ECU NISSAN LATIO 2011 Service Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2011, Model line: LATIO, Model: NISSAN LATIO 2011Pages: 3787, PDF Size: 78.35 MB

Page 1 of 3787

-1

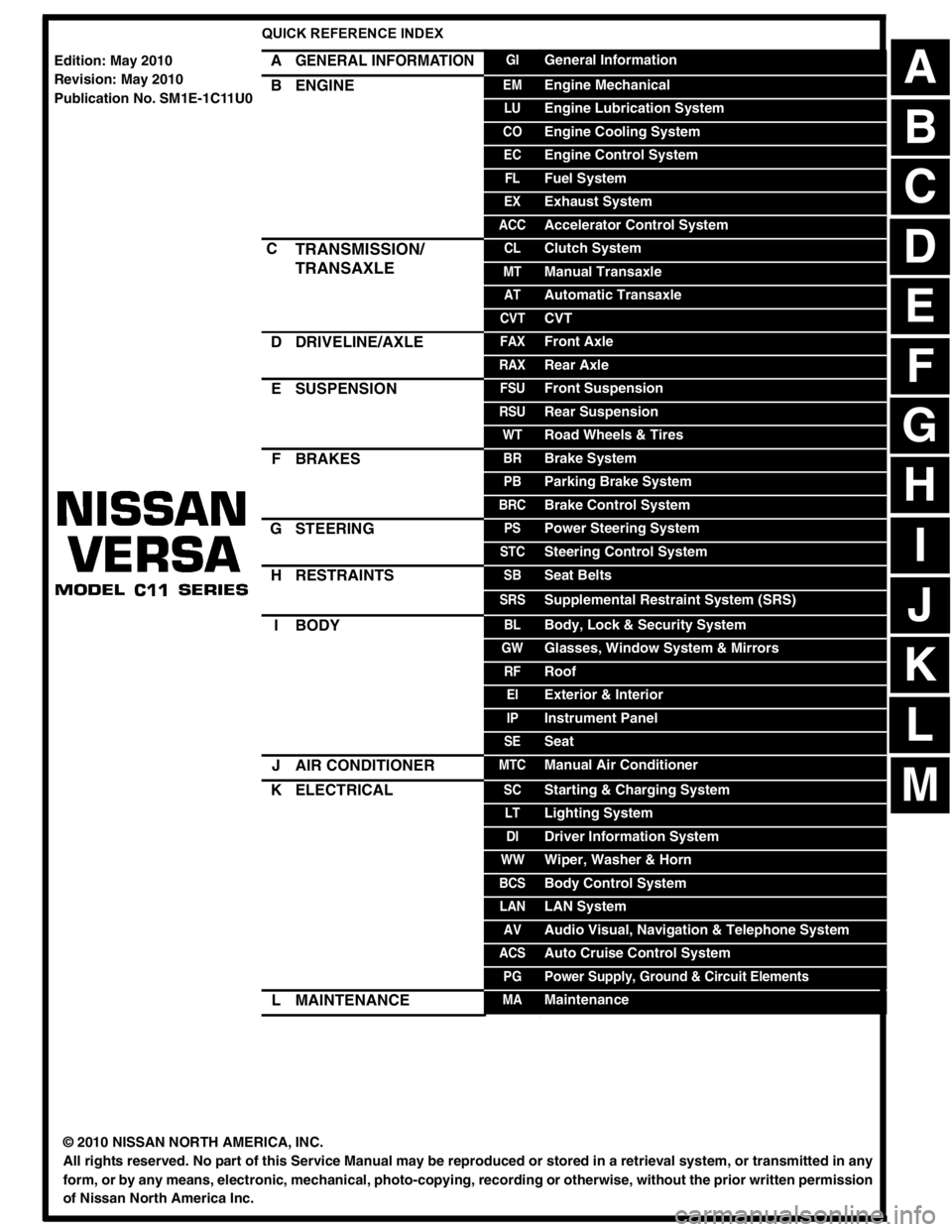

QUICK REFERENCE INDEX

AGENERAL INFORMATIONGIGeneral Information

BENGINEEMEngine Mechanical

LUEngine Lubrication System

COEngine Cooling System

ECEngine Control System

FLFuel System

EXExhaust System

ACCAccelerator Control System

CTRANSMISSION/

TRANSAXLECLClutch System

MTManual Transaxle

ATAutomatic Transaxle

CVTCVT

DDRIVELINE/AXLEFAXFront Axle

RAXRear Axle

ESUSPENSIONFSUFront Suspension

RSURear Suspension

WTRoad Wheels & Tires

FBRAKESBRBrake System

PBParking Brake System

BRCBrake Control System

GSTEERINGPSPower Steering System

STCSteering Control System

HRESTRAINTSSBSeat Belts

SRSSupplemental Restraint System (SRS)

IBODYBLBody, Lock & Security System

GWGlasses, Window System & Mirrors

RFRoof

EIExterior & Interior

IPInstrument Panel

SESeat

JAIR CONDITIONERMTCManual Air Conditioner

KELECTRICALSCStarting & Charging System

LTLighting System

DIDriver Information System

WWWiper, Washer & Horn

BCSBody Control System

LANLAN System

AVAudio Visual, Navigation & Telephone System

ACSAuto Cruise Control System

PGPower Supply, Ground & Circuit Elements

LMAINTENANCEMAMaintenance

Edition: May 2010

Revision: May 2010

Publication No. SM1E-1C11U0

B

D

© 2010 NISSAN NORTH AMERICA, INC.

All rights reserved. No part of this Service Manual may be reproduced or stored in a retrieval system, or transmitted in any

form, or by any means, electronic, mechanical, photo-copying, recording or otherwise, without the prior written permission

of Nissan North America Inc.

A

C

E

F

G

H

I

J

K

L

M

Page 15 of 3787

ACC-4

< SERVICE INFORMATION >

ACCELERATOR CONTROL SYSTEM

ACCELERATOR CONTROL SYSTEM

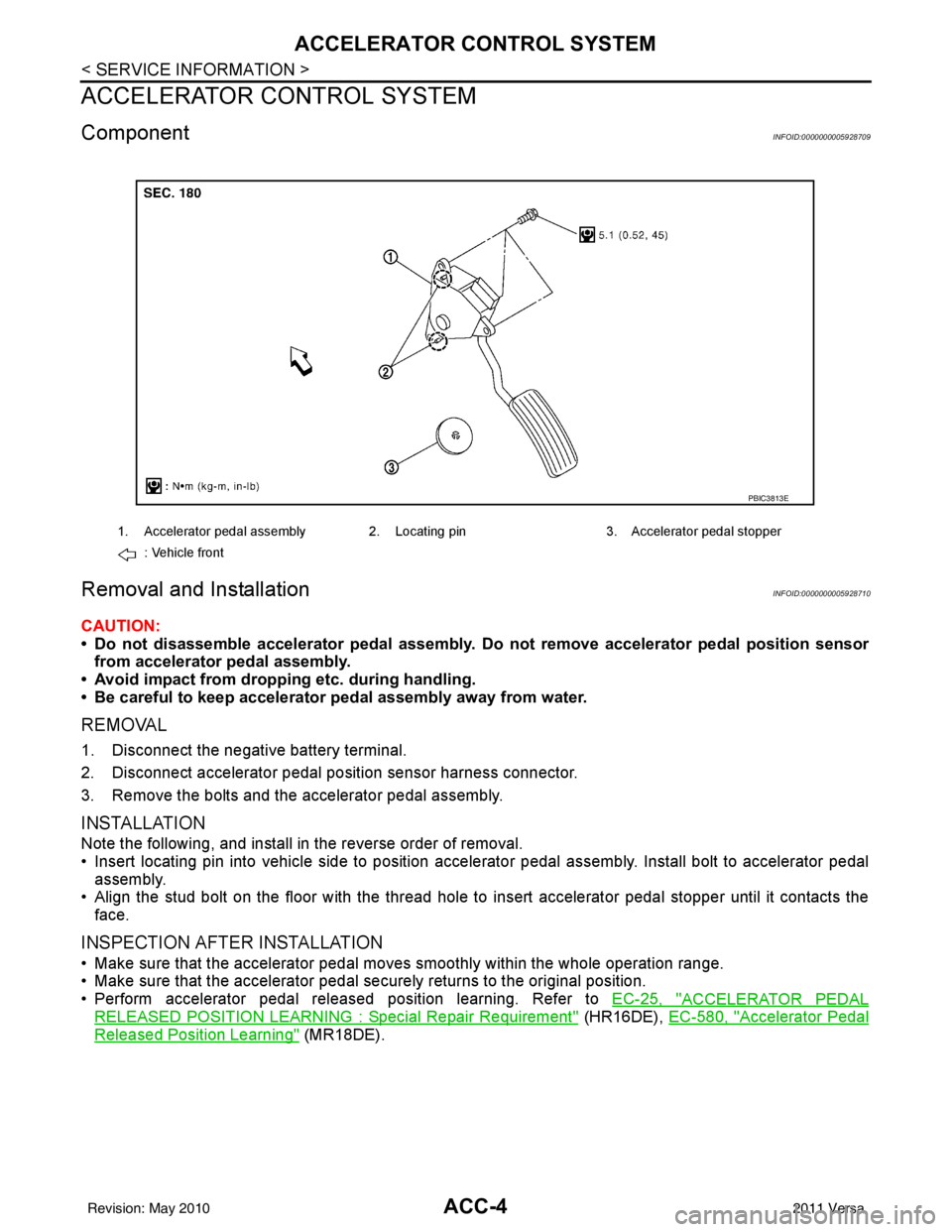

ComponentINFOID:0000000005928709

Removal and InstallationINFOID:0000000005928710

CAUTION:

• Do not disassemble accelerator pedal assembly. Do not remove accelerator pedal position sensor

from accelerator pedal assembly.

• Avoid impact from dropping etc. during handling.

• Be careful to keep accelerator pedal assembly away from water.

REMOVAL

1. Disconnect the negative battery terminal.

2. Disconnect accelerator pedal position sensor harness connector.

3. Remove the bolts and the accelerator pedal assembly.

INSTALLATION

Note the following, and install in the reverse order of removal.

• Insert locating pin into vehicle side to position accelerator pedal assembly. Install bolt to accelerator pedal assembly.

• Align the stud bolt on the floor with the thread hole to insert accelerator pedal stopper until it contacts the

face.

INSPECTION AFTER INSTALLATION

• Make sure that the accelerator pedal moves smoothly within the whole operation range.

• Make sure that the accelerator pedal securely returns to the original position.

• Perform accelerator pedal released position learning. Refer to EC-25, "

ACCELERATOR PEDAL

RELEASED POSITION LEARNING : Special Repair Requirement" (HR16DE), EC-580, "Accelerator Pedal

Released Position Learning" (MR18DE).

1. Accelerator pedal assembly 2. Locating pin 3. Accelerator pedal stopper

: Vehicle front

PBIC3813E

Revision: May 2010 2011 Versa

Page 25 of 3787

AT-8

< SERVICE INFORMATION >

PRECAUTIONS

6. Perform a self-diagnosis check of all control units using CONSULT-III.

Precaution for On Board Diagnosis (OBD) System of A/T and EngineINFOID:0000000005928065

The ECM has an on board diagnostic system. It will light up the malfunction indicator lamp (MIL) to warn the

driver of a malfunction causing emission deterioration.

CAUTION:

• Be sure to turn the ignition switch OFF and disconnect battery negative cable from battery negative

terminal before any repair or inspection work. The open/short circuit of related switches, sensors,

solenoid valves, etc. will cause the MIL to light up.

• Be sure to connect and lock the connectors secure ly after work. A loose (unlocked) connector will

cause the MIL to light up due to an open circuit. (Be sure the connectors are free from water, grease,

dirt, bent terminals, etc.)

• Be sure to route and secure th e harnesses properly after work. Interference of the harness with a

bracket, etc. may cause the MIL to light up due to a short circuit.

• Be sure to erase the unnecessary malfunction informa tion (repairs completed) from the TCM and

ECM before returning the vehicle to the customer.

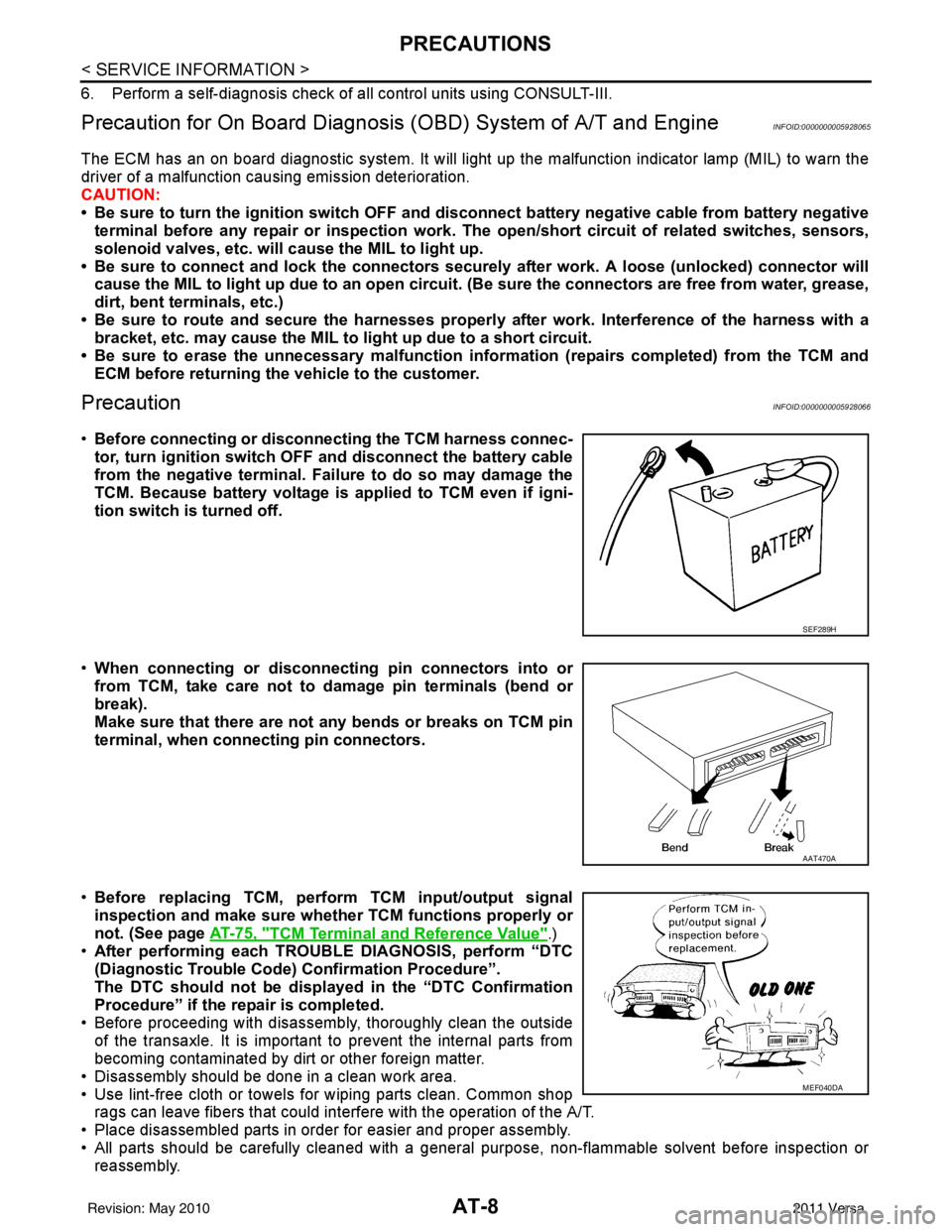

PrecautionINFOID:0000000005928066

•Before connecting or disconn ecting the TCM harness connec-

tor, turn ignition switch OF F and disconnect the battery cable

from the negative terminal. Failure to do so may damage the

TCM. Because battery voltage is applied to TCM even if igni-

tion switch is turned off.

• When connecting or disconnect ing pin connectors into or

from TCM, take care not to damage pin terminals (bend or

break).

Make sure that there are not any bends or breaks on TCM pin

terminal, when connecting pin connectors.

• Before replacing TCM, perform TCM input/output signal

inspection and make sure whether TCM functions properly or

not. (See page AT-75, "

TCM Terminal and Reference Value".)

• After performing each TROUBLE DIAGNOSIS, perform “DTC

(Diagnostic Trouble Code) Confirmation Procedure”.

The DTC should not be displ ayed in the “DTC Confirmation

Procedure” if the repair is completed.

• Before proceeding with disassembly, thoroughly clean the outside of the transaxle. It is important to prevent the internal parts from

becoming contaminated by dirt or other foreign matter.

• Disassembly should be done in a clean work area.

• Use lint-free cloth or towels for wiping parts clean. Common shop rags can leave fibers that could in terfere with the operation of the A/T.

• Place disassembled parts in order for easier and proper assembly.

• All parts should be carefully cleaned with a general purpose, non-flammable solvent before inspection or reassembly.

SEF289H

AAT470A

MEF040DA

Revision: May 2010 2011 Versa

Page 94 of 3787

TROUBLE DIAGNOSISAT-77

< SERVICE INFORMATION >

DE

F

G H

I

J

K L

M A

B

AT

N

O P

*1: These terminals are connected to the data link connector.

*2: These terminals are connected to the ECM.

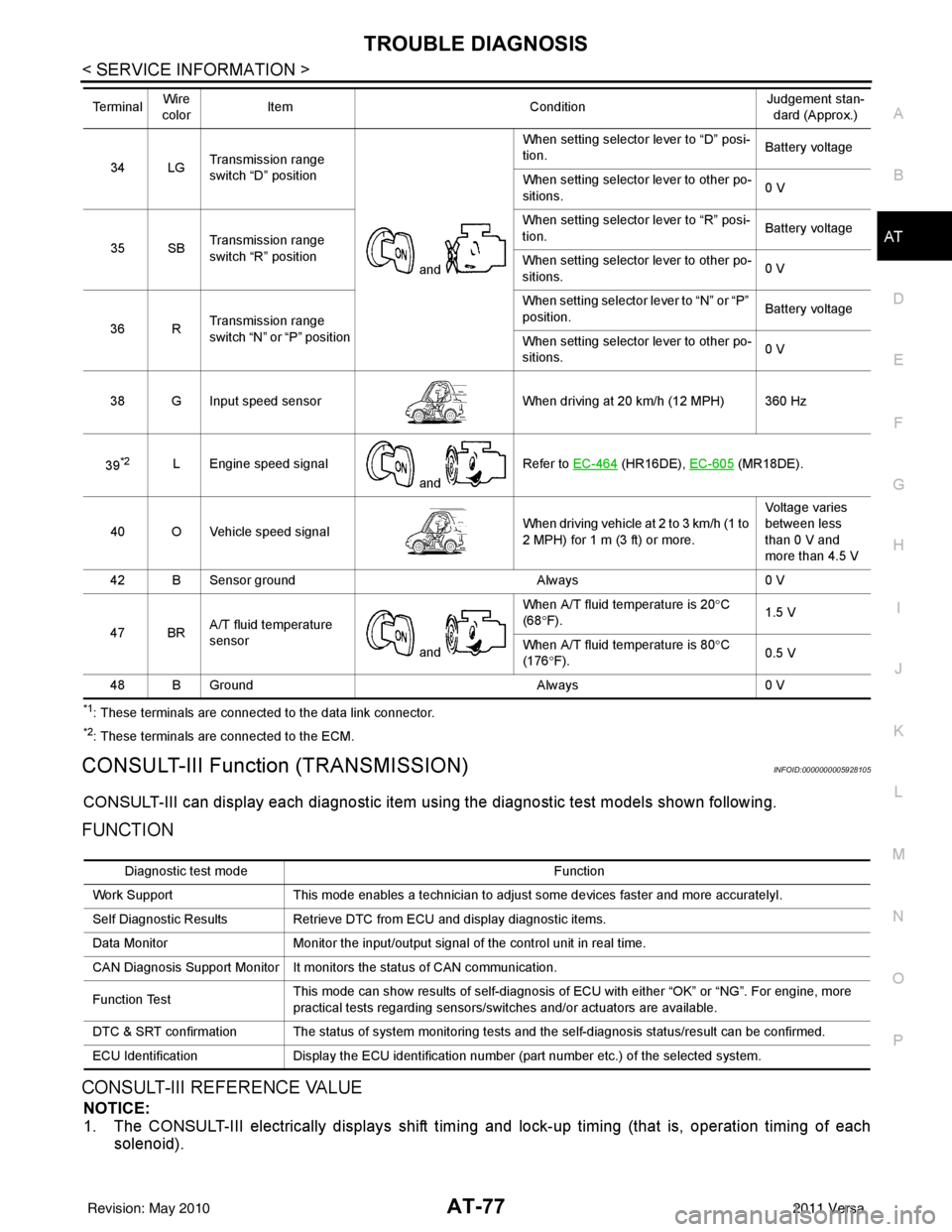

CONSULT-III Function (TRANSMISSION)INFOID:0000000005928105

CONSULT-III can display each diagnostic item using the diagnostic test models shown following.

FUNCTION

CONSULT-III REFERENCE VALUE

NOTICE:

1. The CONSULT-III electrically displays shift timi ng and lock-up timing (that is, operation timing of each

solenoid).

34 LG Transmission range

switch “D” position

and When setting selector lever to “D” posi-

tion.

Battery voltage

When setting selector lever to other po-

sitions. 0 V

35 SB Transmission range

switch “R” position When setting selector lever to “R” posi-

tion.

Battery voltage

When setting selector lever to other po-

sitions. 0 V

36 R Transmission range

switch “N” or “P” position When setting selector

lever to “N” or “P”

position. Battery voltage

When setting selector lever to other po-

sitions. 0 V

38 G Input speed sensor When driving at 20 km/h (12 MPH) 360 Hz

39

*2L Engine speed signal and Refer to EC-464 (HR16DE),

EC-605 (MR18DE).

40 O Vehicle speed signal When driving vehicle at 2 to 3 km/h (1 to

2 MPH) for 1 m (3 ft) or more.Voltage varies

between less

than 0 V and

more than 4.5 V

42 B Sensor ground Always0 V

47 BR A/T fluid temperature

sensor

and When A/T fluid temperature is 20°

C

(68 °F). 1.5 V

When A/T fluid temperature is 80° C

(176 °F). 0.5 V

48 B Ground Always0 V

Te r m i n a l

Wire

color Item

ConditionJudgement stan-

dard (Approx.)

Diagnostic test mode Function

Work Support This mode enables a technician to adjust some devices faster and more accuratelyI.

Self Diagnostic Results Retrieve DTC from ECU and display diagnostic items.

Data Monitor Monitor the input/output signal of the control unit in real time.

CAN Diagnosis Support Monitor It monitors the status of CAN communication.

Function Test This mode can show results of self-diagnosis of ECU with either “OK” or “NG”. For engine, more

practical tests regarding sensors/switches and/or actuators are available.

DTC & SRT confirmation The status of system monitoring tests and the self-diagnosis status/result can be confirmed.

ECU Identification Display the ECU identification number (part number etc.) of the selected system.

Revision: May 2010 2011 Versa

Page 107 of 3787

AT-90

< SERVICE INFORMATION >

P0705 TRANSMISSION RANGE SWITCH A

P0705 TRANSMISSION RANGE SWITCH A

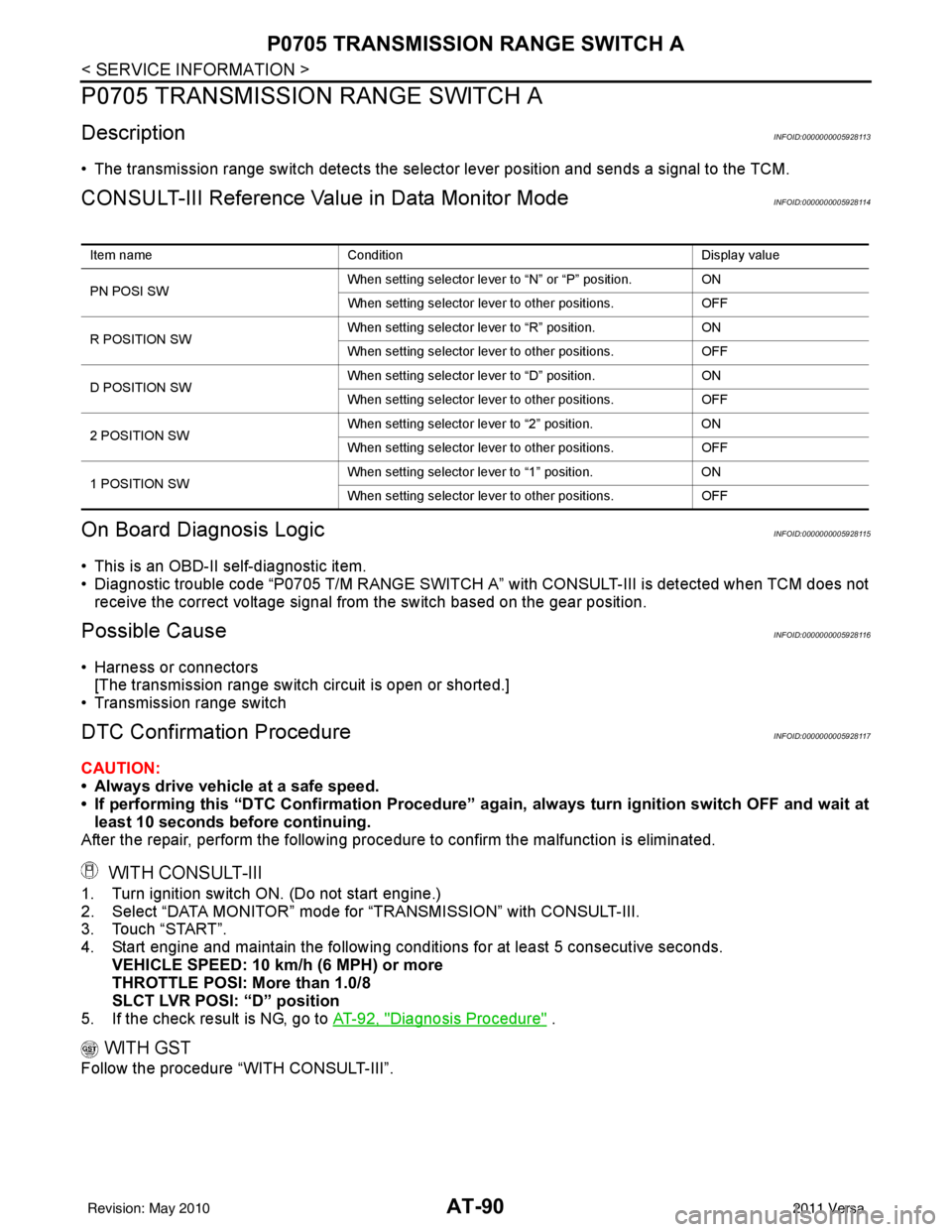

DescriptionINFOID:0000000005928113

• The transmission range switch detects the selector lever position and sends a signal to the TCM.

CONSULT-III Reference Value in Data Monitor ModeINFOID:0000000005928114

On Board Diagnosis LogicINFOID:0000000005928115

• This is an OBD-II self-diagnostic item.

• Diagnostic trouble code “P0705 T/M RANGE SWITCH A” with CONSULT-III is detected when TCM does not

receive the correct voltage signal from the switch based on the gear position.

Possible CauseINFOID:0000000005928116

• Harness or connectors [The transmission range switch circuit is open or shorted.]

• Transmission range switch

DTC Confirmation ProcedureINFOID:0000000005928117

CAUTION:

• Always drive vehicle at a safe speed.

• If performing this “DTC Confirmation Procedure” again, always turn ignition switch OFF and wait at

least 10 seconds before continuing.

After the repair, perform the following proc edure to confirm the malfunction is eliminated.

WITH CONSULT-III

1. Turn ignition switch ON. (Do not start engine.)

2. Select “DATA MONITOR” mode for “TRANSMISSION” with CONSULT-III.

3. Touch “START”.

4. Start engine and maintain the following conditions for at least 5 consecutive seconds. VEHICLE SPEED: 10 km/h (6 MPH) or more

THROTTLE POSI: More than 1.0/8

SLCT LVR POSI: “D” position

5. If the check result is NG, go to AT-92, "

Diagnosis Procedure" .

WITH GST

Follow the procedure “WITH CONSULT-III”.

Item name Condition Display value

PN POSI SW When setting selector lever

to “N” or “P” position. ON

When setting selector lever to other positions. OFF

R POSITION SW When setting selector lever to “R” position.

ON

When setting selector lever to other positions. OFF

D POSITION SW When setting selector lever to “D” position.

ON

When setting selector lever to other positions. OFF

2 POSITION SW When setting selector lever to “2” position.

ON

When setting selector lever to other positions. OFF

1 POSITION SW When setting selector lever to “1” position.

ON

When setting selector lever to other positions. OFF

Revision: May 2010 2011 Versa

Page 117 of 3787

AT-100

< SERVICE INFORMATION >

P0720 OUTPUT SPEED SENSOR

P0720 OUTPUT SPEED SENSOR

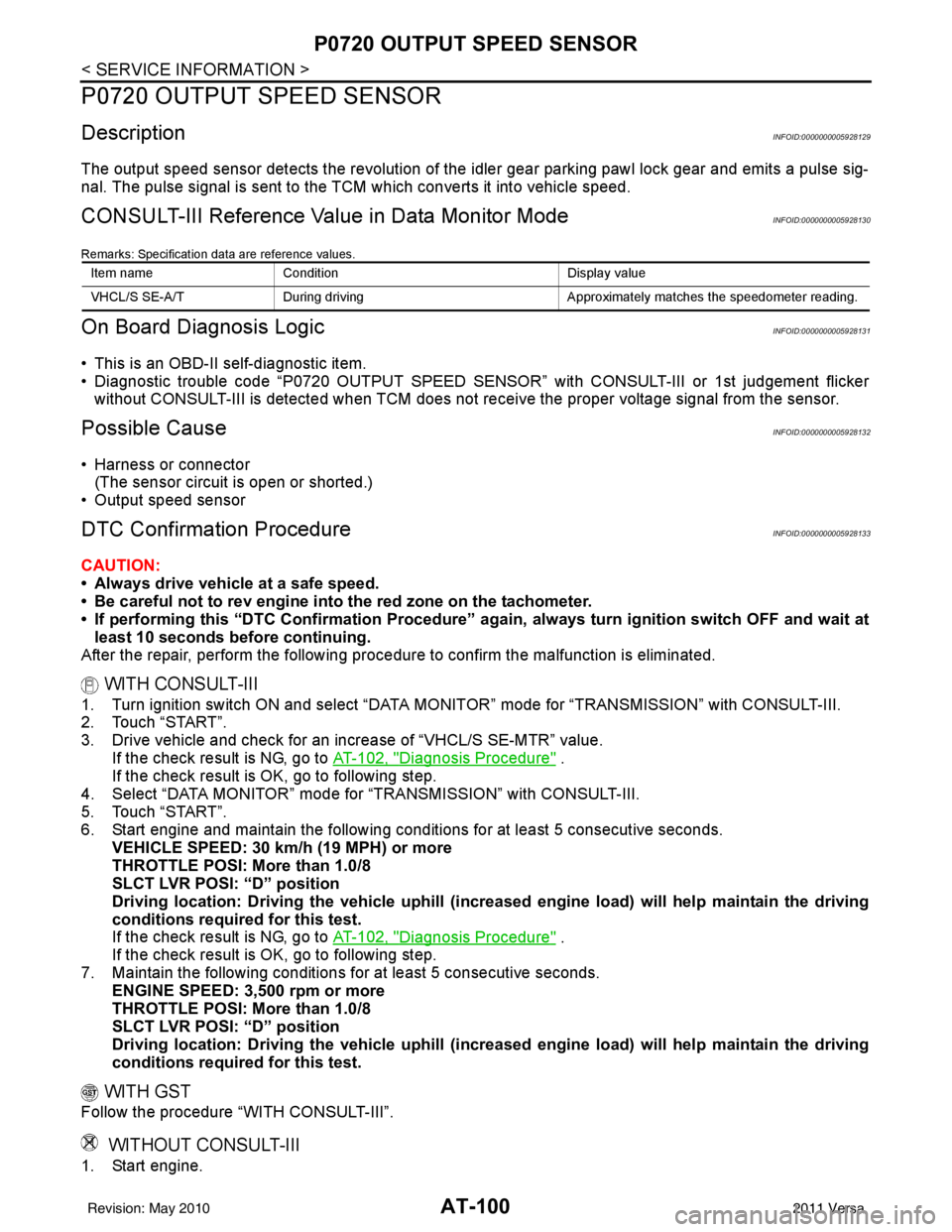

DescriptionINFOID:0000000005928129

The output speed sensor detects the revolution of the idler gear parking pawl lock gear and emits a pulse sig-

nal. The pulse signal is sent to the TCM which converts it into vehicle speed.

CONSULT-III Reference Value in Data Monitor ModeINFOID:0000000005928130

Remarks: Specification data are reference values.

On Board Diagn osis LogicINFOID:0000000005928131

• This is an OBD-II self-diagnostic item.

• Diagnostic trouble code “P0720 OUTPUT SPEED SENSOR ” with CONSULT-III or 1st judgement flicker

without CONSULT-III is detected when TCM does not re ceive the proper voltage signal from the sensor.

Possible CauseINFOID:0000000005928132

• Harness or connector

(The sensor circuit is open or shorted.)

• Output speed sensor

DTC Confirmation ProcedureINFOID:0000000005928133

CAUTION:

• Always drive vehicle at a safe speed.

• Be careful not to rev engine into the red zone on the tachometer.

• If performing this “DTC Confirmation Procedure” again, always turn ignition switch OFF and wait at

least 10 seconds before continuing.

After the repair, perform the following proc edure to confirm the malfunction is eliminated.

WITH CONSULT-III

1. Turn ignition switch ON and select “DATA MONI TOR” mode for “TRANSMISSION” with CONSULT-III.

2. Touch “START”.

3. Drive vehicle and check for an increase of “VHCL/S SE-MTR” value. If the check result is NG, go to AT-102, "

Diagnosis Procedure" .

If the check result is OK, go to following step.

4. Select “DATA MONITOR” mode fo r “TRANSMISSION” with CONSULT-III.

5. Touch “START”.

6. Start engine and maintain the following conditions for at least 5 consecutive seconds.

VEHICLE SPEED: 30 km/h (19 MPH) or more

THROTTLE POSI: More than 1.0/8

SLCT LVR POSI: “D” position

Driving location: Driving the vehicle uphill (increased engine load) will help maintain the driving

conditions required for this test.

If the check result is NG, go to AT-102, "

Diagnosis Procedure" .

If the check result is OK, go to following step.

7. Maintain the following conditions for at least 5 consecutive seconds. ENGINE SPEED: 3,500 rpm or more

THROTTLE POSI: More than 1.0/8

SLCT LVR POSI: “D” position

Driving location: Driving the vehicle uphill (increased engine load) will help maintain the driving

conditions required for this test.

WITH GST

Follow the procedure “WITH CONSULT-III”.

WITHOUT CONSULT-III

1. Start engine.

Item name Condition Display value

VHCL/S SE-A/T During driving Approximately matches the speedometer reading.

Revision: May 2010 2011 Versa

Page 122 of 3787

P0725 ENGINE SPEEDAT-105

< SERVICE INFORMATION >

DE

F

G H

I

J

K L

M A

B

AT

N

O P

P0725 ENGINE SPEED

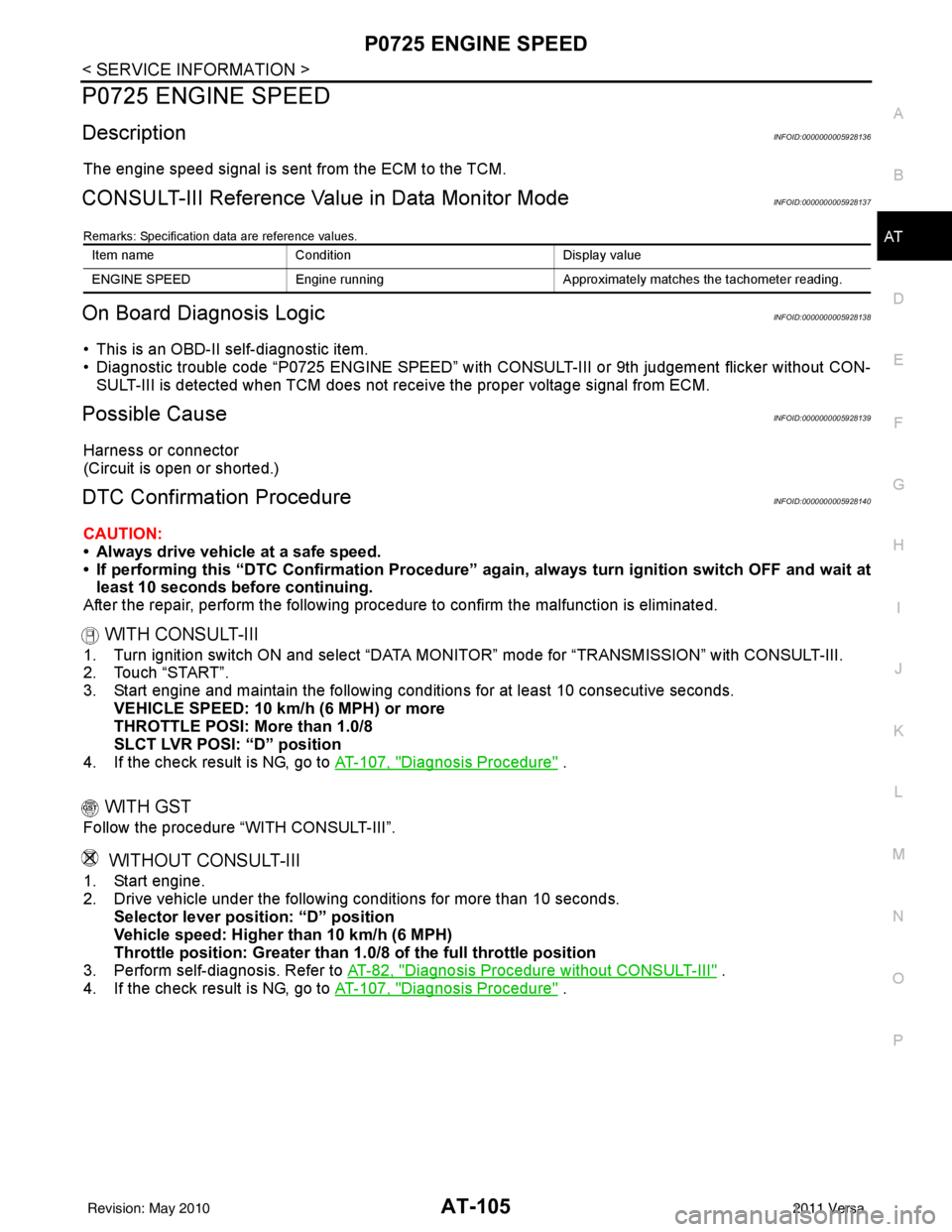

DescriptionINFOID:0000000005928136

The engine speed signal is sent from the ECM to the TCM.

CONSULT-III Reference Val ue in Data Monitor ModeINFOID:0000000005928137

Remarks: Specification data are reference values.

On Board Diagnosis LogicINFOID:0000000005928138

• This is an OBD-II self-diagnostic item.

• Diagnostic trouble code “P0725 ENGINE SPEED” with CONSULT-III or 9th judgement flicker without CON-

SULT-III is detected when TCM does not receive the proper voltage signal from ECM.

Possible CauseINFOID:0000000005928139

Harness or connector

(Circuit is open or shorted.)

DTC Confirmation ProcedureINFOID:0000000005928140

CAUTION:

• Always drive vehicle at a safe speed.

• If performing this “DTC Confirmation Procedure” again, always turn ignition switch OFF and wait at

least 10 seconds before continuing.

After the repair, perform the following procedure to confirm the malfunction is eliminated.

WITH CONSULT-III

1. Turn ignition switch ON and select “DATA MO NITOR” mode for “TRANSMISSION” with CONSULT-III.

2. Touch “START”.

3. Start engine and maintain the following conditions for at least 10 consecutive seconds.

VEHICLE SPEED: 10 km/h (6 MPH) or more

THROTTLE POSI: More than 1.0/8

SLCT LVR POSI: “D” position

4. If the check result is NG, go to AT-107, "

Diagnosis Procedure" .

WITH GST

Follow the procedure “WITH CONSULT-III”.

WITHOUT CONSULT-III

1. Start engine.

2. Drive vehicle under the following conditions for more than 10 seconds.

Selector lever posi tion: “D” position

Vehicle speed: Higher than 10 km/h (6 MPH)

Throttle position: Greater than 1. 0/8 of the full throttle position

3. Perform self-diagnosis. Refer to AT-82, "

Diagnosis Procedure without CONSULT-III" .

4. If the check result is NG, go to AT-107, "

Diagnosis Procedure" .

Item nameCondition Display value

ENGINE SPEED Engine running Approximately matches the ta chometer reading.

Revision: May 2010 2011 Versa

Page 140 of 3787

P0740 TORQUE CONVERTERAT-123

< SERVICE INFORMATION >

DE

F

G H

I

J

K L

M A

B

AT

N

O P

P0740 TORQUE CONVERTER

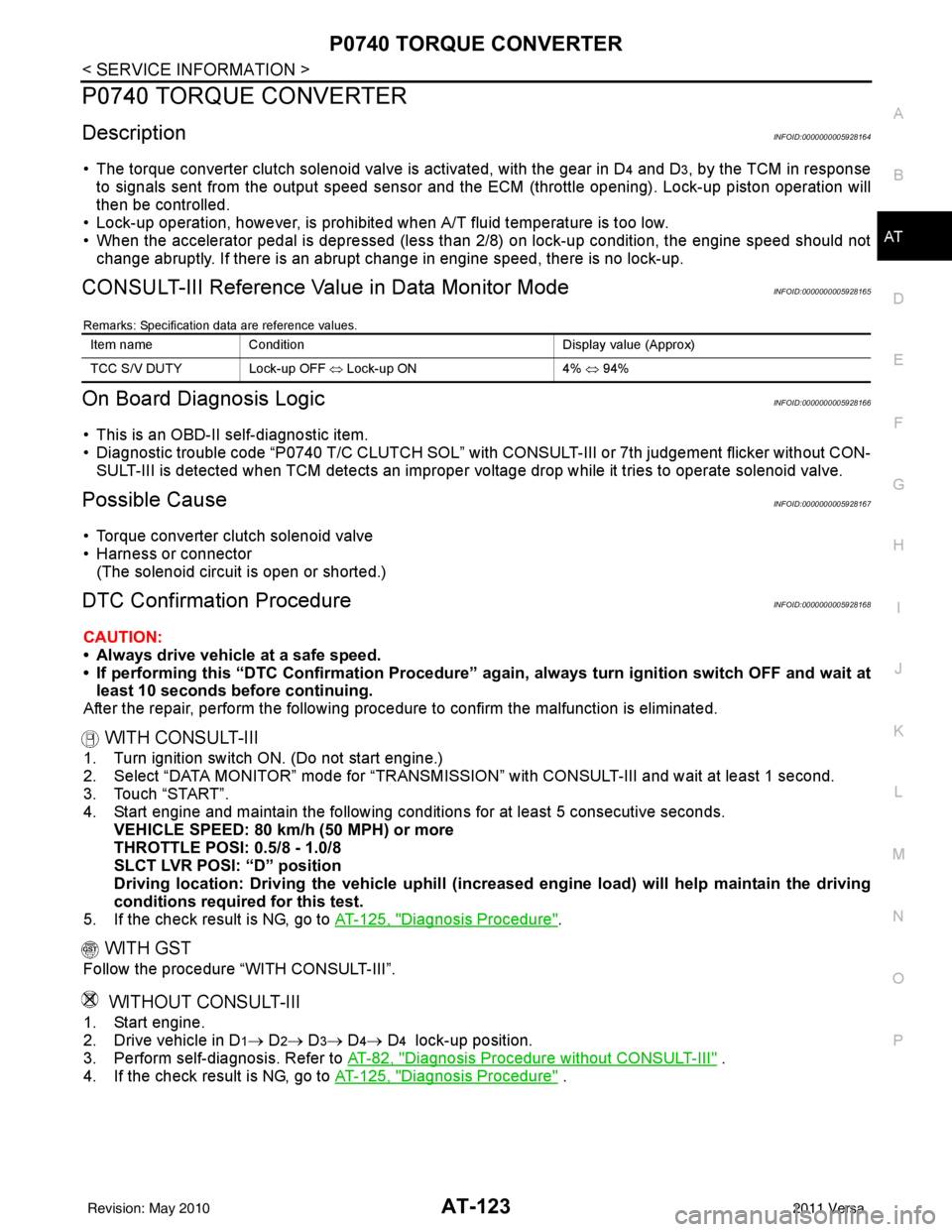

DescriptionINFOID:0000000005928164

• The torque converter clutch solenoid valve is activated, with the gear in D4 and D3, by the TCM in response

to signals sent from the output speed sensor and t he ECM (throttle opening). Lock-up piston operation will

then be controlled.

• Lock-up operation, however, is prohibited when A/T fluid temperature is too low.

• When the accelerator pedal is depressed (less than 2/8) on lock-up condition, the engine speed should not

change abruptly. If there is an abrupt change in engine speed, there is no lock-up.

CONSULT-III Reference Val ue in Data Monitor ModeINFOID:0000000005928165

Remarks: Specification data are reference values.

On Board Diagnosis LogicINFOID:0000000005928166

• This is an OBD-II self-diagnostic item.

• Diagnostic trouble code “P0740 T/C CLUTCH SOL” with CO NSULT-III or 7th judgement flicker without CON-

SULT-III is detected when TCM detects an improper vo ltage drop while it tries to operate solenoid valve.

Possible CauseINFOID:0000000005928167

• Torque converter clutch solenoid valve

• Harness or connector

(The solenoid circuit is open or shorted.)

DTC Confirmation ProcedureINFOID:0000000005928168

CAUTION:

• Always drive vehicle at a safe speed.

• If performing this “DTC Confirmation Procedure” again, always turn ignition switch OFF and wait at

least 10 seconds before continuing.

After the repair, perform the following procedure to confirm the malfunction is eliminated.

WITH CONSULT-III

1. Turn ignition switch ON. (Do not start engine.)

2. Select “DATA MONITOR” mode for “TRANSMISSION” with CONSULT-III and wait at least 1 second.

3. Touch “START”.

4. Start engine and maintain the following conditions for at least 5 consecutive seconds. VEHICLE SPEED: 80 km/h (50 MPH) or more

THROTTLE POSI: 0.5/8 - 1.0/8

SLCT LVR POSI: “D” position

Driving location: Driving the vehic le uphill (increased engine load) will help maintain the driving

conditions required for this test.

5. If the check result is NG, go to AT-125, "

Diagnosis Procedure".

WITH GST

Follow the procedure “WITH CONSULT-III”.

WITHOUT CONSULT-III

1. Start engine.

2. Drive vehicle in D

1→ D2→ D3→ D4→ D4 lock-up position.

3. Perform self-diagnosis. Refer to AT-82, "

Diagnosis Procedure without CONSULT-III" .

4. If the check result is NG, go to AT-125, "

Diagnosis Procedure" .

Item nameCondition Display value (Approx)

TCC S/V DUTY Lock-up OFF ⇔ Lock-up ON 4% ⇔ 94%

Revision: May 2010 2011 Versa

Page 234 of 3787

SHIFT CONTROL SYSTEMAT-217

< SERVICE INFORMATION >

DE

F

G H

I

J

K L

M A

B

AT

N

O P

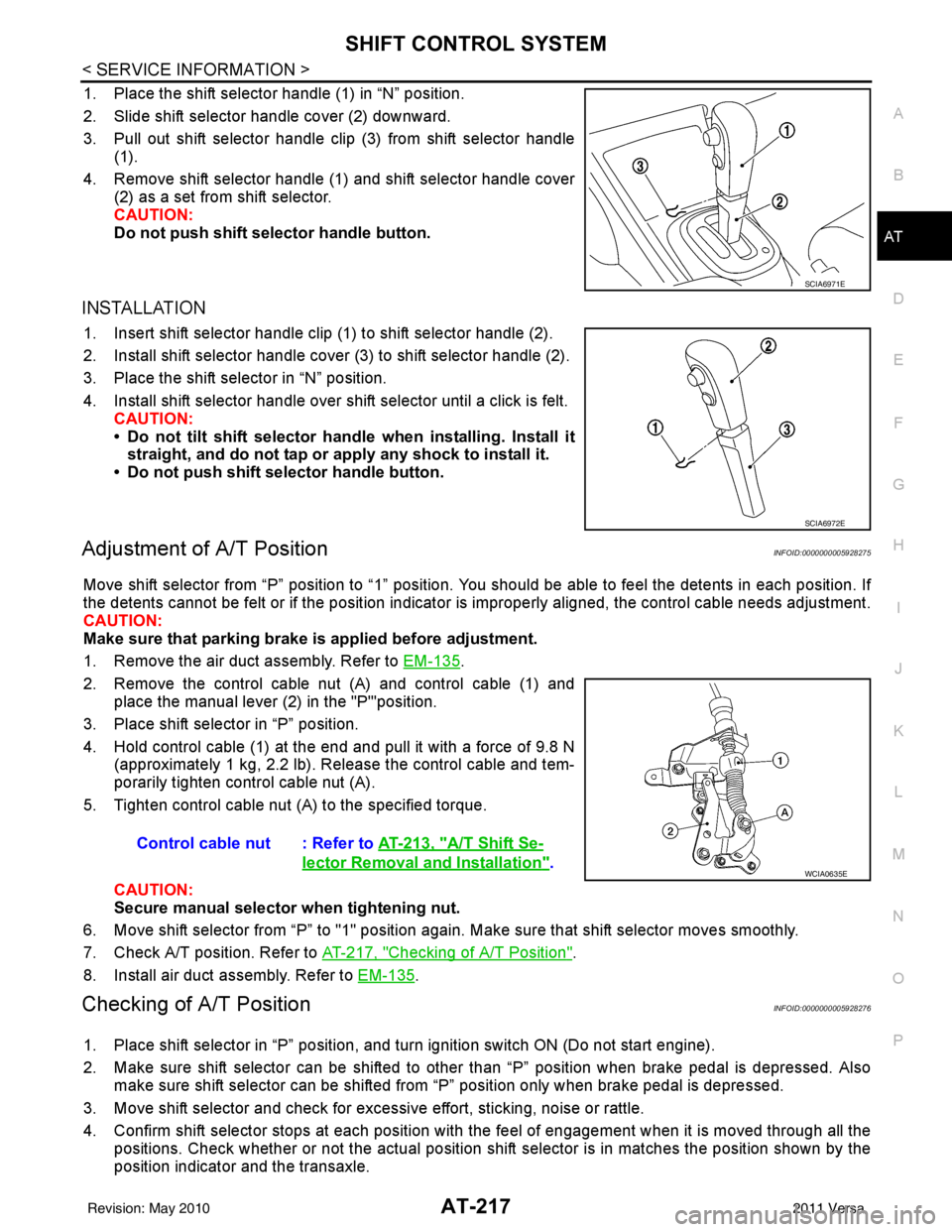

1. Place the shift selector handle (1) in “N” position.

2. Slide shift selector handle cover (2) downward.

3. Pull out shift selector handle clip (3) from shift selector handle (1).

4. Remove shift selector handle (1) and shift selector handle cover (2) as a set from shift selector.

CAUTION:

Do not push shift selector handle button.

INSTALLATION

1. Insert shift selector handle clip (1) to shift selector handle (2).

2. Install shift selector handle cover (3) to shift selector handle (2).

3. Place the shift selector in “N” position.

4. Install shift selector handle over shift selector until a click is felt.

CAUTION:

• Do not tilt shift selector hand le when installing. Install it

straight, and do not tap or ap ply any shock to install it.

• Do not push shift selector handle button.

Adjustment of A/T PositionINFOID:0000000005928275

Move shift selector from “P” position to “1” position. You should be able to feel the detents in each position. If

the detents cannot be felt or if the position indicator is improperly aligned, the control cable needs adjustment.

CAUTION:

Make sure that parking brake is applied before adjustment.

1. Remove the air duct assembly. Refer to EM-135

.

2. Remove the control cable nut (A) and control cable (1) and place the manual lever (2) in the "P'"position.

3. Place shift selector in “P” position.

4. Hold control cable (1) at the end and pull it with a force of 9.8 N (approximately 1 kg, 2.2 lb). Release the control cable and tem-

porarily tighten control cable nut (A).

5. Tighten control cable nut (A) to the specified torque.

CAUTION:

Secure manual selector when tightening nut.

6. Move shift selector from “P” to "1" position again. Make sure that shift selector moves smoothly.

7. Check A/T position. Refer to AT-217, "

Checking of A/T Position".

8. Install air duct assembly. Refer to EM-135

.

Checking of A/T PositionINFOID:0000000005928276

1. Place shift selector in “P” position, and tu rn ignition switch ON (Do not start engine).

2. Make sure shift selector can be shifted to other than “P” position when brake pedal is depressed. Also make sure shift selector can be shifted from “P” position only when brake pedal is depressed.

3. Move shift selector and check for excessive effort, sticking, noise or rattle.

4. Confirm shift selector stops at each position with the feel of engagement when it is moved through all the

positions. Check whether or not the ac tual position shift selector is in matches the position shown by the

position indicator and the transaxle.

SCIA6971E

SCIA6972E

Control cable nut : Refer to AT-213, "A/T Shift Se-

lector Removal and Installation".WCIA0635E

Revision: May 2010 2011 Versa

Page 237 of 3787

AT-220

< SERVICE INFORMATION >

KEY INTERLOCK CABLE

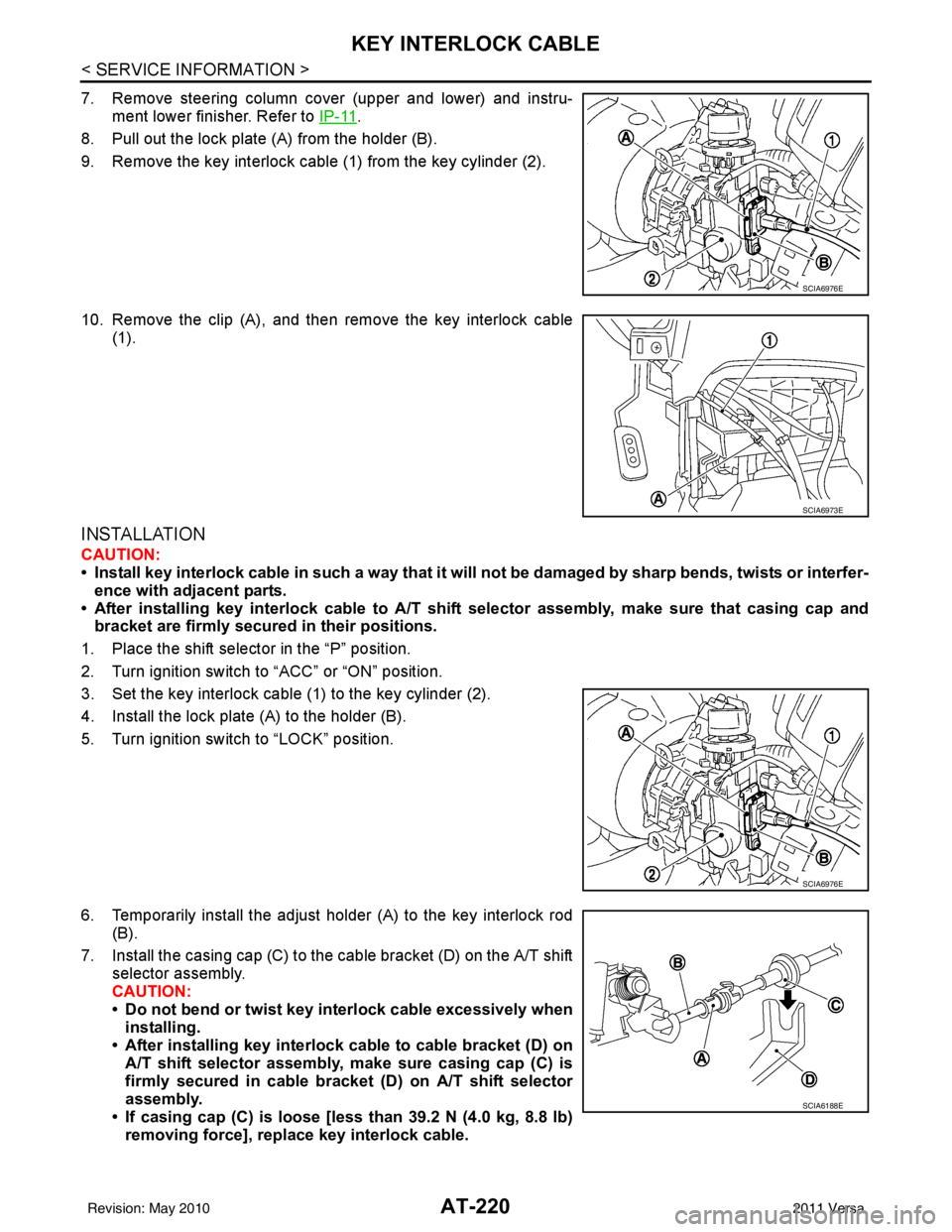

7. Remove steering column cover (upper and lower) and instru-ment lower finisher. Refer to IP-11

.

8. Pull out the lock plate (A) from the holder (B).

9. Remove the key interlock cable (1) from the key cylinder (2).

10. Remove the clip (A), and then remove the key interlock cable (1).

INSTALLATION

CAUTION:

• Install key interlock cable in such a way that it will not be damaged by sharp bends, twists or interfer-

ence with adjacent parts.

• After installing key interlock cable to A/T shift selector assembly, make sure that casing cap and bracket are firmly secured in their positions.

1. Place the shift selector in the “P” position.

2. Turn ignition switch to “ACC” or “ON” position.

3. Set the key interlock cable (1) to the key cylinder (2).

4. Install the lock plate (A) to the holder (B).

5. Turn ignition switch to “LOCK” position.

6. Temporarily install the adjust holder (A) to the key interlock rod (B).

7. Install the casing cap (C) to the cable bracket (D) on the A/T shift selector assembly.

CAUTION:

• Do not bend or twist key interlock cable excessively wheninstalling.

• After installing key interlock cable to cable bracket (D) on A/T shift selector assembly, make sure casing cap (C) is

firmly secured in cable bracket (D) on A/T shift selector

assembly.

• If casing cap (C) is loose [less than 39.2 N (4.0 kg, 8.8 lb)

removing force], replace key interlock cable.

SCIA6976E

SCIA6973E

SCIA6976E

SCIA6188E

Revision: May 2010 2011 Versa