power steering NISSAN NOTE 2016 Service Manual PDF

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2016, Model line: NOTE, Model: NISSAN NOTE 2016Pages: 3641, PDF Size: 28.72 MB

Page 1905 of 3641

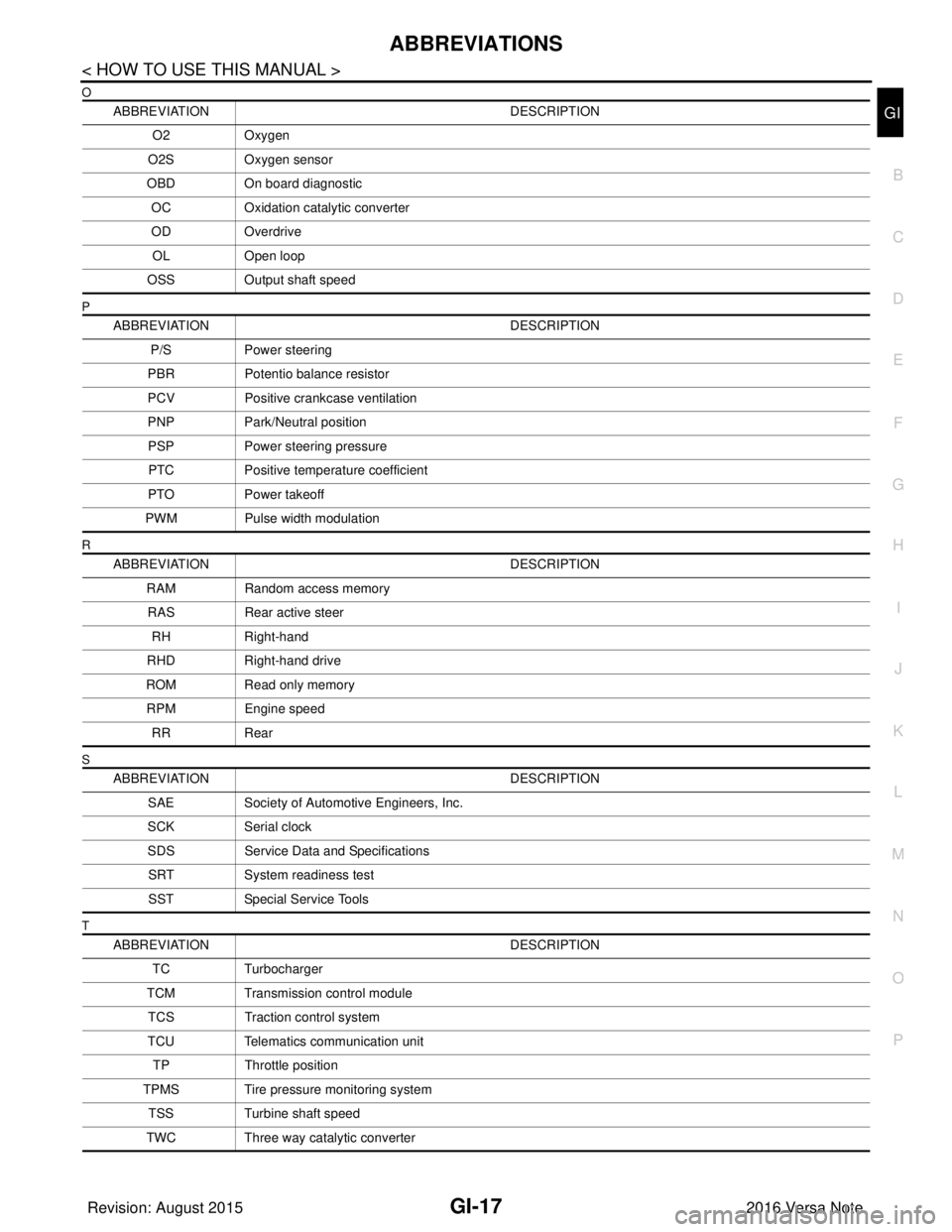

ABBREVIATIONSGI-17

< HOW TO USE THIS MANUAL >

C

DE

F

G H

I

J

K L

M B

GI

N

O P

O

P

R

S

T

ABBREVIATION DESCRIPTION

O2 Oxygen

O2S Oxygen sensor

OBD On board diagnostic

OC Oxidation catalytic converter

OD Overdrive

OL Open loop

OSS Output shaft speed

ABBREVIATION DESCRIPTION

P/S Power steering

PBR Potentio balance resistor

PCV Positive crankcase ventilation

PNP Park/Neutral position

PSP Power steering pressure

PTC Positive temperature coefficient

PTO Power takeoff

PWM Pulse width modulation

ABBREVIATION DESCRIPTION

RAM Random access memory

RAS Rear active steer

RH Right-hand

RHD Right-hand drive

ROM Read only memory

RPM Engine speed

RR Rear

ABBREVIATION DESCRIPTION

SAE Society of Automoti ve Engineers, Inc.

SCK Serial clock

SDS Service Data and Specifications

SRT System readiness test

SST Special Service Tools

ABBREVIATION DESCRIPTION

TC Turbocharger

TCM Transmission control module

TCS Traction control system

TCU Telematics communication unit

TP Throttle position

TPMS Tire pressure monitoring system TSS Turbine shaft speed

TWC Three way catalytic converter

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 2242 of 3641

![NISSAN NOTE 2016 Service Manual PDF LAN-54

< DTC/CIRCUIT DIAGNOSIS >[CAN]

STRG BRANCH LINE CIRCUIT

STRG BRANCH LINE CIRCUIT

Diagnosis ProcedureINFOID:0000000012433368

1.CHECK CONNECTOR

1. Turn the ignition switch OFF.

2. Disconnect the NISSAN NOTE 2016 Service Manual PDF LAN-54

< DTC/CIRCUIT DIAGNOSIS >[CAN]

STRG BRANCH LINE CIRCUIT

STRG BRANCH LINE CIRCUIT

Diagnosis ProcedureINFOID:0000000012433368

1.CHECK CONNECTOR

1. Turn the ignition switch OFF.

2. Disconnect the](/img/5/57363/w960_57363-2241.png)

LAN-54

< DTC/CIRCUIT DIAGNOSIS >[CAN]

STRG BRANCH LINE CIRCUIT

STRG BRANCH LINE CIRCUIT

Diagnosis ProcedureINFOID:0000000012433368

1.CHECK CONNECTOR

1. Turn the ignition switch OFF.

2. Disconnect the battery cable from the negative terminal.

3. Check the terminals and connectors of the steering angle sensor for damage, bend and loose connection (unit side and connector side).

Is the inspection result normal?

YES >> GO TO 2.

NO >> Repair the terminal and connector.

2.CHECK HARNESS FOR OPEN CIRCUIT

1. Disconnect the connector of steering angle sensor.

2. Check the resistance between the steeri ng angle sensor harness connector terminals.

Is the measurement value within the specification?

YES >> GO TO 3.

NO >> Repair the steering angle sensor branch line.

3.CHECK POWER SUPPLY AND GROUND CIRCUIT

Check the power supply and the ground circuit of the steering angle sensor. Refer to BRC-44, "

Wiring Dia-

gram".

Is the inspection result normal?

YES (Present error)>>Replace the steering angle sensor. Refer to BRC-147, "Removal and Installation".

YES (Past error)>>Error was detected in the steering angle sensor branch line.

NO >> Repair the power supply and the ground circuit.

Steering angle sensor harness connector Resistance (Ω)

Connector No. Terminal No.

M64 5 2 Approx. 54 – 66

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 2254 of 3641

![NISSAN NOTE 2016 Service Manual PDF LAN-66

< DTC/CIRCUIT DIAGNOSIS >[CAN SYSTEM (TYPE 501)]

STRG BRANCH LINE CIRCUIT

STRG BRANCH LINE CIRCUIT

Diagnosis ProcedureINFOID:0000000012785686

1.CHECK CONNECTOR

1. Turn the ignition switch OFF.

NISSAN NOTE 2016 Service Manual PDF LAN-66

< DTC/CIRCUIT DIAGNOSIS >[CAN SYSTEM (TYPE 501)]

STRG BRANCH LINE CIRCUIT

STRG BRANCH LINE CIRCUIT

Diagnosis ProcedureINFOID:0000000012785686

1.CHECK CONNECTOR

1. Turn the ignition switch OFF.](/img/5/57363/w960_57363-2253.png)

LAN-66

< DTC/CIRCUIT DIAGNOSIS >[CAN SYSTEM (TYPE 501)]

STRG BRANCH LINE CIRCUIT

STRG BRANCH LINE CIRCUIT

Diagnosis ProcedureINFOID:0000000012785686

1.CHECK CONNECTOR

1. Turn the ignition switch OFF.

2. Disconnect the battery cable from the negative terminal.

3. Check the terminals and connectors of the steering angle sensor for damage, bend and loose connection (unit side and connector side).

Is the inspection result normal?

YES >> GO TO 2.

NO >> Repair the terminal and connector.

2.CHECK HARNESS FOR OPEN CIRCUIT

1. Disconnect the connector of steering angle sensor.

2. Check the resistance between the steeri ng angle sensor harness connector terminals.

Is the measurement value within the specification?

YES >> GO TO 3.

NO >> Repair the steering angle sensor branch line.

3.CHECK POWER SUPPLY AND GROUND CIRCUIT

Check the power supply and the ground circuit of the steering angle sensor. Refer to BRC-44, "

Wiring Dia-

gram".

Is the inspection result normal?

YES (Present error)>>Replace the steering angle sensor. Refer to BRC-147, "Removal and Installation".

YES (Past error)>>Error was detected in the steering angle sensor branch line.

NO >> Repair the power supply and the ground circuit.

Steering angle sensor harness connector Resistance (Ω)

Connector No. Terminal No.

M64 5 2 Approx. 54 – 66

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 2269 of 3641

![NISSAN NOTE 2016 Service Manual PDF LAN

STRG BRANCH LINE CIRCUITLAN-81

< DTC/CIRCUIT DIAGNOSIS > [CAN SYSTEM (TYPE 502)]

C

D

E

F

G H

I

J

K L

B A

O P

N

STRG BRANCH

LINE CIRCUIT

Diagnosis ProcedureINFOID:0000000012785706

1.CHECK CONNECTO NISSAN NOTE 2016 Service Manual PDF LAN

STRG BRANCH LINE CIRCUITLAN-81

< DTC/CIRCUIT DIAGNOSIS > [CAN SYSTEM (TYPE 502)]

C

D

E

F

G H

I

J

K L

B A

O P

N

STRG BRANCH

LINE CIRCUIT

Diagnosis ProcedureINFOID:0000000012785706

1.CHECK CONNECTO](/img/5/57363/w960_57363-2268.png)

LAN

STRG BRANCH LINE CIRCUITLAN-81

< DTC/CIRCUIT DIAGNOSIS > [CAN SYSTEM (TYPE 502)]

C

D

E

F

G H

I

J

K L

B A

O P

N

STRG BRANCH

LINE CIRCUIT

Diagnosis ProcedureINFOID:0000000012785706

1.CHECK CONNECTOR

1. Turn the ignition switch OFF.

2. Disconnect the battery cabl e from the negative terminal.

3. Check the terminals and connectors of the steer ing angle sensor for damage, bend and loose connection

(unit side and connector side).

Is the inspection result normal?

YES >> GO TO 2.

NO >> Repair the terminal and connector.

2.CHECK HARNESS FOR OPEN CIRCUIT

1. Disconnect the connector of steering angle sensor.

2. Check the resistance between the steering angle sensor harness connector terminals.

Is the measurement value within the specification?

YES >> GO TO 3.

NO >> Repair the steering angle sensor branch line.

3.CHECK POWER SUPPLY AND GROUND CIRCUIT

Check the power supply and the ground circuit of the steering angle sensor. Refer to BRC-44, "

Wiring Dia-

gram".

Is the inspection result normal?

YES (Present error)>>Replace the steering angle sensor. Refer to BRC-147, "Removal and Installation".

YES (Past error)>>Error was detected in the steering angle sensor branch line.

NO >> Repair the power supply and the ground circuit.

Steering angle sensor harness connector Resistance (Ω)

Connector No. Terminal No.

M64 5 2 Approx. 54 – 66

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 2282 of 3641

![NISSAN NOTE 2016 Service Manual PDF LAN-94

< DTC/CIRCUIT DIAGNOSIS >[CAN SYSTEM (TYPE 503)]

STRG BRANCH LINE CIRCUIT

STRG BRANCH LINE CIRCUIT

Diagnosis ProcedureINFOID:0000000012785719

1.CHECK CONNECTOR

1. Turn the ignition switch OFF.

NISSAN NOTE 2016 Service Manual PDF LAN-94

< DTC/CIRCUIT DIAGNOSIS >[CAN SYSTEM (TYPE 503)]

STRG BRANCH LINE CIRCUIT

STRG BRANCH LINE CIRCUIT

Diagnosis ProcedureINFOID:0000000012785719

1.CHECK CONNECTOR

1. Turn the ignition switch OFF.](/img/5/57363/w960_57363-2281.png)

LAN-94

< DTC/CIRCUIT DIAGNOSIS >[CAN SYSTEM (TYPE 503)]

STRG BRANCH LINE CIRCUIT

STRG BRANCH LINE CIRCUIT

Diagnosis ProcedureINFOID:0000000012785719

1.CHECK CONNECTOR

1. Turn the ignition switch OFF.

2. Disconnect the battery cable from the negative terminal.

3. Check the terminals and connectors of the steering angle sensor for damage, bend and loose connection (unit side and connector side).

Is the inspection result normal?

YES >> GO TO 2.

NO >> Repair the terminal and connector.

2.CHECK HARNESS FOR OPEN CIRCUIT

1. Disconnect the connector of steering angle sensor.

2. Check the resistance between the steeri ng angle sensor harness connector terminals.

Is the measurement value within the specification?

YES >> GO TO 3.

NO >> Repair the steering angle sensor branch line.

3.CHECK POWER SUPPLY AND GROUND CIRCUIT

Check the power supply and the ground circuit of the steering angle sensor. Refer to BRC-44, "

Wiring Dia-

gram".

Is the inspection result normal?

YES (Present error)>>Replace the steering angle sensor. Refer to BRC-147, "Removal and Installation".

YES (Past error)>>Error was detected in the steering angle sensor branch line.

NO >> Repair the power supply and the ground circuit.

Steering angle sensor harness connector Resistance (Ω)

Connector No. Terminal No.

M64 5 2 Approx. 54 – 66

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 2298 of 3641

![NISSAN NOTE 2016 Service Manual PDF LAN-110

< DTC/CIRCUIT DIAGNOSIS >[CAN SYSTEM (TYPE 504)]

STRG BRANCH LINE CIRCUIT

STRG BRANCH LINE CIRCUIT

Diagnosis ProcedureINFOID:0000000012785747

1.CHECK CONNECTOR

1. Turn the ignition switch OFF. NISSAN NOTE 2016 Service Manual PDF LAN-110

< DTC/CIRCUIT DIAGNOSIS >[CAN SYSTEM (TYPE 504)]

STRG BRANCH LINE CIRCUIT

STRG BRANCH LINE CIRCUIT

Diagnosis ProcedureINFOID:0000000012785747

1.CHECK CONNECTOR

1. Turn the ignition switch OFF.](/img/5/57363/w960_57363-2297.png)

LAN-110

< DTC/CIRCUIT DIAGNOSIS >[CAN SYSTEM (TYPE 504)]

STRG BRANCH LINE CIRCUIT

STRG BRANCH LINE CIRCUIT

Diagnosis ProcedureINFOID:0000000012785747

1.CHECK CONNECTOR

1. Turn the ignition switch OFF.

2. Disconnect the battery cable from the negative terminal.

3. Check the terminals and connectors of the steering angle sensor for damage, bend and loose connection (unit side and connector side).

Is the inspection result normal?

YES >> GO TO 2.

NO >> Repair the terminal and connector.

2.CHECK HARNESS FOR OPEN CIRCUIT

1. Disconnect the connector of steering angle sensor.

2. Check the resistance between the steeri ng angle sensor harness connector terminals.

Is the measurement value within the specification?

YES >> GO TO 3.

NO >> Repair the steering angle sensor branch line.

3.CHECK POWER SUPPLY AND GROUND CIRCUIT

Check the power supply and the ground circuit of the steering angle sensor. Refer to BRC-44, "

Wiring Dia-

gram".

Is the inspection result normal?

YES (Present error)>>Replace the steering angle sensor. Refer to BRC-147, "Removal and Installation".

YES (Past error)>>Error was detected in the steering angle sensor branch line.

NO >> Repair the power supply and the ground circuit.

Steering angle sensor harness connector Resistance (Ω)

Connector No. Terminal No.

M64 5 2 Approx. 54 – 66

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 2312 of 3641

![NISSAN NOTE 2016 Service Manual PDF LAN-124

< DTC/CIRCUIT DIAGNOSIS >[CAN SYSTEM (TYPE 505)]

STRG BRANCH LINE CIRCUIT

STRG BRANCH LINE CIRCUIT

Diagnosis ProcedureINFOID:0000000012785732

1.CHECK CONNECTOR

1. Turn the ignition switch OFF. NISSAN NOTE 2016 Service Manual PDF LAN-124

< DTC/CIRCUIT DIAGNOSIS >[CAN SYSTEM (TYPE 505)]

STRG BRANCH LINE CIRCUIT

STRG BRANCH LINE CIRCUIT

Diagnosis ProcedureINFOID:0000000012785732

1.CHECK CONNECTOR

1. Turn the ignition switch OFF.](/img/5/57363/w960_57363-2311.png)

LAN-124

< DTC/CIRCUIT DIAGNOSIS >[CAN SYSTEM (TYPE 505)]

STRG BRANCH LINE CIRCUIT

STRG BRANCH LINE CIRCUIT

Diagnosis ProcedureINFOID:0000000012785732

1.CHECK CONNECTOR

1. Turn the ignition switch OFF.

2. Disconnect the battery cable from the negative terminal.

3. Check the terminals and connectors of the steering angle sensor for damage, bend and loose connection (unit side and connector side).

Is the inspection result normal?

YES >> GO TO 2.

NO >> Repair the terminal and connector.

2.CHECK HARNESS FOR OPEN CIRCUIT

1. Disconnect the connector of steering angle sensor.

2. Check the resistance between the steeri ng angle sensor harness connector terminals.

Is the measurement value within the specification?

YES >> GO TO 3.

NO >> Repair the steering angle sensor branch line.

3.CHECK POWER SUPPLY AND GROUND CIRCUIT

Check the power supply and the ground circuit of the steering angle sensor. Refer to BRC-44, "

Wiring Dia-

gram".

Is the inspection result normal?

YES (Present error)>>Replace the steering angle sensor. Refer to BRC-147, "Removal and Installation".

YES (Past error)>>Error was detected in the steering angle sensor branch line.

NO >> Repair the power supply and the ground circuit.

Steering angle sensor harness connector Resistance (Ω)

Connector No. Terminal No.

M64 5 2 Approx. 54 – 66

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 2361 of 3641

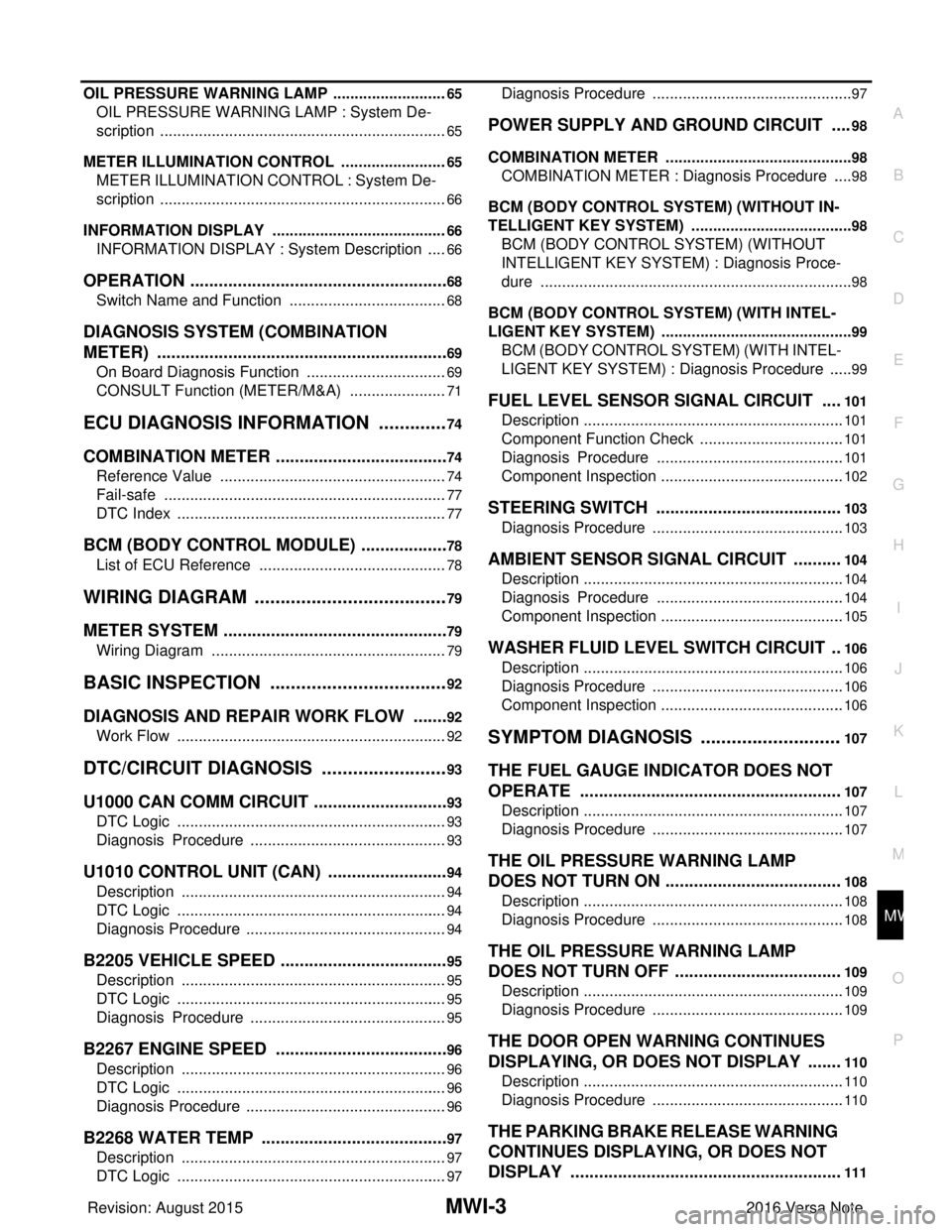

MWI

MWI-3

C

DE

F

G H

I

J

K L

M B

A

O P

OIL PRESSURE WARNING

LAMP ...........................

65

OIL PRESSURE WARNING LAMP : System De-

scription ............................................................... ....

65

METER ILLUMINATION CONTROL ..................... ....65

METER ILLUMINATION CONTROL : System De-

scription ...................................................................

66

INFORMATION DISPLAY ..................................... ....66

INFORMATION DISPLAY : System Description .....66

OPERATION ................................................... ....68

Switch Name and Function ................................. ....68

DIAGNOSIS SYSTEM (COMBINATION

METER) ..............................................................

69

On Board Diagnosis Function ............................. ....69

CONSULT Function (METER/M&A) .......................71

ECU DIAGNOSIS INFORMATION ..............74

COMBINATION METER ................................. ....74

Reference Value ................................................. ....74

Fail-safe ..................................................................77

DTC Index ...............................................................77

BCM (BODY CONTROL MODULE) ...................78

List of ECU Reference ........................................ ....78

WIRING DIAGRAM ......................................79

METER SYSTEM ............................................ ....79

Wiring Diagram ................................................... ....79

BASIC INSPECTION ...................................92

DIAGNOSIS AND REPAIR WORK FLOW .... ....92

Work Flow ........................................................... ....92

DTC/CIRCUIT DIAGNOSIS .........................93

U1000 CAN COMM CI RCUIT .............................93

DTC Logic ........................................................... ....93

Diagnosis Procedure ..............................................93

U1010 CONTROL UNIT (CAN) ..........................94

Description ..............................................................94

DTC Logic ...............................................................94

Diagnosis Procedure ...............................................94

B2205 VEHICLE SPEED ....................................95

Description ..............................................................95

DTC Logic ...............................................................95

Diagnosis Procedure ..............................................95

B2267 ENGINE SPEED .....................................96

Description .......................................................... ....96

DTC Logic ...............................................................96

Diagnosis Procedure ...............................................96

B2268 WATER TEMP ........................................97

Description .......................................................... ....97

DTC Logic ...............................................................97

Diagnosis Procedure ........................................... ....97

POWER SUPPLY AND GROUND CIRCUIT ....98

COMBINATION METER ........................................ ....98

COMBINATION METER : Diagnosis Procedure .....98

BCM (BODY CONTROL SYSTEM) (WITHOUT IN-

TELLIGENT KEY SYSTEM) .................................. ....

98

BCM (BODY CONTROL SYSTEM) (WITHOUT

INTELLIGENT KEY SYSTEM) : Diagnosis Proce-

dure ..................................................................... ....

98

BCM (BODY CONTROL SYSTEM) (WITH INTEL-

LIGENT KEY SYSTEM) .............................................

99

BCM (BODY CONTROL SYSTEM) (WITH INTEL-

LIGENT KEY SYSTEM) : Diagnosis Procedure .. ....

99

FUEL LEVEL SENSOR SIGNAL CIRCUIT ....101

Description .............................................................101

Component Function Check ..................................101

Diagnosis Procedure ............................................101

Component Inspection ...........................................102

STEERING SWITCH .......................................103

Diagnosis Procedure .............................................103

AMBIENT SENSOR SIGNAL CIRCUIT ..........104

Description .............................................................104

Diagnosis Procedure ............................................104

Component Inspection ...........................................105

WASHER FLUID LEVEL SWITCH CIRCUIT ..106

Description .............................................................106

Diagnosis Procedure .............................................106

Component Inspection ...........................................106

SYMPTOM DIAGNOSIS ............................107

THE FUEL GAUGE INDICATOR DOES NOT

OPERATE .......................................................

107

Description ........................................................... ..107

Diagnosis Procedure .............................................107

THE OIL PRESSURE WARNING LAMP

DOES NOT TURN ON .....................................

108

Description .............................................................108

Diagnosis Procedure .............................................108

THE OIL PRESSURE WARNING LAMP

DOES NOT TURN OFF ...................................

109

Description .............................................................109

Diagnosis Procedure .............................................109

THE DOOR OPEN WARNING CONTINUES

DISPLAYING, OR DOES NOT DISPLAY .......

110

Description .............................................................110

Diagnosis Procedure .............................................110

THE PARKING BRAKE RELEASE WARNING

CONTINUES DISPLAYING, OR DOES NOT

DISPLAY .........................................................

111

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 2434 of 3641

![NISSAN NOTE 2016 Service Manual PDF MWI-76

< ECU DIAGNOSIS INFORMATION >[TYPE B]

COMBINATION METER

TERMINAL LAYOUT

PHYSICAL VALUES

JSNIA5390ZZ

Te r m i n a l

No. Wire

color Item Condition

Reference value (V)

(Approx.)

Ignition

switch NISSAN NOTE 2016 Service Manual PDF MWI-76

< ECU DIAGNOSIS INFORMATION >[TYPE B]

COMBINATION METER

TERMINAL LAYOUT

PHYSICAL VALUES

JSNIA5390ZZ

Te r m i n a l

No. Wire

color Item Condition

Reference value (V)

(Approx.)

Ignition

switch](/img/5/57363/w960_57363-2433.png)

MWI-76

< ECU DIAGNOSIS INFORMATION >[TYPE B]

COMBINATION METER

TERMINAL LAYOUT

PHYSICAL VALUES

JSNIA5390ZZ

Te r m i n a l

No. Wire

color Item Condition

Reference value (V)

(Approx.)

Ignition

switch Operation or condition

1 L CAN high —— —

2 P CAN low —— —

4LG8P/R — — —

6 W Fuel level sensor signal (+) — —Refer to

MWI-102, "

Component Inspec-

tion".

7VAir bag — — —

8 P O/D OFF switch ONO/D OFF switch pressed

0

O/D OFF switch released Battery voltage

9 V Seat belt buckle switch LH ON Unfastened (ON)

0

Fastened (OFF) Battery voltage

10 SB Parking Brake switch ONParking brake is inactive

Battery voltage

Parking brake is active 0

11 BR Brake fluid level switch ON Brake fluid level low

0

Brake fluid level normal Battery voltage

15 R Ignition switch ON or ACC — —Battery voltage

16 B Illumination control switch (-) — ——

17

*1V Washer fluid level switch ON Washer fluid level low 0

Washer fluid level normal

Battery voltage

18 GR Security —— —

19 V Ambient sensor signal (+) ON ——

20 R Ambient sensor ground (-) — —0

21 B Ground —— 0

22 B

23 B

24 GR Fuel level sensor ground (-) ON —0

27 R/W Battery power supply OFF— Battery voltage

28 GR Ignition switch ON or START ON —Battery voltage

29 G Seat belt buckle switch RH ON Unfastened (ON)

0

Fastened (OFF) Battery voltage

36 LG Steering switch

(meter control switch)

——

—

38 Y Generator ONGenerator voltage low

0

Generator voltage no rmalBattery voltage

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 2631 of 3641

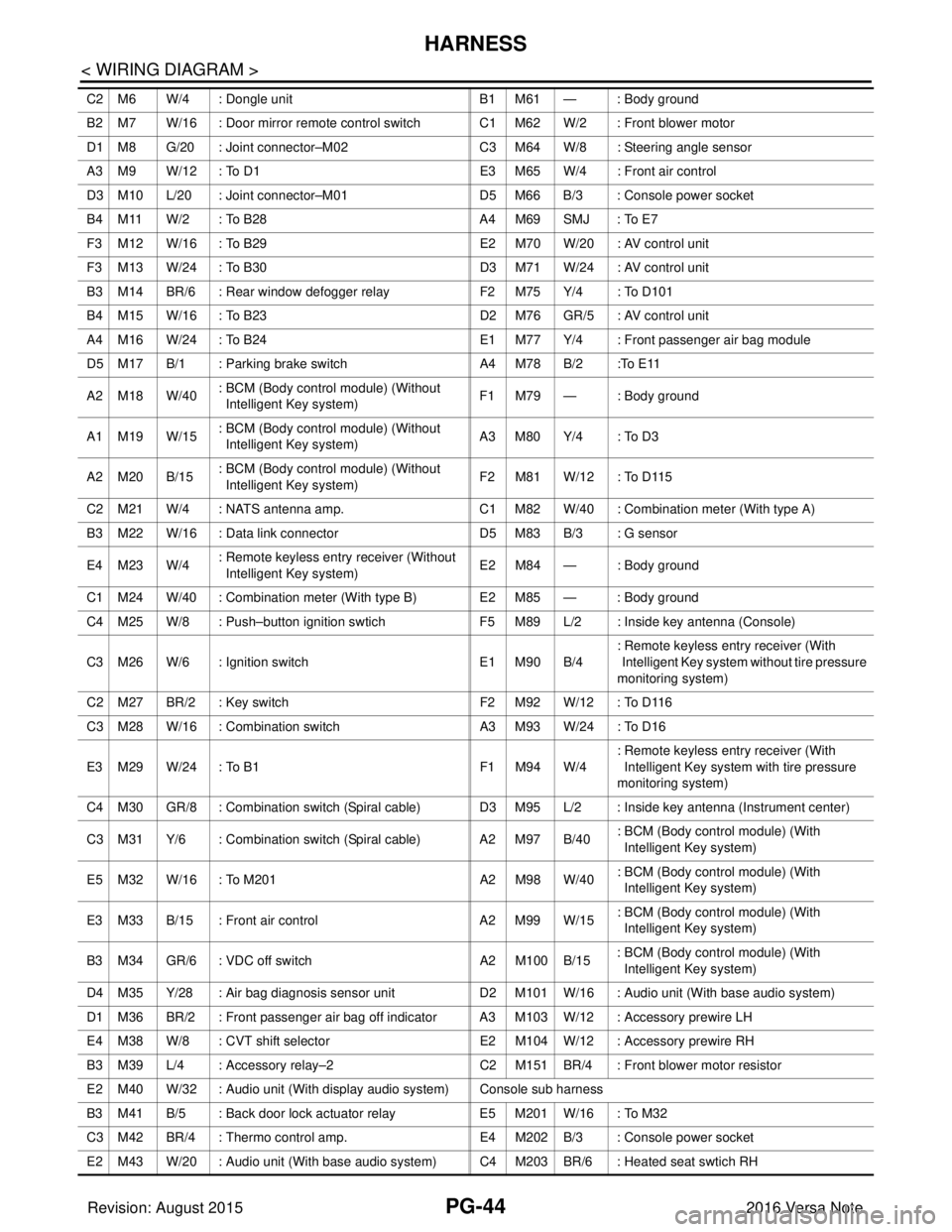

PG-44

< WIRING DIAGRAM >

HARNESS

C2 M6 W/4 : Dongle unitB1 M61 — : Body ground

B2 M7 W/16 : Door mirror remote control switch C1 M62 W/2 : Front blower motor

D1 M8 G/20 : Joint connector–M02 C3 M64 W/8 : Steering angle sensor

A3 M9 W/12 : To D1 E3 M65 W/4 : Front air control

D3 M10 L/20 : Joint connector–M01 D5 M66 B/3 : Console power socket

B4 M11 W/2 : To B28 A4 M69 SMJ : To E7

F3 M12 W/16 : To B29 E2 M70 W/20 : AV control unit

F3 M13 W/24 : To B30 D3 M71 W/24 : AV control unit

B3 M14 BR/6 : Rear window defogger relay F2 M75 Y/4 : To D101

B4 M15 W/16 : To B23 D2 M76 GR/5 : AV control unit

A4 M16 W/24 : To B24 E1 M77 Y/4 : Front passenger air bag module

D5 M17 B/1 : Parking brake switch A4 M78 B/2 :To E11

A2 M18 W/40 : BCM (Body contro

l module) (Without

Intelligent Key system) F1 M79 — : Body ground

A1 M19 W/15 : BCM (Body contro

l module) (Without

Intelligent Key system) A 3 M 8 0 Y / 4 : T o D 3

A2 M20 B/15 : BCM (Body contro

l module) (Without

Intelligent Key system) F2 M81 W/12 : To D115

C2 M21 W/4 : NATS antenna amp. C1 M82 W/40 : Combination meter (With type A)

B3 M22 W/16 : Data link connector D5 M83 B/3 : G sensor

E 4 M 2 3 W / 4 : Remote keyless entry receiver (Without

Intelligent Key system) E2 M84 — : Body ground

C1 M24 W/40 : Combination meter (With type B) E2 M85 — : Body ground

C4 M25 W/8 : Push–button ignition swtich F5 M89 L/2 : Inside key antenna (Console)

C3 M26 W/6 : Ignition switch E1 M90 B/4: Remote keyless entry receiver (With

Intelligent Key system without tire pressure

monitoring system)

C2 M27 BR/2 : Key switch F2 M92 W/12 : To D116

C3 M28 W/16 : Combination switch A3 M93 W/24 : To D16

E 3 M 2 9 W / 2 4 : T o B 1 F 1 M 9 4 W / 4: Remote keyless entry receiver (With

Intelligent Key system with tire pressure

monitoring system)

C4 M30 GR/8 : Combination switch (Spiral cable) D3 M95 L/2 : Inside key antenna (Instrument center)

C3 M31 Y/6 : Combination switch (Spiral cable) A2 M97 B/40 : BCM (Body contro

l module) (With

Intelligent Key system)

E5 M32 W/16 : To M201 A2 M98 W/40: BCM (Body contro

l module) (With

Intelligent Key system)

E3 M33 B/15 : Front air control A2 M99 W/15: BCM (Body contro

l module) (With

Intelligent Key system)

B3 M34 GR/6 : VDC off switch A2 M100 B / 1 5: BCM (Body contro

l module) (With

Intelligent Key system)

D4 M35 Y/28 : Air bag diagnosis sensor unit D2 M101 W/16 : Audio unit (With base audio system)

D1 M36 BR/2 : Front passenger air bag off indicator A3 M103 W/12 : Accessory prewire LH

E4 M38 W/8 : CVT shift selector E2 M104 W/12 : Accessory prewire RH

B3 M39 L/4 : Accessory relay–2 C2 M151 BR/4 : Front blower motor resistor

E2 M40 W/32 : Audio unit (With display audio system) Console sub harness

B3 M41 B/5 : Back door lock actuator relay E5 M201 W / 1 6 : T o M 3 2

C3 M42 BR/4 : Thermo control amp. E4 M202 B/3 : Console power socket

E2 M43 W/20 : Audio unit (With base audio system) C4 M203 BR/6 : Heated seat swtich RH

Revision: August 2015 2016 Versa Note

cardiagn.com