lock NISSAN LATIO 2011 Service Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2011, Model line: LATIO, Model: NISSAN LATIO 2011Pages: 3787, PDF Size: 78.35 MB

Page 3748 of 3787

WW-2

< SERVICE INFORMATION >

PRECAUTION

SERVICE INFORMATION

PRECAUTION

Precaution for Supplemental Restraint System (SRS) "AIR BAG" and "SEAT BELT

PRE-TENSIONER"

INFOID:0000000005929204

The Supplemental Restraint System such as “A IR BAG” and “SEAT BELT PRE-TENSIONER”, used along

with a front seat belt, helps to reduce the risk or severity of injury to the driver and front passenger for certain

types of collision. This system includes seat belt switch inputs and dual stage front air bag modules. The SRS

system uses the seat belt switches to determine the front air bag deployment, and may only deploy one front

air bag, depending on the severity of a collision and w hether the front occupants are belted or unbelted.

Information necessary to service the system safely is included in the SRS and SB section of this Service Man-

ual.

WARNING:

• To avoid rendering the SRS inopera tive, which could increase the risk of personal injury or death in

the event of a collision which would result in air bag inflation, all maintenance must be performed by

an authorized NISSAN/INFINITI dealer.

• Improper maintenance, including incorrect removal and installation of the SRS can lead to personal

injury caused by unintent ional activation of the system. For re moval of Spiral Cable and Air Bag

Module, see the SRS section.

• Do not use electrical test equipmen t on any circuit related to the SRS unless instructed to in this

Service Manual. SRS wiring harn esses can be identified by yellow and/or orange harnesses or har-

ness connectors.

PRECAUTIONS WHEN USING POWER TOOLS (AIR OR ELECTRIC) AND HAMMERS

WARNING:

• When working near the Airbag Diagnosis Sensor Unit or other Airbag System sensors with the Igni-

tion ON or engine running, DO NOT use air or electri c power tools or strike near the sensor(s) with a

hammer. Heavy vibration could activate the sensor( s) and deploy the air bag(s), possibly causing

serious injury.

• When using air or electric power tools or hammers , always switch the Ignition OFF, disconnect the

battery, and wait at least 3 minu tes before performing any service.

Precaution Necessary for Steering W heel Rotation After Battery Disconnect

INFOID:0000000006413346

NOTE:

• This Procedure is applied only to models with Intelligent Key system and NATS (NISSAN ANTI-THEFT SYS-

TEM).

• Remove and install all control units after disconnecting both battery cables with the ignition knob in the

″LOCK ″ position.

• Always use CONSULT-III to perform self-diagnosis as a part of each function inspection after finishing work.

If DTC is detected, perform trouble diagnosis according to self-diagnostic results.

For models equipped with the Intelligent Key system and NATS, an electrically controlled steering lock mech-

anism is adopted on the key cylinder.

For this reason, if the battery is disconnected or if the battery is discharged, the steering wheel will lock and

steering wheel rotation will become impossible.

If steering wheel rotation is required when battery pow er is interrupted, follow the procedure below before

starting the repair operation.

OPERATION PROCEDURE

1. Connect both battery cables. NOTE:

Supply power using jumper cables if battery is discharged.

2. Use the Intelligent Key or mechanical key to turn the ignition switch to the ″ACC ″ position. At this time, the

steering lock will be released.

3. Disconnect both battery cables. The steering lock will remain released and the steering wheel can be rotated.

4. Perform the necessary repair operation.

Revision: May 2010 2011 Versa

Page 3749 of 3787

PRECAUTIONWW-3

< SERVICE INFORMATION >

C

DE

F

G H

I

J

L

M A

B

WW

N

O P

5. When the repair work is completed, return the ignition switch to the ″LOCK ″ position before connecting

the battery cables. (At this time, the steering lock mechanism will engage.)

6. Perform a self-diagnosis check of al l control units using CONSULT-III.

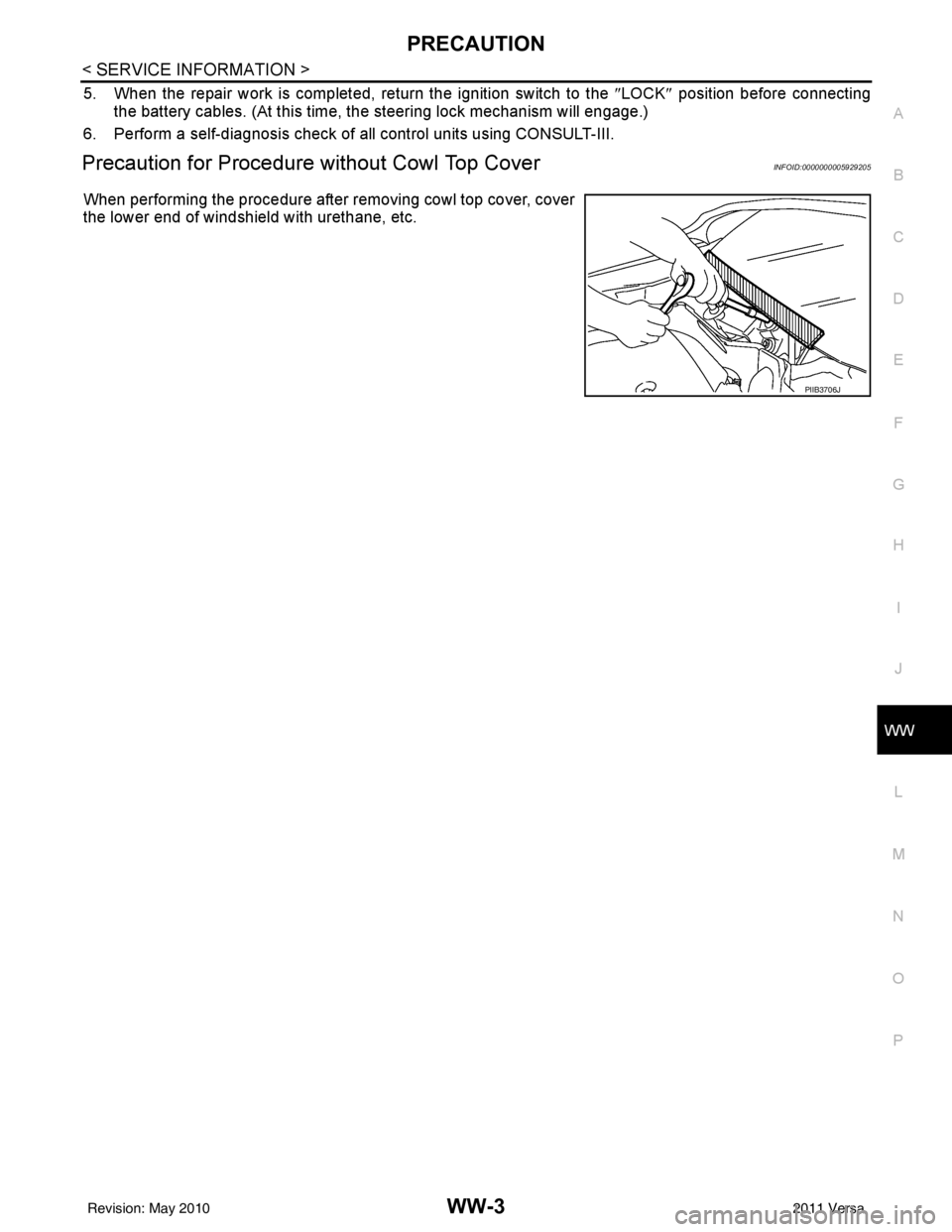

Precaution for Procedure without Cowl Top CoverINFOID:0000000005929205

When performing the procedure after removing cowl top cover, cover

the lower end of windshield with urethane, etc.

PIIB3706J

Revision: May 2010 2011 Versa

Page 3752 of 3787

WW-6

< SERVICE INFORMATION >

FRONT WIPER AND WASHER SYSTEM

• to front wiper high relay (located in IPDM E/R), and

• to CPU (located in IPDM E/R),

• through 10A fuse [No. 6, located in fuse block (J/B)]

• to BCM terminal 38,

• through 15A fuse [No. 4, located in fuse block (J/B)]

• to combination switch (wiper switch) terminal 14.

Ground is supplied

• to IPDM E/R terminals 39 and 59, and

• to front wiper motor terminal 2

• through grounds E15 and E24

• to BCM terminal 67, and

• to combination switch (wiper switch) terminal 12

• through grounds M57 and M61.

LOW SPEED WIPER OPERATION

When the front combination switch (wiper switch) is in LO position, the BCM detects the low speed wiper ON

signal by means of the BCM combination switch (wiper switch) reading function.

The BCM sends a front wiper request signal (LO) through the CAN communication line

• from BCM terminals 39 and 40

• to IPDM E/R terminals 40 and 41.

When the IPDM E/R receives front wiper request signal (LO) , it turns ON front wiper relay, located in IPDM E/

R, power is supplied

• through IPDM E/R terminal 33 and front wiper high relay and front wiper relay

• to front wiper motor terminal 3.

Ground is supplied

• to front wiper motor terminal 2

• through grounds E15 and E24.

With power and ground is supplied, front wiper motor operates at low speed.

HIGH SPEED WIPER OPERATION

When the front combination switch (wiper switch) is in HI position, the BCM detects a high speed wiper ON

signal by means of the BCM combination switch (wiper switch) reading function.

The BCM sends a front wiper request signal (HI) through the CAN communication line

• from BCM terminals 39 and 40

• to IPDM E/R terminals 40 and 41.

When the IPDM E/R receives front wiper request signal (HI), it turns ON front wiper relay and front wiper high

relay, located in IPDM E/R, power is supplied

• through IPDM E/R terminal 32

• to front wiper motor terminal 5.

Ground is supplied

• to front wiper motor terminal 2

• through grounds E15 and E24.

With power and ground is supplied, front wiper motor operates at high speed.

INTERMITTENT OPERATION

Wiper intermittent operation delay interval is determined from the intermittent wiper dial position inputs. During

each intermittent operation delay interval, the BCM s ends a front wiper request signal to the IPDM E/R to

operate the wipers.

When the ignition switch is in the ON or START positi on, and the front combination switch (wiper switch) is

turned to the intermittent position, the BCM detects a fr ont wiper (intermittent) ON signal by means of the BCM

combination switch (wiper switch) reading function.

BCM then sends front wiper (intermittent) request signal through the CAN communication lines

• from BCM terminals 39 and 40

• to IPDM E/R terminals 40 and 41.

When BCM determines that combination switch (wiper swit ch) status is front wiper intermittent ON, it performs

the following operations.

• BCM detects ON/OFF status of intermittent wiper dial position

• BCM calculates operation interval from wiper dial position.

• BCM sends a front wiper request signal (INT) to IPDM E/R at calculated operation interval.

When IPDM E/R receives the front wiper request signal (INT), it supplies ground to energize the front wiper

relay. It then sends auto-stop signal to the BCM and conducts intermittent front wiper motor operation.

Revision: May 2010 2011 Versa

Page 3759 of 3787

FRONT WIPER AND WASHER SYSTEMWW-13

< SERVICE INFORMATION >

C

DE

F

G H

I

J

L

M A

B

WW

N

O P

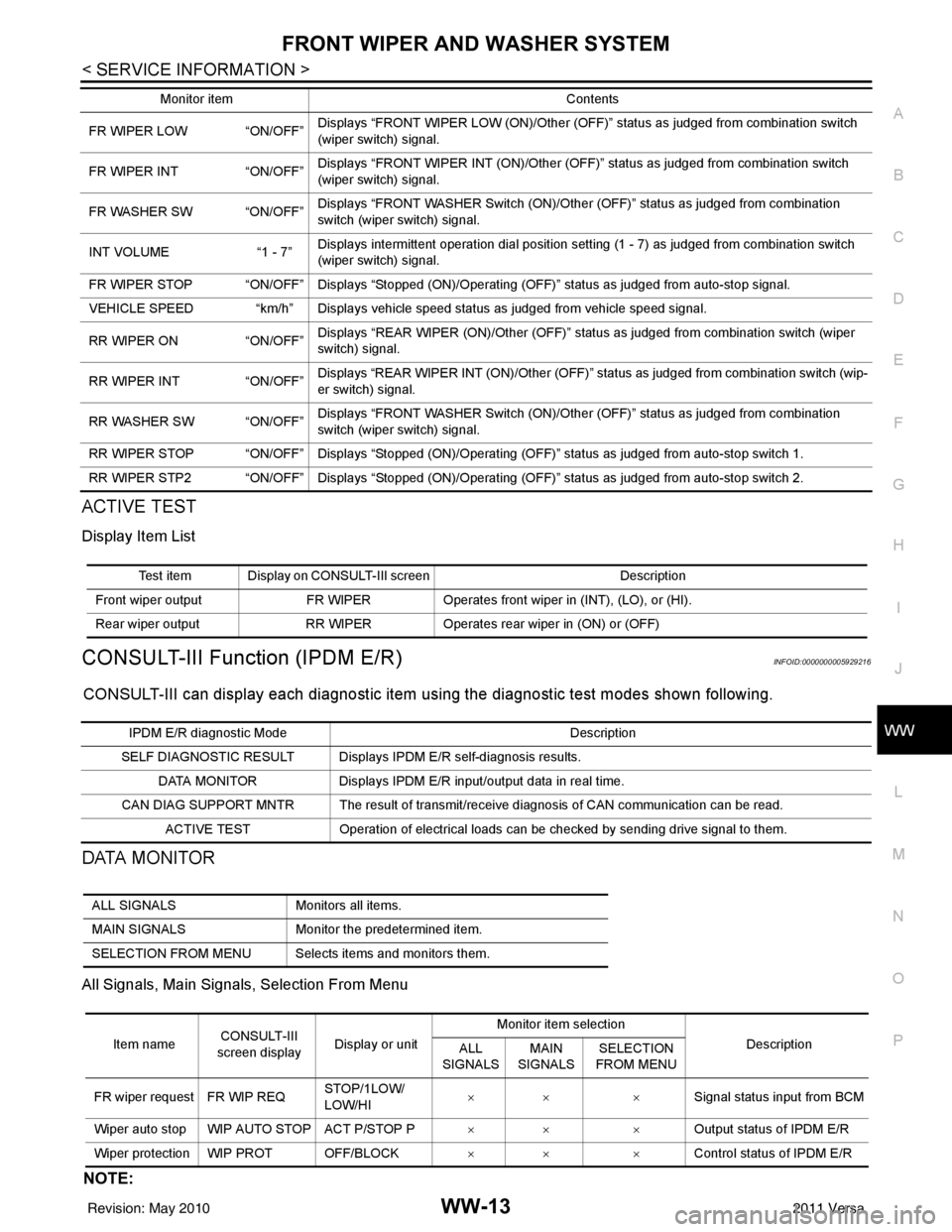

ACTIVE TEST

Display Item List

CONSULT-III Function (IPDM E/R)INFOID:0000000005929216

CONSULT-III can display each diagnostic item using the diagnostic test modes shown following.

DATA MONITOR

All Signals, Main Signals, Selection From Menu

NOTE:

FR WIPER LOW “ON/OFF” Displays “FRONT WIPER LOW (ON)/Other (OFF)” status as judged from combination switch

(wiper switch) signal.

FR WIPER INT “ON/OFF”Displays “FRONT WIPER INT (ON)

/Other (OFF)” status as judged from combination switch

(wiper switch) signal.

FR WASHER SW “ON/OFF” Displays “FRONT WASHER Swit

ch (ON)/Other (OFF)” status as judged from combination

switch (wiper switch) signal.

INT VOLUME “1 - 7”Displays intermittent operation dial position setting (1 - 7) as judged from combination switch

(wiper switch) signal.

FR WIPER STOP “ON/OFF” Displays “Stopped (ON)/Operati ng (OFF)” status as judged from auto-stop signal.

VEHICLE SPEED “km/h” Displays vehicle speed stat us as judged from vehicle speed signal.

RR WIPER ON “ON/OFF”Displays “REAR WIPER (ON)/Other (OFF)” status as judged from combination switch (wiper

switch) signal.

RR WIPER INT “ON/OFF” Displays “REAR WIPER INT (ON)/Other (OFF)” status as judged from combination switch (wip-

er switch) signal.

RR WASHER SW “ON/OFF” Displays “FRONT WASHER Swit

ch (ON)/Other (OFF)” status as judged from combination

switch (wiper switch) signal.

RR WIPER STOP “ON/OFF” Displays “Stopp ed (ON)/Operating (OFF)” status as judged from auto-stop switch 1.

RR WIPER STP2 “ON/OFF” Displays “Stopp ed (ON)/Operating (OFF)” status as judged from auto-stop switch 2.

Monitor item

Contents

Test item Display on CONSULT-III screen Description

Front wiper output FR WIPEROperates front wiper in (INT), (LO), or (HI).

Rear wiper output RR WIPEROperates rear wiper in (ON) or (OFF)

IPDM E/R diagnostic Mode Description

SELF DIAGNOSTIC RESULT Displays IPDM E/R self-diagnosis results.

DATA MONITOR Displays IPDM E/R input/output data in real time.

CAN DIAG SUPPORT MNTR The result of transmit/receive diagnosis of CAN communication can be read. ACTIVE TEST Operation of electrical loads can be checked by sending drive signal to them.

ALL SIGNALS Monitors all items.

MAIN SIGNALS Monitor the predetermined item.

SELECTION FROM MENU Selects items and monitors them.

Item name CONSULT-III

screen display Display or unit Monitor item selection

Description

ALL

SIGNALS MAIN

SIGNALS SELECTION

FROM MENU

FR wiper request FR WIP REQ STOP/1LOW/

LOW/HI×× ×

Signal status input from BCM

Wiper auto stop WIP AUTO STOP ACT P/STOP P ×× ×Output status of IPDM E/R

Wiper protection WIP PROT OFF/BLOCK ×× ×Control status of IPDM E/R

Revision: May 2010 2011 Versa

Page 3762 of 3787

WW-16

< SERVICE INFORMATION >

FRONT WIPER AND WASHER SYSTEM

3. Start auto active test. Refer to PG-20, "Auto Active Test" .

4. Check voltage between IPDM E/R connector and ground while front wiper (HI, LO) is operating.

OK or NG

OK >> Replace front wiper motor. Refer to WW-22, "Removal and Installation of Front Wiper Drive

Assembly" .

NG >> Replace IPDM E/R. Refer to PG-28, "

Removal and Installation of IPDM E/R" .

Front Wiper Does Not Return to Stop Positi on (After Front Wiper Operates for 10 Sec-

onds, They Stop for 20 Second s, and After Repeating the Operation Five Times, They

Become Inoperative)

INFOID:0000000005929218

CAUTION:

• When auto-stop signal has not varied for 10 seconds or longer while IPDM E/R is operating front wip-

ers, IPDM E/R considers that front wipers are locked, and stops wiper output. That causes this symp-

tom.

• This status can be checked by “DATA MONITOR” of “IPDM E/R” on which “WIPER PROT” item

shows “BLOCK”.

1.CHECK FRONT WIPER STOP SIGNAL

With CONSULT-lIl

Select “IPDM E/R” on CONSULT-III. With “DATA MONITOR”, make sure that “WIP AUTO STOP” turns “ACT

P” - “STOP P” linked with wiper operation.

Without CONSULT-llI

GO TO 2.

OK or NG

OK >> Replace IPDM E/R. Refer to PG-28, "Removal and Installation of IPDM E/R" .

NG >> GO TO 2.

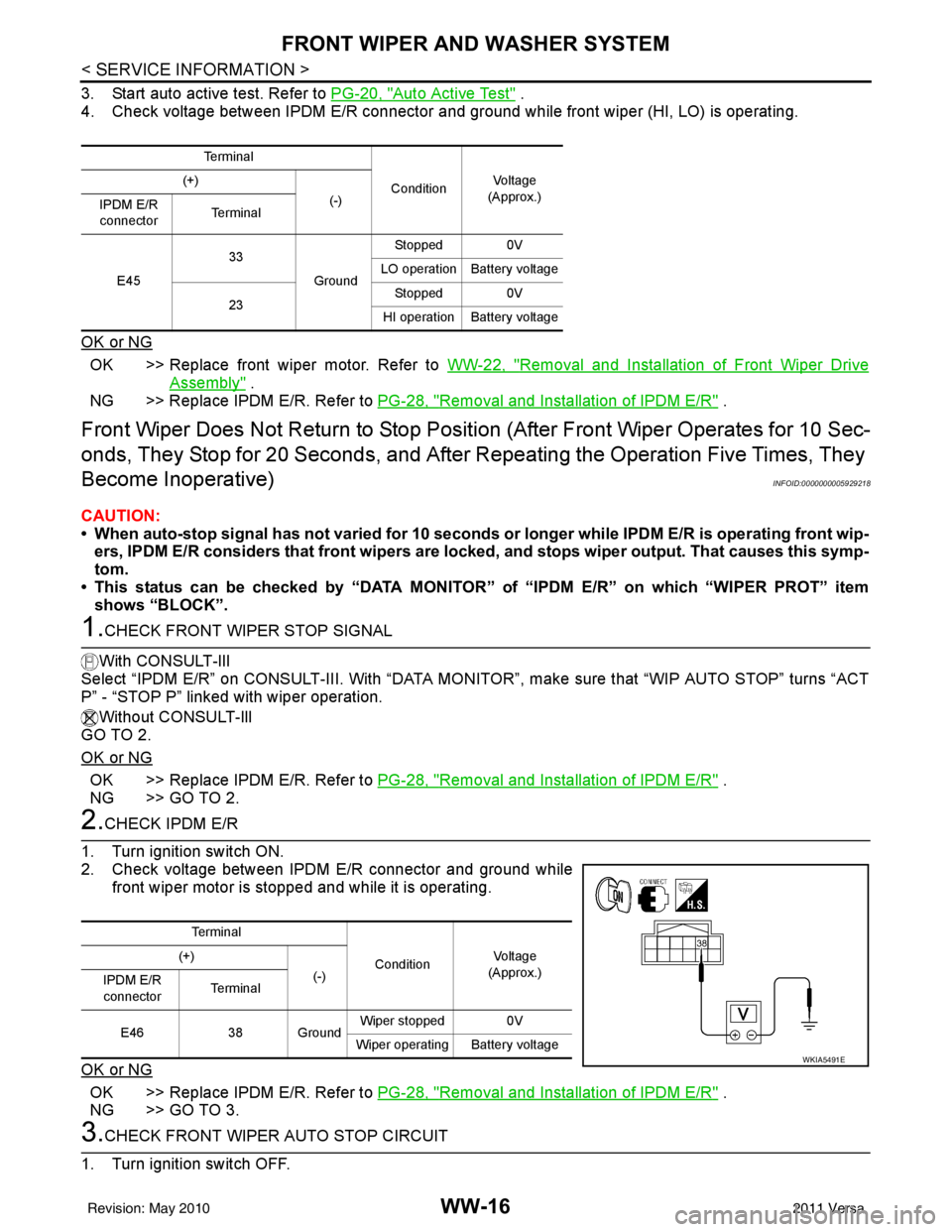

2.CHECK IPDM E/R

1. Turn ignition switch ON.

2. Check voltage between IPDM E/R connector and ground while front wiper motor is stopped and while it is operating.

OK or NG

OK >> Replace IPDM E/R. Refer to PG-28, "Removal and Installation of IPDM E/R" .

NG >> GO TO 3.

3.CHECK FRONT WIPER AUTO STOP CIRCUIT

1. Turn ignition switch OFF.

Te r m i n a l

ConditionVo l ta g e

(Approx.)

(+)

(-)

IPDM E/R

connector Te r m i n a l

E45 33

GroundStopped 0V

LO operation Battery voltage

23 Stopped 0V

HI operation Battery voltage

Te r m i n a l

ConditionVo l ta g e

(Approx.)

(+)

(-)

IPDM E/R

connector Te r m i n a l

E46 38 Ground Wiper stopped 0V

Wiper operating Battery voltage

WKIA5491E

Revision: May 2010 2011 Versa

Page 3773 of 3787

REAR WIPER AND WASHER SYSTEMWW-27

< SERVICE INFORMATION >

C

DE

F

G H

I

J

L

M A

B

WW

N

O P

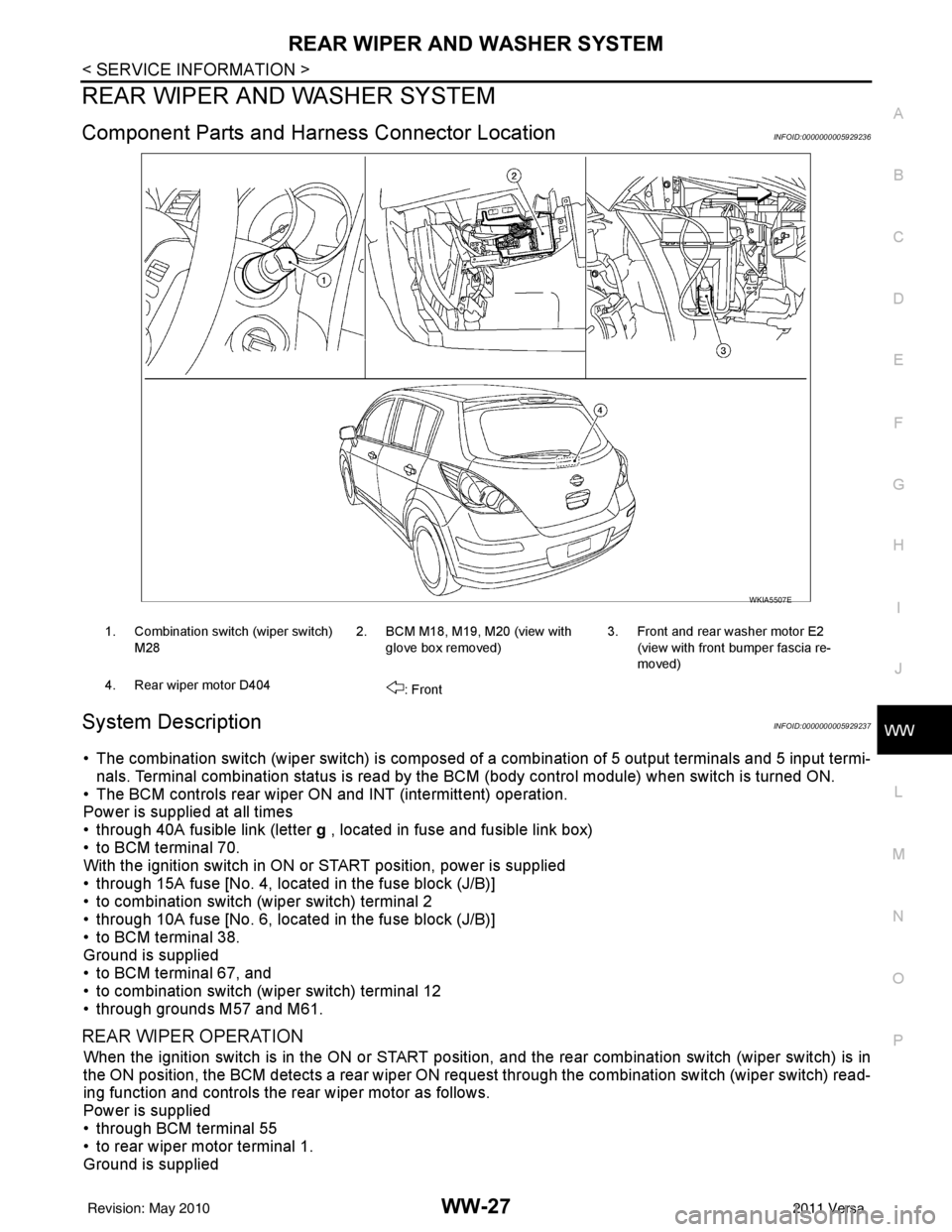

REAR WIPER AND WASHER SYSTEM

Component Parts and Har ness Connector LocationINFOID:0000000005929236

System DescriptionINFOID:0000000005929237

• The combination switch (wiper switch) is composed of a combination of 5 output terminals and 5 input termi-

nals. Terminal combination status is read by the BCM (body control module) when switch is turned ON.

• The BCM controls rear wiper ON and INT (intermittent) operation.

Power is supplied at all times

• through 40A fusible link (letter g , located in fuse and fusible link box)

• to BCM terminal 70.

With the ignition switch in ON or START position, power is supplied

• through 15A fuse [No. 4, located in the fuse block (J/B)]

• to combination switch (wiper switch) terminal 2

• through 10A fuse [No. 6, located in the fuse block (J/B)]

• to BCM terminal 38.

Ground is supplied

• to BCM terminal 67, and

• to combination switch (wiper switch) terminal 12

• through grounds M57 and M61.

REAR WIPER OPERATION

When the ignition switch is in the ON or START position, and the rear combination switch (wiper switch) is in

the ON position, the BCM detects a rear wiper ON r equest through the combination switch (wiper switch) read-

ing function and controls the rear wiper motor as follows.

Power is supplied

• through BCM terminal 55

• to rear wiper motor terminal 1.

Ground is supplied

WKIA5507E

1. Combination switch (wiper switch)

M28 2. BCM M18, M19, M20 (view with

glove box removed) 3. Front and rear washer motor E2

(view with front bumper fascia re-

moved)

4. Rear wiper motor D404 : Front

Revision: May 2010 2011 Versa

Page 3774 of 3787

WW-28

< SERVICE INFORMATION >

REAR WIPER AND WASHER SYSTEM

• to rear wiper motor terminal 3

• through grounds B117, B132 and D402.

With power and ground supplied, the rear wiper motor operates.

INTERMITTENT OPERATION

The rear wiper motor operates the wiper arm at low speed approximately every 7 seconds.

When the combination switch (wiper switch) is in the r ear wiper INT position, the BCM detects a rear wiper INT

request through the combination switch (wiper switch) reading function.

When BCM operates rear wiper motor, power is supplied

• through BCM terminal 55

• to rear wiper motor terminal 1.

Ground is supplied

• to rear wiper motor terminal 3

• through grounds B117, B132 and D402.

With power and ground supplied, the rear wiper operates in intermittent mode.

AUTO STOP OPERATION

When the rear wiper arm is not located at the base of the rear window, and the rear combination switch (wiper

switch) is turned OFF, the rear wiper motor will continue to operate until the rear wiper arm is at the base of the

rear window. When the rear wiper arm reaches the bas e, rear wiper motor terminals 2 and 1 are connected.

Ground is supplied

• to BCM terminal 44

• through rear wiper motor terminal 2, and

• through rear wiper motor terminal 3, and

• through grounds B117, B132 and D402.

REAR WASHER OPERATION

When the ignition switch is in the ON or START positi on, and the front and rear washer switches are OFF, the

front and rear washer motor is supplied power

• through 15A fuse [No. 4, located in the fuse block (J/B)]

• to combination switch (wiper switch) terminal 14

• through combination switch (wiper switch) terminal 11

• to front and rear washer motor terminal 2.

When the rear combination switch (wiper switch) is in rear washer position, the BCM detects a rear washer

signal by BCM combination switch (wiper switch) readi ng function. Combination switch (wiper switch) ground

is supplied

• to front and rear washer motor terminal 1

• through combination switch (wiper switch) terminal 13, and

• through combination switch (wiper switch) terminal 12

• through grounds M57 and M61.

With ground supplied, the front and rear washer motor is operated in the rear direction.

When the BCM detects that the rear washer motor has operated for 0.4 seconds or longer, BCM operates the

rear wiper motor.

When the BCM detects that the rear washer switch is in OFF, the rear wiper motor cycles approximately 3

times and then stops.

If the rear washer is operated with the rear combinati on switch (wiper switch) in the INT position, normal rear

wiper operation will take over. Once the rear washer switch is released the rear wiper will return to INT opera-

tion.

BCM Combination Switch (Wiper Switch) Reading Function

Refer to BCS-4, "System Description" .

Revision: May 2010 2011 Versa