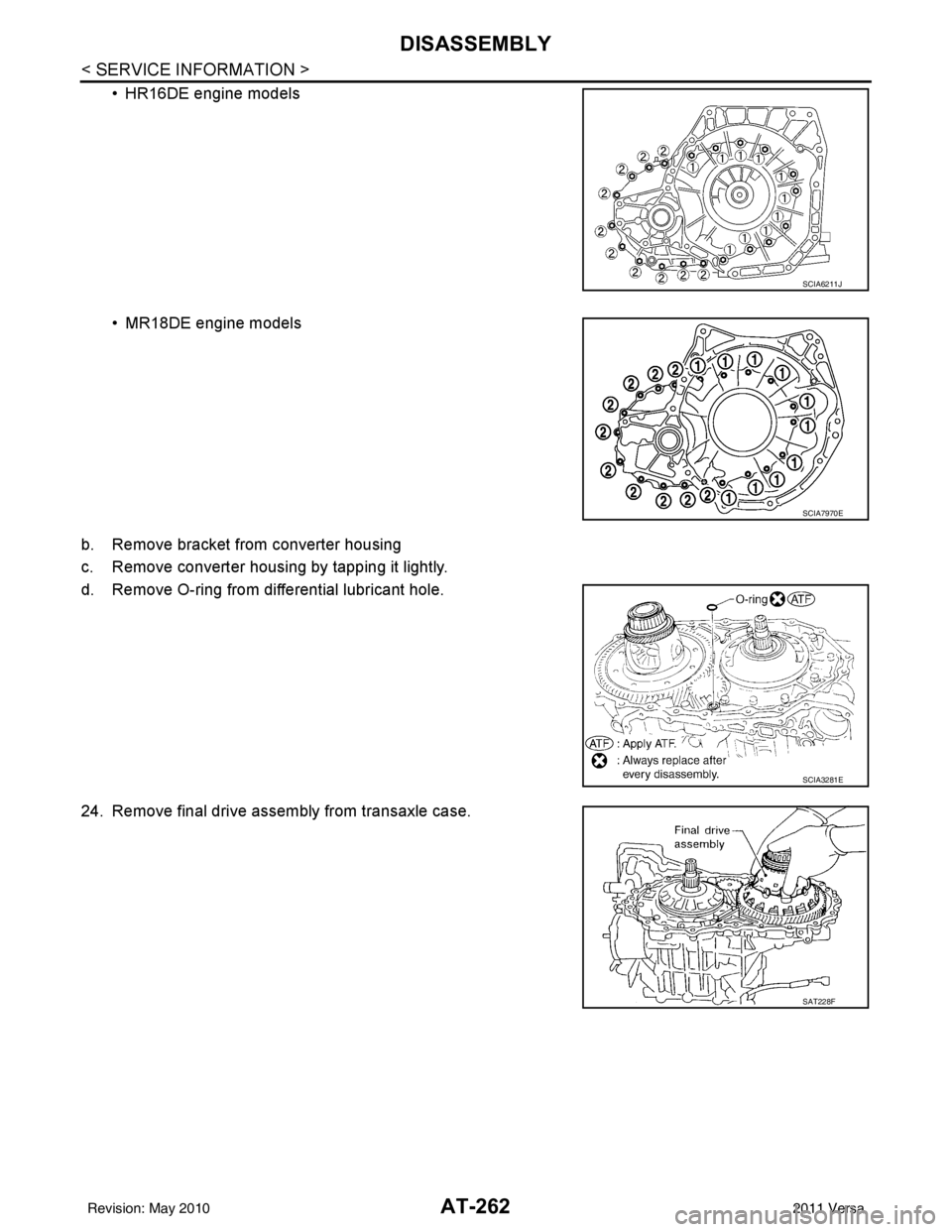

• HR16DE engine models

• MR18DE engine models

b. Remove bracket from converter housing

c. Remove converter housing by tapping it lightly.

d. Remove O-ring from differential lubricant hole.

24. Remove final drive assembly from transaxle case.

SCIA6211J

SCIA7970E

SCIA3281E

SAT228F

Revision: May 2010 2011 Versa

Page 280 of 3787

DISASSEMBLYAT-263

< SERVICE INFORMATION >

DE

F

G H

I

J

K L

M A

B

AT

N

O P

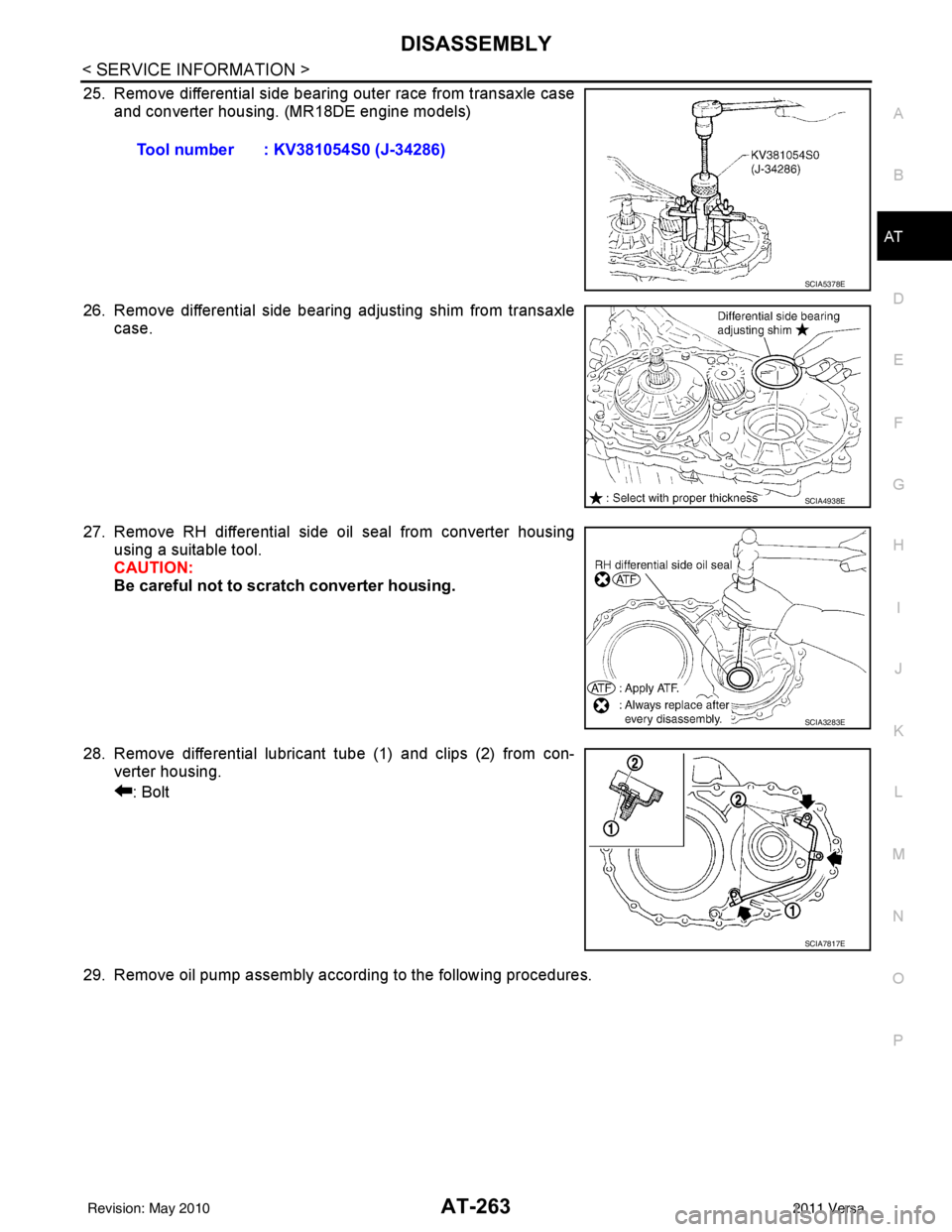

25. Remove differential side bearing outer race from transaxle case and converter housing. (MR18DE engine models)

26. Remove differential side bearing adjusting shim from transaxle case.

27. Remove RH differential side oil seal from converter housing using a suitable tool.

CAUTION:

Be careful not to scratch converter housing.

28. Remove differential lubricant tube (1) and clips (2) from con- verter housing.

: Bolt

29. Remove oil pump assembly according to the following procedures. Tool number : KV381054S0 (J-34286)

SCIA5378E

SCIA4938E

SCIA3283E

SCIA7817E

Revision: May 2010

2011 Versa

Page 291 of 3787

AT-274

< SERVICE INFORMATION >

DISASSEMBLY

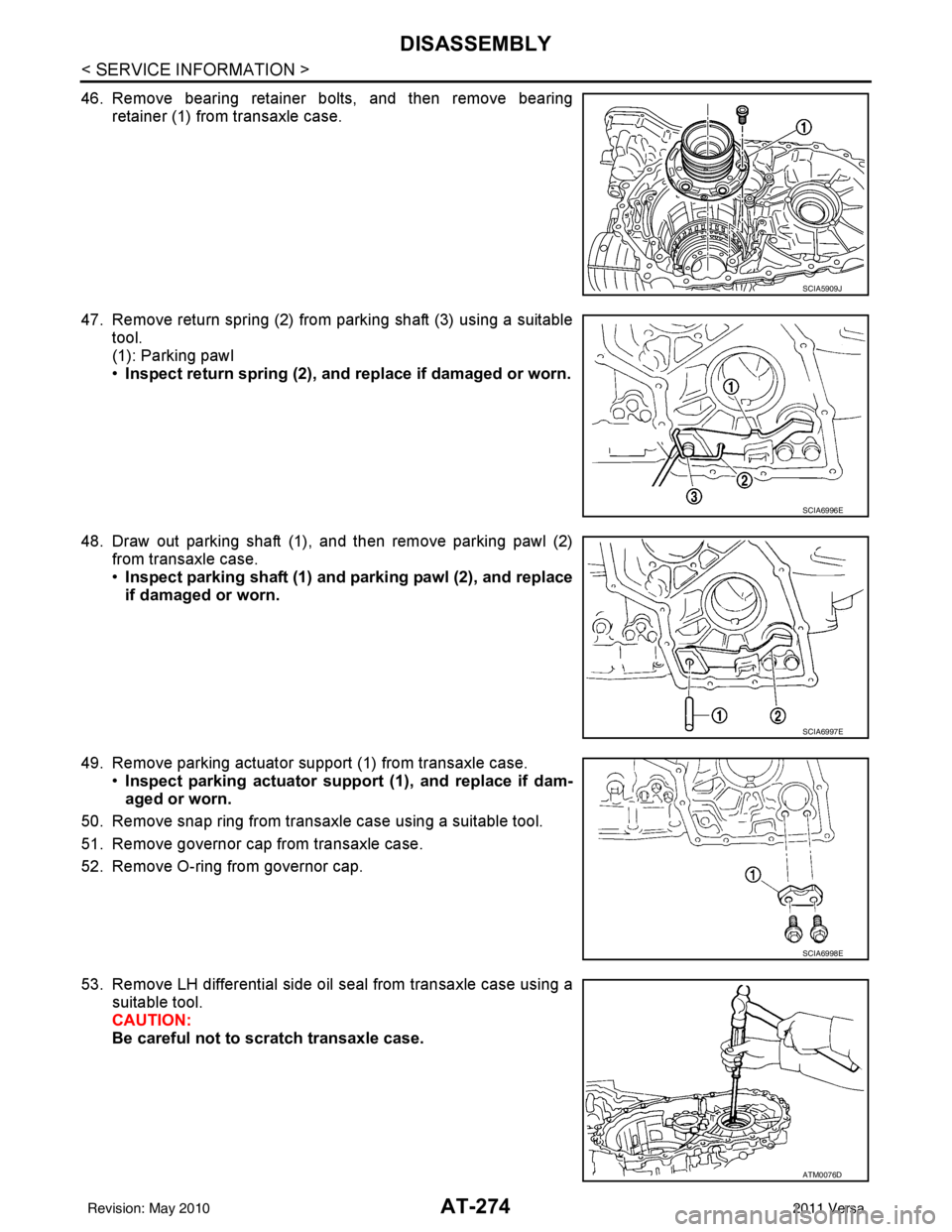

46. Remove bearing retainer bolts, and then remove bearingretainer (1) from transaxle case.

47. Remove return spring (2) from parking shaft (3) using a suitable tool.

(1): Parking pawl

•Inspect return spring (2), and replace if damaged or worn.

48. Draw out parking shaft (1), and then remove parking pawl (2) from transaxle case.

•Inspect parking shaft (1) and parking pawl (2), and replace

if damaged or worn.

49. Remove parking actuator support (1) from transaxle case. •Inspect parking actuator support (1), and replace if dam-

aged or worn.

50. Remove snap ring from transaxle case using a suitable tool.

51. Remove governor cap from transaxle case.

52. Remove O-ring from governor cap.

53. Remove LH differential side oil seal from transaxle case using a suitable tool.

CAUTION:

Be careful not to scratch transaxle case.

SCIA5909J

SCIA6996E

SCIA6997E

SCIA6998E

ATM0076D

Revision: May 2010 2011 Versa

Page 355 of 3787

AT-338

< SERVICE INFORMATION >

REPAIR FOR COMPONENT PARTS

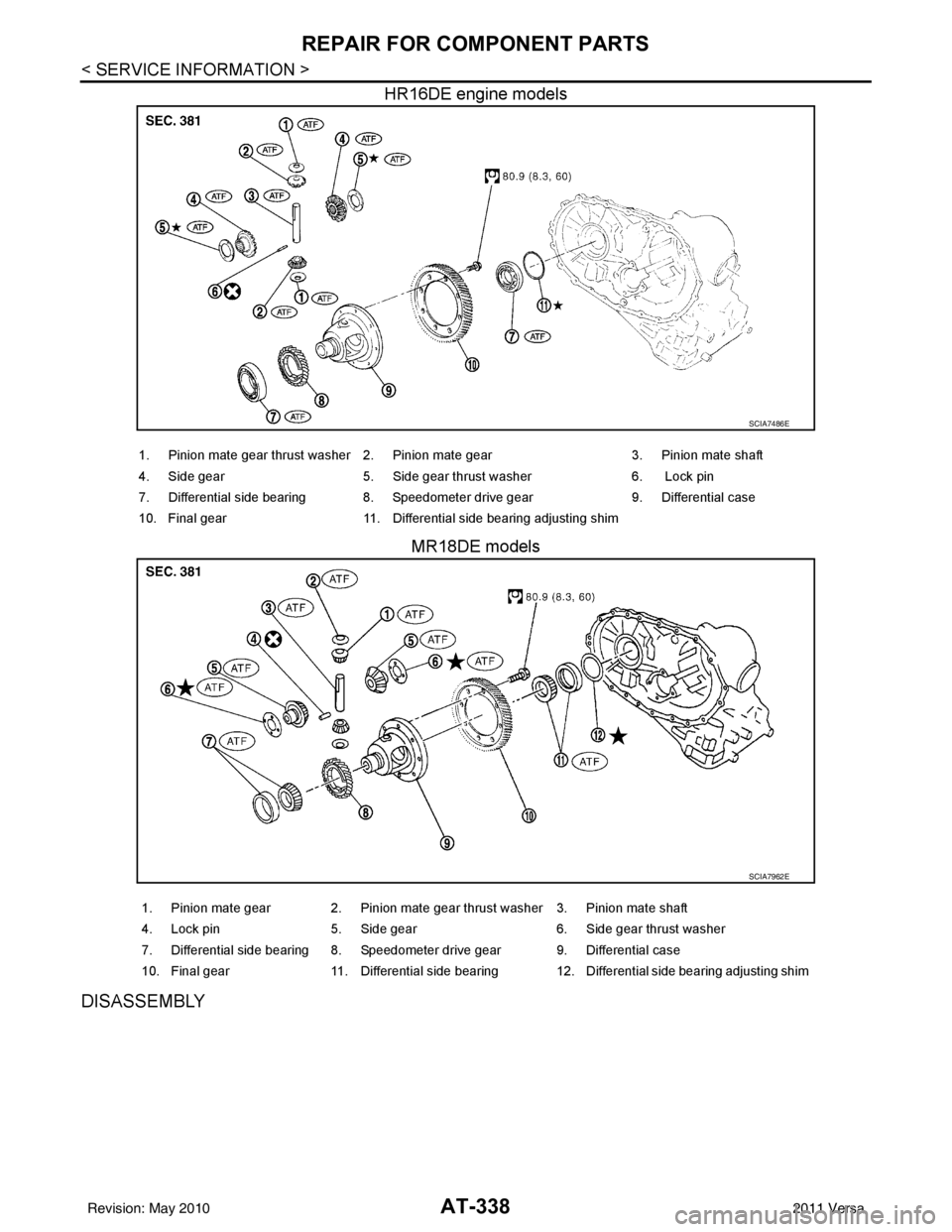

HR16DE engine modelsMR18DE models

DISASSEMBLY

SCIA7486E

1. Pinion mate gear thrust washer 2. Pinion mate gear 3. Pinion mate shaft

4. Side gear 5. Side gear thrust washer 6. Lock pin

7. Differential side bearing 8. Speedometer drive gear 9. Differential case

10. Final gear 11. Differential side bearing adjusting shim

SCIA7962E

1. Pinion mate gear 2. Pinion mate gear thrust washer 3. Pinion mate shaft

4. Lock pin 5. Side gear 6. Side gear thrust washer

7. Differential side bearing 8. Speedometer drive gear 9. Differential case

10. Final gear 11. Differential side bearing 12. Differential side bearing adjusting shim

Revision: May 2010 2011 Versa

Page 356 of 3787

REPAIR FOR COMPONENT PARTSAT-339

< SERVICE INFORMATION >

DE

F

G H

I

J

K L

M A

B

AT

N

O P

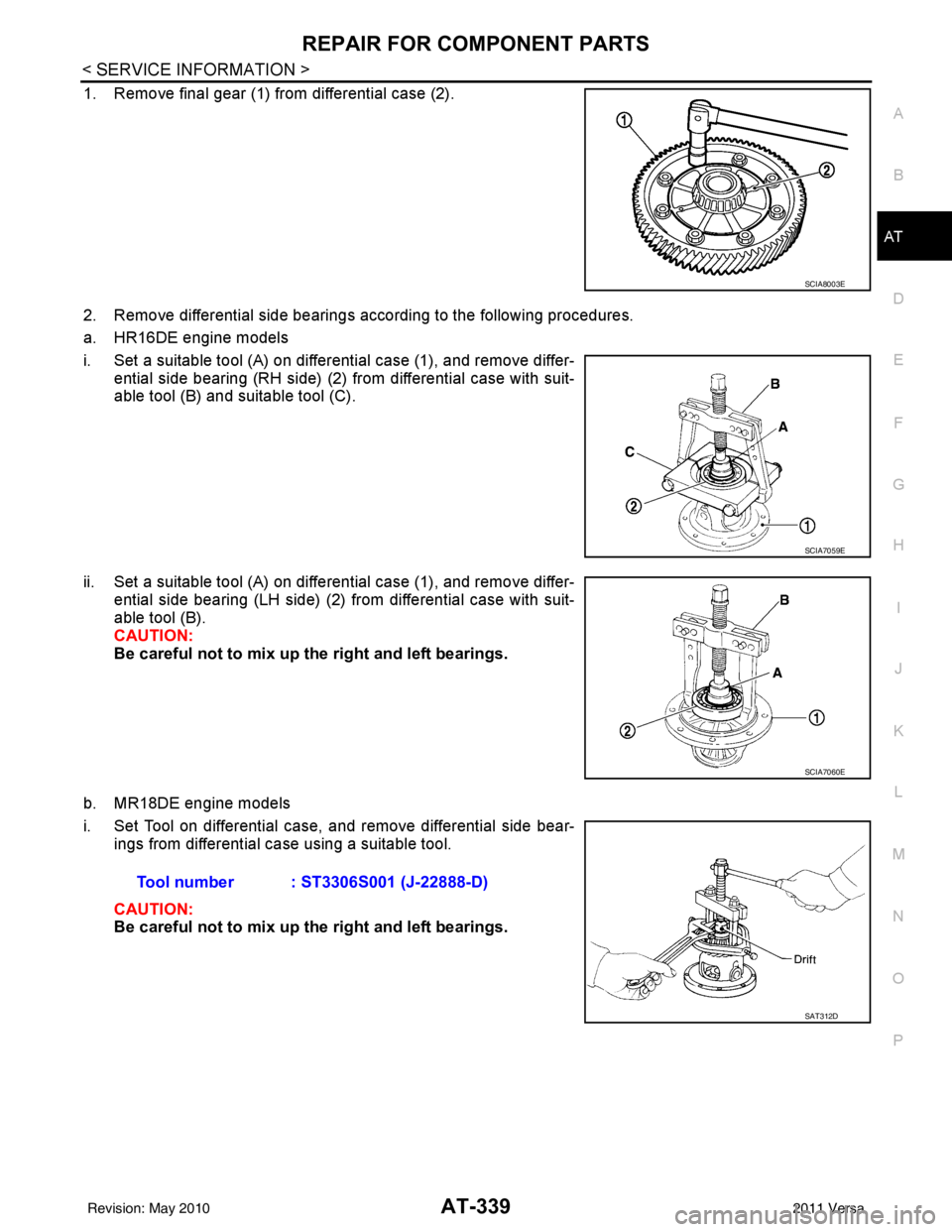

1. Remove final gear (1) from differential case (2).

2. Remove differential side bearings according to the following procedures.

a. HR16DE engine models

i. Set a suitable tool (A) on differential case (1), and remove differ- ential side bearing (RH side) (2) from differential case with suit-

able tool (B) and suitable tool (C).

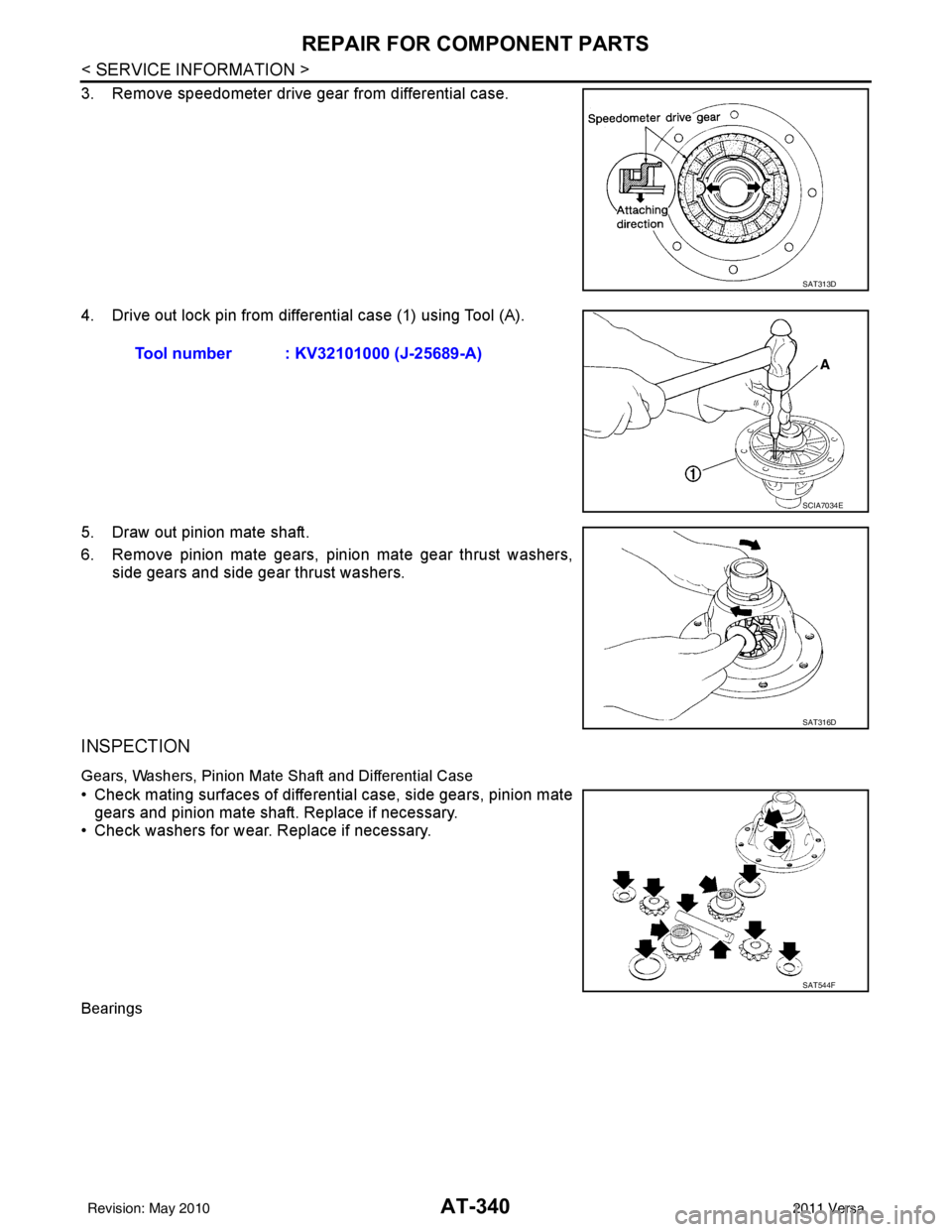

ii. Set a suitable tool (A) on differential case (1), and remove differ- ential side bearing (LH side) (2) from differential case with suit-

able tool (B).

CAUTION:

Be careful not to mix up the right and left bearings.

b. MR18DE engine models

i. Set Tool on differential case, and remove differential side bear- ings from differential case using a suitable tool.

CAUTION:

Be careful not to mix up the right and left bearings.

SCIA8003E

SCIA7059E

SCIA7060E

Tool number : ST3306S001 (J-22888-D)

SAT312D

Revision: May 2010 2011 Versa

Page 357 of 3787

AT-340

< SERVICE INFORMATION >

REPAIR FOR COMPONENT PARTS

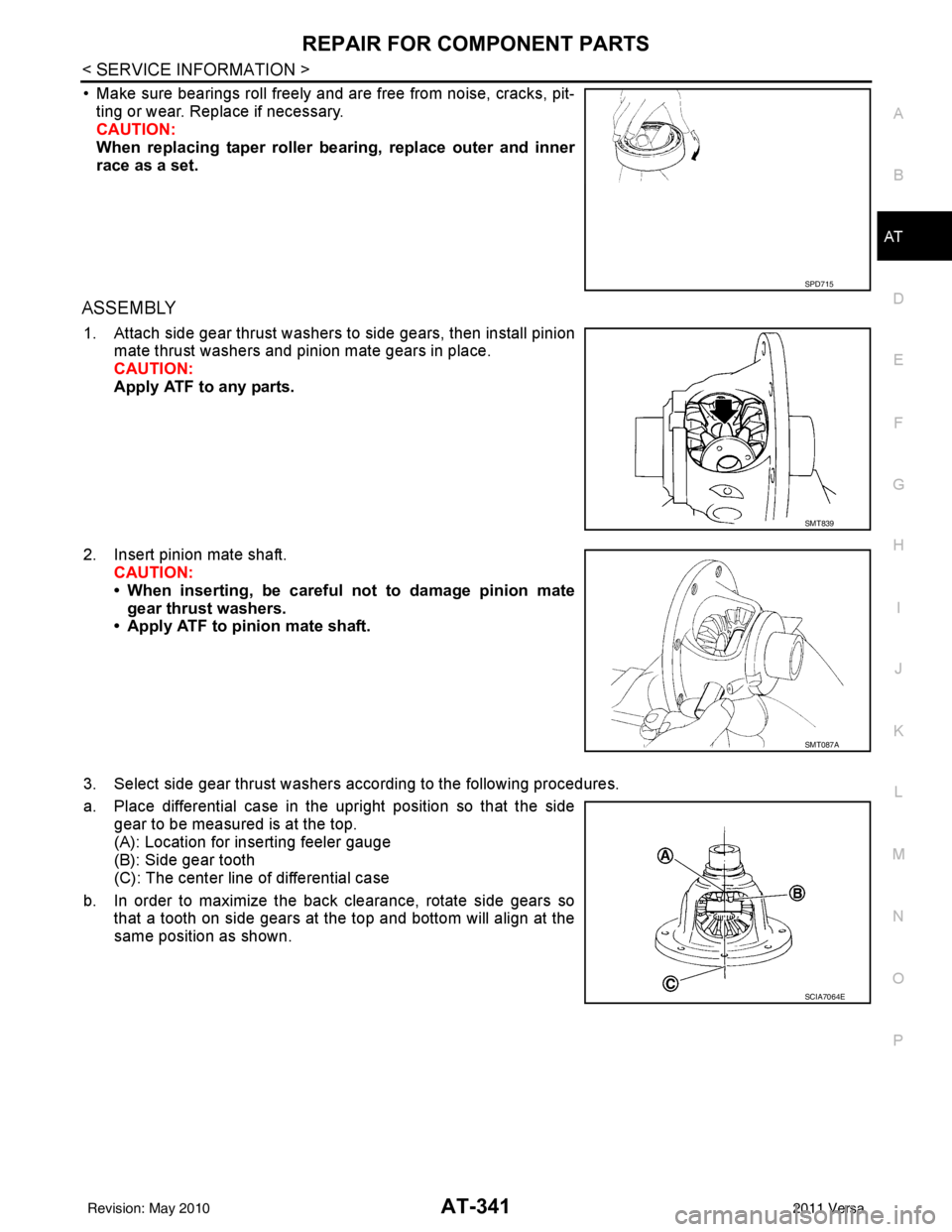

3. Remove speedometer drive gear from differential case.

4. Drive out lock pin from differential case (1) using Tool (A).

5. Draw out pinion mate shaft.

6. Remove pinion mate gears, pinion mate gear thrust washers,side gears and side gear thrust washers.

INSPECTION

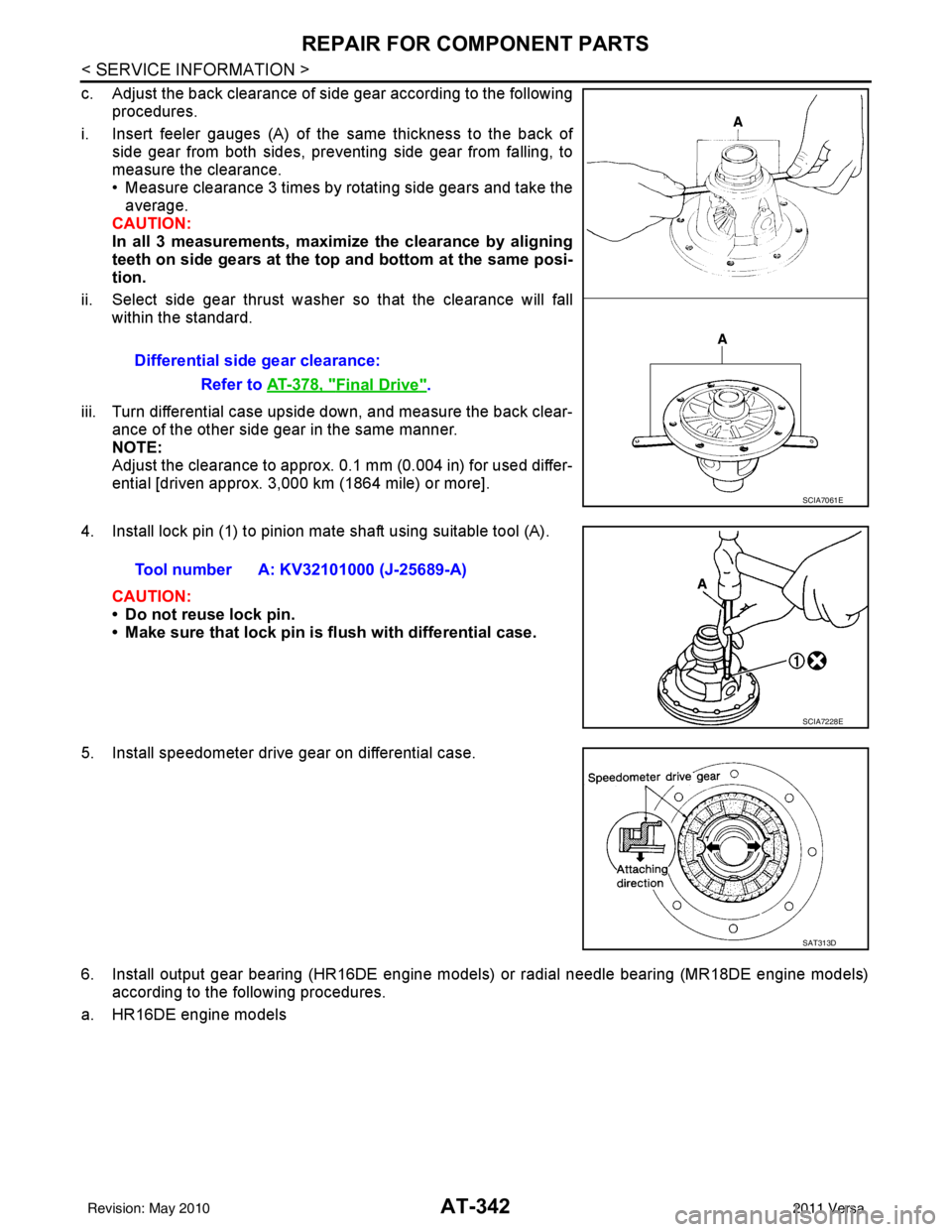

Gears, Washers, Pinion Mate Shaft and Differential Case

• Check mating surfaces of differential case, side gears, pinion mate

gears and pinion mate shaft. Replace if necessary.

• Check washers for wear. Replace if necessary.

Bearings

SAT313D

Tool number : KV32101000 (J-25689-A)

SCIA7034E

SAT316D

SAT544F

Revision: May 2010 2011 Versa

Page 358 of 3787

REPAIR FOR COMPONENT PARTSAT-341

< SERVICE INFORMATION >

DE

F

G H

I

J

K L

M A

B

AT

N

O P

• Make sure bearings roll freely and are free from noise, cracks, pit- ting or wear. Replace if necessary.

CAUTION:

When replacing taper roller bearing, replace outer and inner

race as a set.

ASSEMBLY

1. Attach side gear thrust washers to side gears, then install pinion mate thrust washers and pinion mate gears in place.

CAUTION:

Apply ATF to any parts.

2. Insert pinion mate shaft. CAUTION:

• When inserting, be careful not to damage pinion mate

gear thrust washers.

• Apply ATF to pinion mate shaft.

3. Select side gear thrust washers according to the following procedures.

a. Place differential case in the upright position so that the side gear to be measured is at the top.

(A): Location for inserting feeler gauge

(B): Side gear tooth

(C): The center line of differential case

b. In order to maximize the back clearance, rotate side gears so that a tooth on side gears at the top and bottom will align at the

same position as shown.

SPD715

SMT839

SMT087A

SCIA7064E

Revision: May 2010 2011 Versa

Page 359 of 3787

AT-342

< SERVICE INFORMATION >

REPAIR FOR COMPONENT PARTS

c. Adjust the back clearance of side gear according to the followingprocedures.

i. Insert feeler gauges (A) of the same thickness to the back of side gear from both sides, preventing side gear from falling, to

measure the clearance.

• Measure clearance 3 times by rotating side gears and take theaverage.

CAUTION:

In all 3 measurements, maximi ze the clearance by aligning

teeth on side gears at the top and bottom at the same posi-

tion.

ii. Select side gear thrust washer so that the clearance will fall within the standard.

iii. Turn differential case upside down, and measure the back clear- ance of the other side gear in the same manner.

NOTE:

Adjust the clearance to approx. 0.1 mm (0.004 in) for used differ-

ential [driven approx. 3,000 km (1864 mile) or more].

4. Install lock pin (1) to pinion mate shaft using suitable tool (A).

CAUTION:

• Do not reuse lock pin.

• Make sure that lock pin is flush with differential case.

5. Install speedometer drive gear on differential case.

6. Install output gear bearing (HR16DE engine models) or radial needle bearing (MR18DE engine models) according to the following procedures.

a. HR16DE engine models Differential side gear clearance:

Refer to AT-378, "

Final Drive".

SCIA7061E

Tool number A: KV32101000 (J-25689-A)

SCIA7228E

SAT313D

Revision: May 2010 2011 Versa

Page 360 of 3787

REPAIR FOR COMPONENT PARTSAT-343

< SERVICE INFORMATION >

DE

F

G H

I

J

K L

M A

B

AT

N

O P

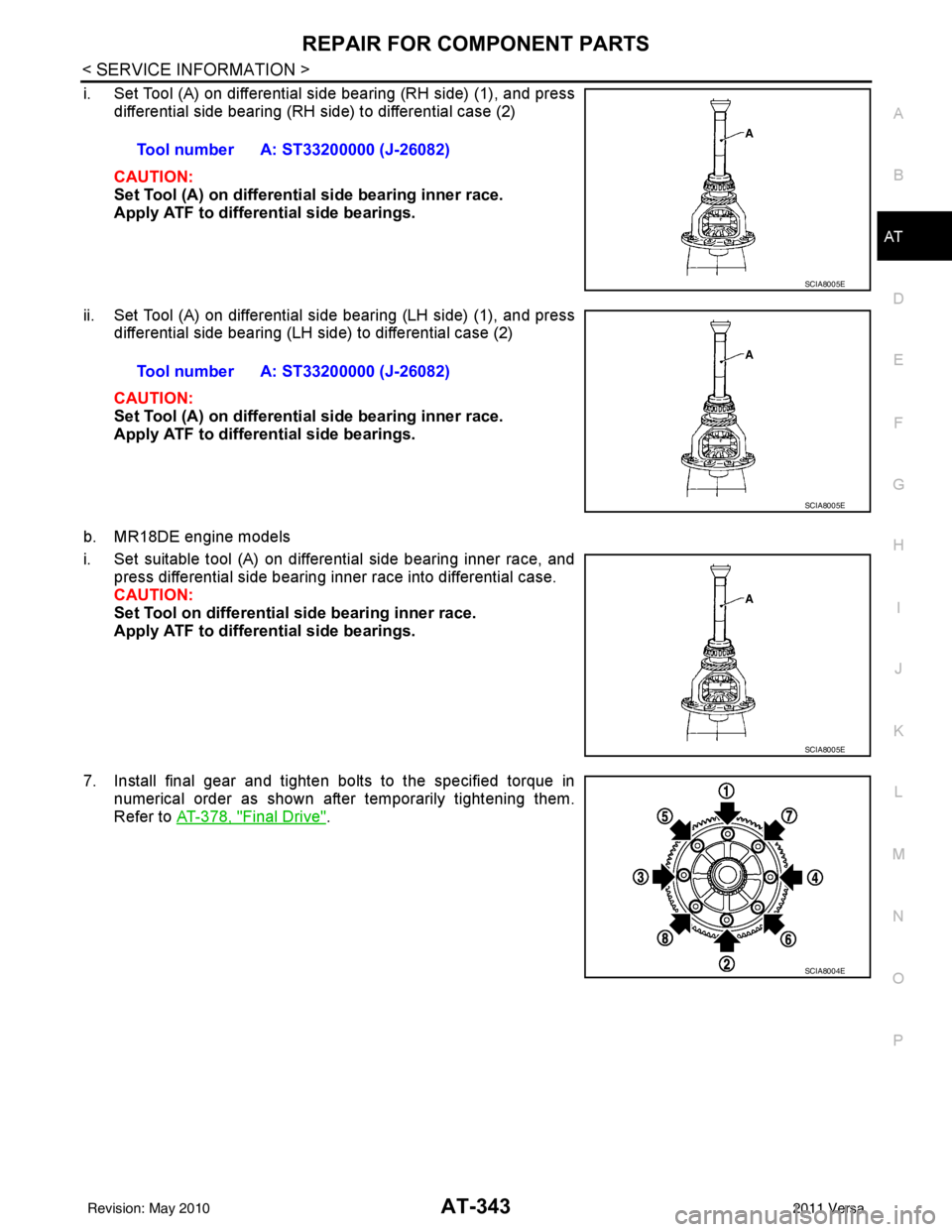

i. Set Tool (A) on differential side bearing (RH side) (1), and press differential side bearing (RH side) to differential case (2)

CAUTION:

Set Tool (A) on differential side bearing inner race.

Apply ATF to differential side bearings.

ii. Set Tool (A) on differential side bearing (LH side) (1), and press differential side bearing (LH side) to differential case (2)

CAUTION:

Set Tool (A) on differential side bearing inner race.

Apply ATF to differential side bearings.

b. MR18DE engine models

i. Set suitable tool (A) on differential side bearing inner race, and press differential side bearing inner race into differential case.

CAUTION:

Set Tool on differential side bearing inner race.

Apply ATF to differential side bearings.

7. Install final gear and tighten bolts to the specified torque in numerical order as shown after temporarily tightening them.

Refer to AT-378, "

Final Drive".

Tool number A: ST33200000 (J-26082)

SCIA8005E

Tool number A: ST33200000 (J-26082)

SCIA8005E

SCIA8005E

SCIA8004E

Revision: May 2010

2011 Versa

Page 361 of 3787

AT-344

< SERVICE INFORMATION >

ASSEMBLY

ASSEMBLY

Assembly (1)INFOID:0000000005928303

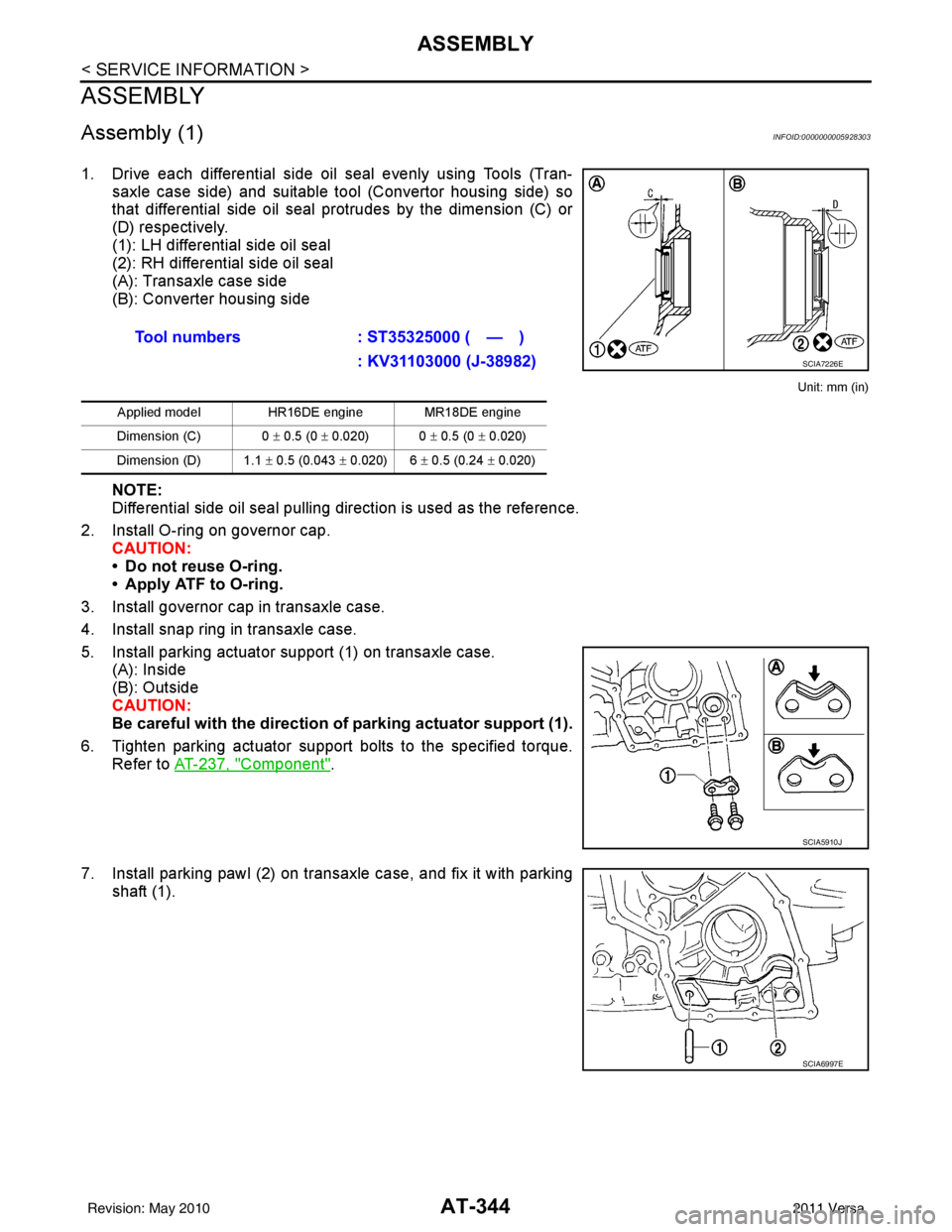

1. Drive each differential side oil seal evenly using Tools (Tran-saxle case side) and suitable tool (Convertor housing side) so

that differential side oil seal protrudes by the dimension (C) or

(D) respectively.

(1): LH differential side oil seal

(2): RH differential side oil seal

(A): Transaxle case side

(B): Converter housing side

Unit: mm (in)

NOTE:

Differential side oil seal pulling direction is used as the reference.

2. Install O-ring on governor cap. CAUTION:

• Do not reuse O-ring.

• Apply ATF to O-ring.

3. Install governor cap in transaxle case.

4. Install snap ring in transaxle case.

5. Install parking actuator support (1) on transaxle case. (A): Inside

(B): Outside

CAUTION:

Be careful with the direction of parking actuator support (1).

6. Tighten parking actuator support bolts to the specified torque. Refer to AT-237, "

Component".

7. Install parking pawl (2) on transaxle case, and fix it with parking shaft (1).Tool numbers

: ST35325000 ( — )

: KV31103000 (J-38982)

Applied model HR16DE engine MR18DE engine

Dimension (C) 0 ± 0.5 (0 ± 0.020) 0 ± 0.5 (0 ± 0.020)

Dimension (D) 1.1 ± 0.5 (0.043 ± 0.020) 6 ± 0.5 (0.24 ± 0.020)

SCIA7226E

SCIA5910J

SCIA6997E

Revision: May 2010 2011 Versa