check engine light NISSAN NOTE 2016 Service Owner's Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2016, Model line: NOTE, Model: NISSAN NOTE 2016Pages: 3641, PDF Size: 28.72 MB

Page 1439 of 3641

![NISSAN NOTE 2016 Service Owners Manual EC-312

< DTC/CIRCUIT DIAGNOSIS >[HR16DE]

P0451 EVAP CONTROL SYSTEM PRESSURE SENSOR

With CONSULT

Check 1st trip DTC.

Is 1st trip DTC detected?

YES >> Proceed to EC-312, "Diagnosis Procedure".

NO >> IN NISSAN NOTE 2016 Service Owners Manual EC-312

< DTC/CIRCUIT DIAGNOSIS >[HR16DE]

P0451 EVAP CONTROL SYSTEM PRESSURE SENSOR

With CONSULT

Check 1st trip DTC.

Is 1st trip DTC detected?

YES >> Proceed to EC-312, "Diagnosis Procedure".

NO >> IN](/img/5/57363/w960_57363-1438.png)

EC-312

< DTC/CIRCUIT DIAGNOSIS >[HR16DE]

P0451 EVAP CONTROL SYSTEM PRESSURE SENSOR

With CONSULT

Check 1st trip DTC.

Is 1st trip DTC detected?

YES >> Proceed to EC-312, "Diagnosis Procedure".

NO >> INSPECTION END

5.PERFORM DTC CONFIRMATION PROCEDURE-4

With GST

1. Start engine and let it idle for least 40 seconds.

NOTE:

Do not depress accelerator pedal even slightly.

2. Check 1st trip DTC.

Is 1st trip DTC detected?

YES >> Proceed to EC-312, "Diagnosis Procedure".

NO >> GO TO 6.

6.PERFORM DTC CONFIRMATION PROCEDURE-5

With GST

1. Let it idle for at least 2 hours.

2. Turn ignition switch OFF and wait at least 90 minutes. NOTE:

Never turn ignition switch ON during 90 minutes.

3. Turn ignition switch ON.

4. Check 1st trip DTC.

Is 1st trip DTC detected?

YES >> Proceed to EC-312, "Diagnosis Procedure".

NO >> INSPECTION END

Diagnosis ProcedureINFOID:0000000012431506

1.CHECK EVAP CONTROL SYSTEM PRESS URE SENSOR CONNECTOR FOR WATER

1. Turn ignition switch OFF.

2. Disconnect EVAP control system pressure sensor harness connector.

3. Check sensor harness connector for water.

Is the inspection result normal?

YES >> GO TO 2.

NO >> Repair or replace harness connector.

2.CHECK EVAP CONTROL SYSTEM PR ESSURE SENSOR POWER SUPPLY

1. Turn ignition switch ON.

2. Check the voltage between EVAP control syst em pressure sensor harness connector and ground.

Is the inspection result normal?

YES >> GO TO 4.

NO >> GO TO 3.

3.CHECK EVAP CONTROL SY STEM PRESSURE SENSOR POWER SUPPLY CIRCUIT

1. Turn ignition switch OFF.

2. Disconnect ECM harness connector.

3. Check the continuity between EVAP control system pressure sensor harness connector and ECM har- ness connector.

Water should not exist.

EVAP control system pressure sensor GroundVo l ta g e

(Approx.)

Connector Terminal

B3 3Ground 5 V

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 1511 of 3641

![NISSAN NOTE 2016 Service Owners Manual EC-384

< DTC/CIRCUIT DIAGNOSIS >[HR16DE]

P1572 ASCD BRAKE SWITCH

Always drive vehicle at a safe speed.

NOTE:

This procedure may be conducted with the drive wheel

s lifted in the shop or by driving the NISSAN NOTE 2016 Service Owners Manual EC-384

< DTC/CIRCUIT DIAGNOSIS >[HR16DE]

P1572 ASCD BRAKE SWITCH

Always drive vehicle at a safe speed.

NOTE:

This procedure may be conducted with the drive wheel

s lifted in the shop or by driving the](/img/5/57363/w960_57363-1510.png)

EC-384

< DTC/CIRCUIT DIAGNOSIS >[HR16DE]

P1572 ASCD BRAKE SWITCH

Always drive vehicle at a safe speed.

NOTE:

This procedure may be conducted with the drive wheel

s lifted in the shop or by driving the vehicle.

If a road test is expected to be easier , it is unnecessary to lift the vehicle.

2. Check DTC.

Is DTC detected?

YES >> Proceed to EC-388, "Diagnosis Procedure".

NO >> INSPECTION END

Diagnosis ProcedureINFOID:0000000012431594

1.CHECK OVERALL FUNCTION-I

With CONSULT

1. Turn ignition switch ON.

2. Select “BRAKE SW1” in “DATA MONITOR” mode of “ENGINE” using CONSULT.

3. Check “BRAKE SW1” indication as per the following conditions.

Without CONSULT

1. Turn ignition switch ON.

2. Check the voltage between ECM harness connector terminals as per the following.

Is the inspection result normal?

YES >> GO TO 2.

NO >> GO TO 3.

2.CHECK OVERALL FUNCTION-II

With CONSULT

Select “BRAKE SW2” and check indication as per the following conditions.

Without CONSULT

Check the voltage between ECM harness connector terminals as per the following conditions.

Vehicle speed More than 30 km/h (19 mph)

Selector lever Suitable position

Driving location Depress the brake pedal for more than five seconds so as

not to come off from the above-mentioned vehicle speed.

Monitor item

ConditionIndication

BRAKE SW1 Brake pedal Slightly depressed OFF

Fully released

ON

ECM ConditionVoltag e

(Approx.)

Connector +–

Te r m i n a l

E16 100 108 Brake pedal Slightly depressed

0 V

Fully released Battery voltage

Monitor item ConditionIndication

BRAKE SW2 Brake pedal Slightly depressed ON

Fully released

OFF

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 1564 of 3641

![NISSAN NOTE 2016 Service Owners Manual ASCD BRAKE SWITCHEC-437

< DTC/CIRCUIT DIAGNOSIS > [HR16DE]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

ASCD BRAKE SWITCH

Component Function CheckINFOID:0000000012431635

1.CHECK ASCD BRAKE SWITCH FUNCTION

With CON NISSAN NOTE 2016 Service Owners Manual ASCD BRAKE SWITCHEC-437

< DTC/CIRCUIT DIAGNOSIS > [HR16DE]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

ASCD BRAKE SWITCH

Component Function CheckINFOID:0000000012431635

1.CHECK ASCD BRAKE SWITCH FUNCTION

With CON](/img/5/57363/w960_57363-1563.png)

ASCD BRAKE SWITCHEC-437

< DTC/CIRCUIT DIAGNOSIS > [HR16DE]

C

D

E

F

G H

I

J

K L

M A

EC

NP

O

ASCD BRAKE SWITCH

Component Function CheckINFOID:0000000012431635

1.CHECK ASCD BRAKE SWITCH FUNCTION

With CONSULT

1. Turn ignition switch ON.

2. Select “BRAKE SW1” in “DATA MONI TOR” mode of “ENGINE” using CONSULT.

3. Check “BRAKE SW1” indication as per the following conditions.

Without CONSULT

1. Turn ignition switch ON.

2. Check the voltage between ECM harness connector terminals as per the following.

Is the inspection result normal?

YES >> INSPECTION END

NO >> Proceed to EC-437, "

Diagnosis Procedure".

Diagnosis ProcedureINFOID:0000000012431636

1.CHECK ASCD BRAKE SWITCH POWER SUPPLY

1. Turn ignition switch OFF.

2. Disconnect ASCD brake switch harness connector.

3. Turn ignition switch ON.

4. Check the voltage between ASCD brake switch harness connector and ground.

Is the inspection result normal?

YES >> GO TO 2.

NO >> Perform the trouble diagnosis for power supply circuit.

2.CHECK ASCD BRAKE SWITCH INPUT SIGNAL CIRCUIT

1. Turn ignition switch OFF.

2. Disconnect ECM harness connector.

3. Check the continuity between ASCD brake switch harness connector and ECM harness connector.

4. Also check harness for short to ground and to power.

Is the inspection result normal?

Monitor item ConditionIndication

BRAKE SW1 Brake pedal Slightly depressed OFF

Fully released

ON

ECM ConditionVo l ta g e

(Approx.)

Connector +–

Te r m i n a l

E16 100 108 Brake

pedalSlightly depressed 0 V

Fully released Battery voltage

ASCD brake switch

GroundVoltage

Connector Terminal

E36 1Ground Battery voltage

ASCD brake switch ECM

Continuity

Connector Terminal Connector Terminal

E36 2E16 100 Existed

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 1615 of 3641

![NISSAN NOTE 2016 Service Owners Manual CO-10

< PERIODIC MAINTENANCE >[HR16DE]

ENGINE COOLANT

4. Install the Tool by installing the radiator cap adapter onto the

radiator neck opening. Then attach the gauge body assembly

with the refill tub NISSAN NOTE 2016 Service Owners Manual CO-10

< PERIODIC MAINTENANCE >[HR16DE]

ENGINE COOLANT

4. Install the Tool by installing the radiator cap adapter onto the

radiator neck opening. Then attach the gauge body assembly

with the refill tub](/img/5/57363/w960_57363-1614.png)

CO-10

< PERIODIC MAINTENANCE >[HR16DE]

ENGINE COOLANT

4. Install the Tool by installing the radiator cap adapter onto the

radiator neck opening. Then attach the gauge body assembly

with the refill tube and the venturi assembly to the radiator cap

adapter.

5. Insert the refill hose into the engine coolant mixture container that is placed at floor level. Make sure the ball valve is in the

closed position.

•Use recommended engine coolant or equivalent.

Refer to MA-11, "

Fluids and Lubricants".

CAUTION:

Do not use any cooling system additives such as radiator

sealer. Additives may clog th e cooling system and cause

damage to the engine, transmission and/or cooling system.

6. Install an air hose to the venturi assembly, the air pressure must be within specification.

CAUTION:

The compressed air supply must be equipped with an air dryer.

7. The vacuum gauge will begin to rise and there will be an audible hissing noise. During this process open the ball valve on the refill hose slightly. Engine coolant wi ll be visible rising in the refill hose. Once the refill

hose is full of engine coolant, close the ball valve. This will purge any air trapped in the refill hose.

8. Continue to draw the vacuum until the gauge reaches 28 inches of vacuum. The gauge may not reach 28 inches in high altitude

locations, use the vacuum specifications based on the altitude

above sea level.

9. When the vacuum gauge has reached the specifi ed amount, disconnect the air hose and wait 20 seconds

to see if the system loses any vacuum. If the vacuum level drops, perform any necessary repairs to the

system and repeat steps 6 - 8 to bring the vacuum to the specified amount. Recheck for any leaks.

10. Place the engine coolant container (with the refill hose inserted) at the same level as the top of the radia- tor. Then open the ball valve on the refill hose so the engine coolant will be drawn up to fill the cooling sys-

tem. The cooling system is full when the vacuum gauge reads zero.

CAUTION:

Do not allow the engine coolant co ntainer to get too low when filling, to avoid air from being drawn

into the cooling system.

11. Remove the Tool from the radiator neck opening.

12. Fill the cooling system reservoir tank to the specified level and install the radiator cap. Run the engine to warm up the cooling system and t op up the system as necessary.

13. Install the front under cover. Refer to EXT-39, "

FRONT UNDER COVER : Removal and Installation".

Tool number : KV991J0070 (J-45695)

Engine coolant capacity

(with reservoir tank)

: Refer to MA-11, "

Fluids and

Lubricants".

Compressed air

supply pressure : 549 - 824 kPa (5.6 - 8.4 kg/cm

2,

80 - 119 psi)LLIA0058E

Altitude above sea level Vacuum gauge reading

0 - 100 m (328 ft) : 28 inches of vacuum

300 m (984 ft) : 27 inches of vacuum

500 m (1,641 ft) : 26 inches of vacuum

1,000 m (3,281 ft) : 24 - 25 inches of vacuum

LLIA0057E

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 1731 of 3641

HEADLAMP (LO) CIRCUITEXL-79

< DTC/CIRCUIT DIAGNOSIS >

C

DE

F

G H

I

J

K

M A

B

EXL

N

O P

HEADLAMP (LO) CIRCUIT

DescriptionINFOID:0000000012432807

The IPDM E/R (intelligent power distribution modul e engine room) controls the headlamp low relay based on

inputs from the BCM via the CAN communication li nes. When the headlamp low relay is energized, power

flows through fuses 40 and 41, located in the IPDM E/R.

(Without daytime running light system) power then flow s to the front combination lamp LH and RH low beams.

(With daytime running light system) power then flows to the front combination lamp LH low beam and the day-

time running light relay 2 which becomes energized and t hen power is sent to the front combination lamp RH

low beam.

Component Function CheckINFOID:0000000012432808

1.CHECK HEADLAMP (LO) OPERATION

WITHOUT CONSULT

1. Start IPDM E/R auto active test. Refer to PCS-9, "

Diagnosis Description".

2. Check that the headlamp is turned ON.

CONSULT

1. Select EXTERNAL LAMPS of IP DM E/R active test item.

2. While operating the test items, check that the headlamp is turned ON.

Is the headlamp turned ON?

YES >> Headlamp (LO) is normal.

NO >> Refer to EXL-79, "

Diagnosis Procedure".

Diagnosis ProcedureINFOID:0000000012432809

Regarding Wiring Diagram information, refer to EXL-25, "Wiring Diagram - For USA" or EXL-31, "Wiring Dia-

gram - For Canada".

1.CHECK HEADLAMP (LO) FUSES

1. Turn the ignition switch OFF.

2. Check that the following fuses are not blown:

Is the fuse blown?

YES >> Replace the blown fuse after repairing the affected circuit.

NO >> GO TO 2.

2.CHECK LOW BEAM BULB

Check the applicable low beam bulb to be sure the proper bulb standard is in use and the bulb is not open.

Is the bulb OK?

YES >> GO TO 3.

NO >> Replace the bulb.

3.CHECK HEADLAMP (LO) OUTPUT VOLTAGE

1. Turn the ignition switch OFF.

2. Disconnect the front combination lamp connector E25 or E26.

3. Turn the ignition switch ON. LO : Headlamp ON

OFF : Headlamp OFF

Unit

LocationFuse No.Capacity

Headlamp LO (L H) IPDM E/R 4115A

Headlamp LO (RH) IPDM E/R4015A

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 1930 of 3641

GI-42

< BASIC INSPECTION >

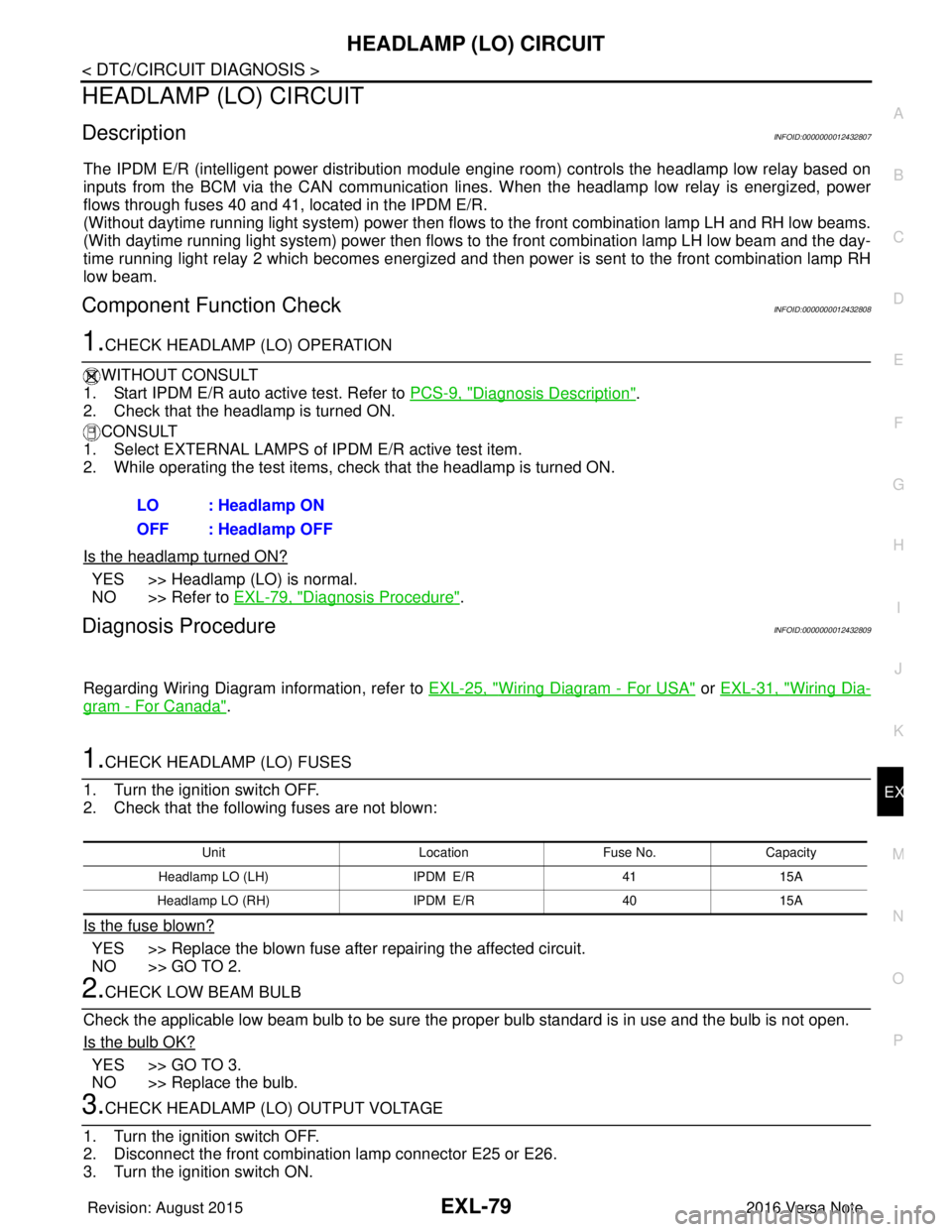

SERVICE INFORMATION FOR ELECTRICAL INCIDENT

• Most waterproof connectors are provided with a rubber sealbetween the male and female connectors. If the seal is missing,

the waterproof performance may not meet specifications.

• The rubber seal may come off when connectors are disconnected. Whenever connectors are reconnected, make sure the rubber seal

is properly installed on either side of male or female connector.

WIRE SEAL INSPECTION

• The wire seal must be installed on the wire insertion area of awaterproof connector. Be sure that the seal is installed properly.

Terminal Lock Inspection

Check for unlocked terminals by pulling wire at the end of connector.

An unlocked terminal may create intermittent signals in the circuit.

Intermittent IncidentINFOID:0000000012433186

DESCRIPTION

Sometimes the symptom is not present when the vehicle is brought in for service. If possible, re-create the

conditions present at the time of the incident. Doi ng so may help avoid a No Trouble Found Diagnosis. The fol-

lowing section illustrates ways to simulate the condi tions/environment under which the owner experiences an

electrical incident.

The section is broken into the six following topics:

• Vehicle vibration

• Heat sensitive

• Freezing

• Water intrusion

• Electrical load

• Cold or hot start up

Get a thorough description of the incident from the customer. It is important for simulating the conditions of the

problem.

VEHICLE VIBRATION

The problem may occur or become worse while driving on a rough road or when engine is vibrating (idle with

A/C on). In such a case, you will want to check for a vi bration related condition. Refer to the following illustra-

tion.

Connector & Harness

Determine which connectors and wiring harness would affect the electrical system you are inspecting. Gently

shake each connector and harness while monitoring the sy stem for the incident you are trying to duplicate.

This test may indicate a loose or poor electrical connection.

Hint

Connectors can be exposed to moisture. It is possible to get a thin film of corrosion on the connector termi-

nals. A visual inspection may not reveal this without disconnecting the connector. If the problem occurs inter-

mittently, perhaps the problem is caused by corrosion. It is a good idea to disconnect, inspect and clean the

terminals on related connectors in the system.

Sensor & Relay

Gently apply a slight vibration to sensors and relays in the system you are inspecting.

SEL275V

SEL330V

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 2017 of 3641

![NISSAN NOTE 2016 Service Owners Manual INSUFFICIENT HEATINGHAC-49

< SYMPTOM DIAGNOSIS > [MANUAL AIR CONDITIONING]

C

D

E

F

G H

J

K L

M A

B

HAC

N

O P

INSUFFICIENT HEATING

DescriptionINFOID:0000000012430752

Symptom

• Insufficient heating

� NISSAN NOTE 2016 Service Owners Manual INSUFFICIENT HEATINGHAC-49

< SYMPTOM DIAGNOSIS > [MANUAL AIR CONDITIONING]

C

D

E

F

G H

J

K L

M A

B

HAC

N

O P

INSUFFICIENT HEATING

DescriptionINFOID:0000000012430752

Symptom

• Insufficient heating

�](/img/5/57363/w960_57363-2016.png)

INSUFFICIENT HEATINGHAC-49

< SYMPTOM DIAGNOSIS > [MANUAL AIR CONDITIONING]

C

D

E

F

G H

J

K L

M A

B

HAC

N

O P

INSUFFICIENT HEATING

DescriptionINFOID:0000000012430752

Symptom

• Insufficient heating

• No warm air comes out. (Air flow volume is normal.)

Diagnosis ProcedureINFOID:0000000012430753

NOTE:

Perform self-diagnosis with CONSULT before performing sy mptom diagnosis. If any malfunction result or DTC

is detected, perform the corresponding diagnosis.

1.CHECK COOLING SYSTEM

1. Check engine coolant level and check for leakage. Refer to CO-8, "

Inspection".

2. Check radiator cap. Refer to CO-12, "

RADIATOR CAP : Inspection".

3. Check water flow sounds of the engine coolant. Refer to CO-9, "

Refilling".

Is the inspection result normal?

YES >> GO TO 2.

NO >> Refill engine coolant and repair or replace the parts depending on the inspection results.

2.CHECK HEATER HOSE

Check installation of heater hose by visually or touching.

Is the inspection result normal?

YES >> GO TO 3.

NO >> Repair or replace parts depending on the inspection results.

3.CHECK HEATER CORE

1. Check temperature of inlet hose and outlet hose of heater core.

2. Check that inlet side of heater core is hot and the outle t side is slightly lower than/almost equal to the inlet

side.

CAUTION:

Always perform the temperature inspection in a sh ort period of time because the engine coolant

temperature is very hot.

Is the inspection result normal?

YES >> GO TO 4.

NO >> Replace heater core. Refer to HA-35, "

HEATER CORE : Removal and Installation".

4.CHECK AIR LEAKAGE FROM EACH DUCT

Check duct and nozzle, etc. of air conditioning system for air leakage.

Is the inspection result normal?

YES >> Check air mix door cable inst allation and air mix door operation.

NO >> Repair or replace parts depending on the inspection results.

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 2044 of 3641

REFRIGERANTHA-19

< PERIODIC MAINTENANCE >

C

DE

F

G H

J

K L

M A

B

HA

N

O P

4. Press UV lamp switch (5) and check A/C system for re frigerant leaks. (Where refrigerant leaks occur, flu-

orescent leak detection dye appears green in color.)

WARNING:

Do not look directly into UV lamp light source.

NOTE:

• For continuous operating time of UV lamp, fo llow the manufacturer’s operating instructions.

• Illuminate pipe joints from different angles using UV lamp to check for leaks.

• Use a mirror in areas that are di fficult to see to check for leaks.

• Refrigerant leaks from the evaporator can be detected by soaking a cotton swab or similar material with

drain hose water and illuminating it using the UV lamp.

• Dust, dirt, and packing material adhesives used for condenser, evaporator, and other components may fluoresce. Be careful not to misidentify leaks.

5. Repair or replace parts where refrigerant lea ks occur and wipe off fluorescent leak detection dye.

NOTE:

Completely wipe off fluorescent leak detection dye from gaps between parts, screw threads, and other

components using a cotton swab or similar material.

6. Use a UV lamp to check that no fluorescent leak detection dye remains after finishing work. WARNING:

Do not look directly into UV lamp light source.

NOTE:

• For continuous operating time of UV lamp, fo llow the manufacturer’s operating instructions.

• Dust, dirt, and packing material adhesives used for condenser, evaporator, and other components may

fluoresce. Be careful not to misidentify leaks.

CHECK REFRIGERANT LEAKS USING ELECTRONIC LEAK DETECTOR

WARNING:

Do not check for refrigerant leaks while the engine is running.

CAUTION:

Be careful of the following items so that in accurate checks or misidentifications are avoided.

• Do not allow refrigerant vapor, shop chemical vapors, cigarette smoke or other contaminates around the vehicle.

• Always check refrigerant leaks in a low air flow en vironment so that refrigerant may not disperse.

1. Stop the engine.

2. Connect recovery/recycling/recharging equipment or manifold gauge set to the A/C service valves.

3. Check that A/C refrigerant pressure is 345 kPa (3.52 kg/cm

2, 50 psi) or more when temperature is 16 °C

(61 °F) or more. When pressure is lower than the specified value, recycle refrigerant completely and

recharge refrigerant to the specified level.

NOTE:

Leaks may not be detected if A/C refriger ant pressure is 345 kPa (3.52 kg/cm

2, 50 psi) or less when tem-

perature is less than 16° C (61°F).

4. Clean the area where the refrigerant leak check is performed and check for refrigerant leaks along all sur- faces of pipe connections and A/C system co mponents using electronic leak detector probe.

CAUTION:

• Continue checking once leaks are found. Always co ntinue and complete checking along all pipe

connections and A/C system comp onents for additional leaks.

• When leaks are detected, clean leak ar ea using compressed air and re-check.

• When checking the evaporator for leaks, always clean inside of drain hose so that the probe sur-

face may not be exposed to water or dirt.

NOTE:

• Always check for leaks starting from the high-pressure side and continue to the low-pressure side.

• When checking the evaporator for leaks, operate blower motor for 15 minut\

es or more at the maximum speed while the engine is stopped. Insert electronic leak detector probe into drain hose and hold for 10

minutes or more.

• When disconnecting shut-off valve that is connected to A/C service valve, always evacuate remaining

refrigerant so that misidentification can be avoided.

5. Repair or replace parts where refrigerant leaks occur.

6. Start the engine and set A/C control in the following conditions. • A/C switch: ON

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 2049 of 3641

HA-24

< PERIODIC MAINTENANCE >

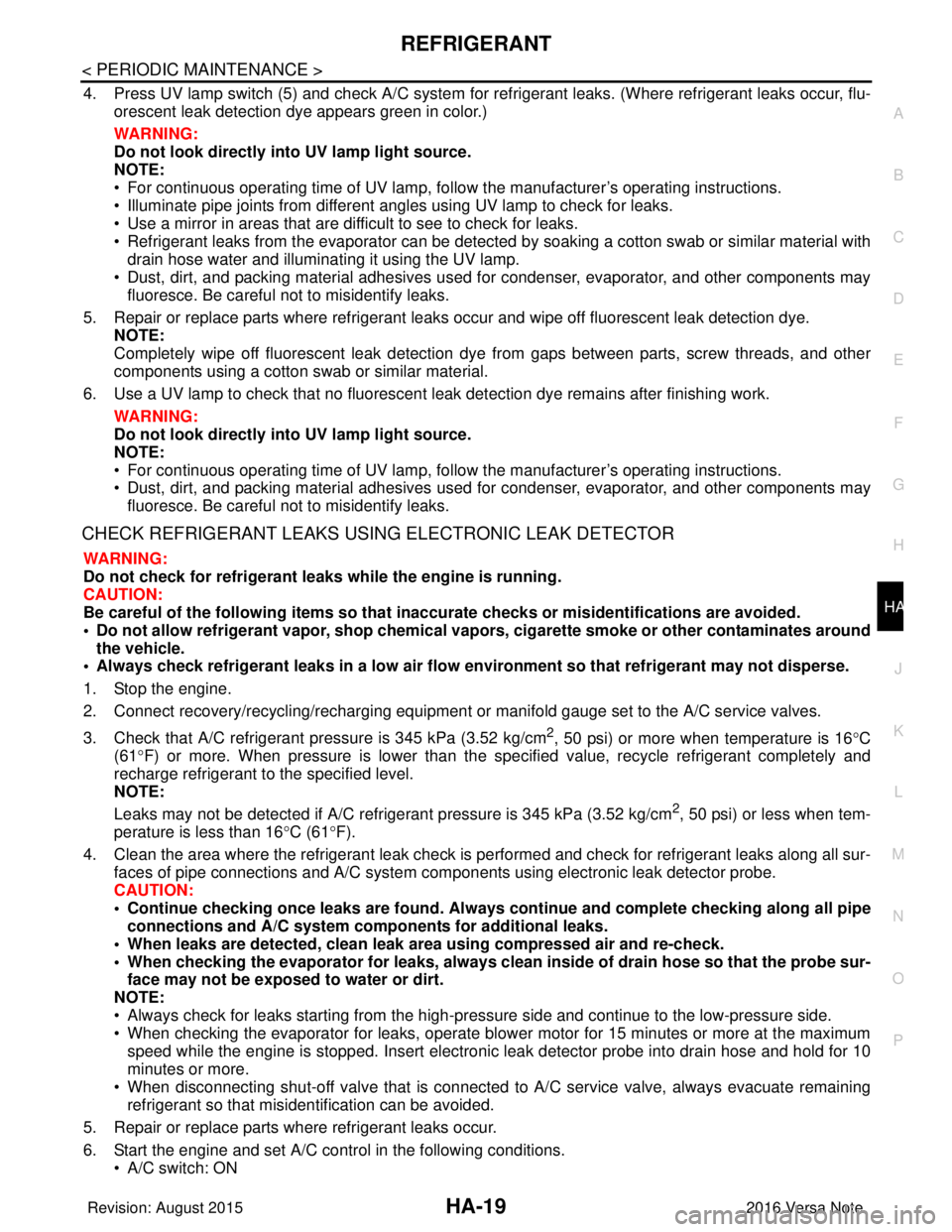

PERFORMANCE TEST

PERFORMANCE TEST

InspectionINFOID:0000000012432006

INSPECTION PROCEDURE

1. Connect recovery/recycling/recharging equipment (for HFC-134a) or manifold gauge set.

2. Start the engine, and set to the following condition.

Test condition

3. Maintain test condition until A/C system becomes stable. (Approximately 10 minutes)

4. Check that test results of “recirculating-to-disc harge air temperature” and “ambient air temperature-to-

operating pressure” are within the specified value.

5. When test results are within the spec ified value, inspection is complete.

If any test result is out of the specified val ue, perform diagnosis by manifold gauge set. Refer to HA-15,

"Symptom Table".

RECIRCULATING-TO-DISCHARGE AIR TEMPERATURE TABLE

FRONT

AMBIENT AIR TEMPERATURE-TO-OPERATING PRESSURE TABLE

Surrounding condition In a well-ventilated place away from direct sunlight.

Vehicle condition Doors

Closed

Door glass Closed

Hood Open

Engine speed Idle speed

A/C condition (front/rear) Temperature control

Full cold

A/C switch ON

Air outlet VENT (ventilation)

Intake door position Recirculation

Blower speed Maximum

Inside air (Recirculating air) at blower assembly inlet

Discharge air temperature from center ventilator

°C ( °F)

Relative humidity

% Air temperature

°C ( °F)

50 – 60 20 (68)

4.7 - 6.7 (40 - 44)

25 (77) 8.6 - 11.1 (47 - 52)

30 (86) 12.6 - 15.6 (55 - 60)

35 (95) 19.0 - 22.5 (66 - 73)

60 – 70 20 (68)

6.7 - 8.7 (44 - 48)

25 (77) 11.1 - 13.6 (52 - 56)

30 (86) 15.6 - 18.6 (60 - 65)

35 (95) 22.5 - 26.0 (73 - 79)

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 2332 of 3641

ENGINE MAINTENANCEMA-17

< PERIODIC MAINTENANCE >

C

DE

F

G H

I

J

K L

M B

MA

N

O A

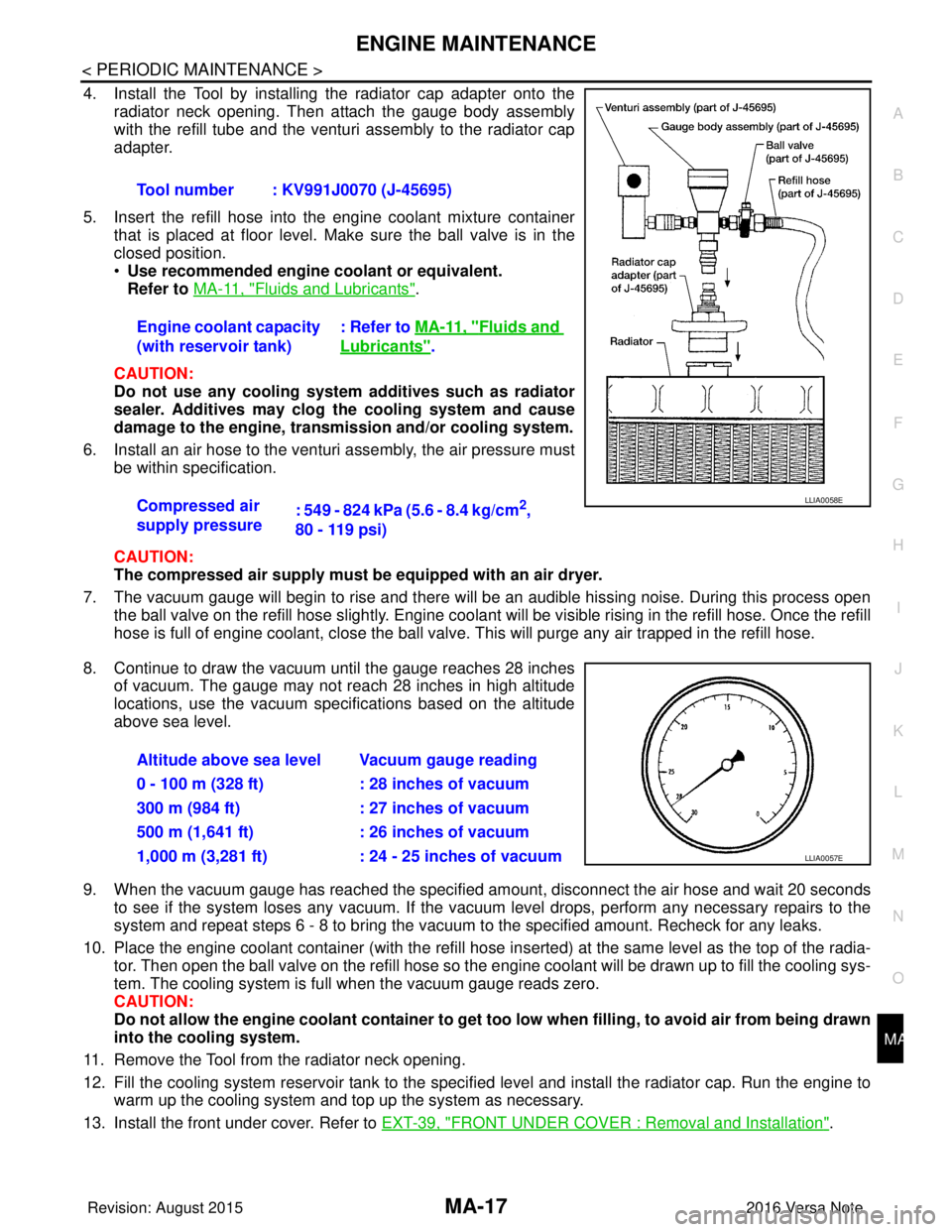

4. Install the Tool by installing the radiator cap adapter onto the

radiator neck opening. Then attach the gauge body assembly

with the refill tube and the venturi assembly to the radiator cap

adapter.

5. Insert the refill hose into the engine coolant mixture container that is placed at floor level. Make sure the ball valve is in the

closed position.

•Use recommended engine coolant or equivalent.

Refer to MA-11, "

Fluids and Lubricants".

CAUTION:

Do not use any cooling system additives such as radiator

sealer. Additives may clog the cooling system and cause

damage to the engine, transmission and/or cooling system.

6. Install an air hose to the venturi assembly, the air pressure must be within specification.

CAUTION:

The compressed air supply must be equipped with an air dryer.

7. The vacuum gauge will begin to rise and there will be an audible hissing noise. During this process open the ball valve on the refill hose slightly. Engine coolant will be visible rising in the refill hose. Once the refill

hose is full of engine coolant, close the ball valve. This will purge any air trapped in the refill hose.

8. Continue to draw the vacuum until the gauge reaches 28 inches of vacuum. The gauge may not reach 28 inches in high altitude

locations, use the vacuum specifications based on the altitude

above sea level.

9. When the vacuum gauge has reached the specified amount, disconnect the air hose and wait 20 seconds

to see if the system loses any vacuum. If the vacuum level drops, perform any necessary repairs to the

system and repeat steps 6 - 8 to br ing the vacuum to the specified amount. Recheck for any leaks.

10. Place the engine coolant container (with the refill hose in serted) at the same level as the top of the radia-

tor. Then open the ball valve on the refill hose so the engine coolant will be drawn up to fill the cooling sys-

tem. The cooling system is full when the vacuum gauge reads zero.

CAUTION:

Do not allow the engine coolant co ntainer to get too low when filling, to avoid air from being drawn

into the cooling system.

11. Remove the Tool from the radiator neck opening.

12. Fill the cooling system reservoir tank to the specif ied level and install the radiator cap. Run the engine to

warm up the cooling system and top up the system as necessary.

13. Install the front under cover. Refer to EXT-39, "

FRONT UNDER COVER : Removal and Installation".

Tool number : KV991J0070 (J-45695)

Engine coolant capacity

(with reservoir tank)

: Refer to

MA-11, "

Fluids and

Lubricants".

Compressed air

supply pressure : 549 - 824 kPa (5.6 - 8.4 kg/cm

2,

80 - 119 psi)LLIA0058E

Altitude above sea level Vacuum gauge reading

0 - 100 m (328 ft) : 28 inches of vacuum

300 m (984 ft) : 27 inches of vacuum

500 m (1,641 ft) : 26 inches of vacuum

1,000 m (3,281 ft) : 24 - 25 inches of vacuum

LLIA0057E

Revision: August 2015 2016 Versa Note

cardiagn.com