NISSAN LATIO 2011 Service Repair Manual

Manufacturer: NISSAN, Model Year: 2011, Model line: LATIO, Model: NISSAN LATIO 2011Pages: 3787, PDF Size: 78.35 MB

Page 861 of 3787

BR-14

< SERVICE INFORMATION >

DUAL PROPORTIONING VALVE

DUAL PROPORTIONING VALVE

Removal and InstallationINFOID:0000000005928400

Removal

1. Remove the cowl top. Refer to EI-24, "Removal and Installation".

2. Disconnect brake lines from dual proportioning valve. • Mark brake lines for installation.

3. Remove dual proportioning valve bolt and dual proportioning valve.

4. Remove two bolts and bracket.

Installation

Installation is in the reverse order of removal.

• When installing brake lines to the dual proportioning valve, tighten to specifications. Refer to BR-11,

"Hydraulic Circuit".

InspectionINFOID:0000000005928401

CAUTION:

• Carefully monitor brake fluid level at master cylinder.

• Use the recommended new brake fluid. Refer to MA-14, "

Fluids and Lubricants".

• Be careful not to splash brake fluid on painted areas; it may cause paint damage. If brake fluid is

splashed on paint areas, wash it away with water immediately.

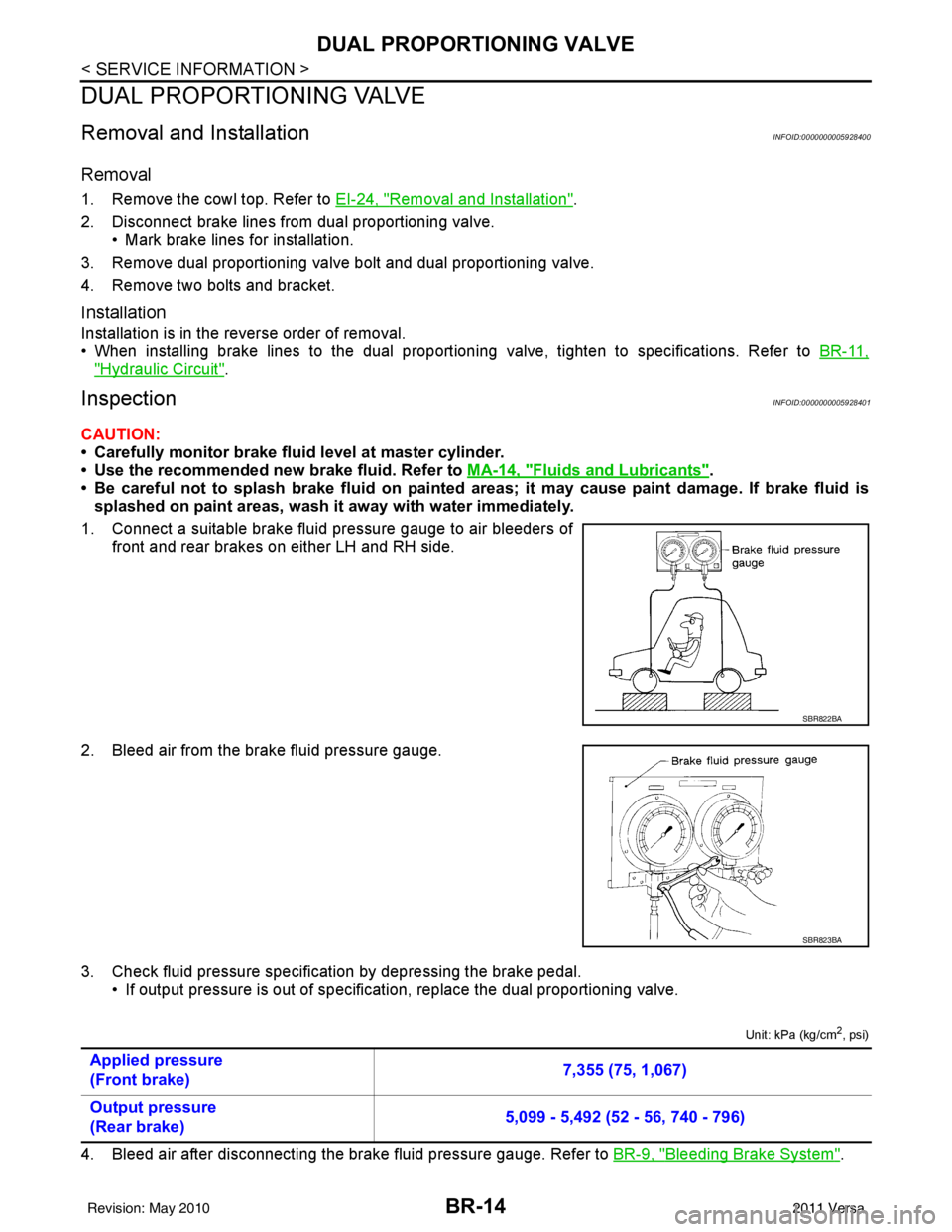

1. Connect a suitable brake fluid pressure gauge to air bleeders of front and rear brakes on either LH and RH side.

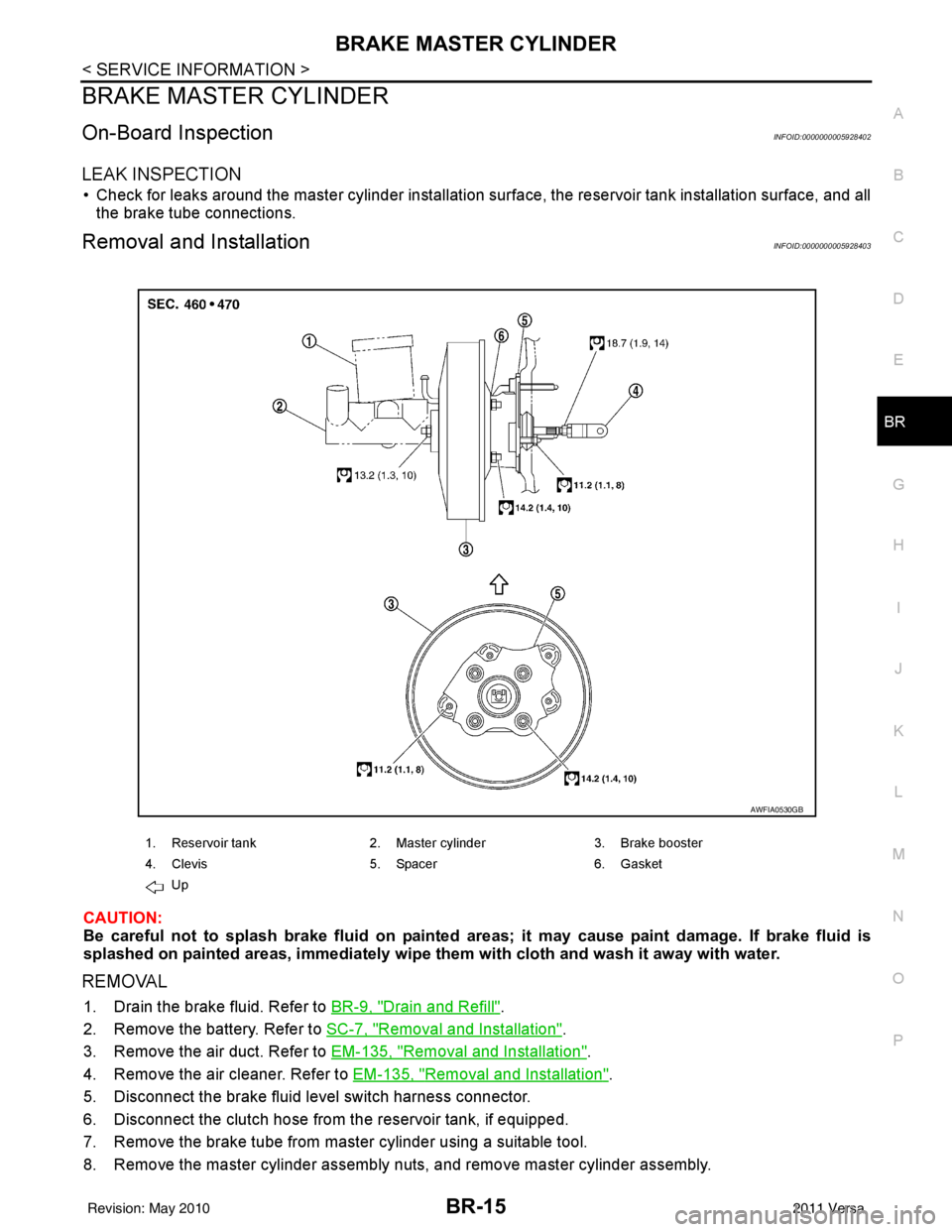

2. Bleed air from the brake fluid pressure gauge.

3. Check fluid pressure specific ation by depressing the brake pedal.

• If output pressure is out of specification, replace the dual proportioning valve.

Unit: kPa (kg/cm2, psi)

4. Bleed air after disconnecting the brake fluid pressure gauge. Refer to BR-9, "Bleeding Brake System".

SBR822BA

SBR823BA

Applied pressure

(Front brake) 7,355 (75, 1,067)

Output pressure

(Rear brake) 5,099 - 5,492 (52 - 56, 740 - 796)

Revision: May 2010

2011 Versa

Page 862 of 3787

BRAKE MASTER CYLINDERBR-15

< SERVICE INFORMATION >

C

DE

G H

I

J

K L

M A

B

BR

N

O P

BRAKE MASTER CYLINDER

On-Board InspectionINFOID:0000000005928402

LEAK INSPECTION

• Check for leaks around the master cylinder installation surface, the reservoir tank installation surface, and all the brake tube connections.

Removal and InstallationINFOID:0000000005928403

CAUTION:

Be careful not to splash brake fluid on painted areas; it may cause paint damage. If brake fluid is

splashed on painted areas, immediately wipe th em with cloth and wash it away with water.

REMOVAL

1. Drain the brake fluid. Refer to BR-9, "Drain and Refill".

2. Remove the battery. Refer to SC-7, "

Removal and Installation".

3. Remove the air duct. Refer to EM-135, "

Removal and Installation".

4. Remove the air cleaner. Refer to EM-135, "

Removal and Installation".

5. Disconnect the brake fluid level switch harness connector.

6. Disconnect the clutch hose from the reservoir tank, if equipped.

7. Remove the brake tube from master cylinder using a suitable tool.

8. Remove the master cylinder assembly nuts, and remove master cylinder assembly.

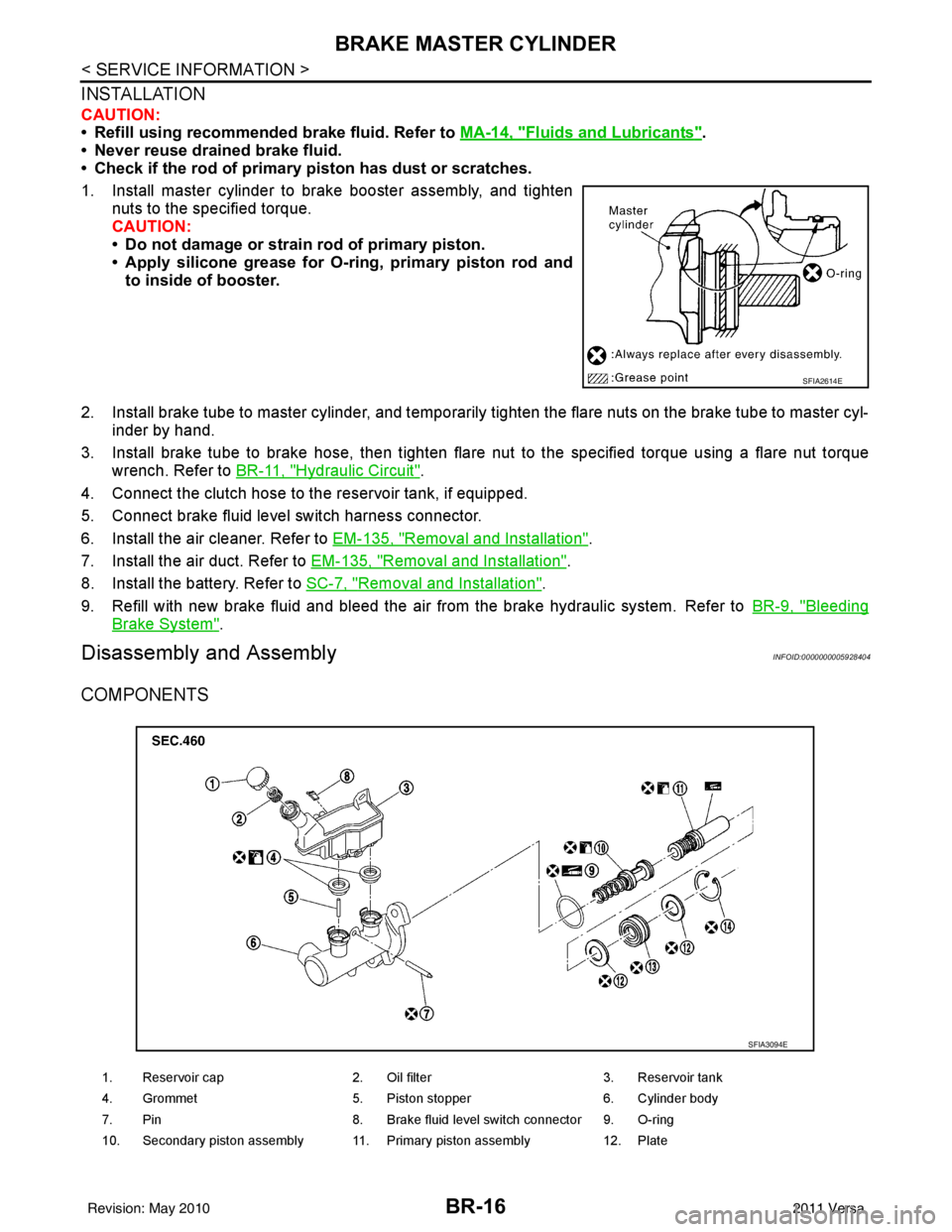

1. Reservoir tank 2. Master cylinder 3. Brake booster

4. Clevis 5. Spacer 6. Gasket

Up

AWFIA0530GB

Revision: May 2010 2011 Versa

Page 863 of 3787

BR-16

< SERVICE INFORMATION >

BRAKE MASTER CYLINDER

INSTALLATION

CAUTION:

• Refill using recommended brake fluid. Refer to MA-14, "

Fluids and Lubricants".

• Never reuse drained brake fluid.

• Check if the rod of primary piston has dust or scratches.

1. Install master cylinder to brake booster assembly, and tighten nuts to the specified torque.

CAUTION:

• Do not damage or strain rod of primary piston.

• Apply silicone grease for O-ring, primary piston rod andto inside of booster.

2. Install brake tube to master cylinder, and temporarily tighten the flare nuts on the brake tube to master cyl- inder by hand.

3. Install brake tube to brake hose, then tighten flare nut to the specified torque using a flare nut torque

wrench. Refer to BR-11, "

Hydraulic Circuit".

4. Connect the clutch hose to the reservoir tank, if equipped.

5. Connect brake fluid level switch harness connector.

6. Install the air cleaner. Refer to EM-135, "

Removal and Installation".

7. Install the air duct. Refer to EM-135, "

Removal and Installation".

8. Install the battery. Refer to SC-7, "

Removal and Installation".

9. Refill with new brake fluid and bleed the air from the brake hydraulic system. Refer toBR-9, "

Bleeding

Brake System".

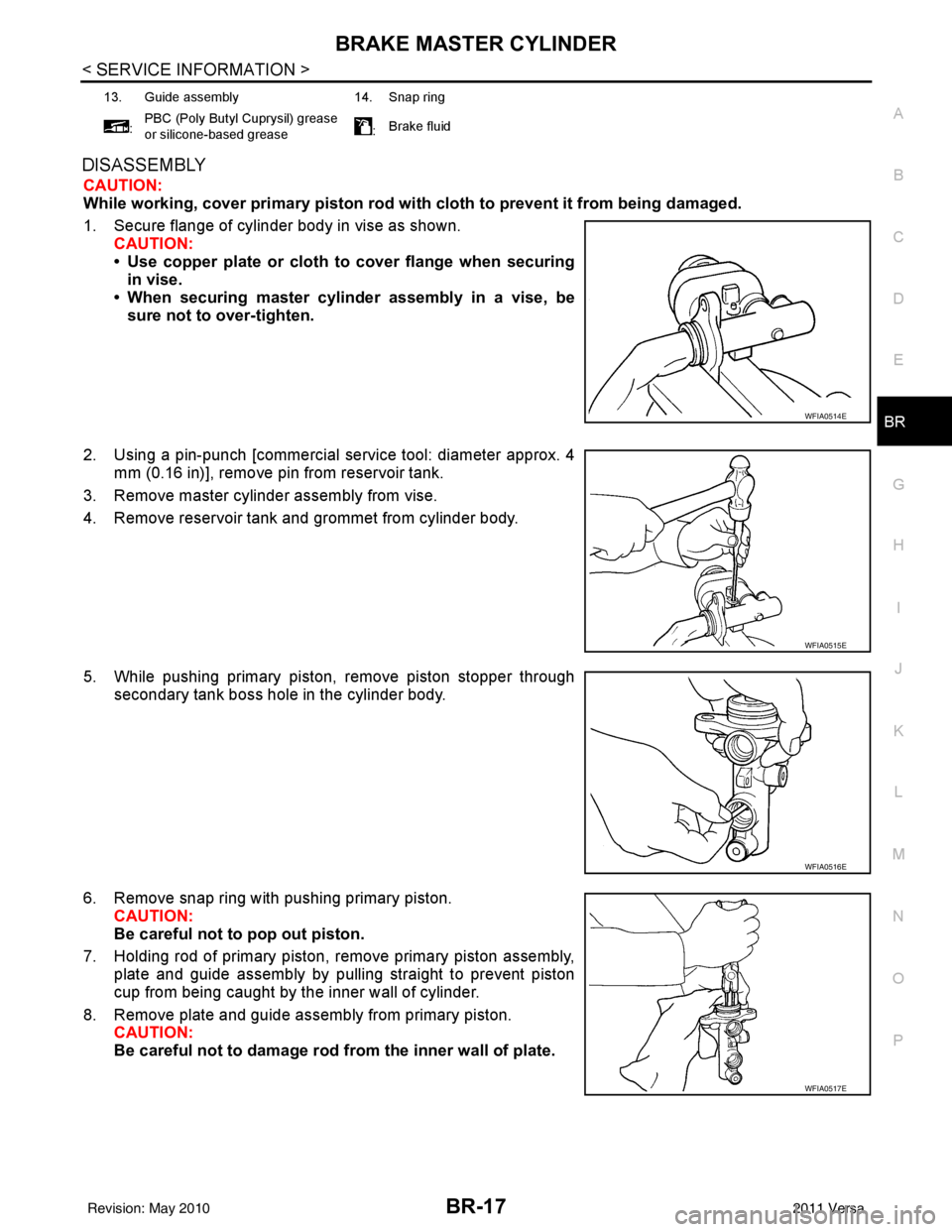

Disassembly and AssemblyINFOID:0000000005928404

COMPONENTS

SFIA2614E

1. Reservoir cap2. Oil filter 3. Reservoir tank

4. Grommet 5. Piston stopper 6. Cylinder body

7. Pin 8. Brake fluid level switch connector 9. O-ring

10. Secondary piston assembly 11. Primary piston assembly 12. Plate

SFIA3094E

Revision: May 2010 2011 Versa

Page 864 of 3787

BRAKE MASTER CYLINDERBR-17

< SERVICE INFORMATION >

C

DE

G H

I

J

K L

M A

B

BR

N

O P

DISASSEMBLY

CAUTION:

While working, cover primary piston rod wi th cloth to prevent it from being damaged.

1. Secure flange of cylinder body in vise as shown. CAUTION:

• Use copper plate or cloth to cover flange when securingin vise.

• When securing master cylinder assembly in a vise, be

sure not to over-tighten.

2. Using a pin-punch [commercial service tool: diameter approx. 4 mm (0.16 in)], remove pin from reservoir tank.

3. Remove master cylinder assembly from vise.

4. Remove reservoir tank and grommet from cylinder body.

5. While pushing primary piston, remove piston stopper through secondary tank boss hole in the cylinder body.

6. Remove snap ring with pushing primary piston. CAUTION:

Be careful not to pop out piston.

7. Holding rod of primary piston, remove primary piston assembly, plate and guide assembly by pulling straight to prevent piston

cup from being caught by the inner wall of cylinder.

8. Remove plate and guide assembly from primary piston. CAUTION:

Be careful not to damage rod from the inner wall of plate.

13. Guide assembly 14. Snap ring

: PBC (Poly Butyl Cuprysil) grease

or silicone-based grease

:Brake fluid

WFIA0514E

WFIA0515E

WFIA0516E

BRA0561DWFIA0517E

Revision: May 2010

2011 Versa

Page 865 of 3787

BR-18

< SERVICE INFORMATION >

BRAKE MASTER CYLINDER

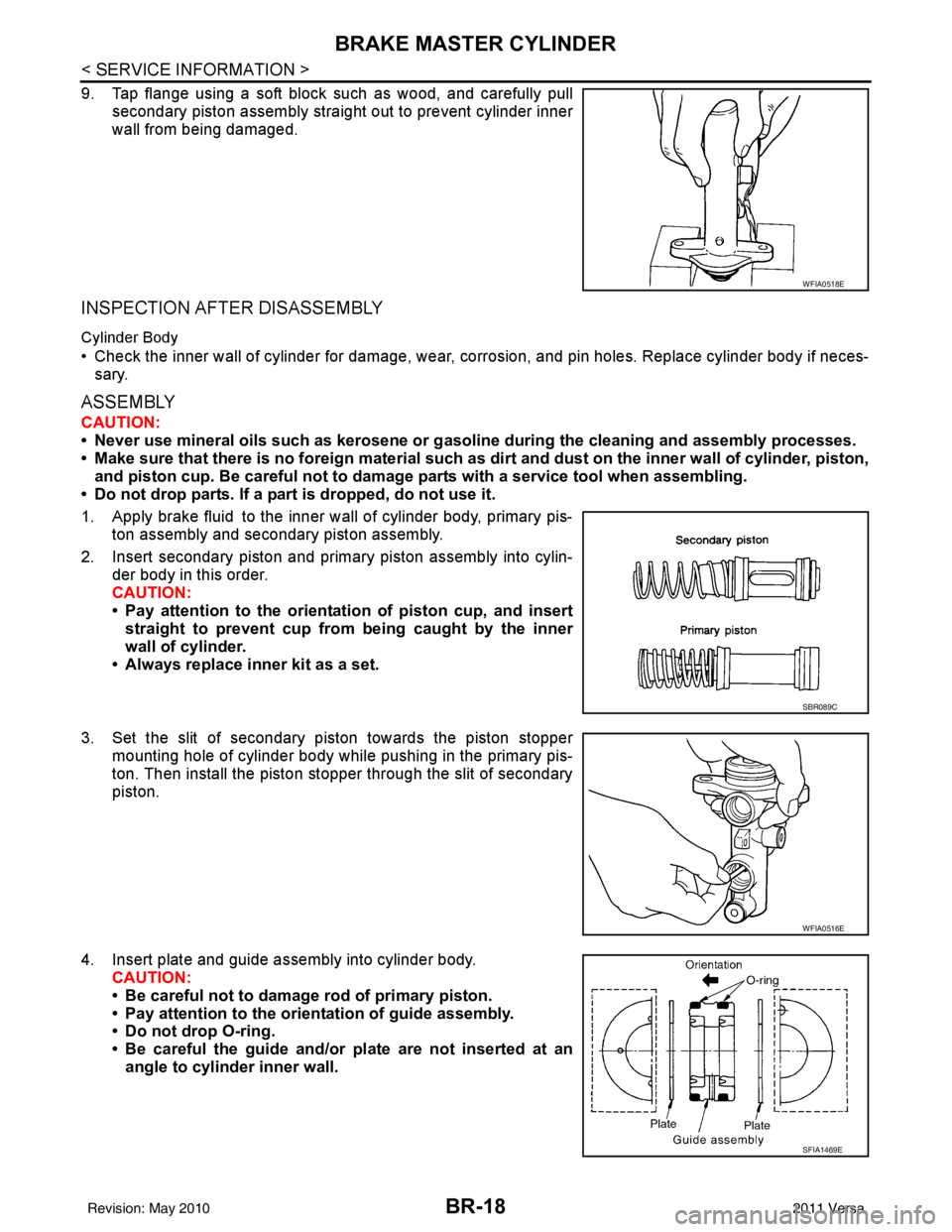

9. Tap flange using a soft block such as wood, and carefully pullsecondary piston assembly straight out to prevent cylinder inner

wall from being damaged.

INSPECTION AFTER DISASSEMBLY

Cylinder Body

• Check the inner wall of cylinder for damage, wear, corrosion, and pin holes. Replace cylinder body if neces-sary.

ASSEMBLY

CAUTION:

• Never use mineral oils such as kerosene or g asoline during the cleaning and assembly processes.

• Make sure that there is no foreign material such as dirt and dust on the inner wall of cylinder, piston,

and piston cup. Be careful not to damage parts with a service tool when assembling.

• Do not drop parts. If a part is dropped, do not use it.

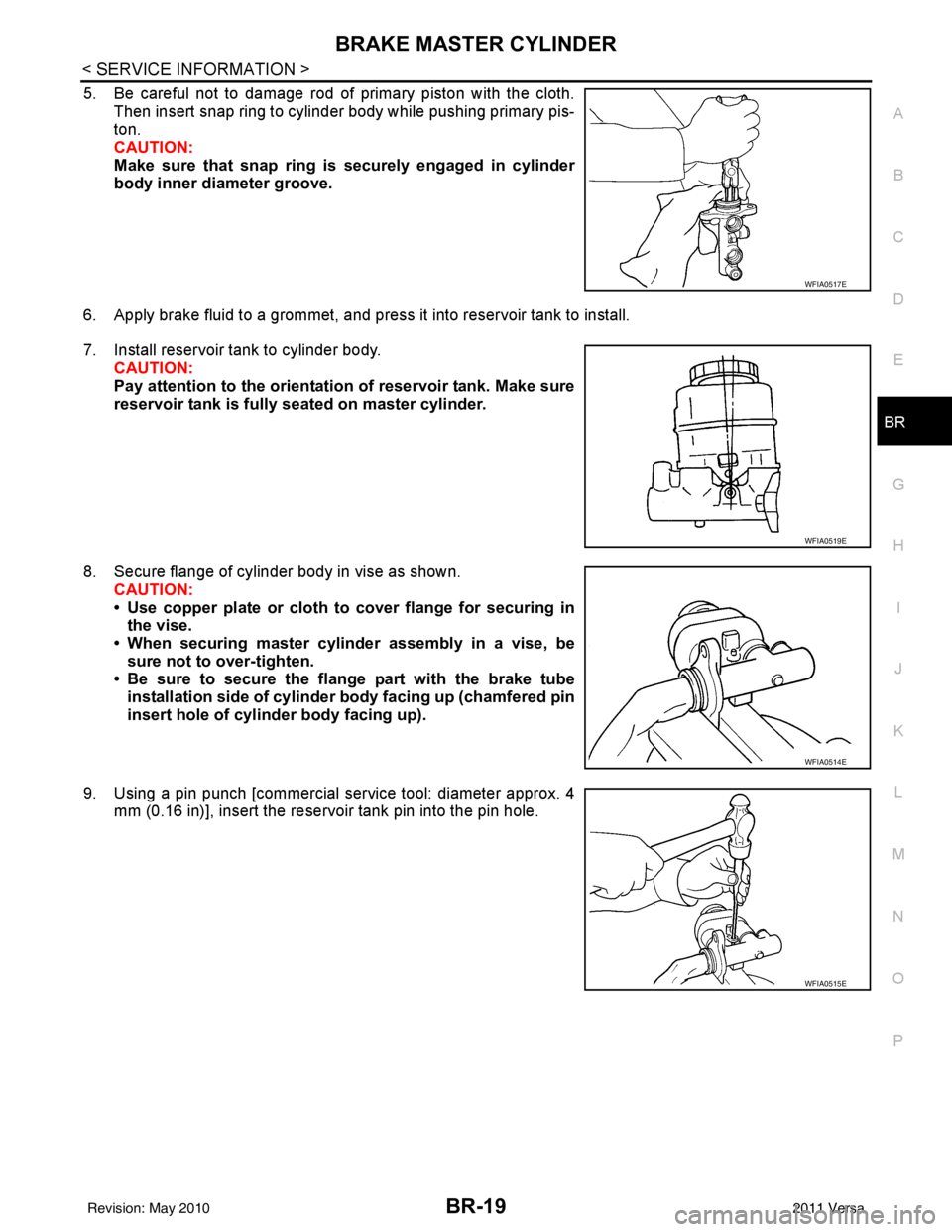

1. Apply brake fluid to the inner wall of cylinder body, primary pis- ton assembly and secondary piston assembly.

2. Insert secondary piston and primary piston assembly into cylin- der body in this order.

CAUTION:

• Pay attention to the orientation of piston cup, and insert

straight to prevent cup from being caught by the inner

wall of cylinder.

• Always replace inner kit as a set.

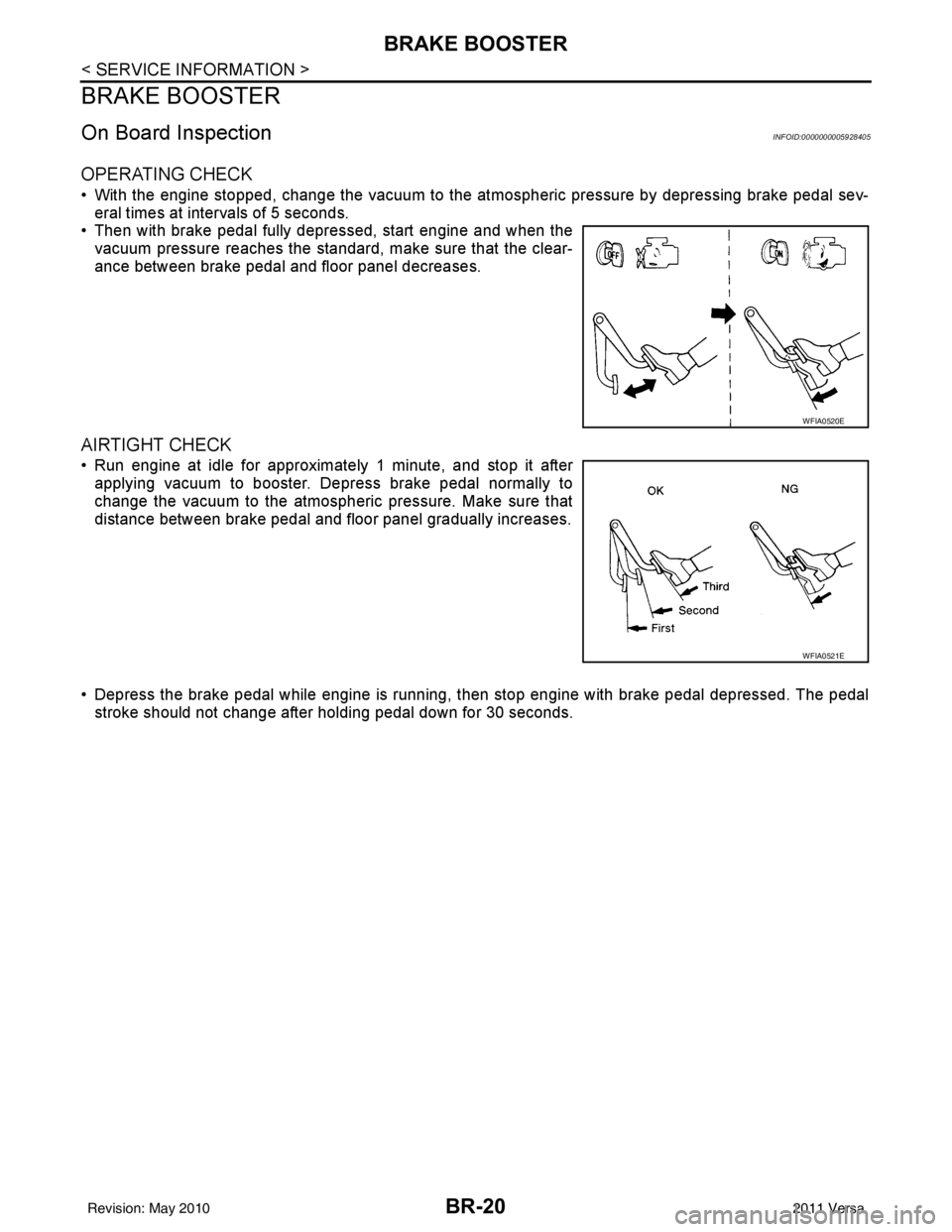

3. Set the slit of secondary piston towards the piston stopper mounting hole of cylinder body while pushing in the primary pis-

ton. Then install the piston stopper through the slit of secondary

piston.

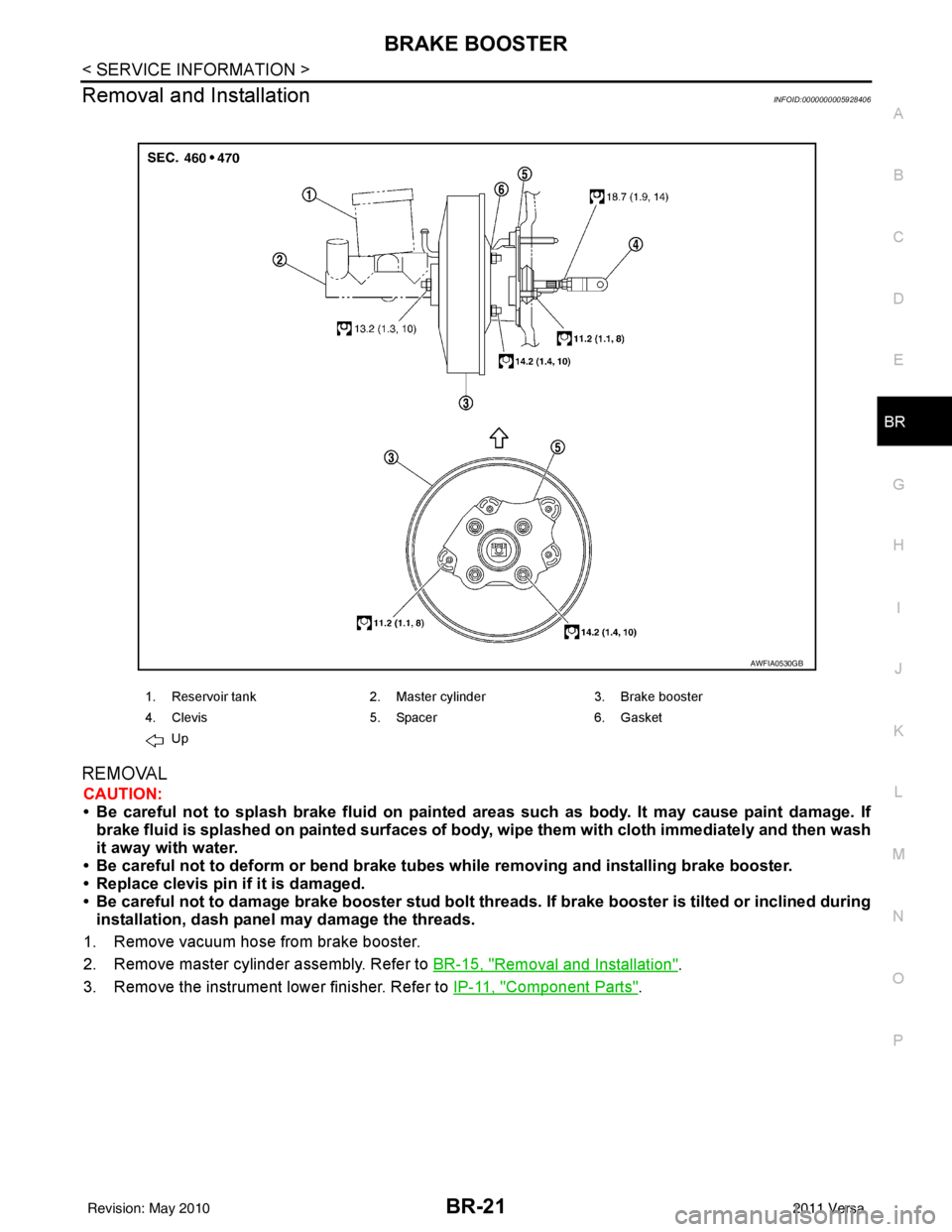

4. Insert plate and guide assembly into cylinder body. CAUTION:

• Be careful not to damage rod of primary piston.

• Pay attention to the orientation of guide assembly.

• Do not drop O-ring.

• Be careful the guide and/or plate are not inserted at an

angle to cylinder inner wall.

WFIA0518E

SBR089C

WFIA0516E

SFIA1469E

Revision: May 2010 2011 Versa

Page 866 of 3787

BRAKE MASTER CYLINDERBR-19

< SERVICE INFORMATION >

C

DE

G H

I

J

K L

M A

B

BR

N

O P

5. Be careful not to damage rod of primary piston with the cloth. Then insert snap ring to cylinder body while pushing primary pis-

ton.

CAUTION:

Make sure that snap ring is securely engaged in cylinder

body inner diameter groove.

6. Apply brake fluid to a grommet, and press it into reservoir tank to install.

7. Install reservoir tank to cylinder body. CAUTION:

Pay attention to the orientation of reservoir tank. Make sure

reservoir tank is fully seated on master cylinder.

8. Secure flange of cylinder body in vise as shown. CAUTION:

• Use copper plate or cloth to cover flange for securing in

the vise.

• When securing master cylinder assembly in a vise, be sure not to over-tighten.

• Be sure to secure the flange part with the brake tube

installation side of cylinder body facing up (chamfered pin

insert hole of cylinder body facing up).

9. Using a pin punch [commercial service tool: diameter approx. 4 mm (0.16 in)], insert the reservoir tank pin into the pin hole.

WFIA0517E

WFIA0519E

WFIA0514E

WFIA0515E

Revision: May 2010 2011 Versa

Page 867 of 3787

BR-20

< SERVICE INFORMATION >

BRAKE BOOSTER

BRAKE BOOSTER

On Board InspectionINFOID:0000000005928405

OPERATING CHECK

• With the engine stopped, change the vacuum to the atmospheric pressure by depressing brake pedal sev-

eral times at intervals of 5 seconds.

• Then with brake pedal fully depressed, start engine and when the vacuum pressure reaches the standard, make sure that the clear-

ance between brake pedal and floor panel decreases.

AIRTIGHT CHECK

• Run engine at idle for approximately 1 minute, and stop it afterapplying vacuum to booster. Depress brake pedal normally to

change the vacuum to the atmospheric pressure. Make sure that

distance between brake pedal and floor panel gradually increases.

• Depress the brake pedal while engine is running, then stop engine with brake pedal depressed. The pedal

stroke should not change after holding pedal down for 30 seconds.

WFIA0520E

WFIA0521E

Revision: May 2010 2011 Versa

Page 868 of 3787

BRAKE BOOSTERBR-21

< SERVICE INFORMATION >

C

DE

G H

I

J

K L

M A

B

BR

N

O P

Removal and InstallationINFOID:0000000005928406

REMOVAL

CAUTION:

• Be careful not to splash brake fluid on painted areas such as body. It may cause paint damage. If brake fluid is splashed on painte d surfaces of body, wipe them with cloth immediately and then wash

it away with water.

• Be careful not to deform or bend brake tub es while removing and installing brake booster.

• Replace clevis pin if it is damaged.

• Be careful not to damage brake booster stud bolt thr eads. If brake booster is tilted or inclined during

installation, dash panel may damage the threads.

1. Remove vacuum hose from brake booster.

2. Remove master cylinder assembly. Refer to BR-15, "

Removal and Installation".

3. Remove the instrument lower finisher. Refer to IP-11, "

Component Parts".

1. Reservoir tank2. Master cylinder 3. Brake booster

4. Clevis 5. Spacer 6. Gasket

Up

AWFIA0530GB

Revision: May 2010 2011 Versa

Page 869 of 3787

BR-22

< SERVICE INFORMATION >

BRAKE BOOSTER

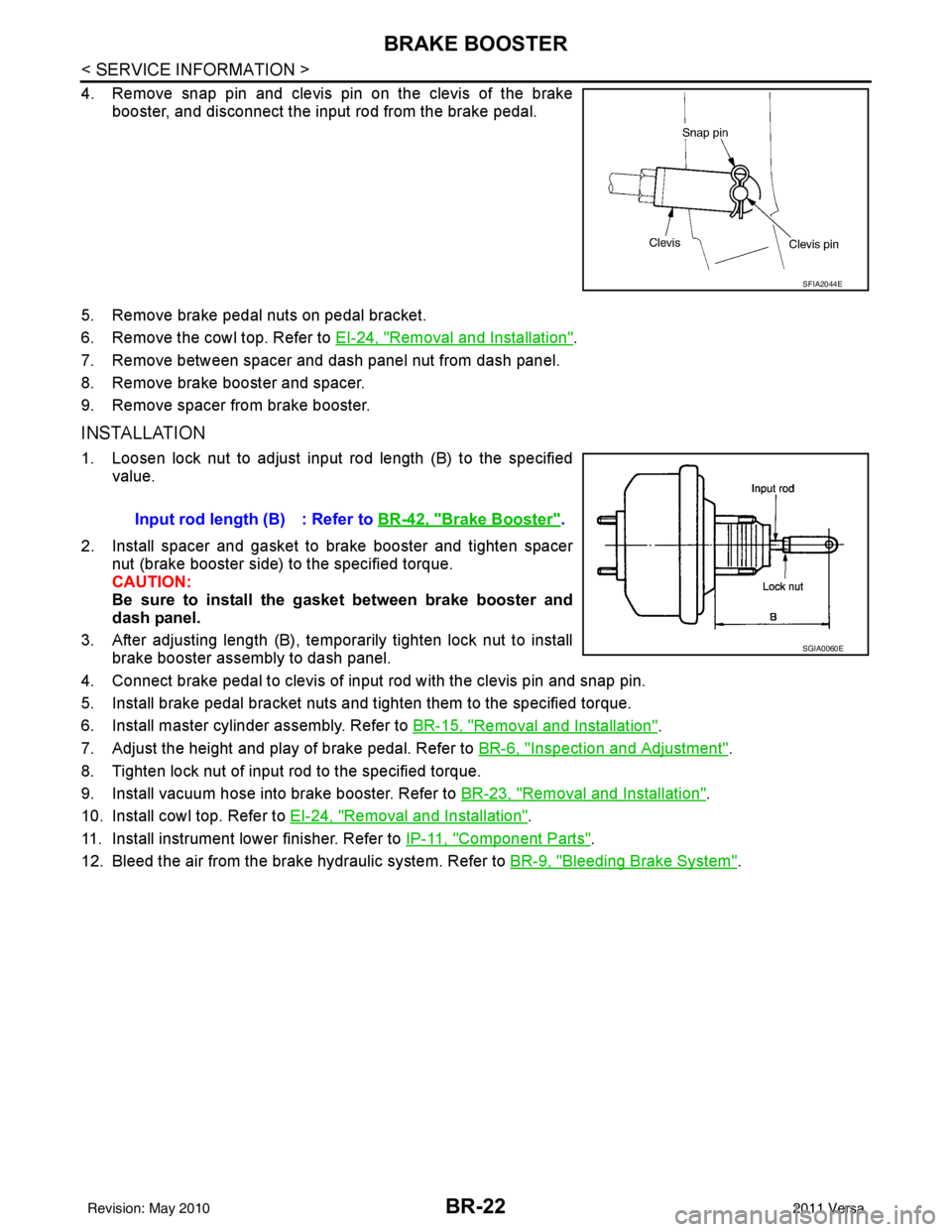

4. Remove snap pin and clevis pin on the clevis of the brakebooster, and disconnect the input rod from the brake pedal.

5. Remove brake pedal nuts on pedal bracket.

6. Remove the cowl top. Refer to EI-24, "

Removal and Installation".

7. Remove between spacer and dash panel nut from dash panel.

8. Remove brake booster and spacer.

9. Remove spacer from brake booster.

INSTALLATION

1. Loosen lock nut to adjust input rod length (B) to the specified value.

2. Install spacer and gasket to brake booster and tighten spacer nut (brake booster side) to the specified torque.

CAUTION:

Be sure to install the gasket between brake booster and

dash panel.

3. After adjusting length (B), temporarily tighten lock nut to install brake booster assembly to dash panel.

4. Connect brake pedal to clevis of input rod with the clevis pin and snap pin.

5. Install brake pedal bracket nuts and tighten them to the specified torque.

6. Install master cylinder assembly. Refer to BR-15, "

Removal and Installation".

7. Adjust the height and play of brake pedal. Refer to BR-6, "

Inspection and Adjustment".

8. Tighten lock nut of input rod to the specified torque.

9. Install vacuum hose into brake booster. Refer to BR-23, "

Removal and Installation".

10. Install cowl top. Refer to EI-24, "

Removal and Installation".

11. Install instrument lower finisher. Refer to IP-11, "

Component Parts".

12. Bleed the air from the brake hydraulic system. Refer to BR-9, "

Bleeding Brake System".

SFIA2044E

Input rod length (B) : Refer to BR-42, "Brake Booster".

SGIA0060E

Revision: May 2010 2011 Versa

Page 870 of 3787

VACUUM LINESBR-23

< SERVICE INFORMATION >

C

DE

G H

I

J

K L

M A

B

BR

N

O P

VACUUM LINES

ComponentINFOID:0000000005928407

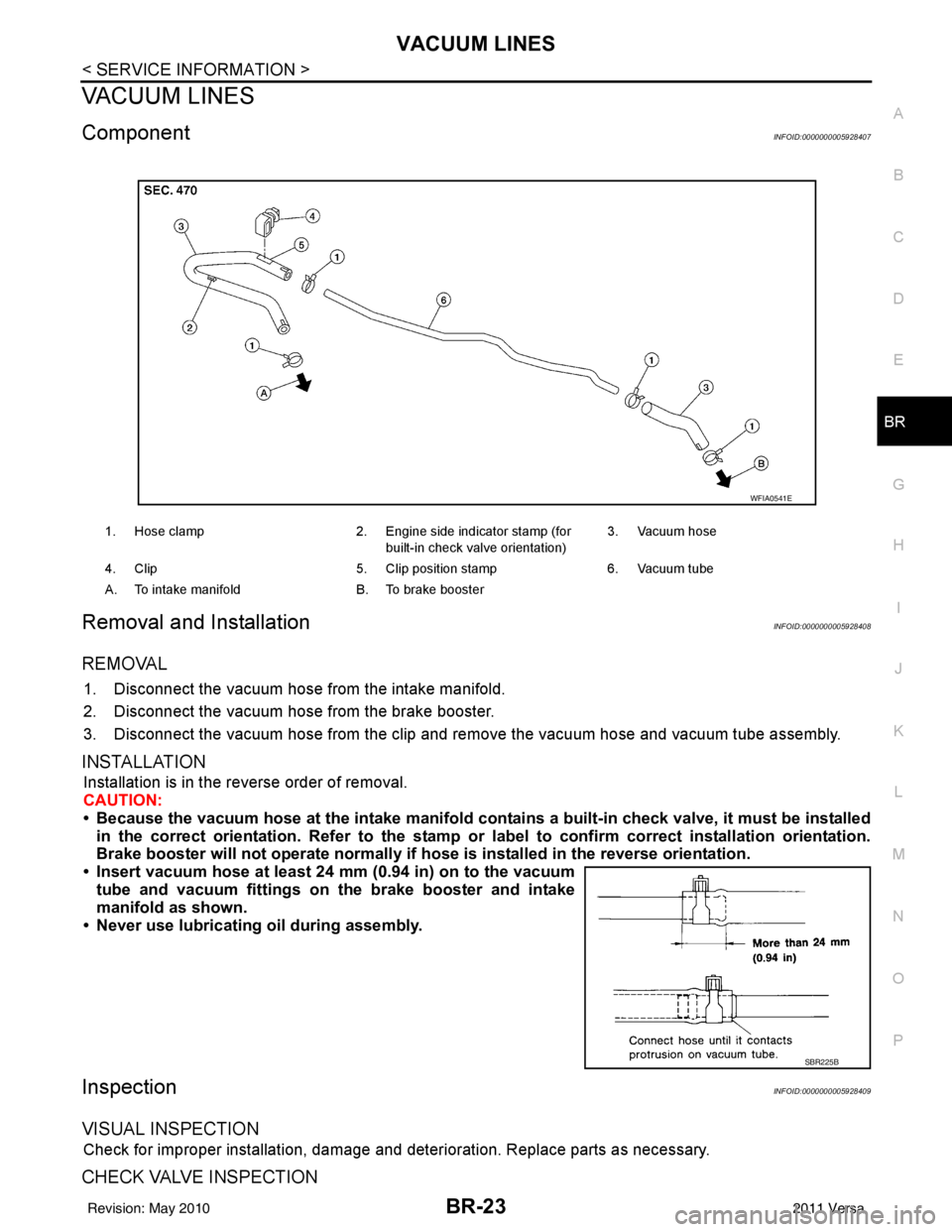

Removal and InstallationINFOID:0000000005928408

REMOVAL

1. Disconnect the vacuum hose from the intake manifold.

2. Disconnect the vacuum hose from the brake booster.

3. Disconnect the vacuum hose from the clip and re move the vacuum hose and vacuum tube assembly.

INSTALLATION

Installation is in the reverse order of removal.

CAUTION:

• Because the vacuum hose at the intake manifold contains a built-in check valve, it must be installed

in the correct orientation. Refer to the stamp or label to confirm correct installation orientation.

Brake booster will not operate normally if ho se is installed in the reverse orientation.

• Insert vacuum hose at least 24 mm (0.94 in) on to the vacuum tube and vacuum fittings on the brake booster and intake

manifold as shown.

• Never use lubricating oil during assembly.

InspectionINFOID:0000000005928409

VISUAL INSPECTION

Check for improper installation, damage and deterioration. Replace parts as necessary.

CHECK VALVE INSPECTION

1. Hose clamp 2. Engine side indicator stamp (for

built-in check valve orientation) 3. Vacuum hose

4. Clip 5. Clip position stamp6. Vacuum tube

A. To intake manifold B. To brake booster

WFIA0541E

SBR225B

Revision: May 2010 2011 Versa