Em-49 NISSAN NAVARA 2005 Repair Workshop Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2005, Model line: NAVARA, Model: NISSAN NAVARA 2005Pages: 3171, PDF Size: 49.59 MB

Page 1065 of 3171

DTC P0088 FUEL SYSTEM

EC-85

C

D

E

F

G

H

I

J

K

L

MA

EC

3.CHECK FUEL PUMP

Refer toEC-221, "

Component Inspection".

OK or NG

OK >> GO TO 5.

NG >> GO TO 4.

4.REPLACE FUEL PUMP

1. Replace fuel pump.

2. Perform Fuel Pump Learning Value Clearing. Refer toEC-24, "

Fuel Pump Learning Value Clearing".

>>INSPECTION END

5.CHECK INTERMITTENT INCIDENT

Refer toEC-70, "

TROUBLE DIAGNOSIS FOR INTERMITTENT INCIDENT".

>>INSPECTION END

Removal and InstallationEBS01KDL

FUEL INJECTOR

Refer toEM-44, "INJECTION TUBE AND FUEL INJECTOR".

FUEL PUMP

Refer toEM-49, "FUEL PUMP".

Page 1067 of 3171

DTC P0089 FUEL PUMP

EC-87

C

D

E

F

G

H

I

J

K

L

MA

EC

Diagnostic ProcedureEBS01KDO

1.PERFORM FUEL PUMP LEARNING VALUE CLEARING

NOTE:

If the DTC is detected because of air mixed with fuel (i.e.: caused by lack of fuel), it may become normal by

performing following procedure.

With CONSULT-II

1. Turn ignition switch ON.

2. Perform Fuel Pump Learning Value Clearing. Refer toEC-24, "

Fuel Pump Learning Value Clearing".

3. Start engine and let it idle for at least 60 seconds.

4. Select “SELF-DIAG RESULT” mode with CONSULT-II.

5. Touch “ERASE”.

6. PerformEC-86, "

DTC Confirmation Procedure",again.

7. Is DTC detected again?

Without CONSULT-II

1. Turn ignition switch ON.

2. Perform Fuel Pump Learning Value Clearing. Refer toEC-24, "

Fuel Pump Learning Value Clearing".

3. Start engine and let it idle for at least 60 seconds.

4. Erase the Diagnostic Test Mode II (Self-diagnostic results) memory. Refer toEC-27

.

5. PerformEC-86, "

DTC Confirmation Procedure",again.

6. Is DTC detected again?

Ye s o r N o

Ye s > > G O T O 2 .

No >>INSPECTION END

2.CHECK FUEL RAIL PRESSURE SENSOR

Refer toEC-122, "

Component Inspection".

OK or NG

OK >> GO TO 3.

NG >> Replace fuel rail.

3.CHECK FUEL PUMP

Refer toEC-221, "

Component Inspection".

OK or NG

OK >> GO TO 5.

NG >> GO TO 4.

4.REPLACE FUEL PUMP

1. Replace Fuel pump.

2. Perform Fuel Pump Learning Value Clearing. Refer toEC-24, "

Fuel Pump Learning Value Clearing".

>>INSPECTION END

5.CHECK INTERMITTENT INCIDENT

Refer toEC-70, "

TROUBLE DIAGNOSIS FOR INTERMITTENT INCIDENT".

>>INSPECTION END

Removal and InstallationEBS01KDP

FUEL PUMP

Refer toEM-49, "FUEL PUMP".

Page 1071 of 3171

DTC P0093 FUEL SYSTEM

EC-91

C

D

E

F

G

H

I

J

K

L

MA

EC

Removal and InstallationEBS01KDU

FUEL RAIL

Refer toEM-44, "INJECTION TUBE AND FUEL INJECTOR".

FUEL PUMP

Refer toEM-49, "FUEL PUMP".

Page 1097 of 3171

DTC P0182, P0183 FUEL PUMP TEMPERATURE SENSOR

EC-117

C

D

E

F

G

H

I

J

K

L

MA

EC

3.CHECK FUEL PUMP TEMPERATURE SENSOR GROUND CIRCUIT FOR OPEN AND SHORT

1. Turn ignition switch OFF.

2. Disconnect ECM harness connector.

3. Check harness continuity between fuel pump temperature sensor terminal 2 and ECM terminal 69.

Refer to Wiring Diagram.

4. Also check harness for short to ground and short to power.

OK or NG

OK >> GO TO 4.

NG >> Repair open circuit or short to ground or short to power in harness or connectors.

4.CHECK INTERMITTENT INCIDENT

Refer toEC-70, "

TROUBLE DIAGNOSIS FOR INTERMITTENT INCIDENT".

OK or NG

OK >> GO TO 5.

NG >> Repair or replace.

5.REPLACE FUEL PUMP

1. Replace fuel pump.

2. Perform Fuel Pump Learning Value Clearing. Refer toEC-24, "

Fuel Pump Learning Value Clearing".

>>INSPECTION END

Removal and InstallationEBS01KEY

FUEL PUMP

Refer toEM-49, "FUEL PUMP". Continuity should exist.

Page 1201 of 3171

DTC P0628, P0629 FUEL PUMP

EC-221

C

D

E

F

G

H

I

J

K

L

MA

EC

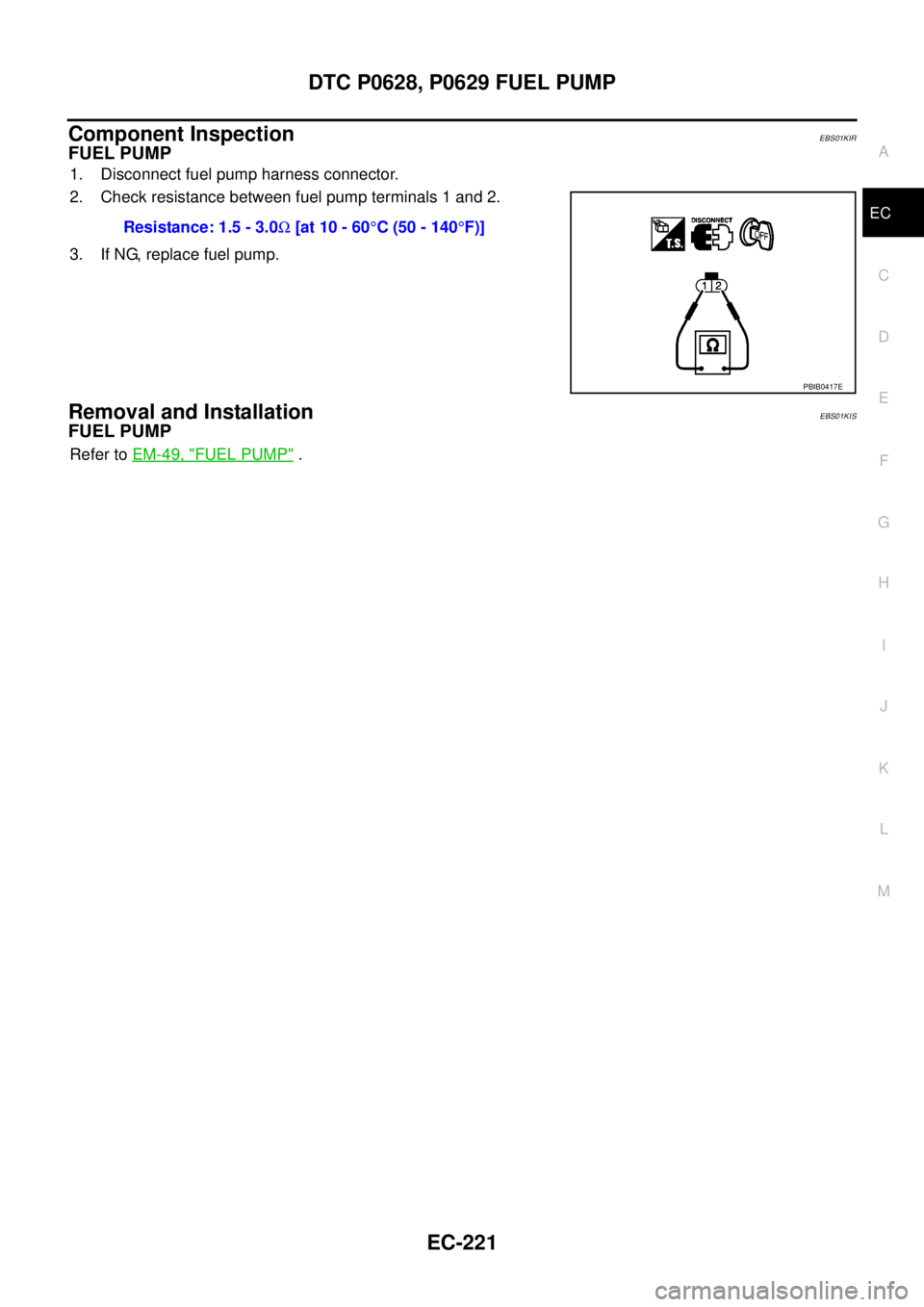

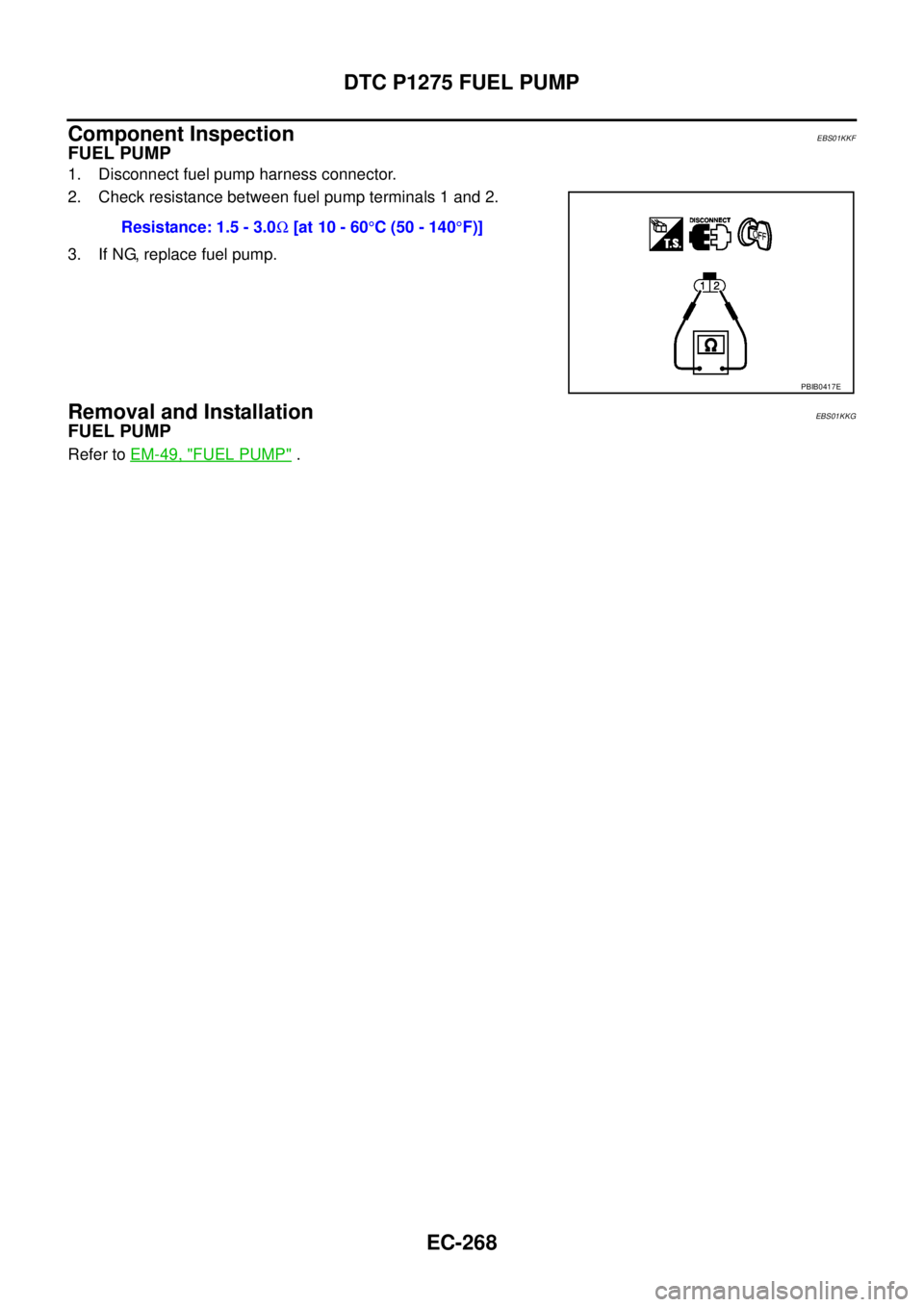

Component InspectionEBS01KIR

FUEL PUMP

1. Disconnect fuel pump harness connector.

2. Check resistance between fuel pump terminals 1 and 2.

3. If NG, replace fuel pump.

Removal and InstallationEBS01KIS

FUEL PUMP

Refer toEM-49, "FUEL PUMP". Resistance: 1.5 - 3.0W[at 10 - 60°C(50-140°F)]

PBIB0417E

Page 1230 of 3171

EC-250

DTC P1272 FUEL PUMP

4.CHECK FUEL PUMP

Refer toEC-250, "

Component Inspection".

OK or NG

OK >> GO TO 5.

NG >> GO TO 7.

5.CHECK FUEL RAIL PRESSURE SENSOR

Refer toEC-122, "

Component Inspection".

OK or NG

OK >> GO TO 6.

NG >> Replace fuel rail.

6.CHECK INTERMITTENT INCIDENT

Refer toEC-70, "

TROUBLE DIAGNOSIS FOR INTERMITTENT INCIDENT".

OK or NG

OK >> GO TO 7.

NG >> Repair or replace.

7.REPLACE FUEL PUMP

1. Replace fuel pump.

2. Perform Fuel Pump Learning Value Clearing. Refer toEC-24, "

Fuel Pump Learning Value Clearing".

>>INSPECTION END

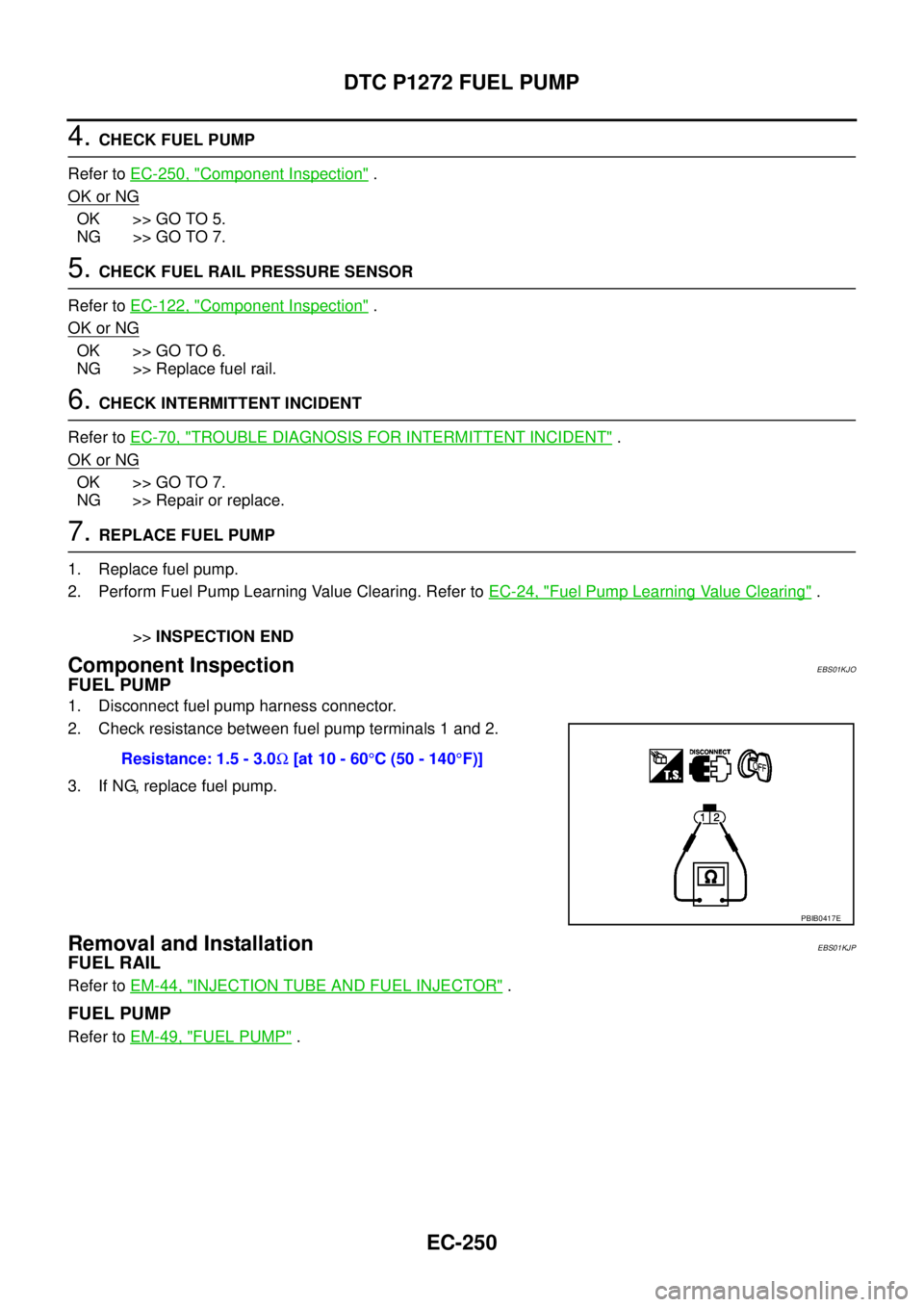

Component InspectionEBS01KJO

FUEL PUMP

1. Disconnect fuel pump harness connector.

2. Check resistance between fuel pump terminals 1 and 2.

3. If NG, replace fuel pump.

Removal and InstallationEBS01KJP

FUEL RAIL

Refer toEM-44, "INJECTION TUBE AND FUEL INJECTOR".

FUEL PUMP

Refer toEM-49, "FUEL PUMP". Resistance: 1.5 - 3.0W[at 10 - 60°C (50 - 140°F)]

PBIB0417E

Page 1237 of 3171

DTC P1273 FUEL PUMP

EC-257

C

D

E

F

G

H

I

J

K

L

MA

EC

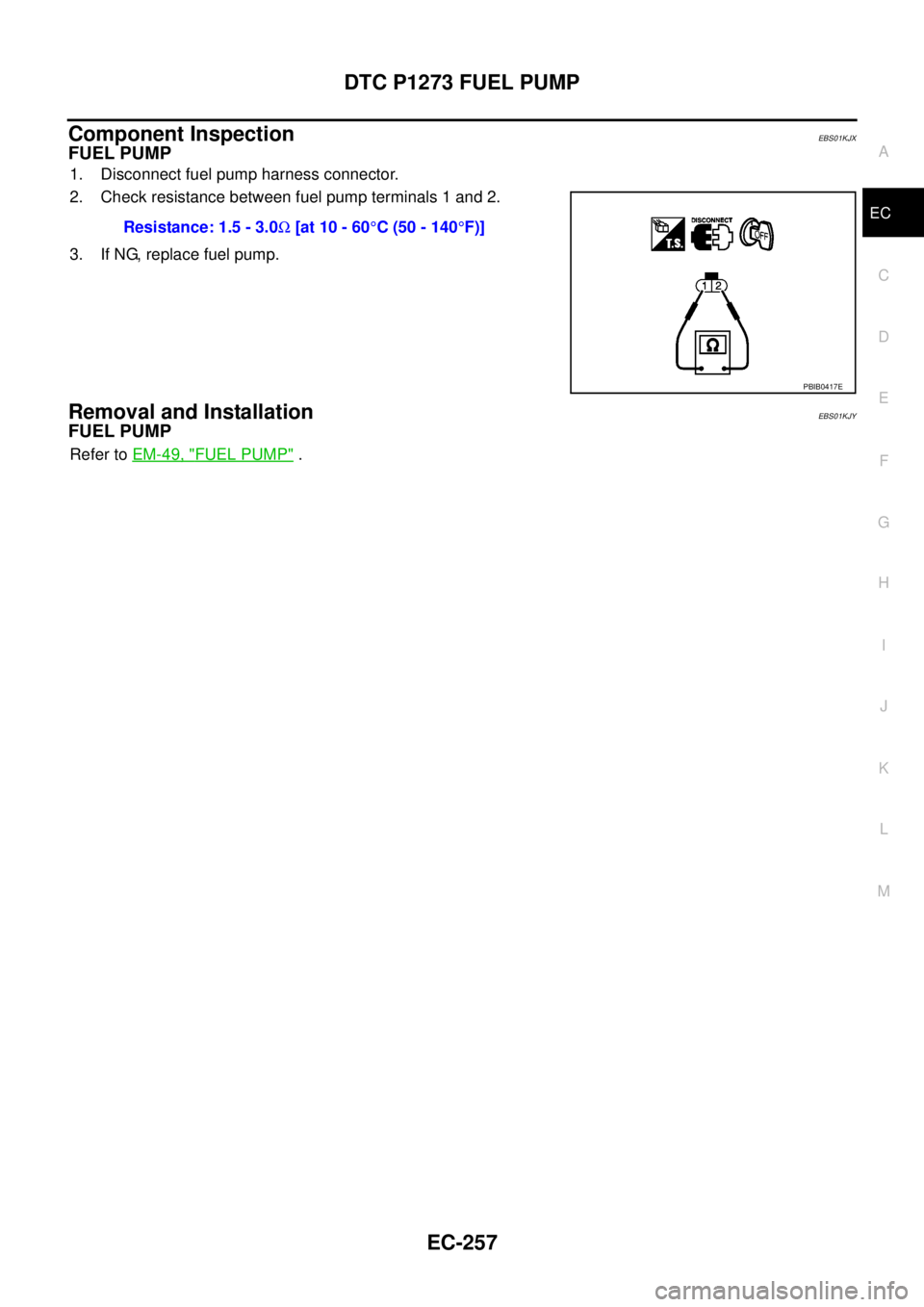

Component InspectionEBS01KJX

FUEL PUMP

1. Disconnect fuel pump harness connector.

2. Check resistance between fuel pump terminals 1 and 2.

3. If NG, replace fuel pump.

Removal and InstallationEBS01KJY

FUEL PUMP

Refer toEM-49, "FUEL PUMP". Resistance: 1.5 - 3.0W[at 10 - 60°C(50-140°F)]

PBIB0417E

Page 1242 of 3171

EC-262

DTC P1274 FUEL PUMP

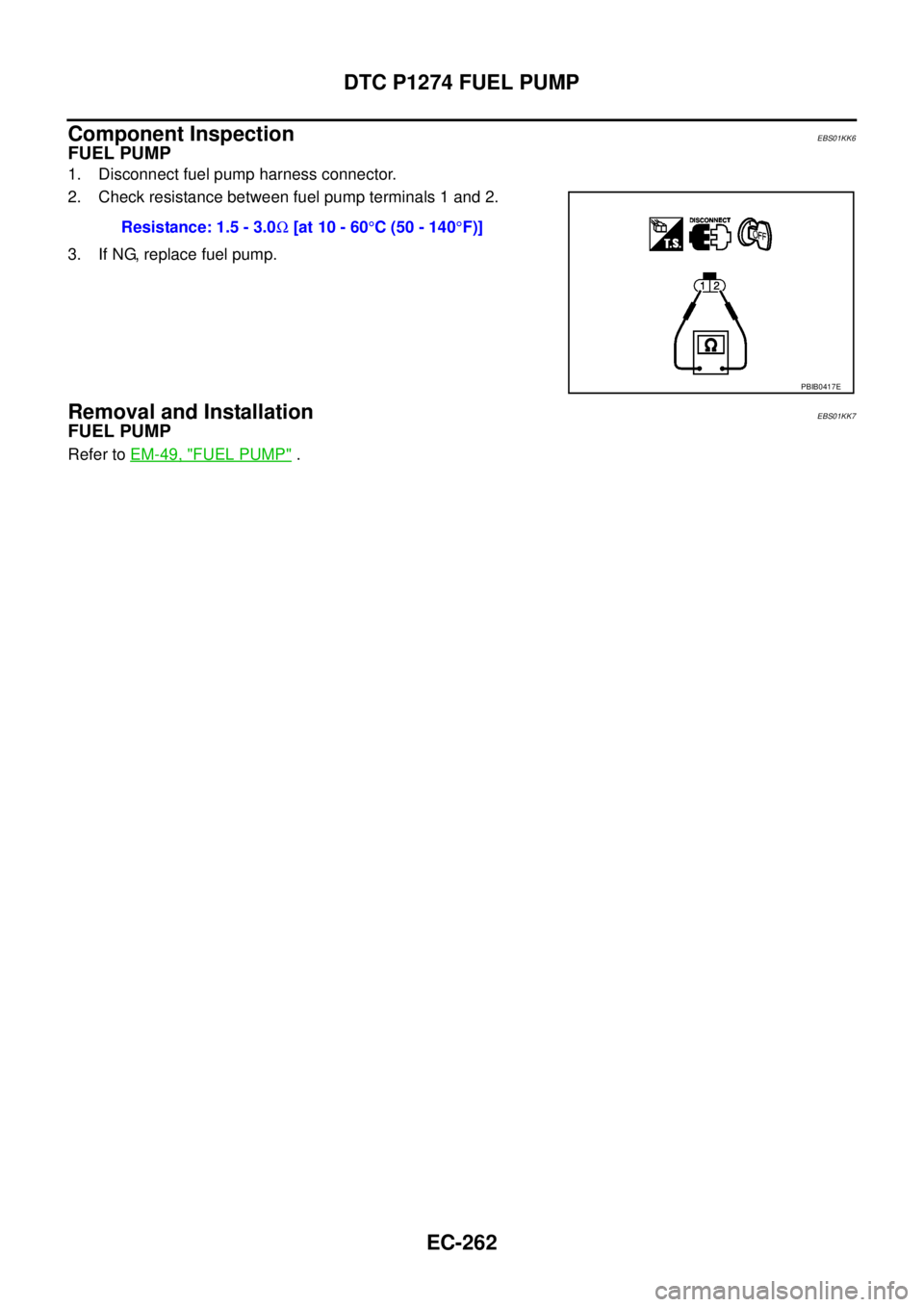

Component Inspection

EBS01KK6

FUEL PUMP

1. Disconnect fuel pump harness connector.

2. Check resistance between fuel pump terminals 1 and 2.

3. If NG, replace fuel pump.

Removal and InstallationEBS01KK7

FUEL PUMP

Refer toEM-49, "FUEL PUMP". Resistance: 1.5 - 3.0W[at 10 - 60°C (50 - 140°F)]

PBIB0417E

Page 1248 of 3171

EC-268

DTC P1275 FUEL PUMP

Component Inspection

EBS01KKF

FUEL PUMP

1. Disconnect fuel pump harness connector.

2. Check resistance between fuel pump terminals 1 and 2.

3. If NG, replace fuel pump.

Removal and InstallationEBS01KKG

FUEL PUMP

Refer toEM-49, "FUEL PUMP". Resistance: 1.5 - 3.0W[at 10 - 60°C (50 - 140°F)]

PBIB0417E

Page 1431 of 3171

FUEL PUMP

EM-49

C

D

E

F

G

H

I

J

K

L

MA

EM

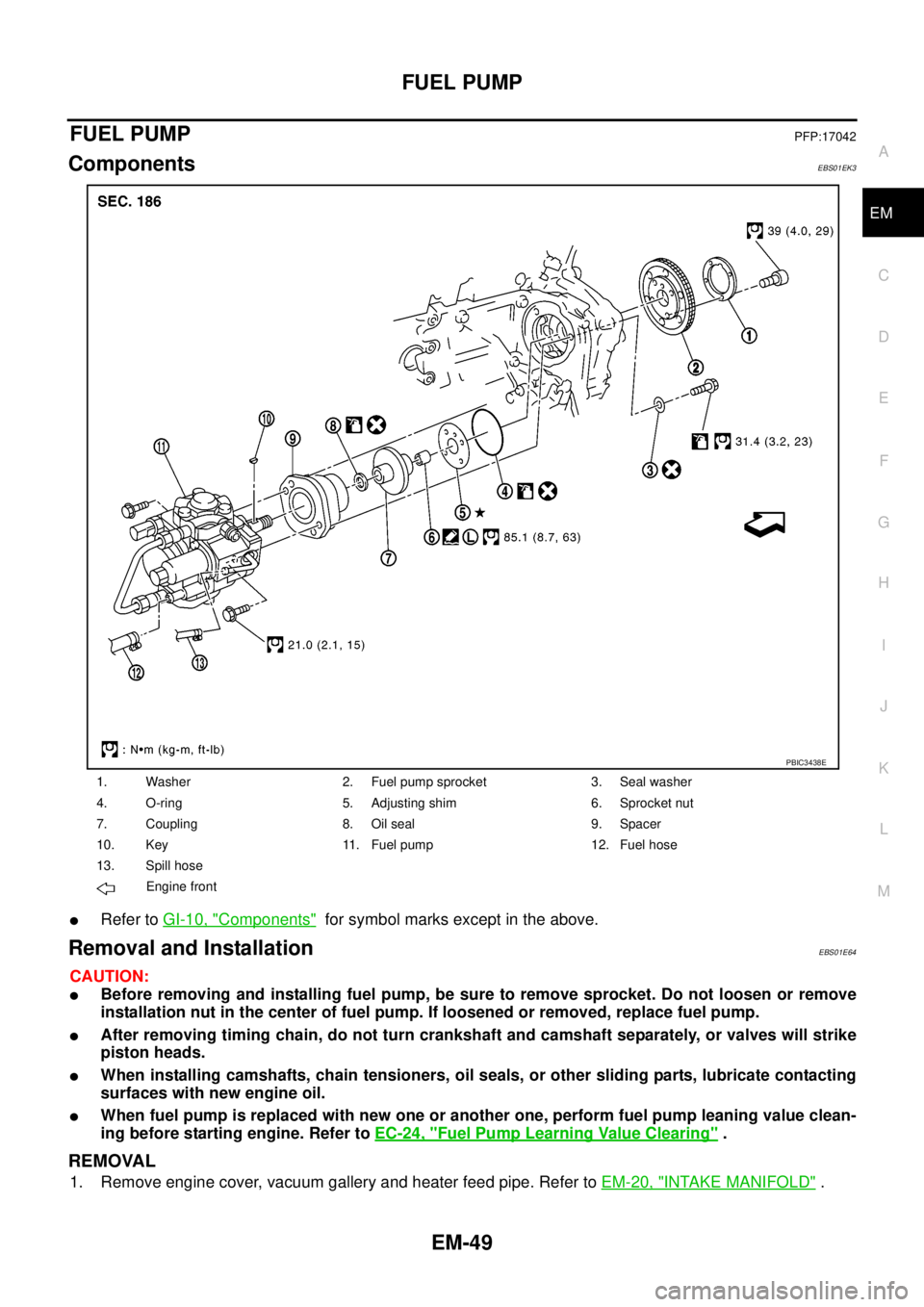

FUEL PUMPPFP:17042

ComponentsEBS01EK3

lRefer toGI-10, "Components"for symbol marks except in the above.

Removal and InstallationEBS01E64

CAUTION:

lBefore removing and installing fuel pump, be sure to remove sprocket. Do not loosen or remove

installation nut in the center of fuel pump. If loosened or removed, replace fuel pump.

lAfter removing timing chain, do not turn crankshaft and camshaft separately, or valves will strike

piston heads.

lWhen installing camshafts, chain tensioners, oil seals, or other sliding parts, lubricate contacting

surfaces with new engine oil.

lWhen fuel pump is replaced with new one or another one, perform fuel pump leaning value clean-

ing before starting engine. Refer toEC-24, "

Fuel Pump Learning Value Clearing".

REMOVAL

1. Remove engine cover, vacuum gallery and heater feed pipe. Refer toEM-20, "INTAKE MANIFOLD".

1. Washer 2. Fuel pump sprocket 3. Seal washer

4. O-ring 5. Adjusting shim 6. Sprocket nut

7. Coupling 8. Oil seal 9. Spacer

10. Key 11. Fuel pump 12. Fuel hose

13. Spill hose

Engine front

PBIC3438E