ground clearance NISSAN NAVARA 2005 Repair Workshop Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2005, Model line: NAVARA, Model: NISSAN NAVARA 2005Pages: 3171, PDF Size: 49.59 MB

Page 585 of 3171

BL-1

BODY, LOCK & SECURITY SYSTEM

IBODY

CONTENTS

C

D

E

F

G

H

J

K

L

M

SECTIONBL

A

B

BL

BODY, LOCK & SECURITY SYSTEM

PRECAUTIONS .......................................................... 4

Precautions for Supplemental Restraint System

(SRS)“AIRBAG”and“SEATBELTPRE-TEN-

SIONER” .................................................................. 4

Precautions for procedures with out cowl top cover..... 4

Precautions for Work ................................................ 4

Wiring Diagrams and Trouble Diagnosis .................. 4

PREPARATION ........................................................... 5

Commercial Service Tools ........................................ 5

SQUEAK AND RATTLE TROUBLE DIAGNOSES..... 6

Work Flow ................................................................ 6

CUSTOMER INTERVIEW ..................................... 6

DUPLICATE THE NOISE AND TEST DRIVE ....... 7

CHECK RELATED SERVICE BULLETINS ........... 7

LOCATE THE NOISE AND IDENTIFY THE

ROOT CAUSE ...................................................... 7

REPAIR THE CAUSE ........................................... 7

CONFIRM THE REPAIR ....................................... 8

Generic Squeak and Rattle Troubleshooting ........... 8

INSTRUMENT PANEL .......................................... 8

CENTER CONSOLE ............................................. 8

DOORS ................................................................. 8

TRUNK .................................................................. 9

SUNROOF/HEADLINING ..................................... 9

SEATS ................................................................... 9

UNDERHOOD ....................................................... 9

Diagnostic Worksheet ............................................ 10

HOOD ....................................................................... 12

Fitting Adjustment .................................................. 12

LONGITUDINAL AND LATERAL CLEARANCE

ADJUSTMENT .................................................... 13

FRONT END HEIGHT ADJUSTMENT ............... 13

SURFACE HEIGHT ADJUSTMENT ................... 13

Removal and Installation of Hood Assembly .......... 14

REMOVAL ........................................................... 14

INSTALLATION ................................................... 14

Removal and Installation of Hood Hinge ................ 15

REMOVAL ........................................................... 15

INSTALLATION ................................................... 15

Removal and Installation of Hood Lock Control ..... 15REMOVAL ........................................................... 15

INSTALLATION ................................................... 16

Hood Lock Control Inspection ................................ 17

RADIATOR CORE SUPPORT .................................. 18

Removal and Installation ........................................ 18

REMOVAL ........................................................... 18

INSTALLATION ................................................... 19

FRONT FENDER ...................................................... 20

Removal and Installation ........................................ 20

REMOVAL ........................................................... 20

INSTALLATION ................................................... 20

POWER DOOR LOCK SYSTEM .............................. 21

Component Parts and Harness Connector Location... 21

KING CAB ........................................................... 21

DOUBLE CAB ..................................................... 22

System Description ................................................. 23

OUTLINE ............................................................. 24

CAN Communication System Description .............. 25

CAN Communication Unit ....................................... 25

Schematic ............................................................... 26

Wiring Diagram —D/LOCK— ................................. 27

Terminals and Reference Value for BCM ............... 34

CONSULT-II Function (BCM) ................................. 35

CONSULT-II BASIC OPERATION PROCEDURE

... 35

CONSULT-II APPLICATION ITEMS .................... 36

Work Flow ............................................................... 37

Trouble Diagnoses Chart by Symptom ................... 37

Check Power Supply and Ground Circuit ............... 37

Check Door Switch ................................................. 39

CHECK DOOR SWITCH (DOUBLE CAB) .......... 39

CHECK DOOR SWITCH (KING CAB) ................ 41

Check Key Switch ................................................... 43

Check Door Key Cylinder Switch (LHD Model Only)... 45

Check Front Door Lock Actuator (Driver Side) ....... 48

Check Front Door Lock Actuator (Passenger Side)... 49

Check Front Door Lock Actuator Switch ................. 50

Check Rear Door Lock Actuator LH (Double Cab

Model) ..................................................................... 50

Check Rear Door Lock Actuator RH (Double Cab

Page 2084 of 3171

LT-1

LIGHTING SYSTEM

K ELECTRICAL

CONTENTS

C

D

E

F

G

H

I

J

L

M

SECTIONLT

A

B

LT

LIGHTING SYSTEM

PRECAUTIONS .......................................................... 4

Precautions for Supplemental Restraint System

(SRS)“AIRBAG”and“SEATBELTPRE-TEN-

SIONER” .................................................................. 4

General Precautions for Service Operations ............ 4

Wiring Diagrams and Trouble Diagnosis .................. 4

HEADLAMP -CONVENTIONAL TYPE- ..................... 5

Component Parts and Harness Connector Location..... 5

System Description .................................................. 5

OUTLINE ............................................................... 5

FRIENDLY LIGHTING FUNCTION ....................... 6

CAN Communication System Description ................ 6

Schematic ................................................................ 7

Wiring Diagram - H/LAMP - ...................................... 8

Terminals and Reference Value for BCM ............... 12

Terminals and Reference Values for IPDM E/R ..... 12

How to Proceed With Trouble Diagnosis ................ 13

Preliminary Check .................................................. 13

CHECK POWER SUPPLY AND GROUND CIR-

CUIT .................................................................... 13

CONSULT-II Functions (BCM) ............................... 15

CONSULT-II BASIC OPERATION ....................... 15

WORK SUPPORT ............................................... 16

DATA MONITOR ................................................. 16

ACTIVE TEST ..................................................... 17

CONSULT-II Functions (IPDM E/R) ....................... 18

CONSULT-II BASIC OPERATION ....................... 18

DATA MONITOR ................................................. 19

ACTIVE TEST ..................................................... 19

Headlamp High Beam Does Not Illuminate (Both

Sides) ..................................................................... 20

Headlamp HI Beam Does Not Illuminate (One Side)... 22

High Beam Indicator Lamp Does Not Illuminate .... 23

Headlamp LO Beam Does Not Illuminate (Both

Sides) ..................................................................... 23

Headlamp LO Beam Does Not Illuminate (One Side)

... 25

Headlamps Do Not Turn OFF ................................ 26

Aiming Adjustment ................................................. 28

LOW BEAM AND HIGH BEAM ........................... 28Bulb Replacement .................................................. 29

HEADLAMP HIGH/LOW BEAM .......................... 29

FRONT TURN SIGNAL LAMP ............................ 29

CLEARANCE LAMP ............................................ 29

Removal and Installation ........................................ 30

REMOVAL ........................................................... 30

INSTALLATION ................................................... 30

Disassembly and Assembly .................................... 30

DISASSEMBLY ................................................... 30

HEADLAMP - DAYTIME LIGHT SYSTEM - ............. 31

Component Parts and Harness Connector Location... 31

System Description ................................................. 31

OUTLINE ............................................................. 32

DAYTIME LIGHT OPERATION ........................... 32

COMBINATION SWITCH READING FUNCTION... 33

AUTO LIGHT OPERATION ................................. 33

CAN Communication System Description .............. 33

CAN Communication Unit ....................................... 33

Schematic ............................................................... 34

Wiring Diagram — DTRL — ................................... 35

Terminals and Reference Values for BCM .............. 39

Terminals and Reference Values for IPDM E/R ...... 39

How to Proceed With Trouble Diagnosis ................ 40

Preliminary Check .................................................. 40

CHECK POWER SUPPLY AND GROUND CIR-

CUIT .................................................................... 40

CONSULT-II Functions (BCM) ................................ 42

CONSULT-II BASIC OPERATION ....................... 42

DATA MONITOR ................................................. 43

ACTIVE TEST ..................................................... 44

CONSULT-II Functions (IPDM E/R) ........................ 45

CONSULT-II BASIC OPERATION ....................... 45

DATA MONITOR ................................................. 46

ACTIVE TEST ..................................................... 46

Daytime Light Control Does Not Operate Properly

(Normal Headlamps Operate Properly) .................. 47

Aiming Adjustment .................................................. 48

Bulb Replacement .................................................. 48

Removal and Installation ........................................ 48

Disassembly and Assembly .................................... 48

Page 2086 of 3171

LT-3

C

D

E

F

G

H

I

J

L

MA

B

LT Combination Switch Reading Function ................. 115

CONSULT-II Function (BCM) ................................ 115

CONSULT-II OPERATION ................................. 115

DATA MONITOR ................................................ 116

Combination Switch Inspection ............................. 118

Removal and Installation ...................................... 120

Switch Circuit Inspection ...................................... 120

STOP LAMP ........................................................... 121

Wiring Diagram — STOP/L — .............................. 121

Bulb Replacement ................................................ 122

Removal and Installation ...................................... 122

BACK-UP LAMP .................................................... 123

Wiring Diagram — BACK/L — ............................. 123

Bulb Replacement ................................................ 124

Removal and Installation ...................................... 124

PARKING, LICENSE PLATE AND TAIL LAMPS ... 125

Component Parts and Harness Connector Location. 125

System Description .............................................. 125

OUTLINE ........................................................... 125

OPERATION BY LIGHTING SWITCH .............. 126

COMBINATION SWITCH READING FUNCTION. 126

CAN Communication System Description ............ 126

Schematic ............................................................ 127

WITHOUT DAYTIME LIGHT SYSTEM ............. 127

Wiring Diagram — TAIL/L — ................................ 128

WITHOUT DAYTIME LIGHT SYSTEM ............. 128

Schematic ............................................................ 131

WITH DAYTIME LIGHT SYSTEM ..................... 131

Wiring Diagram — TAIL/L — ................................ 132

WITH DAYTIME LIGHT SYSTEM ..................... 132

Terminals and Reference Values for BCM ........... 135

Terminals and Reference Values for IPDM E/R ... 135

How to Proceed With Trouble Diagnosis .............. 136

Preliminary Check ................................................ 136

CHECK POWER SUPPLY AND GROUND CIR-

CUIT .................................................................. 136

CONSULT-II Functions (BCM) ............................. 137

CONSULT-II Functions (IPDM E/R) ..................... 137

Clarence, License Plate and Tail Lamps Do Not Illu-

minate .................................................................. 138

Clearance, License Plate and Tail Lamps Do Not

Turn OFF (After Approx. 10 Minutes) ................... 141

Front Clearance Lamp ......................................... 142BULB REPLACEMENT .....................................142

Tail Lamp ..............................................................142

BULB REPLACEMENT .....................................142

REAR COMBINATION LAMP .................................143

Bulb Replacement ................................................143

REMOVAL .........................................................143

INSTALLATION .................................................143

Removal and Installation ......................................144

REMOVAL .........................................................144

INSTALLATION .................................................144

INTERIOR ROOM LAMP ........................................145

Component Parts and Harness Connector Location.145

System Description ...............................................145

POWER SUPPLY AND GROUND ....................145

SWITCH OPERATION ......................................147

ROOM LAMP TIMER OPERATION ..................147

INTERIOR LAMP BATTERY SAVER CONTROL.147

Schematic .............................................................148

Wiring Diagram — INT/L — ..................................149

Terminals and Reference Values for BCM ............154

How to Proceed With Trouble Diagnosis ..............155

Preliminary Check ................................................155

INSPECTION FOR POWER SUPPLY AND

GROUND CIRCUIT ...........................................155

CONSULT-II Function ...........................................157

CONSULT-II OPERATION .................................157

WORK SUPPORT .............................................158

DATA MONITOR ...............................................158

ACTIVE TEST ...................................................159

Map Lamp Control Does Not Operate ..................160

All Interior Room Lamps Do Not Operate .............161

ILLUMINATION .......................................................162

System Description ...............................................162

ILLUMINATION OPERATION BY LIGHTING

SWITCH ............................................................162

CAN Communication System Description ............163

CAN Communication Unit .....................................163

Schematic .............................................................164

Wiring Diagram — ILL — ......................................166

BULB SPECIFICATIONS ........................................173

Headlamp .............................................................173

Exterior Lamp .......................................................173

Interior Lamp/Illumination .....................................173

Page 2115 of 3171

LT-32

HEADLAMP - DAYTIME LIGHT SYSTEM -

OUTLINE

Power is supplied at all times

lto ignition relay (located in IPDM E/R)

lto headlamp high relay (located in IPDM E/R) and

lto headlamp low relay (located in IPDM E/R), from battery directly,

lthrough 50A fusible link (letter G, located in fuse and fusible link box)

lto BCM terminal 57,

lthrough 20A fuse (No. 52, located in IPDM E/R) and

lthrough 20A fuse (No. 53, located in IPDM E/R)

lto CPU (located in IPDM E/R),

lthrough 10A fuse [No. 19, located in fuse block (J/B)]

lto combination meter terminal 3.

With the ignition switch in the ON or START position, power is supplied

lto ignition relay (located in IPDM E/R),

lthrough 10A fuse [No. 1, located in fuse block (J/B)]

lto BCM terminal 3,

lthrough 10A fuse [No. 14, located in fuse block (J/B)]

lto combination meter terminal 16.

Ground is supplied at all times

lto BCM terminal 55 and

lto combination meter terminal 23

lthrough grounds M21, M80 and M83,

lto IPDM E/R terminals 38 and 59

lthrough grounds E21, E41 and E61.

DAYTIME LIGHT OPERATION

With the lighting switch in the OFF position and engine running, the BCM receives input signal requesting

headlamp low beam, clearance lamp, license plate lamp, and tail lamp to illuminate. This input signal is com-

municated to the IPDM E/R through the CAN communication. The CPU located in the IPDM E/R controls

headlamp low relay.

lthrough 15A fuse (No. 41, located in IPDM E/R)

lthrough IPDM E/R terminal 54

lto front combination lamp RH terminal 1,

lthrough 15A fuse (No. 40, located in IPDM E/R)

lthrough IPDM E/R terminal 52

lto front combination lamp LH terminal 1.

Ground is supplied at all times

lto front combination lamp RH and LH terminals 3

lthrough grounds E21, E41 and E61.

With power and ground supplied, the headlamp low beam, clearance, license plate and tail lamps illuminate.

Page 2140 of 3171

AUTO LIGHT SYSTEM

LT-57

C

D

E

F

G

H

I

J

L

MA

B

LT

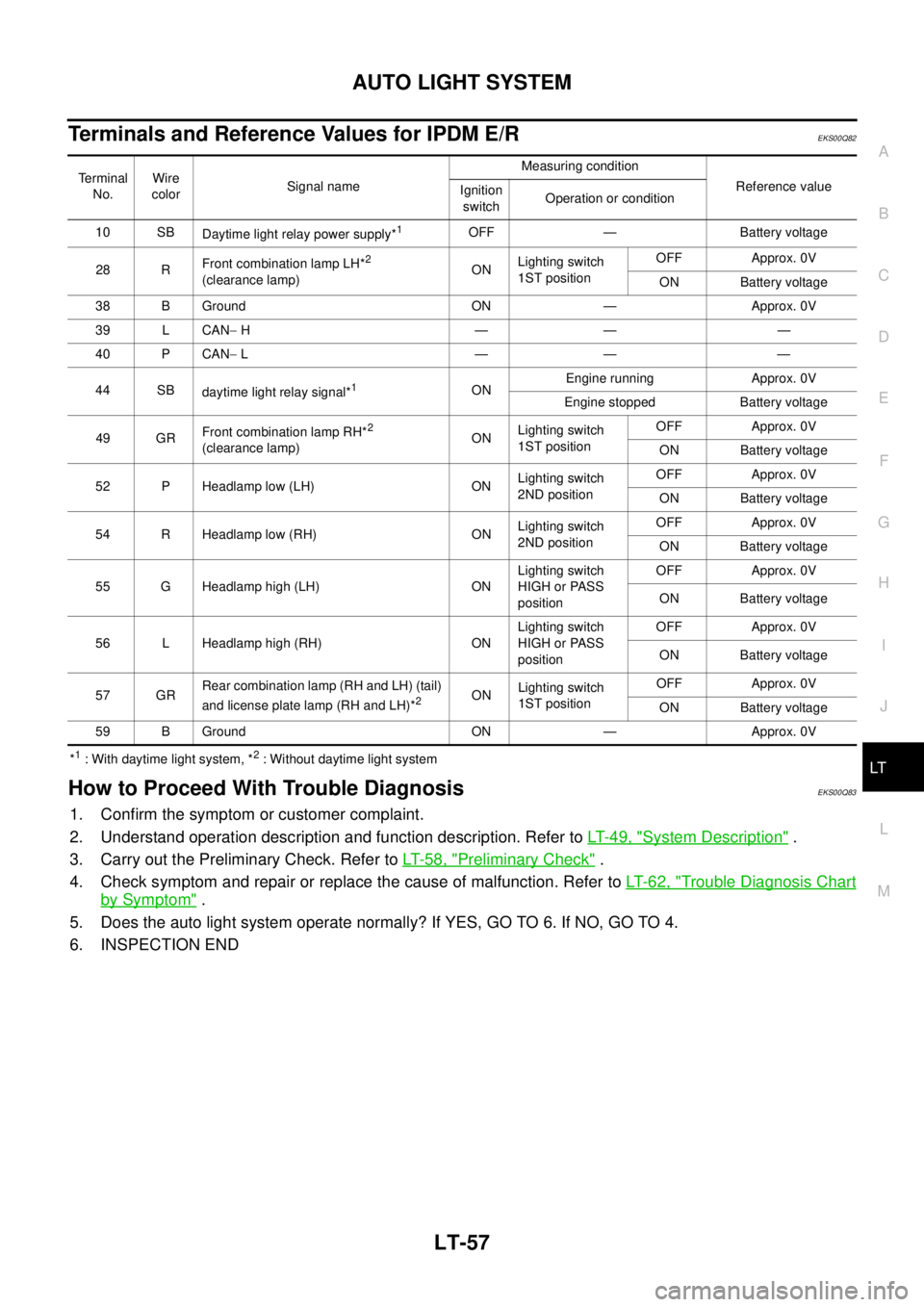

Terminals and Reference Values for IPDM E/REKS00Q82

*1: With daytime light system, *2: Without daytime light system

How to Proceed With Trouble DiagnosisEKS00Q83

1. Confirm the symptom or customer complaint.

2. Understand operation description and function description. Refer toLT-49, "

System Description".

3. Carry out the Preliminary Check. Refer toLT-58, "

Preliminary Check".

4. Check symptom and repair or replace the cause of malfunction. Refer toLT-62, "

Trouble Diagnosis Chart

by Symptom".

5. Does the auto light system operate normally? If YES, GO TO 6. If NO, GO TO 4.

6. INSPECTION END

Terminal

No.Wire

colorSignal nameMeasuring condition

Reference value

Ignition

switchOperation or condition

10 SB

Daytime light relay power supply*

1OFF — Battery voltage

28 RFront combination lamp LH*

2

(clearance lamp)ONLighting switch

1ST positionOFF Approx. 0V

ON Battery voltage

38 B Ground ON — Approx. 0V

39 L CAN-H———

40 P CAN-L———

44 SB

daytime light relay signal*

1ONEngine running Approx. 0V

Engine stopped Battery voltage

49 GRFront combination lamp RH*

2

(clearance lamp)ONLighting switch

1ST positionOFF Approx. 0V

ON Battery voltage

52 P Headlamp low (LH) ONLighting switch

2ND positionOFF Approx. 0V

ON Battery voltage

54 R Headlamp low (RH) ONLighting switch

2ND positionOFF Approx. 0V

ON Battery voltage

55 G Headlamp high (LH) ONLighting switch

HIGH or PASS

positionOFF Approx. 0V

ON Battery voltage

56 L Headlamp high (RH) ONLighting switch

HIGH or PASS

positionOFF Approx. 0V

ON Battery voltage

57 GRRear combination lamp (RH and LH) (tail)

and license plate lamp (RH and LH)*

2ONLighting switch

1ST positionOFF Approx. 0V

ON Battery voltage

59 B Ground ON — Approx. 0V

Page 2222 of 3171

PARKING, LICENSE PLATE AND TAIL LAMPS

LT-139

C

D

E

F

G

H

I

J

L

MA

B

LT

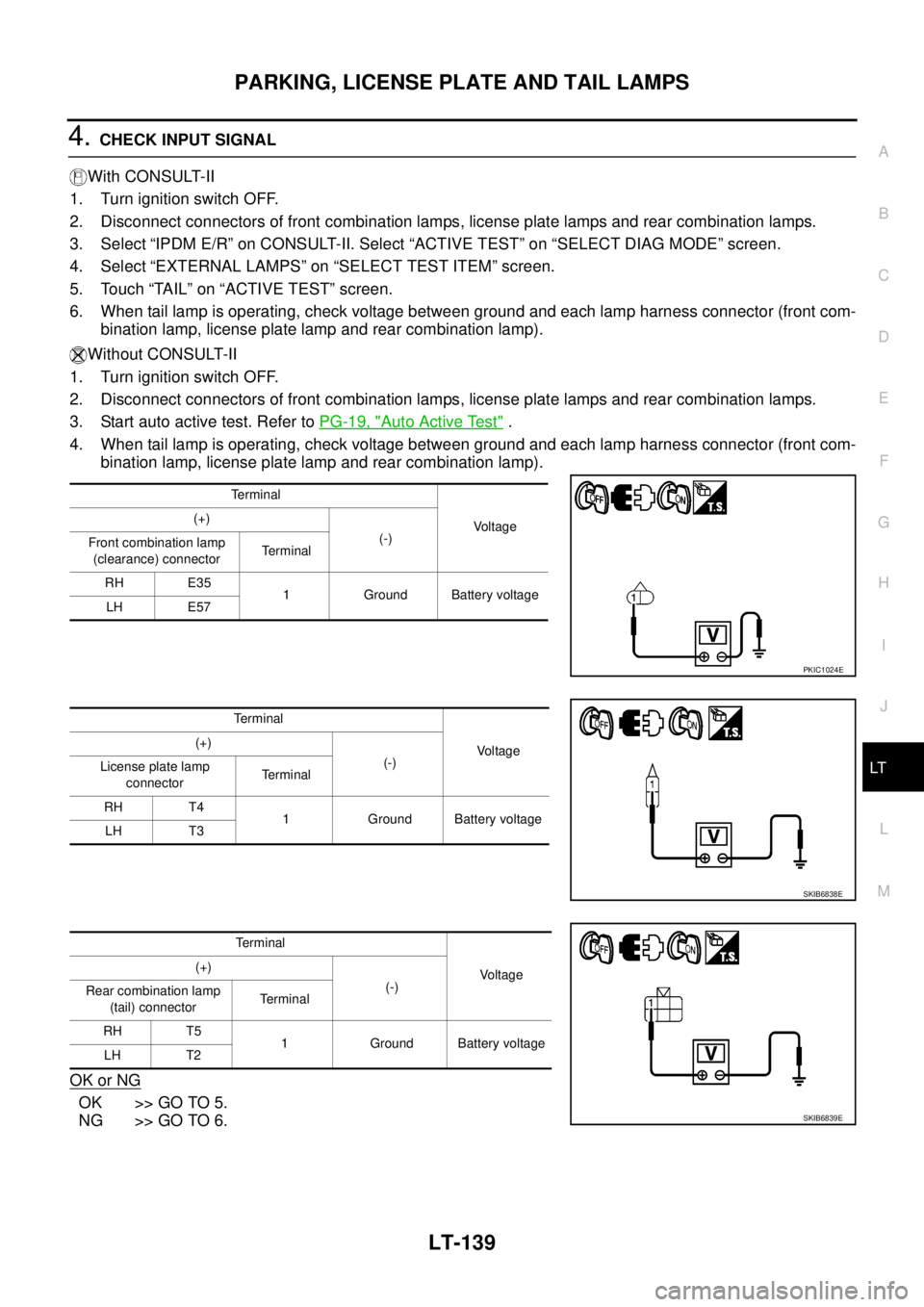

4.CHECK INPUT SIGNAL

With CONSULT-II

1. Turn ignition switch OFF.

2. Disconnect connectors of front combination lamps, license plate lamps and rear combination lamps.

3. Select “IPDM E/R” on CONSULT-II. Select “ACTIVE TEST” on “SELECT DIAG MODE” screen.

4. Select “EXTERNAL LAMPS” on “SELECT TEST ITEM” screen.

5. Touch “TAIL” on “ACTIVE TEST” screen.

6. When tail lamp is operating, check voltage between ground and each lamp harness connector (front com-

bination lamp, license plate lamp and rear combination lamp).

Without CONSULT-II

1. Turn ignition switch OFF.

2. Disconnect connectors of front combination lamps, license plate lamps and rear combination lamps.

3. Start auto active test. Refer toPG-19, "

Auto Active Test".

4. When tail lamp is operating, check voltage between ground and each lamp harness connector (front com-

bination lamp, license plate lamp and rear combination lamp).

OK or NG

OK >> GO TO 5.

NG >> GO TO 6.

Terminal

Voltage (+)

(-)

Front combination lamp

(clearance) connectorTerminal

RH E35

1 Ground Battery voltage

LH E57

PKIC1024E

Terminal

Vo l ta g e (+)

(-)

License plate lamp

connectorTerminal

RH T4

1 Ground Battery voltage

LH T3

SKIB6838E

Terminal

Voltage (+)

(-)

Rear combination lamp

(tail) connectorTe r m i n a l

RH T5

1 Ground Battery voltage

LH T2

SKIB6839E

Page 2224 of 3171

PARKING, LICENSE PLATE AND TAIL LAMPS

LT-141

C

D

E

F

G

H

I

J

L

MA

B

LT

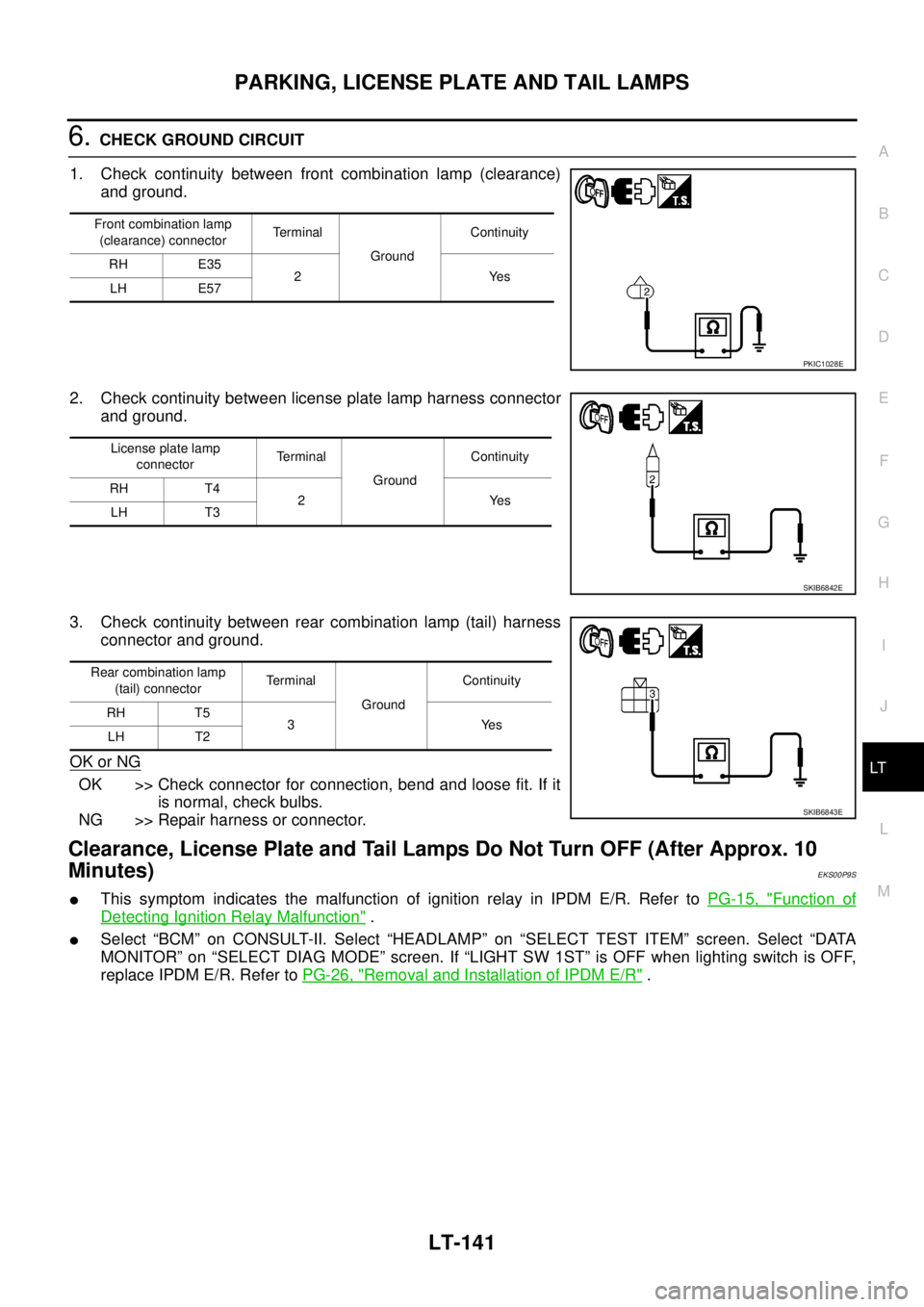

6.CHECK GROUND CIRCUIT

1. Check continuity between front combination lamp (clearance)

and ground.

2. Check continuity between license plate lamp harness connector

and ground.

3. Check continuity between rear combination lamp (tail) harness

connector and ground.

OK or NG

OK >> Check connector for connection, bend and loose fit. If it

is normal, check bulbs.

NG >> Repair harness or connector.

Clearance, License Plate and Tail Lamps Do Not Turn OFF (After Approx. 10

Minutes)

EKS00P9S

lThis symptom indicates the malfunction of ignition relay in IPDM E/R. Refer toPG-15, "Function of

Detecting Ignition Relay Malfunction".

lSelect “BCM” on CONSULT-II. Select “HEADLAMP” on “SELECT TEST ITEM” screen. Select “DATA

MONITOR” on “SELECT DIAG MODE” screen. If “LIGHT SW 1ST” is OFF when lighting switch is OFF,

replace IPDM E/R. Refer toPG-26, "

Removal and Installation of IPDM E/R".

Front combination lamp

(clearance) connectorTerminal

GroundContinuity

RH E35

2Yes

LH E57

PKIC1028E

License plate lamp

connectorTerminal

GroundContinuity

RH T4

2Yes

LH T3

SKIB6842E

Rear combination lamp

(tail) connectorTerminal

GroundContinuity

RH T5

3Yes

LH T2

SKIB6843E

Page 2870 of 3171

SERVICE DATA AND SPECIFICATIONS (SDS)

SC-37

C

D

E

F

G

H

I

J

L

MA

B

SC

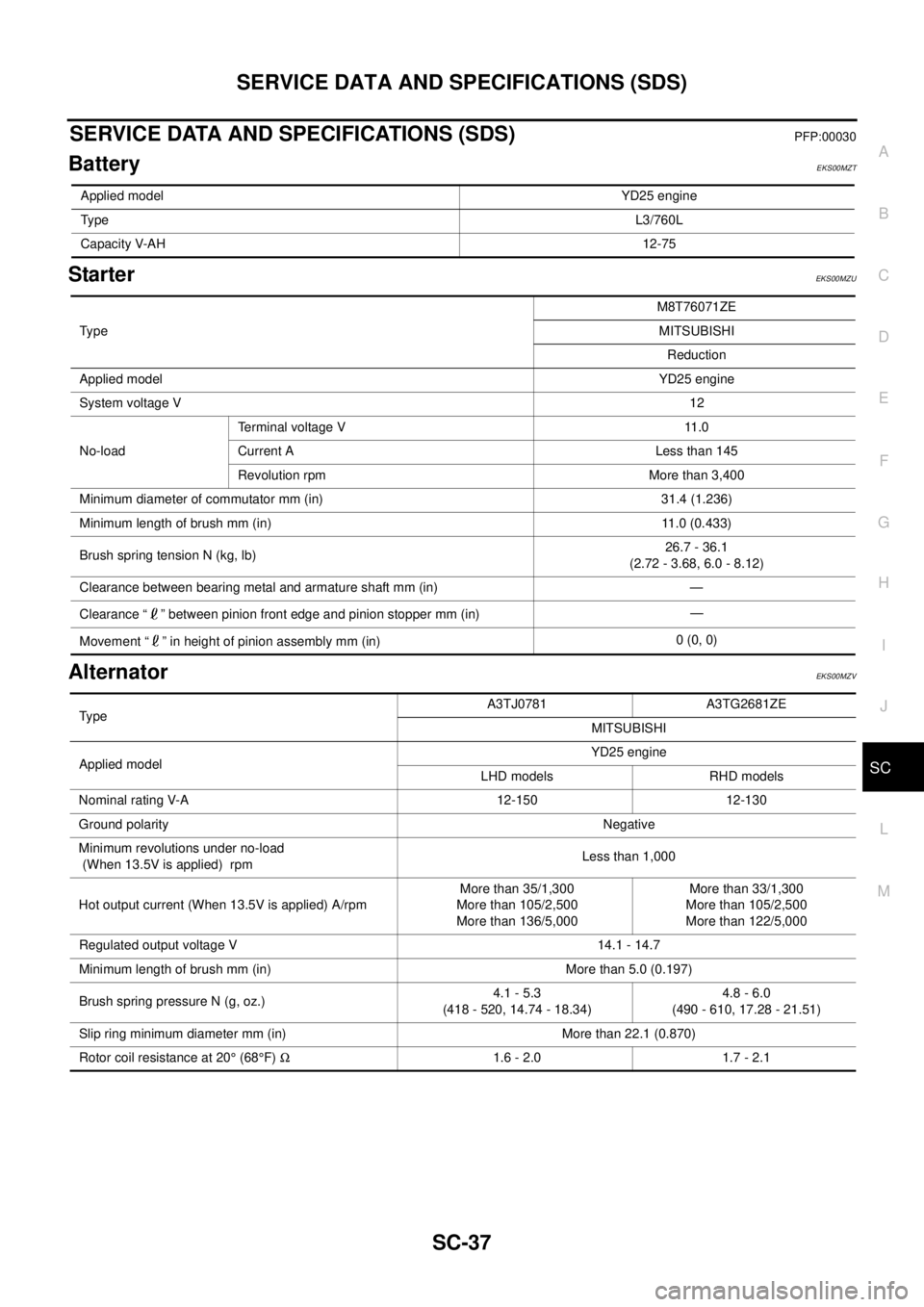

SERVICE DATA AND SPECIFICATIONS (SDS)PFP:00030

BatteryEKS00MZT

StarterEKS00MZU

AlternatorEKS00MZV

Applied modelYD25 engine

TypeL3/760L

Capacity V-AH12-75

Ty p eM8T76071ZE

MITSUBISHI

Reduction

Applied modelYD25 engine

System voltage V12

No-loadTerminal voltage V 11.0

Current A Less than 145

Revolution rpm More than 3,400

Minimum diameter of commutator mm (in) 31.4 (1.236)

Minimum length of brush mm (in) 11.0 (0.433)

Brush spring tension N (kg, lb)26.7 - 36.1

(2.72 - 3.68, 6.0 - 8.12)

Clearance between bearing metal and armature shaft mm (in) —

Clearance “ ” between pinion front edge and pinion stopper mm (in)—

Movement “ ” in height of pinion assembly mm (in)0 (0, 0)

TypeA3TJ0781 A3TG2681ZE

MITSUBISHI

Applied modelYD25 engine

LHD models RHD models

Nominal rating V-A 12-150 12-130

Ground polarityNegative

Minimum revolutions under no-load

(When 13.5V is applied) rpmLess than 1,000

Hot output current (When 13.5V is applied) A/rpmMore than 35/1,300

More than 105/2,500

More than 136/5,000More than 33/1,300

More than 105/2,500

More than 122/5,000

Regulated output voltage V 14.1 - 14.7

Minimum length of brush mm (in) More than 5.0 (0.197)

Brush spring pressure N (g, oz.)4.1 - 5.3

(418 - 520, 14.74 - 18.34)4.8 - 6.0

(490 - 610, 17.28 - 21.51)

Slip ring minimum diameter mm (in) More than 22.1 (0.870)

Rotor coil resistance at 20°(68°F)W1.6 - 2.0 1.7 - 2.1