ECO mode NISSAN MAXIMA 1997 A32 / 4.G User Guide

[x] Cancel search | Manufacturer: NISSAN, Model Year: 1997, Model line: MAXIMA, Model: NISSAN MAXIMA 1997 A32 / 4.GPages: 215, PDF Size: 1.75 MB

Page 137 of 215

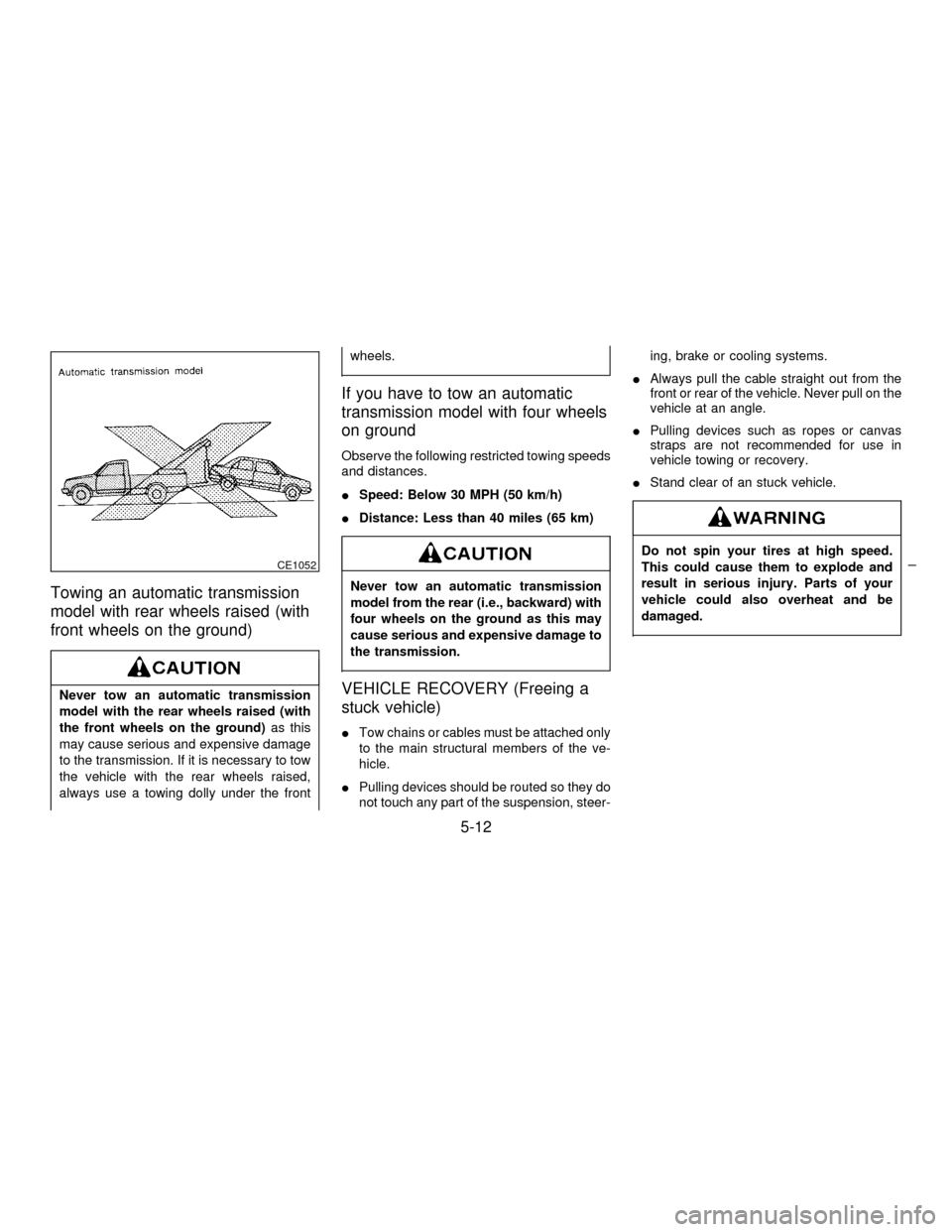

Towing an automatic transmission

model with rear wheels raised (with

front wheels on the ground)

Never tow an automatic transmission

model with the rear wheels raised (with

the front wheels on the ground)as this

may cause serious and expensive damage

to the transmission. If it is necessary to tow

the vehicle with the rear wheels raised,

always use a towing dolly under the frontwheels.

If you have to tow an automatic

transmission model with four wheels

on ground

Observe the following restricted towing speeds

and distances.

ISpeed: Below 30 MPH (50 km/h)

IDistance: Less than 40 miles (65 km)

Never tow an automatic transmission

model from the rear (i.e., backward) with

four wheels on the ground as this may

cause serious and expensive damage to

the transmission.

VEHICLE RECOVERY (Freeing a

stuck vehicle)

ITow chains or cables must be attached only

to the main structural members of the ve-

hicle.

IPulling devices should be routed so they do

not touch any part of the suspension, steer-ing, brake or cooling systems.

IAlways pull the cable straight out from the

front or rear of the vehicle. Never pull on the

vehicle at an angle.

IPulling devices such as ropes or canvas

straps are not recommended for use in

vehicle towing or recovery.

IStand clear of an stuck vehicle.

Do not spin your tires at high speed.

This could cause them to explode and

result in serious injury. Parts of your

vehicle could also overheat and be

damaged.CE1052

5-12

Z01.2.1/A32-DX

Page 142 of 215

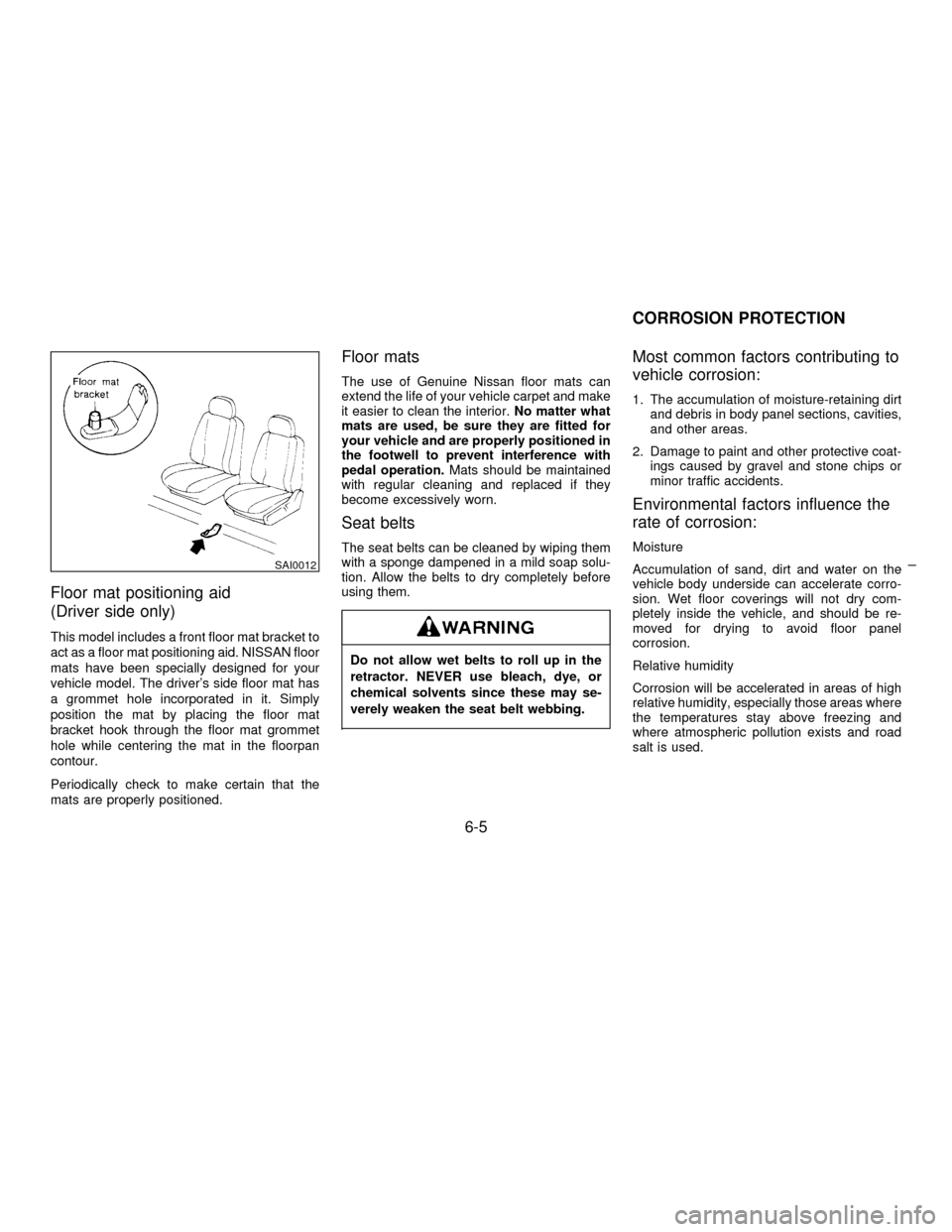

Floor mat positioning aid

(Driver side only)

This model includes a front floor mat bracket to

act as a floor mat positioning aid. NISSAN floor

mats have been specially designed for your

vehicle model. The driver's side floor mat has

a grommet hole incorporated in it. Simply

position the mat by placing the floor mat

bracket hook through the floor mat grommet

hole while centering the mat in the floorpan

contour.

Periodically check to make certain that the

mats are properly positioned.

Floor mats

The use of Genuine Nissan floor mats can

extend the life of your vehicle carpet and make

it easier to clean the interior.No matter what

mats are used, be sure they are fitted for

your vehicle and are properly positioned in

the footwell to prevent interference with

pedal operation.Mats should be maintained

with regular cleaning and replaced if they

become excessively worn.

Seat belts

The seat belts can be cleaned by wiping them

with a sponge dampened in a mild soap solu-

tion. Allow the belts to dry completely before

using them.

Do not allow wet belts to roll up in the

retractor. NEVER use bleach, dye, or

chemical solvents since these may se-

verely weaken the seat belt webbing.

Most common factors contributing to

vehicle corrosion:

1. The accumulation of moisture-retaining dirt

and debris in body panel sections, cavities,

and other areas.

2. Damage to paint and other protective coat-

ings caused by gravel and stone chips or

minor traffic accidents.

Environmental factors influence the

rate of corrosion:

Moisture

Accumulation of sand, dirt and water on the

vehicle body underside can accelerate corro-

sion. Wet floor coverings will not dry com-

pletely inside the vehicle, and should be re-

moved for drying to avoid floor panel

corrosion.

Relative humidity

Corrosion will be accelerated in areas of high

relative humidity, especially those areas where

the temperatures stay above freezing and

where atmospheric pollution exists and road

salt is used.

SAI0012

CORROSION PROTECTION

6-5

Z01.2.1/A32-DX

Page 152 of 215

6. Remove the drain plug with a wrench and

completely drain the oil.

If oil filter is to be changed, remove and

replace it at this time. See ªChanging oil

filterº.

Be careful not to burn yourself, as the

engine oil is hot.

Waste oil must be disposed of properly.

Check your local regulations.

7. Clean and re-install the drain plug and new

washer. Securely tighten the drain plug with

a wrench.

Drain plug tightening torque:

22 to 29 ft-lb

(29 to 39 N×m)

Do not use excessive force.

8. Refill engine with recommended oil and

install the cap securely.

See the ªTechnical informationº section for

refill capacity.

Never pull out the dipstick while filling the

engine with oil.9. Start the engine.

Check for leakage around the drain plug.

Correct as required.

10.Turn the engine off and wait more than 10

minutes. Check the oil level with the dip-

stick. Add engine oil if necessary.

11.Dispose of waste oil in the proper manner.IProlonged and repeated contact with

used engine oil may cause skin can-

cer.

ITry to avoid direct skin contact with

used oil. If skin contact is made, wash

thoroughly with soap or hand cleaner

as soon as possible.

IKeep used engine oil out of reach of

children.

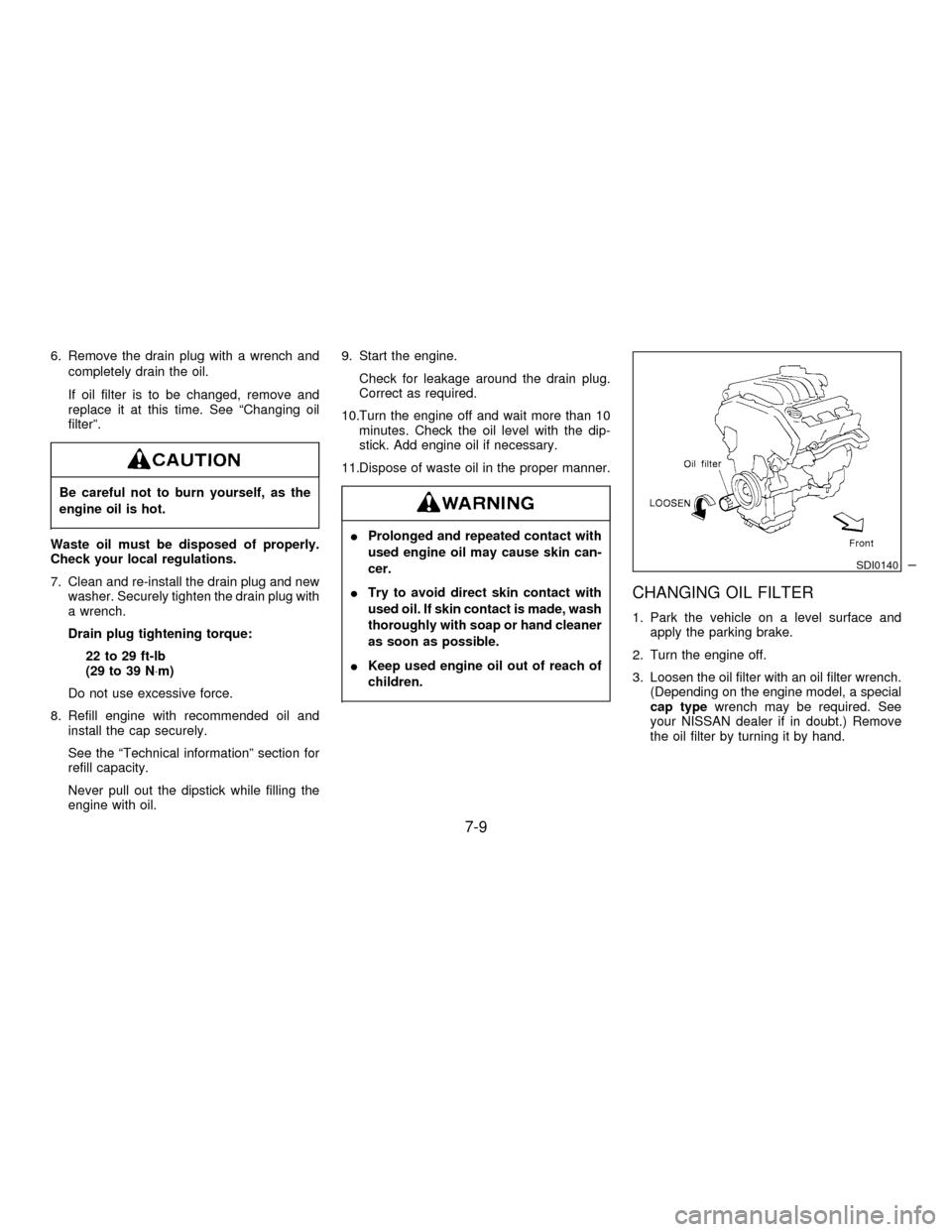

CHANGING OIL FILTER

1. Park the vehicle on a level surface and

apply the parking brake.

2. Turn the engine off.

3. Loosen the oil filter with an oil filter wrench.

(Depending on the engine model, a special

cap typewrench may be required. See

your NISSAN dealer if in doubt.) Remove

the oil filter by turning it by hand.

SDI0140

7-9

Z01.2.1/A32-DX

Page 174 of 215

Types of tires

When changing or replacing tires, be

sure all four tires are of the same type

(i.e., Summer, All Season or Snow) and

construction. Your NISSAN dealer may

be able to help you with information

about tire type, size, speed rating and

availability. Replacement tires may have

a lower speed rating than the factory

equipped tires, and may not match the

potential maximum vehicle speed. Never

exceed the maximum speed rating of the

tire.

All season tires

NISSAN specifies All Season tires on some

models to provide good performance for use

all year around, including snowy and icy road

conditions. All Season Tires are identified by

ªALL SEASONº and/or ªM&Sº on the tire side-

wall. Snow tires have better snow traction than

All Season tires and may be more appropriate

in some areas.Summer tires

NISSAN specifies summer tires on some mod-

els to provide superior performance on dry

roads. Summer tire performance in snow and

ice will be substantially reduced. Summer tires

do not have the tire traction rating ªM&Sº on

the tire sidewall.

If you plan to operate your vehicle in snowy or

icy conditions, NISSAN recommends the use

of ªSNOWº or ªALL SEASONº tires on all four

wheels.

Snow tires

If snow tires are needed, it is necessary to

select tires equivalent in size and load rating to

the original equipment tires. If you do not, it

can adversely affect the safety and handling of

your vehicle.

Generally, snow tires will have lower speed

ratings than factory equipped tires and may

not match the potential maximum vehicle

speed. Never exceed the maximum speed

rating of the tire.

For additional traction on icy roads, studded

tires may be used. However, some provinces

and states prohibit their use. Check local, state

and provincial laws before installing studded

tires. Skid and traction capabilities of studded

snow tires, on wet or dry surfaces, may bepoorer than that of non-studded snow tires.

Tire chains

Use of tire chains may be prohibited according

to location. Check the local laws before install-

ing tire chains. When installing tire chains,

make sure they are of proper size for the tires

on your vehicle and are installed according to

the chain manufacturer's suggestions.Use

only SAE class ªSº chains.Other types may

damage your vehicle. Use chain tensioners

when recommended by the tire chain manu-

facturer to ensure a tight fit. Loose end links of

the tire chain must be secured or removed to

prevent the possibility of whipping action dam-

age to the fenders or undercarriage. If pos-

sible, avoid fully loading your vehicle when

using tire chains. In addition, drive at a re-

duced speed. Otherwise, your vehicle may be

damaged and/or vehicle handling and perfor-

mance may be adversely affected.

Never install tire chains on a T-type spare tire.

Do not use the chains on dry roads.

7-31

Z01.2.1/A32-DX

Page 196 of 215

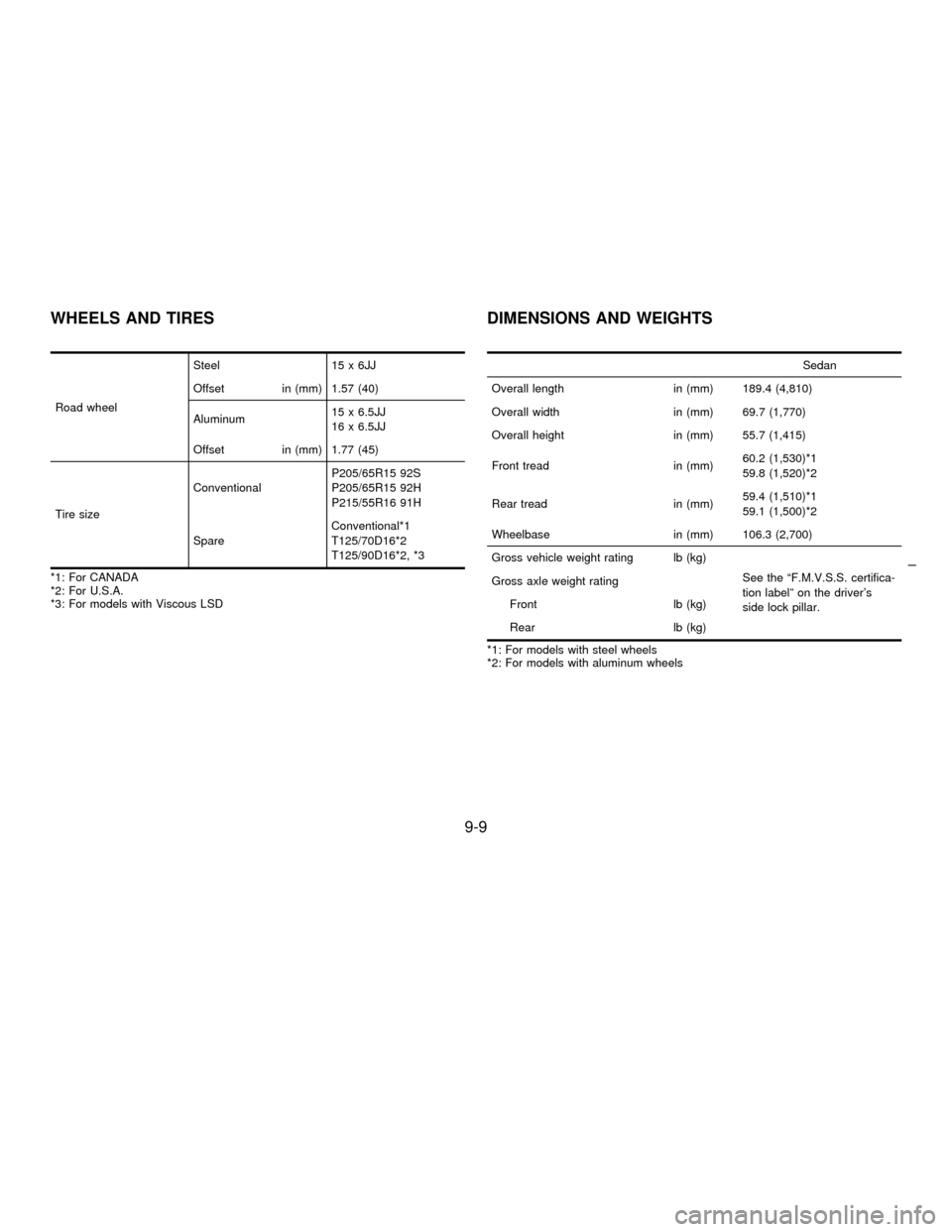

Road wheelSteel 15 x 6JJ

Offset in (mm) 1.57 (40)

Aluminum15 x 6.5JJ

16 x 6.5JJ

Offset in (mm) 1.77 (45)

Tire sizeConventionalP205/65R15 92S

P205/65R15 92H

P215/55R16 91H

SpareConventional*1

T125/70D16*2

T125/90D16*2, *3

*1: For CANADA

*2: For U.S.A.

*3: For models with Viscous LSD

Sedan

Overall length in (mm) 189.4 (4,810)

Overall width in (mm) 69.7 (1,770)

Overall height in (mm) 55.7 (1,415)

Front tread in (mm)60.2 (1,530)*1

59.8 (1,520)*2

Rear tread in (mm)59.4 (1,510)*1

59.1 (1,500)*2

Wheelbase in (mm) 106.3 (2,700)

Gross vehicle weight rating lb (kg)

See the ªF.M.V.S.S. certifica-

tion labelº on the driver's

side lock pillar. Gross axle weight rating

Front lb (kg)

Rear lb (kg)

*1: For models with steel wheels

*2: For models with aluminum wheels

WHEELS AND TIRES DIMENSIONS AND WEIGHTS

9-9

Z01.2.1/A32-DX

Page 203 of 215

hitch when not in use. Remove the

receiver when not in use. After the

hitch is removed, seal the bolt holes

to prevent exhaust fumes, water or

dust from entering the passenger

compartment.

IRegularly check that all hitch mount-

ing bolts are securely mounted.

Tire pressures

IWhen towing a trailer, inflate the vehicle

tires to the recommended cold tire pressure

indicated on the tire placard (located on the

inside of the center console lid.)

ITrailer tire condition, size, load rating and

proper inflation pressure should be in ac-

cordance with the trailer and tire manufac-

turers' specifications.

Safety chain

Always use a suitable chain between your

vehicle and the trailer. The chain should be

crossed and should be attached to the hitch,

not to the vehicle bumper or axle. Be sure to

leave enough slack in the chain to permit

turning corners.

Trailer lights

Trailer lights should comply with Federal

and/or local regulations. When wiring the ve-

hicle for towing, connect the stop and tail light

pickup into the vehicle electrical circuit at a

point between the sensor and stop light or light

switch.

Trailer brakes

If your trailer is equipped with a braking sys-

tem, make sure it conforms to Federal and/or

local regulations and that it is properly in-

stalled.

Never connect a trailer brake system

directly to the vehicle brake system.

Pre-towing tips

IBe certain your vehicle maintains a level

position when a loaded and/or unloaded

trailer is hitched. Do not drive the vehicle if

it has an abnormal nose-up or nose-down

condition; check for improper tongue load,

overload, worn suspension or other pos-

sible causes of either condition.

IAlways secure items in the trailer to preventload shifts while driving.

IBe certain your rear view mirrors conform to

all federal, state or local regulations. If not,

install any mirrors required for towing be-

fore driving the vehicle.

Trailer towing tips

In order to gain skill and an understanding of

the vehicle's behavior, you should practice

turning, stopping and backing up in an area

which is free from traffic. Steering stability, and

braking performance will be somewhat differ-

ent than under normal driving conditions.

IAlways secure items in the trailer to prevent

load shift while driving.

IAvoid abrupt starts, acceleration or stops.

IAvoid sharp turns or lane changes.

IAlways drive your vehicle at a moderate

speed.

IAlways block the wheels on both vehicle

and trailer when parking. Parking on a

slope is not recommended; however, if you

must do so, and if your vehicle is equipped

with automatic transmission, first block the

wheels and apply the parking brake, and

then move the transmission shift lever into

the ªPº position. If you move the shift lever

to the ªPº position before blocking the

9-16

Z01.2.1/A32-DX

Page 207 of 215

2. Accelerate the vehicle to 55 MPH (88

km/h), then quickly release the accelerator

pedal completely and keep it released for at

least 6 seconds.

3. Quickly depress the accelerator pedal for a

moment, then drive the vehicle at a speed

of 53 to 60 MPH (86 to 96 km/h) for at least

5 minutes.

4. Stop the vehicle and turn the engine off.

5. Repeat steps 1 through 4 at least one more

time.

If step 1, 2 or 3 is interrupted, repeat the

preceding step. Any safe driving mode is ac-

ceptable between steps. Do not stop the en-

gine until step 3 is completed.

9-20

Z01.2.1/A32-DX