wheel NISSAN LATIO 2011 Service Service Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2011, Model line: LATIO, Model: NISSAN LATIO 2011Pages: 3787, PDF Size: 78.35 MB

Page 480 of 3787

![NISSAN LATIO 2011 Service Service Manual TELEPHONEAV-83

< SERVICE INFORMATION > [AUDIO WITH NAVIGATION]

C

D

E

F

G H

I

J

L

M A

B

AV

N

O P

WorkflowINFOID:0000000006216720

Power Supply and Ground Cir cuit Inspection for Bluetooth Control UnitIN NISSAN LATIO 2011 Service Service Manual TELEPHONEAV-83

< SERVICE INFORMATION > [AUDIO WITH NAVIGATION]

C

D

E

F

G H

I

J

L

M A

B

AV

N

O P

WorkflowINFOID:0000000006216720

Power Supply and Ground Cir cuit Inspection for Bluetooth Control UnitIN](/img/5/57357/w960_57357-479.png)

TELEPHONEAV-83

< SERVICE INFORMATION > [AUDIO WITH NAVIGATION]

C

D

E

F

G H

I

J

L

M A

B

AV

N

O P

WorkflowINFOID:0000000006216720

Power Supply and Ground Cir cuit Inspection for Bluetooth Control UnitINFOID:0000000006216721

1.CHECK FUSES

Make sure the following fuses for the Bluetooth control unit are not blown.

OK or NG

OK >> GO TO 2.

NG >> If fuse is blown, be sure to eliminate cause of malfunction before installing new fuse. Refer to PG-

6, "Wiring Diagram - POWER -".

2.CHECK POWER SUPPLY CIRCUIT

1. Disconnect Bluetooth control unit connector B121.

2. Check voltage between connector terminals and ground as fol- lows.

OK or NG

OK >> GO TO 3.

NG >> Check harness for open between Bluetooth control unit and fuse.

3.CHECK GROUND CIRCUITS

1. Turn ignition switch OFF.

Failure Message Action

“Internal failure” Replace Bluetooth control unit. Refer to AV- 8 6 , "

Removal and Installation".

“Bluetooth antenna open” 1. Inspect harness connection.

2. Replace Bluetooth antenna. Refer to AV- 8 6 , "

Removal and Installation".

“Bluetooth antenna shorted”

“Phone/Send for Hands Free System is stuck” Check steering wheel audio control switches. Refer to AV- 6 9 , "

Steering Switch

Check".

“Phone/End for the Hands Free System is stuck”

“Microphone test” (fai led interactive test) 1. Inspect harness between Bluetooth control unit and microphone.

2. Replace microphone. Refer to

AV-86, "

Removal and Installation".

Te r m i n a l s

Ignition Switch Fuse No.

Connector Terminal

B121 1

All positions27

2 ACC/ON20

3 ON/START3

Terminals Ignition switch position

(+) (–) OFF ACC ON

Connector Terminal

B121 1

Ground Battery

voltage Battery

voltage Battery

voltage

20 VBattery

voltage Battery

voltage

30 V0V Battery

voltage

WKIA4389E

Revision: May 2010 2011 Versa

Page 481 of 3787

![NISSAN LATIO 2011 Service Service Manual AV-84

< SERVICE INFORMATION >[AUDIO WITH NAVIGATION]

TELEPHONE

2. Check continuity between the following Bluetooth control unit

terminals and ground.

OK or NG

OK >> Inspection End.

NG >> Repair or rep NISSAN LATIO 2011 Service Service Manual AV-84

< SERVICE INFORMATION >[AUDIO WITH NAVIGATION]

TELEPHONE

2. Check continuity between the following Bluetooth control unit

terminals and ground.

OK or NG

OK >> Inspection End.

NG >> Repair or rep](/img/5/57357/w960_57357-480.png)

AV-84

< SERVICE INFORMATION >[AUDIO WITH NAVIGATION]

TELEPHONE

2. Check continuity between the following Bluetooth control unit

terminals and ground.

OK or NG

OK >> Inspection End.

NG >> Repair or replace harness.

Steering Wheel Audio Control Switch Does Not OperateINFOID:0000000006216722

Refer to AV-69, "Steering Switch Check".

Voice Activated Control Function Does Not OperateINFOID:0000000006216723

NOTE:

Even under the normal condition, Bluetooth voice gui dance may not occur when pressing steering wheel

audio control switch.

BLUETOOTH VOICE GUIDANCE IS HEARD WH EN PRESSING STEERING WHEEL AUDIO CON-

TROL SWITCH

1.CHECK HARNESS BETWEEN BLUETOOTH CONT ROL UNIT AND BLUETOOTH MICROPHONE

1. Turn ignition switch OFF.

2. Disconnect Bluetooth control unit connector and Bluetooth microphone connector.

3. Check continuity between Bluetooth control unit connector B121 (A) and Bluetooth microphone connector R15 (B).

4. Check continuity between Bluetooth control unit harness con- nector B121 and ground.

OK or NG

OK >> GO TO 2.

NG >> Repair harness or connector.

2.CHECK BLUETOOTH MICROPHONE POWER SUPPLY

1. Connect Bluetooth control unit connector and Bluetooth microphone connector.

2. Turn ignition switch ON.

Te r m i n a l s Continuity

Connector Terminal—

B121 4

Ground Yes

21

27

AWNIA2213ZZ

Te r m i n a l s

Continuity

Connector Terminal Connector Terminal

A: B121 7

B: R15 1

Ye s

82

29 4

Te r m i n a l s Continuity

Connector Terminal —

A: B121 7

Ground No

8

29

WKIA5795E

Revision: May 2010 2011 Versa

Page 482 of 3787

![NISSAN LATIO 2011 Service Service Manual TELEPHONEAV-85

< SERVICE INFORMATION > [AUDIO WITH NAVIGATION]

C

D

E

F

G H

I

J

L

M A

B

AV

N

O P

3. Check voltage between Bluetooth microphone connector R15 terminal 4 and ground.

YES or NO

YES >> GO T NISSAN LATIO 2011 Service Service Manual TELEPHONEAV-85

< SERVICE INFORMATION > [AUDIO WITH NAVIGATION]

C

D

E

F

G H

I

J

L

M A

B

AV

N

O P

3. Check voltage between Bluetooth microphone connector R15 terminal 4 and ground.

YES or NO

YES >> GO T](/img/5/57357/w960_57357-481.png)

TELEPHONEAV-85

< SERVICE INFORMATION > [AUDIO WITH NAVIGATION]

C

D

E

F

G H

I

J

L

M A

B

AV

N

O P

3. Check voltage between Bluetooth microphone connector R15 terminal 4 and ground.

YES or NO

YES >> GO TO 3.

NO >> Replace Bluetooth control unit. Refer to AV-86,

"Removal and Installation".

3.CHECK MIC. SIGNAL

1. Check signal between Bluetooth control unit harness connector B121 terminals 7 and 8.

OK or NG

OK >> Replace Bluetooth control unit. Refer to AV-86, "Removal and Installation".

NG >> Replace Bluetooth microphone. Refer to AV-86, "

Removal and Installation".

BLUETOOTH VOICE GUIDANCE IS NOT HEARD WHEN PRESSING STEERING WHEEL AUDIO

CONTROL SWITCH

1.CHECK STEERING WHEEL AUDIO CONTROL SWITCH CIRCUIT

Refer to AV-69, "

Steering Switch Check".

OK or NG

OK >> GO TO 2.

NG >> Replace applicable parts.

2.CHECK BLUETOOTH VOICE SIGNAL CIRCUIT

1. Turn ignition switch OFF.

2. Disconnect Bluetooth control unit c onnector and AV control unit connector.

3. Check continuity between Bluetooth control unit harness con-

nector B121 (A) and AV control unit harness connector M70 (B).

4. Check continuity between Bluetooth control unit harness con- nector B121 (A) and ground.

OK or NG

4 - Ground : Approx. 5 V

WKIA5796E

7 – 8:When giving a voice

LKIA0780EPKIB5037J

Te r m i n a l s

Continuity

Connector Terminal Connector Terminal

A: B121 9

B: M70 43

Ye s

10 42

Te r m i n a l s Continuity

Connector Terminal —

A: B121 9

Ground No

10

AWNIA2195ZZ

Revision: May 2010 2011 Versa

Page 491 of 3787

BCS-1

ELECTRICAL

C

DE

F

G H

I

J

L

M

SECTION BCS

A

B

BCS

N

O P

CONTENTS

BODY CONTROL SYSTEM

SERVICE INFORMATION .. ..........................2

PRECAUTIONS .............................................. .....2

Precaution for Supplemental Restraint System

(SRS) "AIR BAG" and "SEAT BELT PRE-TEN-

SIONER" ............................................................. ......

2

Precaution Necessary for Steering Wheel Rota-

tion After Battery Disconnect ............................... ......

2

BCM (BODY CONTROL MODULE) ....................4

System Description ............................................. ......4

CAN Communication System Description .................8

Schematic ............................................................ .....9

BCM Terminal Arrangement ....................................11

Terminal and Reference Value for BCM ..................12

BCM Power Supply and Ground Circuit Inspection

....

16

CONSULT-III Function (BCM) .................................17

CAN Communication Inspection Using CON-

SULT-III (Self-Diagnosis) ..................................... ....

18

Configuration ...........................................................19

Removal and Installation of BCM ............................19

Revision: May 2010 2011 Versa

Page 492 of 3787

BCS-2

< SERVICE INFORMATION >

PRECAUTIONS

SERVICE INFORMATION

PRECAUTIONS

Precaution for Supplemental Restraint System (SRS) "AIR BAG" and "SEAT BELT

PRE-TENSIONER"

INFOID:0000000005929254

The Supplemental Restraint System such as “A IR BAG” and “SEAT BELT PRE-TENSIONER”, used along

with a front seat belt, helps to reduce the risk or severity of injury to the driver and front passenger for certain

types of collision. This system includes seat belt switch inputs and dual stage front air bag modules. The SRS

system uses the seat belt switches to determine the front air bag deployment, and may only deploy one front

air bag, depending on the severity of a collision and w hether the front occupants are belted or unbelted.

Information necessary to service the system safely is included in the SRS and SB section of this Service Man-

ual.

WARNING:

• To avoid rendering the SRS inopera tive, which could increase the risk of personal injury or death in

the event of a collision which would result in air bag inflation, all maintenance must be performed by

an authorized NISSAN/INFINITI dealer.

• Improper maintenance, including incorrect removal and installation of the SRS can lead to personal

injury caused by unintent ional activation of the system. For re moval of Spiral Cable and Air Bag

Module, see the SRS section.

• Do not use electrical test equipmen t on any circuit related to the SRS unless instructed to in this

Service Manual. SRS wiring harn esses can be identified by yellow and/or orange harnesses or har-

ness connectors.

PRECAUTIONS WHEN USING POWER TOOLS (AIR OR ELECTRIC) AND HAMMERS

WARNING:

• When working near the Airbag Diagnosis Sensor Unit or other Airbag System sensors with the Igni-

tion ON or engine running, DO NOT use air or electri c power tools or strike near the sensor(s) with a

hammer. Heavy vibration could activate the sensor( s) and deploy the air bag(s), possibly causing

serious injury.

• When using air or electric power tools or hammers , always switch the Ignition OFF, disconnect the

battery, and wait at least 3 minu tes before performing any service.

Precaution Necessary for Steering W heel Rotation After Battery Disconnect

INFOID:0000000006413290

NOTE:

• This Procedure is applied only to models with Intelligent Key system and NATS (NISSAN ANTI-THEFT SYS-

TEM).

• Remove and install all control units after disconnecting both battery cables with the ignition knob in the

″LOCK ″ position.

• Always use CONSULT-III to perform self-diagnosis as a part of each function inspection after finishing work.

If DTC is detected, perform trouble diagnosis according to self-diagnostic results.

For models equipped with the Intelligent Key system and NATS, an electrically controlled steering lock mech-

anism is adopted on the key cylinder.

For this reason, if the battery is disconnected or if the battery is discharged, the steering wheel will lock and

steering wheel rotation will become impossible.

If steering wheel rotation is required when battery pow er is interrupted, follow the procedure below before

starting the repair operation.

OPERATION PROCEDURE

1. Connect both battery cables. NOTE:

Supply power using jumper cables if battery is discharged.

2. Use the Intelligent Key or mechanical key to turn the ignition switch to the ″ACC ″ position. At this time, the

steering lock will be released.

3. Disconnect both battery cables. The steering lock will remain released and the steering wheel can be rotated.

4. Perform the necessary repair operation.

Revision: May 2010 2011 Versa

Page 511 of 3787

BL-1

BODY

C

DE

F

G H

J

K L

M

SECTION BL

A

B

BL

N

O P

CONTENTS

BODY, LOCK & SECURITY SYSTEM

SERVICE INFORMATION .. ..........................4

PRECAUTIONS .............................................. .....4

Precaution for Supplemental Restraint System

(SRS) "AIR BAG" and "SEAT BELT PRE-TEN-

SIONER" ............................................................. ......

4

Precaution Necessary for Steering Wheel Rota-

tion After Battery Disconnect ............................... ......

4

Precaution for Procedure without Cowl Top Cover ......5

Precaution for Work ..................................................5

PREPARATION ...................................................6

Special Service Tool ........................................... ......6

Commercial Service Tool ..........................................6

SQUEAK AND RATTLE TROUBLE DIAG-

NOSES ................................................................

7

Work Flow ........................................................... ......7

Generic Squeak and Rattle Troubleshooting ............9

Diagnostic Worksheet .............................................11

HOOD .................................................................13

Fitting Adjustment ............................................... ....13

Removal and Installation .........................................14

Removal and Installation of Hood Lock Control .. ....15

Hood Lock Control Inspection .................................17

RADIATOR CORE SUPPORT ....................... ....19

Removal and Installation .........................................19

FRONT FENDER ................................................21

Removal and Installation .........................................21

POWER DOOR LOCK SYSTEM .................... ....22

Component Parts and Harness Connector Loca-

tion ...................................................................... ....

22

System Description .................................................23

CAN Communication System Description ...............25

Schematic ...............................................................26

Wiring Diagram - D/LOCK - .....................................27

Schematic ...............................................................31

Wiring Diagram - D/LOCK - .....................................32

Terminal and Reference Value for BCM ..................37

Work Flow ............................................................ ....41

CONSULT-III Function (BCM) .................................41

Trouble Diagnosis Symptom Chart ...................... ....43

BCM Power Supply and Ground Circuit Inspection

....

43

Door Switch Check (Hatchback) ..............................44

Door Switch Check (Sedan) ....................................47

Key Switch (Insert) Check .......................................48

Door Lock and Unlock Switch Check ......................49

Front Door Lock Assembly LH (Actuator) Check .....52

Front Door Lock Assembly RH (Actuator) Check ....53

Rear Door Lock Actuator LH/RH Check .............. ....54

Front Door Lock Assembly LH (Key Cylinder

Switch) Check ..........................................................

54

Passenger Select Unlock Relay Circuit Inspection

(With Intelligent Key) ........................................... ....

56

REMOTE KEYLESS ENTRY SYSTEM .............58

Component Parts and Harness Connector Loca-

tion ...........................................................................

58

System Description ..................................................58

CAN Communication System Description ...............60

Schematic ................................................................61

Wiring Diagram - KEYLES - ....................................62

Terminal and Reference Value for BCM ..................65

How to Perform Trouble Diagnosis ...................... ....69

Preliminary Check ...................................................69

CONSULT-III Function (BCM) .................................69

Work Flow ............................................................ ....71

Trouble Diagnosis Symptom Chart ..........................71

Keyfob Battery and Function Check ........................72

ACC Switch Circuit Check .......................................74

Door Switch Check (Hatchback) ..............................74

Door Switch Check (Sedan) ....................................76

Key Switch (Insert) Check .......................................78

Hazard Function Check ...........................................79

Horn Function Check ...............................................79

Interior Lamp and Ignition Keyhole Illumination

Function Check ........................................................

80

Remote Keyless Entry Receiver Check ...................80

Revision: May 2010 2011 Versa

Page 514 of 3787

BL-4

< SERVICE INFORMATION >

PRECAUTIONS

SERVICE INFORMATION

PRECAUTIONS

Precaution for Supplemental Restraint System (SRS) "AIR BAG" and "SEAT BELT

PRE-TENSIONER"

INFOID:0000000005929267

The Supplemental Restraint System such as “A IR BAG” and “SEAT BELT PRE-TENSIONER”, used along

with a front seat belt, helps to reduce the risk or severity of injury to the driver and front passenger for certain

types of collision. This system includes seat belt switch inputs and dual stage front air bag modules. The SRS

system uses the seat belt switches to determine the front air bag deployment, and may only deploy one front

air bag, depending on the severity of a collision and w hether the front occupants are belted or unbelted.

Information necessary to service the system safely is included in the SRS and SB section of this Service Man-

ual.

WARNING:

• To avoid rendering the SRS inopera tive, which could increase the risk of personal injury or death in

the event of a collision which would result in air bag inflation, all maintenance must be performed by

an authorized NISSAN/INFINITI dealer.

• Improper maintenance, including incorrect removal and installation of the SRS can lead to personal

injury caused by unintent ional activation of the system. For re moval of Spiral Cable and Air Bag

Module, see the SRS section.

• Do not use electrical test equipmen t on any circuit related to the SRS unless instructed to in this

Service Manual. SRS wiring harn esses can be identified by yellow and/or orange harnesses or har-

ness connectors.

PRECAUTIONS WHEN USING POWER TOOLS (AIR OR ELECTRIC) AND HAMMERS

WARNING:

• When working near the Airbag Diagnosis Sensor Unit or other Airbag System sensors with the Igni-

tion ON or engine running, DO NOT use air or electri c power tools or strike near the sensor(s) with a

hammer. Heavy vibration could activate the sensor( s) and deploy the air bag(s), possibly causing

serious injury.

• When using air or electric power tools or hammers , always switch the Ignition OFF, disconnect the

battery, and wait at least 3 minu tes before performing any service.

Precaution Necessary for Steering W heel Rotation After Battery Disconnect

INFOID:0000000005929268

NOTE:

• This procedure is applied only to models with Intell igent Key system and NVIS/IVIS (NISSAN/INFINITI

VEHICLE IMMOBILIZER SYSTEM - NATS).

• Remove and install all control units after disconnec ting both battery cables with the ignition in the ″LOCK ″

position.

• Always use CONSULT-III to perform self-diagnosis as a part of each function inspection after finishing work.

If DTC is detected, perform trouble diagnosis according to self-diagnostic results.

For models equipped with the Intelligent Key system and NVIS /IVIS, an electrically controlled steering lock

mechanism is adopted on the key cylinder.

For this reason, if the battery is disconnected or if the battery is discharged, the steering wheel will lock and

steering wheel rotation will become impossible.

If steering wheel rotation is required when battery pow er is interrupted, follow the procedure below before

starting the repair operation.

OPERATION PROCEDURE

1. Connect both battery cables. NOTE:

Supply power using jumper cables if battery is discharged.

2. Use the Intelligent Key or mechanical key to turn the ignition switch to the ″ACC ″ position. At this time, the

steering lock will be released.

3. Disconnect both battery cables. The steering lock will remain released and the steering wheel can be rotated.

4. Perform the necessary repair operation.

Revision: May 2010 2011 Versa

Page 598 of 3787

BL-88

< SERVICE INFORMATION >

INTELLIGENT KEY SYSTEM

System Description

INFOID:0000000005929328

• The Intelligent Key system is a system that makes it possible to lock and unlock the door locks (door lock/

unlock function), and start the engine (engine start func tion) by carrying around the Intelligent Key (without

some key operation), which operates based on the results of electronic ID verification using two-way com-

munications between the Intelligent Key and the vehicle (Intelligent Key unit).

• Vehicles equipped with a manual transmission include a key interlock solenoid located in the steering col- umn to prevent accidental shut-off of the ignition sw itch and locking of the steering wheel during driving con-

dition when the vehicle is moving.

CAUTION:

The driver should always carry the Intelligent Key

• Operation of the remote controller buttons on the Inte lligent Key also provides the same functions as the

remote control entry system. (Remote keyless entry functions)

• If an action that does not meet the operating conditions of the Intelligent Key system is taken, the buzzer

goes off to inform the driver. (Warning chime functions)

• When a door lock is locked or unlocked with request switch or remote controller button operation, the hazard

lamps flash and the buzzer (outside vehicle) sounds (Hazard and buzzer reminder function).

• Even if the Intelligent Key battery is completely discharged, the door locks can be locked and unlocked and the engine started with the mechanical key built into the Intelligent Key.

• The settings for each function can be changed with the CONSULT-III.

• If an Intelligent Key is lost, a new Intelligent Key can be registered. A maximum of 4 Intelligent Keys can be registered.

• It has been made possible to diagnose the system and r egister an Intelligent Key with the CONSULT-III.

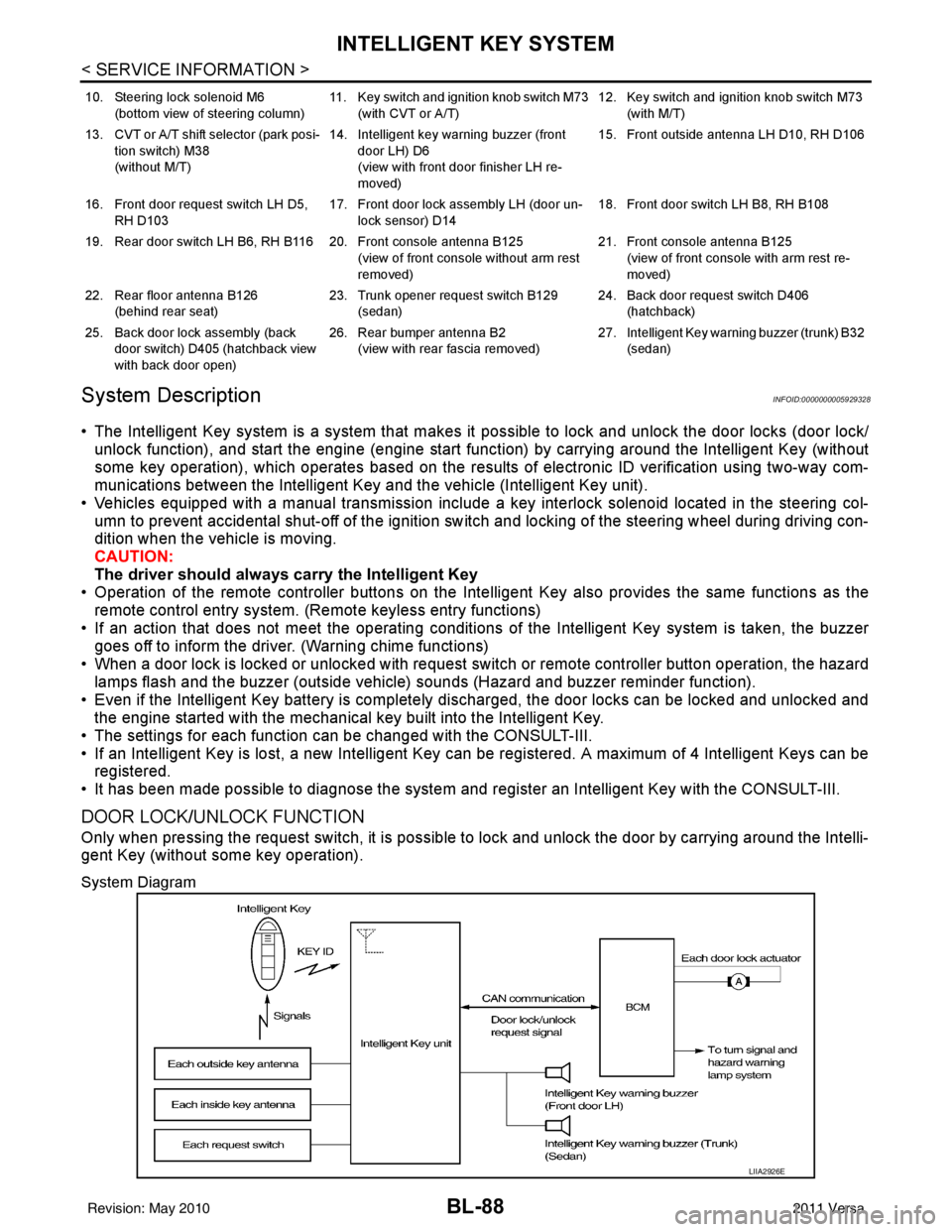

DOOR LOCK/UNLOCK FUNCTION

Only when pressing the request switch, it is possible to lock and unlock the door by carrying around the Intelli-

gent Key (without some key operation).

System Diagram

10. Steering lock solenoid M6

(bottom view of steering column) 11. Key switch and ignition knob switch M73

(with CVT or A/T) 12. Key switch and ignition knob switch M73

(with M/T)

13. CVT or A/T shift selector (park posi- tion switch) M38

(without M/T) 14. Intelligent key warning buzzer (front

door LH) D6

(view with front door finisher LH re-

moved) 15. Front outside antenna LH D10, RH D106

16. Front door request switch LH D5, RH D103 17. Front door lock assembly LH (door un-

lock sensor) D14 18. Front door switch LH B8, RH B108

19. Rear door switch LH B6, RH B116 20. Front console antenna B125 (view of front console without arm rest

removed)21. Front console antenna B125

(view of front console with arm rest re-

moved)

22. Rear floor antenna B126 (behind rear seat) 23. Trunk opener request switch B129

(sedan) 24. Back door request switch D406

(hatchback)

25. Back door lock assembly (back door switch) D405 (hatchback view

with back door open) 26. Rear bumper antenna B2

(view with rear fascia removed) 27. Intelligent Key warn

ing buzzer (trunk) B32

(sedan)

LIIA2926E

Revision: May 2010 2011 Versa

Page 780 of 3787

BL-270

< SERVICE INFORMATION >

BODY REPAIR

6. 1st roof rail assembly

7. Front roof rail assembly

8. Sun roof assembly

9. Front roof rail assembly (if equipped with sunroof)

10. Roof side rail reinforcement (RH & LH)

11. Inner center pillar (RH & LH)

12. Hood assembly

13. Center pillar reinforcement (RH & LH)

14. Front pillar inner (RH & LH)

15. Front pillar upper reinforcement (RH & LH)

16. Front pillar lower reinforcement (RH & LH)

17. Fender (RH & LH)

18. Side body (RH & LH)

19. Side body assembly (RH & LH)

20. Outer sill (RH & LH)

21. Outer sill reinforcement (RH & LH)

22. Front door assembly (RH & LH)

23. Outer front door panel (RH & LH)

24. Outer rear door panel (RH & LH)

25. Rear door assembly (RH & LH)

26. Rear fender (RH & LH)

27. Rear fender assembly (RH & LH)

28. Rear fender corner (RH & LH)

29. Rear fender extension (RH & LH)

30. Rear combination lamp base (RH & LH)

31. Rear pillar inner reinforcement (RH & LH)

32. Rear wheel housing outer (RH & LH)

33. Rear wheel housing inner (RH & LH)

34. Rear spring base assembly (RH & LH)

35. Rear seatback hinge bracket (RH & LH)

36. Rear seatback catch bracket (RH & LH)

37. Rear pillar inner (RH & LH)

38. Rear roof rail reinforcement (RH & LH)

39. Rear roof rail brace (RH & LH)

40. Rear panel

41. Rear bumper fascia lower bracket

42. Rear bumper fascia upper bracket

43. Rear bumper fascia center bracket

44. Rear panel assembly

45. Back door assembly

Revision: May 20102011 Versa

Page 782 of 3787

BL-272

< SERVICE INFORMATION >

BODY REPAIR

7. Front roof rail assembly

8. Sun roof assembly

9. Front roof rail assembly (if equipped with sunroof)

10. Roof side rail reinforcement (RH & LH)

11. Inner center pillar (RH & LH)

12. Hood assembly

13. Center pillar reinforcement (RH & LH)

14. Front pillar inner (RH & LH)

15. Front pillar upper reinforcement (RH & LH)

16. Front pillar lower reinforcement (RH & LH)

17. Fender (RH & LH)

18. Side body (RH & LH)

19. Side body assembly (RH & LH)

20. Outer sill (RH & LH)

21. Outer sill reinforcement (RH & LH)

22. Front door assembly (RH & LH)

23. Outer front door panel (RH & LH)

24. Outer rear door panel (RH & LH)

25. Rear door assembly (RH & LH)

26. Rear fender (RH & LH)

27. Rear fender corner (RH & LH)

28. Rear combination lamp base (RH & LH)

29. Rear wheel housing front extension (RH & LH)

30. Rear wheel housing outer (RH & LH)

31. Rear pillar inner reinforcement (RH & LH)

32. Rear body side inner (RH & LH)

33. Rear wheel housing inner (RH & LH)

34. Rear panel assembly

35. Rear bumper fascia upper bracket

36. Rear bumper fascia center bracket

37. Trunk lid assembly

38. Parcel shelf side (RH & LH)

39. Parcel shelf assembly

40. Rear waist panel

41. Rear bumper fascia lower bracket

Corrosion ProtectionINFOID:0000000005929449

DESCRIPTION

To provide improved corrosion prevention, the following anti-corrosive measures have been implemented in

NISSAN production plants. When repairing or replacing body panels, it is necessary to use the same anti-cor-

rosive measures.

ANTI-CORROSIVE PRECOATED STEEL (GALVANNEALED STEEL)

Revision: May 2010 2011 Versa