oil NISSAN LATIO 2011 Service Owner's Guide

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2011, Model line: LATIO, Model: NISSAN LATIO 2011Pages: 3787, PDF Size: 78.35 MB

Page 92 of 3787

TROUBLE DIAGNOSISAT-75

< SERVICE INFORMATION >

DE

F

G H

I

J

K L

M A

B

AT

N

O P

TCM Terminal and Reference ValueINFOID:0000000005928104

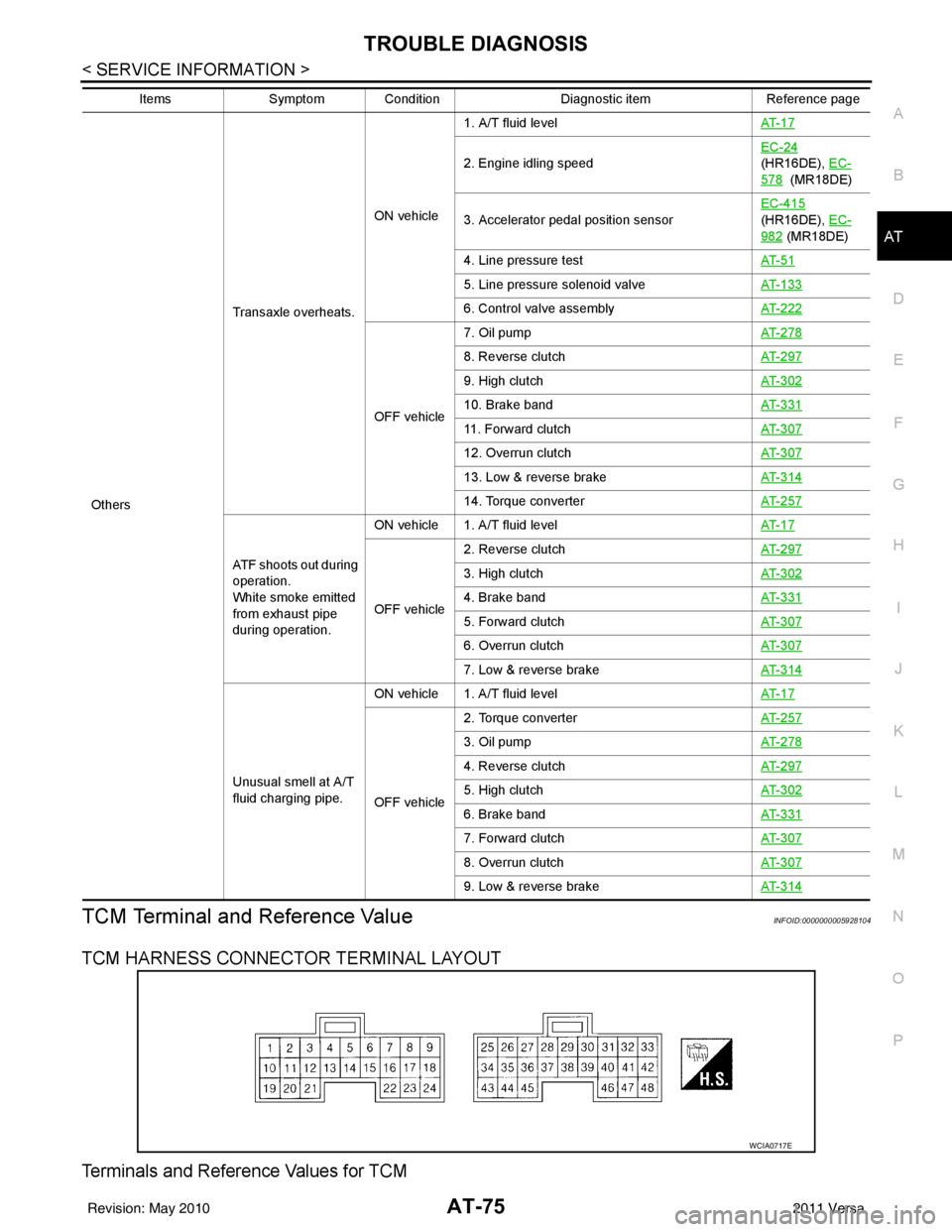

TCM HARNESS CONNECTOR TERMINAL LAYOUT

Terminals and Reference Values for TCM

Others Transaxle overheats.

ON vehicle

1. A/T fluid level

AT- 1 7

2. Engine idling speedEC-24

(HR16DE), EC-

578 (MR18DE)

3. Accelerator pedal position sensor EC-415

(HR16DE), EC-

982 (MR18DE)

4. Line pressure test AT- 5 1

5. Line pressure solenoid valveAT- 1 3 3

6. Control valve assemblyAT- 2 2 2

OFF vehicle7. Oil pump

AT- 2 7 8

8. Reverse clutchAT- 2 9 7

9. High clutchAT- 3 0 2

10. Brake bandAT- 3 3 1

11. Forward clutchAT- 3 0 7

12. Overrun clutchAT- 3 0 7

13. Low & reverse brakeAT- 3 1 4

14. Torque converterAT- 2 5 7

ATF shoots out during

operation.

White smoke emitted

from exhaust pipe

during operation.ON vehicle 1. A/T fluid level

AT- 1 7

OFF vehicle2. Reverse clutch

AT- 2 9 7

3. High clutchAT- 3 0 2

4. Brake bandAT- 3 3 1

5. Forward clutchAT- 3 0 7

6. Overrun clutchAT- 3 0 7

7. Low & reverse brakeAT- 3 1 4

Unusual smell at A/T

fluid charging pipe.ON vehicle 1. A/T fluid level

AT- 1 7

OFF vehicle2. Torque converter

AT- 2 5 7

3. Oil pumpAT- 2 7 8

4. Reverse clutchAT- 2 9 7

5. High clutchAT- 3 0 2

6. Brake bandAT- 3 3 1

7. Forward clutchAT- 3 0 7

8. Overrun clutchAT- 3 0 7

9. Low & reverse brakeAT- 3 1 4

ItemsSymptom Condition Diagnostic itemReference page

WCIA0717E

Revision: May 2010 2011 Versa

Page 115 of 3787

AT-98

< SERVICE INFORMATION >

P0710 TRANSMISSION FLUID TEMPERATURE SENSOR A

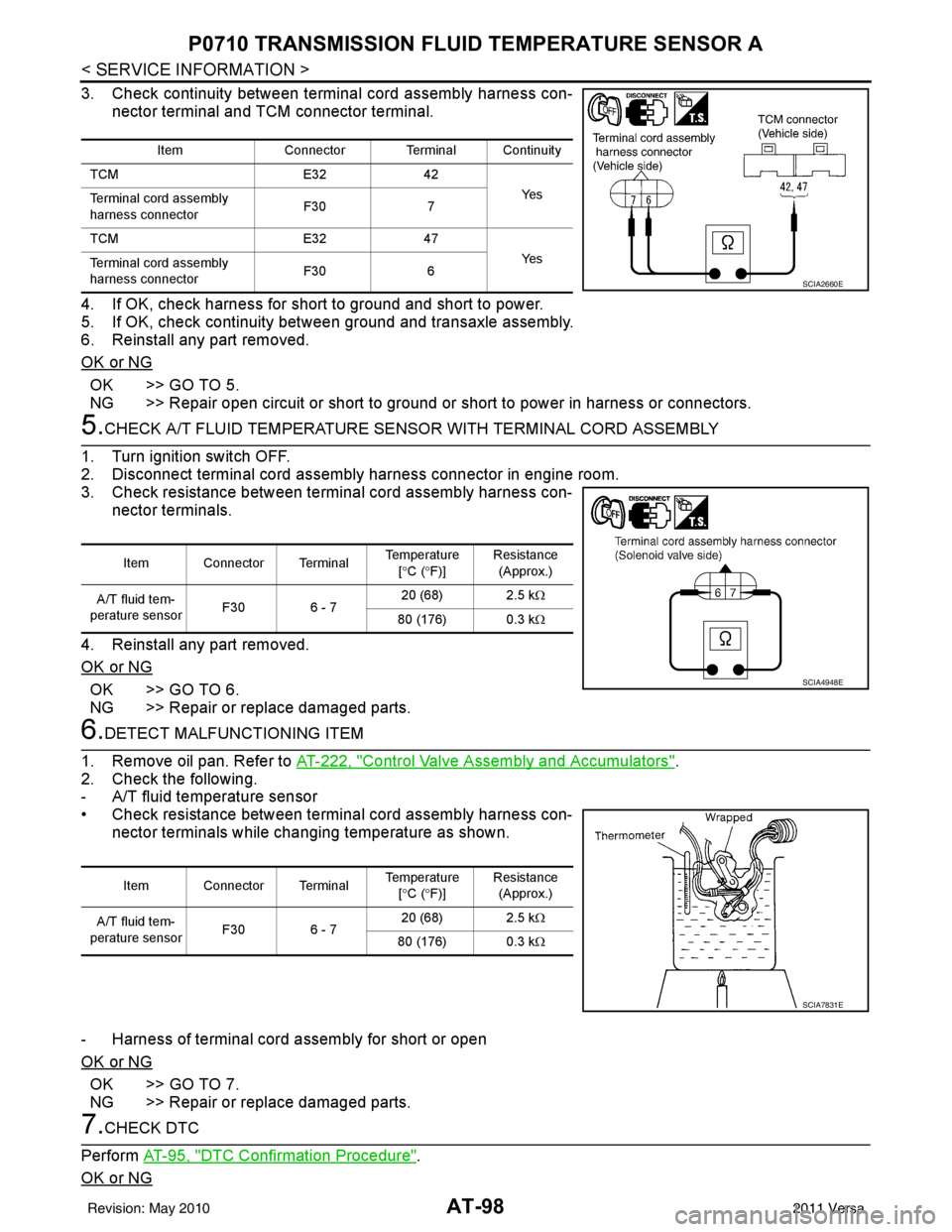

3. Check continuity between terminal cord assembly harness con-

nector terminal and TCM connector terminal.

4. If OK, check harness for short to ground and short to power.

5. If OK, check continuity bet ween ground and transaxle assembly.

6. Reinstall any part removed.

OK or NG

OK >> GO TO 5.

NG >> Repair open circuit or short to ground or short to power in harness or connectors.

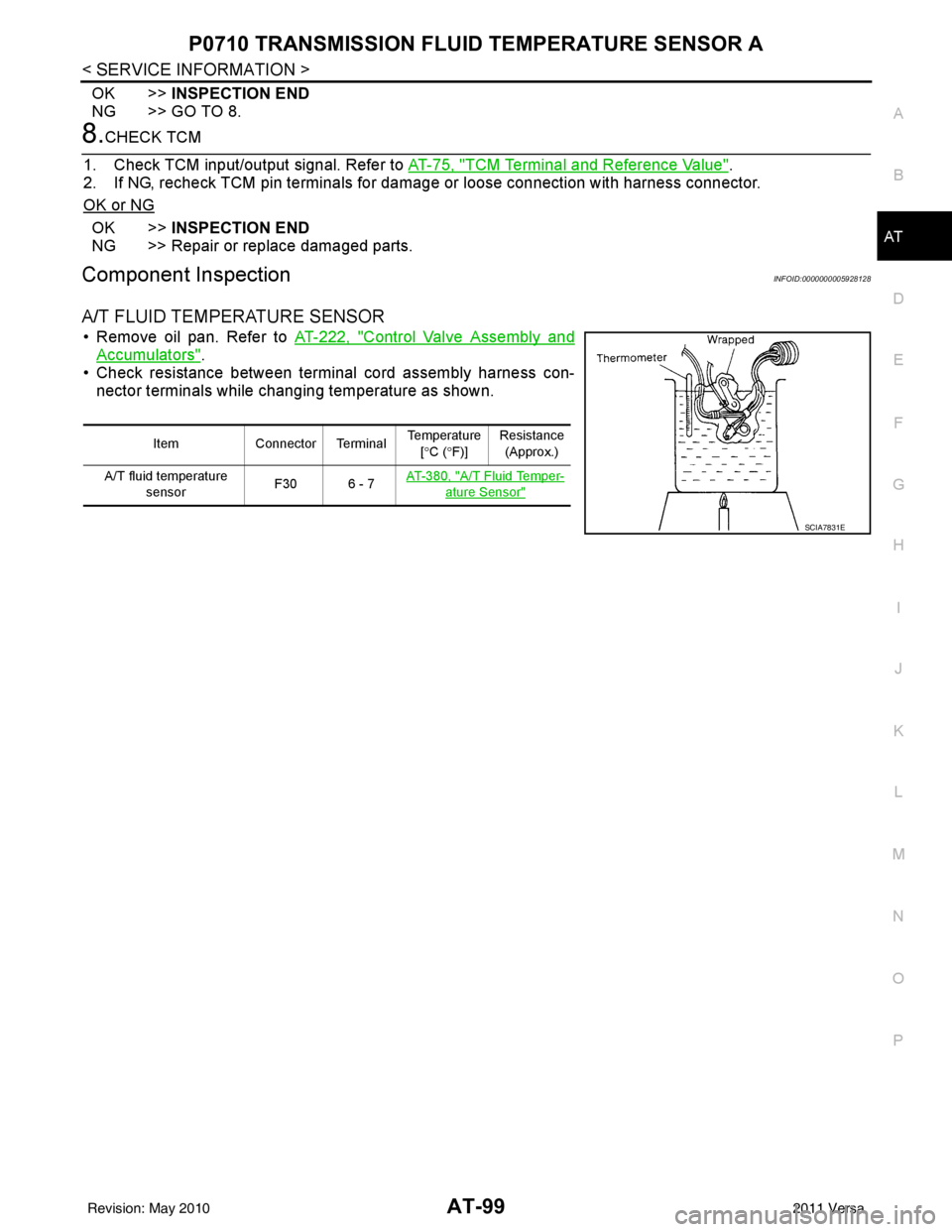

5.CHECK A/T FLUID TEMPERATURE SENSO R WITH TERMINAL CORD ASSEMBLY

1. Turn ignition switch OFF.

2. Disconnect terminal cord assembly harness connector in engine room.

3. Check resistance between terminal cord assembly harness con- nector terminals.

4. Reinstall any part removed.

OK or NG

OK >> GO TO 6.

NG >> Repair or replace damaged parts.

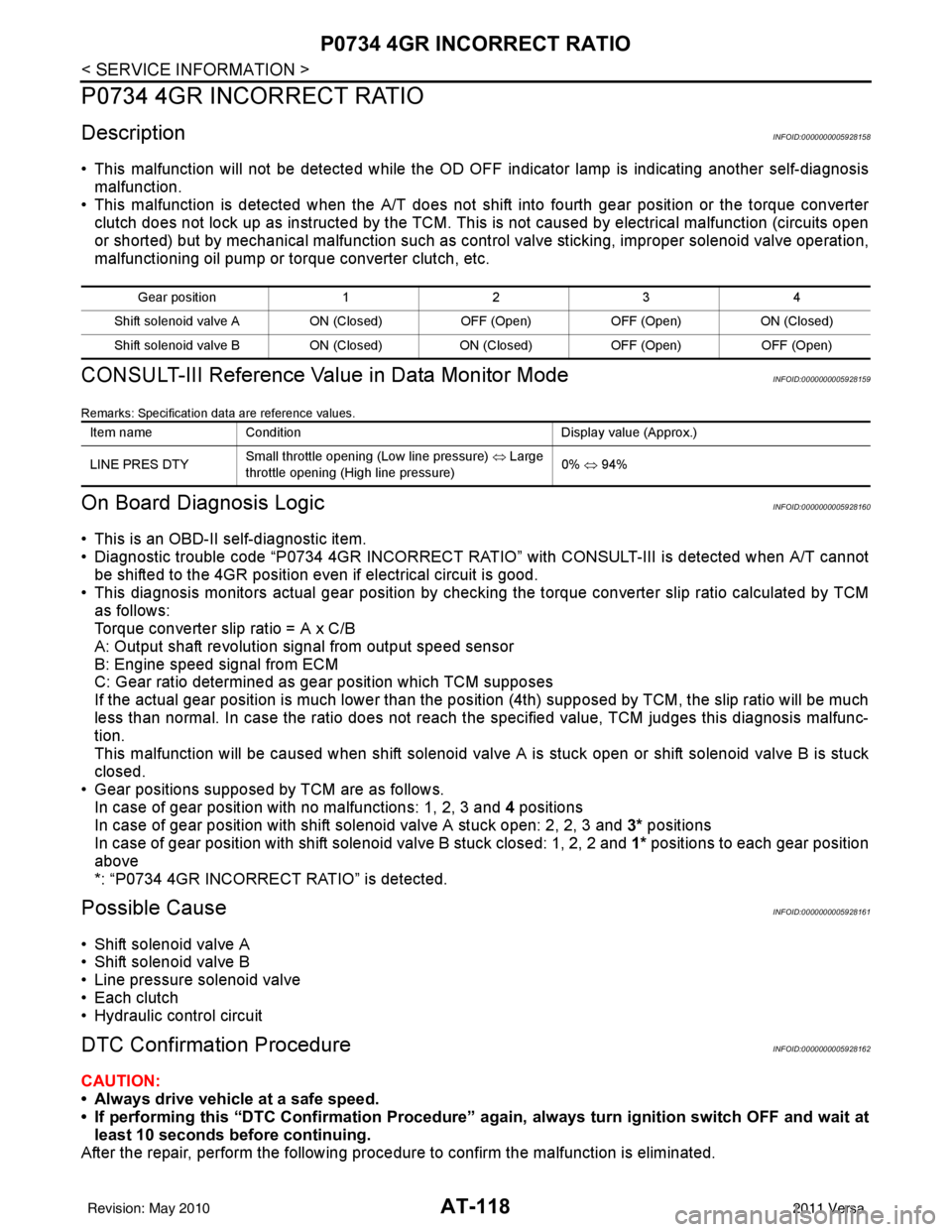

6.DETECT MALFUNCTIONING ITEM

1. Remove oil pan. Refer to AT-222, "

Control Valve Assembly and Accumulators".

2. Check the following.

- A/T fluid temperature sensor

• Check resistance between terminal cord assembly harness con- nector terminals while changing temperature as shown.

- Harness of terminal cord assembly for short or open

OK or NG

OK >> GO TO 7.

NG >> Repair or replace damaged parts.

7.CHECK DTC

Perform AT-95, "

DTC Confirmation Procedure".

OK or NG

Item Connector Terminal Continuity

TCM E3242

Ye s

Terminal cord assembly

harness connector F30

7

TCM E3247

Ye s

Terminal cord assembly

harness connector F30

6

SCIA2660E

Item Connector Terminal Temperature

[° C ( °F)] Resistance

(Approx.)

A/T fluid tem-

perature sensor F30 6 - 7 20 (68) 2.5 k

Ω

80 (176) 0.3 kΩ

SCIA4948E

Item Connector Terminal Temperature

[° C ( °F)] Resistance

(Approx.)

A/T fluid tem-

perature sensor F30 6 - 7 20 (68) 2.5 k

Ω

80 (176) 0.3 kΩ

SCIA7831E

Revision: May 2010 2011 Versa

Page 116 of 3787

P0710 TRANSMISSION FLUID TEMPERATURE SENSOR AAT-99

< SERVICE INFORMATION >

DE

F

G H

I

J

K L

M A

B

AT

N

O P

OK >> INSPECTION END

NG >> GO TO 8.

8.CHECK TCM

1. Check TCM input/output signal. Refer to AT-75, "

TCM Terminal and Reference Value".

2. If NG, recheck TCM pin terminals for dam age or loose connection with harness connector.

OK or NG

OK >> INSPECTION END

NG >> Repair or replace damaged parts.

Component InspectionINFOID:0000000005928128

A/T FLUID TEMPERATURE SENSOR

• Remove oil pan. Refer to AT-222, "Control Valve Assembly and

Accumulators".

• Check resistance between terminal cord assembly harness con-

nector terminals while changing temperature as shown.

Item Connector Terminal Temperature

[° C ( °F)] Resistance

(Approx.)

A/T fluid temperature sensor F30 6 - 7

AT- 3 8 0 , "

A/T Fluid Temper-

ature Sensor"

SCIA7831E

Revision: May 2010

2011 Versa

Page 135 of 3787

AT-118

< SERVICE INFORMATION >

P0734 4GR INCORRECT RATIO

P0734 4GR INCORRECT RATIO

DescriptionINFOID:0000000005928158

• This malfunction will not be detected while the OD OFF indicator lamp is indicating another self-diagnosismalfunction.

• This malfunction is detected when the A/T does not shif t into fourth gear position or the torque converter

clutch does not lock up as instructed by the TCM. This is not caused by electrical malfunction (circuits open

or shorted) but by mechanical malfunction such as c ontrol valve sticking, improper solenoid valve operation,

malfunctioning oil pump or torque converter clutch, etc.

CONSULT-III Reference Value in Data Monitor ModeINFOID:0000000005928159

Remarks: Specification data are reference values.

On Board Diagn osis LogicINFOID:0000000005928160

• This is an OBD-II self-diagnostic item.

• Diagnostic trouble code “P0734 4GR INCORRECT RATIO” with CONSULT-III is detected when A/T cannot

be shifted to the 4GR position even if electrical circuit is good.

• This diagnosis monitors actual gear position by checki ng the torque converter slip ratio calculated by TCM

as follows:

Torque converter slip ratio = A x C/B

A: Output shaft revolution signal from output speed sensor

B: Engine speed signal from ECM

C: Gear ratio determined as gear position which TCM supposes

If the actual gear position is much lower than the pos ition (4th) supposed by TCM, the slip ratio will be much

less than normal. In case the ratio does not reach t he specified value, TCM judges this diagnosis malfunc-

tion.

This malfunction will be caused when shift solenoid valve A is stuck open or shift solenoid valve B is stuck

closed.

• Gear positions supposed by TCM are as follows.

In case of gear position with no malfunctions: 1, 2, 3 and 4 positions

In case of gear position with shift so lenoid valve A stuck open: 2, 2, 3 and 3* positions

In case of gear position with shift sol enoid valve B stuck closed: 1, 2, 2 and 1* positions to each gear position

above

*: “P0734 4GR INCORRECT RATIO” is detected.

Possible CauseINFOID:0000000005928161

• Shift solenoid valve A

• Shift solenoid valve B

• Line pressure solenoid valve

• Each clutch

• Hydraulic control circuit

DTC Confirmation ProcedureINFOID:0000000005928162

CAUTION:

• Always drive vehicle at a safe speed.

• If performing this “DTC Confirmation Procedure” again, always turn ignition switch OFF and wait at

least 10 seconds before continuing.

After the repair, perform the following proc edure to confirm the malfunction is eliminated.

Gear position123 4

Shift solenoid valve A ON (Closed)OFF (Open)OFF (Open)ON (Closed)

Shift solenoid valve B ON (Closed)ON (Closed) OFF (Open)OFF (Open)

Item name Condition Display value (Approx.)

LINE PRES DTY Small throttle opening (Low line pressure) ⇔

Large

throttle opening (High line pressure) 0%

⇔ 94%

Revision: May 2010 2011 Versa

Page 145 of 3787

AT-128

< SERVICE INFORMATION >

P0744 TORQUE CONVERTER

P0744 TORQUE CONVERTER

DescriptionINFOID:0000000005928172

• This malfunction will not be detected while the OD OFF indicator lamp is indicating another self-diagnosismalfunction.

• This malfunction is detected when the A/T does not shif t into fourth gear position or the torque converter

clutch does not lock-up as instructed by the TCM. This is not caused by electrical malfunction (circuits open

or shorted) but by mechanical malfunction such as c ontrol valve sticking, improper solenoid valve operation,

malfunctioning oil pump or torque converter clutch, etc.

CONSULT-III Reference Value in Data Monitor ModeINFOID:0000000005928173

Remarks: Specification data are reference values.

On Board Diagn osis LogicINFOID:0000000005928174

• This is an OBD-II self-diagnostic item.

• Diagnostic trouble code “P0744 T/C CLUTCH FNCTN” wit h CONSULT-III is detected when A/T cannot per-

form lock-up even if electrical circuit is good.

• This diagnosis monitors actual gear position by checki ng the torque converter slip ratio calculated by TCM

as follows:

Torque converter slip ratio = A x C/B

A: Output shaft revolution signal from output speed sensor

B: Engine speed signal from ECM

C: Gear ratio determined as gear position which TCM supposes

If the actual gear position is much lower than the pos ition (4th) supposed by TCM, the slip ratio will be much

less than normal. In case the ratio does not reach t he specified value, TCM judges this diagnosis malfunc-

tion.

This malfunction will be caused when shift solenoid valve B is stuck closed.

• Gear positions supposed by TCM are as follows.

In case of gear position with no malfunctions: 1, 2, 3 and 4 positions

In case of gear position with shift solenoid valve B stuc k closed: 1, 2, 2 and 1* positions to each gear position

above

*: “P0744 T/C CLUTCH FNCTN” is detected.

Possible CauseINFOID:0000000005928175

• Line pressure solenoid valve

• Torque converter clutch solenoid valve

• Each clutch

• Hydraulic control circuit

DTC Confirmation ProcedureINFOID:0000000005928176

CAUTION:

• Always drive vehicle at a safe speed.

• If performing this “DTC Confirmation Procedure” again, always turn ignition switch OFF and wait at

least 10 seconds before continuing.

After the repair, perform the following proc edure to confirm the malfunction is eliminated.

WITH CONSULT-III

1. Start engine and select “DATA MONITOR” m ode for “TRANSMISSION” with CONSULT-III.

2. Touch “START”.

3. Make sure that output voltage of A/T fluid temperature sensor is within the range below.

FLUID TEMP SE: 0.4 - 1.5 V

If out of range, drive vehicle to decrease voltage (warm up the fluid) or stop engine to increase voltage

(cool down the fluid).

4. Select “TCC S/V FNCTN P0744” of “DTC & SR T CONFIRMATION” mode for “TRANSMISSION” with

CONSULT-III and touch “START”.

Item name Condition Display value (Approx)

TCC S/V DUTY Lock-up OFF ⇔ Lock-up ON 4% ⇔ 94%

Revision: May 2010 2011 Versa

Page 150 of 3787

P0745 PRESSURE CONTROL SOLENOID AAT-133

< SERVICE INFORMATION >

DE

F

G H

I

J

K L

M A

B

AT

N

O P

P0745 PRESSURE CONTROL SOLENOID A

DescriptionINFOID:0000000005928178

The line pressure solenoid valve regulates the oil pum p discharge pressure to suit the driving condition in

response to signals sent from the TCM.

The line pressure duty cycle value is not constant when the closed throttle po sition switch is ON. To

confirm the line pressure duty cycle at low-pressure, the accelerator (throttle) sh ould be open until the

closed throttle position switch is OFF.

CONSULT-III Reference Val ue in Data Monitor ModeINFOID:0000000005928179

Remarks: Specification data are reference values.

On Board Diagnosis LogicINFOID:0000000005928180

• This is an OBD-II self-diagnostic item.

• Diagnostic trouble code “P0745 PC SOLENOID A” with CO NSULT-III or 11th judgement flicker without CON-

SULT-III is detected when TCM detects an improper volt age drop while it tries to operate the solenoid valve.

Possible CauseINFOID:0000000005928181

• Harness or connector

(The solenoid circuit is open or shorted.)

• Line pressure solenoid valve

DTC Confirmation ProcedureINFOID:0000000005928182

CAUTION:

If performing this “DTC Confirmati on Procedure” again, always turn ignition switch OFF and wait at

least 10 seconds before continuing.

After the repair, perform the following procedure to confirm the malfunction is eliminated.

WITH CONSULT-III

1. Turn ignition switch ON and select “DATA MO NITOR” mode for “TRANSMISSION” with CONSULT-III.

2. Touch “START”.

3. Depress accelerator pedal completely and wait at least 1 second.

4. If the check result is NG, go to AT-135, "

Diagnosis Procedure" .

WITH GST

Follow the procedure “WITH CONSULT-III”.

WITHOUT CONSULT-III

1. Start engine.

2. With brake pedal depressed, shift the lever from “P” →“N” →“D” →“N” →“P” positions.

3. Perform self-diagnosis. Refer to AT-82, "

Diagnosis Procedure without CONSULT-III" .

4. If the check result is NG, go to AT-135, "

Diagnosis Procedure" .

Item nameCondition Display value (Approx.)

LINE PRES DTY Small throttle opening (Low line pressure)

⇔ Large

throttle opening (High line pressure) 0%

⇔ 94%

Revision: May 2010 2011 Versa

Page 177 of 3787

AT-160

< SERVICE INFORMATION >

BATT/FLUID TEMP SEN

OK >> GO TO 7.

NG >> Repair open circuit or short to ground or short to power in harness or connectors.

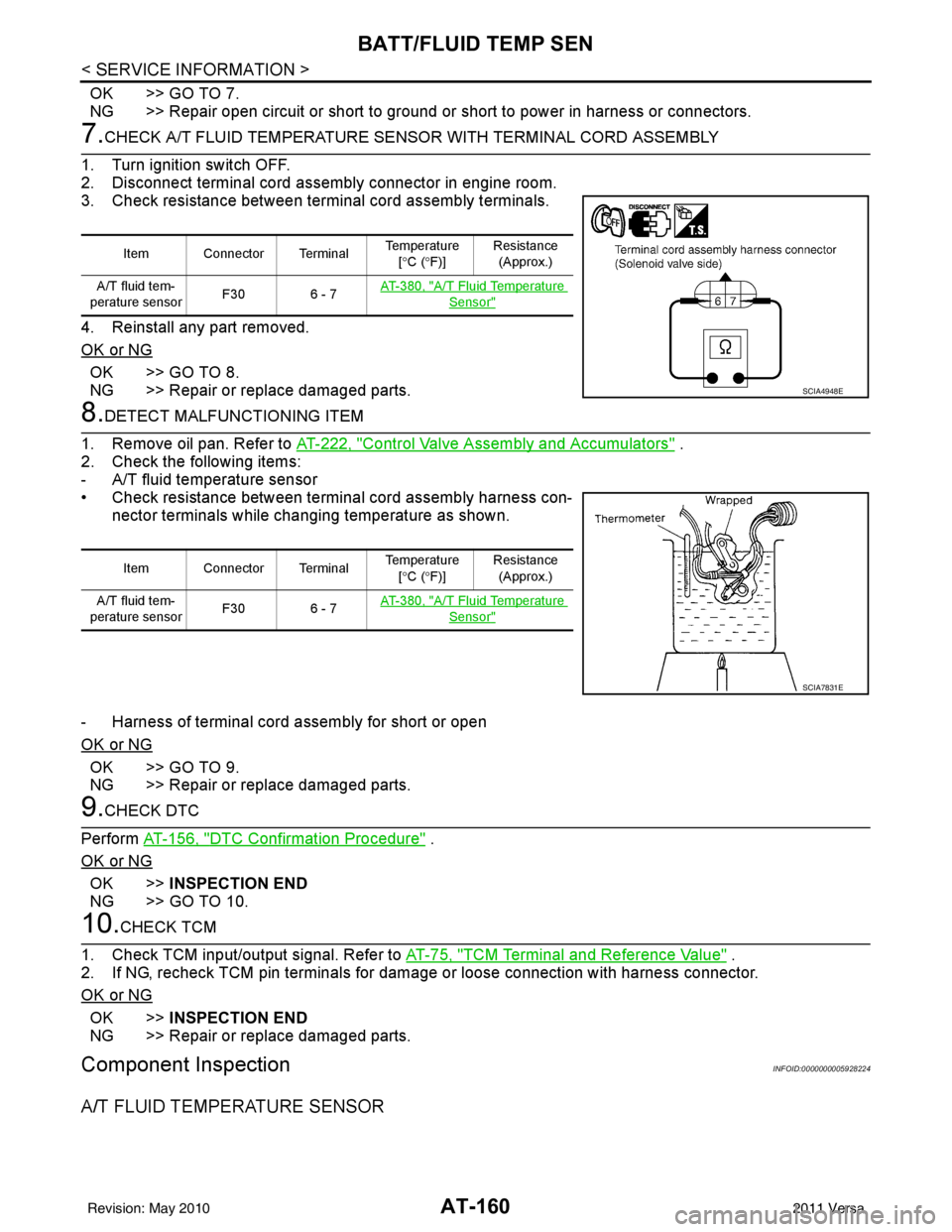

7.CHECK A/T FLUID TEMPERATURE SENSOR WITH TERMINAL CORD ASSEMBLY

1. Turn ignition switch OFF.

2. Disconnect terminal cord assembly connector in engine room.

3. Check resistance between terminal cord assembly terminals.

4. Reinstall any part removed.

OK or NG

OK >> GO TO 8.

NG >> Repair or replace damaged parts.

8.DETECT MALFUNCTIONING ITEM

1. Remove oil pan. Refer to AT-222, "

Control Valve Assembly and Accumulators" .

2. Check the following items:

- A/T fluid temperature sensor

• Check resistance between terminal cord assembly harness con- nector terminals while changing temperature as shown.

- Harness of terminal cord assembly for short or open

OK or NG

OK >> GO TO 9.

NG >> Repair or replace damaged parts.

9.CHECK DTC

Perform AT-156, "

DTC Confirmation Procedure" .

OK or NG

OK >> INSPECTION END

NG >> GO TO 10.

10.CHECK TCM

1. Check TCM input/output signal. Refer to AT-75, "

TCM Terminal and Reference Value" .

2. If NG, recheck TCM pin terminals for damage or loose connection with harness connector.

OK or NG

OK >> INSPECTION END

NG >> Repair or replace damaged parts.

Component InspectionINFOID:0000000005928224

A/T FLUID TEMPERATURE SENSOR

Item Connector Terminal Temperature

[° C ( °F)] Resistance

(Approx.)

A/T fluid tem-

perature sensor F30 6 - 7 AT- 3 8 0 , "

A/T Fluid Temperature

Sensor"

SCIA4948E

Item Connector Terminal Temperature

[° C ( °F)] Resistance

(Approx.)

A/T fluid tem-

perature sensor F30 6 - 7 AT- 3 8 0 , "

A/T Fluid Temperature

Sensor"

SCIA7831E

Revision: May 2010

2011 Versa

Page 178 of 3787

BATT/FLUID TEMP SENAT-161

< SERVICE INFORMATION >

DE

F

G H

I

J

K L

M A

B

AT

N

O P

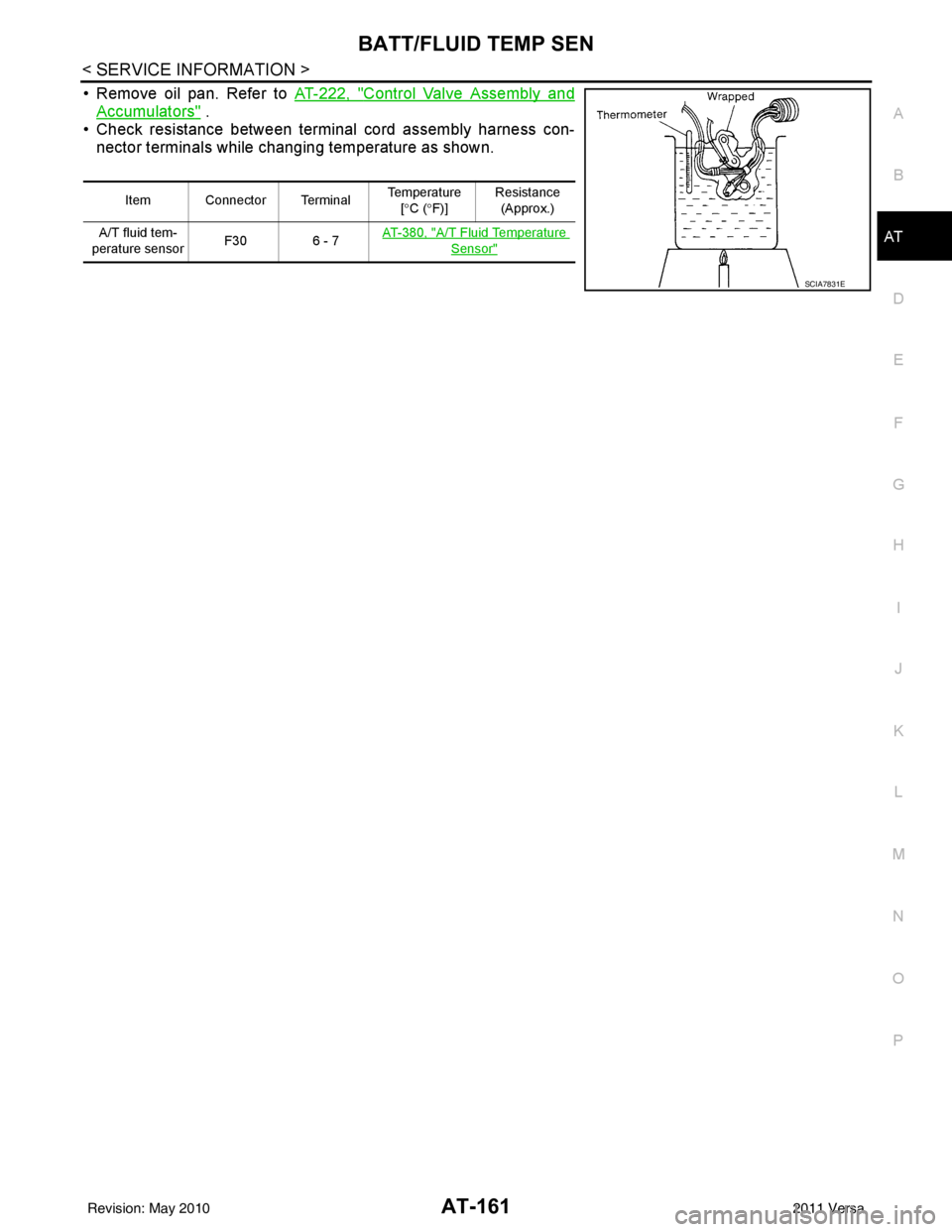

• Remove oil pan. Refer to AT-222, "Control Valve Assembly and

Accumulators" .

• Check resistance between terminal cord assembly harness con-

nector terminals while changing temperature as shown.

Item Connector Terminal Temperature

[° C ( °F)] Resistance

(Approx.)

A/T fluid tem-

perature sensor F30 6 - 7 AT- 3 8 0 , "

A/T Fluid Temperature

Sensor"

SCIA7831E

Revision: May 2010

2011 Versa

Page 200 of 3787

TROUBLE DIAGNOSIS FOR SYMPTOMSAT-183

< SERVICE INFORMATION >

DE

F

G H

I

J

K L

M A

B

AT

N

O P

NG >> 1. Check transmission range switch (Refer to test group 1.) again after adjusting transmission

range switch (Refer to AT-225

).

- If OK, INSPECTION END

- If NG, repair or replace transmission range switch. Refer to AT-225, "

Transmission Range

Switch" .

3.CHECK STARTING SYSTEM

Check starting system. Refer to SC-9

.

OK or NG

OK >> INSPECTION END

NG >> Repair or replace damaged parts.

In "P" Position, Vehicle Moves Forward or Backward When PushedINFOID:0000000005928249

SYMPTOM:

Vehicle moves when it is pushed forward or backward with selector lever in “P” position.

DIAGNOSTIC PROCEDURE

1.CHECK A/T POSITION

Check A/T position. Refer to AT-217, "

Checking of A/T Position" .

OK or NG

OK >> GO TO 2.

NG >> Adjust A/T position. Refer to AT-217, "

Adjustment of A/T Position" .

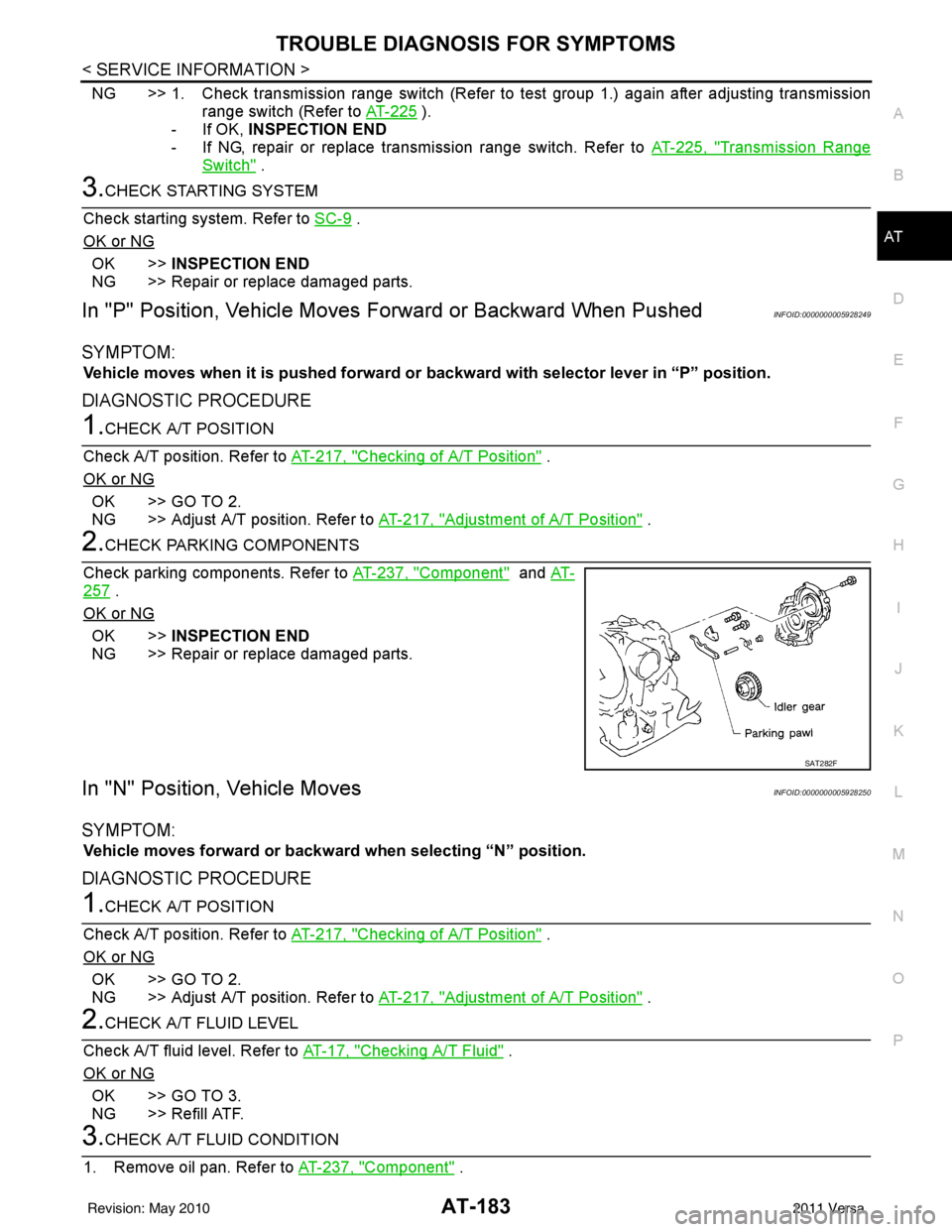

2.CHECK PARKING COMPONENTS

Check parking components. Refer to AT-237, "

Component" and AT-

257 .

OK or NG

OK >> INSPECTION END

NG >> Repair or replace damaged parts.

In "N" Position, Vehicle MovesINFOID:0000000005928250

SYMPTOM:

Vehicle moves forward or backwar d when selecting “N” position.

DIAGNOSTIC PROCEDURE

1.CHECK A/T POSITION

Check A/T position. Refer to AT-217, "

Checking of A/T Position" .

OK or NG

OK >> GO TO 2.

NG >> Adjust A/T position. Refer to AT-217, "

Adjustment of A/T Position" .

2.CHECK A/T FLUID LEVEL

Check A/T fluid level. Refer to AT-17, "

Checking A/T Fluid" .

OK or NG

OK >> GO TO 3.

NG >> Refill ATF.

3.CHECK A/T FLUID CONDITION

1. Remove oil pan. Refer to AT-237, "

Component" .

SAT282F

Revision: May 2010 2011 Versa

Page 201 of 3787

AT-184

< SERVICE INFORMATION >

TROUBLE DIAGNOSIS FOR SYMPTOMS

2. Check A/T fluid condition. Refer to AT-51, "Inspections Before Trouble Diagnosis" .

OK or NG

OK >> GO TO 5.

NG >> GO TO 4.

4.DETECT MALFUNCTIONING ITEM

1. Disassemble A/T. Refer to AT-257, "

Disassembly" .

2. Check the following items:

- Forward clutch assembly. Refer to AT-307, "

Forward and Overrun Clutches" .

- Overrun clutch assembly. Refer to AT-307, "

Forward and Overrun Clutches" .

- Reverse clutch assembly. Refer to AT-297, "

Reverse Clutch" .

OK or NG

OK >> GO TO 5.

NG >> Repair or replace damaged parts.

5.CHECK SYMPTOM

Check again. Refer to AT-56, "

Check at Idle" .

OK or NG

OK >> INSPECTION END

NG >> GO TO 6.

6.CHECK TCM

1. Check TCM input/output signals. Refer to AT-75, "

TCM Terminal and Reference Value" .

2. If NG, recheck TCM pin terminals for damage or loose connection with harness connector.

OK or NG

OK >> INSPECTION END

NG >> Repair or replace damaged parts.

Large Shock "N" → "R" PositionINFOID:0000000005928251

SYMPTOM:

There is a large shock when cha nging from “N” to “R” position.

DIAGNOSTIC PROCEDURE

1.CHECK SELF-DIAGNOSTIC RESULTS

Perform self-diagnosis. Refer to AT-77, "

CONSULT-III Function (TRANSMISSION)" or AT-82, "Diagnosis Pro-

cedure without CONSULT-III" .

Is any malfunction detected by self-diagnostic results?

YES >> Check the malfunctioning system. Refer to AT-77, "CONSULT-III Function (TRANSMISSION)" or

AT-82, "

Diagnosis Procedure without CONSULT-III" .

NO >> GO TO 2.

2.CHECK LINE PRESSURE

Check line pressure at idle with selector lever in “D” position. Refer to AT-51, "

Inspections Before Trouble

Diagnosis" .

OK or NG

OK >> GO TO 4.

NG >> GO TO 3.

3.DETECT MALFUNCTIONING ITEM

1. Remove control valve assembly. Refer to AT-222, "

Control Valve Assembly and Accumulators" .

2. Check the following items:

- Valves to control line pressure (Pressure regulator valve, pressure modifier valve, pilot valve and pilot fil- ter)

- Line pressure solenoid valve

- Oil pump assembly. Refer to AT-278, "

Oil Pump" .

OK or NG

Revision: May 2010 2011 Versa