oil level NISSAN LATIO 2011 Service Owner's Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2011, Model line: LATIO, Model: NISSAN LATIO 2011Pages: 3787, PDF Size: 78.35 MB

Page 1042 of 3787

![NISSAN LATIO 2011 Service Owners Manual CO-42

< SERVICE INFORMATION >[MR18DE]

RADIATOR

• Warm up engine thoroughly to make sure there is no leakage of fuel, exhaust gas, or any oils/fluids including

engine oil and engine coolant.

• Blee NISSAN LATIO 2011 Service Owners Manual CO-42

< SERVICE INFORMATION >[MR18DE]

RADIATOR

• Warm up engine thoroughly to make sure there is no leakage of fuel, exhaust gas, or any oils/fluids including

engine oil and engine coolant.

• Blee](/img/5/57357/w960_57357-1041.png)

CO-42

< SERVICE INFORMATION >[MR18DE]

RADIATOR

• Warm up engine thoroughly to make sure there is no leakage of fuel, exhaust gas, or any oils/fluids including

engine oil and engine coolant.

• Bleed air from passages in lines and hoses, such as in cooling system.

• After cooling down engine, again check oil/fluid levels including engine oil and engine coolant. Refill to spec-

ified level, if necessary.

• Summary of the inspection items:

*Power steering fluid, brake fluid, etc. Item

Before starting engine Engine runningAfter engine stopped

Engine coolant LevelLeakage Level

Engine oil LevelLeakage Level

Transmission/

transaxle fluid A/T and CVT Models

LeakageLevel/Leakage Leakage

M/T Models Level/Leakage LeakageLevel/Leakage

Other oils and fluids* LevelLeakage Level

Fuel LeakageLeakage Leakage

Exhaust gas —Leakage —

Revision: May 2010 2011 Versa

Page 1048 of 3787

![NISSAN LATIO 2011 Service Owners Manual CO-48

< SERVICE INFORMATION >[MR18DE]

THERMOSTAT

INSTALLATION

Installation is in the reverse order of removal.

• Use the following procedure to install the thermostat.

- Install thermostat making su NISSAN LATIO 2011 Service Owners Manual CO-48

< SERVICE INFORMATION >[MR18DE]

THERMOSTAT

INSTALLATION

Installation is in the reverse order of removal.

• Use the following procedure to install the thermostat.

- Install thermostat making su](/img/5/57357/w960_57357-1047.png)

CO-48

< SERVICE INFORMATION >[MR18DE]

THERMOSTAT

INSTALLATION

Installation is in the reverse order of removal.

• Use the following procedure to install the thermostat.

- Install thermostat making sure rubber ring (1) groove fits securely

to thermostat flange (A).

CAUTION:

Replace the rubber ring with a new one.

- Install thermostat (1) into the thermostat housing (2) with jiggle valve (A) facing upwards.

• Use the following procedure to install the thermostat housing.

- Securely insert the rubber ring into the mating groove of thermostat housing and install it. CAUTION:

Replace the rubber ring with a new one.

- Install the thermostat housing to the cylinder block without displacing the gasket from the gasket position.

InspectionINFOID:0000000006413349

INSPECTION AFTER INSTALLATION

• Before starting engine, check oil/fluid levels incl uding engine coolant and engine oil. If less than required

quantity, fill to the specified level. Refer to MA-14, "

Fluids and Lubricants".

• Use procedure below to check for fuel leakage.

• Turn ignition switch ON (with engine stopped). With fuel pressure applied to fuel piping, check for fuel leak-

age at connection points.

• Start engine. With engine speed increased, che ck again for fuel leakage at connection points.

• Run engine to check for unusual noise and vibration.

• Warm up engine thoroughly to make sure there is no leakage of fuel, exhaust gas, or any oils/fluids including engine oil and engine coolant.

• Bleed air from passages in lines and hoses, such as in cooling system.

• After cooling down engine, again check oil/fluid levels including engine oil and engine coolant. Refill to spec- ified level, if necessary.

• Summary of the inspection items:

PBIC3315J

PBIC3548J

Item Before starting engine Engine runningAfter engine stopped

Engine coolant LevelLeakage Level

Engine oil LevelLeakage Level

Transmission/

transaxle fluid A/T and CVT Models

LeakageLevel/Leakage Leakage

M/T Models Level/Leakage LeakageLevel/Leakage

Other oils and fluids* LevelLeakage Level

Revision: May 2010 2011 Versa

Page 1053 of 3787

![NISSAN LATIO 2011 Service Owners Manual WATER OUTLET AND WATER CONTROL VALVECO-53

< SERVICE INFORMATION > [MR18DE]

C

D

E

F

G H

I

J

K L

M A

CO

NP

O

- Install water hoses (3),(5) as shown.

• Electric throttle control actuator (1)

• Clamp NISSAN LATIO 2011 Service Owners Manual WATER OUTLET AND WATER CONTROL VALVECO-53

< SERVICE INFORMATION > [MR18DE]

C

D

E

F

G H

I

J

K L

M A

CO

NP

O

- Install water hoses (3),(5) as shown.

• Electric throttle control actuator (1)

• Clamp](/img/5/57357/w960_57357-1052.png)

WATER OUTLET AND WATER CONTROL VALVECO-53

< SERVICE INFORMATION > [MR18DE]

C

D

E

F

G H

I

J

K L

M A

CO

NP

O

- Install water hoses (3),(5) as shown.

• Electric throttle control actuator (1)

• Clamp (2)

• Water outlet (4)

• Paint mark (A)

• Clamp shall not interfere with the bulged area (B)

• : Engine front

- Water Hoses (CVT Models)

- Install water hoses (3),(5) as shown.

• Electric throttle control actuator (1)

• Clamp (2)

• Water outlet (4)

• Paint mark (A)

• Clamp shall not interfere with the bulged area (B)

• : Engine front

InspectionINFOID:0000000006413350

INSPECTION AFTER INSTALLATION

• Before starting engine, check oil/fluid levels incl

uding engine coolant and engine oil. If less than required

quantity, fill to the specified level. Refer to MA-14, "

Fluids and Lubricants".

• Use procedure below to check for fuel leakage.

• Turn ignition switch ON (with engine stopped). With fuel pressure applied to fuel piping, check for fuel leak- age at connection points.

• Start engine. With engine speed increased, check again for fuel leakage at connection points.

• Run engine to check for unusual noise and vibration.

PBIC4703E

WBIA0821E

Revision: May 2010 2011 Versa

Page 1054 of 3787

![NISSAN LATIO 2011 Service Owners Manual CO-54

< SERVICE INFORMATION >[MR18DE]

WATER OUTLET AND WATER CONTROL VALVE

• Warm up engine thoroughly to make sure there is no leakage of fuel, exhaust gas, or any oils/fluids including

engine oil NISSAN LATIO 2011 Service Owners Manual CO-54

< SERVICE INFORMATION >[MR18DE]

WATER OUTLET AND WATER CONTROL VALVE

• Warm up engine thoroughly to make sure there is no leakage of fuel, exhaust gas, or any oils/fluids including

engine oil](/img/5/57357/w960_57357-1053.png)

CO-54

< SERVICE INFORMATION >[MR18DE]

WATER OUTLET AND WATER CONTROL VALVE

• Warm up engine thoroughly to make sure there is no leakage of fuel, exhaust gas, or any oils/fluids including

engine oil and engine coolant.

• Bleed air from passages in lines and hoses, such as in cooling system.

• After cooling down engine, again check oil/fluid levels including engine oil and engine coolant. Refill to spec-

ified level, if necessary.

• Summary of the inspection items:

*Power steering fluid, brake fluid, etc. Item

Before starting engine Engine runningAfter engine stopped

Engine coolant LevelLeakage Level

Engine oil LevelLeakage Level

Transmission/

transaxle fluid A/T and CVT Models

LeakageLevel/Leakage Leakage

M/T Models Level/Leakage LeakageLevel/Leakage

Other oils and fluids* LevelLeakage Level

Fuel LeakageLeakage Leakage

Exhaust gas —Leakage —

Revision: May 2010 2011 Versa

Page 1070 of 3787

![NISSAN LATIO 2011 Service Owners Manual CVT FLUIDCVT-15

< SERVICE INFORMATION > [RE0F08B]

D

E

F

G H

I

J

K L

M A

B

CVT

N

O P

FLUID CONDITION CHECK

Changing CVT FluidINFOID:0000000005928731

1. Warm up CVT fluid by driving the vehicle for 10 m NISSAN LATIO 2011 Service Owners Manual CVT FLUIDCVT-15

< SERVICE INFORMATION > [RE0F08B]

D

E

F

G H

I

J

K L

M A

B

CVT

N

O P

FLUID CONDITION CHECK

Changing CVT FluidINFOID:0000000005928731

1. Warm up CVT fluid by driving the vehicle for 10 m](/img/5/57357/w960_57357-1069.png)

CVT FLUIDCVT-15

< SERVICE INFORMATION > [RE0F08B]

D

E

F

G H

I

J

K L

M A

B

CVT

N

O P

FLUID CONDITION CHECK

Changing CVT FluidINFOID:0000000005928731

1. Warm up CVT fluid by driving the vehicle for 10 minutes.

• : Vehicle front

• Radiator (2)

• CVT fluid cooler hose [inlet side (3)]

• Transaxle assembly (4)

2. Drain CVT fluid from CVT fluid cooler hose [outlet side (1)] and refill with new specified NISSAN CVT fluid in the CVT fluid

charging pipe with the engine running at idle speed.

CAUTION:

Only use the specifi ed NISSAN CVT fluid.

3. Refill until new CVT fluid comes out from CVT fluid cooler hose [outlet side (1)]. NOTE:

About 30 to 50% extra fluid will be required for this procedure.

4. Check fluid level and condition. Refer to CVT-14, "

Checking CVT Fluid".

CAUTION:

Delete CVT fluid deterioration date with CONSULT-III after changing CVT fluid. Refer to CVT-48,

"CONSULT-III Function (TRANSMISSION)".

CVT Fluid Cooler CleaningINFOID:0000000005928732

Whenever a CVT is repaired, overhauled, or replaced, the CVT fluid cooler mounted in the radiator must be

inspected and cleaned.

Metal debris and friction material, if present, can be trapped or become deposit in the CVT fluid cooler. This

debris can contaminate the newly serviced CVT or, in severe cases, can block or restrict the flow of CVT fluid.

In either case, malfunction of the newly serviced CVT may occur.

Debris, if present, may deposit as CVT fluid enters the cool er inlet. It will be necessary to back flush the cooler

through the cooler outlet in order to flush out any built up debris.

CVT FLUID COOLER CLEANING PROCEDURE

1. Identify the CVT inlet and outlet fluid cooler hoses.

2. Position an oil pan under the inlet and outlet cooler hoses.

Fluid status Conceivable cause Required operation

Varnished (viscous

varnish state) Clutch, brake

scorchedReplace the CVT fluid and check the

CVT main unit and the vehicle for

malfunctions (wire harness, cooler

pipes, etc.)

Milky white or cloudy Water in the fluid Replace the CVT fluid and check for places where water is getting in.

Large amount of

metal powder mixed

in fluid Unusual wear of

sliding parts within

CVTReplace the CVT fluid and check for

improper operation of the CVT.

ATA0022D

Fluid capacity and grade: Refer to

MA-14, "Fluids

and Lubricants".SCIA6088E

Revision: May 2010 2011 Versa

Page 1093 of 3787

![NISSAN LATIO 2011 Service Owners Manual CVT-38

< SERVICE INFORMATION >[RE0F08B]

TROUBLE DIAGNOSIS

• Inspect for fluid leakage and check the fluid level. Refer to

CVT-14, "Checking CVT Fluid" .

Fluid Condition Check

Inspect the fluid cond NISSAN LATIO 2011 Service Owners Manual CVT-38

< SERVICE INFORMATION >[RE0F08B]

TROUBLE DIAGNOSIS

• Inspect for fluid leakage and check the fluid level. Refer to

CVT-14, "Checking CVT Fluid" .

Fluid Condition Check

Inspect the fluid cond](/img/5/57357/w960_57357-1092.png)

CVT-38

< SERVICE INFORMATION >[RE0F08B]

TROUBLE DIAGNOSIS

• Inspect for fluid leakage and check the fluid level. Refer to

CVT-14, "Checking CVT Fluid" .

Fluid Condition Check

Inspect the fluid condition.

STALL TEST

Stall Test Procedure

1. Inspect the amount of engine oil. Replenish the engine oil if necessary.

2. Drive for about 10 minutes to warm up the vehicle so that the

CVT fluid temperature is 50 to 80 °C (122 to 176° F). Inspect the

amount of CVT fluid. Replenish if necessary.

3. Securely engage the parking brake so that the tires do not turn.

4. Install a tachometer where it can be seen by driver during test. •It is good practice to mark the point of specified engine

rpm on indicator.

5. Start engine, apply foot brake, and place selector lever in “D” position.

Fluid status Conceivable cause Required operation

Varnished (viscous

varnish state) Clutch, brake

scorchedReplace the CVT fluid and check the

CVT main unit and the vehicle for

malfunctions (wire harnesses, cool-

er pipes, etc.)

Milky white or

cloudy Water in the fluidReplace the CVT fluid and check for

places where water is getting in.

Large amount of

metal powder mixed

in Unusual wear of

sliding parts within

CVT

Replace the CVT fluid and check for

improper operation of the CVT.

SAT638A

SAT647B

SAT513G

SAT775B

Revision: May 2010

2011 Versa

Page 1228 of 3787

![NISSAN LATIO 2011 Service Owners Manual OIL PANCVT-173

< SERVICE INFORMATION > [RE0F08B]

D

E

F

G H

I

J

K L

M A

B

CVT

N

O P

• Never reuse oil pan gasket and drain plug gasket.

• Completely remove all moisture, oil and old gasket, etc. f NISSAN LATIO 2011 Service Owners Manual OIL PANCVT-173

< SERVICE INFORMATION > [RE0F08B]

D

E

F

G H

I

J

K L

M A

B

CVT

N

O P

• Never reuse oil pan gasket and drain plug gasket.

• Completely remove all moisture, oil and old gasket, etc. f](/img/5/57357/w960_57357-1227.png)

OIL PANCVT-173

< SERVICE INFORMATION > [RE0F08B]

D

E

F

G H

I

J

K L

M A

B

CVT

N

O P

• Never reuse oil pan gasket and drain plug gasket.

• Completely remove all moisture, oil and old gasket, etc. from the oil pan gasket mounting surface of

transaxle case and oil pan.

InspectionINFOID:0000000006413340

INSPECTION AFTER REMOVAL

Check oil pan for foreign material.

• If a large amount of worn material is found, clutch plate may be worn.

• If iron powder is found, bearings, gears, or clutch plates may be worn.

• If aluminum powder is found, bushing may be worn, or ch ips or burrs of aluminum casting parts may enter.

Check points where wear is found in all cases.

INSPECTION AFTER INSTALLATION

Check for CVT fluid leakage and check CVT fluid level. Refer to CVT-14, "Checking CVT Fluid".

Revision: May 2010 2011 Versa

Page 1229 of 3787

![NISSAN LATIO 2011 Service Owners Manual CVT-174

< SERVICE INFORMATION >[RE0F08B]

DIFFERENTIAL SIDE OIL SEAL

DIFFERENTIAL SIDE OIL SEAL

Removal and InstallationINFOID:0000000005928975

COMPONENTS

REMOVAL

1. Remove drive shaft assembly. Refer NISSAN LATIO 2011 Service Owners Manual CVT-174

< SERVICE INFORMATION >[RE0F08B]

DIFFERENTIAL SIDE OIL SEAL

DIFFERENTIAL SIDE OIL SEAL

Removal and InstallationINFOID:0000000005928975

COMPONENTS

REMOVAL

1. Remove drive shaft assembly. Refer](/img/5/57357/w960_57357-1228.png)

CVT-174

< SERVICE INFORMATION >[RE0F08B]

DIFFERENTIAL SIDE OIL SEAL

DIFFERENTIAL SIDE OIL SEAL

Removal and InstallationINFOID:0000000005928975

COMPONENTS

REMOVAL

1. Remove drive shaft assembly. Refer to

FAX-9.

2. Remove differential side oil seal using a suitable tool. CAUTION:

Do not scratch transaxle case or converter housing.

INSTALLATION

1. Drive the new differential side oil seal into the transaxle caseside (B) and converter housing side (C) until it is flush using

Tool.

Unit: mm (in)

CAUTION:

• Do not reuse differential side oil seals.

• Apply specified NISSAN CVT fluid to side oil seals.

2. Install drive shaft assembly. Refer to FA X - 9

.

3. Check CVT fluid level and leakage. Refer to CVT-14, "

Checking CVT Fluid".

1. CVT2. Differential side oil seal : Apply CVT Fluid NS-2.

WCIA0610E

SCIA2412E

Tool number : — (J-47244)

: ST33400001 (J-47005)

Dimensions (A) 0±0.5 (0 ±0.020)

WCIA0611E

Revision: May 2010 2011 Versa

Page 1234 of 3787

![NISSAN LATIO 2011 Service Owners Manual CVT OIL WARMER SYSTEMCVT-179

< SERVICE INFORMATION > [RE0F08B]

D

E

F

G H

I

J

K L

M A

B

CVT

N

O P

CVT FLUID COOLER HOSE : InspectionINFOID:0000000006068651

INSPECTION AFTER INSTALLATION

Check for CVT f NISSAN LATIO 2011 Service Owners Manual CVT OIL WARMER SYSTEMCVT-179

< SERVICE INFORMATION > [RE0F08B]

D

E

F

G H

I

J

K L

M A

B

CVT

N

O P

CVT FLUID COOLER HOSE : InspectionINFOID:0000000006068651

INSPECTION AFTER INSTALLATION

Check for CVT f](/img/5/57357/w960_57357-1233.png)

CVT OIL WARMER SYSTEMCVT-179

< SERVICE INFORMATION > [RE0F08B]

D

E

F

G H

I

J

K L

M A

B

CVT

N

O P

CVT FLUID COOLER HOSE : InspectionINFOID:0000000006068651

INSPECTION AFTER INSTALLATION

Check for CVT fluid leakage and check CVT fluid level. Refer to CVT-14, "Checking CVT Fluid".

CVT OIL WARMER

CVT OIL WARMER : Exploded ViewINFOID:0000000006068652

CVT OIL WARMER : Removal and InstallationINFOID:0000000006068653

REMOVAL

WARNING:

Never remove the radiator cap when the engine is hot. Serious burns could occur from high pressure

coolant escaping from the radiator.

CAUTION:

Perform this step engine is cold.

1. Remove CVT water hose from CVT oil warmer. Refer to CVT-175, "

WATER HOSE : Exploded View".

2. Remove CVT fluid cooler hose from CVT oil warmer. Refer to CVT-177, "

CVT FLUID COOLER HOSE :

Exploded View".

3. Remove CVT oil warmer.

4. Remove bracket.

INSTALLATION

Installation is in the reverse order of removal.

CVT OIL WARMER : InspectionINFOID:0000000006068654

INSPECTION AFTER INSTALLATION

• Check for CVT fluid leakage and check CVT fluid level. Refer to CVT-14, "Checking CVT Fluid".

• Start and warm up the engine. Visually check that there is no leakage of engine coolant and CVT fluid.

1. CVT oil warmer2. Bracket3. Transaxle assembly

Refer to GI-8, "

Component" for symbols in the figure.

JPDIA0725GB

Revision: May 2010 2011 Versa

Page 1240 of 3787

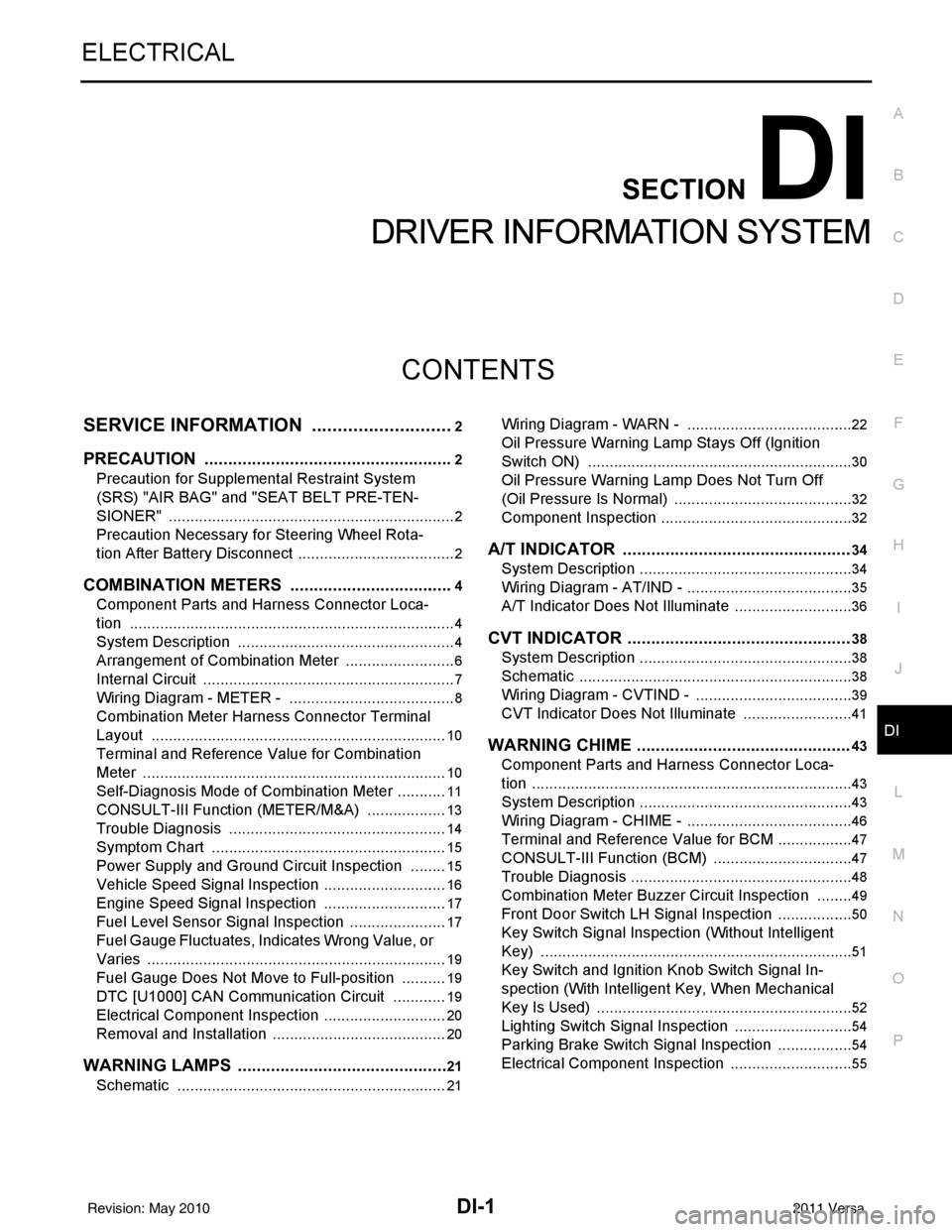

DI-1

ELECTRICAL

C

DE

F

G H

I

J

L

M

SECTION DI

A

B

DI

N

O P

CONTENTS

DRIVER INFORMATION SYSTEM

SERVICE INFORMATION .. ..........................2

PRECAUTION ................................................ .....2

Precaution for Supplemental Restraint System

(SRS) "AIR BAG" and "SEAT BELT PRE-TEN-

SIONER" ............................................................. ......

2

Precaution Necessary for Steering Wheel Rota-

tion After Battery Disconnect ............................... ......

2

COMBINATION METERS ...................................4

Component Parts and Harness Connector Loca-

tion ...................................................................... ......

4

System Description ...................................................4

Arrangement of Combination Meter ..........................6

Internal Circuit ...........................................................7

Wiring Diagram - METER - .......................................8

Combination Meter Harness Connector Terminal

Layout .....................................................................

10

Terminal and Reference Value for Combination

Meter .......................................................................

10

Self-Diagnosis Mode of Combination Meter ........ ....11

CONSULT-III Function (METER/M&A) ............... ....13

Trouble Diagnosis ...................................................14

Symptom Chart .......................................................15

Power Supply and Ground Circuit Inspection .........15

Vehicle Speed Signal Inspection .............................16

Engine Speed Signal Inspection .............................17

Fuel Level Sensor Signal Inspection .......................17

Fuel Gauge Fluctuates, Indicates Wrong Value, or

Varies ......................................................................

19

Fuel Gauge Does Not Move to Full-position ...........19

DTC [U1000] CAN Communication Circuit ......... ....19

Electrical Component Inspection .............................20

Removal and Installation .........................................20

WARNING LAMPS ......................................... ....21

Schematic ........................................................... ....21

Wiring Diagram - WARN - ................................... ....22

Oil Pressure Warning Lamp Stays Off (Ignition

Switch ON) .......................................................... ....

30

Oil Pressure Warning Lamp Does Not Turn Off

(Oil Pressure Is Normal) ...................................... ....

32

Component Inspection .............................................32

A/T INDICATOR ................................................34

System Description ..................................................34

Wiring Diagram - AT/IND - .......................................35

A/T Indicator Does Not Illuminate ............................36

CVT INDICATOR ...............................................38

System Description ..................................................38

Schematic ................................................................38

Wiring Diagram - CVTIND - .....................................39

CVT Indicator Does Not Illuminate ..........................41

WARNING CHIME .............................................43

Component Parts and Harness Connector Loca-

tion ....................................................................... ....

43

System Description ..................................................43

Wiring Diagram - CHIME - .......................................46

Terminal and Reference Value for BCM ..................47

CONSULT-III Function (B CM) .................................47

Trouble Diagnosis ................................................ ....48

Combination Meter Buzzer Circuit Inspection .........49

Front Door Switch LH Signal Inspection .............. ....50

Key Switch Signal Inspection (Without Intelligent

Key) ..................................................................... ....

51

Key Switch and Ignition Knob Switch Signal In-

spection (With Intelligent Key, When Mechanical

Key Is Used) ........................................................ ....

52

Lighting Switch Signal Inspection ............................54

Parking Brake Switch Signal Inspection ..................54

Electrical Component Inspection .............................55

Revision: May 2010 2011 Versa