NISSAN LEAF 2017 1.G First Responders Guide

Manufacturer: NISSAN, Model Year: 2017, Model line: LEAF, Model: NISSAN LEAF 2017 1.GPages: 44, PDF Size: 5.26 MB

Page 11 of 44

2-4 Preventing Electrical Shock

1. If it is necessary to touch any of the high-voltage harnesses or components, you must always

wear appropriate Personal Protective Equipment (PPE)

(refer to 3-1 Preparation Items (FRG–13) ) and shut off the high-voltage system by referring

to 3-3.1 High-voltage System Shut-Down Procedures (FRG–17).

2.

To avoid the risk of electrocution, NEVER touch the inside of the high-voltage battery unless

appropriate PPE is worn even after shutting off the high-voltage system. The high-voltage battery

maintains charge even though the high-voltage system is shut down.

3. Cover any damaged high-voltage components with insulated tape.

2-5 Emergency Medical Equipment

The high-voltage system should not interfere with emergency medical equipment which must be used in or

near the vehicle at an accident scene.

FRG–11

Page 12 of 44

3. Emergency Response Steps

• Failure to properly shut down the high-voltage electrical system before the

Emergency Response Procedures are performed will result in serious injury or death

from electrical shock. To prevent serious injury or death, NEVER touch high-voltage

harnesses or components without always wearing appropriate Personal Protective

Equipment (PPE) .

• If it is necessary to touch any of the high-voltage harnesses or components you

must

always wear appropriate PPE to avoid electrical shock. Shut down the

high-voltage system by following the steps outlined in 3-3.1 High-voltage System

Shut-Down

Procedures (FRG–17) . Wait at least ten (10) minutes for complete

discharge

of the high-voltage capacitor after the high-voltage system has been

shut down. • NEVER assume the LEAF is shut OFF simply because it is quiet.

• If the READY indicator or charging indicator are ON, the high-voltage system

is

active.

• If possible, be sure to verify that the READY indicator on the instrument

cluster

is OFF and the high-voltage system is stopped.

• Some of the under hood parts get hot and may cause serious burns. Use caution when working on or around these parts.

FRG–12

Page 13 of 44

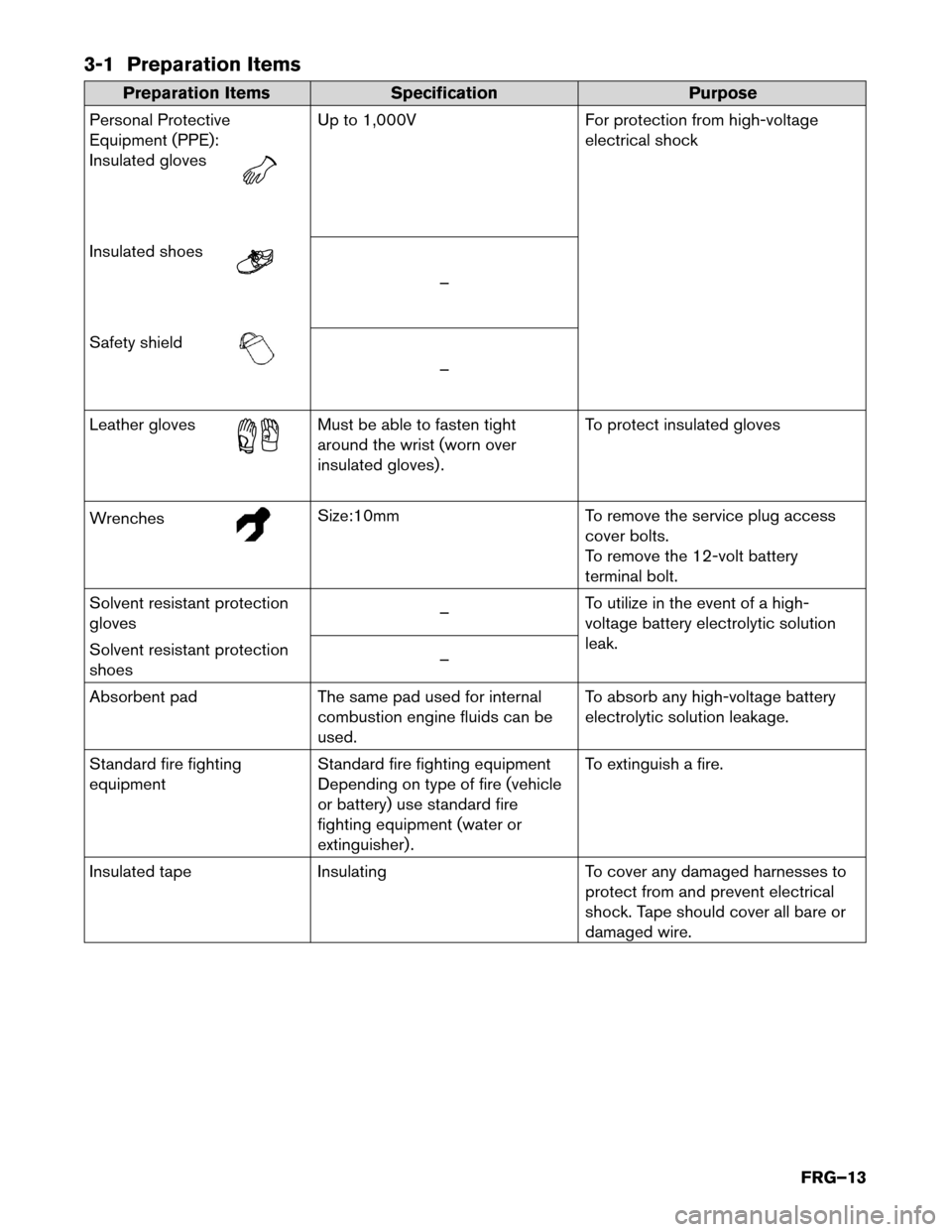

3-1 Preparation Items

Preparation Items

Specification Purpose

Personal Protective

Equipment (PPE):

Insulated gloves Up to 1,000V

For protection from high-voltage

electrical

shock

Insulated shoes –

Safety

shield –

Leather

gloves Must be able to fasten tight

around

the wrist (worn over

insulated gloves) . To protect insulated gloves

Wrenches Size:10mm

To remove the service plug access

cover

bolts.

To remove the 12-volt battery

terminal bolt.

Solvent resistant protection

gloves –

To utilize in the event of a high-

voltage battery electrolytic solution

leak.

Solvent resistant protection

shoes –

Absorbent pad The same pad used for internal

combustion engine fluids can be

used. To absorb any high-voltage battery

electrolytic solution leakage.

Standard fire fighting

equipment Standard fire fighting equipment

Depending on type of fire (vehicle

or battery) use standard fire

fighting equipment (water or

extinguisher) . To extinguish a fire.

Insulated tape Insulating To cover any damaged harnesses to

protect from and prevent electrical

shock. Tape should cover all bare or

damaged wire.

FRG–13

Page 14 of 44

3-1.1 Personal Protective Equipment (PPE) Protective Wear Control

Perform

an inspection of the Personal Protective Equipment (PPE) items before beginning work. Do not use

any damaged PPE items.

3-1.2 Daily Inspection

This inspection is performed before and after use. The responder who will be using the items should

perform the inspection and check for deterioration and damage. • Insulated rubber gloves should be inspected for scratches, holes and tears. (Visual check and airleakage test)

• Insulated safety boots should be inspected for holes, damage, nails, metal pieces, wear or other problems on the soles. (Visual check)

• Insulated rubber sheet should be inspected for tears. (Visual check)

3-1.3 Insulated Tools

When performing work at locations where high-voltage is applied (such as terminals) , use insulated tools

meeting 1,000V/300A specifications.

FRG–14

Page 15 of 44

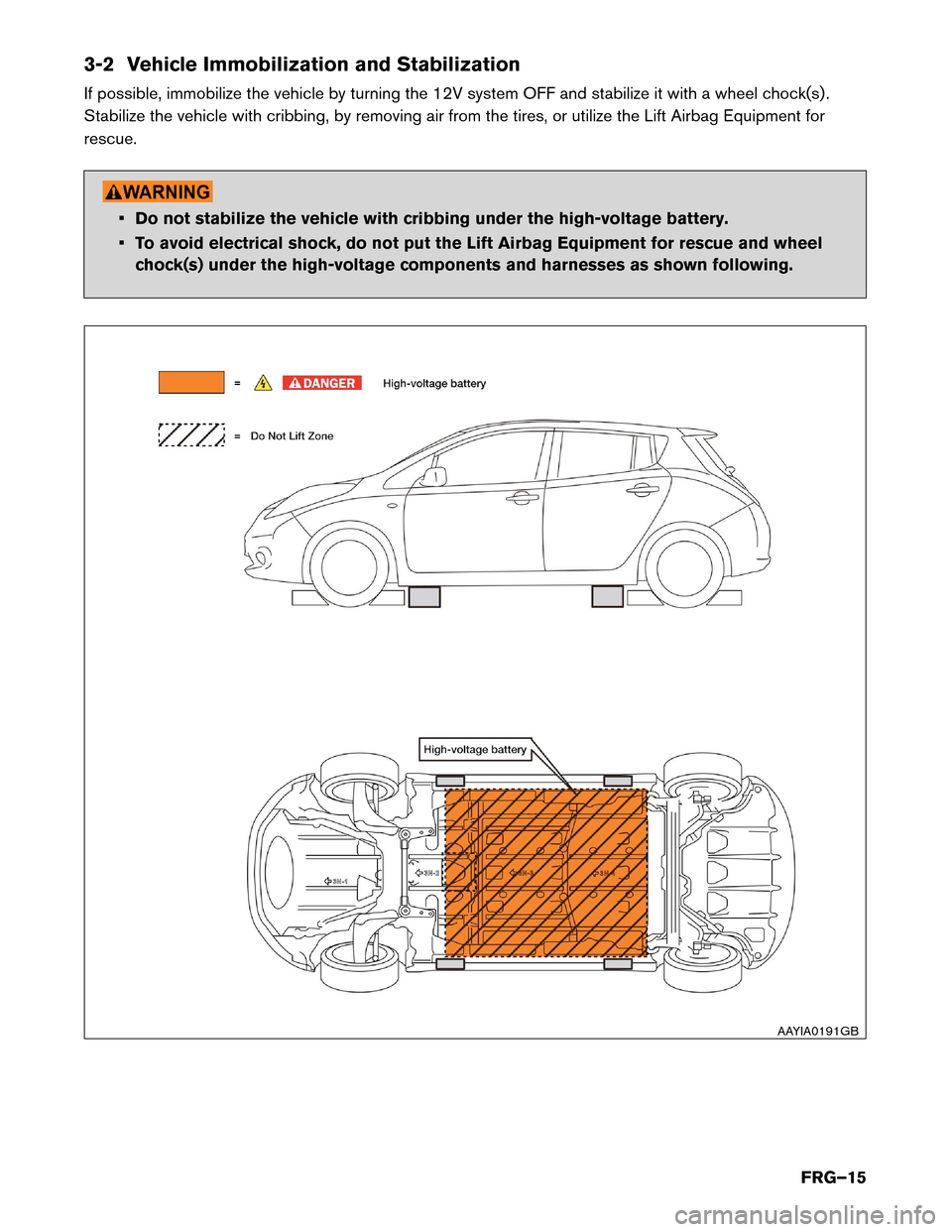

3-2 Vehicle Immobilization and Stabilization

If

possible, immobilize the vehicle by turning the 12V system OFF and stabilize it with a wheel chock(s) .

Stabilize the vehicle with cribbing, by removing air from the tires, or utilize the Lift Airbag Equipment for

rescue. • Do not stabilize the vehicle with cribbing under the high-voltage battery.

•

To avoid electrical shock, do not put the Lift Airbag Equipment for rescue and wheel

chock(s) under the high-voltage components and harnesses as shown following. AAYIA0191GB

FRG–15

Page 16 of 44

3-3 How to Handle a Damaged Vehicle at an Accident Scene

NO

TE:

If any air bags have deployed in the following 3 situations, the high-voltage (HV) system has

been designed to automatically shut off at the time of deployment.

The Nissan LEAF high-voltage system incorporates capacitors which are energized whenever the high-

voltage system is on. If the high-voltage system is shut down (either through one of the built-in automatic

mechanisms or manually through one of the procedures explained in this FRG) , the capacitors will begin to

gradually discharge. After 5 minutes, the voltage level will have dropped below 60V, and complete

discharge requires approximately 10 minutes after high-voltage system shut down. It is within

this period of time that responders must be most cautious.

When arriving to an incident involving a Nissan LEAF, the vehicle should be approached with caution and

inspected for the level of damage. In addition to overall vehicle condition (location and severity of body

damage, air bag deployment, etc.) , the high-voltage system should be assessed specifically. The locations

of the high-voltage component parts are illustrated in this FRG. Refer to 2-1 High-Voltage-Related and

12-volt-Related

Component Locations and Descriptions (FRG–8) . Appropriate Personal Protective

Equipment

(PPE) must always be worn when approaching a vehicle of unknown condition, as described

in this FRG.

Situation 1) High-voltage system intact, occupants can be accessed without extrication tools

The HV system can be shut down by following the procedures in this guide, while wearing appropriate PPE.

After HV system shut down, occupant assistance can begin immediately, and no wait period is necessary.

Situation 2) High-voltage system intact, occupants cannot be accessed without extrication tools

The HV system can be shut down by following the procedure in this guide, while wearing appropriate PPE.

After HV system shut down, absolute care must be taken not to cut through or damage any HV system

wiring, battery or components within ten (10) minutes of HV system shut down, but occupant

assistance operations using extrication equipment can begin immediately. The locations of the HV

components are illustrated in this guide.

Situation 3) High-voltage (HV) system damaged

If there is any evidence that the HV system has been compromised (such as arcing/sparking, orange wiring

harnesses cut or damaged, HV component casings damaged, etc.) , the responder may still be at risk of

high-voltage exposure. The vehicle must be approached with extreme caution prior to initiating any system

shut down procedures or rendering assistance to occupants. Appropriate PPE must always be worn as

described in this guide, and the ten (10) minute wait time must be observed after HV system shut

down in order to ensure the system is de-energized.

In rare situations where vehicle damage is very severe, HV system shut down procedures as described in

this guide may not work. In these instances extreme caution and appropriate risk management must be

followed to prevent shock or electrocution to the responder or occupant.

FRG–16

Page 17 of 44

3-3.1 High-voltage System Shut-Down Procedures

Any

of the following procedures can shut down and isolate the high-voltage system. The first response

operation should only begin after shutting down the high-voltage system. If the vehicle is heavily damaged,

for example the high-voltage battery is deformed, broken or cracked, appropriate Personal Protective

Equipment (PPE) must always be used and the high-voltage battery and high-voltage components must not

be touched. • Failure to properly shut down the high-voltage system before the Emergency

Response

Procedures are performed will result in serious injury or death from

electrical shock. To prevent serious injury or death, NEVER touch high-voltage

harnesses or components without always wearing appropriate Personal Protective

Equipment (PPE) . PPE must always be worn when touching or working on high-

voltage components

• When contact with high-voltage components or high-voltage harnesses is

unavoidable,

or when there is risk of such contact, you must always wear appropriate

PPE. PPE must always be worn when touching or working on high-voltage

components.

FRG–17

Page 18 of 44

• If the charge connector is connected to the vehicle, remove it. Refer to

Removing the

Charge

Connector (FRG–19) .

• The vehicle contains parts that contain powerful magnets. If a person who is wearing a

pacemaker

or other medical device is close to these parts, the medical device may be

affected by the magnets. Such persons must not perform work on the vehicle.

• Be sure to verify that the READY indicator is off and the high-voltage system is

stopped.

•

After the high-voltage system is shut down, please wait at least ten (10) minutes for

complete discharge of the high-voltage capacitor. While waiting, do not operate any

vehicle functions.

NOTE:

The high-voltage full discharge takes ten (10) minutes, but after five (5) minutes the

voltage has dropped below 60V.

• After shutting down the high-voltage system and removing the 12-volt battery negative (-) terminal, wait at least three (3) minutes to discharge the air bag capacitor. Even though

the 12-volt battery negative (-) is disconnected, the Supplemental Restraint System (SRS)

air bag maintains voltage at least three (3) minutes. During this time, there is a possibility

of sudden SRS air bag inflation due to harness short circuit or damage and it may cause

serious injuries.

• Always shut down the high-voltage system before disconnecting the 12-volt battery. Not doing so may result in serious injury or death from electrical shock.

• The 12V system will remain active even after the 12-volt battery negative (-) terminal is removed while the high-voltage system is active. The high-voltage system is active

during any of the following conditions:

– charging indicator is turned ON

– READY indicator is turned ON

Refer to 1-1.2 Interior Component Location (FRG–6) for location of these indicators.

This

is because DC/DC converter will not shut down and power will be supplied to

the 12V system and high-voltage system continuously.

FRG–18

Page 19 of 44

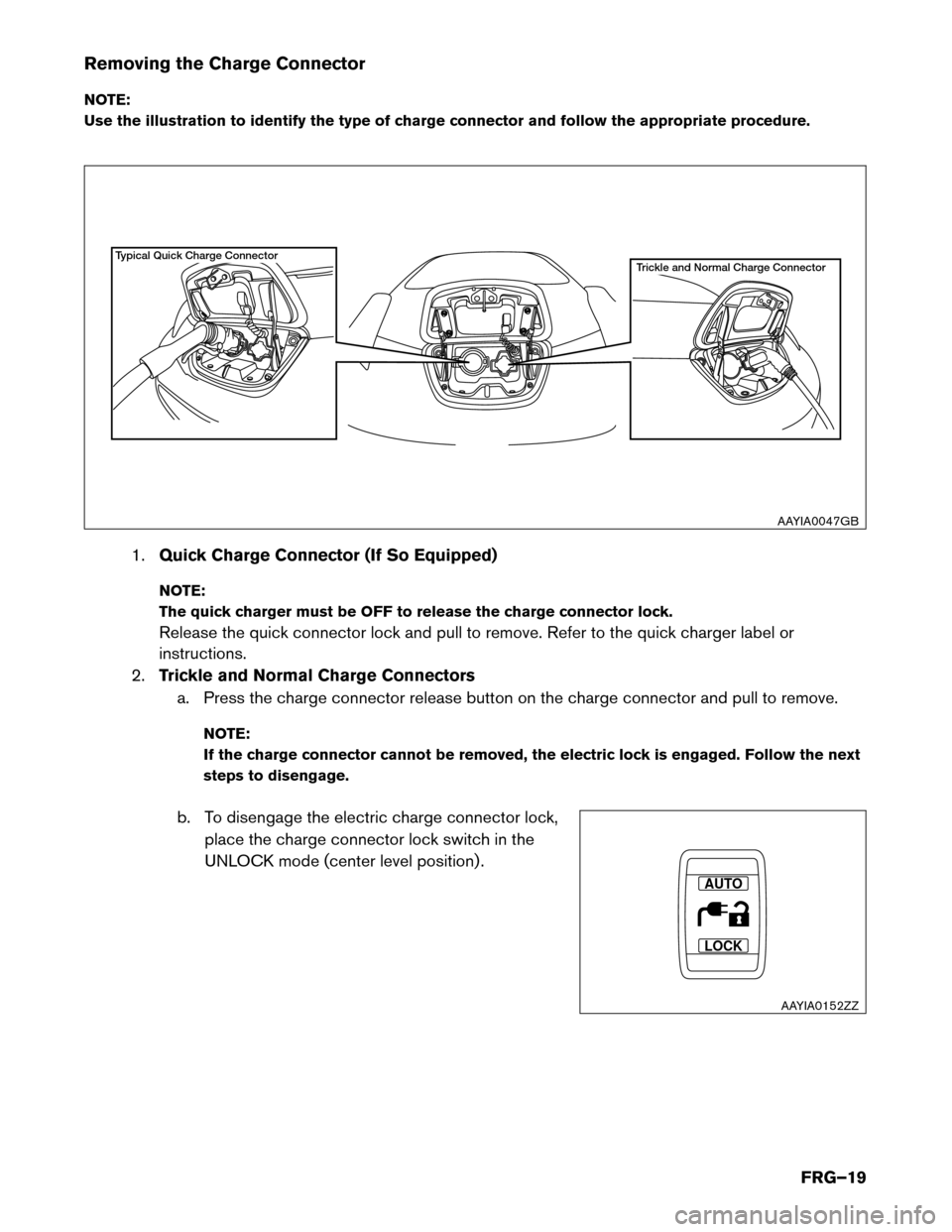

Removing the Charge Connector

NO

TE:

Use the illustration to identify the type of charge connector and follow the appropriate procedure.

1.Quick Charge Connector (If So Equipped)

NOTE:

The quick charger must be OFF to release the charge connector lock.

Release the quick connector lock and pull to remove. Refer to the quick charger label or

instructions.

2. Trickle and Normal Charge Connectors

a. Press the charge connector release button on the charge connector and pull to remove.

NOTE:

If the charge connector cannot be removed, the electric lock is engaged. Follow the next

steps to disengage.

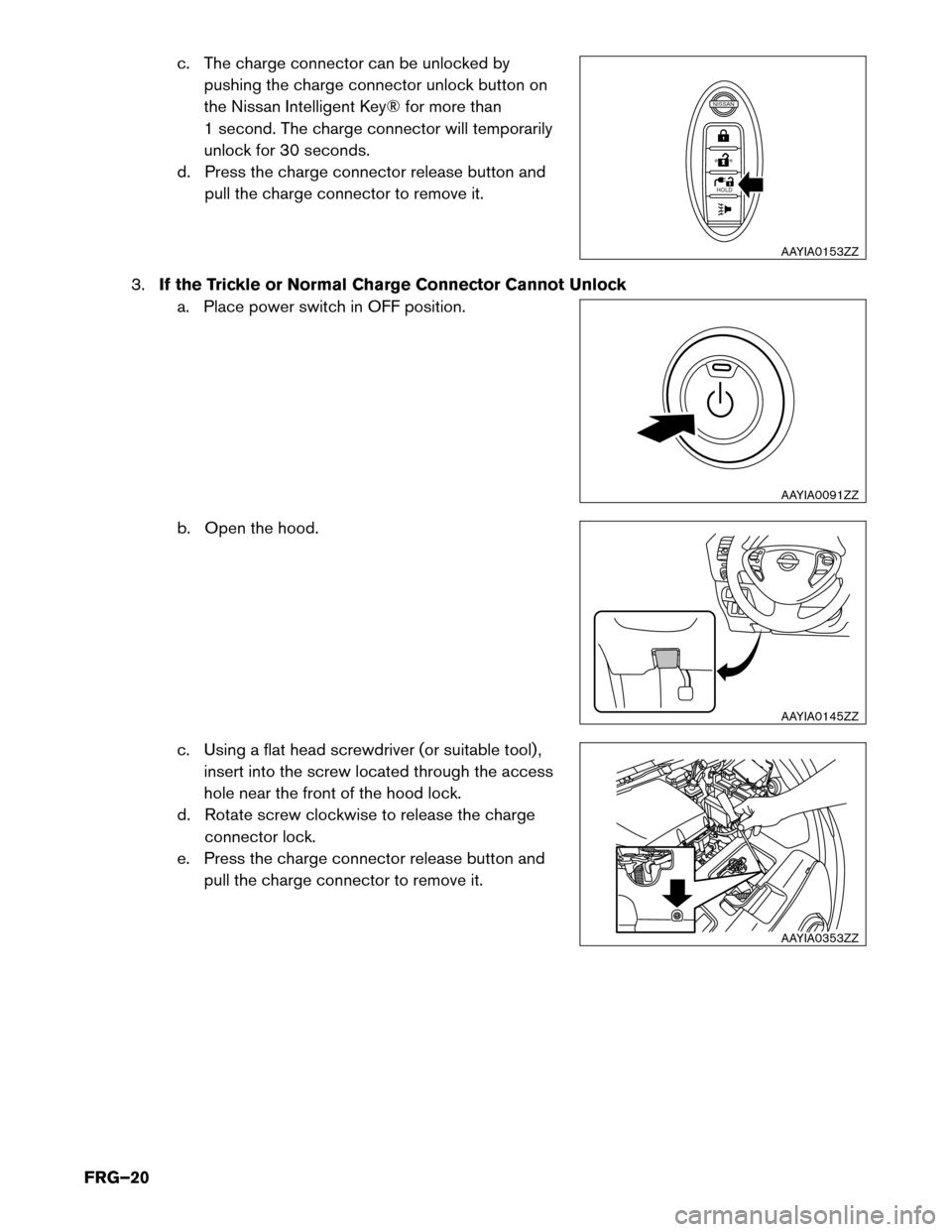

b. To disengage the electric charge connector lock, place the charge connector lock switch in the

UNLOCK mode (center level position) . Trickle and Normal Charge Connector

T

ypical Quick Charge Connector

AAYIA0047GB

LOCKAUTO AAYIA0152ZZ

FRG–19

Page 20 of 44

c. The charge connector can be unlocked by

pushing the charge connector unlock button on

the Nissan Intelligent Key® for more than

1 second. The charge connector will temporarily

unlock for 30 seconds.

d. Press the charge connector release button and pull the charge connector to remove it.

3. If the Trickle or Normal Charge Connector Cannot Unlock

a. Place power switch in OFF position.

b. Open the hood.

c. Using a flat head screwdriver (or suitable tool) , insert into the screw located through the access

hole near the front of the hood lock.

d. Rotate screw clockwise to release the charge connector lock.

e. Press the charge connector release button and pull the charge connector to remove it. HOLD

NISSAN

AAYIA0153ZZ

AAYIA0091ZZ

AAYIA0145ZZ

AAYIA0353ZZ

FRG–20