air bleeding NISSAN NAVARA 2005 Repair Owner's Guide

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2005, Model line: NAVARA, Model: NISSAN NAVARA 2005Pages: 3171, PDF Size: 49.59 MB

Page 2633 of 3171

PS-6

POWER STEERING FLUID

POWER STEERING FLUID

PFP:KLF20

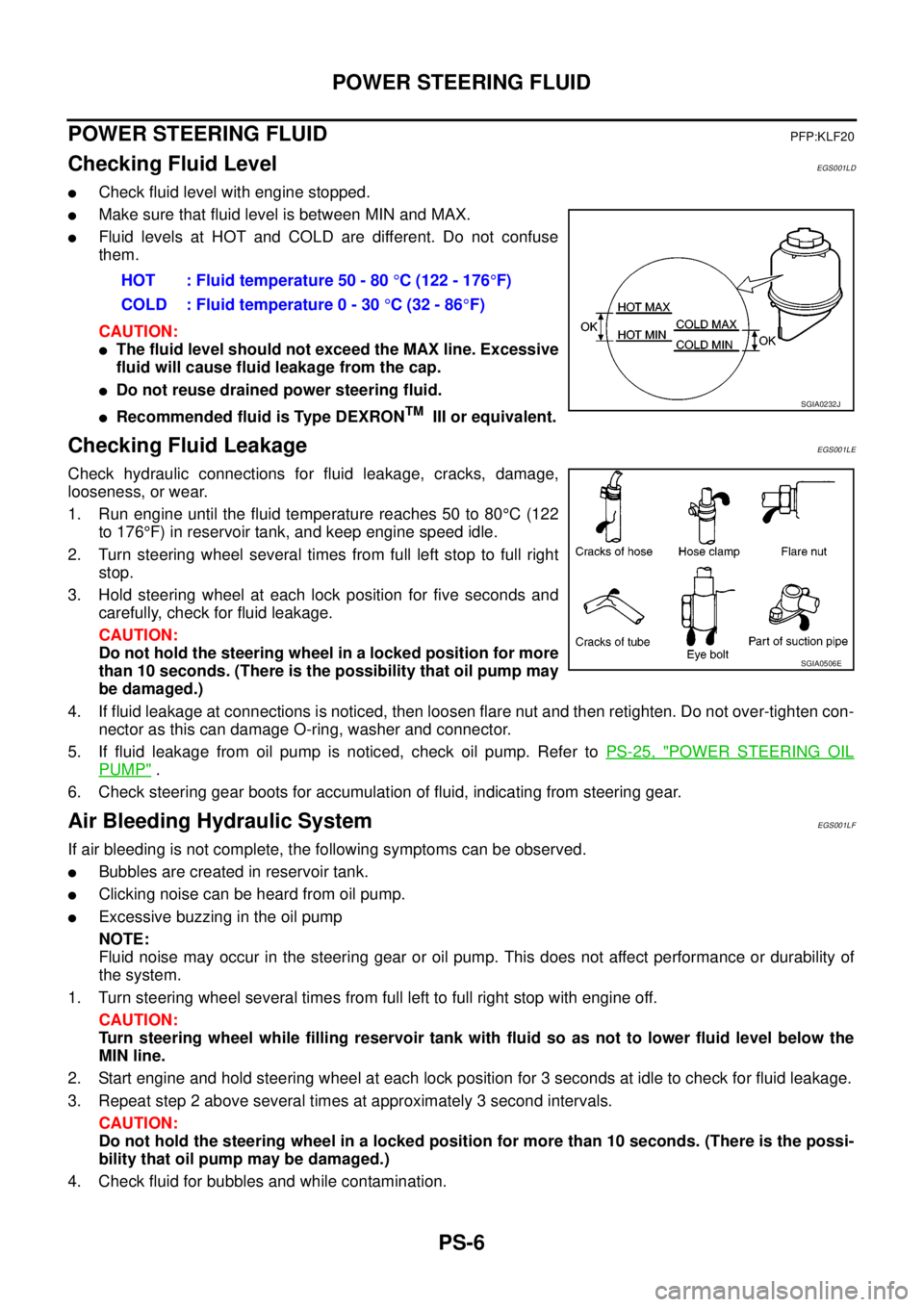

Checking Fluid LevelEGS001LD

lCheck fluid level with engine stopped.

lMake sure that fluid level is between MIN and MAX.

lFluid levels at HOT and COLD are different. Do not confuse

them.

CAUTION:

lThe fluid level should not exceed the MAX line. Excessive

fluid will cause fluid leakage from the cap.

lDo not reuse drained power steering fluid.

lRecommended fluid is Type DEXRONTMIII or equivalent.

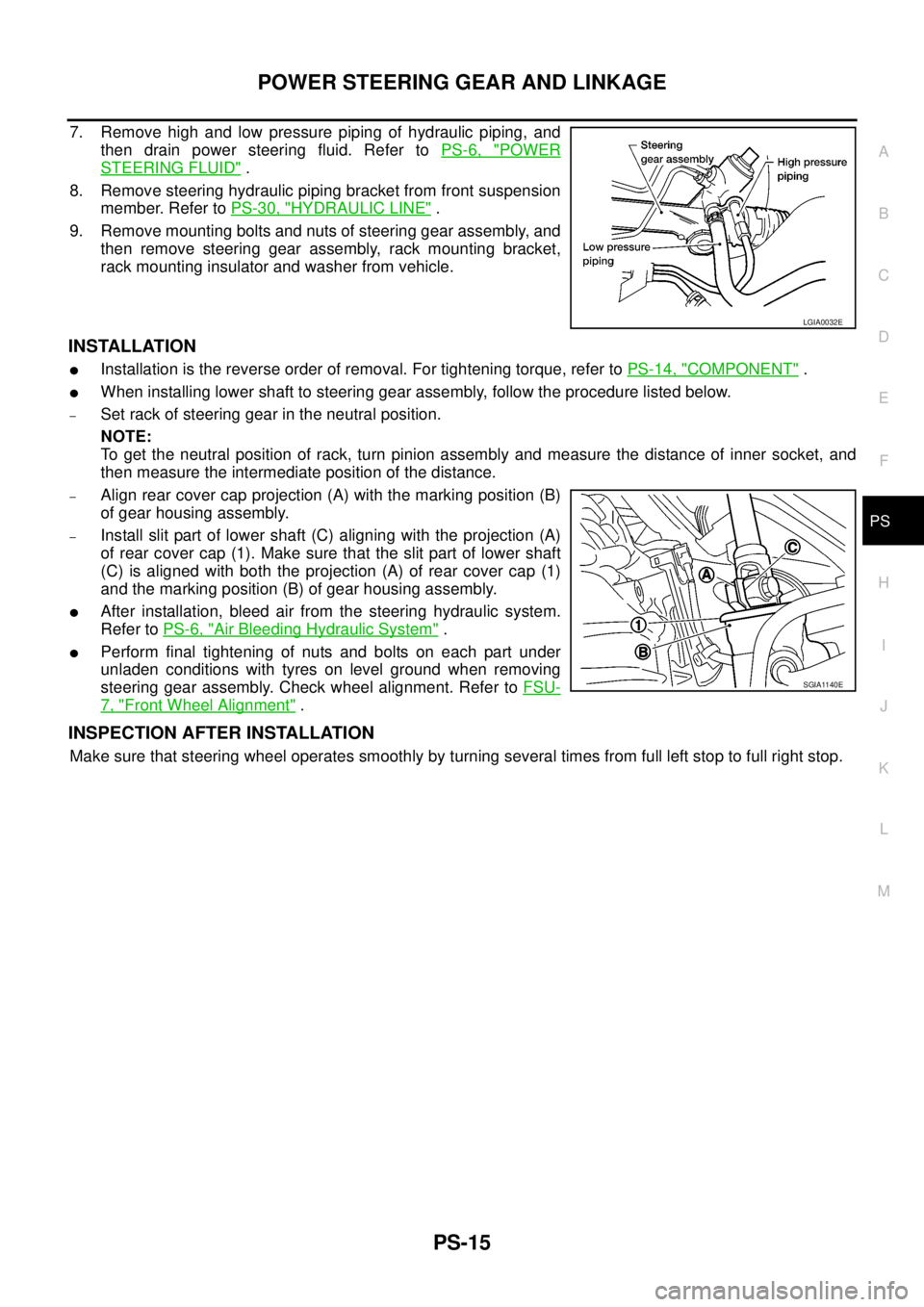

Checking Fluid LeakageEGS001LE

Check hydraulic connections for fluid leakage, cracks, damage,

looseness, or wear.

1. Run engine until the fluid temperature reaches 50 to 80°C(122

to 176°F) in reservoir tank, and keep engine speed idle.

2. Turn steering wheel several times from full left stop to full right

stop.

3. Hold steering wheel at each lock position for five seconds and

carefully, check for fluid leakage.

CAUTION:

Do not hold the steering wheel in a locked position for more

than 10 seconds. (There is the possibility that oil pump may

be damaged.)

4. If fluid leakage at connections is noticed, then loosen flare nut and then retighten. Do not over-tighten con-

nector as this can damage O-ring, washer and connector.

5. If fluid leakage from oil pump is noticed, check oil pump. Refer toPS-25, "

POWER STEERING OIL

PUMP".

6. Check steering gear boots for accumulation of fluid, indicating from steering gear.

Air Bleeding Hydraulic SystemEGS001LF

If air bleeding is not complete, the following symptoms can be observed.

lBubbles are created in reservoir tank.

lClicking noise can be heard from oil pump.

lExcessive buzzing in the oil pump

NOTE:

Fluid noise may occur in the steering gear or oil pump. This does not affect performance or durability of

the system.

1. Turn steering wheel several times from full left to full right stop with engine off.

CAUTION:

Turn steering wheel while filling reservoir tank with fluid so as not to lower fluid level below the

MIN line.

2. Start engine and hold steering wheel at each lock position for 3 seconds at idle to check for fluid leakage.

3. Repeat step 2 above several times at approximately 3 second intervals.

CAUTION:

Do not hold the steering wheel in a locked position for more than 10 seconds. (There is the possi-

bility that oil pump may be damaged.)

4. Check fluid for bubbles and while contamination.HOT : Fluid temperature 50 - 80°C (122 - 176°F)

COLD : Fluid temperature 0 - 30°C(32-86°F)

SGIA0232J

SGIA0506E

Page 2642 of 3171

POWER STEERING GEAR AND LINKAGE

PS-15

C

D

E

F

H

I

J

K

L

MA

B

PS

7. Remove high and low pressure piping of hydraulic piping, and

then drain power steering fluid. Refer toPS-6, "

POWER

STEERING FLUID".

8. Remove steering hydraulic piping bracket from front suspension

member. Refer toPS-30, "

HYDRAULIC LINE".

9. Remove mounting bolts and nuts of steering gear assembly, and

then remove steering gear assembly, rack mounting bracket,

rack mounting insulator and washer from vehicle.

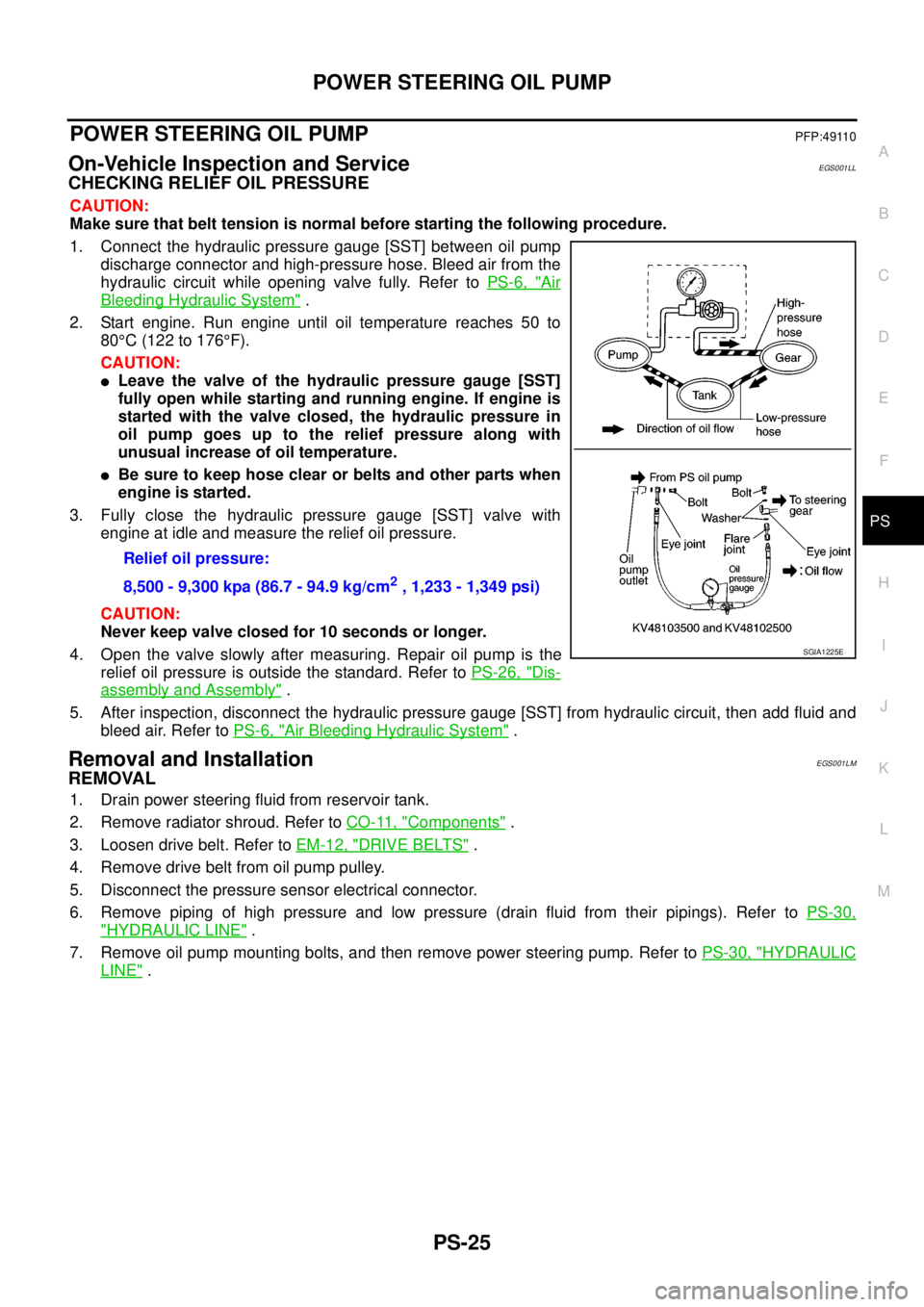

INSTALLATION

lInstallation is the reverse order of removal. For tightening torque, refer toPS-14, "COMPONENT".

lWhen installing lower shaft to steering gear assembly, follow the procedure listed below.

–Set rack of steering gear in the neutral position.

NOTE:

To get the neutral position of rack, turn pinion assembly and measure the distance of inner socket, and

then measure the intermediate position of the distance.

–Align rear cover cap projection (A) with the marking position (B)

of gear housing assembly.

–Install slit part of lower shaft (C) aligning with the projection (A)

of rear cover cap (1). Make sure that the slit part of lower shaft

(C) is aligned with both the projection (A) of rear cover cap (1)

and the marking position (B) of gear housing assembly.

lAfter installation, bleed air from the steering hydraulic system.

Refer toPS-6, "

Air Bleeding Hydraulic System".

lPerform final tightening of nuts and bolts on each part under

unladen conditions with tyres on level ground when removing

steering gear assembly. Check wheel alignment. Refer toFSU-

7, "Front Wheel Alignment".

INSPECTION AFTER INSTALLATION

Make sure that steering wheel operates smoothly by turning several times from full left stop to full right stop.

LGIA0032E

SGIA1140E

Page 2652 of 3171

POWER STEERING OIL PUMP

PS-25

C

D

E

F

H

I

J

K

L

MA

B

PS

POWER STEERING OIL PUMPPFP:49110

On-Vehicle Inspection and ServiceEGS001LL

CHECKING RELIEF OIL PRESSURE

CAUTION:

Make sure that belt tension is normal before starting the following procedure.

1. Connect the hydraulic pressure gauge [SST] between oil pump

discharge connector and high-pressure hose. Bleed air from the

hydraulic circuit while opening valve fully. Refer toPS-6, "

Air

Bleeding Hydraulic System".

2. Start engine. Run engine until oil temperature reaches 50 to

80°C(122to176°F).

CAUTION:

lLeave the valve of the hydraulic pressure gauge [SST]

fully open while starting and running engine. If engine is

started with the valve closed, the hydraulic pressure in

oil pump goes up to the relief pressure along with

unusual increase of oil temperature.

lBe sure to keep hose clear or belts and other parts when

engineisstarted.

3. Fully close the hydraulic pressure gauge [SST] valve with

engine at idle and measure the relief oil pressure.

CAUTION:

Never keep valve closed for 10 seconds or longer.

4. Open the valve slowly after measuring. Repair oil pump is the

relief oil pressure is outside the standard. Refer toPS-26, "

Dis-

assembly and Assembly".

5. After inspection, disconnect the hydraulic pressure gauge [SST] from hydraulic circuit, then add fluid and

bleed air. Refer toPS-6, "

Air Bleeding Hydraulic System".

Removal and InstallationEGS001LM

REMOVAL

1. Drain power steering fluid from reservoir tank.

2. Remove radiator shroud. Refer toCO-11, "

Components".

3. Loosen drive belt. Refer toEM-12, "

DRIVE BELTS".

4. Remove drive belt from oil pump pulley.

5. Disconnect the pressure sensor electrical connector.

6. Remove piping of high pressure and low pressure (drain fluid from their pipings). Refer toPS-30,

"HYDRAULIC LINE".

7. Remove oil pump mounting bolts, and then remove power steering pump. Refer toPS-30, "

HYDRAULIC

LINE". Relief oil pressure:

8,500 - 9,300 kpa (86.7 - 94.9 kg/cm

2, 1,233 - 1,349 psi)

SGIA1225E

Page 2653 of 3171

PS-26

POWER STEERING OIL PUMP

INSTALLATION

Installation is the reverse order of removal. For tightening torque, refer toPS-30, "HYDRAULIC LINE".

lPerform the following procedure after installing.

–Adjust belt tension. Refer toEM-12, "DRIVE BELTS".

–Bleed air. Refer toPS-6, "Air Bleeding Hydraulic System".

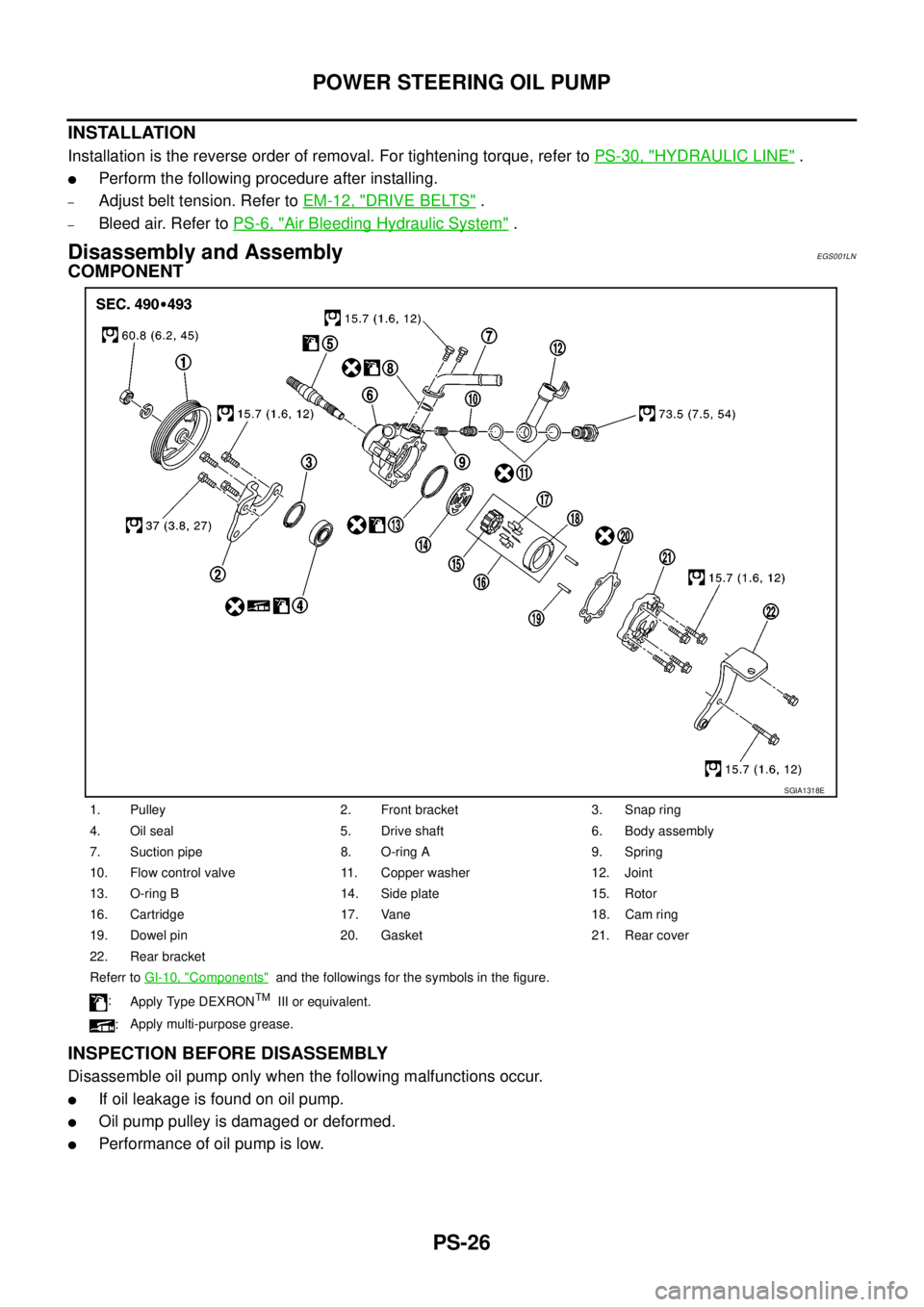

Disassembly and AssemblyEGS001LN

COMPONENT

INSPECTION BEFORE DISASSEMBLY

Disassemble oil pump only when the following malfunctions occur.

lIf oil leakage is found on oil pump.

lOil pump pulley is damaged or deformed.

lPerformance of oil pump is low.

1. Pulley 2. Front bracket 3. Snap ring

4. Oil seal 5. Drive shaft 6. Body assembly

7. Suction pipe 8. O-ring A 9. Spring

10. Flow control valve 11. Copper washer 12. Joint

13. O-ring B 14. Side plate 15. Rotor

16. Cartridge 17. Vane 18. Cam ring

19. Dowel pin 20. Gasket 21. Rear cover

22. Rear bracket

Referr toGI-10, "

Components"and the followings for the symbols in the figure.

:

Apply Type DEXRON

TMIII or equivalent.

:Apply multi-purpose grease.

SGIA1318E

Page 2717 of 3171

![NISSAN NAVARA 2005 Repair Owners Guide RFD-14

[WITH LIMITED SLIP DIFFERENTIAL]

REAR FINAL DRIVE ASSEMBLY

REAR FINAL DRIVE ASSEMBLY

PFP:38300

Removal and InstallationEDS00398

REMOVAL

1. Remove the rear propeller shaft. Refer toPR-8, "Remova NISSAN NAVARA 2005 Repair Owners Guide RFD-14

[WITH LIMITED SLIP DIFFERENTIAL]

REAR FINAL DRIVE ASSEMBLY

REAR FINAL DRIVE ASSEMBLY

PFP:38300

Removal and InstallationEDS00398

REMOVAL

1. Remove the rear propeller shaft. Refer toPR-8, "Remova](/img/5/57362/w960_57362-2716.png)

RFD-14

[WITH LIMITED SLIP DIFFERENTIAL]

REAR FINAL DRIVE ASSEMBLY

REAR FINAL DRIVE ASSEMBLY

PFP:38300

Removal and InstallationEDS00398

REMOVAL

1. Remove the rear propeller shaft. Refer toPR-8, "Removal and Installation".

lPlug rear end of transmission or transfer.

2. Remove the axle shafts and back plate and torque members. Refer toRAX-7, "

Removal and Installation".

3. Disconnect the following components from the rear final drive.

lABS sensor wire harness

lRear cable (LH) and rear cable (RH)

lBrake hoses and brake tube

CAUTION:

Position the wire harness, cable and hoses away from the final drive assembly. Failure to do so

may result in components being damaged during rear axle assembly removal.

4. Support the rear final drive using a suitable jack.

5. Remove rear shock absorber lower bolts. Refer toRSU-6, "

Removal and Installation".

6. Remove leaf spring U-bolt nuts. Refer toRSU-7, "

Removal and Installation".

WARNING:

Support the rear final drive assembly using suitable jack before removing leaf spring U-bolt nuts.

7. Remove rear final drive assembly using suitable jack.

INSTALLATION

Installation is the reverse order of removal.

lWhen oil leaks while removing rear final drive assembly, check oil level after the installation. Refer to

RFD-9, "

Checking Differential Gear Oil".

lRefill brake fluid and bleed the air from the brake system. Refer toBR-11, "Bleeding Brake System".

Page 2784 of 3171

![NISSAN NAVARA 2005 Repair Owners Guide REAR FINAL DRIVE ASSEMBLY

RFD-81

[WITH ELECTRONIC LOCKING DIFFERENTIAL]

C

E

F

G

H

I

J

K

L

MA

B

RFD

REAR FINAL DRIVE ASSEMBLYPFP:38300

Removal and InstallationEDS003BF

REMOVAL

1. Remove the rear propel NISSAN NAVARA 2005 Repair Owners Guide REAR FINAL DRIVE ASSEMBLY

RFD-81

[WITH ELECTRONIC LOCKING DIFFERENTIAL]

C

E

F

G

H

I

J

K

L

MA

B

RFD

REAR FINAL DRIVE ASSEMBLYPFP:38300

Removal and InstallationEDS003BF

REMOVAL

1. Remove the rear propel](/img/5/57362/w960_57362-2783.png)

REAR FINAL DRIVE ASSEMBLY

RFD-81

[WITH ELECTRONIC LOCKING DIFFERENTIAL]

C

E

F

G

H

I

J

K

L

MA

B

RFD

REAR FINAL DRIVE ASSEMBLYPFP:38300

Removal and InstallationEDS003BF

REMOVAL

1. Remove the rear propeller shaft. Refer toPR-8, "Removal and Installation".

lPlug rear end of transmission or transfer.

2. Remove the axle shafts and back plate and torque members. Refer toRAX-7, "

Removal and Installation".

3. Disconnect the following components from the rear final drive.

lABS sensor wire harness

lRear cable (LH) and rear cable (RH)

lBrake hoses and brake tube

lDifferential lock position switch harness connector

lDifferential lock solenoid harness connector

CAUTION:

Position the wire harness, cable and hoses away from the final drive assembly. Failure to do so

may result in components being damaged during rear axle assembly removal.

4. Support the rear final drive using a suitable jack.

5. Remove rear shock absorber lower bolts. Refer toRSU-6, "

Removal and Installation".

6. Remove leaf spring U-bolt nuts. Refer toRSU-7, "

Removal and Installation".

WARNING:

Support the rear final drive assembly using suitable jack before removing leaf spring U-bolt nuts.

7. Remove rear final drive assembly using suitable jack.

INSTALLATION

Installation is the reverse order of removal.

lWhen oil leaks while removing rear final drive assembly, check oil level after the installation. Refer to

RFD-40, "

Checking Differential Gear Oil".

lRefill brake fluid and bleed the air from the brake system. Refer toBR-11, "Bleeding Brake System".

lAfter the installation, check DIFF LOCK indicator lamp. Refer toRFD-33, "Precautions for Differential

Case Assembly and Differential Lock Control Unit Replacement".