tire size NISSAN NOTE 2016 Service Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2016, Model line: NOTE, Model: NISSAN NOTE 2016Pages: 3641, PDF Size: 28.72 MB

Page 453 of 3641

![NISSAN NOTE 2016 Service Repair Manual PRECAUTIONSBRC-5

< PRECAUTION > [VDC/TCS/ABS]

C

D

E

G H

I

J

K L

M A

B

BRC

N

O P

Precaution for Brake Control SystemINFOID:0000000012430822

• Just after starting vehicle after ignition switch is ON, NISSAN NOTE 2016 Service Repair Manual PRECAUTIONSBRC-5

< PRECAUTION > [VDC/TCS/ABS]

C

D

E

G H

I

J

K L

M A

B

BRC

N

O P

Precaution for Brake Control SystemINFOID:0000000012430822

• Just after starting vehicle after ignition switch is ON,](/img/5/57363/w960_57363-452.png)

PRECAUTIONSBRC-5

< PRECAUTION > [VDC/TCS/ABS]

C

D

E

G H

I

J

K L

M A

B

BRC

N

O P

Precaution for Brake Control SystemINFOID:0000000012430822

• Just after starting vehicle after ignition switch is ON, brake pedal may vibrate or motor operating noise may be heard from engine compartment. This is a normal condition.

• When an error is indicated by ABS or another warning lamp, collect all necessary information from customer

(what symptoms are present under what conditions) and check for simple causes before starting diagnostic

servicing. Besides electrical system inspection, c heck brake booster operation, brake fluid level and oil

leaks.

• If tire size and type are used in an improper combinati on or brake pads are not Genuine NISSAN parts, stop-

ping distance or steering stability may deteriorate.

• ABS might be out of order or malfunctions by putting a radio (wiring inclusive), an antenna and a lead-in wire

near the control unit.

• If aftermarket parts (car stereo, CD player, etc.) have been installed, check for incidents such as harness pinches, open circuits, and improper wiring.

• VDC system may not operate normally or a VDC OFF indi cator lamp or SLIP indicator lamp may light.

- When replacing the following parts with parts other than genuine parts or making modifications: Suspension- related parts (shock absorber, spring, bushing, etc.), tire s, wheels (other than specified sizes), brake-related

parts (pad, rotor, caliper, etc.), engine-related parts (muffler, ECM, etc.) and body reinforcement-related parts

(roll bar, tower bar, etc.).

- When driving with worn or deteriorated suspension, tires and brake-related parts.

Precaution for Harness RepairINFOID:0000000012430823

• Solder the repair part, and wrap it with tape. [Twisted wire fray

must be 110 mm (4.33 in) or less.]

• Do not bypass the repair point with wire. (If it is bypassed, the turn- out point cannot be separated and the twisted wire characteristics

are lost.)

SKIB8766E

SKIB8767E

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 511 of 3641

![NISSAN NOTE 2016 Service Repair Manual C1105, C1106, C1107, C1108 WHEEL SENSOR

BRC-63

< DTC/CIRCUIT DIAGNOSIS > [VDC/TCS/ABS]

C

D

E

G H

I

J

K L

M A

B

BRC

N

O P

C1105, C1106, C1107, C1108 WHEEL SENSOR

DTC DescriptionINFOID:0000000012430856

NISSAN NOTE 2016 Service Repair Manual C1105, C1106, C1107, C1108 WHEEL SENSOR

BRC-63

< DTC/CIRCUIT DIAGNOSIS > [VDC/TCS/ABS]

C

D

E

G H

I

J

K L

M A

B

BRC

N

O P

C1105, C1106, C1107, C1108 WHEEL SENSOR

DTC DescriptionINFOID:0000000012430856](/img/5/57363/w960_57363-510.png)

C1105, C1106, C1107, C1108 WHEEL SENSOR

BRC-63

< DTC/CIRCUIT DIAGNOSIS > [VDC/TCS/ABS]

C

D

E

G H

I

J

K L

M A

B

BRC

N

O P

C1105, C1106, C1107, C1108 WHEEL SENSOR

DTC DescriptionINFOID:0000000012430856

DTC DETECTION LOGIC

POSSIBLE CAUSE

NOTE:

Confirm if DTC is PAST or CRNT. If DTC is CRNT, proceed with Diagnosis Procedure. If DTC is PAST, clear

the DTC. Do not replace the ABS actuator and electric unit (control unit) for a PAST DTC.

DTC CONFIRMATION PROCEDURE

1.PRECONDITIONING

If “DTC CONFIRMATION PROCEDURE” has been previously conducted, always turn the ignition switch OFF

and wait at least 10 seconds before conducting the next test.

>> GO TO 2.

2.CHECK DTC DETECTION

With CONSULT

1. Start the engine.

2. Drive the vehicle at approx. 50 km/h ( 31 MPH) or more for approx. 2 minutes.

3. Stop the vehicle.

4. Turn the ignition switch OFF.

DTC Display Item

(Trouble diagnosis content) Malfunction detected condition

C1105 RR RH SENSOR-2

(Rear RH wheel sensor-2) • When power supply voltage of rear RH wheel sensor is low.

• When distance between rear RH wheel sensor and rear RH wheel sensor rotor is large.

• When installation of rear RH wheel sensor or rear RH wheel sensor rotor is not normal.

• When there is contamination on or damage to the rear RH wheel sensor or rear RH sen-

sor rotor.

C1106 RR LH SENSOR-2

(Rear LH wheel sensor-2) • When power supply voltage of rear LH wheel sensor is low.

• When distance between rear LH wheel sensor and rear LH wheel sensor rotor is large.

• When installation of rear LH wheel sensor or rear LH wheel sensor rotor is not normal.

• When there is contamination on or damage to the rear LH wheel sensor or rear LH sen-

sor rotor.

C1107 FR RH SENSOR-2

(Front RH wheel sensor-2) • When power supply voltage of front RH wheel sensor is low.

• When distance between front RH wheel sensor and front RH wheel sensor rotor is large.

• When installation of front RH wheel sensor or front RH wheel sensor rotor is not normal.

• When there is contamination on or damage to the front RH wheel sensor or front RH sen-

sor rotor.

C1108 FR LH SENSOR-2

(Front LH wheel sensor-2) • When power supply voltage of front LH wheel sensor is low.

• When distance between front LH wheel sensor and front LH wheel sensor rotor is large.

• When installation of front LH wheel sensor or front LH wheel sensor rotor is not normal.

• When there is contamination on or damage to the front LH wheel sensor or front LH sen-

sor rotor.

PAST DTC CRNT DTC

• Harness or connector

• Wheel sensor

• Sensor rotor

• Tire size

• ABS actuator and electric unit (control unit) power supply sys-

tem

•Fuse

• Fusible link

•Battery • Harness or connector

• Wheel sensor

• Sensor rotor

• ABS actuator and electric unit (control unit)

• Tire size

• ABS actuator and electric unit

(control unit) power supply sys-

tem

•Fuse

• Fusible link

•Battery

• Vehicle was not driven after previous repair

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 512 of 3641

![NISSAN NOTE 2016 Service Repair Manual BRC-64

< DTC/CIRCUIT DIAGNOSIS >[VDC/TCS/ABS]

C1105, C1106, C1107, C1108 WHEEL SENSOR

NOTE:

Wait at least 10 seconds after turning ignition switch OFF.

5. Start the engine.

NOTE:

Wait at least 10 seco NISSAN NOTE 2016 Service Repair Manual BRC-64

< DTC/CIRCUIT DIAGNOSIS >[VDC/TCS/ABS]

C1105, C1106, C1107, C1108 WHEEL SENSOR

NOTE:

Wait at least 10 seconds after turning ignition switch OFF.

5. Start the engine.

NOTE:

Wait at least 10 seco](/img/5/57363/w960_57363-511.png)

BRC-64

< DTC/CIRCUIT DIAGNOSIS >[VDC/TCS/ABS]

C1105, C1106, C1107, C1108 WHEEL SENSOR

NOTE:

Wait at least 10 seconds after turning ignition switch OFF.

5. Start the engine.

NOTE:

Wait at least 10 seconds after starting the engine.

6. Perform “Self Diagnostic Result” of “ABS”.

Is DTC

“C1105”, “C1106”, “C1107” or “C1108” detected?

YES-1 >> “C1105”, “C1106”, “C1107” or “C1108” is displayed as “CRNT”: Proceed to BRC-64, "Diagnosis

Procedure".

YES-2 >> “C1105”, “C1106”, “C1107” or “C1108” is disp layed as “PAST”: Inspection End (Erase “Self Diag-

nostic Result” of “ABS”).

NO-1 >> To check malfunction symptom before repair: Refer to GI-42, "

Intermittent Incident".

NO-2 >> Confirmation after repair: Inspection End.

Diagnosis ProcedureINFOID:0000000012430857

CAUTION:

Never check between wheel senso r harness connector terminals.

1.CHECK WHEEL HUB ASSEMBLY

Check that there is no excessive looseness in wheel hub assembly.

• Front: Refer to FA X - 7 , "

Inspection".

• Rear: Refer to RAX-5, "

Inspection".

Is the inspection result normal?

YES >> GO TO 2.

NO >> Repair or replace the wheel hub assembly, and GO TO 2. • Front: Refer to FA X - 9 , "

Removal and Installation".

• Rear: Refer to RAX-6, "

Removal and Installation".

2.CHECK ABS ACTUATOR AND ELECTRIC UNIT (CONTROL UNIT) POWER SUPPLY AND GROUND CIR-

CUIT

Check the ABS actuator and electric unit (contro l unit) power supply and ground circuits. Refer to BRC-121,

"Diagnosis Procedure".

Is the inspection result normal?

YES >> GO TO 3.

NO >> Repair / replace harness, connector, fuse, or fusible link.

3.CHECK TIRE

1. Turn the ignition switch OFF.

2. Check the tire air pressure, wear and size. Refer to WT-54, "

Tire Air Pressure".

Is the inspection result normal?

YES >> GO TO 6.

NO >> Adjust air pressure or replace tire, and GO TO 4.

4.CHECK DATA MONITOR (1)

With CONSULT

1. Erase “Self Diagnostic Result” of “ABS”.

2. Turn the ignition switch OFF → ON → OFF.

NOTE:

Wait at least 10 seconds after turning ignition switch OFF or ON.

3. Start the engine.

4. Select “DATA MONITOR” of “ABS”, check “FR LH SENSOR”, “FR RH SENSOR”, “RR LH SENSOR” and

“RR RH SENSOR”.

NOTE:

Set the “DATA MONITOR” recording speed to “10 msec”.

5. Read the values (wheel speed) of both the norma l wheel sensors and malfunctioning wheel sensor.

NOTE:

Vehicle must be driven after repair or replacement to erase the previous DTCs.

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 525 of 3641

![NISSAN NOTE 2016 Service Repair Manual C1115 WHEEL SENSORBRC-77

< DTC/CIRCUIT DIAGNOSIS > [VDC/TCS/ABS]

C

D

E

G H

I

J

K L

M A

B

BRC

N

O P

C1115 WHEEL SENSOR

DTC DescriptionINFOID:0000000012430864

DTC DETECTION LOGIC

POSSIBLE CAUSE

NOTE:

Co NISSAN NOTE 2016 Service Repair Manual C1115 WHEEL SENSORBRC-77

< DTC/CIRCUIT DIAGNOSIS > [VDC/TCS/ABS]

C

D

E

G H

I

J

K L

M A

B

BRC

N

O P

C1115 WHEEL SENSOR

DTC DescriptionINFOID:0000000012430864

DTC DETECTION LOGIC

POSSIBLE CAUSE

NOTE:

Co](/img/5/57363/w960_57363-524.png)

C1115 WHEEL SENSORBRC-77

< DTC/CIRCUIT DIAGNOSIS > [VDC/TCS/ABS]

C

D

E

G H

I

J

K L

M A

B

BRC

N

O P

C1115 WHEEL SENSOR

DTC DescriptionINFOID:0000000012430864

DTC DETECTION LOGIC

POSSIBLE CAUSE

NOTE:

Confirm if DTC is PAST or CRNT. If DTC is CRNT, proceed with Diagnosis Procedure. If DTC is PAST, clear

the DTC. Do not replace the ABS actuator and electric unit (control unit) for a PAST DTC.

DTC CONFIRMATION PROCEDURE

1.PRECONDITIONING

If “DTC CONFIRMATION PROCEDURE” has been previously conducted, always turn the ignition switch OFF

and wait at least 10 seconds before conducting the next test.

>> GO TO 2.

2.CHECK DTC DETECTION

With CONSULT

1. Start the engine.

2. Drive the vehicle at approx. 50 km/h ( 31 MPH) or more for approx. 2 minutes.

3. Stop the vehicle.

4. Turn the ignition switch OFF. NOTE:

Wait at least 10 seconds after turning ignition switch OFF.

5. Start the engine.

NOTE:

Wait at least 10 seconds after starting the engine.

6. Perform “Self Diagnostic Result” of “ABS”.

Is DTC

“C 111 5” detected?

YES-1 >> “C1115” is displayed as “CRNT”: Proceed to BRC-77, "Diagnosis Procedure".

YES-2 >> “C1115” is displayed as “PAST”: Inspec tion End (Erase “Self Diagnostic Result” of “ABS”).

NO-1 >> To check malfunction symptom before repair: Refer to GI-42, "

Intermittent Incident".

NO-2 >> Confirmation after repair: Inspection End.

Diagnosis ProcedureINFOID:0000000012430865

CAUTION:

Never check between wheel sensor harness connector terminals.

DTC Display Item

(Trouble diagnosis content) Malfunction detected condition

C 111 5 ABS SENSOR [ABNORMAL

SIGNAL]

(Wheel sensor [abnormal sig-

nal]) When difference in wheel speed between any wheel and others is detected when the ve-

hicle is driven, because of installation of other tires than specified.

PAST DTC

CRNT DTC

• Harness or connector

• Wheel sensor

• Sensor rotor

• ABS actuator and electric unit (control unit) power supply sys-

tem

•Fuse

• Fusible link

•Battery • Harness or connector

• Wheel sensor

• Sensor rotor

• ABS actuator and electric unit (control unit)

• ABS actuator and electric unit

(control unit) power supply sys-

tem

•Fuse

• Fusible link

•Battery

• Tire size

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 526 of 3641

![NISSAN NOTE 2016 Service Repair Manual BRC-78

< DTC/CIRCUIT DIAGNOSIS >[VDC/TCS/ABS]

C1115 WHEEL SENSOR

1.CHECK TIRE

Check the tire air pressure, wear and size. Refer to WT-54, "

Tire Air Pressure".

Is the inspection result normal?

YES >> NISSAN NOTE 2016 Service Repair Manual BRC-78

< DTC/CIRCUIT DIAGNOSIS >[VDC/TCS/ABS]

C1115 WHEEL SENSOR

1.CHECK TIRE

Check the tire air pressure, wear and size. Refer to WT-54, "

Tire Air Pressure".

Is the inspection result normal?

YES >>](/img/5/57363/w960_57363-525.png)

BRC-78

< DTC/CIRCUIT DIAGNOSIS >[VDC/TCS/ABS]

C1115 WHEEL SENSOR

1.CHECK TIRE

Check the tire air pressure, wear and size. Refer to WT-54, "

Tire Air Pressure".

Is the inspection result normal?

YES >> GO TO 4.

NO >> Adjust air pressure or replace tire and GO TO 2.

2.CHECK DATA MONITOR (1)

With CONSULT

1. Erase “Self Diagnostic Result” of “ABS”

2. Turn the ignition switch OFF → ON → OFF.

NOTE:

Wait at least 10 seconds after turning ignition switch OFF or ON.

3. Start the engine.

4. Select “DATA MONITOR” of “ABS”, check “FR LH SENSOR”, “FR RH SENSOR”, “RR LH SENSOR” and

“RR RH SENSOR”.

NOTE:

Set the “DATA MONITOR” recording speed to “10 msec”.

5. Read the values (wheel speed) of both the norma l wheel sensors and malfunctioning wheel sensor.

NOTE:

Vehicle must be driven after repair or replacement to erase the previous DTCs.

Note the difference at 50 km/h (31 MPH) between the wheel speed detected by the malfunctioning wheel sen-

sor and the maximum/minimum wheel speed detected by t he normal wheel sensors, is the difference within

5%, respectively?

YES >> GO TO 3.

NO >> GO TO 4.

3.PERFORM SELF-DIAGNOSIS (1)

With CONSULT

1. Stop the vehicle.

2. Turn the ignition switch OFF. NOTE:

Wait at least 10 seconds after turning ignition switch OFF.

3. Start the engine. NOTE:

Wait at least 10 seconds after starting the engine.

4. Perform “Self Diagnostic Result” of “ABS”.

Is DTC

“C1115” detected?

YES >> GO TO 4.

NO >> Inspection End.

4.CHECK ABS ACTUATOR AND ELECTRIC UNIT (CONTROL UNIT) POWER SUPPLY AND GROUND CIR-

CUIT

Check the ABS actuator and electric unit (contro l unit) power supply and ground circuits. Refer to BRC-121,

"Diagnosis Procedure".

Is the inspection result normal?

YES >> GO TO 5.

NO >> Repair / replace harness, connector, fuse, or fusible link.

5.CHECK WHEEL SENSOR AND SENSOR ROTOR

1. Turn the ignition switch OFF.

2. Disconnect wheel sensor harness connector.

3. Remove dust and foreign matter adhered to the wheel sensor and sensor rotor with a vacuum dust collec- tor through the wheel sensor mounting hole.

CAUTION:

Install wheel sensor with no backlash and float, and tighten the mounting bolt to the specified

torque.

• Front: Refer to BRC-140, "

FRONT WHEEL SENSOR : Exploded View".

•Rear: Refer to BRC-141, "

REAR WHEEL SENSOR : Exploded View".

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 1612 of 3641

![NISSAN NOTE 2016 Service Repair Manual OVERHEATING CAUSE ANALYSISCO-7

< SYMPTOM DIAGNOSIS > [HR16DE]

C

D

E

F

G H

I

J

K L

M A

CO

NP

O

Except cool-

ing system

parts mal-

function —

Overload on engine Abusive driving

High engine rpm under NISSAN NOTE 2016 Service Repair Manual OVERHEATING CAUSE ANALYSISCO-7

< SYMPTOM DIAGNOSIS > [HR16DE]

C

D

E

F

G H

I

J

K L

M A

CO

NP

O

Except cool-

ing system

parts mal-

function —

Overload on engine Abusive driving

High engine rpm under](/img/5/57363/w960_57363-1611.png)

OVERHEATING CAUSE ANALYSISCO-7

< SYMPTOM DIAGNOSIS > [HR16DE]

C

D

E

F

G H

I

J

K L

M A

CO

NP

O

Except cool-

ing system

parts mal-

function —

Overload on engine Abusive driving

High engine rpm under no

load

Driving in low gear for ex-

tended time

Driving at extremely high

speed

Power train system mal-

function

—

Installed improper size

wheels and tires

Dragging brakes

Improper ignition timing

Blocked or restricted air

flow Blocked bumper

Installed front bumper fas-

cia cover

—

Blocked radiator grille Mud contamination or paper

clogging

Blocked radiator Blocked air flow

Blocked condenser

Installed large fog lamp

Symptom

Check items

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 1866 of 3641

SERVICE DATA AND SPECIFICATIONS (SDS)FSU-21

< SERVICE DATA AND SPECIFICATIONS (SDS)

C

DF

G H

I

J

K L

M A

B

FSU

N

O P

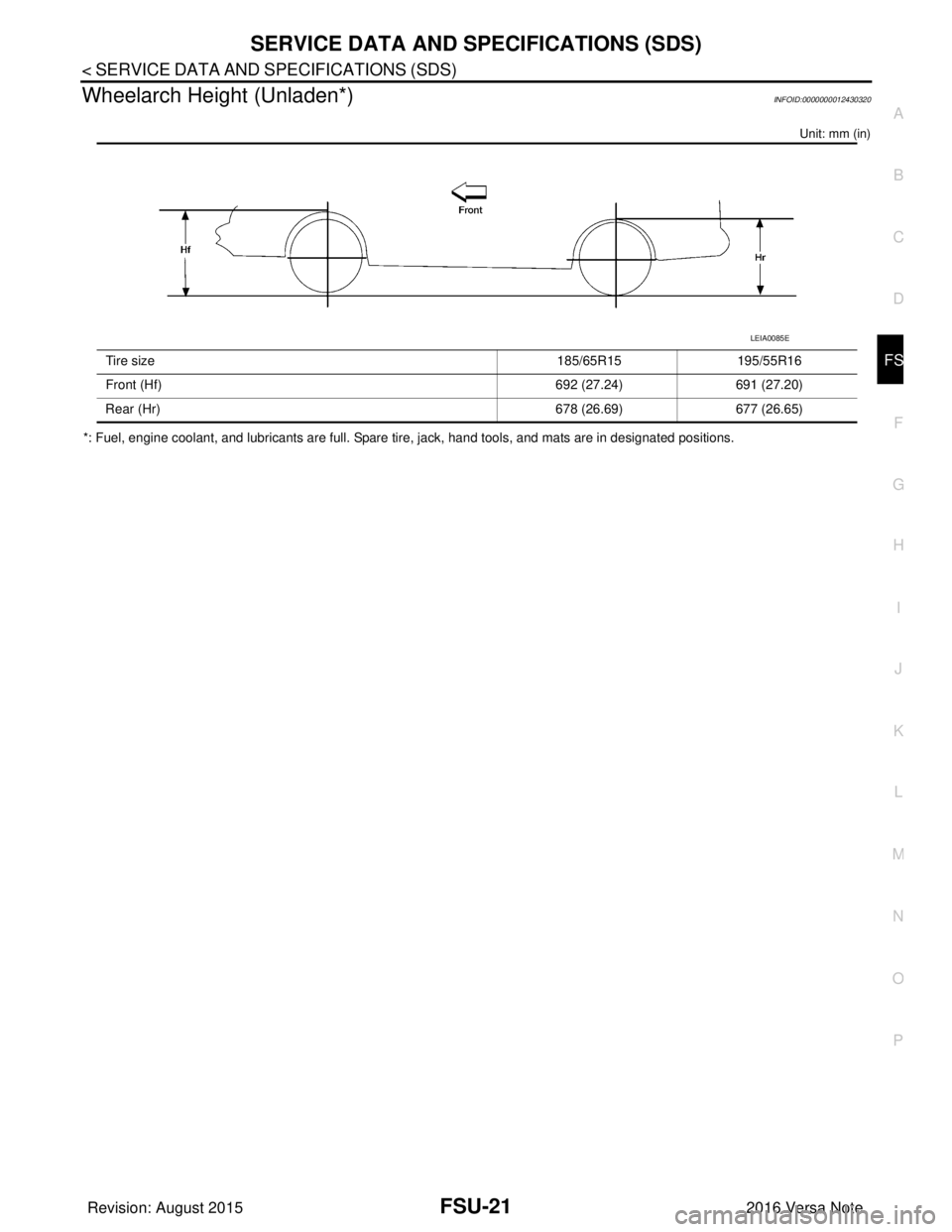

Wheelarch Height (Unladen*)INFOID:0000000012430320

Unit: mm (in)

*: Fuel, engine coolant, and lubricants are full. Spare tire, jack, hand tools, and mats are in designated positions. Tire size

185/65R15195/55R16

Front (Hf) 692 (27.24)691 (27.20)

Rear (Hr) 678 (26.69)677 (26.65)

LEIA0085E

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 1925 of 3641

IDENTIFICATION INFORMATIONGI-37

< VEHICLE INFORMATION >

C

DE

F

G H

I

J

K L

M B

GI

N

O P

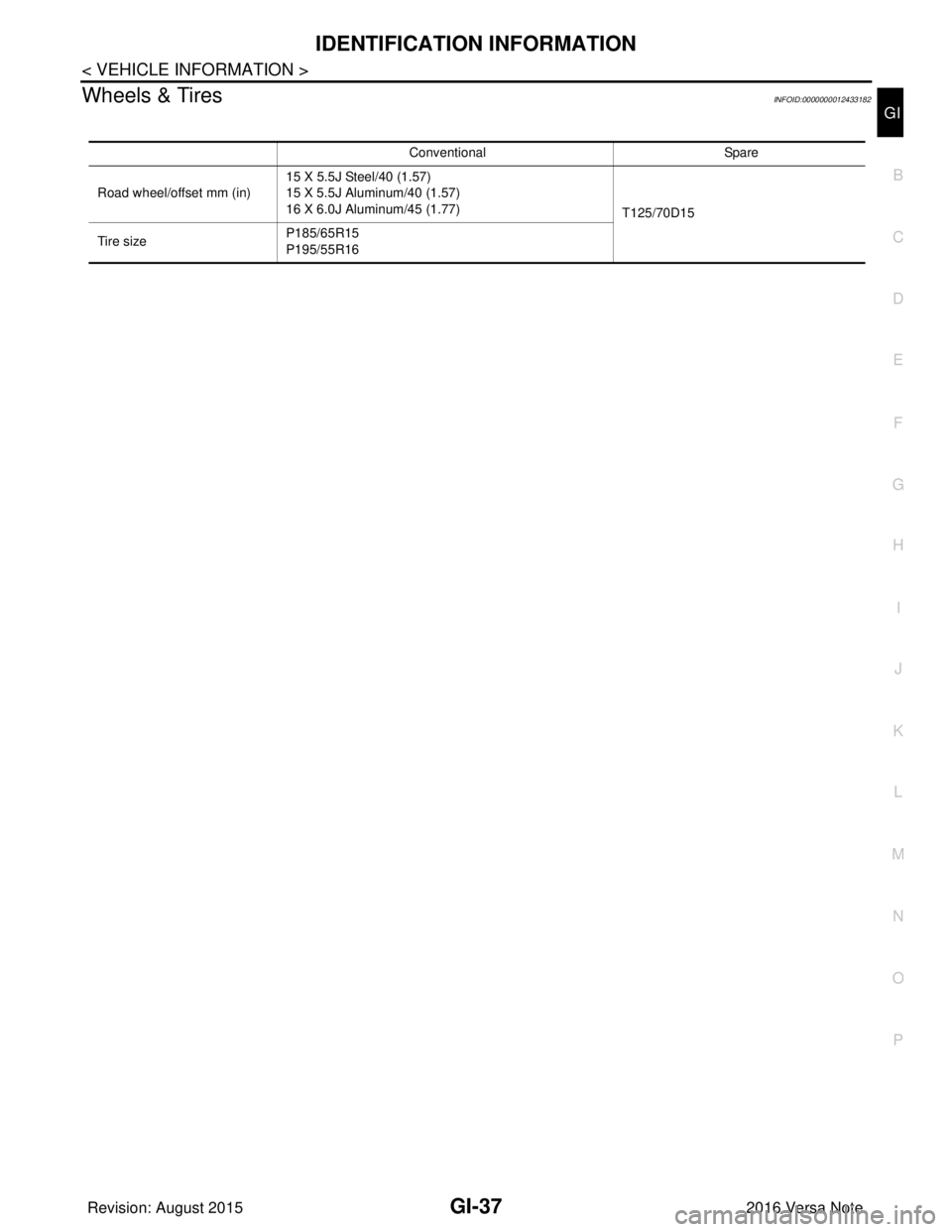

Wheels & TiresINFOID:0000000012433182

Conventional Spare

Road wheel/offset mm (in) 15 X 5.5J Steel/40 (1.57)

15 X 5.5J Aluminum/40 (1.57)

16 X 6.0J Aluminum/45 (1.77)

T125/70D15

Tire size P185/65R15

P195/55R16

Revision: August 2015

2016 Versa Note

cardiagn.com

Page 2347 of 3641

MA-32

< PERIODIC MAINTENANCE >

CHASSIS AND BODY MAINTENANCE

GEAR OIL : Refilling

INFOID:0000000012432275

1. Remove filler plug (1) and gasket from transaxle case.

2. Fill with new gear oil until gear oil level reaches the specified limit at filler plug hole as shown.

CAUTION:

Do not start engine whil e checking gear oil level.

3. Install a new gasket on filler plug and then install filler plug to transaxle case.

CAUTION:

Do not reuse gasket.

4. Tighten filler plug to the specified torque. Refer to TM-26, "

Exploded View".

WHEELS

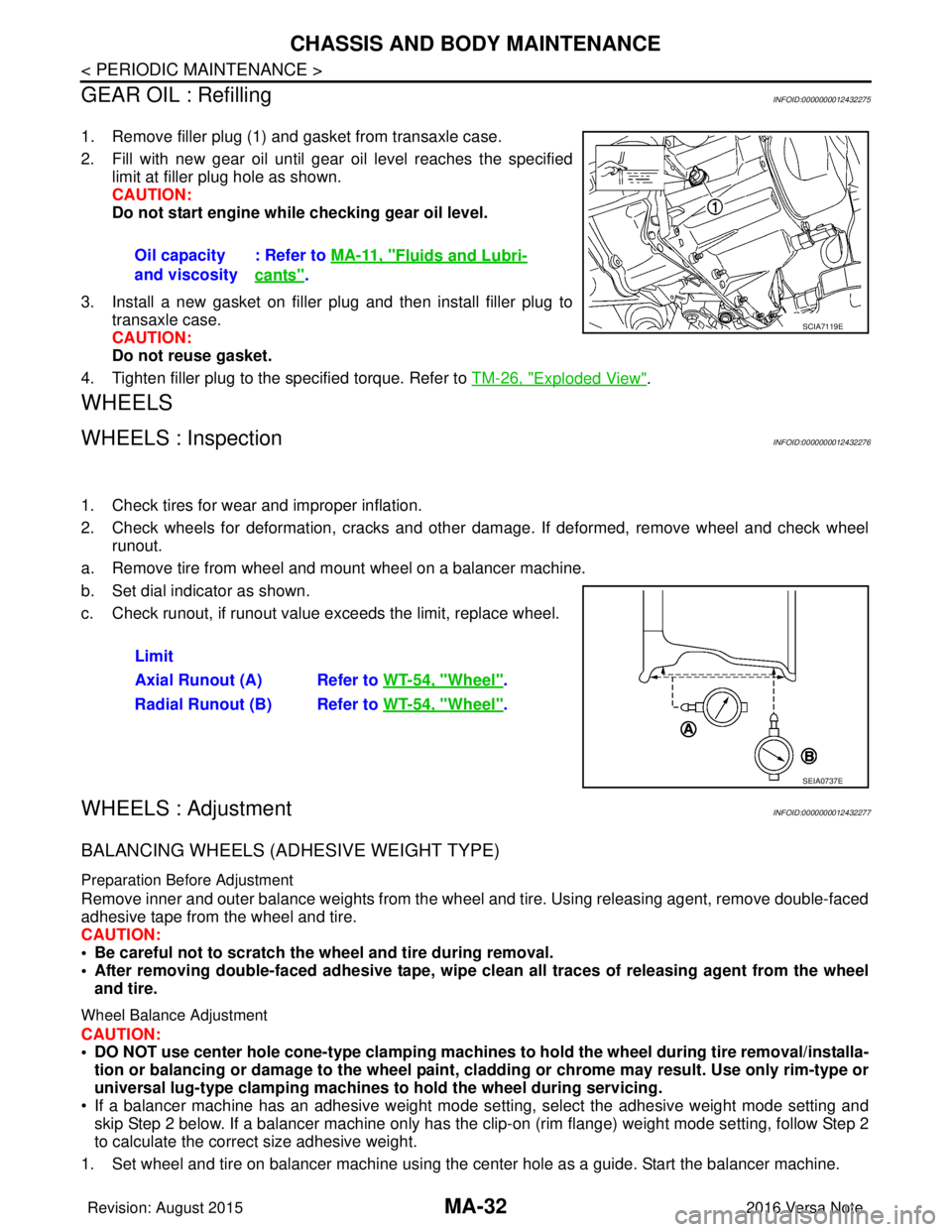

WHEELS : InspectionINFOID:0000000012432276

1. Check tires for wear and improper inflation.

2. Check wheels for deformation, cracks and other dam age. If deformed, remove wheel and check wheel

runout.

a. Remove tire from wheel and mount wheel on a balancer machine.

b. Set dial indicator as shown.

c. Check runout, if runout value exceeds the limit, replace wheel.

WHEELS : AdjustmentINFOID:0000000012432277

BALANCING WHEELS (ADHESIVE WEIGHT TYPE)

Preparation Before Adjustment

Remove inner and outer balance weights from the wheel and tire. Using releasing agent, remove double-faced

adhesive tape from the wheel and tire.

CAUTION:

• Be careful not to scratch the wheel and tire during removal.

• After removing double-faced adh esive tape, wipe clean all traces of releasing agent from the wheel

and tire.

Wheel Balance Adjustment

CAUTION:

• DO NOT use center hole cone-type clamping machines to hold the wheel during tire removal/installa-

tion or balancing or damage to the wheel paint, cladding or chrome may result. Use only rim-type or

universal lug-type clamping machines to hold the wheel during servicing.

• If a balancer machine has an adhesive weight mode se tting, select the adhesive weight mode setting and

skip Step 2 below. If a balancer machine only has the clip -on (rim flange) weight mode setting, follow Step 2

to calculate the correct size adhesive weight.

1. Set wheel and tire on balancer machine using the center hole as a guide. Start the balancer machine. Oil capacity

and viscosity

: Refer to

MA-11, "

Fluids and Lubri-

cants".

SCIA7119E

Limit

Axial Runout (A) Refer to WT-54, "

Wheel".

Radial Runout (B) Refer to WT-54, "

Wheel".

SEIA0737E

Revision: August 2015 2016 Versa Note

cardiagn.com

Page 2348 of 3641

CHASSIS AND BODY MAINTENANCEMA-33

< PERIODIC MAINTENANCE >

C

DE

F

G H

I

J

K L

M B

MA

N

O A

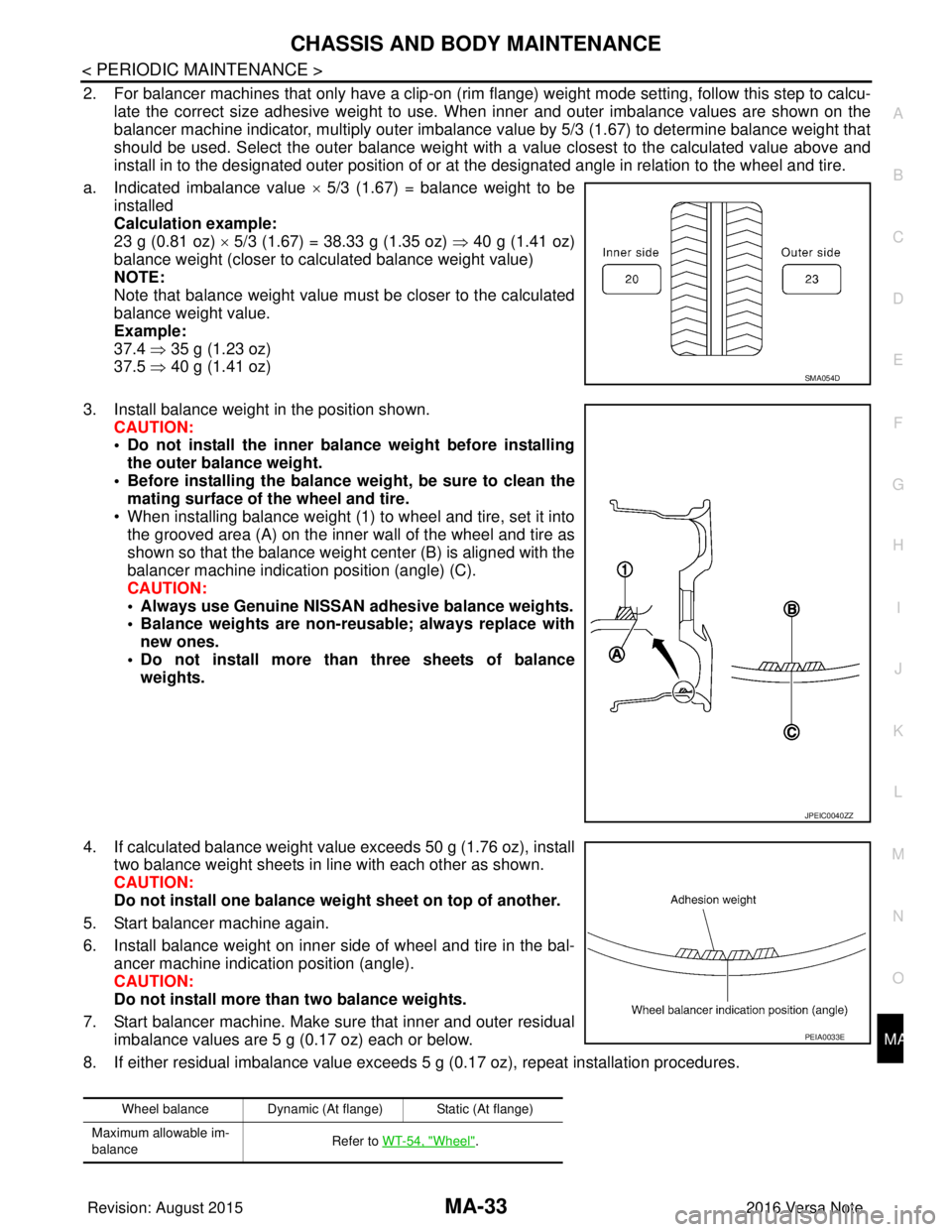

2. For balancer machines that only have a clip-on (rim fl

ange) weight mode setting, follow this step to calcu-

late the correct size adhesive weight to use. W hen inner and outer imbalance values are shown on the

balancer machine indicator, multiply outer imbalance value by 5/3 (1.67) to determine balance weight that

should be used. Select the outer balance weight with a value closest to the calculated value above and

install in to the designated outer position of or at the designated angle in relation to the wheel and tire.

a. Indicated imbalance value × 5/3 (1.67) = balance weight to be

installed

Calculation example:

23 g (0.81 oz) × 5/3 (1.67) = 38.33 g (1.35 oz) ⇒ 40 g (1.41 oz)

balance weight (closer to calculated balance weight value)

NOTE:

Note that balance weight value must be closer to the calculated

balance weight value.

Example:

37.4 ⇒ 35 g (1.23 oz)

37.5 ⇒ 40 g (1.41 oz)

3. Install balance weight in the position shown. CAUTION:

• Do not install the inner bala nce weight before installing

the outer balance weight.

• Before installing the balance weight, be sure to clean the mating surface of the wheel and tire.

• When installing balance weight (1) to wheel and tire, set it into the grooved area (A) on the inner wall of the wheel and tire as

shown so that the balance weight center (B) is aligned with the

balancer machine indication position (angle) (C).

CAUTION:

• Always use Genuine NISSAN adhesive balance weights.

• Balance weights are non-re usable; always replace with

new ones.

• Do not install more than three sheets of balance weights.

4. If calculated balance weight value exceeds 50 g (1.76 oz), install two balance weight sheets in line with each other as shown.

CAUTION:

Do not install one balance weig ht sheet on top of another.

5. Start balancer machine again.

6. Install balance weight on inner side of wheel and tire in the bal- ancer machine indication position (angle).

CAUTION:

Do not install more than two balance weights.

7. Start balancer machine. Make sure that inner and outer residual imbalance values are 5 g (0.17 oz) each or below.

8. If either residual imbalance value exceeds 5 g (0.17 oz), repeat installation procedures.

SMA054D

JPEIC0040ZZ

Wheel balance Dynamic (At flange) Static (At flange)

Maximum allowable im-

balance Refer to WT-54, "

Wheel".

PEIA0033E

Revision: August 2015

2016 Versa Note

cardiagn.com