air bleeding NISSAN NOTE 2016 Service Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2016, Model line: NOTE, Model: NISSAN NOTE 2016Pages: 3641, PDF Size: 28.72 MB

Page 452 of 3641

![NISSAN NOTE 2016 Service Repair Manual BRC-4

< PRECAUTION >[VDC/TCS/ABS]

PRECAUTIONS

PRECAUTION

PRECAUTIONS

Precaution for Supplemental Restraint Syst

em (SRS) "AIR BAG" and "SEAT BELT

PRE-TENSIONER"

INFOID:0000000012430820

The Supplement NISSAN NOTE 2016 Service Repair Manual BRC-4

< PRECAUTION >[VDC/TCS/ABS]

PRECAUTIONS

PRECAUTION

PRECAUTIONS

Precaution for Supplemental Restraint Syst

em (SRS) "AIR BAG" and "SEAT BELT

PRE-TENSIONER"

INFOID:0000000012430820

The Supplement](/img/5/57363/w960_57363-451.png)

BRC-4

< PRECAUTION >[VDC/TCS/ABS]

PRECAUTIONS

PRECAUTION

PRECAUTIONS

Precaution for Supplemental Restraint Syst

em (SRS) "AIR BAG" and "SEAT BELT

PRE-TENSIONER"

INFOID:0000000012430820

The Supplemental Restraint System such as “A IR BAG” and “SEAT BELT PRE-TENSIONER”, used along

with a front seat belt, helps to reduce the risk or severity of injury to the driver and front passenger for certain

types of collision. Information necessary to service the system safely is included in the SR and SB section of

this Service Manual.

WARNING:

• To avoid rendering the SRS inopera tive, which could increase the risk of personal injury or death in

the event of a collision which would result in air bag inflation, all maintenance must be performed by

an authorized NISSAN/INFINITI dealer.

• Improper maintenance, including in correct removal and installation of the SRS, can lead to personal

injury caused by unintent ional activation of the system. For re moval of Spiral Cable and Air Bag

Module, see the SR section.

• Do not use electrical test equipmen t on any circuit related to the SRS unless instructed to in this

Service Manual. SRS wiring harn esses can be identified by yellow and/or orange harnesses or har-

ness connectors.

PRECAUTIONS WHEN USING POWER TOOLS (AIR OR ELECTRIC) AND HAMMERS

WARNING:

• When working near the Airbag Diagnosis Sensor Unit or other Airbag System sensors with the Igni-

tion ON or engine running, DO NOT use air or electri c power tools or strike near the sensor(s) with a

hammer. Heavy vibration could activate the sensor( s) and deploy the air bag(s), possibly causing

serious injury.

• When using air or electric power tools or hammers , always switch the Ignition OFF, disconnect the

battery and wait at least three minutes before performing any service.

Precaution for Brake SystemINFOID:0000000012430821

WARNING:

Clean any dust from the front brake and rear brake using a vacuum dust collector. Do not blow by

compressed air.

• Brake fluid use refer to MA-11, "

Fluids and Lubricants".

• Do not reuse drained brake fluid.

• Do not spill or splash brake fluid on painted surfaces. Brake fluid may seriously damage paint. Wipe it off

immediately and wash with water if it gets on a painted surface.

• Always confirm the specified tightening torque when installing the brake pipes.

• After pressing the brake pedal more deeply or harder t han normal driving, such as air bleeding, check each

item of brake pedal. Adjust brake pedal if it is outside the standard value.

• Do not use mineral oils such as gasoline or light oil to clean. They may damage rubber parts and cause

improper operation.

• Always loosen the brake tube flare nut with a flare nut wrench.

• Tighten the brake tube flare nut to the specified torque with a crow-

foot (A) and torque wrench (B).

• Always connect the battery terminal when moving the vehicle.

• Turn the ignition switch OFF and disconnect the ABS actuator and electric unit (control unit) harness connector or the battery negative

terminal before performing the work.

• Check that no brake fluid leakage is present after replacing the parts.

JPFIA0001ZZ

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 582 of 3641

![NISSAN NOTE 2016 Service Repair Manual BRC-134

< SYMPTOM DIAGNOSIS >[VDC/TCS/ABS]

UNEXPECTED PEDAL REACTION

UNEXPECTED PEDAL REACTION

Diagnosis ProcedureINFOID:0000000012430919

1.CHECK BRAKE PEDAL STROKE

Check brake pedal stroke. Refer to NISSAN NOTE 2016 Service Repair Manual BRC-134

< SYMPTOM DIAGNOSIS >[VDC/TCS/ABS]

UNEXPECTED PEDAL REACTION

UNEXPECTED PEDAL REACTION

Diagnosis ProcedureINFOID:0000000012430919

1.CHECK BRAKE PEDAL STROKE

Check brake pedal stroke. Refer to](/img/5/57363/w960_57363-581.png)

BRC-134

< SYMPTOM DIAGNOSIS >[VDC/TCS/ABS]

UNEXPECTED PEDAL REACTION

UNEXPECTED PEDAL REACTION

Diagnosis ProcedureINFOID:0000000012430919

1.CHECK BRAKE PEDAL STROKE

Check brake pedal stroke. Refer to BR-9, "

Inspection and Adjustment".

Is the stroke too big?

YES >> • Bleed air from brake line and hose. Refer to BR-13, "Bleeding Brake System".

• Check brake pedal, brake booster, and master cylinder for mount play, looseness, brake system fluid leakage, etc. Refer to brake pedal: BR-9, "

Inspection and Adjustment" or brake booster

assembly BR-15, "

Inspection".

NO >> GO TO 2.

2.CHECK ABS FUNCTION

1. Disconnect ABS actuator and electric unit (control unit) connector to deactivate ABS.

2. Check if braking force is normal in this condition.

3. Reconnect connector after inspection.

Is the inspection result normal?

YES >> Inspection End.

NO >> Check brake system.

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 593 of 3641

![NISSAN NOTE 2016 Service Repair Manual ABS ACTUATOR AND ELECTRIC UNIT (CONTROL UNIT)BRC-145

< REMOVAL AND INSTALLATION > [VDC/TCS/ABS]

C

D

E

G H

I

J

K L

M A

B

BRC

N

O P

3. Remove ground harness bolt (A) and ground harness from radi- ator c NISSAN NOTE 2016 Service Repair Manual ABS ACTUATOR AND ELECTRIC UNIT (CONTROL UNIT)BRC-145

< REMOVAL AND INSTALLATION > [VDC/TCS/ABS]

C

D

E

G H

I

J

K L

M A

B

BRC

N

O P

3. Remove ground harness bolt (A) and ground harness from radi- ator c](/img/5/57363/w960_57363-592.png)

ABS ACTUATOR AND ELECTRIC UNIT (CONTROL UNIT)BRC-145

< REMOVAL AND INSTALLATION > [VDC/TCS/ABS]

C

D

E

G H

I

J

K L

M A

B

BRC

N

O P

3. Remove ground harness bolt (A) and ground harness from radi- ator core support.

4. Disconnect high-pressure pipe from expansion valve. Refer to HA-28, "

Exploded View".

CAUTION:

Cap or wrap the joint of the A/C piping and expan sion valve with suitable material such as vinyl

tape to avoid the entry of air.

5. Remove low-pressure flexible hose. Refer to HA-28, "

LOW-PRESSURE FLEXIBLE HOSE : Removal and

Installation".

6. Loosen flare nut from brake tubes using a flare nut wrench, then remove brake tubes from ABS actuator

and electric unit (control unit). Refer to BR-22, "

FRONT : Exploded View".

7. Disconnect the harness connector from the ABS actuator and electric unit (control unit).

8. Remove ABS actuator and electric unit (control unit) bracket bolts.

9. Remove the ABS actuator and electric uni t (control unit) and bracket as an assembly.

10. Remove bracket and bushing from ABS ac tuator and electric unit (if necessary).

INSTALLATION

Installation is in the reverse order of removal.

• Bleed the brake system. Refer to BR-13, "

Bleeding Brake System".

• Adjust the neutral position of steering angle sensor. Refer to BRC-55, "

ADJUSTMENT OF STEERING

ANGLE SENSOR NEUTRAL POSITION : Special Repair Requirement".

CAUTION:

• Replace the ABS actuator electric unit (control unit) if it has been dropped or sustained an impact.

• Do not install actuator by holding harness.

• After installing harness connector in the ABS acu tator and electric until (control unit), make sure

harness connector is securely locked.

ALKIA3174ZZ

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 627 of 3641

CL-1

TRANSMISSION & DRIVELINE

CEF

G H

I

J

K L

M

SECTION CL

A

B

CL

N

O P

CONTENTS

CLUTCH

PRECAUTION ....... ........................................2

PRECAUTIONS .............................................. .....2

Precaution for Supplemental Restraint System

(SRS) "AIR BAG" and "SEAT BELT PRE-TEN-

SIONER" ............................................................. ......

2

General Precautions .................................................2

PREPARATION ............................................3

PREPARATION .............................................. .....3

Special Service Tool ........................................... ......3

Commercial Service Tools ........................................3

SYMPTOM DIAGNOSIS ...............................4

NOISE, VIBRATION AND HARSHNESS

(NVH) TROUBLESHOOTING ........................ .....

4

NVH Troubleshooting Chart ................................ ......4

PERIODIC MAINTENANCE ..........................5

CLUTCH PEDAL .................................................5

Inspection and Adjustment .................................. ......5

CLUTCH FLUID ...................................................7

Inspection ............................................................ ......7

Draining .....................................................................7

Refilling .....................................................................8

Air Bleeding ...............................................................9

REMOVAL AND INSTALLATION ...............11

CLUTCH PEDAL ................................................11

Exploded View .................................................... ....11

Removal and Installation .........................................11

Inspection and Adjustment .................................. ....12

CLUTCH MASTER CYLINDER ........................13

Exploded View .........................................................13

Removal and Installation .........................................13

Inspection and Adjustment ......................................14

CLUTCH PIPING ...............................................15

Exploded View .........................................................15

Hydraulic Layout ......................................................15

Removal and Installation .........................................15

Inspection and Adjustment ......................................16

UNIT REMOVAL AND INSTALLATION ......17

CSC (CONCENTRIC SLAVE CYLINDER) .......17

Exploded View ..................................................... ....17

Removal and Installation .........................................17

Inspection and Adjustment ......................................18

CLUTCH DISC AND CLUTCH COVER ............19

Exploded View .........................................................19

Removal and Installation .........................................19

Inspection ................................................................20

SERVICE DATA AND SPECIFICATIONS

(SDS) ............... .......................................... ...

22

SERVICE DATA AND SPECIFICATIONS

(SDS) .................................................................

22

General Specifications ......................................... ....22

Clutch Pedal ............................................................22

Clutch Disc ..............................................................22

Clutch Cover ............................................................22

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 633 of 3641

CLUTCH FLUIDCL-7

< PERIODIC MAINTENANCE >

CEF

G H

I

J

K L

M A

B

CL

N

O P

CLUTCH FLUID

InspectionINFOID:0000000012432216

CLUTCH FLUID LEAKS

• Check clutch line for cracks, deterioration or other damage. Replace any damaged parts.

• Check for clutch fluid leaks by fully depressing clutch pedal while engine is running. CAUTION:

If leaks occur around connections, reinstall th e lines or replace damaged parts, if necessary.

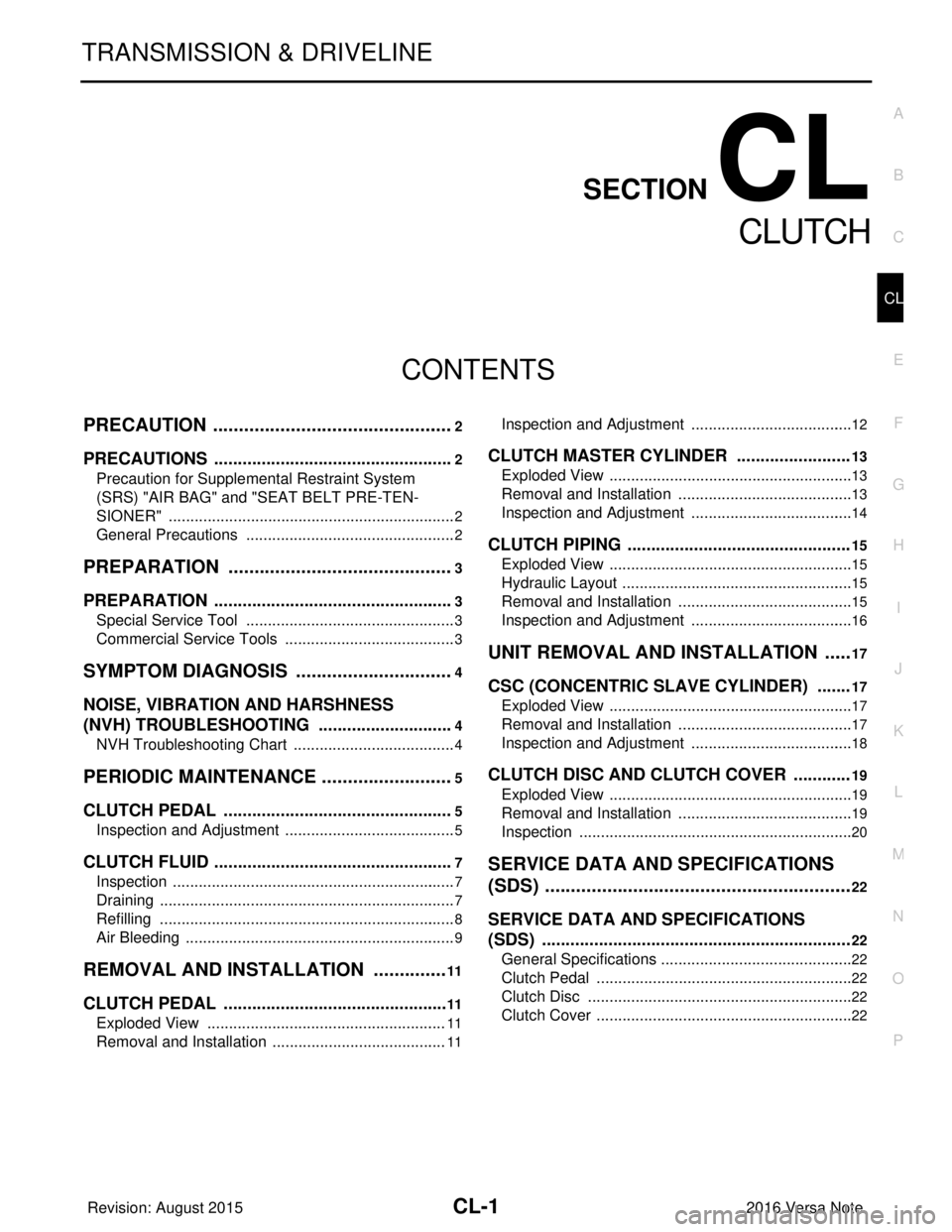

CLUTCH FLUID LEVEL

• Check that the clutch fluid level in the reservoir tank is within the

specified range, between the MAX and MIN lines as shown.

• Visually check for any clutch fluid leaks around the reservoir tank.

• Check the clutch system for any leaks if the clutch fluid level is

extremely low (lower than MIN).

DrainingINFOID:0000000012432217

CAUTION:

Do not spill clutch fluid onto painted surfaces. If clutch fluid spills, wipe up immediately and wash the

affected area with water.

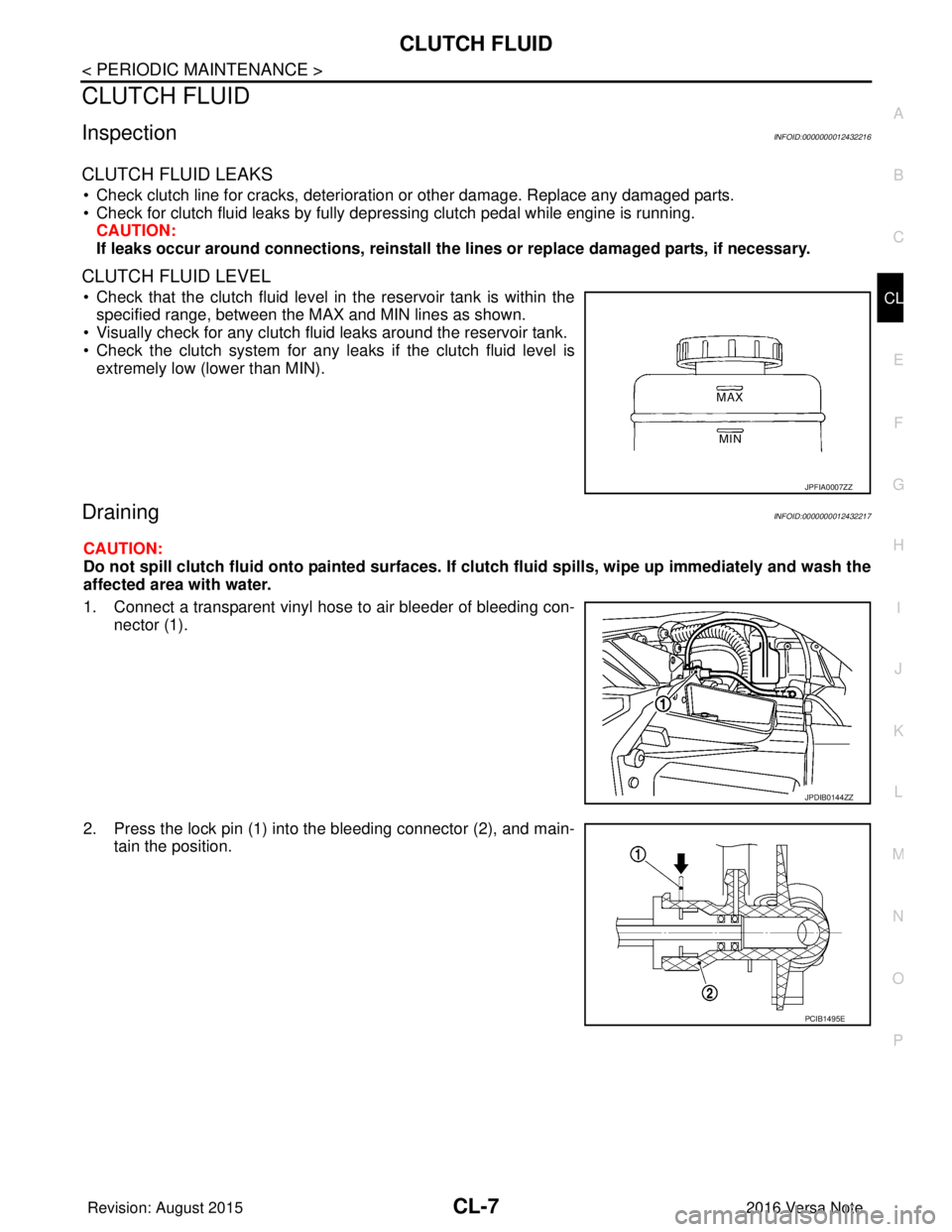

1. Connect a transparent vinyl hose to air bleeder of bleeding con-

nector (1).

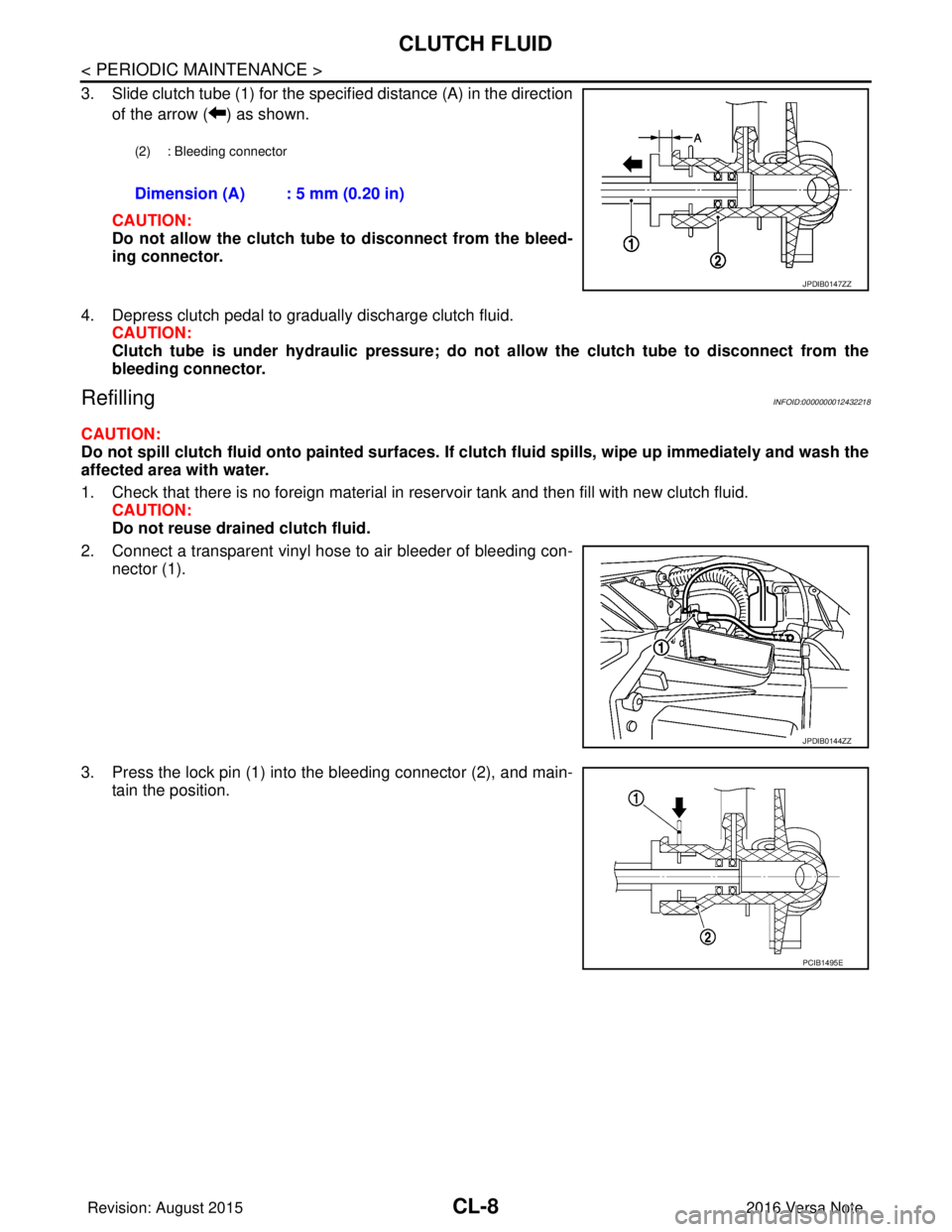

2. Press the lock pin (1) into the bleeding connector (2), and main- tain the position.

JPFIA0007ZZ

JPDIB0144ZZ

PCIB1495E

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 634 of 3641

CL-8

< PERIODIC MAINTENANCE >

CLUTCH FLUID

3. Slide clutch tube (1) for the specified distance (A) in the directionof the arrow ( ) as shown.

CAUTION:

Do not allow the clutch tube to disconnect from the bleed-

ing connector.

4. Depress clutch pedal to gradually discharge clutch fluid. CAUTION:

Clutch tube is under hydraulic pressure; do not allow the clutch tube to disconnect from the

bleeding connector.

RefillingINFOID:0000000012432218

CAUTION:

Do not spill clutch fluid onto painted surfaces. If cl utch fluid spills, wipe up immediately and wash the

affected area with water.

1. Check that there is no foreign material in reservoir tank and then fill with new clutch fluid. CAUTION:

Do not reuse drained clutch fluid.

2. Connect a transparent vinyl hose to air bleeder of bleeding con- nector (1).

3. Press the lock pin (1) into the bleeding connector (2), and main- tain the position.

(2) : Bleeding connector

Dimension (A) : 5 mm (0.20 in)

JPDIB0147ZZ

JPDIB0144ZZ

PCIB1495E

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 635 of 3641

CLUTCH FLUIDCL-9

< PERIODIC MAINTENANCE >

CEF

G H

I

J

K L

M A

B

CL

N

O P

4. Slide clutch tube (1) for the specified distance (A) in the direction of the arrow ( ) as shown.

5. Slowly depress clutch pedal to the full stroke position and then release the pedal. CAUTION:

Clutch tube is under hydraulic pressure; do not allow the clutch tube to disconnect from the

bleeding connector.

6. Repeat step 5 at intervals of 2 or 3 seconds until new clutch fluid is discharged. CAUTION:

Monitor clutch fluid level in reservoir tank so as not to empty the tank.

7. Return clutch tube and lock pin in their original positions while clutch pedal is depressed.

8. Perform the air bleeding. Refer to CL-9, "

Air Bleeding".

Air BleedingINFOID:0000000012432219

CAUTION:

• Monitor clutch fluid level in reservoir tank so as not to empty the tank.

• Do not spill clutch fluid onto painted surfaces. If clutch fluid spil ls, wipe up immediately and wash

the affected area with water.

1. Fill reservoir tank with new clutch fluid. CAUTION:

Do not reuse drained clutch fluid.

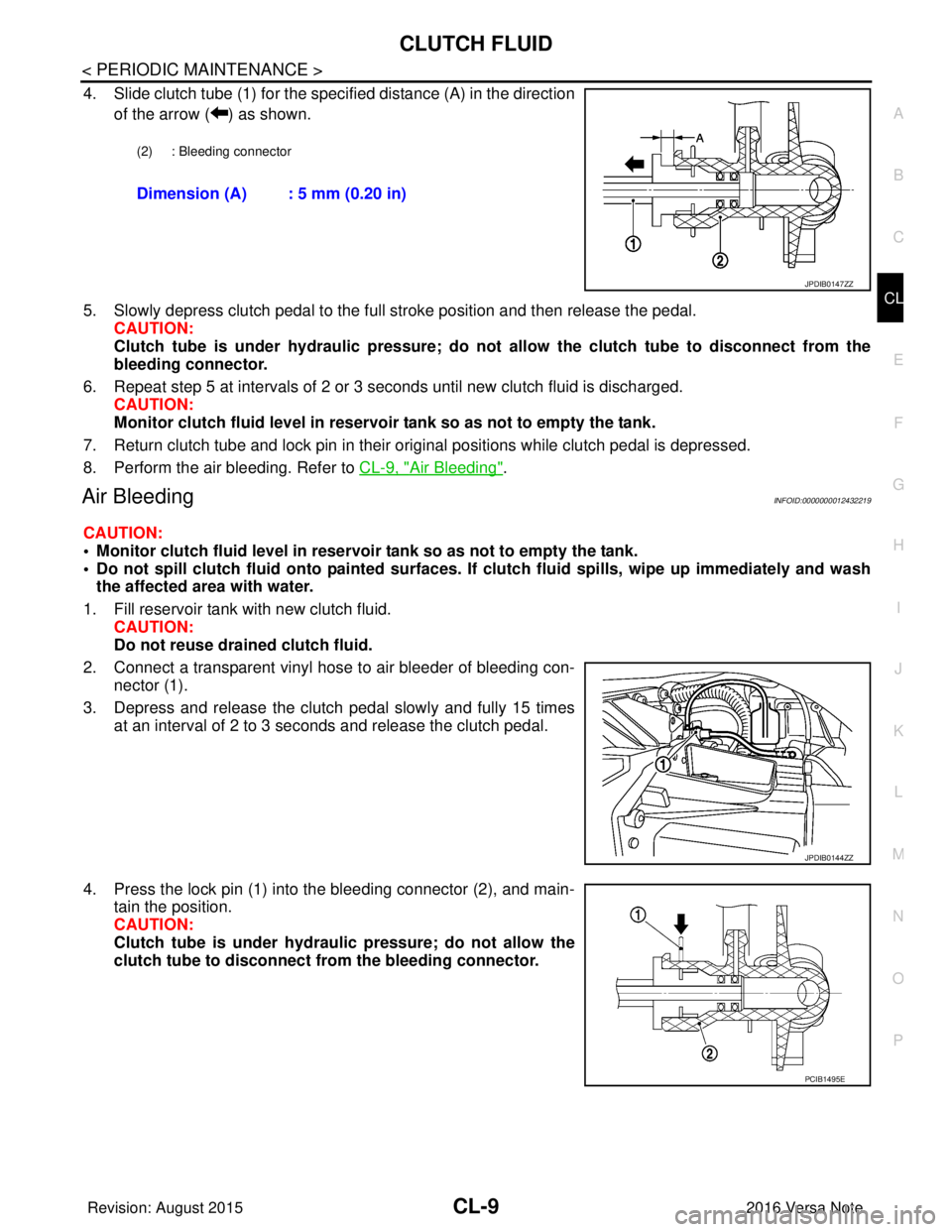

2. Connect a transparent vinyl hose to air bleeder of bleeding con- nector (1).

3. Depress and release the clutch pedal slowly and fully 15 times at an interval of 2 to 3 seconds and release the clutch pedal.

4. Press the lock pin (1) into the bleeding connector (2), and main- tain the position.

CAUTION:

Clutch tube is under hydraulic pressure; do not allow the

clutch tube to disconnect from the bleeding connector.

(2) : Bleeding connector

Dimension (A) : 5 mm (0.20 in)

JPDIB0147ZZ

JPDIB0144ZZ

PCIB1495E

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 636 of 3641

CL-10

< PERIODIC MAINTENANCE >

CLUTCH FLUID

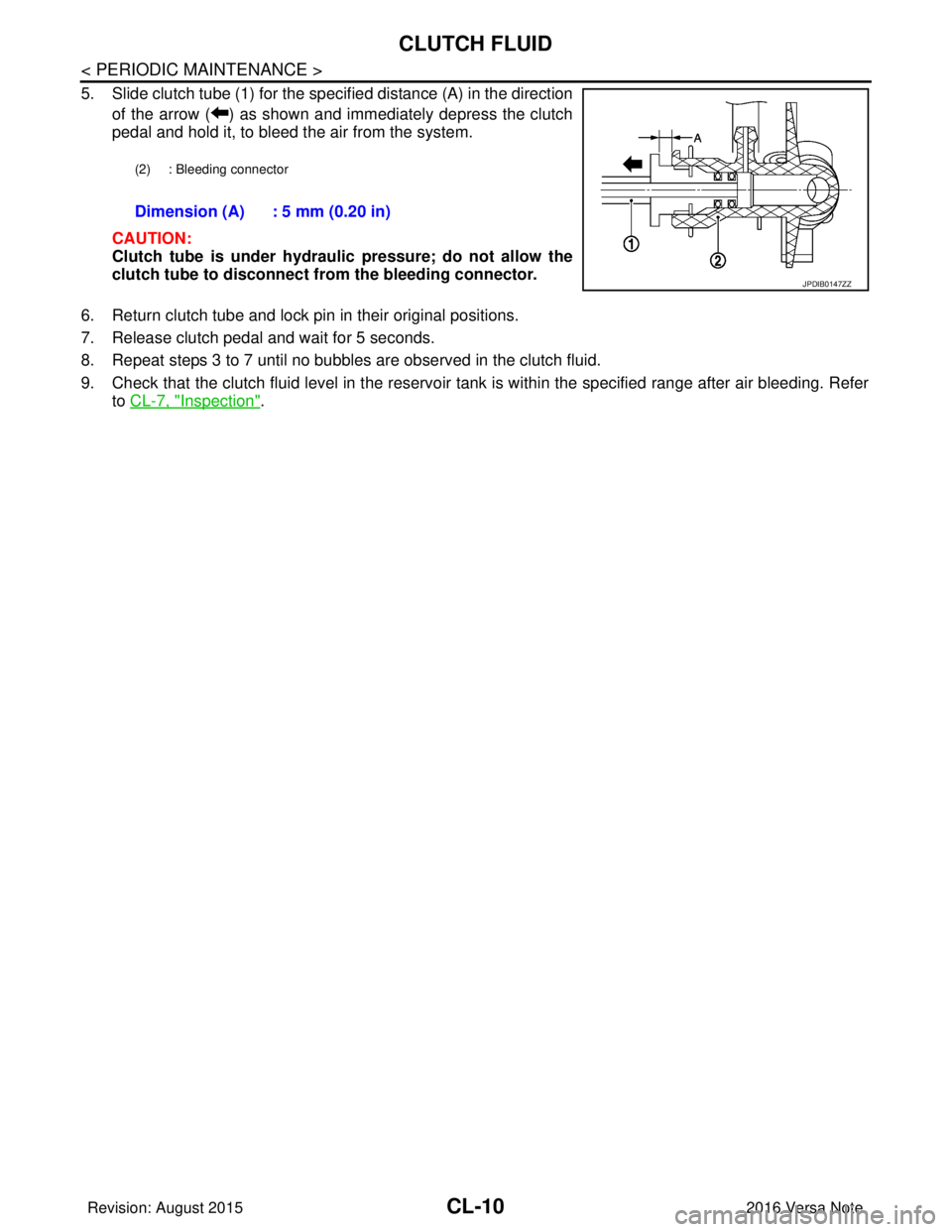

5. Slide clutch tube (1) for the specified distance (A) in the directionof the arrow ( ) as shown and immediately depress the clutch

pedal and hold it, to bleed the air from the system.

CAUTION:

Clutch tube is under hydraulic pressure; do not allow the

clutch tube to disconnect from the bleeding connector.

6. Return clutch tube and lock pin in their original positions.

7. Release clutch pedal and wait for 5 seconds.

8. Repeat steps 3 to 7 until no bubbles are observed in the clutch fluid.

9. Check that the clutch fluid level in the reservoir tank is within the specified range after air bleeding. Refer to CL-7, "

Inspection".

(2) : Bleeding connector

Dimension (A) : 5 mm (0.20 in)

JPDIB0147ZZ

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 642 of 3641

CL-16

< REMOVAL AND INSTALLATION >

CLUTCH PIPING

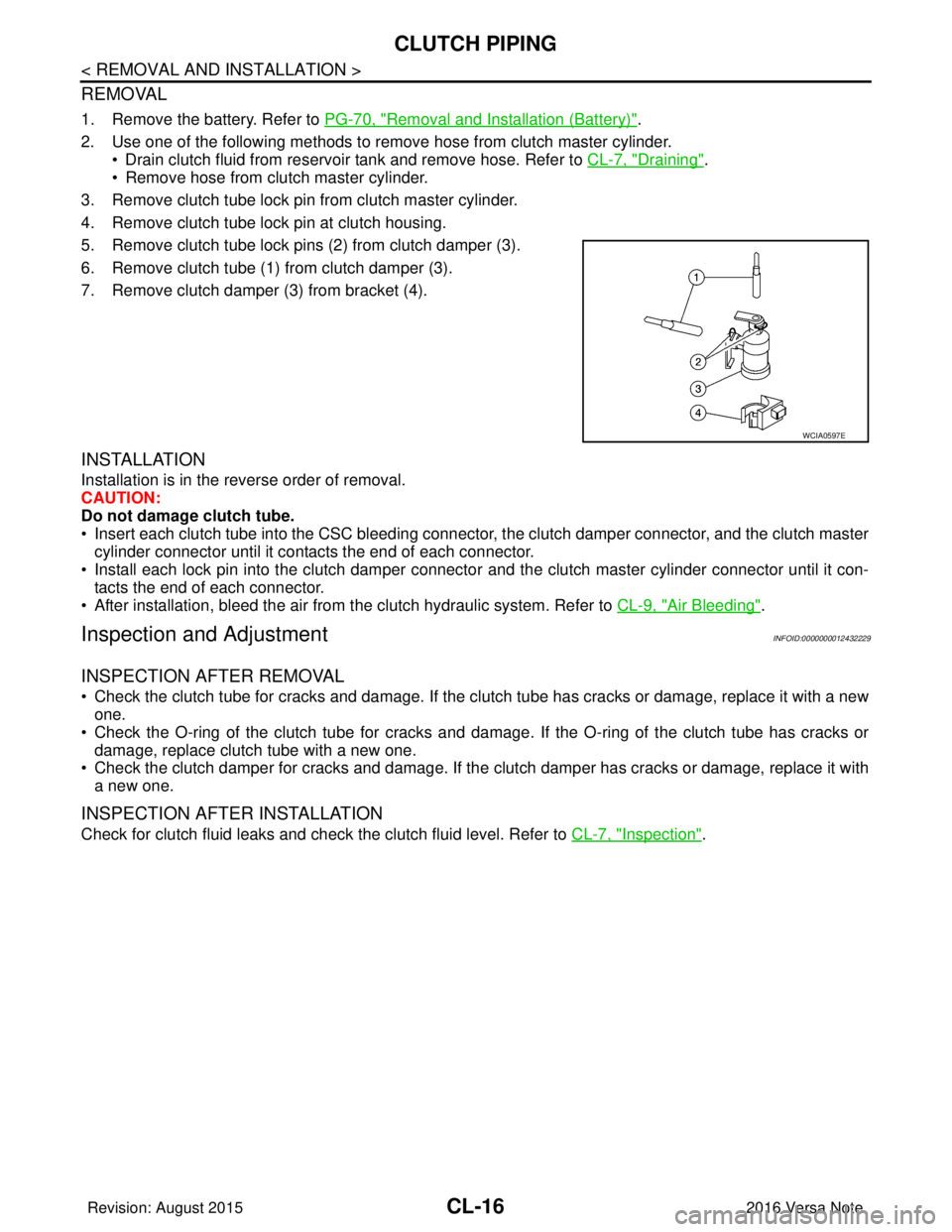

REMOVAL

1. Remove the battery. Refer to PG-70, "Removal and Installation (Battery)".

2. Use one of the following methods to remove hose from clutch master cylinder. • Drain clutch fluid from reservoir tank and remove hose. Refer to CL-7, "

Draining".

• Remove hose from clutch master cylinder.

3. Remove clutch tube lock pin from clutch master cylinder.

4. Remove clutch tube lock pin at clutch housing.

5. Remove clutch tube lock pins (2) from clutch damper (3).

6. Remove clutch tube (1) from clutch damper (3).

7. Remove clutch damper (3) from bracket (4).

INSTALLATION

Installation is in the reverse order of removal.

CAUTION:

Do not damage clutch tube.

• Insert each clutch tube into the CSC bleeding connector, the clutch damper connector, and the clutch master cylinder connector until it contacts the end of each connector.

• Install each lock pin into the clutch damper connecto r and the clutch master cylinder connector until it con-

tacts the end of each connector.

• After installation, bleed the air from the clutch hydraulic system. Refer to CL-9, "

Air Bleeding".

Inspection and AdjustmentINFOID:0000000012432229

INSPECTION AFTER REMOVAL

• Check the clutch tube for cracks and damage. If the cl utch tube has cracks or damage, replace it with a new

one.

• Check the O-ring of the clutch tube for cracks and dam age. If the O-ring of the clutch tube has cracks or

damage, replace clutch tube with a new one.

• Check the clutch damper for cracks and damage. If the clutch damper has cracks or damage, replace it with

a new one.

INSPECTION AFTER INSTALLATION

Check for clutch fluid leaks and check the clutch fluid level. Refer to CL-7, "Inspection".

WCIA0597E

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 644 of 3641

CL-18

< UNIT REMOVAL AND INSTALLATION >

CSC (CONCENTRIC SLAVE CYLINDER)

• Do not insert and operate CSC when transaxle is removed. Piston and stopper of CSC compo-nents may fall off.

2. Install engine and transaxle assembly. Refer to EM-87, "

Removal and Installation".

Inspection and AdjustmentINFOID:0000000012432232

INSPECTION AFTER INSTALLATION

Check for clutch fluid leaks and clutch fluid level. Refer to CL-7, "Inspection".

ADJUSTMENT AFTER INSTALLATION

Perform the air bleeding. Refer to CL-9, "Air Bleeding".

Revision: August 2015 2016 Versa Note

cardiagn.com