check transmission fluid NISSAN NAVARA 2005 Repair User Guide

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2005, Model line: NAVARA, Model: NISSAN NAVARA 2005Pages: 3171, PDF Size: 49.59 MB

Page 204 of 3171

AT-196

TROUBLE DIAGNOSIS FOR SYMPTOMS

A/T Does Not Perform Lock-up

ECS00G2N

SYMPTOM:

A/T does not perform lock-up at the specified speed.

DIAGNOSTIC PROCEDURE

1.CHECK SELF-DIAGNOSTIC RESULTS

Perform self-diagnosis. Refer toAT-80, "

SELF-DIAGNOSTIC RESULT MODE",AT-89, "Diagnostic Procedure

Without CONSULT-II".

Is any malfunction detected by self-diagnostic results?

YES >> Check malfunctioning system. Refer toAT-80, "SELF-DIAGNOSTIC RESULT MODE",AT- 9 0 ,

"Judgement Self-diagnosis Code".

NO >> GO TO 2.

2.CHECK A/T FLUID LEVEL

Check A/T fluid level. Refer toAT-12, "

Checking A/T Fluid".

OK or NG

OK >> GO TO 3.

NG >> Refill ATF.

3.CHECK LINE PRESSURE

Check line pressure at the engine stall point. Refer toAT-44, "

LINE PRESSURE TEST".

OK or NG

OK >> GO TO 6.

NG - 1 >> Line pressure high. GO TO 4.

NG - 2 >> Line pressure low. GO TO 5.

4.DETECT MALFUNCTIONING ITEM

1. Check control valve with TCM. Refer toAT- 2 1 8 , "

Control Valve With TCM and A/T Fluid Temperature Sen-

sor 2".

2. Disassemble A/T. Refer toAT- 2 6 3 , "

DISASSEMBLY".

3. Check the following.

–Oil pump assembly. Refer toAT- 2 8 1 , "Oil Pump".

OK or NG

OK >> GO TO 6.

NG >> Repair or replace damaged parts.

5.DETECT MALFUNCTIONING ITEM

1. Check control valve with TCM. Refer toAT- 2 1 8 , "

Control Valve With TCM and A/T Fluid Temperature Sen-

sor 2".

2. Disassemble A/T. Refer toAT- 2 6 3 , "

DISASSEMBLY".

3. Check the following.

–Oil pump assembly. Refer toAT- 2 8 1 , "Oil Pump".

–Power train system. Refer toAT- 2 6 3 , "DISASSEMBLY".

–Transmission case. Refer toAT- 2 6 3 , "DISASSEMBLY".

OK or NG

OK >> GO TO 6.

NG >> Repair or replace damaged parts.

Page 249 of 3171

ON-VEHICLE SERVICE

AT-241

D

E

F

G

H

I

J

K

L

MA

B

AT

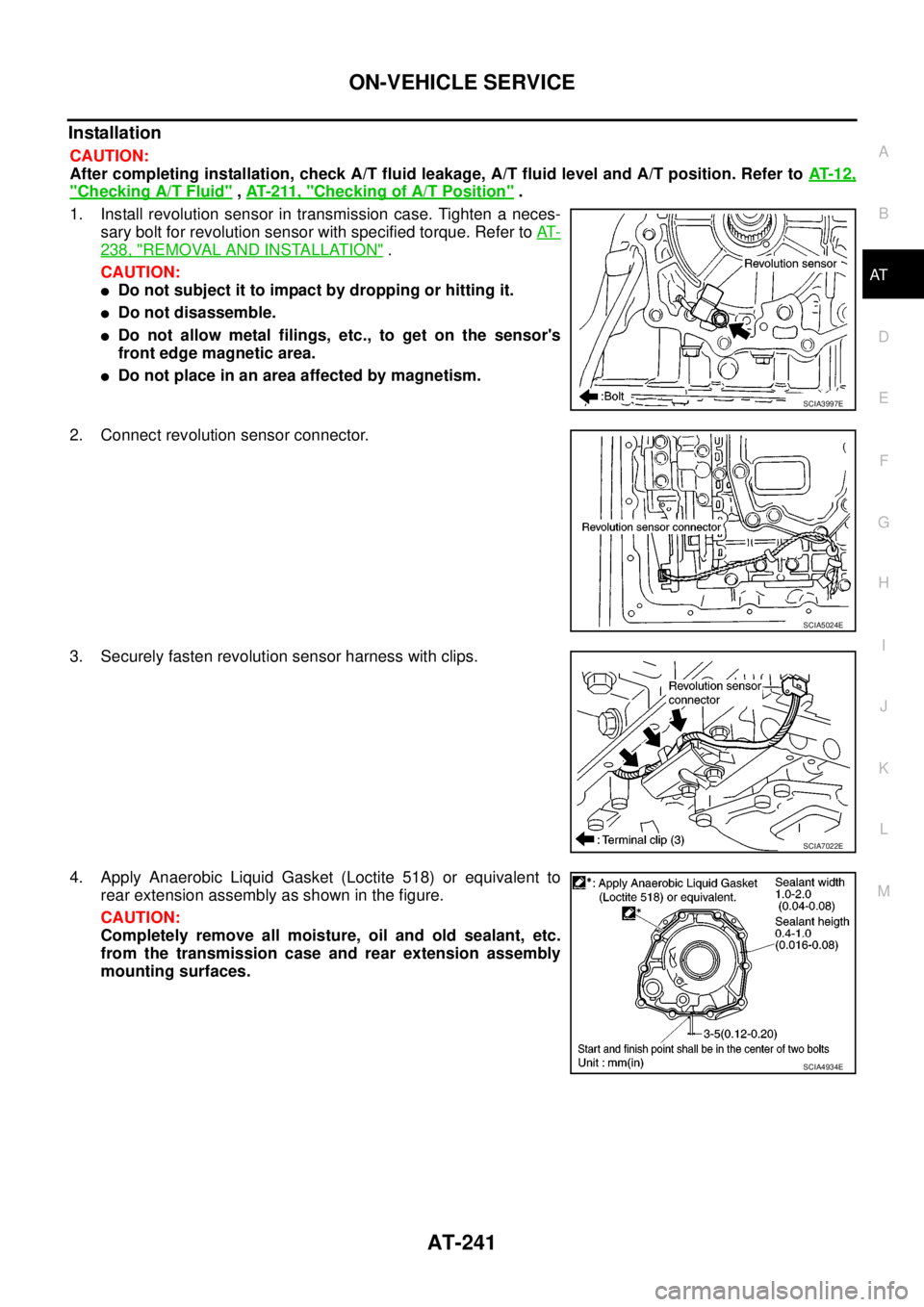

Installation

CAUTION:

After completing installation, check A/T fluid leakage, A/T fluid level and A/T position. Refer toAT- 1 2 ,

"Checking A/T Fluid",AT- 2 11 , "Checking of A/T Position".

1. Install revolution sensor in transmission case. Tighten a neces-

sary bolt for revolution sensor with specified torque. Refer toAT-

238, "REMOVAL AND INSTALLATION".

CAUTION:

lDo not subject it to impact by dropping or hitting it.

lDo not disassemble.

lDo not allow metal filings, etc., to get on the sensor's

front edge magnetic area.

lDo not place in an area affected by magnetism.

2. Connect revolution sensor connector.

3. Securely fasten revolution sensor harness with clips.

4. Apply Anaerobic Liquid Gasket (Loctite 518) or equivalent to

rear extension assembly as shown in the figure.

CAUTION:

Completely remove all moisture, oil and old sealant, etc.

from the transmission case and rear extension assembly

mounting surfaces.

SCIA3997E

SCIA5024E

SCIA7022E

SCIA4934E

Page 258 of 3171

AT-250

TRANSMISSION ASSEMBLY

INSPECTION

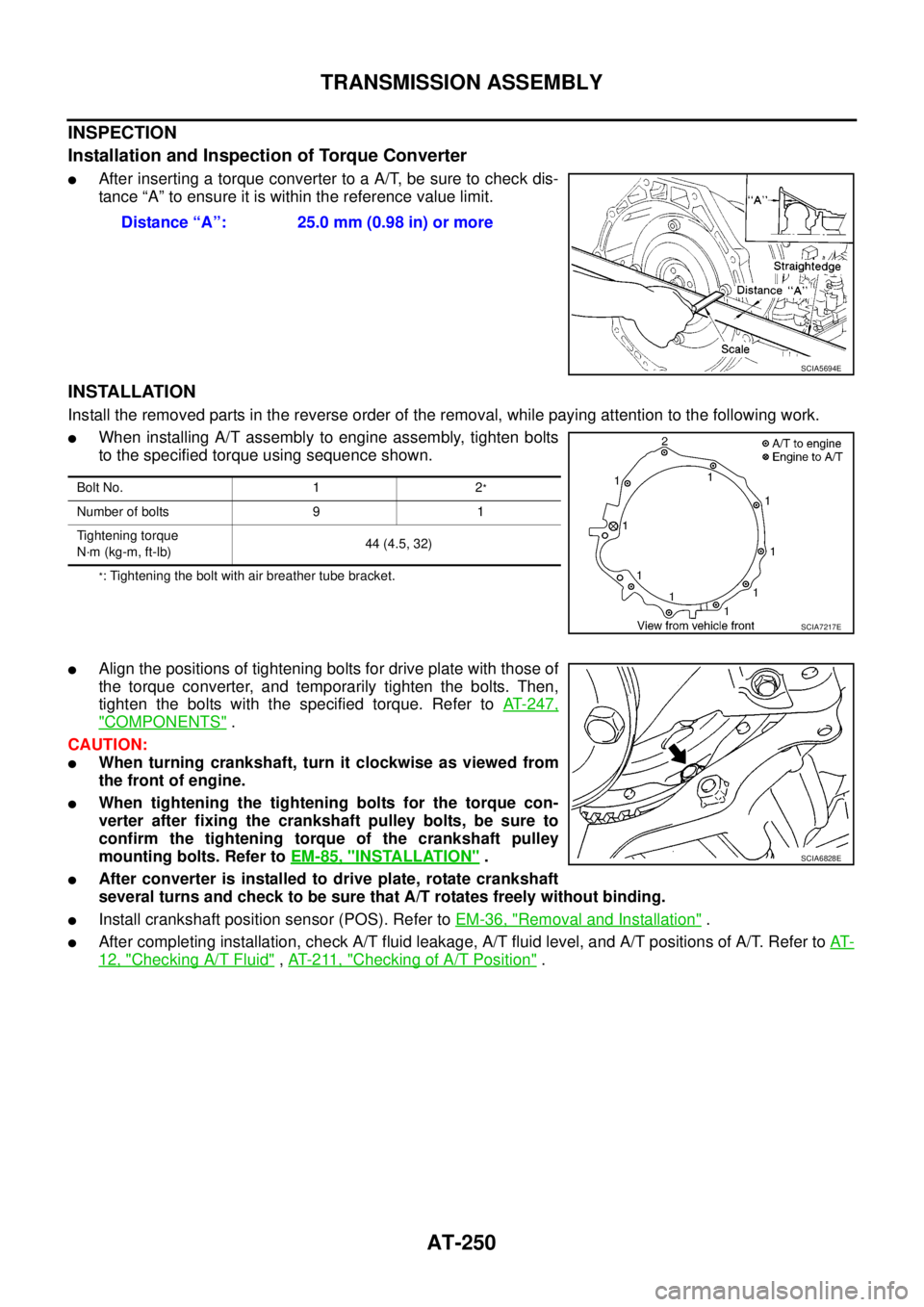

Installation and Inspection of Torque Converter

lAfter inserting a torque converter to a A/T, be sure to check dis-

tance “A” to ensure it is within the reference value limit.

INSTALLATION

Install the removed parts in the reverse order of the removal, while paying attention to the following work.

lWhen installing A/T assembly to engine assembly, tighten bolts

to the specified torque using sequence shown.

*: Tightening the bolt with air breather tube bracket.

lAlign the positions of tightening bolts for drive plate with those of

the torque converter, and temporarily tighten the bolts. Then,

tighten the bolts with the specified torque. Refer toAT-247,

"COMPONENTS".

CAUTION:

lWhen turning crankshaft, turn it clockwise as viewed from

the front of engine.

lWhen tightening the tightening bolts for the torque con-

verter after fixing the crankshaft pulley bolts, be sure to

confirm the tightening torque of the crankshaft pulley

mounting bolts. Refer toEM-85, "

INSTALLATION".

lAfter converter is installed to drive plate, rotate crankshaft

several turns and check to be sure that A/T rotates freely without binding.

lInstall crankshaft position sensor (POS). Refer toEM-36, "Removal and Installation".

lAfter completing installation, check A/T fluid leakage, A/T fluid level, and A/T positions of A/T. Refer toAT-

12, "Checking A/T Fluid",AT- 2 11 , "Checking of A/T Position". Distance “A”: 25.0 mm (0.98 in) or more

SCIA5694E

Bolt No. 1 2*

Number of bolts 9 1

Tightening torque

N·m (kg-m, ft-lb)44 (4.5, 32)

SCIA7217E

SCIA6828E

Page 1447 of 3171

CAMSHAFT

EM-65

C

D

E

F

G

H

I

J

K

L

MA

EM

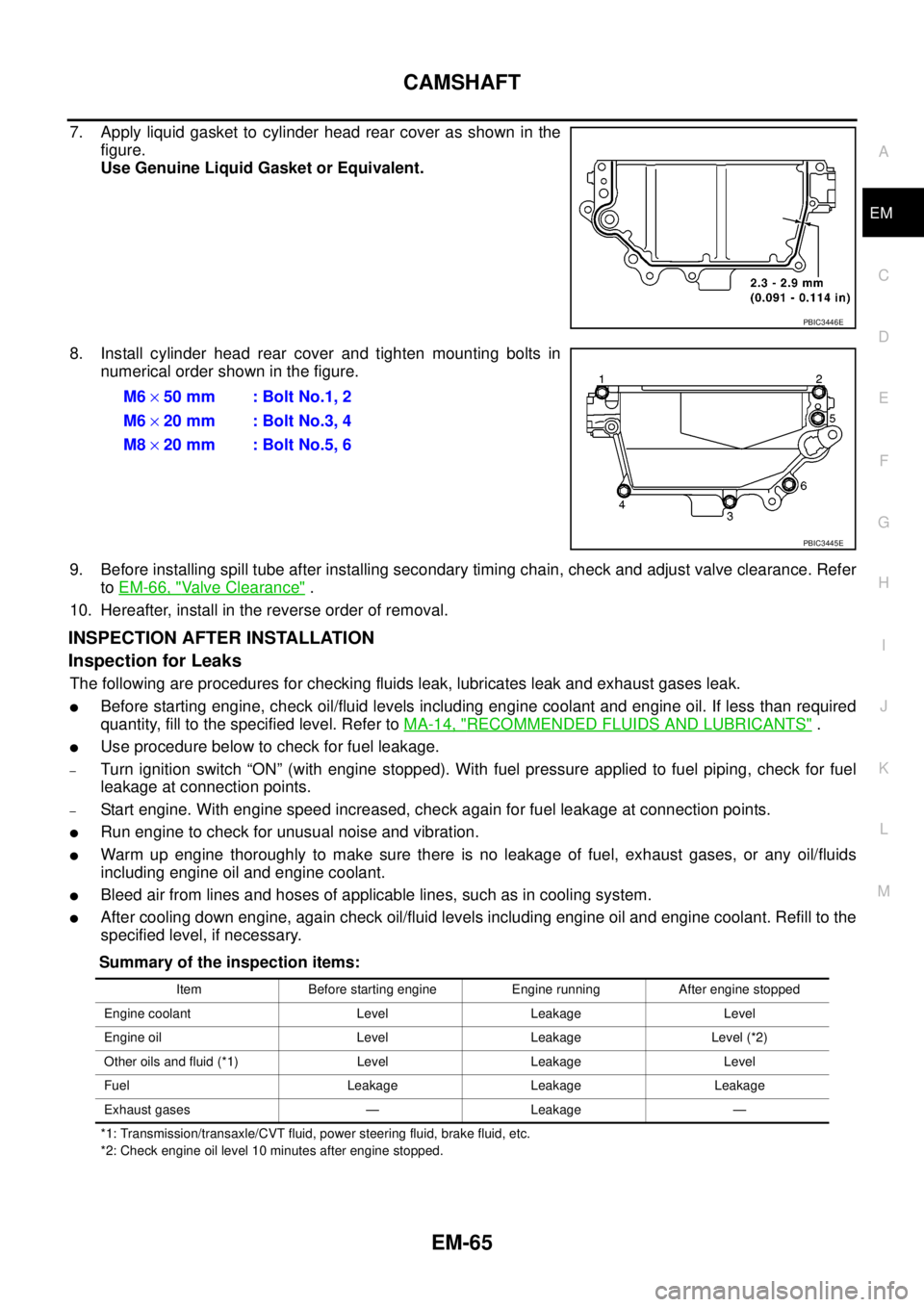

7. Apply liquid gasket to cylinder head rear cover as shown in the

figure.

Use Genuine Liquid Gasket or Equivalent.

8. Install cylinder head rear cover and tighten mounting bolts in

numerical order shown in the figure.

9. Before installing spill tube after installing secondary timing chain, check and adjust valve clearance. Refer

toEM-66, "

Valve Clearance".

10. Hereafter, install in the reverse order of removal.

INSPECTION AFTER INSTALLATION

Inspection for Leaks

The following are procedures for checking fluids leak, lubricates leak and exhaust gases leak.

lBefore starting engine, check oil/fluid levels including engine coolant and engine oil. If less than required

quantity, fill to the specified level. Refer toMA-14, "

RECOMMENDED FLUIDS AND LUBRICANTS".

lUse procedure below to check for fuel leakage.

–Turn ignition switch “ON” (with engine stopped). With fuel pressure applied to fuel piping, check for fuel

leakage at connection points.

–Start engine. With engine speed increased, check again for fuel leakage at connection points.

lRun engine to check for unusual noise and vibration.

lWarm up engine thoroughly to make sure there is no leakage of fuel, exhaust gases, or any oil/fluids

including engine oil and engine coolant.

lBleed air from lines and hoses of applicable lines, such as in cooling system.

lAfter cooling down engine, again check oil/fluid levels including engine oil and engine coolant. Refill to the

specified level, if necessary.

Summary of the inspection items:

*1: Transmission/transaxle/CVT fluid, power steering fluid, brake fluid, etc.

*2: Check engine oil level 10 minutes after engine stopped.

PBIC3446E

M6´50 mm : Bolt No.1, 2

M6´20 mm : Bolt No.3, 4

M8´20 mm : Bolt No.5, 6

PBIC3445E

Item Before starting engine Engine running After engine stopped

Engine coolant Level Leakage Level

Engine oil Level Leakage Level (*2)

Other oils and fluid (*1) Level Leakage Level

Fuel Leakage Leakage Leakage

Exhaust gases — Leakage —

Page 1460 of 3171

EM-78

SECONDARY TIMING CHAIN

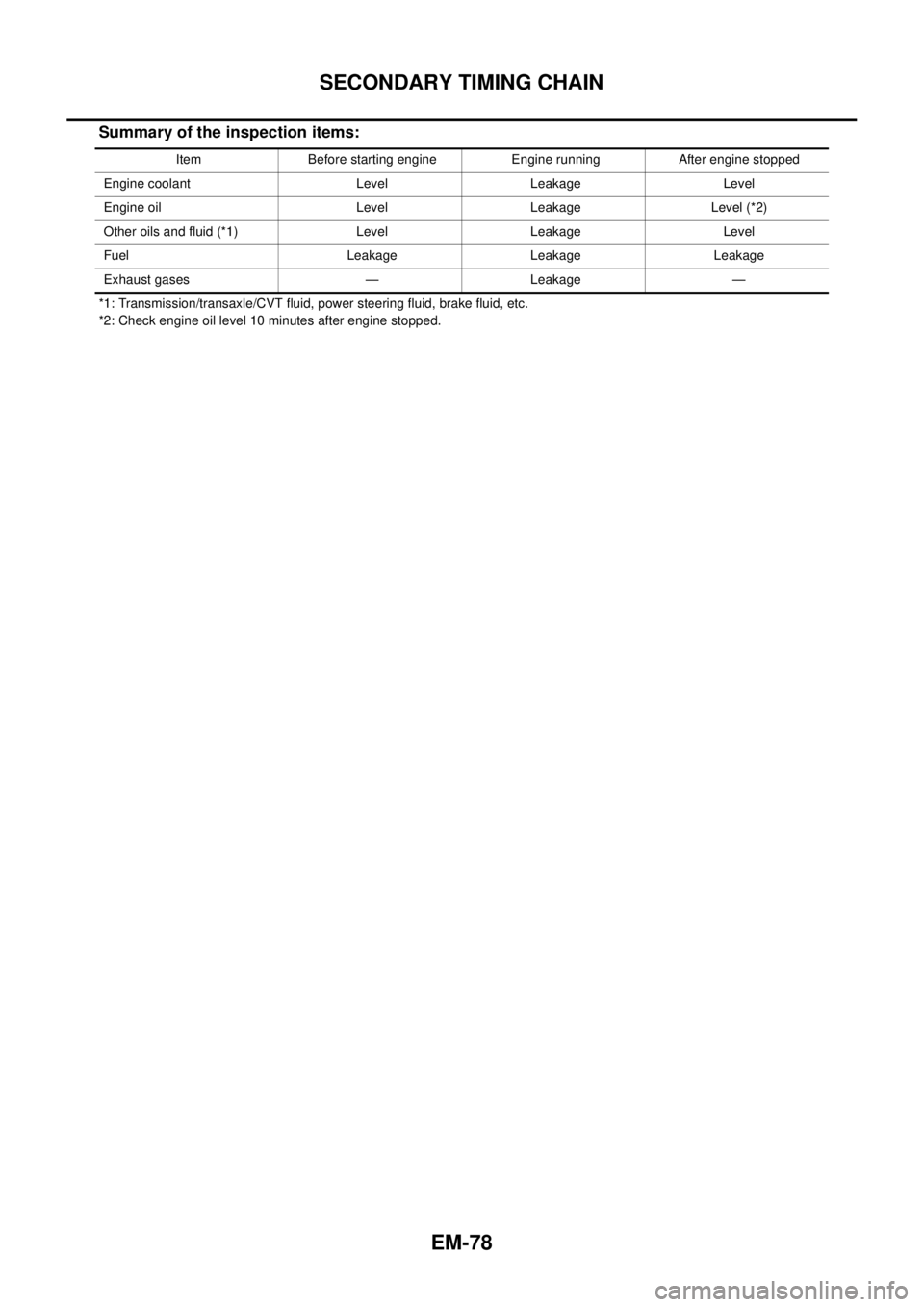

Summary of the inspection items:

*1: Transmission/transaxle/CVT fluid, power steering fluid, brake fluid, etc.

*2: Check engine oil level 10 minutes after engine stopped.Item Before starting engine Engine running After engine stopped

Engine coolant Level Leakage Level

Engine oil Level Leakage Level (*2)

Other oils and fluid (*1) Level Leakage Level

Fuel Leakage Leakage Leakage

Exhaust gases — Leakage —

Page 1473 of 3171

PRIMARY TIMING CHAIN

EM-91

C

D

E

F

G

H

I

J

K

L

MA

EM

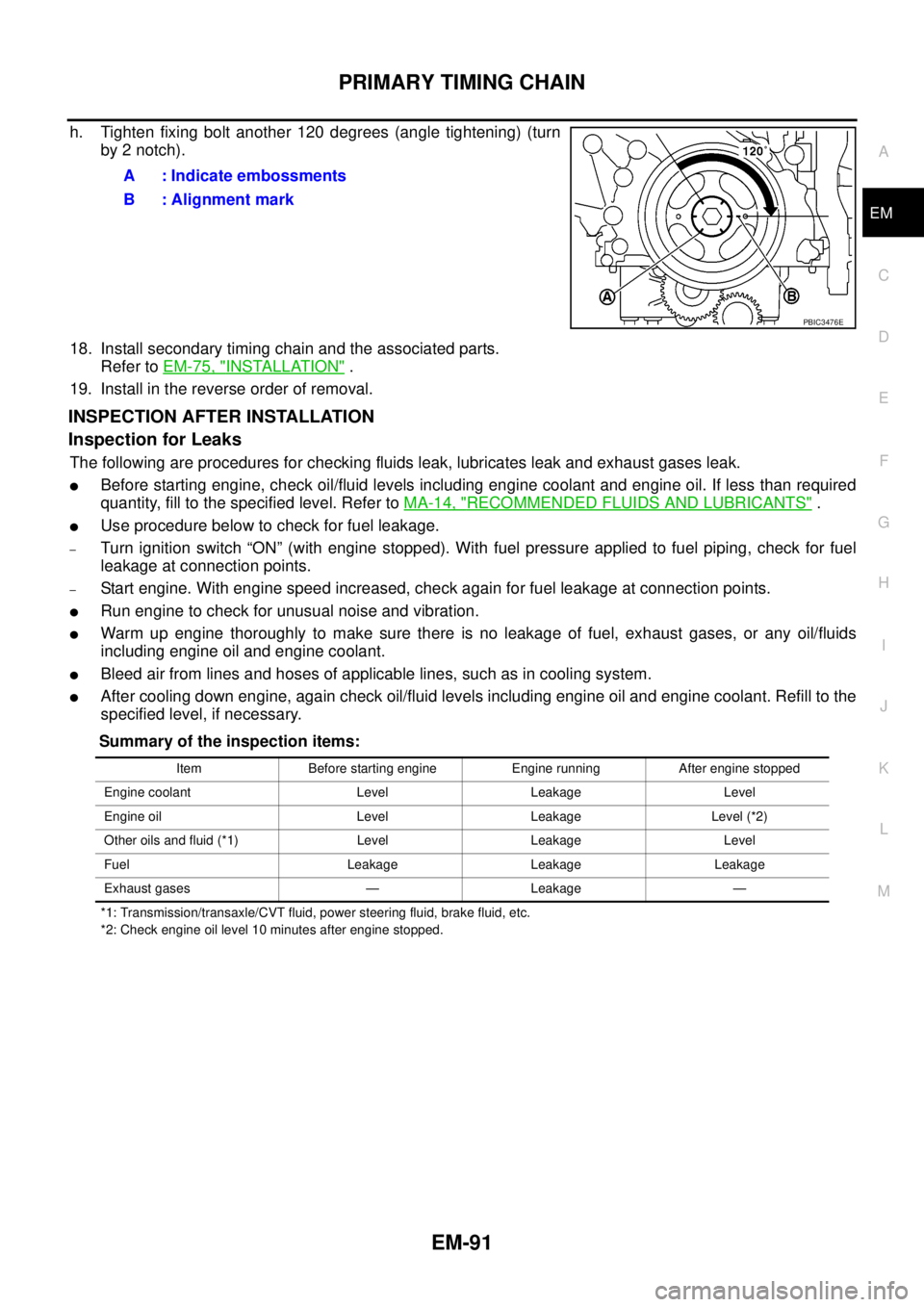

h. Tighten fixing bolt another 120 degrees (angle tightening) (turn

by 2 notch).

18. Install secondary timing chain and the associated parts.

Refer toEM-75, "

INSTALLATION".

19. Install in the reverse order of removal.

INSPECTION AFTER INSTALLATION

Inspection for Leaks

The following are procedures for checking fluids leak, lubricates leak and exhaust gases leak.

lBefore starting engine, check oil/fluid levels including engine coolant and engine oil. If less than required

quantity, fill to the specified level. Refer toMA-14, "

RECOMMENDED FLUIDS AND LUBRICANTS".

lUse procedure below to check for fuel leakage.

–Turn ignition switch “ON” (with engine stopped). With fuel pressure applied to fuel piping, check for fuel

leakage at connection points.

–Start engine. With engine speed increased, check again for fuel leakage at connection points.

lRun engine to check for unusual noise and vibration.

lWarm up engine thoroughly to make sure there is no leakage of fuel, exhaust gases, or any oil/fluids

including engine oil and engine coolant.

lBleed air from lines and hoses of applicable lines, such as in cooling system.

lAfter cooling down engine, again check oil/fluid levels including engine oil and engine coolant. Refill to the

specified level, if necessary.

Summary of the inspection items:

*1: Transmission/transaxle/CVT fluid, power steering fluid, brake fluid, etc.

*2: Check engine oil level 10 minutes after engine stopped.

A : Indicate embossments

B : Alignment mark

PBIC3476E

Item Before starting engine Engine running After engine stopped

Engine coolant Level Leakage Level

Engine oil Level Leakage Level (*2)

Other oils and fluid (*1) Level Leakage Level

Fuel Leakage Leakage Leakage

Exhaust gases — Leakage —

Page 1480 of 3171

EM-98

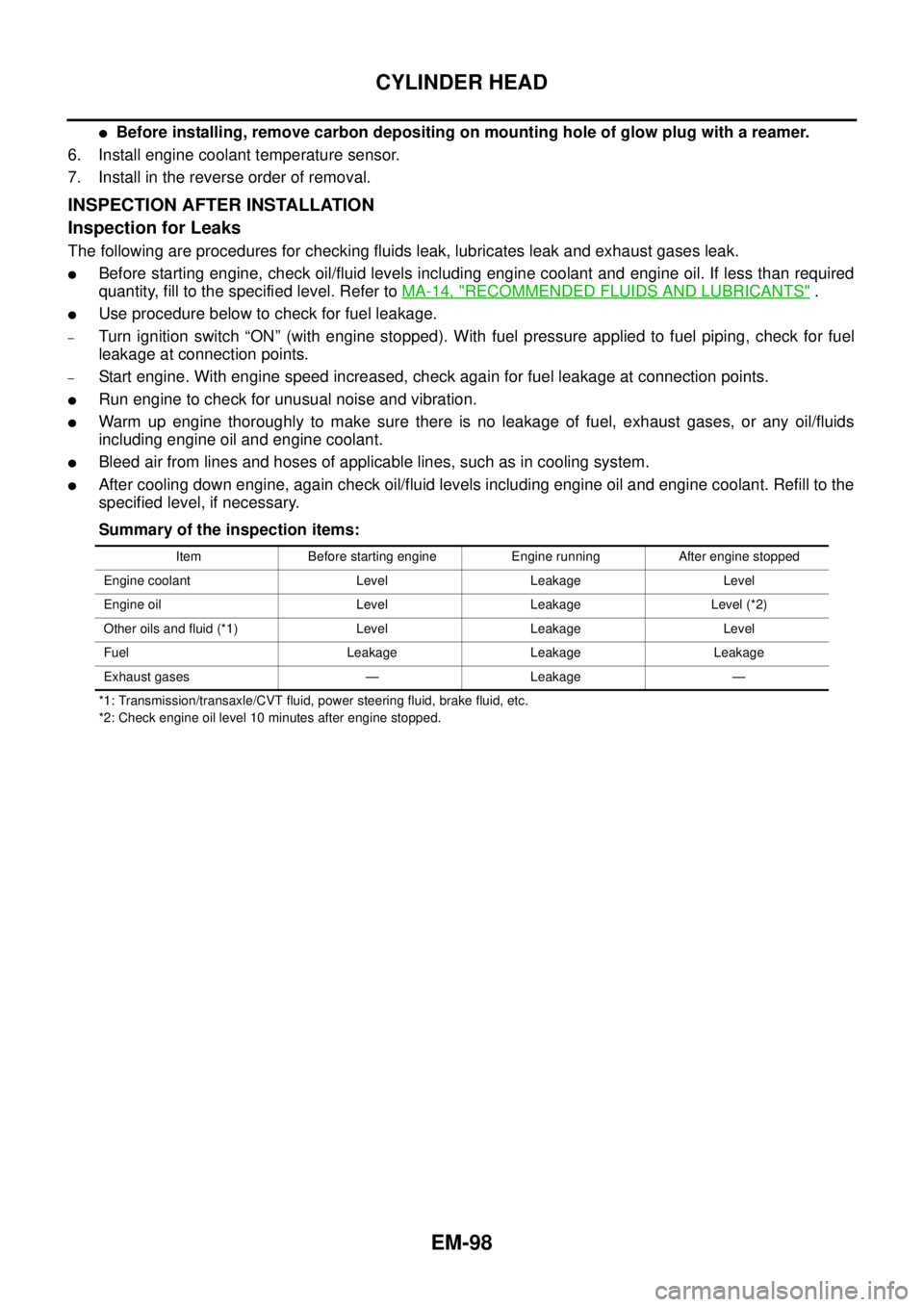

CYLINDER HEAD

lBefore installing, remove carbon depositing on mounting hole of glow plug with a reamer.

6. Install engine coolant temperature sensor.

7. Install in the reverse order of removal.

INSPECTION AFTER INSTALLATION

Inspection for Leaks

The following are procedures for checking fluids leak, lubricates leak and exhaust gases leak.

lBefore starting engine, check oil/fluid levels including engine coolant and engine oil. If less than required

quantity, fill to the specified level. Refer toMA-14, "

RECOMMENDED FLUIDS AND LUBRICANTS".

lUse procedure below to check for fuel leakage.

–Turn ignition switch “ON” (with engine stopped). With fuel pressure applied to fuel piping, check for fuel

leakage at connection points.

–Start engine. With engine speed increased, check again for fuel leakage at connection points.

lRun engine to check for unusual noise and vibration.

lWarm up engine thoroughly to make sure there is no leakage of fuel, exhaust gases, or any oil/fluids

including engine oil and engine coolant.

lBleed air from lines and hoses of applicable lines, such as in cooling system.

lAfter cooling down engine, again check oil/fluid levels including engine oil and engine coolant. Refill to the

specified level, if necessary.

Summary of the inspection items:

*1: Transmission/transaxle/CVT fluid, power steering fluid, brake fluid, etc.

*2: Check engine oil level 10 minutes after engine stopped.Item Before starting engine Engine running After engine stopped

Engine coolant Level Leakage Level

Engine oil Level Leakage Level (*2)

Other oils and fluid (*1) Level Leakage Level

Fuel Leakage Leakage Leakage

Exhaust gases — Leakage —

Page 1491 of 3171

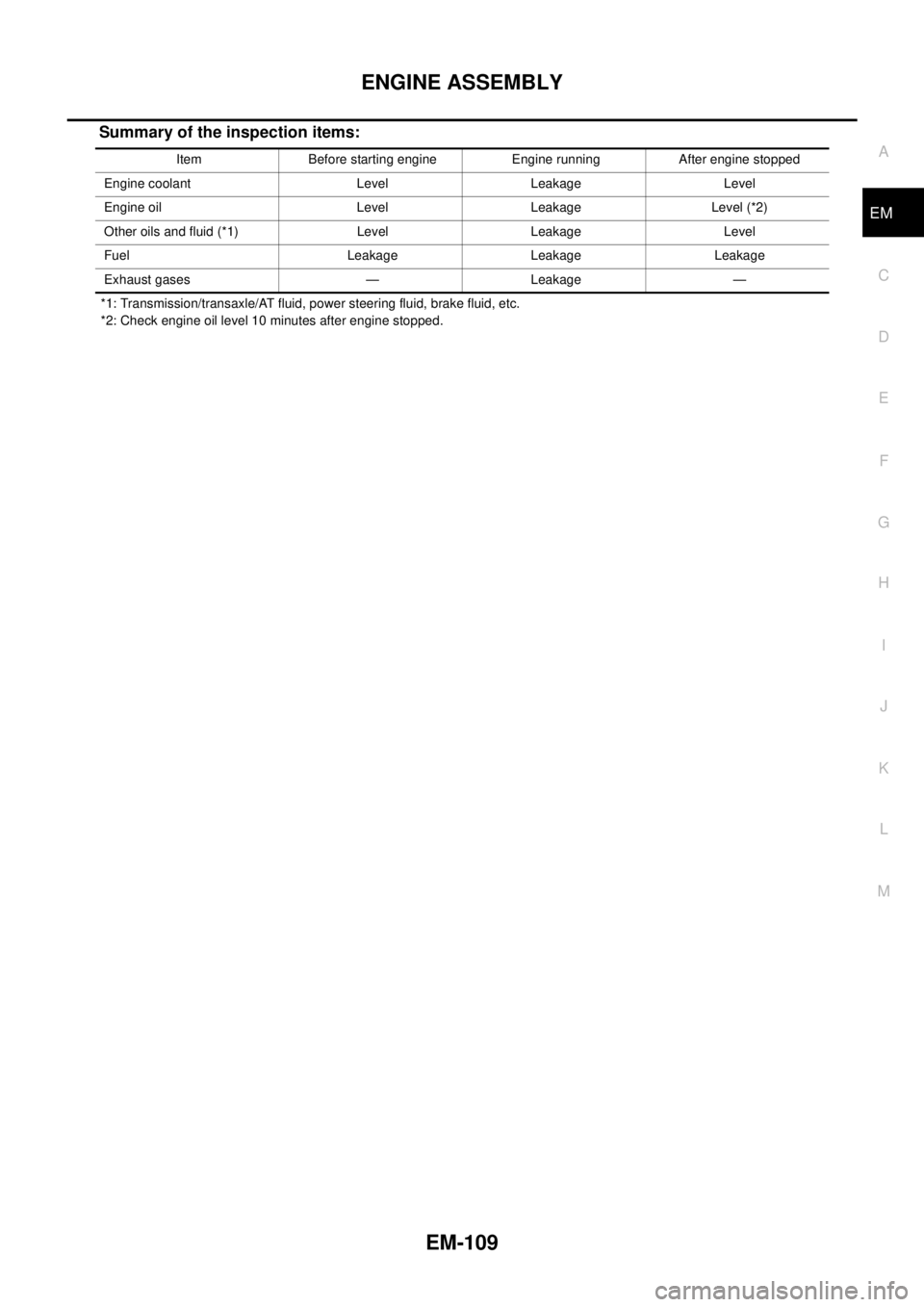

ENGINE ASSEMBLY

EM-109

C

D

E

F

G

H

I

J

K

L

MA

EM

Summary of the inspection items:

*1: Transmission/transaxle/AT fluid, power steering fluid, brake fluid, etc.

*2: Check engine oil level 10 minutes after engine stopped.Item Before starting engine Engine running After engine stopped

Engine coolant Level Leakage Level

Engine oil Level Leakage Level (*2)

Other oils and fluid (*1) Level Leakage Level

Fuel Leakage Leakage Leakage

Exhaust gases — Leakage —

Page 1627 of 3171

PRECAUTIONS

GI-5

C

D

E

F

G

H

I

J

K

L

MB

GI

lTo prevent serious burns:

Avoid contact with hot metal parts.

Do not remove the radiator cap when the engine is hot.

lDispose of drained oil or the solvent used for cleaning parts in

an appropriate manner.

lDo not attempt to top off the fuel tank after the fuel pump nozzle

shuts off automatically.

Continued refueling may cause fuel overflow, resulting in fuel

spray and possibly a fire.

lClean all disassembled parts in the designated liquid or solvent

prior to inspection or assembly.

lReplace oil seals, gaskets, packings, O-rings, locking washers, cotter pins, self-locking nuts, etc. with new

ones.

lReplace inner and outer races of tapered roller bearings and needle bearings as a set.

lArrange the disassembled parts in accordance with their assembled locations and sequence.

lDo not touch the terminals of electrical components which use microcomputers (such as ECM).

Static electricity may damage internal electronic components.

lAfter disconnecting vacuum or air hoses, attach a tag to indicate the proper connection.

lUse only the fluids and lubricants specified in this manual.

lUse approved bonding agent, sealants or their equivalents when required.

lUse tools and recommended special tools where specified for safe and efficient service repairs.

lWhen repairing the fuel, oil, water, vacuum or exhaust systems, check all affected lines for leaks.

lBefore servicing the vehicle:

Protect fenders, upholstery and carpeting with appropriate cov-

ers.

Take caution that keys, buckles or buttons do not scratch paint.

WARNING:

To prevent ECM from storing the diagnostic trouble codes, do not carelessly disconnect the harness

connectors which are related to the engine control system and TCM (transmission control module)

system. The connectors should be disconnected only when working according to the WORK FLOW of

TROUBLE DIAGNOSES in EC and AT sections.

Precautions for Three Way CatalystEAS001GL

If a large amount of unburned fuel flows into the catalyst, the catalyst temperature will be excessively high. To

prevent this, follow the instructions.

lUse unleaded gasoline only. Leaded gasoline will seriously damage the three way catalyst.

lWhen checking for ignition spark or measuring engine compression, make tests quickly and only when

necessary.

lDo not run engine when the fuel tank level is low, otherwise the engine may misfire, causing damage to

the catalyst.

Do not place the vehicle on flammable material. Keep flammable material off the exhaust pipe and the three

way catalyst.

Precautions for FuelEAS001GM

GASOLINE ENGINE

Use unleaded gasoline with an octane rating of at least 95 (RON).

SGI233

SGI234

Page 1754 of 3171

IDX-2

ALPHABETICAL INDEX

Numerics

4LO indicator lamp .............................................TF-16

4LO switch ..............................................TF-56,TF-59

4WD - Wiring diagram .......................................TF-25

4WD shift indicator lamp ....................................TF-16

4WD shift switch .........................TF-16,TF-59,TF-62

4WD system description ....................................TF-15

4WD system diagram ........................................TF-18

4WD warning lamp ............................................TF-17

A

A/C air flow .......................................ATC-30

,MTC-30

A/C compressor clutch removal and installation ...........

ATC-143

,MTC-123

A/C compressor mounting ............ATC-142,MTC-122

A/C compressor precaution ..............ATC-12,MTC-12

A/C compressor special service tool .ATC-16,MTC-16

A/C control operation (auto A/C) .......ATC-28,MTC-28

A/C diagnostic work flow (auto A/C)ATC-103,MTC-95

A/C evaporator ..............................ATC-149,MTC-129

A/C HFC134a (R134a) system precaution .......ATC-4,

MTC-4

A/C HFC134a (R134a) system service procedure .......

ATC-138

,MTC-118

A/C HFC134a (R134a) system service tools ..ATC-16,

MTC-16

A/C HFC134a system service equipment precaution ...

ATC-12

,MTC-12

A/C lubricant (R134a) .......................ATC-24,MTC-24

A/C lubrication oil ..............................ATC-24,MTC-24

A/C operational check .......................ATC-57,MTC-53

A/C self-diagnoses (auto A/C) .......ATC-55,ATC-103,

MTC-51

,MTC-95

A/C service data specification .......ATC-154,MTC-135

A/C trouble diagnoses (auto A/C) .....ATC-33,MTC-33

A/C, A - Wiring diagram ....................ATC-39,MTC-39

A/T fluid checking ......................AT-12,AT-43,MA-29

A/T fluid replacement .............................AT-11,MA-31

A/T fluid temperature sensor ...........................AT-118

A/T IND - Wiring diagram ....................................DI-49

A/T indicator ........................................................DI-48

A/T self-diagnoses .............................................AT-89

A/T shift lock system ........................................AT-212

A/T trouble diagnoses ........................................AT-34

A/T Wiring diagram AT - CAN ............................AT-92

A/T Wiring diagram AT - FTS ..........................AT-119

A/T Wiring diagram AT - MAIN ........................AT-164

A/T Wiring diagram AT - NONDTC ..................AT-174

A/T Wiring diagram AT - PNP/SW ...................AT-100

A/T Wiring diagram AT - STSIG ........................AT-95

A/T Wiring diagram AT - VSS A/T ...................AT-105

ABS - Wiring diagram .....................................BRC-13

Accelerator control system ...............................ACC-2

Accelerator pedal position (APP) sensor ........EC-108,

EC-142

,EC-275

Aiming adjustment ..................................LT-28,LT-85

Air bag ..............................................................SRS-3

Air bag disposal ..............................................SRS-49

Air bleeding (hydraulic clutch) ..............................CL-8

Air cleaner and air duct .....................................EM-15

Air cleaner filter .................................................EM-17

Air cleaner filter replacement ............................MA-25

Air conditioner cut control ..................................EC-20

Air flow meter - See Mass air flow sensor ..........EC-92

Air mix. door motor .........................................ATC-68

Alternator ...........................................................SC-14

Ambient sensor .............................ATC-105,ATC-117

Angular tightening application .............................EM-4

APP2PW - Wiring diagram ..............................EC-229

APPS - Wiring diagram ....................................EC-110

APPS2 - Wiring diagram ..................................EC-144

APPS3 - Wiring diagram ..................................EC-277

ASC/BS - Wiring diagram ................................EC-192

ASC/SW - Wiring diagram ...............................EC-208

ASCBOF - Wiring diagram ...............................EC-331

ASCD ...............................................................EC-355

ASCD (automatic speed control device) ...........ACS-2

ASCD brake switch ...........................EC-189,EC-330

ASCD clutch switch ..........................EC-189,EC-330

ASCD indicator lamp .......................................EC-351

ASCD steering switch ......................................EC-206

ASCIND - Wiring diagram ................................EC-352

ATP switch ..............................................TF-82,TF-85

Auto air conditioner - Wiring diagramATC-39,MTC-39

Auto anti-dazzling inside mirror .......................GW-45

Autolamp ............................................................LT-49

Automatic amplifier ..........................ATC-60,MTC-55

Automatic transmission number ..............GI-58,GI-59

B

Back door trim .....................................................EI-30

BACK/L - Wiring diagram .................................LT-123

Back-up lamp ...................................................LT-123

Back-up lamp switch (M/T) ...................MT-12,MT-19

Ball joint (front) ................................................FSU-15

Barometric pressure (BARO) sensor ...............EC-293

Basic inspection .................................................EC-38

Battery .................................................................SC-5

Baulk ring (M/T) ................................................MT-21

BCM (Body control module) ..............................BCS-3

Blower motor ...ATC-80,ATC-121,MTC-71,MTC-100

Body mounting ....................................BL-189,BL-190

BOOST - Wiring diagram .................................EC-155

Brake booster ....................................................BR-19

Brake fluid level ................................................MA-35

Brake inspection ...............................................MA-35

Brake lines and cables inspection ....................MA-35

Brake master cylinder ........................................BR-17

Brake pedal ..........................................................BR-6

Brake switch ....................................................EC-330

Bulb specifications ...........................................LT-173

Bumper, front ......................................................EI-15

Bumper, rear .......................................................EI-17