boot NISSAN NAVARA 2005 Repair Owner's Guide

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2005, Model line: NAVARA, Model: NISSAN NAVARA 2005Pages: 3171, PDF Size: 49.59 MB

Page 2644 of 3171

POWER STEERING GEAR AND LINKAGE

PS-17

C

D

E

F

H

I

J

K

L

MA

B

PS

DISASSEMBLY

1. Remove cylinder tubes from gear housing assembly.

2. Remove rear cover cap from gear-sub assembly.

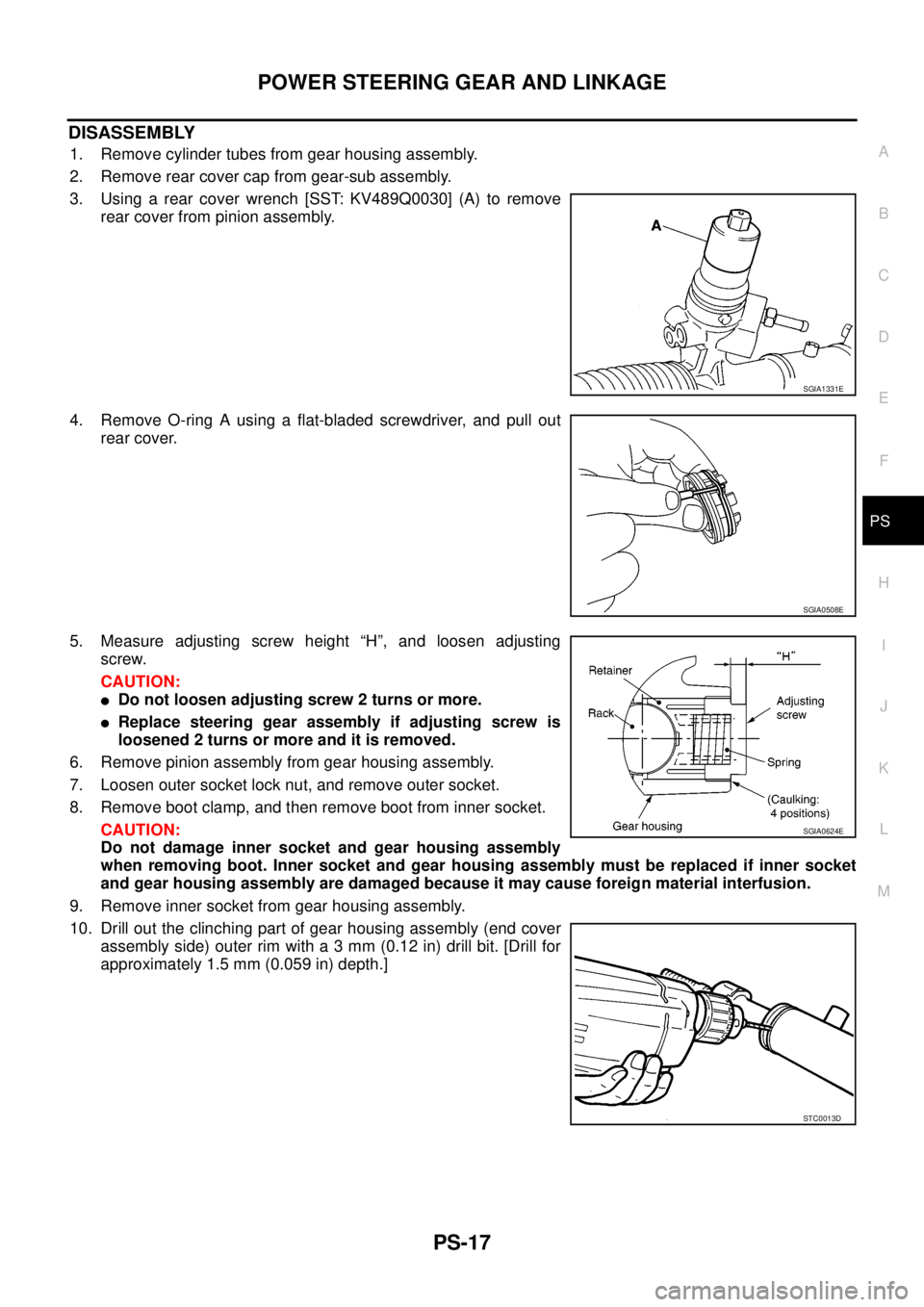

3. Using a rear cover wrench [SST: KV489Q0030] (A) to remove

rear cover from pinion assembly.

4. Remove O-ring A using a flat-bladed screwdriver, and pull out

rear cover.

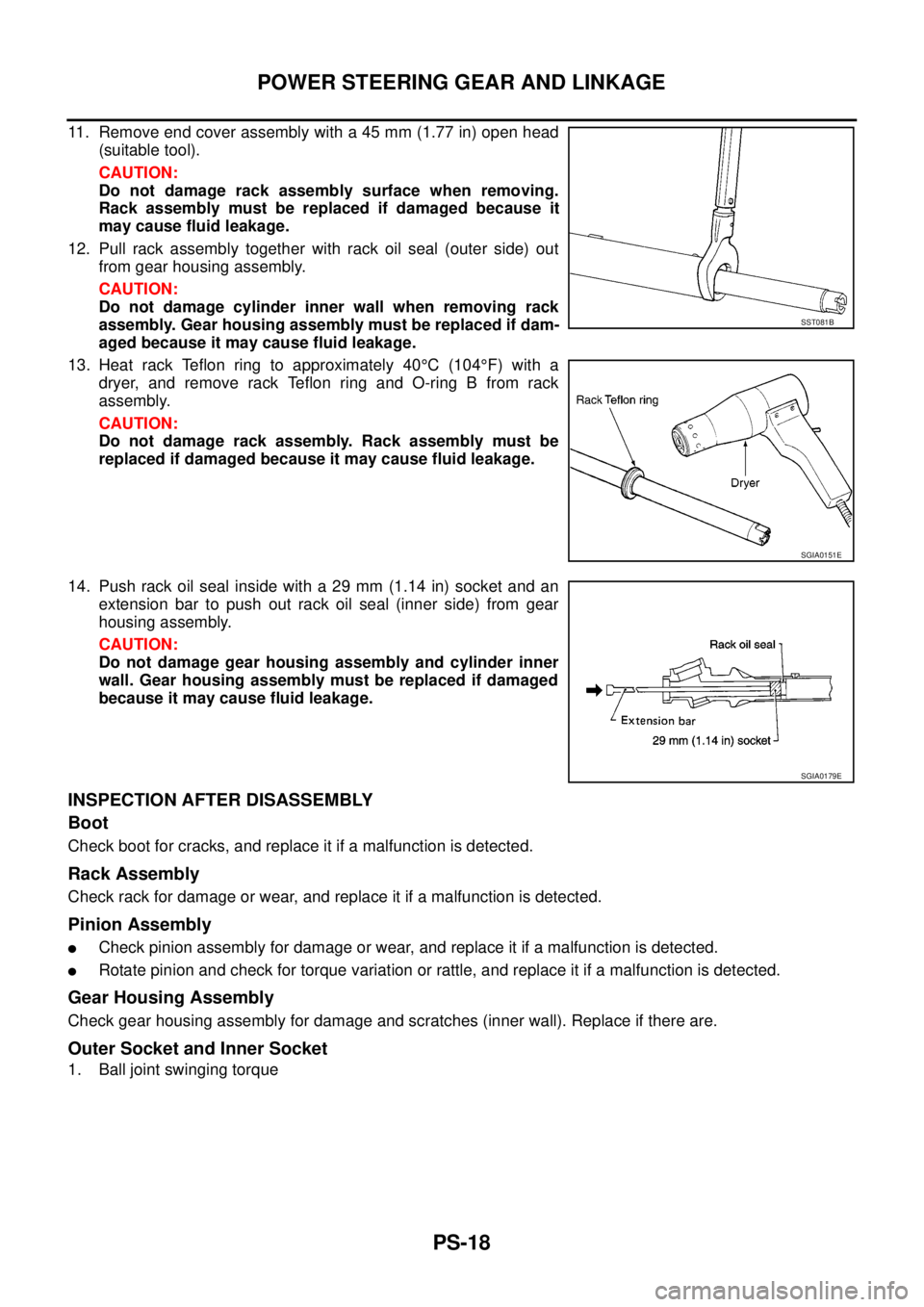

5. Measure adjusting screw height “H”, and loosen adjusting

screw.

CAUTION:

lDo not loosen adjusting screw 2 turns or more.

lReplace steering gear assembly if adjusting screw is

loosened 2 turns or more and it is removed.

6. Remove pinion assembly from gear housing assembly.

7. Loosen outer socket lock nut, and remove outer socket.

8. Remove boot clamp, and then remove boot from inner socket.

CAUTION:

Do not damage inner socket and gear housing assembly

when removing boot. Inner socket and gear housing assembly must be replaced if inner socket

and gear housing assembly are damaged because it may cause foreign material interfusion.

9. Remove inner socket from gear housing assembly.

10. Drill out the clinching part of gear housing assembly (end cover

assemblyside)outerrimwitha3mm(0.12in)drillbit.[Drillfor

approximately 1.5 mm (0.059 in) depth.]

SGIA1331E

SGIA0508E

SGIA0624E

STC0013D

Page 2645 of 3171

PS-18

POWER STEERING GEAR AND LINKAGE

11. Remove end cover assembly with a 45 mm (1.77 in) open head

(suitable tool).

CAUTION:

Do not damage rack assembly surface when removing.

Rack assembly must be replaced if damaged because it

may cause fluid leakage.

12. Pull rack assembly together with rack oil seal (outer side) out

from gear housing assembly.

CAUTION:

Do not damage cylinder inner wall when removing rack

assembly. Gear housing assembly must be replaced if dam-

aged because it may cause fluid leakage.

13. Heat rack Teflon ring to approximately 40°C(104°F) with a

dryer, and remove rack Teflon ring and O-ring B from rack

assembly.

CAUTION:

Do not damage rack assembly. Rack assembly must be

replaced if damaged because it may cause fluid leakage.

14. Push rack oil seal inside with a 29 mm (1.14 in) socket and an

extension bar to push out rack oil seal (inner side) from gear

housing assembly.

CAUTION:

Do not damage gear housing assembly and cylinder inner

wall. Gear housing assembly must be replaced if damaged

because it may cause fluid leakage.

INSPECTION AFTER DISASSEMBLY

Boot

Check boot for cracks, and replace it if a malfunction is detected.

Rack Assembly

Check rack for damage or wear, and replace it if a malfunction is detected.

Pinion Assembly

lCheck pinion assembly for damage or wear, and replace it if a malfunction is detected.

lRotate pinion and check for torque variation or rattle, and replace it if a malfunction is detected.

Gear Housing Assembly

Check gear housing assembly for damage and scratches (inner wall). Replace if there are.

Outer Socket and Inner Socket

1. Ball joint swinging torque

SST081B

SGIA0151E

SGIA0179E

Page 2650 of 3171

POWER STEERING GEAR AND LINKAGE

PS-23

C

D

E

F

H

I

J

K

L

MA

B

PS

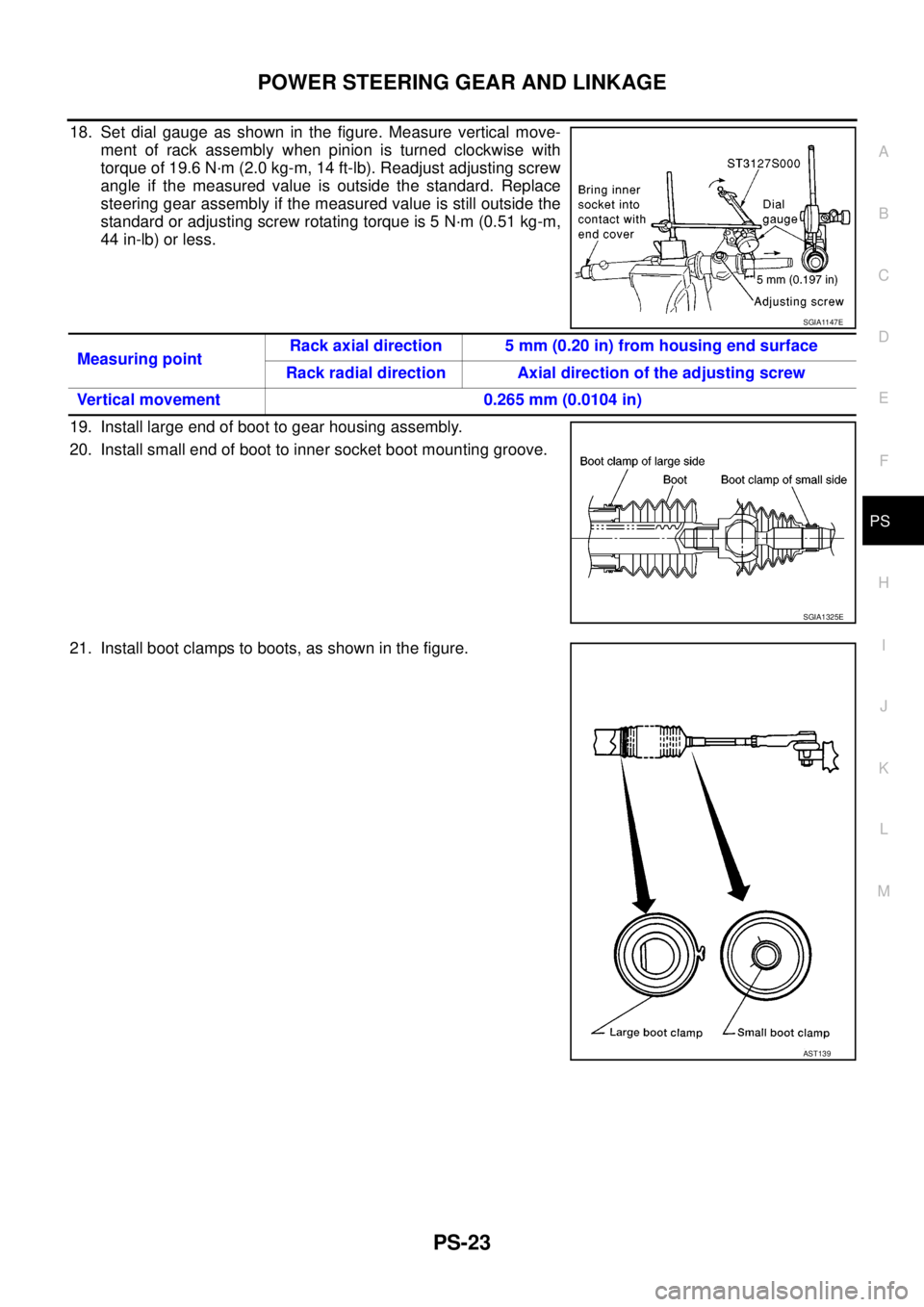

18. Set dial gauge as shown in the figure. Measure vertical move-

ment of rack assembly when pinion is turned clockwise with

torque of 19.6 N·m (2.0 kg-m, 14 ft-lb). Readjust adjusting screw

angle if the measured value is outside the standard. Replace

steering gear assembly if the measured value is still outside the

standard or adjusting screw rotating torque is 5 N·m (0.51 kg-m,

44 in-lb) or less.

19. Install large end of boot to gear housing assembly.

20. Install small end of boot to inner socket boot mounting groove.

21. Install boot clamps to boots, as shown in the figure.

SGIA1147E

Measuring pointRack axial direction 5 mm (0.20 in) from housing end surface

Rack radial direction Axial direction of the adjusting screw

Vertical movement 0.265 mm (0.0104 in)

SGIA1325E

AST139

Page 2651 of 3171

PS-24

POWER STEERING GEAR AND LINKAGE

22. Crimp the large-diameter boot clamp using suitable tool.

23. Install cylinder tubes to gear housing assembly.

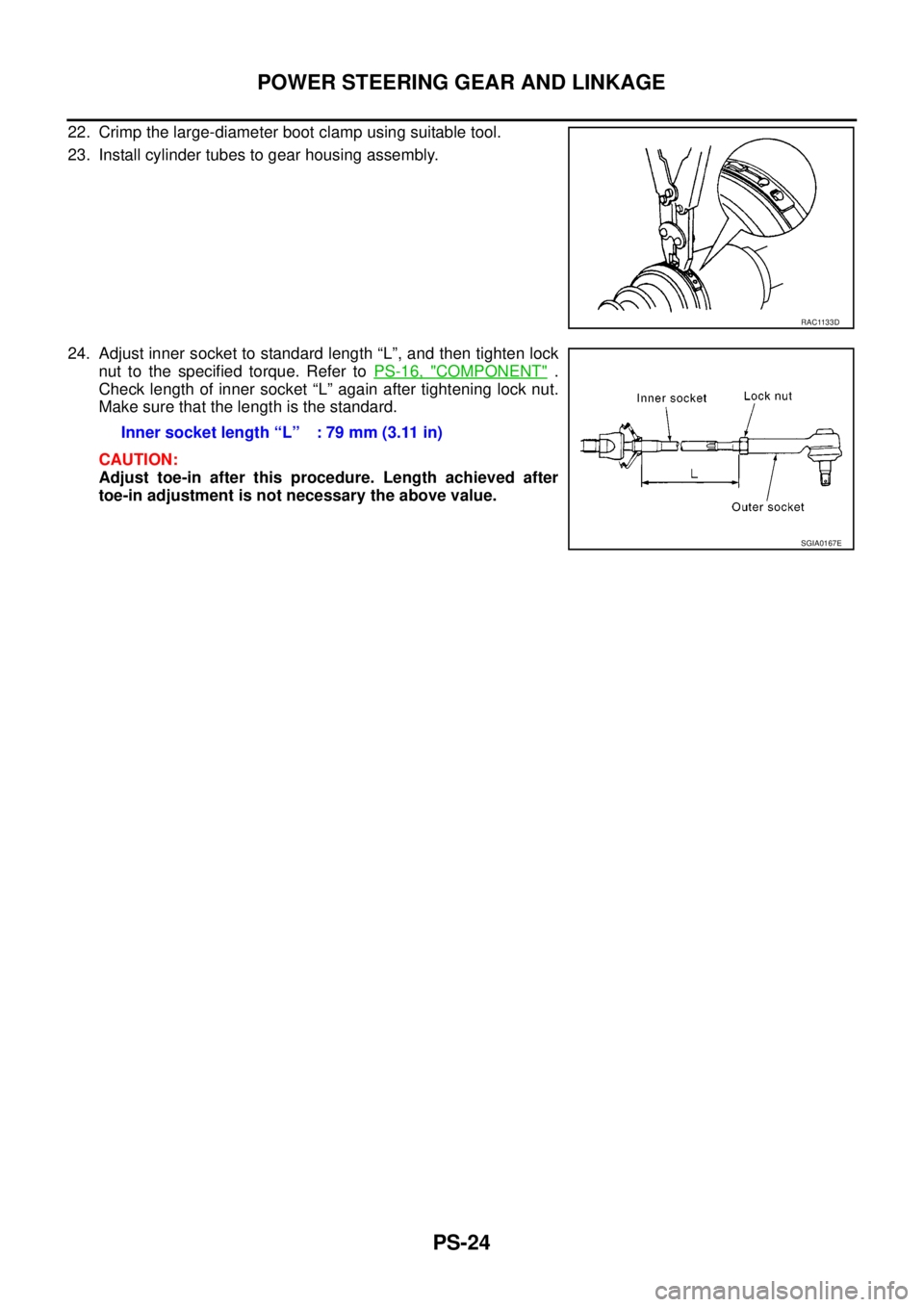

24. Adjust inner socket to standard length “L”, and then tighten lock

nut to the specified torque. Refer toPS-16, "

COMPONENT".

Check length of inner socket “L” again after tightening lock nut.

Make sure that the length is the standard.

CAUTION:

Adjust toe-in after this procedure. Length achieved after

toe-in adjustment is not necessary the above value.

RAC1133D

Inner socket length “L” : 79 mm (3.11 in)

SGIA0167E