change time NISSAN LATIO 2011 Service Manual PDF

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2011, Model line: LATIO, Model: NISSAN LATIO 2011Pages: 3787, PDF Size: 78.35 MB

Page 3125 of 3787

INTERIOR ROOM LAMPLT-93

< SERVICE INFORMATION >

C

DE

F

G H

I

J

L

M A

B

LT

N

O P

INTERIOR ROOM LAMP

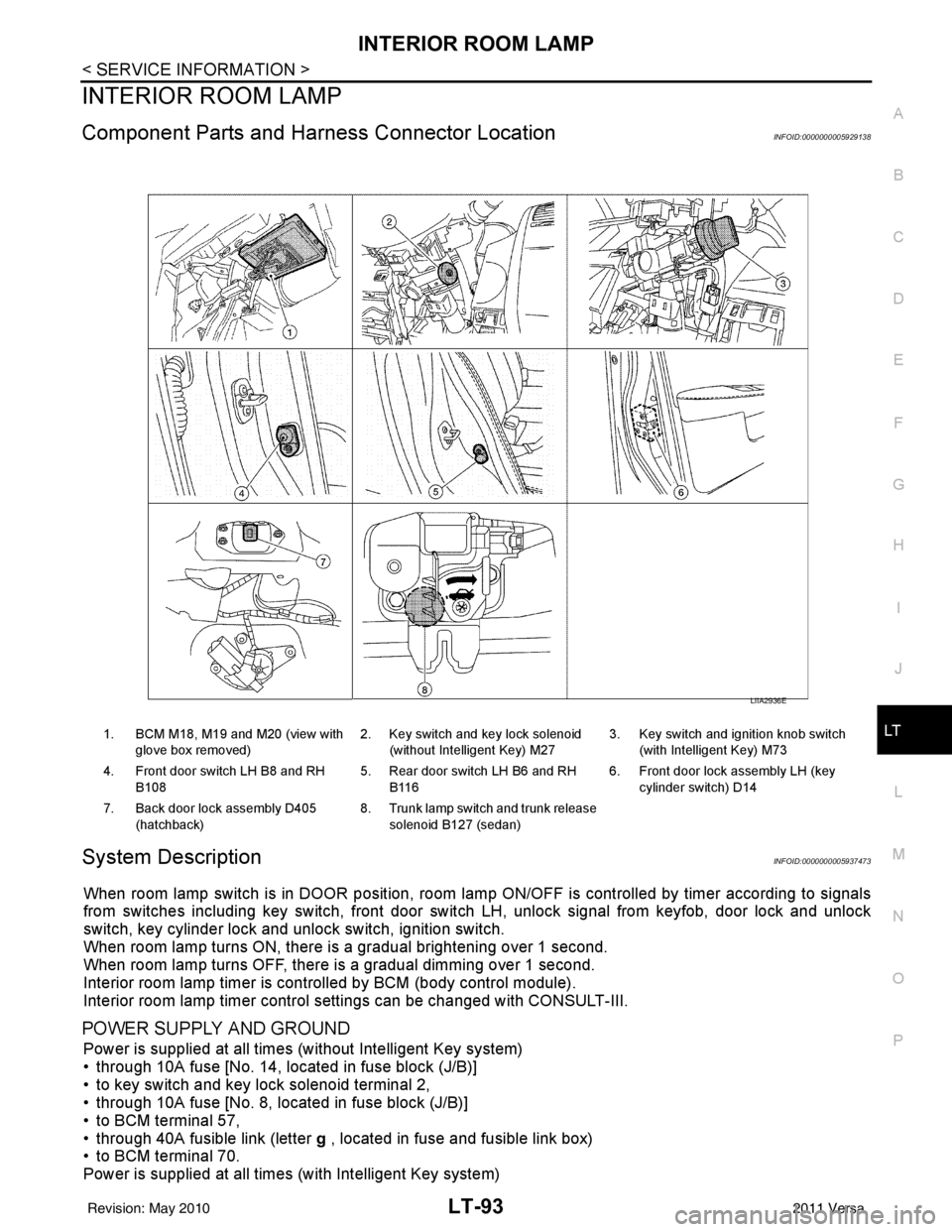

Component Parts and Har ness Connector LocationINFOID:0000000005929138

System DescriptionINFOID:0000000005937473

When room lamp switch is in DOOR position, room la mp ON/OFF is controlled by timer according to signals

from switches including key switch, front door switch LH, unlock signal from keyfob, door lock and unlock

switch, key cylinder lock and unlock switch, ignition switch.

When room lamp turns ON, there is a gradual brightening over 1 second.

When room lamp turns OFF, there is a gradual dimming over 1 second.

Interior room lamp timer is controlled by BCM (body control module).

Interior room lamp timer control settings can be changed with CONSULT-III.

POWER SUPPLY AND GROUND

Power is supplied at all times (without Intelligent Key system)

• through 10A fuse [No. 14, located in fuse block (J/B)]

• to key switch and key lock solenoid terminal 2,

• through 10A fuse [No. 8, located in fuse block (J/B)]

• to BCM terminal 57,

• through 40A fusible link (letter g , located in fuse and fusible link box)

• to BCM terminal 70.

Power is supplied at all times (with Intelligent Key system)

1. BCM M18, M19 and M20 (view with

glove box removed) 2. Key switch and key lock solenoid

(without Intelligent Key) M27 3. Key switch and ignition knob switch

(with Intelligent Key) M73

4. Front door switch LH B8 and RH B108 5. Rear door switch LH B6 and RH

B116 6. Front door lock assembly LH (key

cylinder switch) D14

7. Back door lock assembly D405 (hatchback) 8. Trunk lamp switch and trunk release

solenoid B127 (sedan)

LIIA2936E

Revision: May 2010 2011 Versa

Page 3127 of 3787

INTERIOR ROOM LAMPLT-95

< SERVICE INFORMATION >

C

DE

F

G H

I

J

L

M A

B

LT

N

O P

• through grounds M57 and M61.

• to map lamp terminal 1

Power is supplied

• through BCM terminal 56

• to map lamp terminal 4.

When interior room lamp switch is ON, ground is supplied

• to interior room lamp terminal 1

• through map lamp (with map lamp) terminal 7

• through map lamp (with map lamp) terminal 1

• through grounds M57 and M61.

Power is supplied

• through BCM terminal 56

• through map lamp (with map lamp) terminal 4

• through map lamp (with map lamp) terminal 6

• to room lamp terminal 3.

INTERIOR ROOM LAMP TIMER OPERATION

Without Intelligent Key System

When room lamp switch is in DOOR position, and w hen all conditions below are met, BCM performs timer

control (maximum 30 seconds) for room lamp ON/OFF.

In addition, when the interior room lamp turns ON or OFF there is gradual brightening or dimming over 1 sec-

ond.

Power is supplied

• through 10A fuse [No. 14, located in fuse block (J/B)]

• to key switch and key lock solenoid terminal 2.

When the key is removed from ignition key cylinder (key switch OFF), power will not be supplied to BCM termi-

nal 37.

When front door lock assembly LH (key cyli nder switch) is unlocked, ground is supplied

• to BCM terminal 7

• through front door lock assembly LH (key cylinder switch) terminal 5

• through front door lock assembly LH (key cylinder switch) terminal 4

• through grounds M57 and M61.

At the time that front door LH is opened, BCM detects that front door LH is unlocked. It determines that interior

room lamp timer operation condition is met, and turns the room lamp ON for 30 seconds.

When key is in ignition key cylinder (key switch ON),

Power is supplied

• through key switch and key lock solenoid terminal 1

• to BCM terminal 37.

When key is removed from key switch and key lock solenoid (key switch OFF), the power supply to BCM ter-

minal 37 is terminated. BCM detects that key has been re moved, determines that interior room lamp timer

conditions are met, and turns the room lamp ON for 30 seconds.

When front door LH opens → closes, and the key is not inserted in the key switch and key lock solenoid (key

switch OFF), voltage at BCM terminal 47 changes between 0V (door open) → 12V (door closed). The BCM

determines that conditions for room lamp operation are met and turns the room lamp ON for 30 seconds.

Interior room lamp timer control is canceled under the following conditions:

• Front door LH is locked (locked by front door lock assembly LH (key cylinder switch), keyfob or door lock/

unlock switch).

• Front door LH is opened (front door switch LH).

• Ignition switch ON.

With Intelligent Key System

When the room lamp switch is in DOOR position, and when all conditions below are met, BCM performs timer

control (maximum 30 second) for room lamp ON/OFF.

In addition, when interior room lamp turns ON or OFF there is gradual brightening or dimming over 1 second.

Power is supplied

• through 10A fuse (No. 31, located in fuse and fusible link box)

• to key switch and ignition knob switch terminals 2 and 4.

When key is removed from ignition key cylinder (key switch OFF), power will not be supplied to BCM terminal

37.

When the ignition knob switch is released, power wil l not be supplied to Intelligent Key unit terminal 27.

When front door lock assembly LH (key cyli nder switch) is unlocked, ground is supplied

Revision: May 2010 2011 Versa

Page 3128 of 3787

LT-96

< SERVICE INFORMATION >

INTERIOR ROOM LAMP

• to BCM terminal 7

• through front door lock assembly LH (key cylinder switch) terminal 5

• through front door lock assembly LH (key cylinder switch) terminal 4

• through grounds M57 and M61.

At the time the front door LH is opened, the BCM detects the front door LH is unlocked. It determines that the

interior room lamp timer operation conditions are met, and interior room lamp ON for 30 seconds.

When the key is in ignition key cylinder (key switch ON ), or ignition knob switch is pushed, power is supplied

• through key switch and ignition knob switch terminal 1

• to BCM terminal 37, or

• through key switch and ignition knob switch terminal 3

• to Intelligent Key unit terminal 27.

When the key is removed from key switch (key switch OFF), power supply to BCM terminal 37 is terminated.

When the ignition knob switch is released, power supply to intelligent key unit is terminated. The BCM detects

that the key has been removed, determines that interior room lamp timer conditions are met, and turns room

lamp ON for 30 seconds.

When the front door LH opens → closes, and key is not inserted in key switch (or ignition knob switch is

released), BCM terminal 47 changes between 0V (door open) → 12V (door closed). BCM determines that

conditions for room lamp operation are met, and turns room lamp ON for 30 seconds.

Interior room lamp timer control is canceled under the following conditions:

• Front door LH is locked (with keyfob, front door lock assembly LH (key cylinder switch) or door lock/unlock switch).

• Front door LH is opened (front door switch LH).

• Ignition switch ON.

INTERIOR LAMP BATTERY SAVER CONTROL

If an interior room lamp is left ON, it will not be turned OFF even when door is closed.

BCM turns off interior lamp automatically to save battery 15 minutes after ignition switch is turned off.

After lamps are turned OFF by the battery saver system, the lamps illuminate again when

• front door lock assembly LH (key cylinder switch) is locked or unlocked

• door is opened or closed

• key is removed from ignition key cylinder or inserted in ignition key cylinder, or the ignition knob switch is pushed or released.

Interior lamp battery saver control time period can be changed by the function setting of CONSULT-III.

Revision: May 2010 2011 Versa

Page 3178 of 3787

GENERAL MAINTENANCEMA-7

< SERVICE INFORMATION >

C

DE

F

G H

I

J

K

M A

B

MA

N

O P

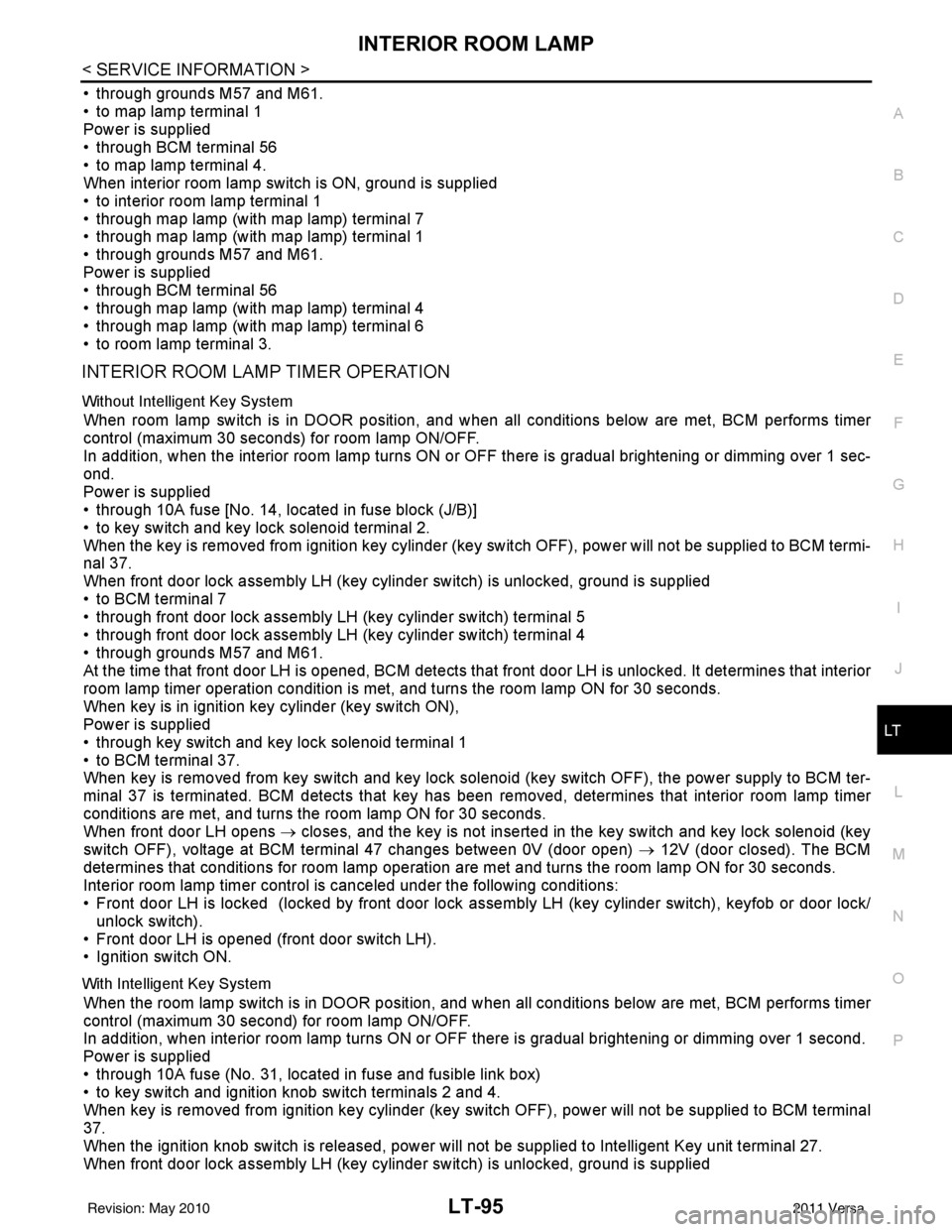

GENERAL MAINTENANCE

Explanation of Gene ral MaintenanceINFOID:0000000005931129

General MaintenanceINFOID:0000000005931130

General maintenance includes those items which shoul d be checked during the normal day-to-day operation

of the vehicle. They are essential if the vehicle is to continue operating properly. The owners can perform

checks and inspections themselves or have their NISSAN dealers do them.

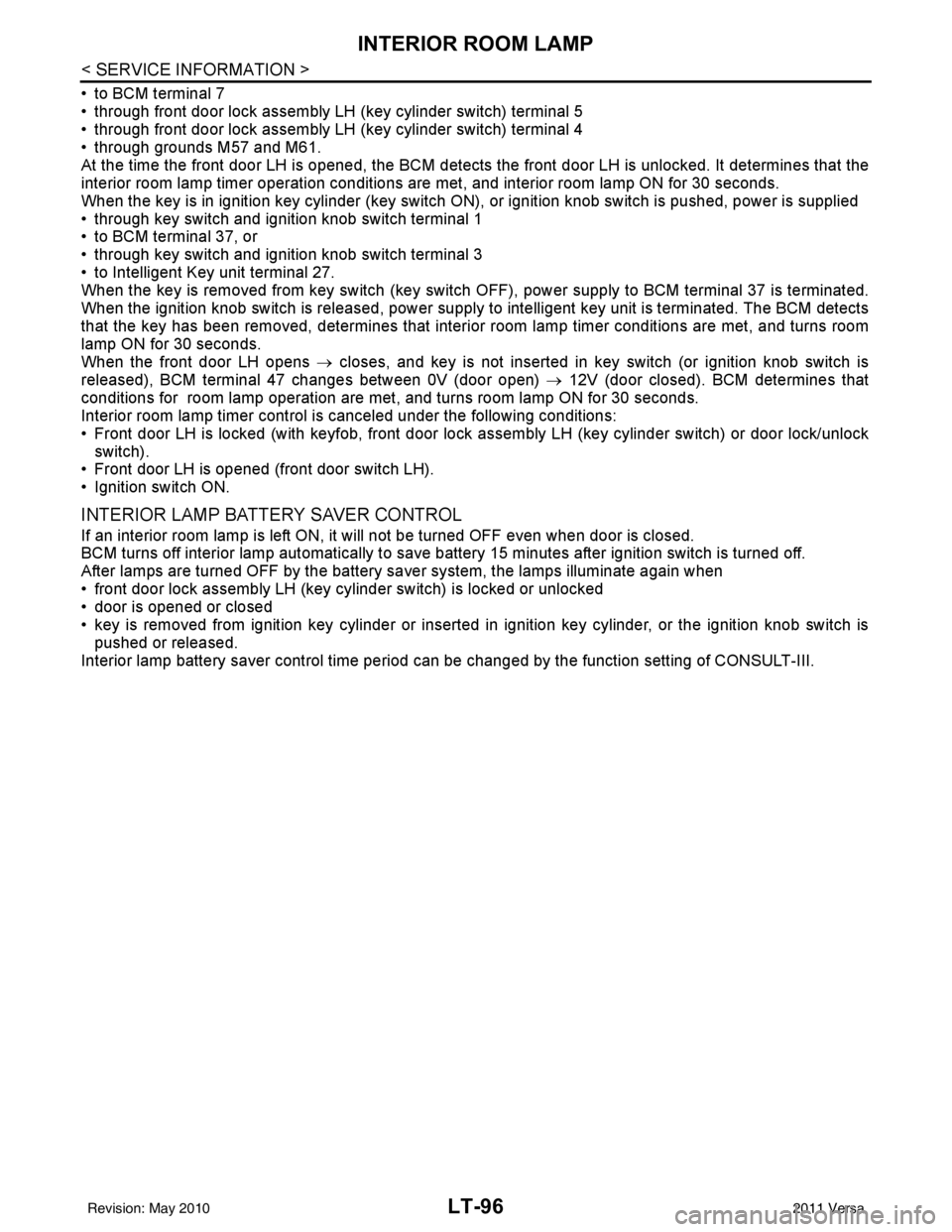

OUTSIDE THE VEHICLE

The maintenance items listed here should be performed from time to time, unless otherwise specified.

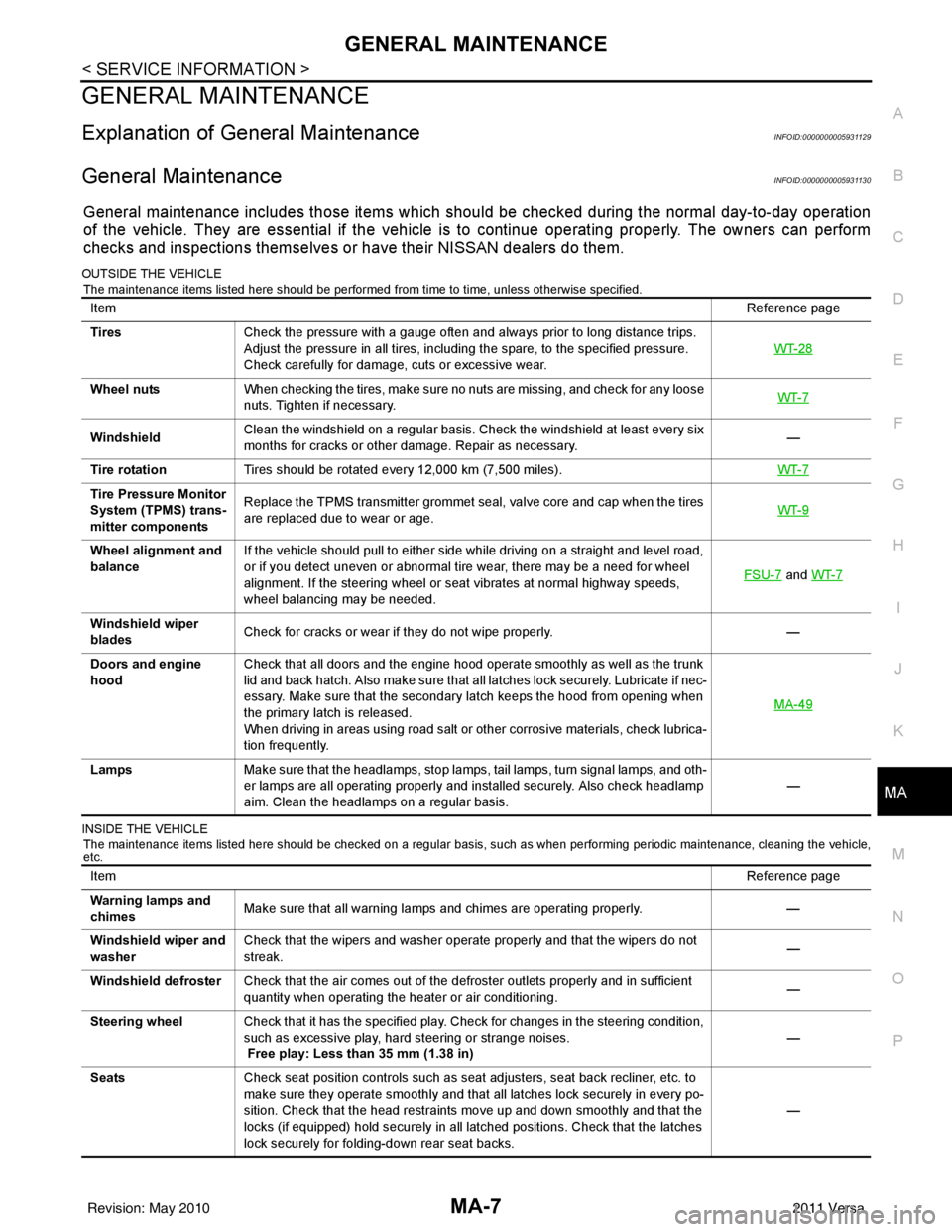

INSIDE THE VEHICLE The maintenance items listed here should be checked on a regular basis, such as when performing periodic maintenance, cleaning the vehicle,

etc.

Item Reference page

Tires Check the pressure with a gauge often and always prior to long distance trips.

Adjust the pressure in all tires, including the spare, to the specified pressure.

Check carefully for damage, cuts or excessive wear. WT-28

Wheel nuts

When checking the tires, make sure no nuts are missing, and check for any loose

nuts. Tighten if necessary. WT-7

WindshieldClean the windshield on a regular basis. Check the windshield at least every six

months for cracks or other damage. Repair as necessary.

—

Tire rotation Tires should be rotated every 12,000 km (7,500 miles). WT-7

Tire Pressure Monitor

System (TPMS) trans-

mitter componentsReplace the TPMS transmitter grommet seal, valve core and cap when the tires

are replaced due to wear or age.

WT-9

Wheel alignment and

balanceIf the vehicle should pull to either side while driving on a straight and level road,

or if you detect uneven or abnormal tire wear, there may be a need for wheel

alignment. If the steering wheel or seat vibrates at normal highway speeds,

wheel balancing may be needed. FSU-7

and

WT-7

Windshield wiper

blades Check for cracks or wear if they do not wipe properly.

—

Doors and engine

hood Check that all doors and the engine hood operate smoothly as well as the trunk

lid and back hatch. Also make sure that all latches lock securely. Lubricate if nec-

essary. Make sure that the secondary latch keeps the hood from opening when

the primary latch is released.

When driving in areas using road salt or other corrosive materials, check lubrica-

tion frequently. MA-49

Lamps

Make sure that the headlamps, stop lamps, tail lamps, turn signal lamps, and oth-

er lamps are all operating properly and installed securely. Also check headlamp

aim. Clean the headlamps on a regular basis. —

Item

Reference page

Warning lamps and

chimes Make sure that all warning lamps and chimes are operating properly.

—

Windshield wiper and

washer Check that the wipers and washer operate properly and that the wipers do not

streak.

—

Windshield defroster Check that the air comes out of the defroster outlets properly and in sufficient

quantity when operating the heater or air conditioning. —

Steering wheel Check that it has the specified play. Check for changes in the steering condition,

such as excessive play, hard steering or strange noises.

Free play: Less than 35 mm (1.38 in) —

Seats Check seat position controls such as seat adjusters, seat back recliner, etc. to

make sure they operate smoothly and that all latches lock securely in every po-

sition. Check that the head restraints move up and down smoothly and that the

locks (if equipped) hold securely in all latched positions. Check that the latches

lock securely for folding-down rear seat backs. —

Revision: May 2010

2011 Versa

Page 3206 of 3787

ENGINE MAINTENANCE (MR18DE)MA-35

< SERVICE INFORMATION >

C

DE

F

G H

I

J

K

M A

B

MA

N

O P

SPARK PLUG : Removal and InstallationINFOID:0000000005931162

REMOVAL

1. Remove intake manifold. Refer to EM-137.

2. Remove ignition coil. CAUTION:

• Handle ignition coil car efully and avoid impacts.

• Never disassemble.

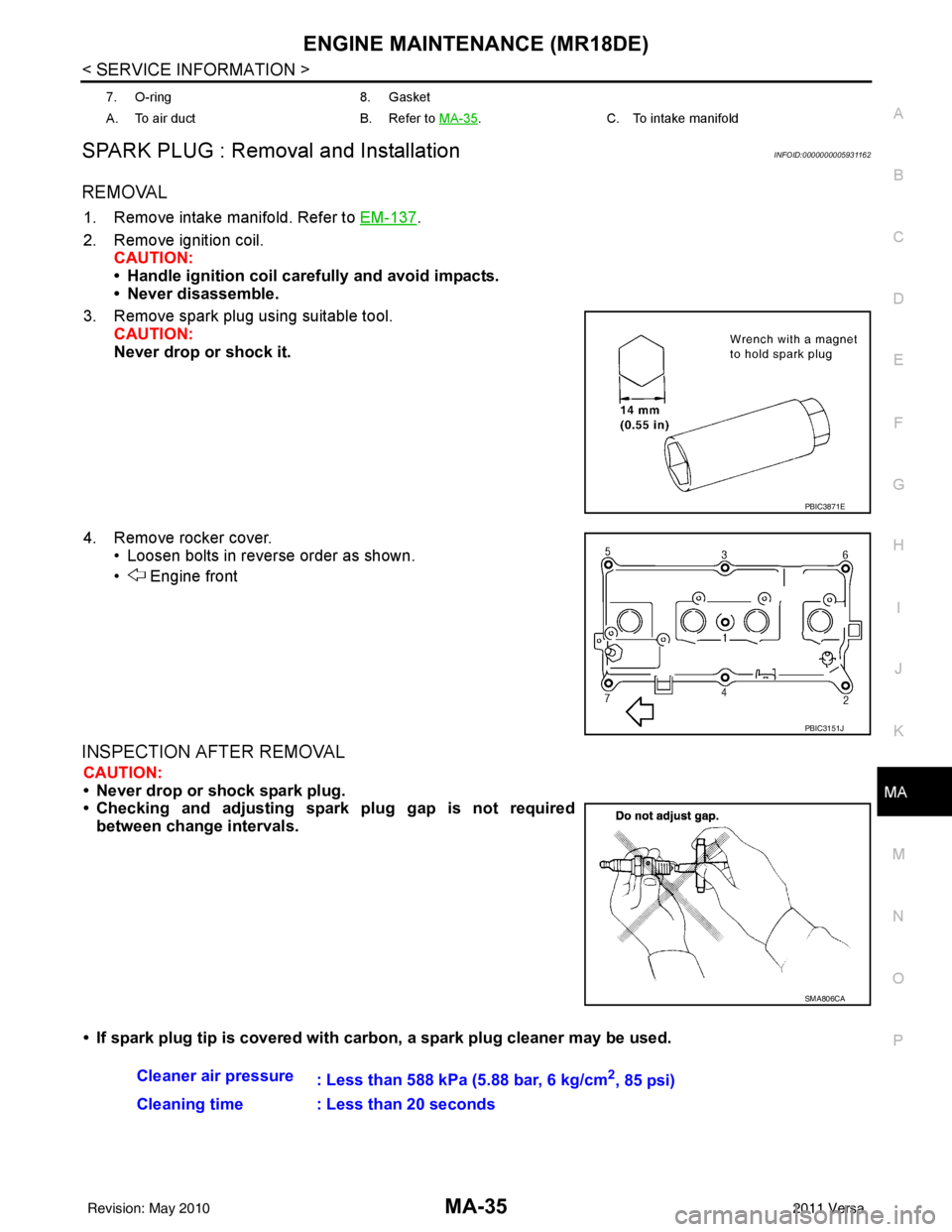

3. Remove spark plug using suitable tool. CAUTION:

Never drop or shock it.

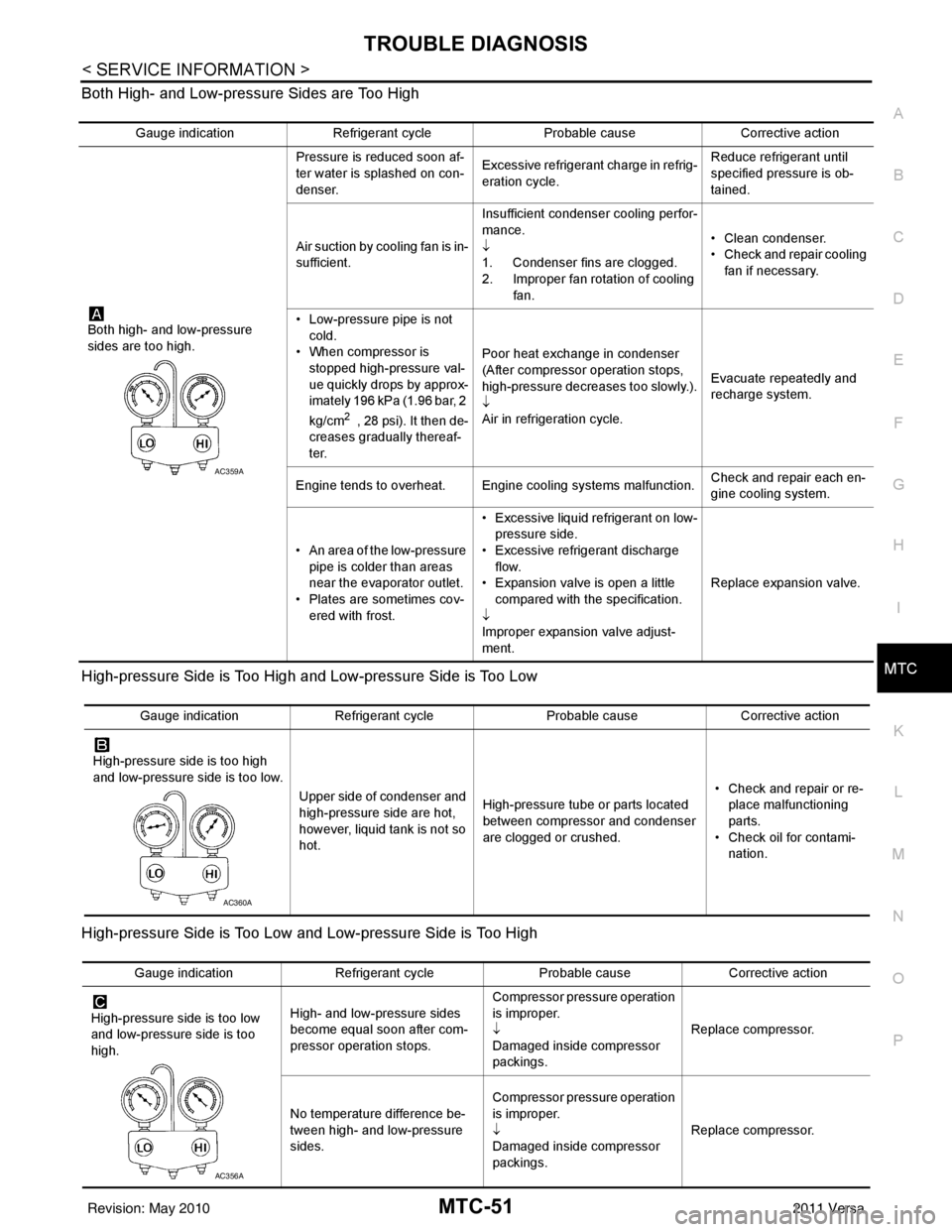

4. Remove rocker cover. • Loosen bolts in reverse order as shown.

• Engine front

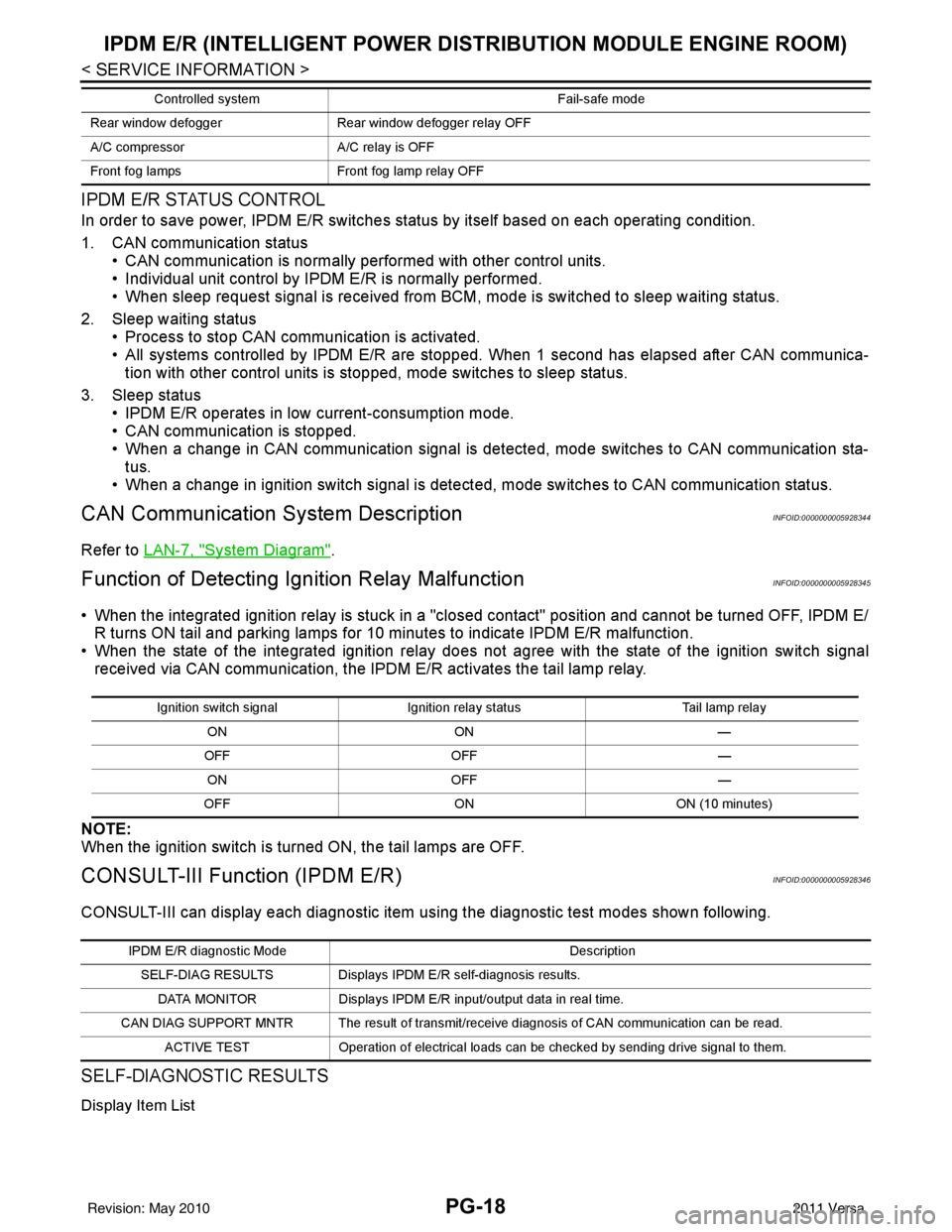

INSPECTION AFTER REMOVAL

CAUTION:

• Never drop or shock spark plug.

• Checking and adjusting spar k plug gap is not required

between change intervals.

• If spark plug tip is covered with carbon, a spark plug cleaner may be used.

7. O-ring8. Gasket

A. To air duct B. Refer to MA-35

.C. To intake manifold

PBIC3871E

PBIC3151J

SMA806CA

Cleaner air pressure

: Less than 588 kPa (5.88 bar, 6 kg/cm2, 85 psi)

Cleaning time : Less than 20 seconds

Revision: May 2010 2011 Versa

Page 3367 of 3787

TROUBLE DIAGNOSISMTC-51

< SERVICE INFORMATION >

C

DE

F

G H

I

K L

M A

B

MTC

N

O P

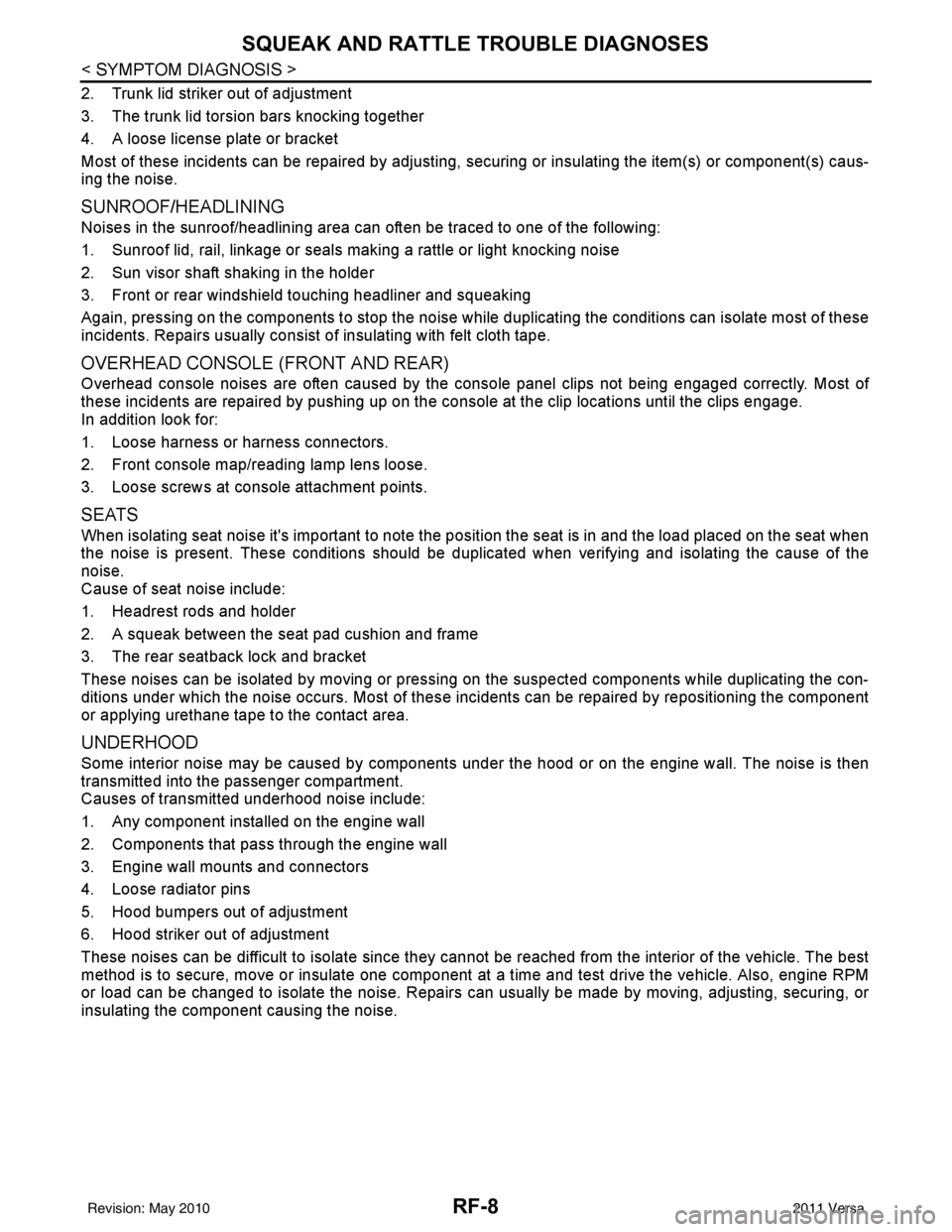

Both High- and Low-pressure Sides are Too High

High-pressure Side is Too High and Low-pressure Side is Too Low

High-pressure Side is Too Low and Low-pressure Side is Too High

Gauge indication

Refrigerant cycle Probable causeCorrective action

Both high- and low-pressure

sides are too high. Pressure is reduced soon af-

ter water is splashed on con-

denser.

Excessive refrigerant charge in refrig-

eration cycle. Reduce refrigerant until

specified pressure is ob-

tained.

Air suction by cooling fan is in-

sufficient. Insufficient condenser cooling perfor-

mance.

↓

1. Condenser fins are clogged.

2. Improper fan rotation of cooling

fan. • Clean condenser.

• Check and repair cooling

fan if necessary.

• Low-pressure pipe is not cold.

• When compressor is

stopped high-pressure val-

ue quickly drops by approx-

imately 196 kPa (1.96 bar, 2

kg/cm

2 , 28 psi). It then de-

creases gradually thereaf-

ter. Poor heat exchange in condenser

(After compressor operation stops,

high-pressure decreases too slowly.).

↓

Air in refrigeration cycle.

Evacuate repeatedly and

recharge system.

Engine tends to overheat. Engine cooling systems malfunction. Check and repair each en-

gine cooling system.

• An area of the low-pressure pipe is colder than areas

near the evaporator outlet.

• Plates are sometimes cov- ered with frost. • Excessive liquid refrigerant on low-

pressure side.

• Excessive refrigerant discharge flow.

• Expansion valve is open a little

compared with the specification.

↓

Improper expansion valve adjust-

ment. Replace expansion valve.

AC359A

Gauge indication

Refrigerant cycle Probable causeCorrective action

High-pressure side is too high

and low-pressure side is too low. Upper side of condenser and

high-pressure side are hot,

however, liquid tank is not so

hot.High-pressure tube or parts located

between compressor and condenser

are clogged or crushed. • Check and repair or re-

place malfunctioning

parts.

• Check oil for contami- nation.

AC360A

Gauge indication Refrigerant cycle Probable causeCorrective action

High-pressure side is too low

and low-pressure side is too

high. High- and low-pressure sides

become equal soon after com-

pressor operation stops. Compressor pressure operation

is improper.

↓

Damaged inside compressor

packings.

Replace compressor.

No temperature difference be-

tween high- and low-pressure

sides. Compressor pressure operation

is improper.

↓

Damaged inside compressor

packings.

Replace compressor.

AC356A

Revision: May 2010

2011 Versa

Page 3438 of 3787

PG-18

< SERVICE INFORMATION >

IPDM E/R (INTELLIGENT POWER DISTRIBUTION MODULE ENGINE ROOM)

IPDM E/R STATUS CONTROL

In order to save power, IPDM E/R switches status by itself based on each operating condition.

1. CAN communication status • CAN communication is normally performed with other control units.

• Individual unit control by IPDM E/R is normally performed.

• When sleep request signal is received from BCM, mode is switched to sleep waiting status.

2. Sleep waiting status • Process to stop CAN communication is activated.

• All systems controlled by IPDM E/R are stopped. When 1 second has elapsed after CAN communica-tion with other control units is st opped, mode switches to sleep status.

3. Sleep status • IPDM E/R operates in low current-consumption mode.

• CAN communication is stopped.

• When a change in CAN communication signal is detec ted, mode switches to CAN communication sta-

tus.

• When a change in ignition switch signal is detected, mode switches to CAN communication status.

CAN Communication System DescriptionINFOID:0000000005928344

Refer to LAN-7, "System Diagram".

Function of Detecting I gnition Relay MalfunctionINFOID:0000000005928345

• When the integrated ignition relay is stuck in a "closed contact" position and cannot be turned OFF, IPDM E/

R turns ON tail and parking lamps for 10 minutes to indicate IPDM E/R malfunction.

• When the state of the integrated ignition relay does not agree with the state of the ignition switch signal

received via CAN communication, the IPDM E/R activates the tail lamp relay.

NOTE:

When the ignition switch is turned ON, the tail lamps are OFF.

CONSULT-III Function (IPDM E/R)INFOID:0000000005928346

CONSULT-III can display each diagnostic item us ing the diagnostic test modes shown following.

SELF-DIAGNOSTIC RESULTS

Display Item List

Rear window defoggerRear window defogger relay OFF

A/C compressor A/C relay is OFF

Front fog lamps Front fog lamp relay OFF

Controlled system

Fail-safe mode

Ignition switch signalIgnition relay status Tail lamp relay

ON ON —

OFF OFF —

ON OFF —

OFF ON ON (10 minutes)

IPDM E/R diagnostic Mode Description

SELF-DIAG RESULTS Displays IPDM E/R self-diagnosis results. DATA MONITOR Displays IPDM E/R input/output data in real time.

CAN DIAG SUPPORT MNTR The result of transmit/receive diagnosis of CAN communication can be read. ACTIVE TEST Operation of electrical loads can be checked by sending drive signal to them.

Revision: May 2010 2011 Versa

Page 3531 of 3787

RF-8

< SYMPTOM DIAGNOSIS >

SQUEAK AND RATTLE TROUBLE DIAGNOSES

2. Trunk lid striker out of adjustment

3. The trunk lid torsion bars knocking together

4. A loose license plate or bracket

Most of these incidents can be repaired by adjusting, securing or insulating the item(s) or component(s) caus-

ing the noise.

SUNROOF/HEADLINING

Noises in the sunroof/headlining area c an often be traced to one of the following:

1. Sunroof lid, rail, linkage or seals making a rattle or light knocking noise

2. Sun visor shaft shaking in the holder

3. Front or rear windshield touching headliner and squeaking

Again, pressing on the components to stop the noise while duplicating the conditions can isolate most of these

incidents. Repairs usually consist of insulating with felt cloth tape.

OVERHEAD CONSOLE (FRONT AND REAR)

Overhead console noises are often caused by the c onsole panel clips not being engaged correctly. Most of

these incidents are repaired by pushing up on the c onsole at the clip locations until the clips engage.

In addition look for:

1. Loose harness or harness connectors.

2. Front console map/reading lamp lens loose.

3. Loose screws at console attachment points.

SEATS

When isolating seat noise it's important to note the pos ition the seat is in and the load placed on the seat when

the noise is present. These conditions should be duplicated when verifying and isolating the cause of the

noise.

Cause of seat noise include:

1. Headrest rods and holder

2. A squeak between the seat pad cushion and frame

3. The rear seatback lock and bracket

These noises can be isolated by moving or pressing on the suspected components while duplicating the con-

ditions under which the noise occurs. Most of thes e incidents can be repaired by repositioning the component

or applying urethane tape to the contact area.

UNDERHOOD

Some interior noise may be caused by components under the hood or on the engine wall. The noise is then

transmitted into the passenger compartment.

Causes of transmitted underhood noise include:

1. Any component installed on the engine wall

2. Components that pass through the engine wall

3. Engine wall mounts and connectors

4. Loose radiator pins

5. Hood bumpers out of adjustment

6. Hood striker out of adjustment

These noises can be difficult to isolate since they cannot be reached from the interior of the vehicle. The best

method is to secure, move or insulate one component at a time and test drive the \

vehicle. Also, engine RPM

or load can be changed to isolate the noise. Repairs can usually be made by moving, adjusting, securing, or

insulating the component causing the noise.

Revision: May 2010 2011 Versa

Page 3535 of 3787

RF-12

< FUNCTION DIAGNOSIS >

TROUBLE DIAGNOSIS

• to sunroof motor assembly terminal 1

• through sunroof switch terminal 3

• through sunroof switch terminal 2

• through grounds M57 and M61.

Then the sunroof will tilt up/slide closed.

TILT DOWN/SLIDE OPEN OPERATION

When down/open switch is pressed, ground is supplied

• to sunroof motor assembly terminal 5

• through sunroof switch terminal 1

• through sunroof switch terminal 2

• through grounds M57 and M61.

Then the sunroof will tilt down/slide open.

AUTO OPERATION

The power sunroof AUTO feature makes it possible to slide open and slide closed or tilt up and tilt down the

sunroof without holding the sunroof switch in the UP/CLOSE or DOWN/OPEN position.

RETAINED POWER OPERATION

When the ignition switch is turned to OFF position from ON position, power is supplied for 45 seconds

• through BCM terminal 68

• to sunroof motor assembly terminal 9.

When power is supplied, the sunroof can be operated.

The retained power operation is canceled when the front door LH or RH is opened.

RAP signal period can be changed by CONSULT-III. Refer to RF-17, "

Work Support" .

ANTI-PINCH FUNCTION

The CPU (central processing unit) of sunroof motor as sembly monitors the sunroof motor operation and the

sunroof position (fully-closed or other ) by the signals from sunroof motor.

When sunroof motor detects an interruption during the following slide close and tilt down operation, sunroof

switch controls the motor for open and the sunroof will oper ate until it reaches full up position (during tilt down

operation) or 125 mm (4.92 in) or more in an open direction (during slide close operation).

• close operation and tilt down when igniti on switch is in the ON position.

• close operation and tilt down during retained power operation.

INITIALIZATION FAILURE CONDITIONS

Initialization and teaching of system should be conducted if the following conditions exist:

• sunroof will only move in the UP/CLOSE direction, having a step by step motion

• sunroof does not have any auto operation.

INITIALIZATION PROCEDURE

If the sunroof does not open or close automatically, use the following procedure to return sunroof operation to

normal.

NOTE:

If the sunroof switch is released at any time during step 3, the procedure must be started over again. Leave

the ignition switch ON for at least 2 seconds after this procedure.

1. Push the ignition switch to the ON position.

2. Hold the sunroof switch in the tilt up position. Release the switch when the s unroof has reached the full tilt

up position.

3. Within 5 seconds of releasing the switch in step 2, hold the sunroof switch in the tilt up position again. The sunroof will move from the open position and back to t he close position. Release the switch only when

the sunroof has reached the full closed position.

RE-TEACHING CONDITIONS

Re-teaching of system should be conducted if any of the following conditions exist:

• the sunroof is manually operated using the sunroof wrench with the battery discharged or disconnected.

• the sunroof is manually operated using the sunroof wrench with the key switch in the OFF position and

retained power timed out (after approximat ely 45 seconds or with a front door open).

• the sunroof motor assembly is replaced with a new one.

• the sunroof motor is removed from the sunroof assembly and operated before it is reinstalled.

• the sunroof motor is removed from the sunroof assembly and the glass panel position is changed.

RE-TEACHING PROCEDURE

1. Using the UP/CLOSE switch, move the sunroof toward the tilt position until it stops.

Revision: May 2010 2011 Versa

Page 3613 of 3787

SE-8

< SERVICE INFORMATION >

SQUEAK AND RATTLE TROUBLE DIAGNOSES

Most of these incidents can be repaired by adjusting, securing or insulating the item(s) or component(s) caus-

ing the noise.

SUNROOF/HEADLINING

Noises in the sunroof/headlining area c an often be traced to one of the following:

1. Sunroof lid, rail, linkage or seals making a rattle or light knocking noise

2. Sun visor shaft shaking in the holder

3. Front or rear windshield touching headliner and squeaking

Again, pressing on the components to stop the noise while duplicating the conditions can isolate most of these

incidents. Repairs usually consist of insulating with felt cloth tape.

OVERHEAD CONSOLE (FRONT AND REAR)

Overhead console noises are often caused by the c onsole panel clips not being engaged correctly. Most of

these incidents are repaired by pushing up on the c onsole at the clip locations until the clips engage.

In addition look for:

1. Loose harness or harness connectors.

2. Front console map/reading lamp lense loose.

3. Loose screws at console attachment points.

SEATS

When isolating seat noise it's important to note the pos ition the seat is in and the load placed on the seat when

the noise is present. These conditions should be duplicated when verifying and isolating the cause of the

noise.

Cause of seat noise include:

1. Headrest rods and holder

2. A squeak between the seat pad cushion and frame

3. The rear seatback lock and bracket

These noises can be isolated by moving or pressing on the suspected components while duplicating the con-

ditions under which the noise occurs. Most of thes e incidents can be repaired by repositioning the component

or applying urethane tape to the contact area.

UNDERHOOD

Some interior noise may be caused by components under the hood or on the engine wall. The noise is then

transmitted into the passenger compartment.

Causes of transmitted underhood noise include:

1. Any component mounted to the engine wall

2. Components that pass through the engine wall

3. Engine wall mounts and connectors

4. Loose radiator mounting pins

5. Hood bumpers out of adjustment

6. Hood striker out of adjustment

These noises can be difficult to isolate since they cannot be reached from the interior of the vehicle. The best

method is to secure, move or insulate one component at a time and test drive the \

vehicle. Also, engine RPM

or load can be changed to isolate the noise. Repairs can usually be made by moving, adjusting, securing, or

insulating the component causing the noise.

Revision: May 2010 2011 Versa