alternator NISSAN NAVARA 2005 Repair Owner's Guide

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2005, Model line: NAVARA, Model: NISSAN NAVARA 2005Pages: 3171, PDF Size: 49.59 MB

Page 2853 of 3171

SC-20

CHARGING SYSTEM

INSPECTION OF INSUFFICIENT ALTERNATOR POWER GENERATION

CAUTION:

Check them using charged battery performed battery inspection.

1.VOLTAGE INSPECTION

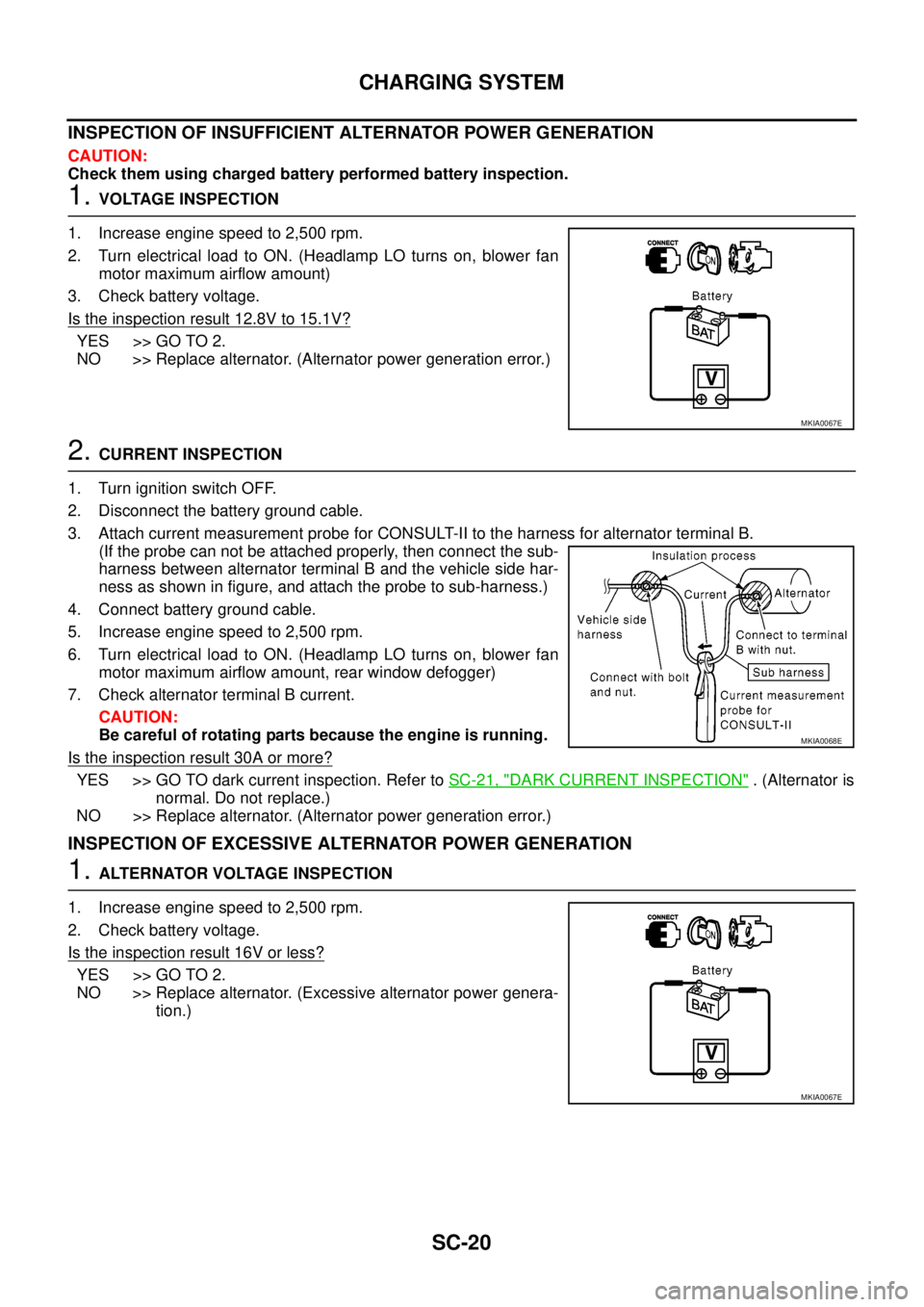

1. Increase engine speed to 2,500 rpm.

2. Turn electrical load to ON. (Headlamp LO turns on, blower fan

motor maximum airflow amount)

3. Check battery voltage.

Is the inspection result 12.8V to 15.1V?

YES >> GO TO 2.

NO >> Replace alternator. (Alternator power generation error.)

2.CURRENT INSPECTION

1. Turn ignition switch OFF.

2. Disconnect the battery ground cable.

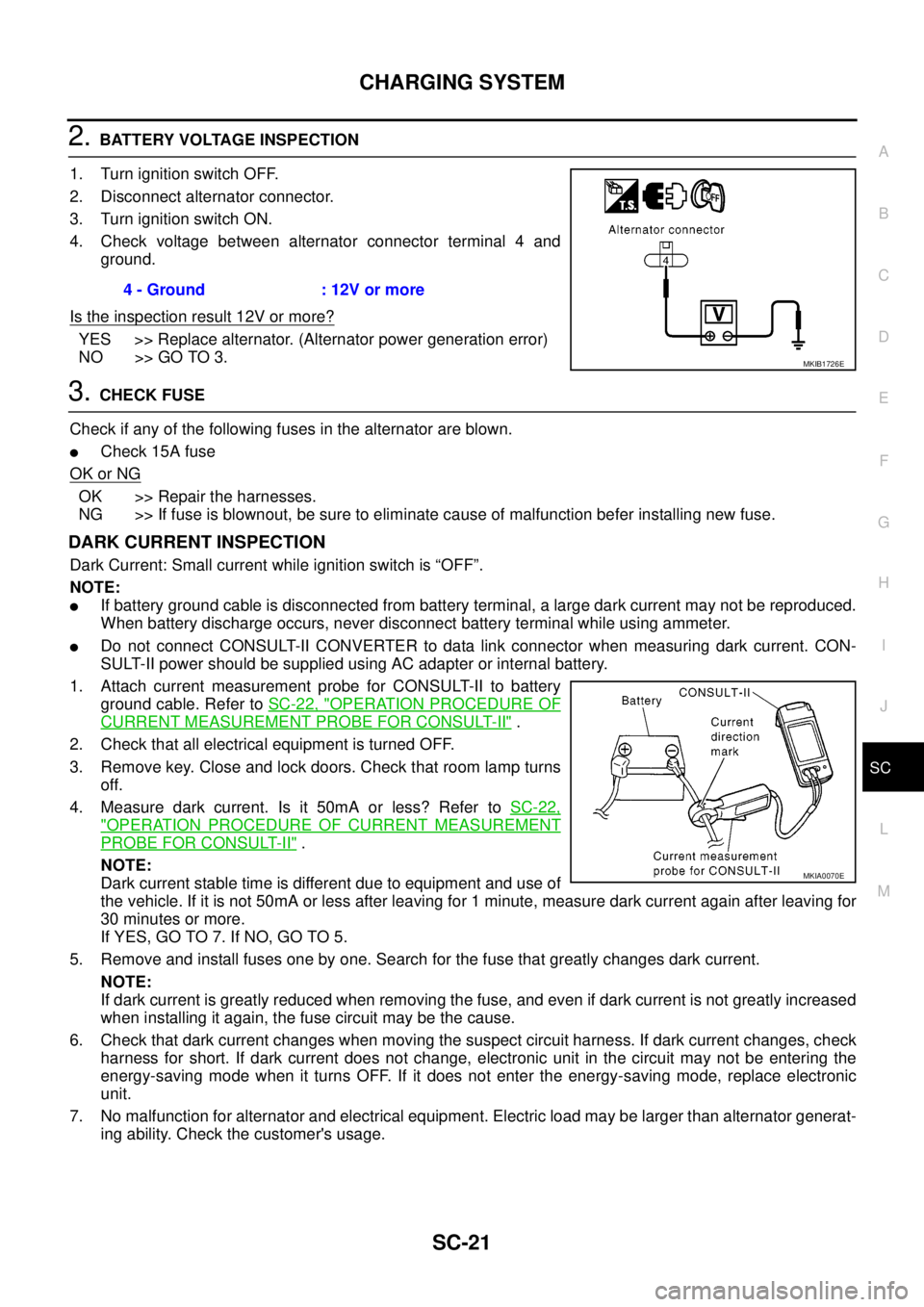

3. Attach current measurement probe for CONSULT-II to the harness for alternator terminal B.

(If the probe can not be attached properly, then connect the sub-

harness between alternator terminal B and the vehicle side har-

ness as shown in figure, and attach the probe to sub-harness.)

4. Connect battery ground cable.

5. Increase engine speed to 2,500 rpm.

6. Turn electrical load to ON. (Headlamp LO turns on, blower fan

motor maximum airflow amount, rear window defogger)

7. Check alternator terminal B current.

CAUTION:

Be careful of rotating parts because the engine is running.

Is the inspection result 30A or more?

YES >> GO TO dark current inspection. Refer toSC-21, "DARK CURRENT INSPECTION". (Alternator is

normal. Do not replace.)

NO >> Replace alternator. (Alternator power generation error.)

INSPECTION OF EXCESSIVE ALTERNATOR POWER GENERATION

1.ALTERNATOR VOLTAGE INSPECTION

1. Increase engine speed to 2,500 rpm.

2. Check battery voltage.

Is the inspection result 16V or less?

YES >> GO TO 2.

NO >> Replace alternator. (Excessive alternator power genera-

tion.)

MKIA0067E

MKIA0068E

MKIA0067E

Page 2854 of 3171

CHARGING SYSTEM

SC-21

C

D

E

F

G

H

I

J

L

MA

B

SC

2.BATTERY VOLTAGE INSPECTION

1. Turn ignition switch OFF.

2. Disconnect alternator connector.

3. Turn ignition switch ON.

4. Check voltage between alternator connector terminal 4 and

ground.

Is the inspection result 12V or more?

YES >> Replace alternator. (Alternator power generation error)

NO >> GO TO 3.

3.CHECK FUSE

Check if any of the following fuses in the alternator are blown.

lCheck 15A fuse

OK or NG

OK >> Repair the harnesses.

NG >> If fuse is blownout, be sure to eliminate cause of malfunction befer installing new fuse.

DARK CURRENT INSPECTION

Dark Current: Small current while ignition switch is “OFF”.

NOTE:

lIf battery ground cable is disconnected from battery terminal, a large dark current may not be reproduced.

When battery discharge occurs, never disconnect battery terminal while using ammeter.

lDo not connect CONSULT-II CONVERTER to data link connector when measuring dark current. CON-

SULT-II power should be supplied using AC adapter or internal battery.

1. Attach current measurement probe for CONSULT-II to battery

ground cable. Refer toSC-22, "

OPERATION PROCEDURE OF

CURRENT MEASUREMENT PROBE FOR CONSULT-II".

2. Check that all electrical equipment is turned OFF.

3. Remove key. Close and lock doors. Check that room lamp turns

off.

4. Measure dark current. Is it 50mA or less? Refer toSC-22,

"OPERATION PROCEDURE OF CURRENT MEASUREMENT

PROBE FOR CONSULT-II".

NOTE:

Dark current stable time is different due to equipment and use of

the vehicle. If it is not 50mA or less after leaving for 1 minute, measure dark current again after leaving for

30 minutes or more.

If YES, GO TO 7. If NO, GO TO 5.

5. Remove and install fuses one by one. Search for the fuse that greatly changes dark current.

NOTE:

If dark current is greatly reduced when removing the fuse, and even if dark current is not greatly increased

when installing it again, the fuse circuit may be the cause.

6. Check that dark current changes when moving the suspect circuit harness. If dark current changes, check

harness for short. If dark current does not change, electronic unit in the circuit may not be entering the

energy-saving mode when it turns OFF. If it does not enter the energy-saving mode, replace electronic

unit.

7. No malfunction for alternator and electrical equipment. Electric load may be larger than alternator generat-

ing ability. Check the customer's usage.4 - Ground : 12V or more

MKIB1726E

MKIA0070E

Page 2856 of 3171

CHARGING SYSTEM

SC-23

C

D

E

F

G

H

I

J

L

MA

B

SC

Removal and InstallationEKS00MZE

REMOVAL

1. Disconnect negative battery cable.

2. Remove intercooler hose and duct

3. Disconnect alternator harness.

4. Remove drive belt. Refer toEM-12, "

Checking Drive Belts".

5. Remove alternator upper mounting bolt.

6. Remove alternator lower mounting nut and bolt .

7. Remove alternator.

INSTALLATION

Install in the reverse order of removal, taking care of the following point.

lInstall alternator, and check tension of drive belt. Refer toEM-13, "Deflection Adjustment".

CAUTION:

Be sure to tighten alternator terminal 1 mounting nut carefully.

Disassembly and AssemblyEKS00PD1

LHD MODELS

MKIB1992E

YD engine models - B terminal nut:

: 7.9 - 11.0 N·m (0.8 - 1.11 kg-m, 70 - 97 in-lb)

1. Rear bearing 2. Rotor 3. Retainer

4. Front bearing 5. Through bolt 6. Front cover

7. Washer 8. Pulley 9. Stator

10. IC voltage regulator assembly 11. Diode assembly 12. Rear cover

13. B terminal

MKIB2000E

Page 2858 of 3171

CHARGING SYSTEM

SC-25

C

D

E

F

G

H

I

J

L

MA

B

SC

InspectionEKS00MZH

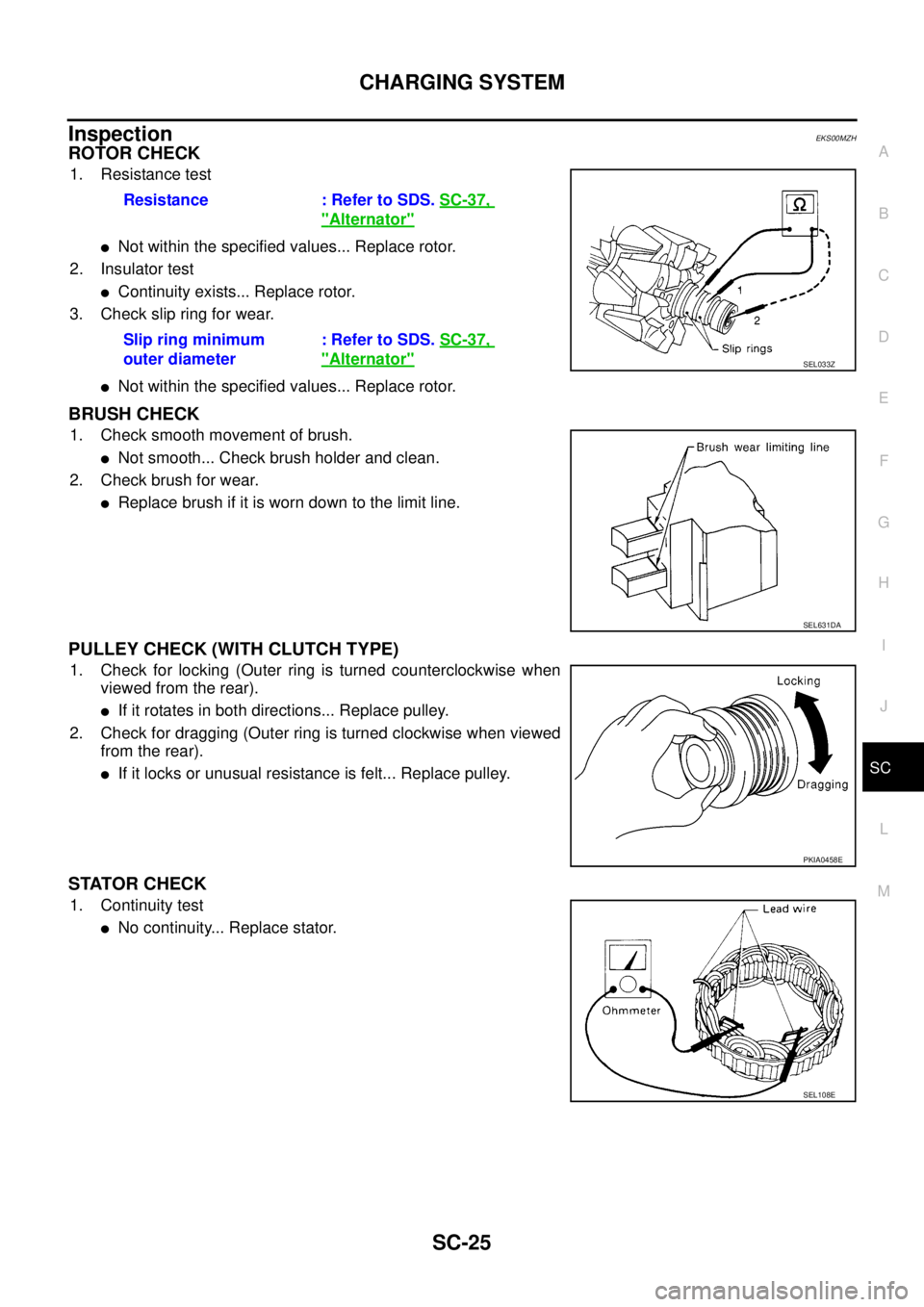

ROTOR CHECK

1. Resistance test

lNot within the specified values... Replace rotor.

2. Insulator test

lContinuity exists... Replace rotor.

3. Check slip ring for wear.

lNot within the specified values... Replace rotor.

BRUSH CHECK

1. Check smooth movement of brush.

lNot smooth... Check brush holder and clean.

2. Check brush for wear.

lReplace brush if it is worn down to the limit line.

PULLEY CHECK (WITH CLUTCH TYPE)

1. Check for locking (Outer ring is turned counterclockwise when

viewed from the rear).

lIf it rotates in both directions... Replace pulley.

2. Check for dragging (Outer ring is turned clockwise when viewed

from the rear).

lIf it locks or unusual resistance is felt... Replace pulley.

STATOR CHECK

1. Continuity test

lNo continuity... Replace stator.Resistance : Refer to SDS.SC-37,

"Alternator"

Slip ring minimum

outer diameter: Refer to SDS.SC-37,

"Alternator"SEL033Z

SEL631DA

PKIA0458E

SEL108E

Page 2870 of 3171

SERVICE DATA AND SPECIFICATIONS (SDS)

SC-37

C

D

E

F

G

H

I

J

L

MA

B

SC

SERVICE DATA AND SPECIFICATIONS (SDS)PFP:00030

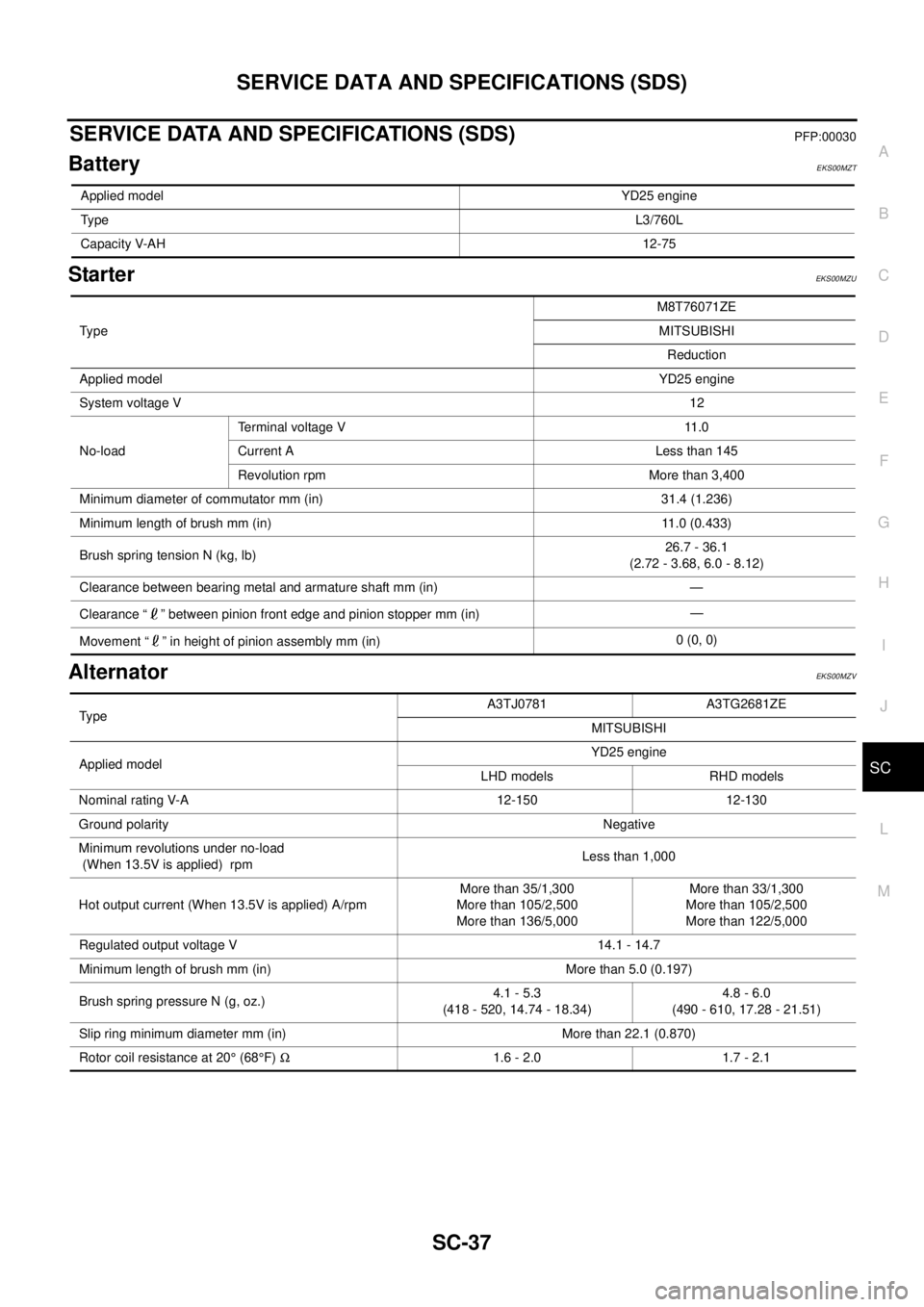

BatteryEKS00MZT

StarterEKS00MZU

AlternatorEKS00MZV

Applied modelYD25 engine

TypeL3/760L

Capacity V-AH12-75

Ty p eM8T76071ZE

MITSUBISHI

Reduction

Applied modelYD25 engine

System voltage V12

No-loadTerminal voltage V 11.0

Current A Less than 145

Revolution rpm More than 3,400

Minimum diameter of commutator mm (in) 31.4 (1.236)

Minimum length of brush mm (in) 11.0 (0.433)

Brush spring tension N (kg, lb)26.7 - 36.1

(2.72 - 3.68, 6.0 - 8.12)

Clearance between bearing metal and armature shaft mm (in) —

Clearance “ ” between pinion front edge and pinion stopper mm (in)—

Movement “ ” in height of pinion assembly mm (in)0 (0, 0)

TypeA3TJ0781 A3TG2681ZE

MITSUBISHI

Applied modelYD25 engine

LHD models RHD models

Nominal rating V-A 12-150 12-130

Ground polarityNegative

Minimum revolutions under no-load

(When 13.5V is applied) rpmLess than 1,000

Hot output current (When 13.5V is applied) A/rpmMore than 35/1,300

More than 105/2,500

More than 136/5,000More than 33/1,300

More than 105/2,500

More than 122/5,000

Regulated output voltage V 14.1 - 14.7

Minimum length of brush mm (in) More than 5.0 (0.197)

Brush spring pressure N (g, oz.)4.1 - 5.3

(418 - 520, 14.74 - 18.34)4.8 - 6.0

(490 - 610, 17.28 - 21.51)

Slip ring minimum diameter mm (in) More than 22.1 (0.870)

Rotor coil resistance at 20°(68°F)W1.6 - 2.0 1.7 - 2.1