roof NISSAN LATIO 2011 Service Owner's Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2011, Model line: LATIO, Model: NISSAN LATIO 2011Pages: 3787, PDF Size: 78.35 MB

Page 815 of 3787

BODY REPAIRBL-305

< SERVICE INFORMATION >

C

DE

F

G H

J

K L

M A

B

BL

N

O P

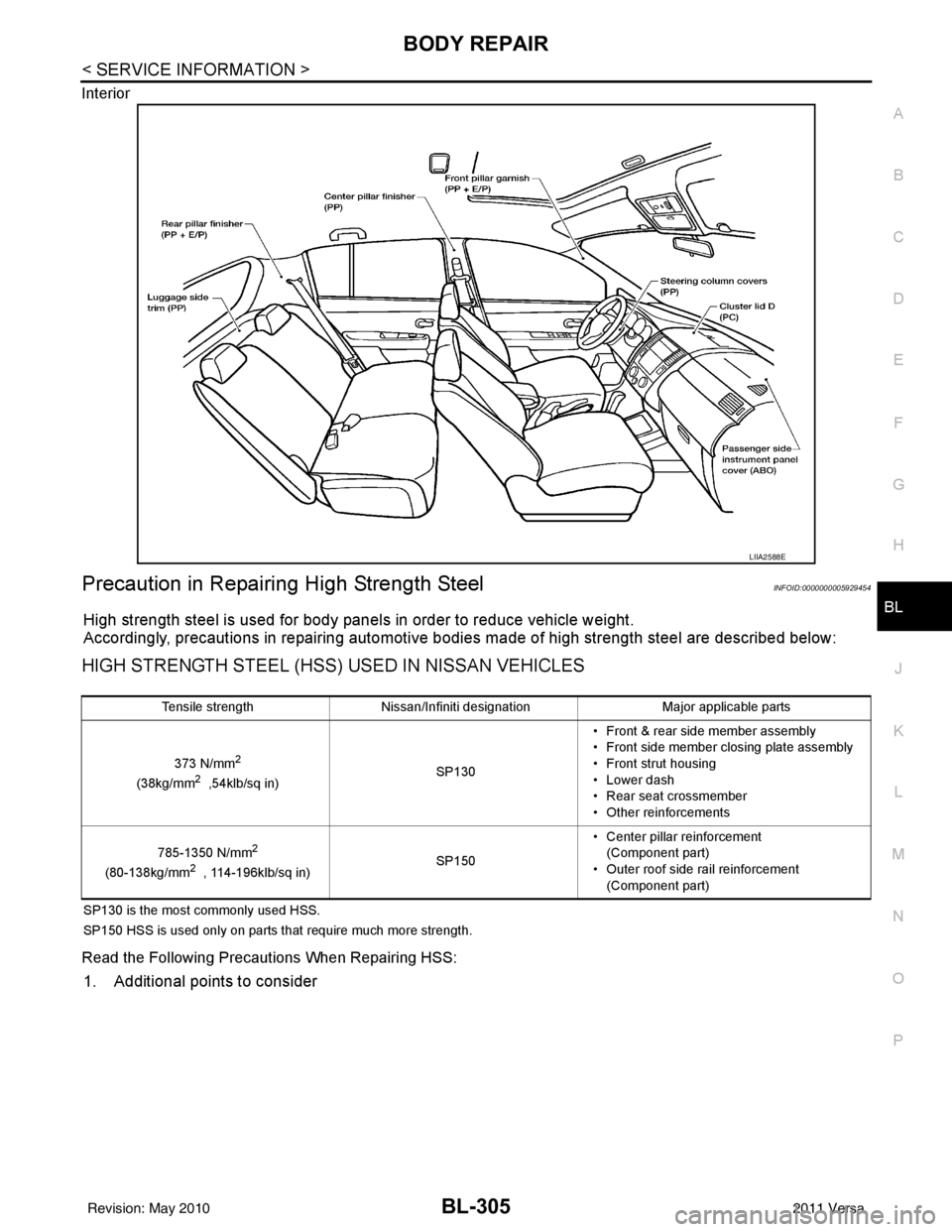

Interior

Precaution in Repairing High Strength SteelINFOID:0000000005929454

High strength steel is used for body panels in order to reduce vehicle weight.

Accordingly, precautions in repairing automotive bodies made of high strength steel are described below:

HIGH STRENGTH STEEL (HSS) USED IN NISSAN VEHICLES

SP130 is the most commonly used HSS.

SP150 HSS is used only on parts that require much more strength.

Read the Following Precautions When Repairing HSS:

1. Additional points to consider

LIIA2588E

Tensile strength

Nissan/Infiniti designation Major applicable parts

373 N/mm

2

(38kg/mm2 ,54klb/sq in) SP130• Front & rear side member assembly

• Front side member closing plate assembly

• Front strut housing

• Lower dash

• Rear seat crossmember

• Other reinforcements

785-1350 N/mm

2

(80-138kg/mm2 , 114-196klb/sq in) SP150• Center pillar reinforcement

(Component part)

• Outer roof side rail reinforcement (Component part)

Revision: May 2010 2011 Versa

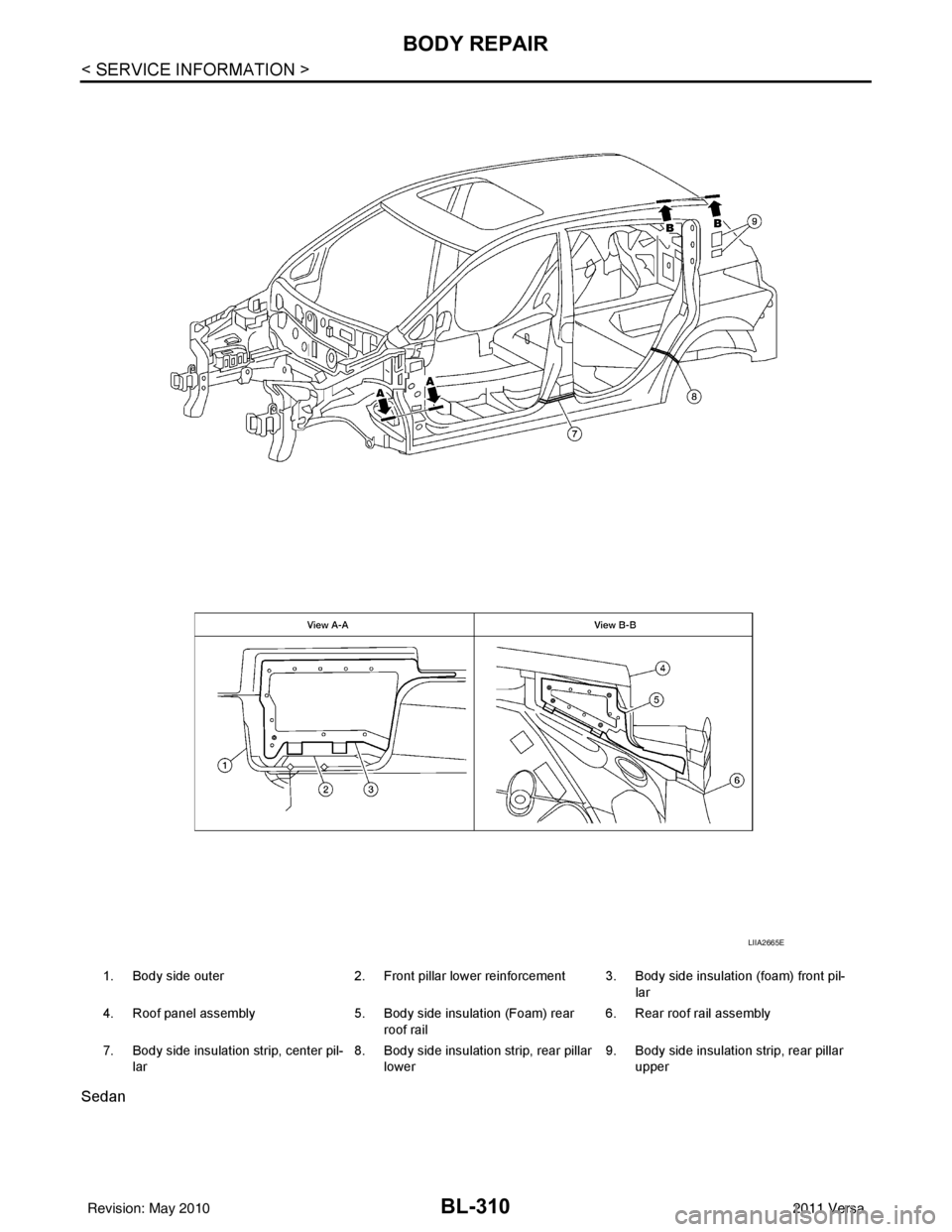

Page 820 of 3787

BL-310

< SERVICE INFORMATION >

BODY REPAIR

Sedan

1. Body side outer2. Front pillar lower reinforcement 3. Body side insulation (foam) front pil-

lar

4. Roof panel assembly 5. Body side insulation (Foam) rear

roof rail 6. Rear roof rail assembly

7. Body side insulation strip, center pil- lar 8. Body side insulation strip, rear pillar

lower 9. Body side insulation strip, rear pillar

upper

LIIA2665E

Revision: May 2010 2011 Versa

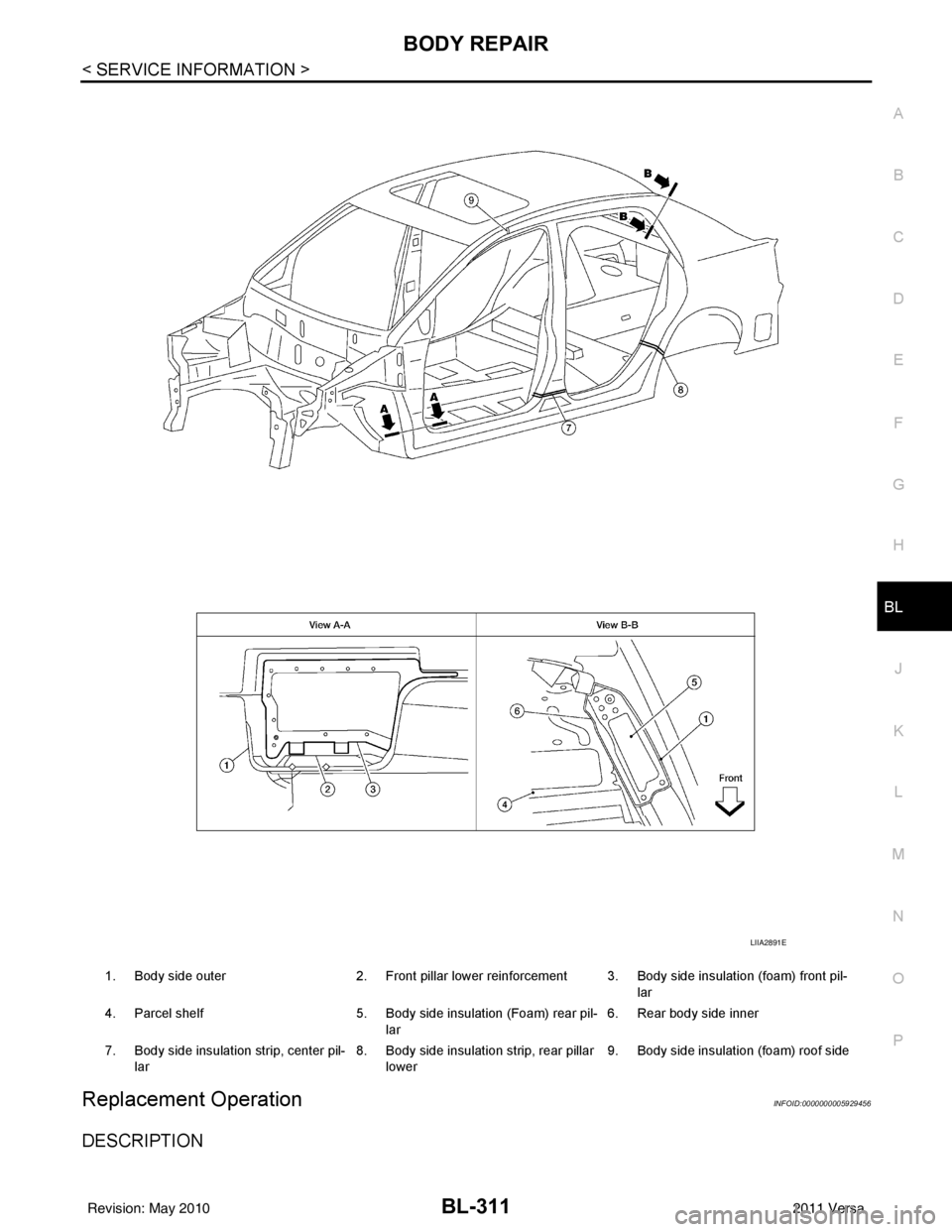

Page 821 of 3787

BODY REPAIRBL-311

< SERVICE INFORMATION >

C

DE

F

G H

J

K L

M A

B

BL

N

O P

Replacement OperationINFOID:0000000005929456

DESCRIPTION

1. Body side outer 2. Front pillar lower reinforcement 3. Body side insulation (foam) front pil-

lar

4. Parcel shelf 5. Body side insulation (Foam) rear pil-

lar 6. Rear body side inner

7. Body side insulation strip, center pil- lar 8. Body side insulation strip, rear pillar

lower 9. Body side insulation (foam) roof side

LIIA2891E

Revision: May 2010

2011 Versa

Page 1747 of 3787

![NISSAN LATIO 2011 Service Owners Manual ON BOARD REFUELING VAPOR RECOVERY (ORVR)EC-453

< COMPONENT DIAGNOSIS > [HR16DE]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

ON BOARD REFUELING VAPOR RECOVERY (ORVR)

DescriptionINFOID:0000000005930139

From the beg NISSAN LATIO 2011 Service Owners Manual ON BOARD REFUELING VAPOR RECOVERY (ORVR)EC-453

< COMPONENT DIAGNOSIS > [HR16DE]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

ON BOARD REFUELING VAPOR RECOVERY (ORVR)

DescriptionINFOID:0000000005930139

From the beg](/img/5/57357/w960_57357-1746.png)

ON BOARD REFUELING VAPOR RECOVERY (ORVR)EC-453

< COMPONENT DIAGNOSIS > [HR16DE]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

ON BOARD REFUELING VAPOR RECOVERY (ORVR)

DescriptionINFOID:0000000005930139

From the beginning of refueling, the air and vapor insi

de the fuel tank go through refueling EVAP vapor cut

valve and EVAP/ORVR line to the EVAP canister. The v apor is absorbed by the EVAP canister and the air is

released to the atmosphere.

When the refueling has reached the full level of the fuel tank, the refueling EVAP vapor cut valve is closed and

refueling is stopped because of auto shut-off. The vapor which was absorbed by the EVAP canister is purged

during driving.

WARNING:

When conducting inspectio ns below, be sure to observe the following:

• Put a “CAUTION: FLAMMABL E” sign in workshop.

• Do not smoke while servicing fuel system. Keep open flames and sparks away from work area.

• Be sure to furnish the workshop with a CO

2 fire extinguisher.

CAUTION:

• Before removing fuel line parts, carry out the following procedures:

- Put drained fuel in an explosion-proof containe r and put lid on securely.

- Release fuel pressure from fuel line. Refer to FL-5, "

Checking Fuel Line".

- Disconnect battery ground cable.

• Always replace O-ring when the fu el gauge retainer is removed.

• Do not kink or twist hose and tube when they are installed.

• Do not tighten hose and clamps excessively to avoid damaging hoses.

• After installation, run engine and check for fuel leaks at connection.

• Do not attempt to top off the fuel tank after the fuel pump nozzle shuts off automatically.

Continued refueling may cause fuel overflow, resulting in fuel spray and possibly a fire.

Component Function CheckINFOID:0000000005930140

1.CHECK ORVR FUNCTION

Check whether the following symptoms are present.

• Fuel odor from EVAP canister is strong.

• Cannot refuel/Fuel odor from the fuel filler opening is strong while refueling.

Is any symptom present?

YES >> Go to EC-453, "Diagnosis Procedure".

NO >> INSPECTION END

Diagnosis ProcedureINFOID:0000000005930141

1.INSPECTION START

Check whether the following symptoms are present.

A: Fuel odor from EVAP canister is strong.

JMBIA1930GB

Revision: May 2010 2011 Versa

Page 2331 of 3787

EI-1

BODY

C

DE

F

G H

J

K L

M

SECTION EI

A

B

EI

N

O P

CONTENTS

EXTERIOR & INTERIOR

PRECAUTION ....... ........................................3

PRECAUTIONS .............................................. .....3

Precaution for Supplemental Restraint System

(SRS) "AIR BAG" and "SEAT BELT PRE-TEN-

SIONER" ............................................................. ......

3

Precaution Necessary for Steering Wheel Rota-

tion After Battery Disconnect ............................... ......

3

Precaution .................................................................4

PREPARATION ............................................5

PREPARATION .............................................. .....5

Special Service Tool ........................................... ......5

Commercial Service Tool ..........................................5

SYMPTOM DIAGNOSIS ...............................6

SQUEAK AND RATTLE TROUBLE DIAGNO-

SIS .................................................................. .....

6

Work Flow ........................................................... ......6

Generic Squeak and Rattle Troubleshooting ............8

Diagnostic Worksheet .............................................10

CLIP AND FASTENER .......................................12

Description .......................................................... ....12

ON-VEHICLE REPAIR .................................15

FRONT BUMPER ........................................... ....15

Removal and Installation .........................................15

REAR BUMPER ............................................. ....18

Component .......................................................... ....18

Removal and Installation - Hatchback .....................19

Removal and Installation - Sedan ....................... ....21

FRONT GRILLE .................................................23

Removal and Installation .........................................23

COWL TOP .........................................................24

Removal and Installation .........................................24

FENDER PROTECTOR ....................................26

Component .......................................................... ....26

Removal and Installation .........................................26

ROOF SIDE MOLDING .....................................27

Component ..............................................................27

Removal and Installation .........................................27

DOOR OUTSIDE MOLDING .............................29

Component ..............................................................29

Removal and Installation .........................................30

CENTER MUD GUARD .....................................32

Removal and Installation .........................................32

TRUNK LID FINISHER ......................................33

Removal and Installation .........................................33

REAR AIR SPOILER .........................................34

Removal and Installation .........................................34

DOOR FINISHER ..............................................36

Removal and Installation .........................................36

BACK DOOR TRIM ...........................................40

Removal and Installation ..................................... ....40

BODY SIDE TRIM .............................................41

Component ..............................................................41

Removal and Installation .........................................42

REAR PARCEL SHELF FINISHER ..................47

Removal and Installation .........................................47

FLOOR TRIM ....................................................48

Removal and Installation .........................................48

HEADLINING ....................................................50

Component ..............................................................50

Removal and Installation - Hatchback .....................52

Removal and Installation - Sedan ............................54

LUGGAGE FLOOR TRIM .................................56

Revision: May 2010 2011 Versa

Page 2339 of 3787

SQUEAK AND RATTLE TROUBLE DIAGNOSISEI-9

< SYMPTOM DIAGNOSIS >

C

DE

F

G H

J

K L

M A

B

EI

N

O P

3. The trunk lid torsion bars knocking together

4. A loose license plate or bracket

Most of these incidents can be repaired by adjusting, se curing or insulating the item(s) or component(s) caus-

ing the noise.

SUNROOF/HEADLINING

Noises in the sunroof/headlining area can often be traced to one of the following:

1. Sunroof lid, rail, linkage or seals making a rattle or light knocking noise

2. Sun visor shaft shaking in the holder

3. Front or rear windshield touching headliner and squeaking

Again, pressing on the components to stop the noise while duplicating the conditions can isolate most of these

incidents. Repairs usually consist of insulating with felt cloth tape.

OVERHEAD CONSOLE (FRONT AND REAR)

Overhead console noises are often caused by the cons ole panel clips not being engaged correctly. Most of

these incidents are repaired by pushing up on the c onsole at the clip locations until the clips engage.

In addition look for:

1. Loose harness or harness connectors.

2. Front console map/reading lamp lens loose.

3. Loose screws at console attachment points.

SEATS

When isolating seat noise it's important to note the position the seat is in and the load placed on the seat when

the noise is present. These conditions should be duplicated when verifying and isolating the cause of the

noise.

Cause of seat noise include:

1. Headrest rods and holder

2. A squeak between the seat pad cushion and frame

3. The rear seatback lock and bracket

These noises can be isolated by moving or pressing on the suspected components while duplicating the con-

ditions under which the noise occurs. Most of thes e incidents can be repaired by repositioning the component

or applying urethane tape to the contact area.

UNDERHOOD

Some interior noise may be caused by components under the hood or on the engine wall. The noise is then

transmitted into the passenger compartment.

Causes of transmitted underhood noise include:

1. Any component installed on the engine wall

2. Components that pass through the engine wall

3. Engine wall mounts and connectors

4. Loose radiator pins

5. Hood bumpers out of adjustment

6. Hood striker out of adjustment

These noises can be difficult to isolate since they cannot be reached from the interior of the vehicle. The best

method is to secure, move or insulate one component at a time and test drive the vehicle. Also, engine RPM

or load can be changed to isolate the noise. Repairs can usually be made by moving, adjusting, securing, or

insulating the component causing the noise.

Revision: May 2010 2011 Versa

Page 2357 of 3787

ROOF SIDE MOLDINGEI-27

< ON-VEHICLE REPAIR >

C

DE

F

G H

J

K L

M A

B

EI

N

O P

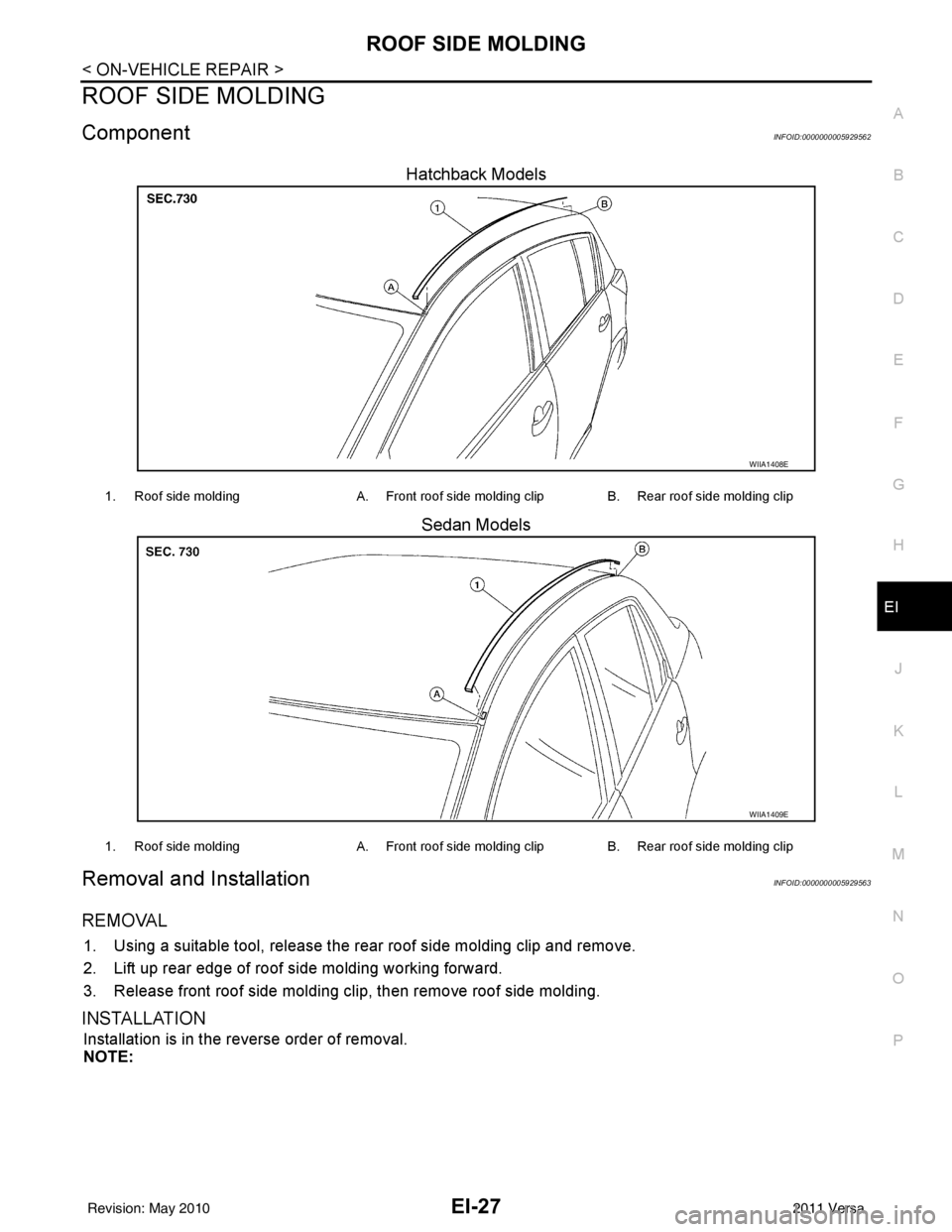

ROOF SIDE MOLDING

ComponentINFOID:0000000005929562

Hatchback Models

Sedan Models

Removal and InstallationINFOID:0000000005929563

REMOVAL

1. Using a suitable tool, release the rear roof side molding clip and remove.

2. Lift up rear edge of roof side molding working forward.

3. Release front roof side molding clip, then remove roof side molding.

INSTALLATION

Installation is in the reverse order of removal.

NOTE:

WIIA1408E

1. Roof side molding A. Front roof side molding clip B. Rear roof side molding clip

WIIA1409E

1. Roof side moldingA. Front roof side molding clip B. Rear roof side molding clip

Revision: May 2010 2011 Versa

Page 2358 of 3787

EI-28

< ON-VEHICLE REPAIR >

ROOF SIDE MOLDING

Make sure front edge of roof side molding contacts windshield mold-

ing with no gap.

• For setting a new clip A or B, use Epoxy Adhesive DP-100C madeby 3M. For adhesive DP-100C application use an applicator 9170

EPX W 1:1 and mixer nozzle 9742 EPX 50ML made by 3M.

PIIB2599J

Revision: May 2010 2011 Versa

Page 2380 of 3787

EI-50

< ON-VEHICLE REPAIR >

HEADLINING

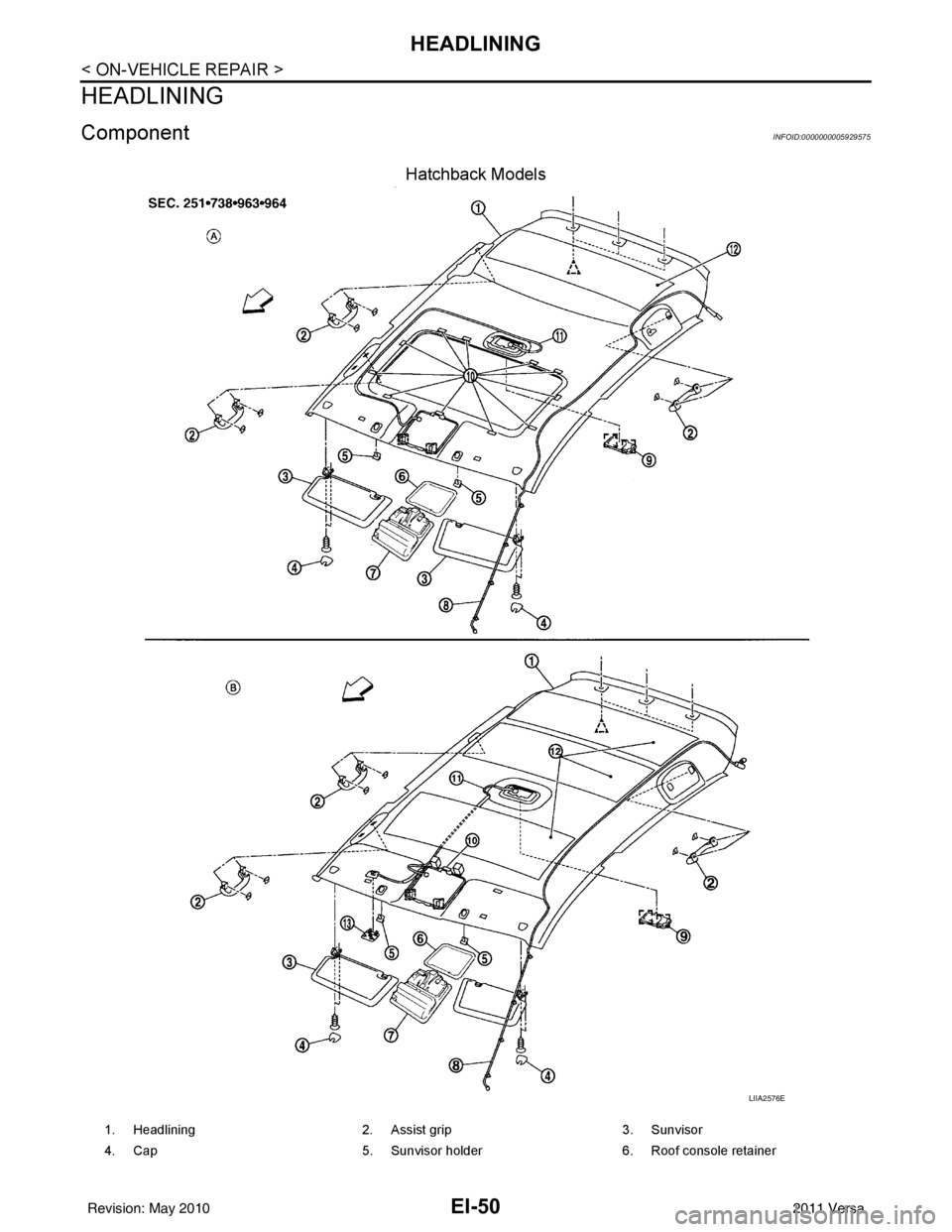

HEADLINING

ComponentINFOID:0000000005929575

Hatchback Models

LIIA2576E

1. Headlining2. Assist grip 3. Sunvisor

4. Cap 5. Sunvisor holder 6. Roof console retainer

Revision: May 2010 2011 Versa

Page 2381 of 3787

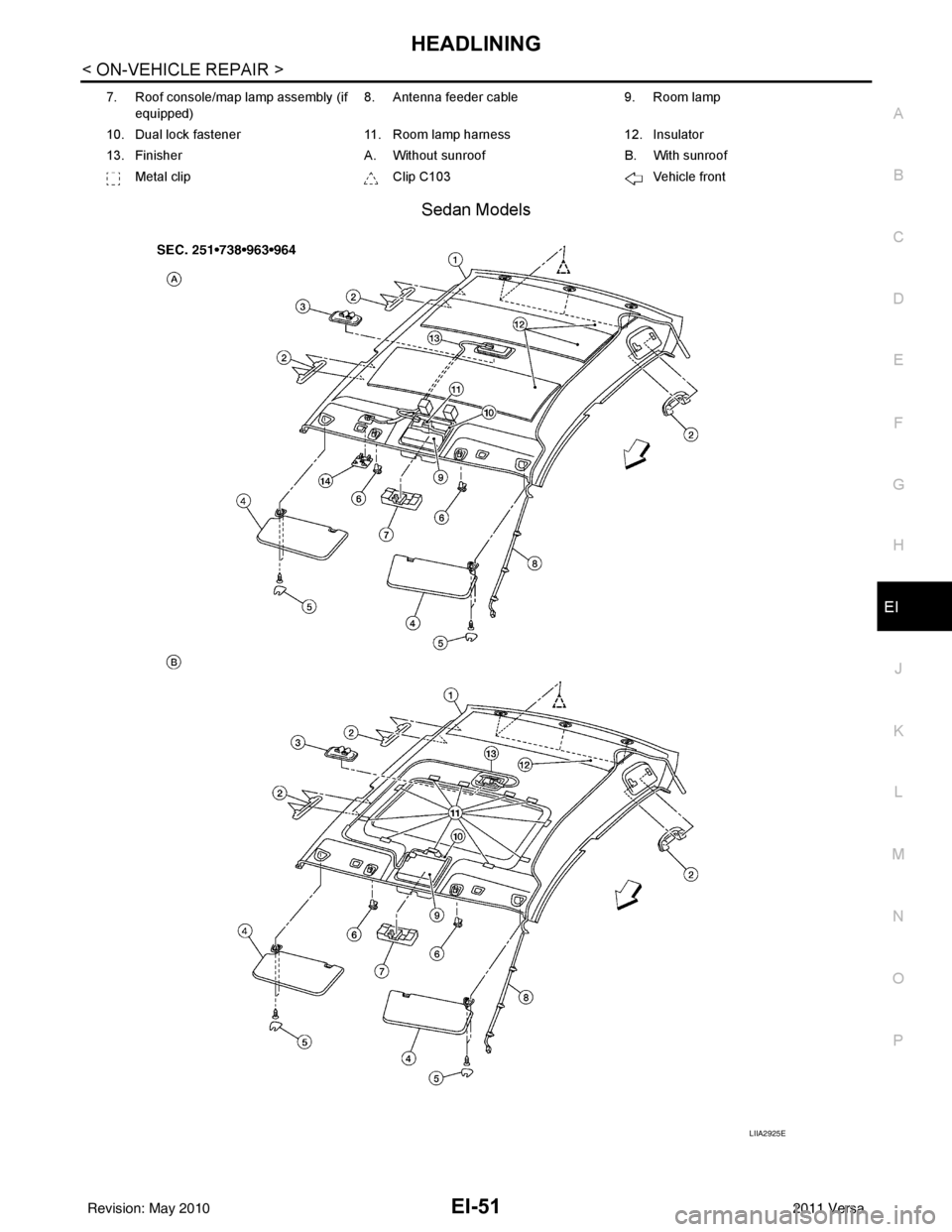

HEADLININGEI-51

< ON-VEHICLE REPAIR >

C

DE

F

G H

J

K L

M A

B

EI

N

O P

Sedan Models

7. Roof console/map lamp assembly (if equipped) 8. Antenna feeder cable

9. Room lamp

10. Dual lock fastener 11. Room lamp harness 12. Insulator

13. Finisher A. Without sunroof B. With sunroof

Metal clip Clip C103 Vehicle front

LIIA2925E

Revision: May 2010 2011 Versa