key NISSAN NOTE 2016 Service Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2016, Model line: NOTE, Model: NISSAN NOTE 2016Pages: 3641, PDF Size: 28.72 MB

Page 3291 of 3641

![NISSAN NOTE 2016 Service Repair Manual TM-50

< UNIT DISASSEMBLY AND ASSEMBLY >[5MT: RS5F91R]

MAINSHAFT AND GEAR

• Be careful with the orientation of 1st-2nd coupling sleeve.

• Be careful with the orientatio

n of 3rd-4th synchronizer hu NISSAN NOTE 2016 Service Repair Manual TM-50

< UNIT DISASSEMBLY AND ASSEMBLY >[5MT: RS5F91R]

MAINSHAFT AND GEAR

• Be careful with the orientation of 1st-2nd coupling sleeve.

• Be careful with the orientatio

n of 3rd-4th synchronizer hu](/img/5/57363/w960_57363-3290.png)

TM-50

< UNIT DISASSEMBLY AND ASSEMBLY >[5MT: RS5F91R]

MAINSHAFT AND GEAR

• Be careful with the orientation of 1st-2nd coupling sleeve.

• Be careful with the orientatio

n of 3rd-4th synchronizer hub.

• Replace 3rd-4th synchronize r hub and 3rd-4th coupling

sleeve as a set.

• Be careful with the orientation of insert key (1) and spring (2).

InspectionINFOID:0000000012430975

INSPECTION AFTER DISASSEMBLY

Mainshaft and Gear

Check the following items and replace if necessary.

• Damage, peeling, uneven wear, and distortion of shaft.

• Excessive wear, damage, and peeling of gear.

Synchronizer

Check the following items and replace if necessary.

(A) : 2nd main gear side

(B) : 1st main gear side

PCIB1567E

(A) : 4th main gear side

(B) : 3rd main gear side

PCIB1565E

PCIB1564E

SCIA1762J

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 3292 of 3641

![NISSAN NOTE 2016 Service Repair Manual MAINSHAFT AND GEARTM-51

< UNIT DISASSEMBLY AND ASSEMBLY > [5MT: RS5F91R]

C

EF

G H

I

J

K L

M A

B

TM

N

O P

• Contact surface breakage, damage, and unusual wear of coupling sleeve, synchronizer hub, in NISSAN NOTE 2016 Service Repair Manual MAINSHAFT AND GEARTM-51

< UNIT DISASSEMBLY AND ASSEMBLY > [5MT: RS5F91R]

C

EF

G H

I

J

K L

M A

B

TM

N

O P

• Contact surface breakage, damage, and unusual wear of coupling sleeve, synchronizer hub, in](/img/5/57363/w960_57363-3291.png)

MAINSHAFT AND GEARTM-51

< UNIT DISASSEMBLY AND ASSEMBLY > [5MT: RS5F91R]

C

EF

G H

I

J

K L

M A

B

TM

N

O P

• Contact surface breakage, damage, and unusual wear of coupling sleeve, synchronizer hub, insert key, and spring.

• Coupling sleeve and synchronizer hub move smoothly.

• Breakage, damage, and excessive wear of baulk ring cam surface

and insert contact surface.

Bearing

Check bearing for damage and rough rotation. Replace if necessary.

SCIA1753J

SCIA0608J

MTF0041D

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 3316 of 3641

![NISSAN NOTE 2016 Service Repair Manual STRUCTURE AND OPERATIONTM-75

< SYSTEM DESCRIPTION > [CVT: RE0F11A]

C

EF

G H

I

J

K L

M A

B

TM

N

O P

SHIFT LOCK SYSTEM : System DescriptionINFOID:0000000012431016

The selector lever cannot be shifted fr NISSAN NOTE 2016 Service Repair Manual STRUCTURE AND OPERATIONTM-75

< SYSTEM DESCRIPTION > [CVT: RE0F11A]

C

EF

G H

I

J

K L

M A

B

TM

N

O P

SHIFT LOCK SYSTEM : System DescriptionINFOID:0000000012431016

The selector lever cannot be shifted fr](/img/5/57363/w960_57363-3315.png)

STRUCTURE AND OPERATIONTM-75

< SYSTEM DESCRIPTION > [CVT: RE0F11A]

C

EF

G H

I

J

K L

M A

B

TM

N

O P

SHIFT LOCK SYSTEM : System DescriptionINFOID:0000000012431016

The selector lever cannot be shifted from “P” position to any other position unless the ignition switch is in the

ON position and the brake pedal is depressed.

KEY LOCK SYSTEM

KEY LOCK SYSTEM : System DescriptionINFOID:0000000012431017

• The key lock mechanism also operates as a shift lock: With the ignition switch turned to ON, selector lever cannot be shifted from “P” position to any other position

unless brake pedal is depressed.

With the key removed, selector lever cannot be shifted from “P” position to any other position.

The key cannot be removed unless selector lever is placed in “P” position.

• The shift lock and key lock mechanisms are controlled by the ON-OFF operation of the shift lock solenoid and by the operation of the rotator and slider located inside key cylinder, respectively.

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 3472 of 3641

![NISSAN NOTE 2016 Service Repair Manual CVT SHIFT SELECTORTM-231

< REMOVAL AND INSTALLATION > [CVT: RE0F11A]

C

EF

G H

I

J

K L

M A

B

TM

N

O P

REMOVAL AND INSTALLATION

CVT SHIFT SELECTOR

Exploded ViewINFOID:0000000012431175

Removal and Instal NISSAN NOTE 2016 Service Repair Manual CVT SHIFT SELECTORTM-231

< REMOVAL AND INSTALLATION > [CVT: RE0F11A]

C

EF

G H

I

J

K L

M A

B

TM

N

O P

REMOVAL AND INSTALLATION

CVT SHIFT SELECTOR

Exploded ViewINFOID:0000000012431175

Removal and Instal](/img/5/57363/w960_57363-3471.png)

CVT SHIFT SELECTORTM-231

< REMOVAL AND INSTALLATION > [CVT: RE0F11A]

C

EF

G H

I

J

K L

M A

B

TM

N

O P

REMOVAL AND INSTALLATION

CVT SHIFT SELECTOR

Exploded ViewINFOID:0000000012431175

Removal and InstallationINFOID:0000000012431176

CAUTION:

Always apply the parking brake before pe rforming removal and installation.

REMOVAL

1. Move the shift selector to the “N” position.

2. Remove the shift selector handle. Refer to TM-232, "

Disassembly and Assembly".

3. Remove the center console. Refer to IP-18, "

Removal and Installation".

4. Disconnect the harness connectors from shift selector.

5. Move the shift selector to the “P” position.

6. Remove the key interlock cable from the shift selector assembly. Refer to TM-237, "

Exploded View".

7. Remove the control cable from the shift selector assembly. Refer to TM-234, "

Exploded View".

8. Remove the shift selector assembly.

INSTALLATION

Installation is in the reverse order of removal.

1. Shift selector handle 2. Lock pin3. Shift selector handle cover

4. Position indication panel 5. Shift selector assembly

ALDIA0263GB

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 3478 of 3641

![NISSAN NOTE 2016 Service Repair Manual KEY INTERLOCK CABLETM-237

< REMOVAL AND INSTALLATION > [CVT: RE0F11A]

C

EF

G H

I

J

K L

M A

B

TM

N

O P

KEY INTERLOCK CABLE

Exploded ViewINFOID:0000000012431182

Removal and InstallationINFOID:0000000012 NISSAN NOTE 2016 Service Repair Manual KEY INTERLOCK CABLETM-237

< REMOVAL AND INSTALLATION > [CVT: RE0F11A]

C

EF

G H

I

J

K L

M A

B

TM

N

O P

KEY INTERLOCK CABLE

Exploded ViewINFOID:0000000012431182

Removal and InstallationINFOID:0000000012](/img/5/57363/w960_57363-3477.png)

KEY INTERLOCK CABLETM-237

< REMOVAL AND INSTALLATION > [CVT: RE0F11A]

C

EF

G H

I

J

K L

M A

B

TM

N

O P

KEY INTERLOCK CABLE

Exploded ViewINFOID:0000000012431182

Removal and InstallationINFOID:0000000012431183

REMOVAL

CAUTION:

Always apply the parking brake before pe rforming removal and installation.

1. Move the shift selector to the “N” position.

2. Remove the shift selector handle. Refer to TM-232, "

Disassembly and Assembly".

3. Remove the instrumental lower panel LH. Refer to IP-24, "

Removal and Installation".

4. Remove steering column covers. Refer to IP-17, "

Removal and Installation".

5. Remove the center console. Refer to IP-18, "

Removal and Installation".

6. Move the shift selector to the “P” position.

7. Press the pawls (B) of the key interlock cable slider (A) while sliding it in the direction of the casing cap (C), and separate the

adjusting holder (D) and slider.

8. Remove the key interlock cable from the shift selector assembly.

1. Shift selector assembly 2. Key interlock cable A: Steering lock unit

B: Lock plate C: Clip

ALDIA0262ZZ

(E) :Key interlock rod

JSDIA1797ZZ

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 3479 of 3641

![NISSAN NOTE 2016 Service Repair Manual TM-238

< REMOVAL AND INSTALLATION >[CVT: RE0F11A]

KEY INTERLOCK CABLE

9. Lift lock plate (A) in the direction of the arrow ( C) and remove

in the direction of the arrow ( D).

10. Remove the key interl NISSAN NOTE 2016 Service Repair Manual TM-238

< REMOVAL AND INSTALLATION >[CVT: RE0F11A]

KEY INTERLOCK CABLE

9. Lift lock plate (A) in the direction of the arrow ( C) and remove

in the direction of the arrow ( D).

10. Remove the key interl](/img/5/57363/w960_57363-3478.png)

TM-238

< REMOVAL AND INSTALLATION >[CVT: RE0F11A]

KEY INTERLOCK CABLE

9. Lift lock plate (A) in the direction of the arrow ( C) and remove

in the direction of the arrow ( D).

10. Remove the key interlock cable from the steering lock unit.

11. Disengage the clips and remove the key interlock cable from the vehicle.

INSTALLATION

Installation is in the reverse order of removal.

• Temporarily install the adjust holder (A) to the key interlock rod (B).

• Install the casing cap (C) to the cable bracket (D) on the shift

selector assembly.

CAUTION:

• Do not bend or twist key interlock cable excessively wheninstalling.

• After installing key interlock cable to cable bracket (D) on shift selector assembly, make sure casing caps (C) is firmly

secured in cable bracket (D) on shift selector assembly.

• If casing cap (C) is loose [less than 39.2 N (4.0 kg, 8.8 lb) removing force], replace key interlock cable.

• Slide the slider (A) toward the key interlock rod (D) while pressing the pull lock (B) down to securely connect the adjust holder (C)

with the key interlock rod (D).

CAUTION:

• Do not press tabs when holding slider (A).

• Do not apply any side to side force to key interlock rod (D)

when sliding slider (A).

InspectionINFOID:0000000012431184

INSPECTION AFTER INSTALLATION

• Check the CVT operation. If a malfunction is found, adjust the CVT position. Refer to TM-232, "Inspection".

• Make sure the key can be removed only when the shift selector is in the “P” position.

• Make sure the ignition switch will not turn to LOCK pos ition when the shift selector is not in the “P” position.

(1) :Key interlock cable

(B) :Steering lock unit

JSDIA1798ZZ

JSDIA1799ZZ

JSDIA1800ZZ

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 3516 of 3641

WCS

WCS-1

DRIVER INFORMATION & MULTIMEDIA

C

DE

F

G H

I

J

K L

M B

SECTION WCS

A

O P

CONTENTS

WARNING CHIME SYSTEM

HOW TO USE THIS MANU AL ......................3

APPLICATION NOTICE ................................. .....3

Information .......................................................... ......3

PRECAUTION ...............................................4

PRECAUTIONS .............................................. .....4

Precaution for Supplemental Restraint System

(SRS) "AIR BAG" and "SEAT BELT PRE-TEN-

SIONER" ............................................................. ......

4

SYSTEM DESCRIPTION ..............................5

COMPONENT PARTS ................................... .....5

Component Parts Location .................................. ......5

Combination Meter ....................................................5

SYSTEM ..............................................................7

WARNING CHIME SYSTEM .......................................7

WARNING CHIME SYSTEM : System Description

......

7

WARNING CHIME SYSTEM : Fail-safe ....................8

LIGHT REMINDER WARNING CHIME ................. ......8

LIGHT REMINDER WARNING CHIME : Light Re-

minder Warning .........................................................

8

PARKING BRAKE RELEASE WARNING CHIME ......9

PARKING BRAKE RELEASE WARNING CHIME

: Parking Brake Release Warning Chime ............ ......

9

SEAT BELT REMINDER WARNING CHIME ........ ....10

SEAT BELT REMINDER WARNING CHIME :

Seat belt Warning ....................................................

10

KEY WARNING CHIME (WITHOUT INTELLIGENT

KEY) ....................................................................... ....

11

KEY WARNING CHIME (WITHOUT INTELLI-

GENT KEY) : Key Warning Chime ..........................

11

DIAGNOSIS SYSTEM (COMBINATION

METER) .............................................................

13

TYPE A ............................................ ...........................13

TYPE A : On Board Diagnosis Function .............. ....13

TYPE A : CONSULT Function (METER/M&A) ........14

TYPE B ............................................ ...........................16

TYPE B : On Board Diagnosis Function .............. ....16

TYPE B : CONSULT Function (METER/M&A) ........18

DIAGNOSIS SYSTEM (BCM) (WITH INTELLI-

GENT KEY SYSTEM) .......................................

21

COMMON ITEM ..................................................... ....21

COMMON ITEM : CONSULT Function (BCM -

COMMON ITEM) .....................................................

21

BUZZER ................................................................. ....22

BUZZER : CONSULT Function (BCM - BUZZER) ....22

DIAGNOSIS SYSTEM (BCM) (WITHOUT IN-

TELLIGENT KEY SYSTEM) .............................

23

COMMON ITEM ..................................................... ....23

COMMON ITEM : CONSULT Function (BCM -

COMMON ITEM) .....................................................

23

BUZZER ................................................................. ....24

BUZZER : CONSULT Function (BCM - BUZZER) ....24

ECU DIAGNOSIS INFORMATION ..............25

BCM, COMBINATION METER .........................25

List of ECU Reference ......................................... ....25

WIRING DIAGRAM ......................................26

WARNING CHIME SYSTEM .............................26

Wiring Diagram .................................................... ....26

BASIC INSPECTION ...................................32

DIAGNOSIS AND REPAIR WORK FLOW .......32

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 3517 of 3641

WCS-2

Work Flow ...............................................................32

DTC/CIRCUIT DIAGNOSIS ...................... ...34

POWER SUPPLY AND GROUND CIRCUIT .. ...34

COMBINATION METER (TYPE A) ........................ ...34

COMBINATION METER (TYPE A) : Diagnosis

Procedure ............................................................ ...

34

COMBINATION METER (TYPE B) ........................ ...34

COMBINATION METER (TYPE B) : Diagnosis

Procedure ............................................................ ...

35

BCM (BODY CONTROL SYSTEM) (WITH INTEL-

LIGENT KEY SYSTEM) ..... .......................................

35

BCM (BODY CONTROL S YSTEM) (WITH INTEL-

LIGENT KEY SYSTEM) : Dia gnosis Procedure .....

35

BCM (BODY CONTROL SYST EM) (WITHOUT IN-

TELLIGENT KEY SYSTEM) . ....................................

36

BCM (BODY CONTROL SYSTEM) (WITHOUT

INTELLIGENT KEY SYSTEM) : Diagnosis Proce-

dure ..................................................................... ...

36

METER BUZZER CIRCUIT ................................38

Component Function Check ................................ ...38

Diagnosis Procedure .............................................38

SEAT BELT BUCKLE SWITCH SIGNAL CIR-

CUIT ...................................................................

39

TYPE A ................................................................... ...39

TYPE A : Description ..............................................39

TYPE A : Component Func tion Check ..................39

TYPE A : Diagnosis Procedu re ..............................39

TYPE A : Component Inspec tion ............................40

TYPE B ............... .................................................... ...40

TYPE B : Description ..............................................40

TYPE B : Component Func tion Check ..................40

TYPE B : Diagnosis Procedu re ..............................40

TYPE B : Component Inspec tion ............................41

PARKING BRAKE SWITCH SIGNAL CIR-

CUIT ................................................................ ...

42

TYPE A ............................................ ..........................42

TYPE A : Component Functi on Check ....................42

TYPE A : Diagnosis Procedur e ...............................42

TYPE A : Component Inspec tion ............................43

TYPE B ............ ................................ ..........................43

TYPE B : Component Functi on Check ....................43

TYPE B : Diagnosis Procedur e ...............................43

TYPE B : Component Inspec tion ............................44

KEY SWITCH SIGNAL CIRCUIT (WITHOUT

INTELLIGENT KEY) ....................................... ...

45

Description ........................................................... ...45

Component Function Check ..................................45

Diagnosis Procedure ..............................................45

Component Inspection ............................................46

SYMPTOM DIAGNOSIS ............................47

THE PARKING BRAKE RELEASE WARNING

CONTINUES SOUNDING, OR DOES NOT

SOUND ........................................................... ...

47

Description ........................................................... ...47

Diagnosis Procedure ...............................................47

THE SEAT BELT REMINDER WARNING

CONTINUES SOUNDING, OR DOES NOT

SOUND ..............................................................

48

Description ........................................................... ...48

Diagnosis Procedure ...............................................48

THE LIGHT REMINDER WARNING DOES

NOT SOUND ......................................................

49

Description ........................................................... ...49

Diagnosis Procedure ...............................................49

THE KEY WARNING DOES NOT SOUND

(WITHOUT INTELLIGENT KEY) .......................

50

Description ..............................................................50

Diagnosis Procedure ...............................................50

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 3520 of 3641

WCS

COMPONENT PARTSWCS-5

< SYSTEM DESCRIPTION >

C

DE

F

G H

I

J

K L

M B A

O P

SYSTEM DESCRIPTION

COMPONENT PARTS

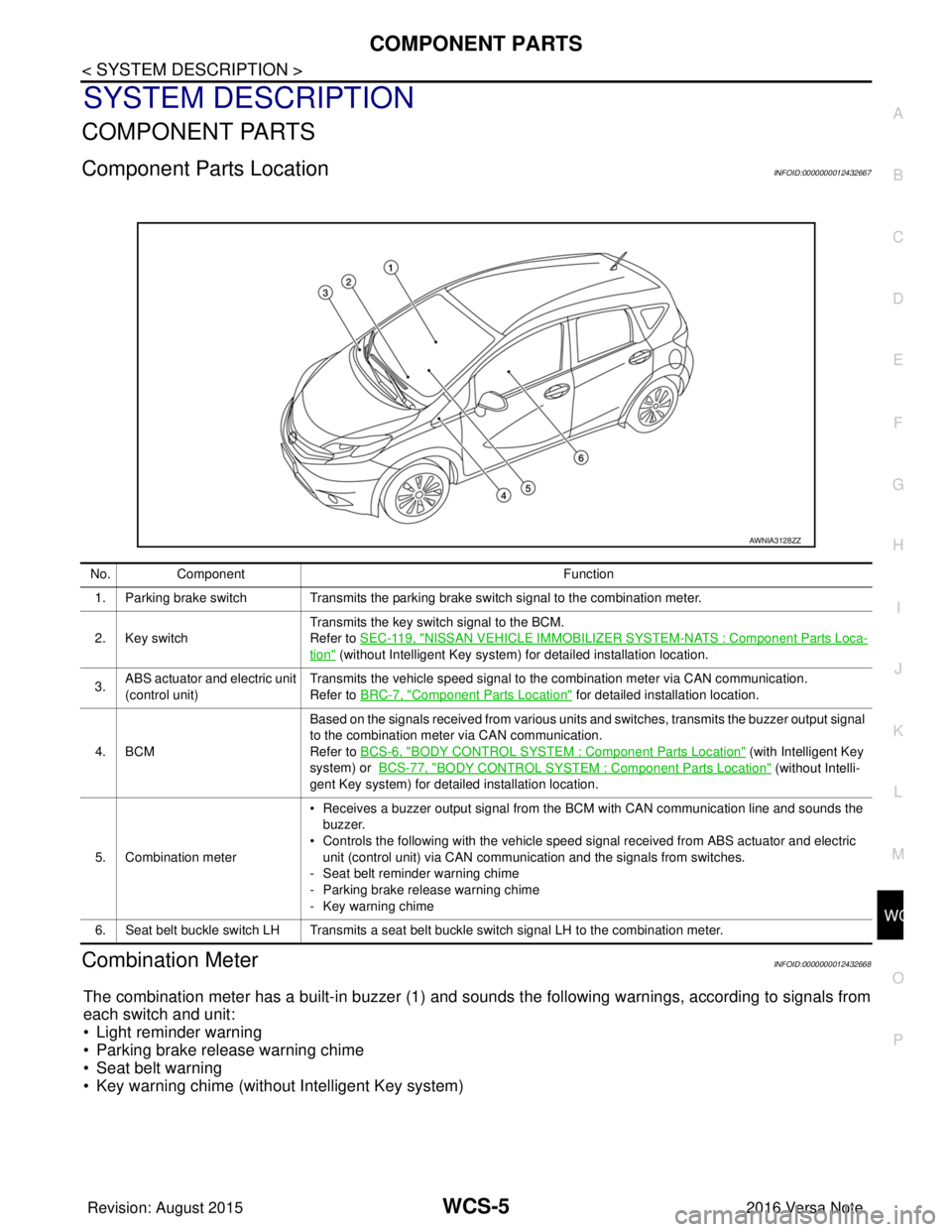

Component Parts LocationINFOID:0000000012432667

Combination MeterINFOID:0000000012432668

The combination meter has a built-in buzzer (1) and sounds the following warnings, according to signals from

each switch and unit:

• Light reminder warning

• Parking brake release warning chime

• Seat belt warning

• Key warning chime (without Intelligent Key system)

AWNIA3128ZZ

No. Component Function

1. Parking brake switch Transmits the parking brake switch signal to the combination meter.

2. Key switch Transmits the key switch signal to the BCM.

Refer to

SEC-119, "

NISSAN VEHICLE IMMOBILIZER SYSTEM -NATS : Component Parts Loca-

tion" (without Intelligent Key system) for detailed installation location.

3. ABS actuator and electric unit

(control unit) Transmits the vehicle speed signal to the combination meter via CAN communication.

Refer to BRC-7, "

Component Parts Location" for detailed installation location.

4. BCM Based on the signals received from various units and switches, transmits the buzzer output signal

to the combination meter via CAN communication.

Refer to BCS-6, "

BODY CONTROL SYSTEM : Co

mponent Parts Location" (with Intelligent Key

system) or BCS-77, "

BODY CONTROL SYSTEM : Component Parts Location" (without Intelli-

gent Key system) for detailed installation location.

5. Combination meter • Receives a buzzer output signal from the BCM with CAN communication line and sounds the

buzzer.

• Controls the following with the vehicle speed signal received from ABS actuator and electric

unit (control unit) via CAN communication and the signals from switches.

- Seat belt reminder warning chime

- Parking brake release warning chime

- Key warning chime

6. Seat belt buckle switch LH Transmits a seat belt buckle switch signal LH to the combination meter.

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 3522 of 3641

WCS

SYSTEMWCS-7

< SYSTEM DESCRIPTION >

C

DE

F

G H

I

J

K L

M B A

O P

SYSTEM

WARNING CHIME SYSTEM

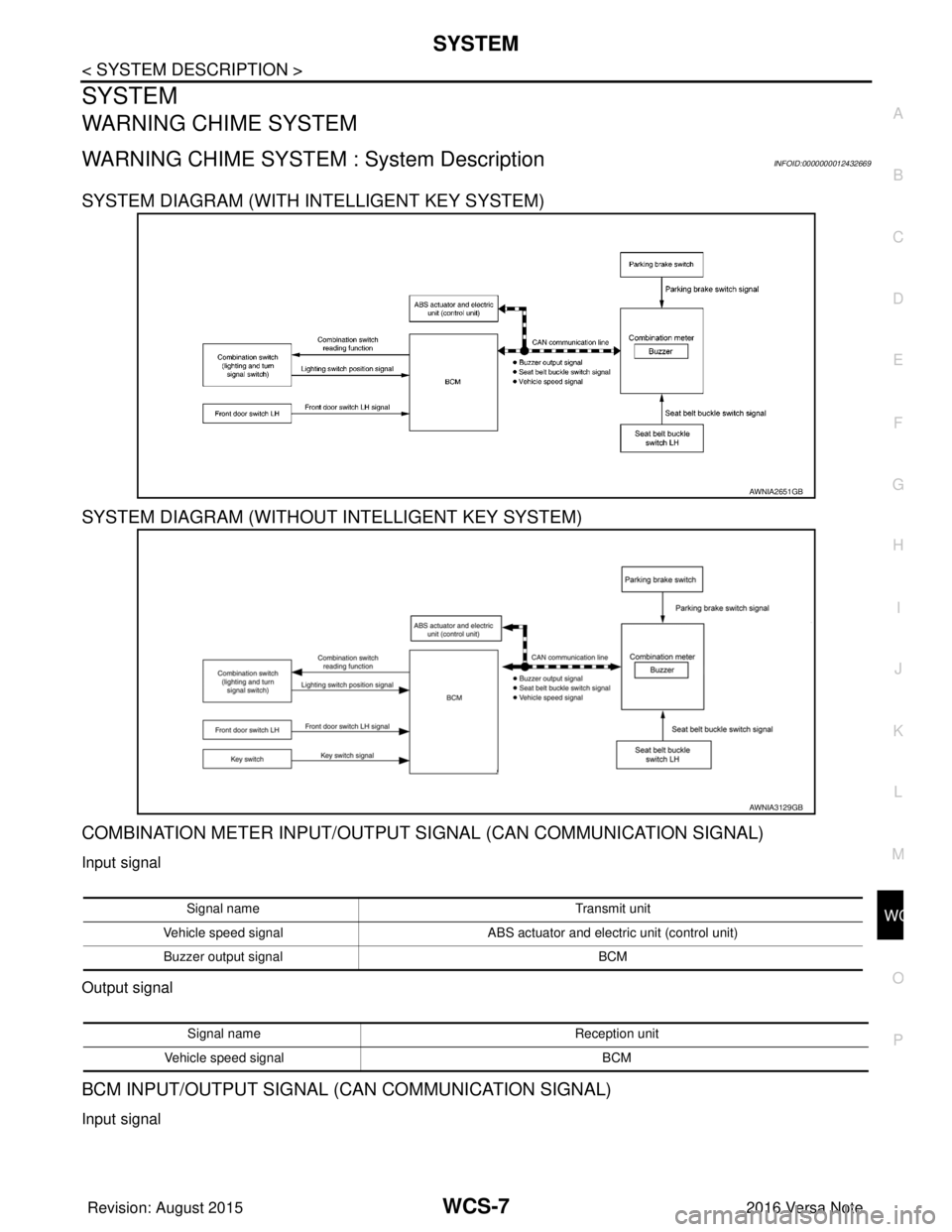

WARNING CHIME SYSTEM : System DescriptionINFOID:0000000012432669

SYSTEM DIAGRAM (WITH INTELLIGENT KEY SYSTEM)

SYSTEM DIAGRAM (WITHOUT INTELLIGENT KEY SYSTEM)

COMBINATION METER INPUT/OUTPUT SIGNAL (CAN COMMUNICATION SIGNAL)

Input signal

Output signal

BCM INPUT/OUTPUT SIGNAL (CAN COMMUNICATION SIGNAL)

Input signal

AWNIA2651GB

AWNIA3129GB

Signal name Transmit unit

Vehicle speed signal ABS actuator and electric unit (control unit)

Buzzer output signal BCM

Signal nameReception unit

Vehicle speed signal BCM

Revision: August 2015 2016 Versa Note

cardiagn.com