sensor NISSAN LATIO 2011 Service Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2011, Model line: LATIO, Model: NISSAN LATIO 2011Pages: 3787, PDF Size: 78.35 MB

Page 3393 of 3787

REFRIGERANT LINESMTC-77

< SERVICE INFORMATION >

C

DE

F

G H

I

K L

M A

B

MTC

N

O P

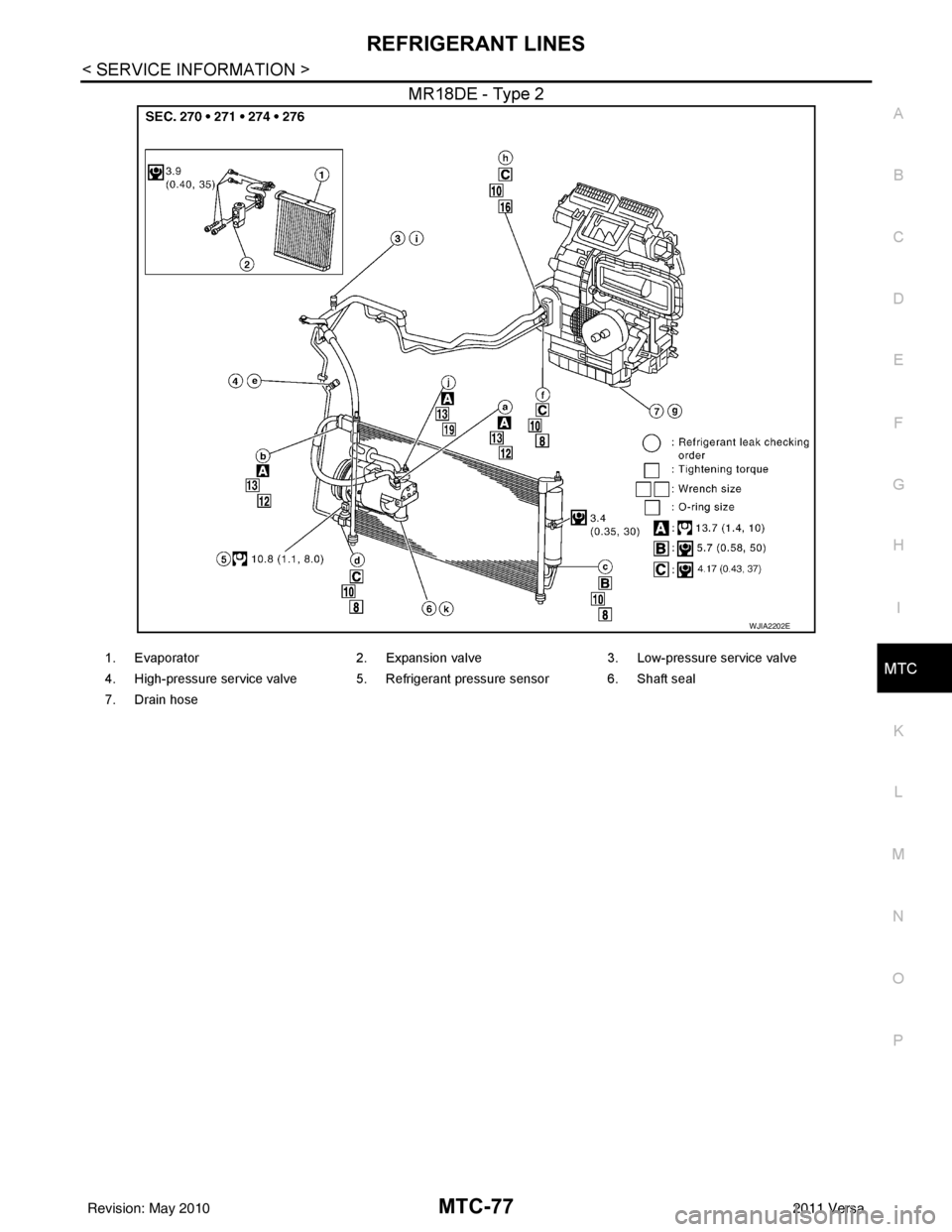

MR18DE - Type 2

WJIA2202E

1. Evaporator 2. Expansion valve3. Low-pressure service valve

4. High-pressure service valve 5. Refrigerant pressure sensor 6. Shaft seal

7. Drain hose

Revision: May 2010 2011 Versa

Page 3405 of 3787

REFRIGERANT LINESMTC-89

< SERVICE INFORMATION >

C

DE

F

G H

I

K L

M A

B

MTC

N

O P

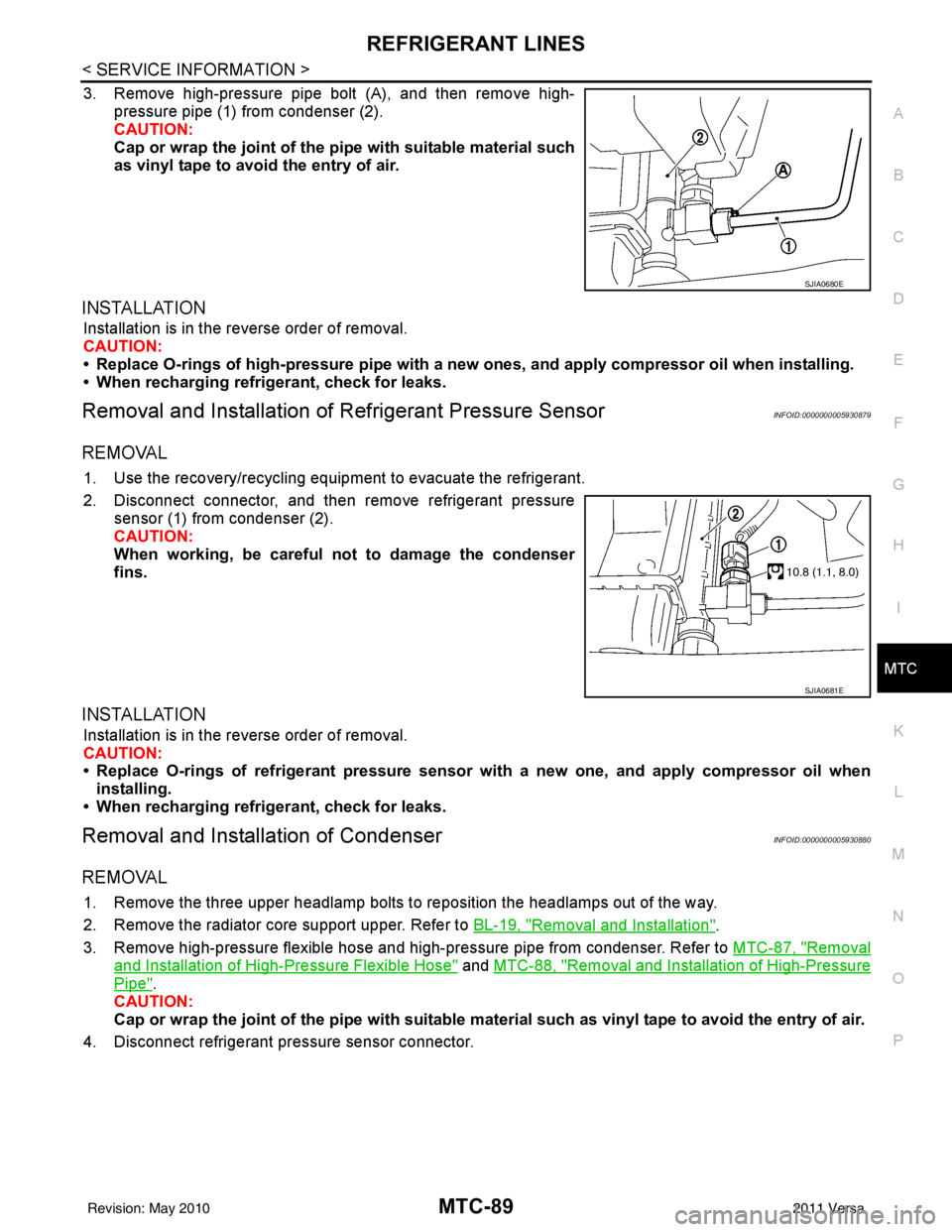

3. Remove high-pressure pipe bolt (A), and then remove high- pressure pipe (1) from condenser (2).

CAUTION:

Cap or wrap the joint of the pi pe with suitable material such

as vinyl tape to avoid the entry of air.

INSTALLATION

Installation is in the reverse order of removal.

CAUTION:

• Replace O-rings of high-pressure pipe with a new ones, and apply compr essor oil when installing.

• When recharging refrigerant, check for leaks.

Removal and Installation of Refrigerant Pressure SensorINFOID:0000000005930879

REMOVAL

1. Use the recovery/recycling equipment to evacuate the refrigerant.

2. Disconnect connector, and then remove refrigerant pressure

sensor (1) from condenser (2).

CAUTION:

When working, be careful not to damage the condenser

fins.

INSTALLATION

Installation is in the reverse order of removal.

CAUTION:

• Replace O-rings of refrigerant pressure senso r with a new one, and apply compressor oil when

installing.

• When recharging refrigerant, check for leaks.

Removal and Installation of CondenserINFOID:0000000005930880

REMOVAL

1. Remove the three upper headlamp bolts to reposition the headlamps out of the way.

2. Remove the radiator core support upper. Refer to BL-19, "

Removal and Installation".

3. Remove high-pressure flexible hose and high-pressure pipe from condenser. Refer to MTC-87, "

Removal

and Installation of High-Pressure Flexible Hose" and MTC-88, "Removal and Installation of High-Pressure

Pipe".

CAUTION:

Cap or wrap the joint of the pipe with suitable ma terial such as vinyl tape to avoid the entry of air.

4. Disconnect refrigerant pr essure sensor connector.

SJIA0680E

SJIA0681E

Revision: May 2010 2011 Versa

Page 3409 of 3787

REFRIGERANT LINESMTC-93

< SERVICE INFORMATION >

C

DE

F

G H

I

K L

M A

B

MTC

N

O P

Other gases in the work area or substances on the A/C components, for example, anti-freeze, windshield

washer fluid, solvents and oils, may falsely trigger the leak detector. Make sure the surfaces to be checked are

clean.

Clean with a dry cloth or blow off with shop air.

Do not allow the sensor tip of the detector to contact with any substance. This can also cause false readings

and may damage the detector.

Dye InjectionINFOID:0000000005930886

(This procedure is only necessary when recharging t he system or when the compressor has seized and was

replaced.)

1. Check A/C system static (at rest) pressure. Pres sure must be at least 345 kPa (3.45 bar, 3.52 kg/cm

2, 50

psi).

2. Pour one bottle (1/4 ounce / 7.4 cc) of the A/C refrigerant dye into the injector tool J-41459.

3. Connect the injector tool to the A/C low-pressure side service fitting.

4. Start engine and switch A/C ON.

5. When the A/C operating (compressor running), inject one bottle (1/4 ounce / 7.4 cc) of fluorescent dye

through the low-pressure service valve using dye injector tool J-41459 (refer to the manufacture’s operat-

ing instructions).

6. With the engine still running, disconnect the injector tool from the service fitting.

CAUTION:

Be careful the A/C system or replacing a componen t, pour the dye directly into the open system

connection and proceed wi th the service procedures.

7. Operate the A/C system for a minimum of 20 minutes to mix the dye with the system oil. Depending on the

leak size, operating conditions and location of the leak , it may take from minutes to days for the dye to

penetrate a leak and become visible.

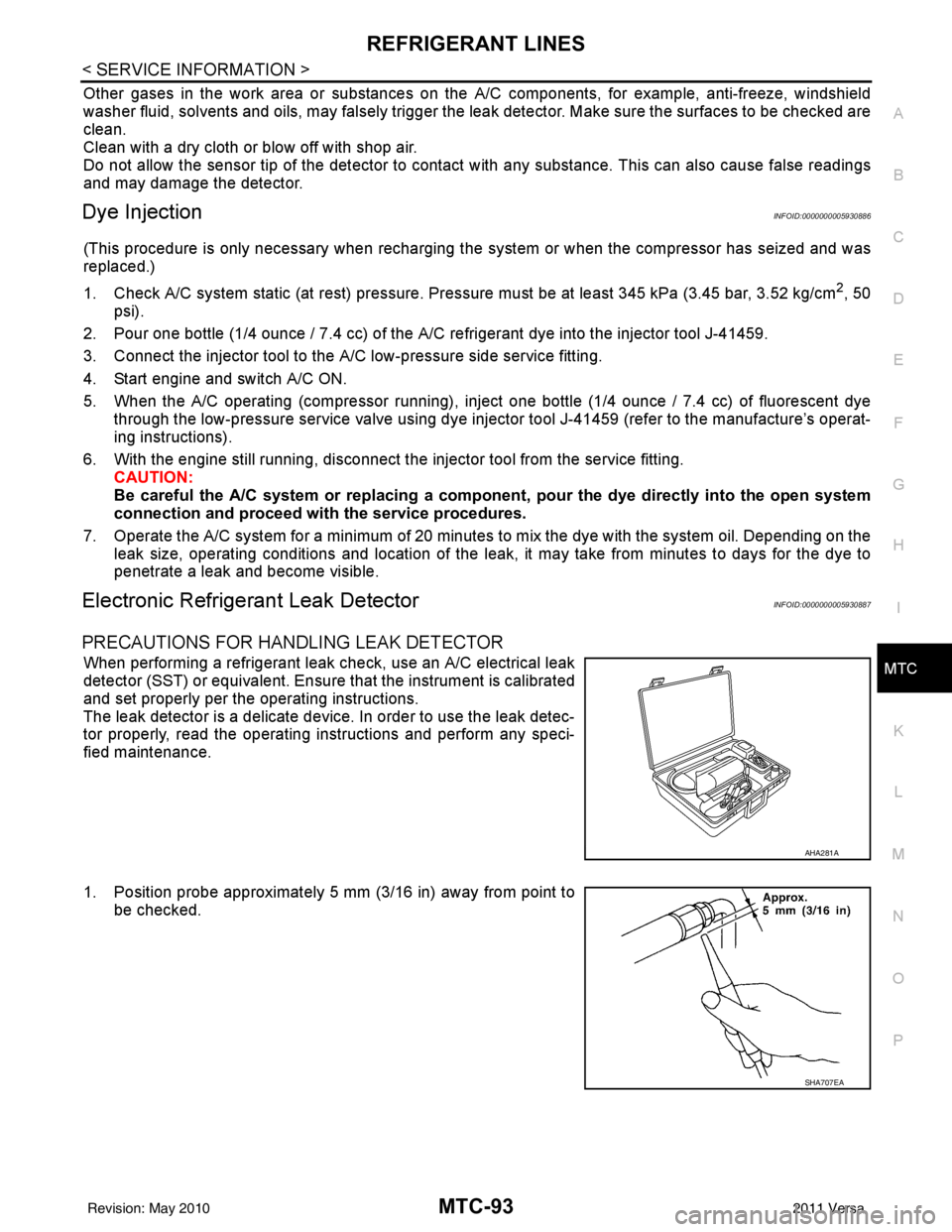

Electronic Refrigerant Leak DetectorINFOID:0000000005930887

PRECAUTIONS FOR HANDLING LEAK DETECTOR

When performing a refrigerant leak check, use an A/C electrical leak

detector (SST) or equivalent. Ensure that the instrument is calibrated

and set properly per the operating instructions.

The leak detector is a delicate device. In order to use the leak detec-

tor properly, read the operating instructions and perform any speci-

fied maintenance.

1. Position probe approximately 5 mm (3/16 in) away from point to

be checked.

AHA281A

SHA707EA

Revision: May 2010 2011 Versa

Page 3410 of 3787

MTC-94

< SERVICE INFORMATION >

REFRIGERANT LINES

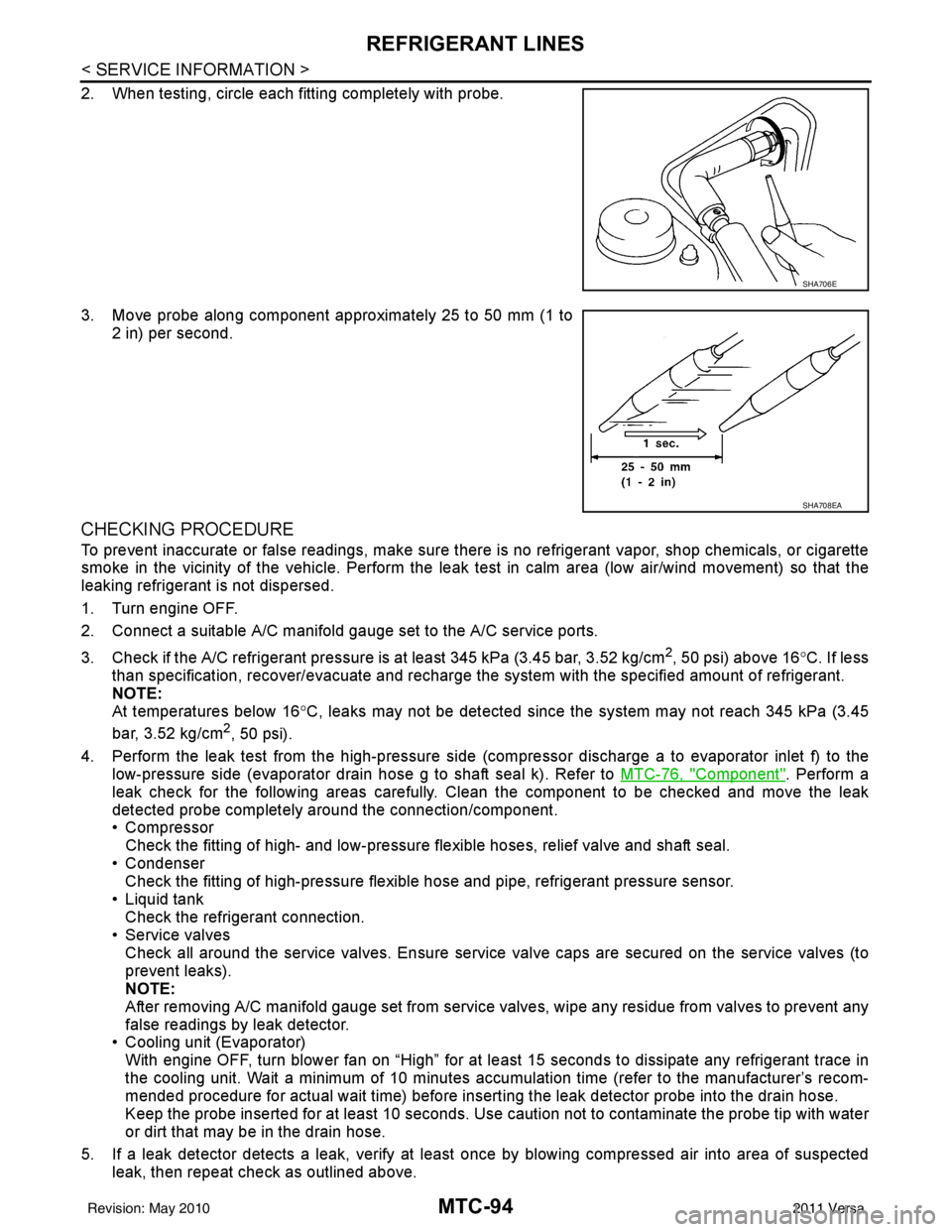

2. When testing, circle each fitting completely with probe.

3. Move probe along component approximately 25 to 50 mm (1 to2 in) per second.

CHECKING PROCEDURE

To prevent inaccurate or false readings, make sure there is no refrigerant vapor, shop chemicals, or cigarette

smoke in the vicinity of the vehicle. Perform the leak test in calm area (low air/wind movement) so that the

leaking refrigerant is not dispersed.

1. Turn engine OFF.

2. Connect a suitable A/C manifold gauge set to the A/C service ports.

3. Check if the A/C refrigerant pressure is at least 345 kPa (3.45 bar, 3.52 kg/cm

2, 50 psi) above 16°C. If less

than specification, recover/evacuate and recharge the system with the specified amount of refrigerant.

NOTE:

At temperatures below 16 °C, leaks may not be detected since t he system may not reach 345 kPa (3.45

bar, 3.52 kg/cm

2, 50 psi).

4. Perform the leak test from the high-pressure side (compressor dischar ge a to evaporator inlet f) to the

low-pressure side (evaporator drain hose g to shaft seal k). Refer to MTC-76, "

Component". Perform a

leak check for the following areas carefully. Clean the component to be checked and move the leak

detected probe completely around the connection/component.

• Compressor Check the fitting of high- and low-pressure flexible hoses, relief valve and shaft seal.

• Condenser Check the fitting of high-pressure flexible hose and pipe, refrigerant pressure sensor.

• Liquid tank Check the refrigerant connection.

• Service valves

Check all around the service valves. Ensure service valve caps are secured on the service valves (to

prevent leaks).

NOTE:

After removing A/C manifold gauge set from service valves, wipe any residue from valves to prevent any

false readings by leak detector.

• Cooling unit (Evaporator)

With engine OFF, turn blower fan on “High” for at l east 15 seconds to dissipate any refrigerant trace in

the cooling unit. Wait a minimum of 10 minutes accumulation time (refer to the manufacturer’s recom-

mended procedure for actual wait time) before insert ing the leak detector probe into the drain hose.

Keep the probe inserted for at least 10 seconds. Use c aution not to contaminate the probe tip with water

or dirt that may be in the drain hose.

5. If a leak detector detects a leak, verify at least once by blowing compressed air into area of suspected

leak, then repeat check as outlined above.

SHA706E

SHA708EA

Revision: May 2010 2011 Versa

Page 3414 of 3787

PB-2

< SERVICE INFORMATION >

PRECAUTIONS

SERVICE INFORMATION

PRECAUTIONS

Precaution for Supplemental Restraint System (SRS) "AIR BAG" and "SEAT BELT

PRE-TENSIONER"

INFOID:0000000005929646

The Supplemental Restraint System such as “A IR BAG” and “SEAT BELT PRE-TENSIONER”, used along

with a front seat belt, helps to reduce the risk or severity of injury to the driver and front passenger for certain

types of collision. This system includes seat belt switch inputs and dual stage front air bag modules. The SRS

system uses the seat belt switches to determine the front air bag deployment, and may only deploy one front

air bag, depending on the severity of a collision and w hether the front occupants are belted or unbelted.

Information necessary to service the system safely is included in the SRS and SB section of this Service Man-

ual.

WARNING:

• To avoid rendering the SRS inopera tive, which could increase the risk of personal injury or death in

the event of a collision which would result in air bag inflation, all maintenance must be performed by

an authorized NISSAN/INFINITI dealer.

• Improper maintenance, including incorrect removal and installation of the SRS can lead to personal

injury caused by unintent ional activation of the system. For re moval of Spiral Cable and Air Bag

Module, see the SRS section.

• Do not use electrical test equipmen t on any circuit related to the SRS unless instructed to in this

Service Manual. SRS wiring harn esses can be identified by yellow and/or orange harnesses or har-

ness connectors.

PRECAUTIONS WHEN USING POWER TOOLS (AIR OR ELECTRIC) AND HAMMERS

WARNING:

• When working near the Airbag Diagnosis Sensor Unit or other Airbag System sensors with the Igni-

tion ON or engine running, DO NOT use air or electri c power tools or strike near the sensor(s) with a

hammer. Heavy vibration could activate the sensor( s) and deploy the air bag(s), possibly causing

serious injury.

• When using air or electric power tools or hammers , always switch the Ignition OFF, disconnect the

battery, and wait at least 3 minu tes before performing any service.

Precaution Necessary for Steering W heel Rotation After Battery Disconnect

INFOID:0000000005929647

NOTE:

• This Procedure is applied only to models with Intelligent Key system and NATS (NISSAN ANTI-THEFT SYS-

TEM).

• Remove and install all control units after disconnecting both battery cables with the ignition knob in the

″LOCK ″ position.

• Always use CONSULT-III to perform self-diagnosis as a part of each function inspection after finishing work.

If DTC is detected, perform trouble diagnosis according to self-diagnostic results.

For models equipped with the Intelligent Key system and NATS, an electrically controlled steering lock mech-

anism is adopted on the key cylinder.

For this reason, if the battery is disconnected or if the battery is discharged, the steering wheel will lock and

steering wheel rotation will become impossible.

If steering wheel rotation is required when battery pow er is interrupted, follow the procedure below before

starting the repair operation.

OPERATION PROCEDURE

1. Connect both battery cables. NOTE:

Supply power using jumper cables if battery is discharged.

2. Use the Intelligent Key or mechanical key to turn the ignition switch to the ″ACC ″ position. At this time, the

steering lock will be released.

3. Disconnect both battery cables. The steering lock will remain released and the steering wheel can be rotated.

4. Perform the necessary repair operation.

Revision: May 2010 2011 Versa

Page 3422 of 3787

PG-2

< SERVICE INFORMATION >

PRECAUTIONS

SERVICE INFORMATION

PRECAUTIONS

Precaution for Supplemental Restraint System (SRS) "AIR BAG" and "SEAT BELT

PRE-TENSIONER"

INFOID:0000000005928336

The Supplemental Restraint System such as “A IR BAG” and “SEAT BELT PRE-TENSIONER”, used along

with a front seat belt, helps to reduce the risk or severity of injury to the driver and front passenger for certain

types of collision. This system includes seat belt switch inputs and dual stage front air bag modules. The SRS

system uses the seat belt switches to determine the front air bag deployment, and may only deploy one front

air bag, depending on the severity of a collision and w hether the front occupants are belted or unbelted.

Information necessary to service the system safely is included in the SRS and SB section of this Service Man-

ual.

WARNING:

• To avoid rendering the SRS inopera tive, which could increase the risk of personal injury or death in

the event of a collision which would result in air bag inflation, all maintenance must be performed by

an authorized NISSAN/INFINITI dealer.

• Improper maintenance, including incorrect removal and installation of the SRS can lead to personal

injury caused by unintent ional activation of the system. For re moval of Spiral Cable and Air Bag

Module, see the SRS section.

• Do not use electrical test equipmen t on any circuit related to the SRS unless instructed to in this

Service Manual. SRS wiring harn esses can be identified by yellow and/or orange harnesses or har-

ness connectors.

PRECAUTIONS WHEN USING POWER TOOLS (AIR OR ELECTRIC) AND HAMMERS

WARNING:

• When working near the Airbag Diagnosis Sensor Unit or other Airbag System sensors with the Igni-

tion ON or engine running, DO NOT use air or electri c power tools or strike near the sensor(s) with a

hammer. Heavy vibration could activate the sensor( s) and deploy the air bag(s), possibly causing

serious injury.

• When using air or electric power tools or hammers , always switch the Ignition OFF, disconnect the

battery, and wait at least 3 minu tes before performing any service.

Precaution Necessary for Steering W heel Rotation After Battery Disconnect

INFOID:0000000006411548

NOTE:

• This Procedure is applied only to models with Intelligent Key system and NATS (NISSAN ANTI-THEFT SYS-

TEM).

• Remove and install all control units after disconnecting both battery cables with the ignition knob in the

″LOCK ″ position.

• Always use CONSULT-III to perform self-diagnosis as a part of each function inspection after finishing work.

If DTC is detected, perform trouble diagnosis according to self-diagnostic results.

For models equipped with the Intelligent Key system and NATS, an electrically controlled steering lock mech-

anism is adopted on the key cylinder.

For this reason, if the battery is disconnected or if the battery is discharged, the steering wheel will lock and

steering wheel rotation will become impossible.

If steering wheel rotation is required when battery pow er is interrupted, follow the procedure below before

starting the repair operation.

OPERATION PROCEDURE

1. Connect both battery cables. NOTE:

Supply power using jumper cables if battery is discharged.

2. Use the Intelligent Key or mechanical key to turn the ignition switch to the ″ACC ″ position. At this time, the

steering lock will be released.

3. Disconnect both battery cables. The steering lock will remain released and the steering wheel can be rotated.

4. Perform the necessary repair operation.

Revision: May 2010 2011 Versa

Page 3461 of 3787

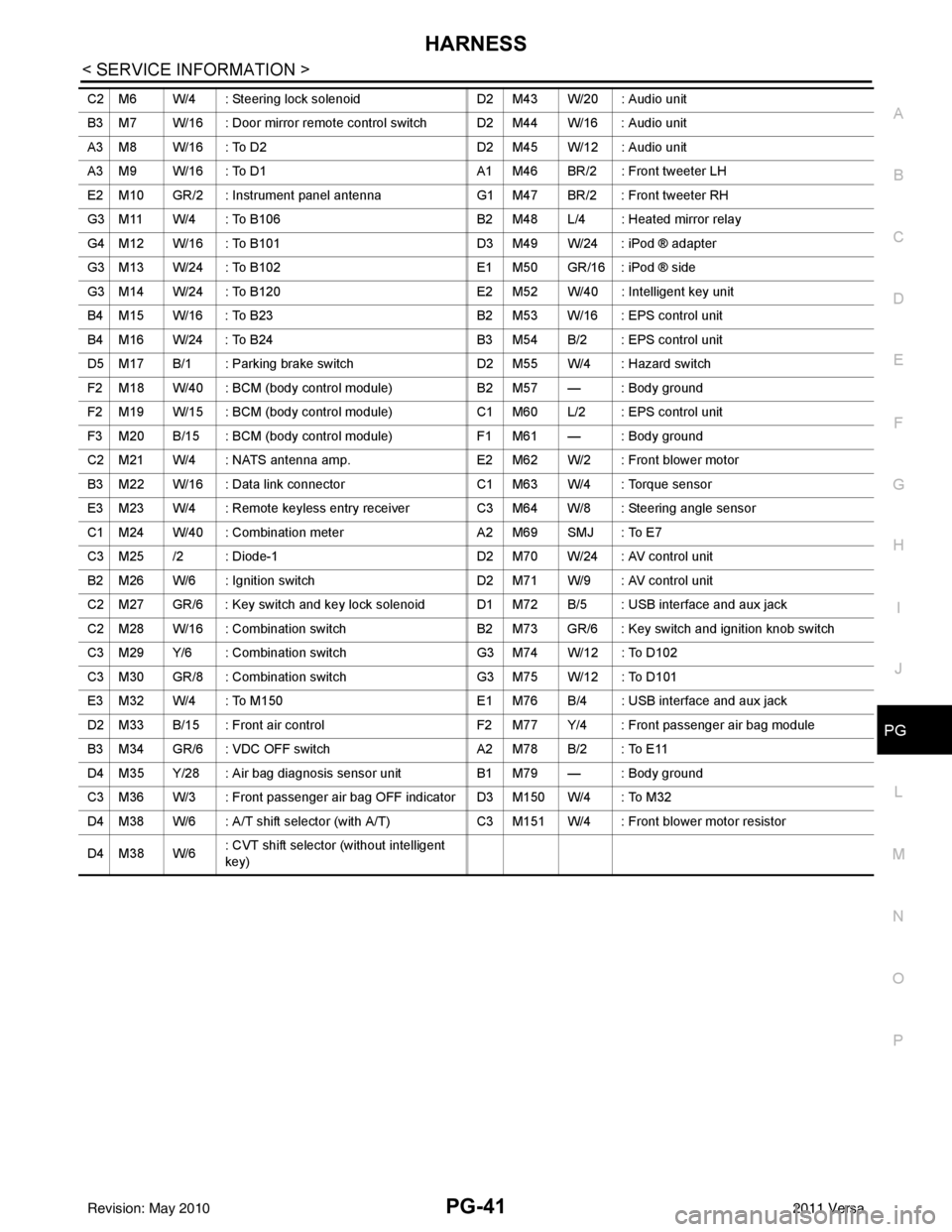

HARNESSPG-41

< SERVICE INFORMATION >

C

DE

F

G H

I

J

L

M A

B

PG

N

O P

C2 M6 W/4 : Steering lock solenoid D2 M43 W/20 : Audio unit

B3 M7 W/16 : Door mirror re mote control switch D2 M44 W/16 : Audio unit

A3 M8 W/16 : To D2 D2 M45 W/12 : Audio unit

A3 M9 W/16 : To D1 A1 M46 BR/2 : Front tweeter LH

E2 M10 GR/2 : Instrument panel antenna G1 M47 BR/2 : Front tweeter RH

G3 M11 W/4 : To B106 B2 M48 L/4 : Heated mirror relay

G4 M12 W/16 : To B101 D3 M49 W/24 : iPod ® adapter

G3 M13 W/24 : To B102 E1 M50 GR/16 : iPod ® side

G3 M14 W/24 : To B120 E2 M52 W/40 : Intelligent key unit

B4 M15 W/16 : To B23 B2 M53 W/16 : EPS control unit

B4 M16 W/24 : To B24 B3 M54 B/2 : EPS control unit

D5 M17 B/1 : Parking brake switch D2 M55 W/4 : Hazard switch

F2 M18 W/40 : BCM (body control module) B2 M57 — : Body ground

F2 M19 W/15 : BCM (body control module) C1 M60 L/2 : EPS control unit

F3 M20 B/15 : BCM (body control module) F1 M61 — : Body ground

C2 M21 W/4 : NATS antenna amp. E2 M62 W/2 : Front blower motor

B3 M22 W/16 : Data link connector C1 M63 W/4 : Torque sensor

E3 M23 W/4 : Remote keyless entry receiver C3 M64 W/8 : Steering angle sensor

C1 M24 W/40 : Combination meter A2 M69 SMJ : To E7

C3 M25 /2 : Diode-1 D2 M70 W/24 : AV control unit

B2 M26 W/6 : Ignition switch D2 M71 W/9 : AV control unit

C2 M27 GR/6 : Key switch and key lock solenoid D1 M72 B/5 : USB interface and aux jack

C2 M28 W/16 : Combination switch B2 M73 GR/6 : Key switch and ignition knob switch

C3 M29 Y/6 : Combination switch G3 M74 W/12 : To D102

C3 M30 GR/8 : Combination switch G3 M75 W/12 : To D101

E3 M32 W/4 : To M150 E1 M76 B/4 : USB interface and aux jack

D2 M33 B/15 : Front air control F2 M77 Y/4 : Front passenger air bag module

B3 M34 GR/6 : VDC OFF switch A2 M78 B/2 : To E11

D4 M35 Y/28 : Air bag diagnosis sensor unit B1 M79 — : Body ground

C3 M36 W/3 : Front passenger air bag OFF indicator D3 M150 W/4 : To M32

D4 M38 W/6 : A/T shift selector (with A/T) C3 M151 W/4 : Front blower motor resistor

D4 M38 W/6 : CVT shift selector (without intelligent

key)

Revision: May 2010

2011 Versa

Page 3463 of 3787

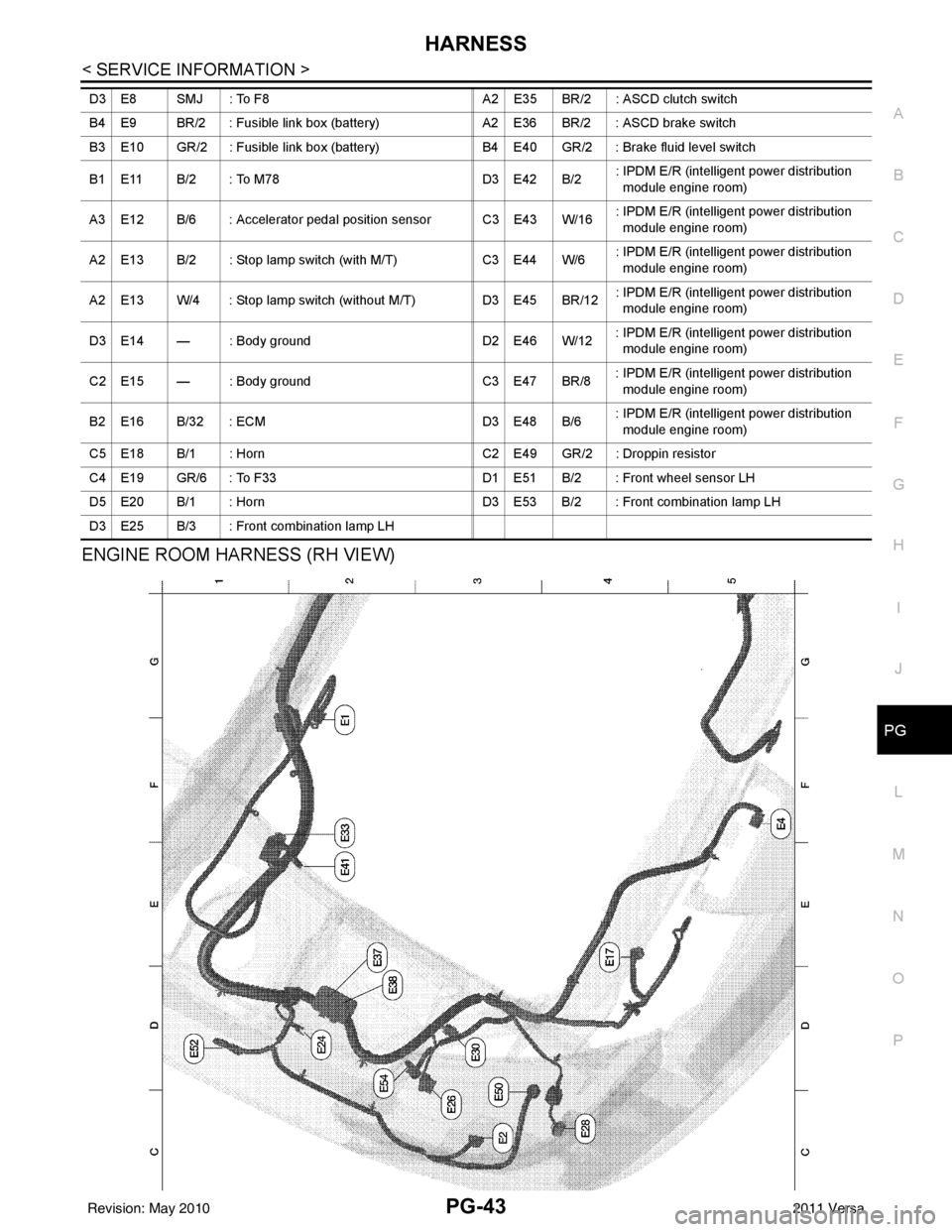

HARNESSPG-43

< SERVICE INFORMATION >

C

DE

F

G H

I

J

L

M A

B

PG

N

O P

ENGINE ROOM HARNESS (RH VIEW)

D3 E8 SMJ : To F8 A2 E35 BR/2 : ASCD clutch switch

B4 E9 BR/2 : Fusible link box (battery) A2 E36 BR/2 : ASCD brake switch

B3 E10 GR/2 : Fusible link box (battery) B4 E40 GR/2 : Brake fluid level switch

B1 E11 B/2 : To M78 D3 E42 B/2: IPDM E/R (intelligent power distribution

module engine room)

A3 E12 B/6 : Accelerator pedal position sensor C3 E43 W/16 : IPDM E/R (intelligent power distribution

module engine room)

A2 E13 B/2 : Stop lamp switch (with M/T) C3 E44 W/6: IPDM E/R (intelligent power distribution

module engine room)

A2 E13 W/4 : Stop lamp switch (without M/T) D3 E45 BR/12: IPDM E/R (intelligent power distribution

module engine room)

D3 E14 — : Body ground D2 E46 W/12: IPDM E/R (intelligent power distribution

module engine room)

C2 E15 — : Body ground C3 E47 BR/8: IPDM E/R (intelligent power distribution

module engine room)

B2 E16 B/32 : ECM D3 E48 B/6: IPDM E/R (intelligent power distribution

module engine room)

C5 E18 B/1 : Horn C2 E49 GR/2 : Droppin resistor

C4 E19 GR/6 : To F33 D1 E51 B/2 : Front wheel sensor LH

D5 E20 B/1 : Horn D3 E53 B/2 : Front combination lamp LH

D3 E25 B/3 : Front combination lamp LH

Revision: May 2010 2011 Versa

Page 3464 of 3787

PG-44

< SERVICE INFORMATION >

HARNESS

Refer to "ENGINE ROOM HARNESS (LH VIEW)" for continuation of engine room harness.

G2 E1 GR/5 : Front wiper motor F2 E33 B/26 : ABS actuator and electric unit (control unit)

C3 E2 B/2 : Front and rear washer motor E2 E37 B/5 : Daytime light relay 1

F5 E4 Y/2 : Crash zone sensor D2 E38 L/5 : Daytime light relay 2

E4 E17 B/3 : Refrigerant pressure sensor E2 E41 — : Ground (ABS)

D2 E24 — : Engine ground C3 E50 W/2 : Washer fluid level switch

C3 E26 B/3 : Front combination lamp RH D1 E52 B/2 : Front wheel sensor RH

C4 E28 B/2 : Front fog lamp RH D2 E54 B/2 : Front combination lamp RH

D3 E30 B/2 : Front combination lamp RH

Revision: May 2010 2011 Versa

Page 3466 of 3787

PG-46

< SERVICE INFORMATION >

HARNESS

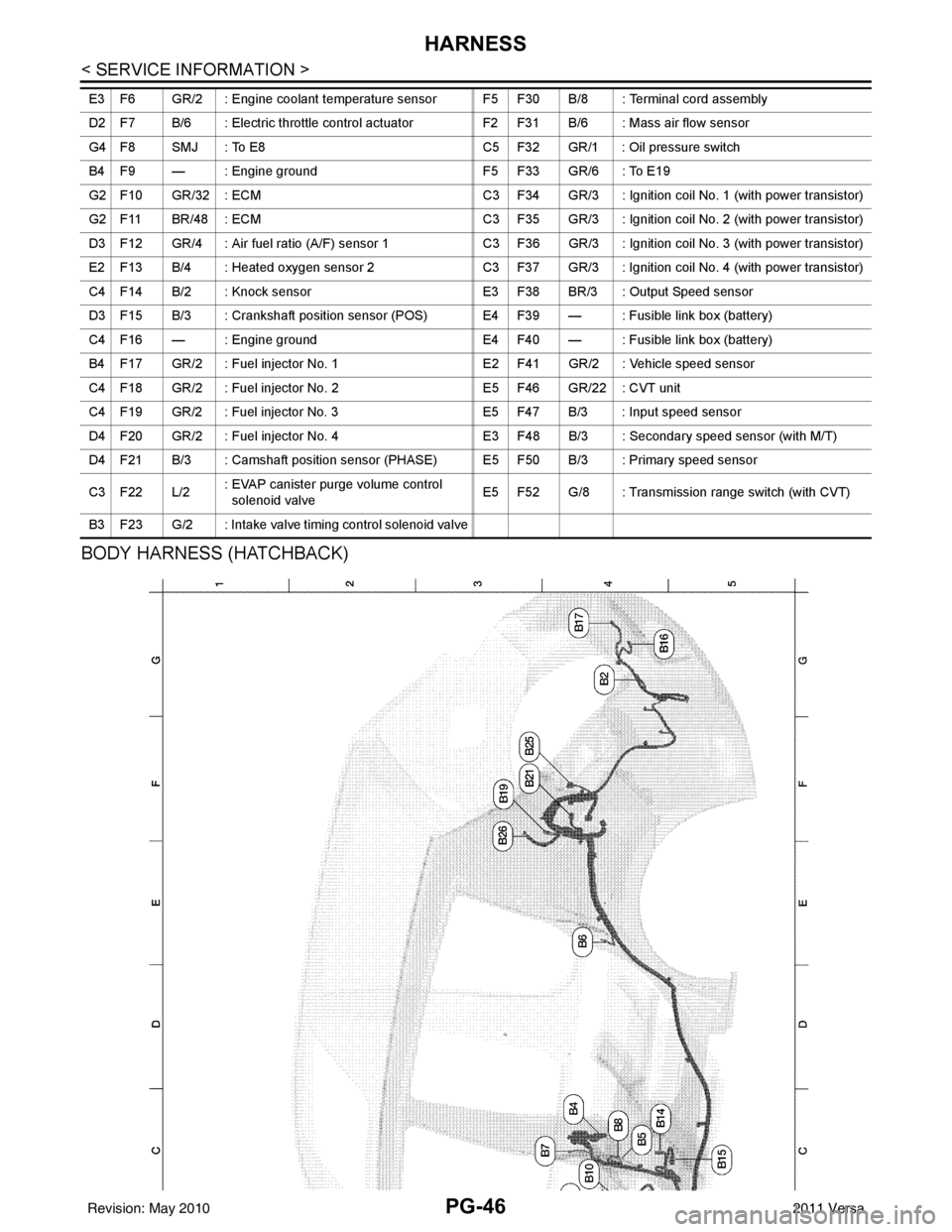

BODY HARNESS (HATCHBACK)

E3 F6 GR/2 : Engine coolant temperature sensor F5 F30 B/8 : Terminal cord assembly

D2 F7 B/6 : Electric throttle control actuatorF2 F31 B/6 : Mass air flow sensor

G4 F8 SMJ : To E8 C5 F32 GR/1 : Oil pressure switch

B4 F9 — : Engine ground F5 F33 GR/6 : To E19

G2 F10 GR/32 : ECM C3 F34 GR/3 : Ignition coil No. 1 (with power transistor)

G2 F11 BR/48 : ECM C3 F35 GR/3 : Ignition coil No. 2 (with power transistor)

D3 F12 GR/4 : Air fuel ratio (A/F) sensor 1 C3 F36 GR/3 : Ignition coil No. 3 (with power transistor)

E2 F13 B/4 : Heated oxygen sensor 2 C3 F37 GR/3 : Ignition coil No. 4 (with power transistor)

C4 F14 B/2 : Knock sensor E3 F38 BR/3 : Output Speed sensor

D3 F15 B/3 : Crankshaft position sensor (POS) E4 F39 — : Fusible link box (battery)

C4 F16 — : Engine ground E4 F40 — : Fusible link box (battery)

B4 F17 GR/2 : Fuel injector No. 1 E2 F41 GR/2 : Vehicle speed sensor

C4 F18 GR/2 : Fuel injector No. 2E5 F46 GR/22 : CVT unit

C4 F19 GR/2 : Fuel injector No. 3 E5 F47 B/3 : Input speed sensor

D4 F20 GR/2 : Fuel injector No. 4 E3 F48 B/3 : Secondary speed sensor (with M/T)

D4 F21 B/3 : Camshaft position sensor (PHASE) E5 F50 B/3 : Primary speed sensor

C3 F22 L/2 : EVAP canister purge volume control

solenoid valve E5 F52 G/8 : Transmission range switch (with CVT)

B3 F23 G/2 : Intake valve timing control solenoid valve

Revision: May 2010 2011 Versa