check engine NISSAN PATHFINDER 1996 R50 / 2.G Owner's Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 1996, Model line: PATHFINDER, Model: NISSAN PATHFINDER 1996 R50 / 2.GPages: 223, PDF Size: 1.71 MB

Page 166 of 223

IKeep the battery surface clean and dry. Any

corrosion should be washed off with a

solution of baking soda and water.

IMake certain the terminal connections are

clean and securely tightened.

IIf the vehicle is not to be used for 30 days or

longer, disconnect the ªþº negative battery

terminal cable to prevent discharge.

Do not expose the battery to flames or

electrical sparks. Hydrogen gas gener-

ated by battery action is explosive. Do

not allow battery fluid to contact your

skin, eyes, fabrics, or painted surfaces.

After touching a battery or battery cap,

do not touch or rub your eyes. Thor-

oughly wash your hands. If the acid

contacts your eyes, skin or clothing,

immediately flush with water for at least

15 minutes and seek medical attention.

JUMP STARTING

If jump starting is necessary, see the ªIn case

of emergencyº section. If the engine does not

start by jump starting, the battery may have tobe replaced. Contact a NISSAN dealer.

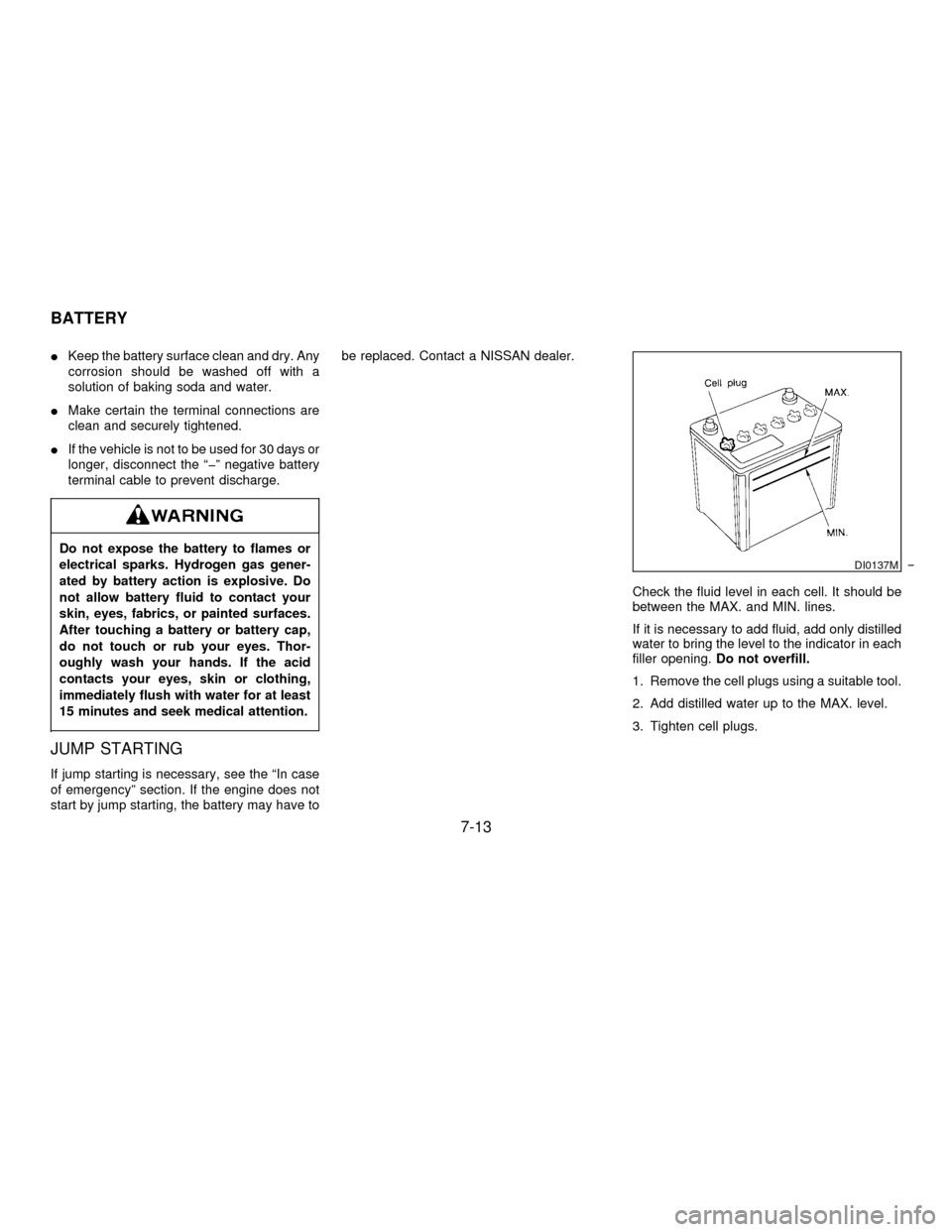

Check the fluid level in each cell. It should be

between the MAX. and MIN. lines.

If it is necessary to add fluid, add only distilled

water to bring the level to the indicator in each

filler opening.Do not overfill.

1. Remove the cell plugs using a suitable tool.

2. Add distilled water up to the MAX. level.

3. Tighten cell plugs.

DI0137M

BATTERY

7-13

Z01.2.1/R50-DX

Page 167 of 223

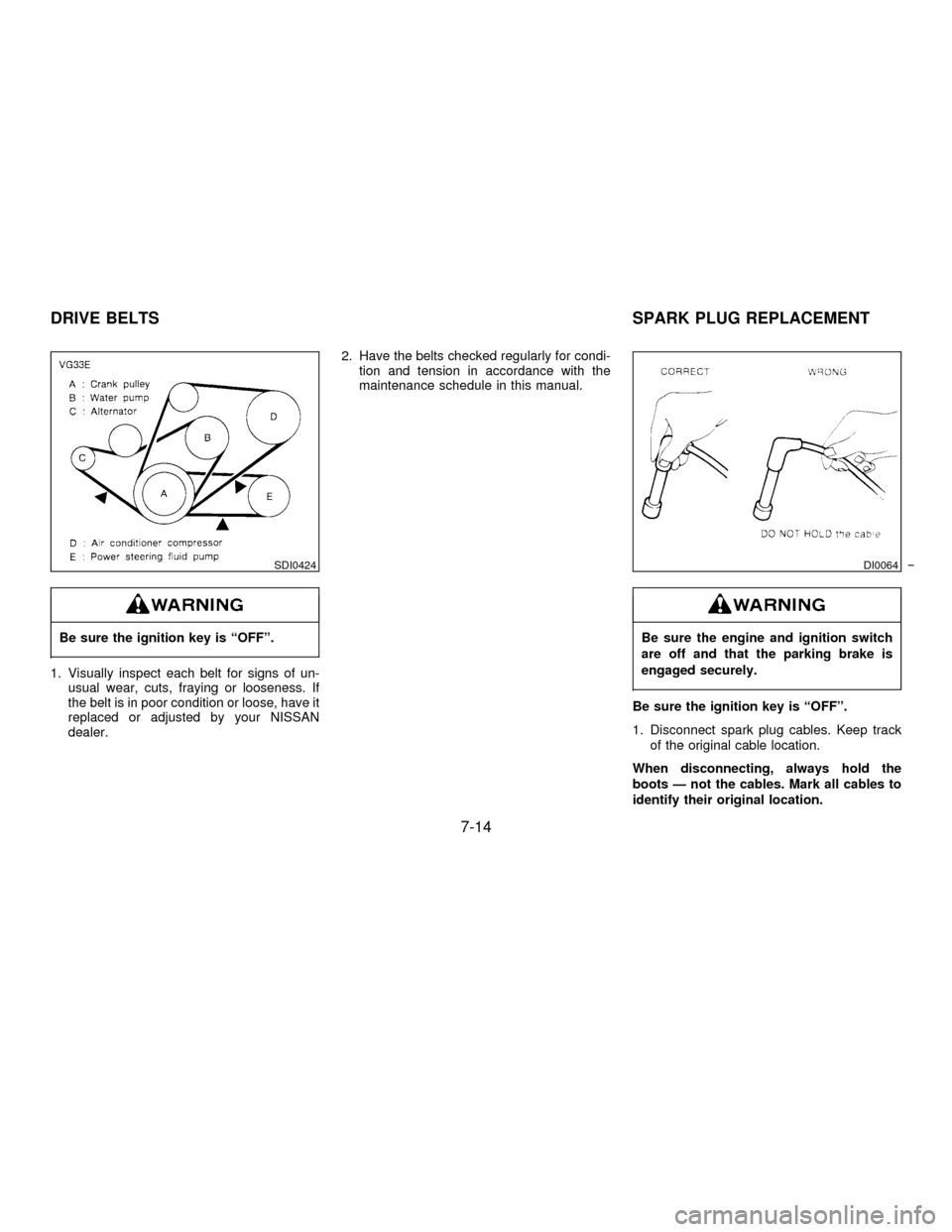

Be sure the ignition key is ªOFFº.

1. Visually inspect each belt for signs of un-

usual wear, cuts, fraying or looseness. If

the belt is in poor condition or loose, have it

replaced or adjusted by your NISSAN

dealer.2. Have the belts checked regularly for condi-

tion and tension in accordance with the

maintenance schedule in this manual.

Be sure the engine and ignition switch

are off and that the parking brake is

engaged securely.

Be sure the ignition key is ªOFFº.

1. Disconnect spark plug cables. Keep track

of the original cable location.

When disconnecting, always hold the

boots Ð not the cables. Mark all cables to

identify their original location.

SDI0424DI0064

DRIVE BELTS SPARK PLUG REPLACEMENT

7-14

Z01.2.1/R50-DX

Page 168 of 223

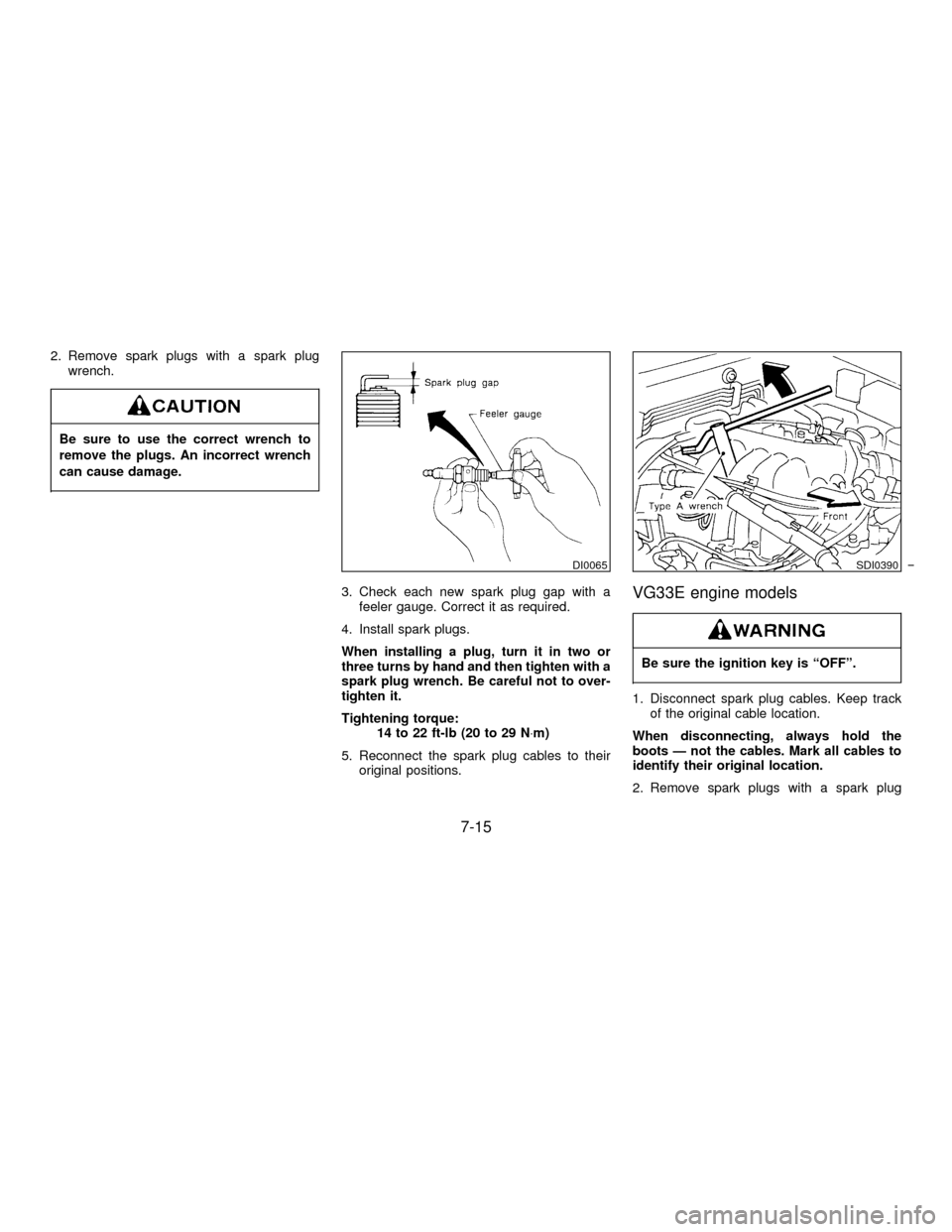

2. Remove spark plugs with a spark plug

wrench.

Be sure to use the correct wrench to

remove the plugs. An incorrect wrench

can cause damage.

3. Check each new spark plug gap with a

feeler gauge. Correct it as required.

4. Install spark plugs.

When installing a plug, turn it in two or

three turns by hand and then tighten with a

spark plug wrench. Be careful not to over-

tighten it.

Tightening torque:

14 to 22 ft-lb (20 to 29 N×m)

5. Reconnect the spark plug cables to their

original positions.VG33E engine models

Be sure the ignition key is ªOFFº.

1. Disconnect spark plug cables. Keep track

of the original cable location.

When disconnecting, always hold the

boots Ð not the cables. Mark all cables to

identify their original location.

2. Remove spark plugs with a spark plug

DI0065SDI0390

7-15

Z01.2.1/R50-DX

Page 172 of 223

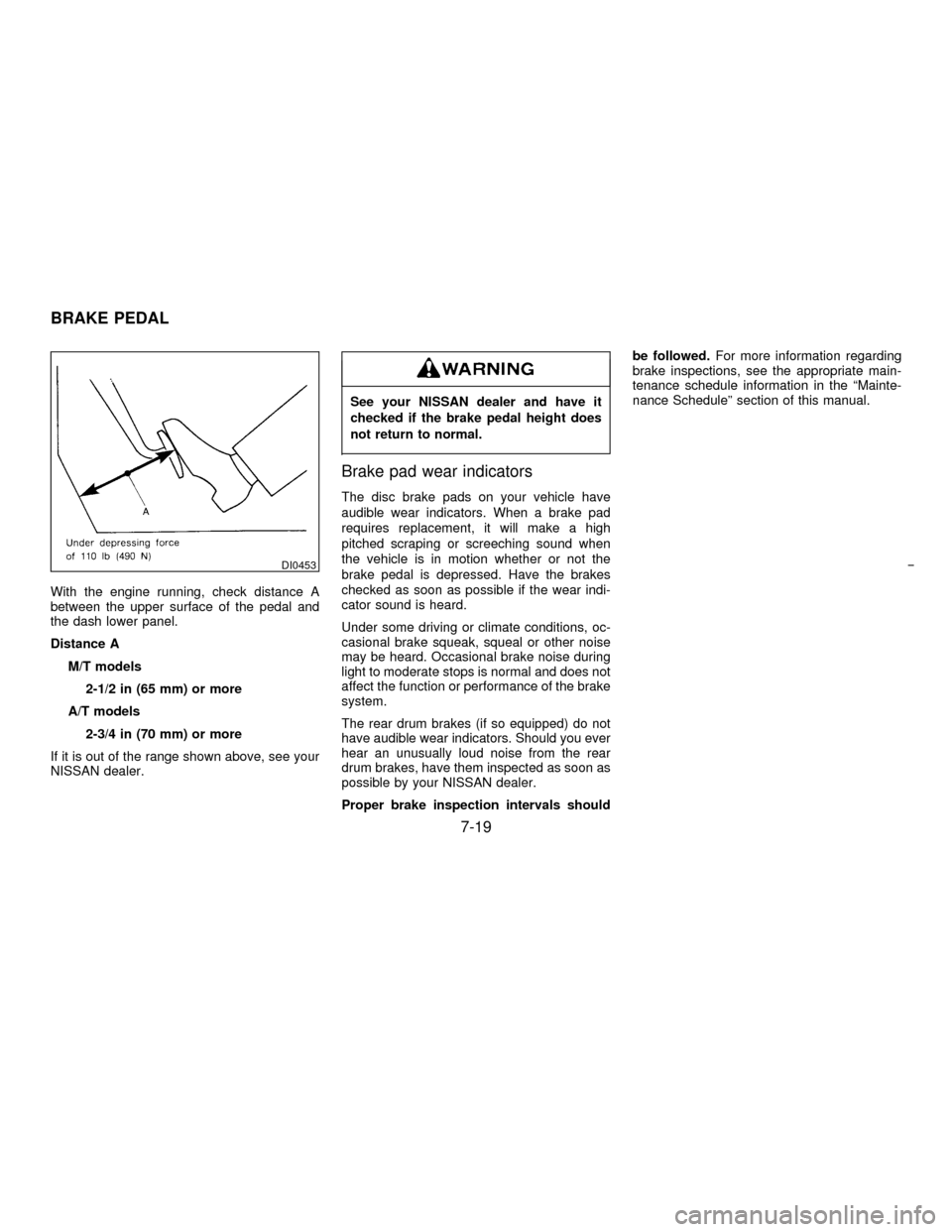

With the engine running, check distance A

between the upper surface of the pedal and

the dash lower panel.

Distance A

M/T models

2-1/2 in (65 mm) or more

A/T models

2-3/4 in (70 mm) or more

If it is out of the range shown above, see your

NISSAN dealer.

See your NISSAN dealer and have it

checked if the brake pedal height does

not return to normal.

Brake pad wear indicators

The disc brake pads on your vehicle have

audible wear indicators. When a brake pad

requires replacement, it will make a high

pitched scraping or screeching sound when

the vehicle is in motion whether or not the

brake pedal is depressed. Have the brakes

checked as soon as possible if the wear indi-

cator sound is heard.

Under some driving or climate conditions, oc-

casional brake squeak, squeal or other noise

may be heard. Occasional brake noise during

light to moderate stops is normal and does not

affect the function or performance of the brake

system.

The rear drum brakes (if so equipped) do not

have audible wear indicators. Should you ever

hear an unusually loud noise from the rear

drum brakes, have them inspected as soon as

possible by your NISSAN dealer.

Proper brake inspection intervals shouldbe followed.For more information regarding

brake inspections, see the appropriate main-

tenance schedule information in the ªMainte-

nance Scheduleº section of this manual.

DI0453

BRAKE PEDAL

7-19

Z01.2.1/R50-DX

Page 173 of 223

Check the brake booster function with the

following steps:

1. With the engine off, press and release the

brake pedal several times. When brake

pedal movement (distance of travel) re-

mains the same from one pedal application

to the next, continue on to the next step.

2. While depressing the brake pedal, start the

engine. The pedal height should drop a

little.

3. With the brake pedal depressed, stop the

engine. Keeping the pedal depressed for

about 30 seconds, the pedal height should

not change.

4. Run the engine for one minute without

depressing the brake pedal, then turn it off.

Depress the brake pedal several times. The

pedal travel distance will decrease gradu-

ally with each depression as the vacuum is

released from the booster.

If the brakes do not operate properly, have the

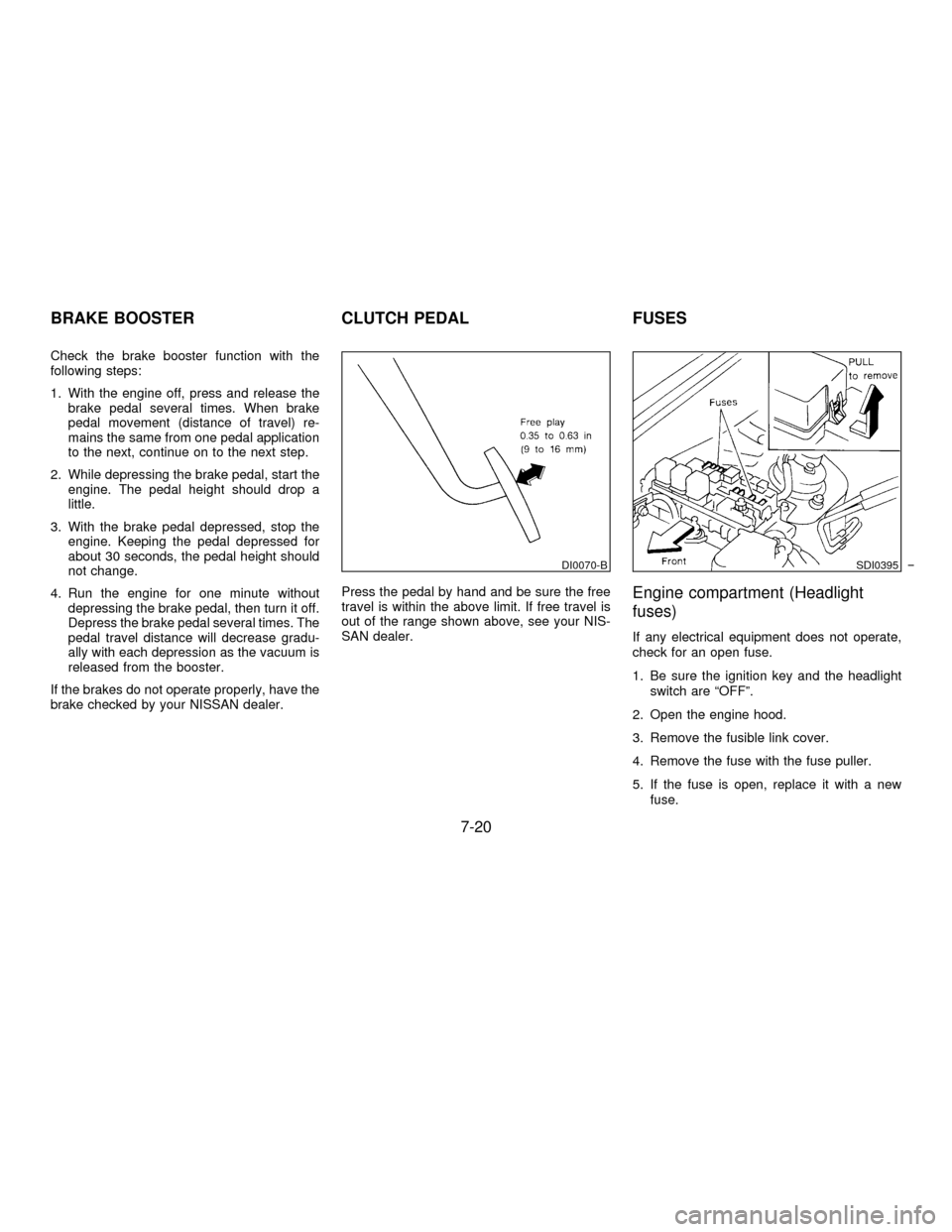

brake checked by your NISSAN dealer.Press the pedal by hand and be sure the free

travel is within the above limit. If free travel is

out of the range shown above, see your NIS-

SAN dealer.

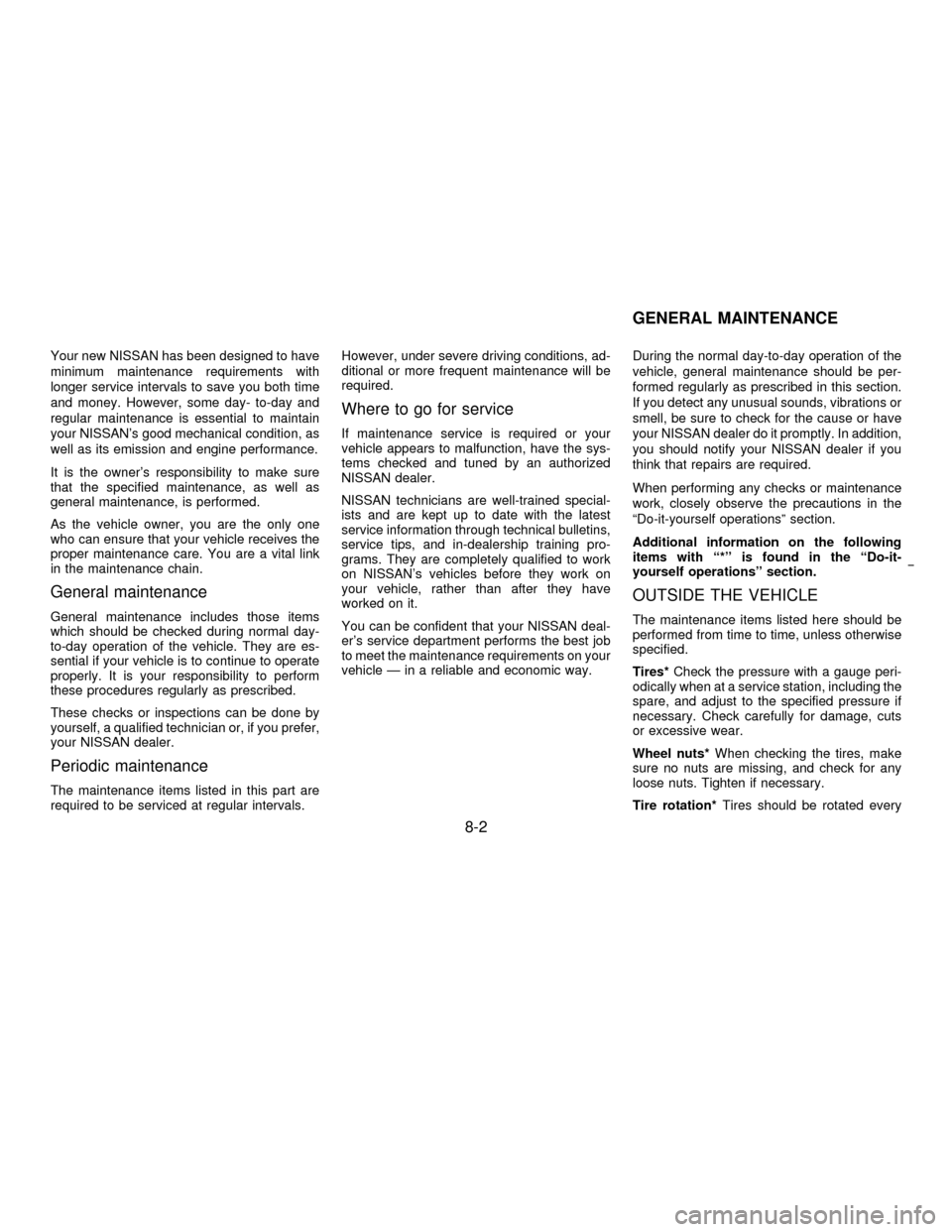

Engine compartment (Headlight

fuses)

If any electrical equipment does not operate,

check for an open fuse.

1. Be sure the ignition key and the headlight

switch are ªOFFº.

2. Open the engine hood.

3. Remove the fusible link cover.

4. Remove the fuse with the fuse puller.

5. If the fuse is open, replace it with a new

fuse.

DI0070-BSDI0395

BRAKE BOOSTER CLUTCH PEDAL FUSES

7-20

Z01.2.1/R50-DX

Page 185 of 223

Your new NISSAN has been designed to have

minimum maintenance requirements with

longer service intervals to save you both time

and money. However, some day- to-day and

regular maintenance is essential to maintain

your NISSAN's good mechanical condition, as

well as its emission and engine performance.

It is the owner's responsibility to make sure

that the specified maintenance, as well as

general maintenance, is performed.

As the vehicle owner, you are the only one

who can ensure that your vehicle receives the

proper maintenance care. You are a vital link

in the maintenance chain.

General maintenance

General maintenance includes those items

which should be checked during normal day-

to-day operation of the vehicle. They are es-

sential if your vehicle is to continue to operate

properly. It is your responsibility to perform

these procedures regularly as prescribed.

These checks or inspections can be done by

yourself, a qualified technician or, if you prefer,

your NISSAN dealer.

Periodic maintenance

The maintenance items listed in this part are

required to be serviced at regular intervals.However, under severe driving conditions, ad-

ditional or more frequent maintenance will be

required.

Where to go for service

If maintenance service is required or your

vehicle appears to malfunction, have the sys-

tems checked and tuned by an authorized

NISSAN dealer.

NISSAN technicians are well-trained special-

ists and are kept up to date with the latest

service information through technical bulletins,

service tips, and in-dealership training pro-

grams. They are completely qualified to work

on NISSAN's vehicles before they work on

your vehicle, rather than after they have

worked on it.

You can be confident that your NISSAN deal-

er's service department performs the best job

to meet the maintenance requirements on your

vehicle Ð in a reliable and economic way.During the normal day-to-day operation of the

vehicle, general maintenance should be per-

formed regularly as prescribed in this section.

If you detect any unusual sounds, vibrations or

smell, be sure to check for the cause or have

your NISSAN dealer do it promptly. In addition,

you should notify your NISSAN dealer if you

think that repairs are required.

When performing any checks or maintenance

work, closely observe the precautions in the

ªDo-it-yourself operationsº section.

Additional information on the following

items with ª*º is found in the ªDo-it-

yourself operationsº section.

OUTSIDE THE VEHICLE

The maintenance items listed here should be

performed from time to time, unless otherwise

specified.

Tires*Check the pressure with a gauge peri-

odically when at a service station, including the

spare, and adjust to the specified pressure if

necessary. Check carefully for damage, cuts

or excessive wear.

Wheel nuts*When checking the tires, make

sure no nuts are missing, and check for any

loose nuts. Tighten if necessary.

Tire rotation*Tires should be rotated every

GENERAL MAINTENANCE

8-2

Z01.2.1/R50-DX

Page 186 of 223

7,500 miles (12,000 km) for 2WD vehicles and

3,750 miles (6,000 km) for 4WD vehicles.

Wheel alignment and balanceIf the vehicle

should pull to either side while driving on a

straight and level road, or if you detect uneven

or abnormal tire wear, there may be a need for

wheel alignment.

If the steering wheel or seat vibrates at normal

highway speeds, wheel balancing may be

needed.

Windshield wiper blades*Check for cracks

or wear if they do not wipe properly.

Doors and engine hoodCheck that all doors

and the engine hood, operate properly. Also

ensure that all latches lock securely. Lubricate

hinges, latches, rollers and links if necessary.

Make sure that the secondary latch keeps the

hood from opening when the primary latch is

released.

When driving in areas using road salt or other

corrosive materials, check lubrication fre-

quently.INSIDE THE VEHICLE

The maintenance items listed here should be

checked on a regular basis, such as when

performing periodic maintenance, cleaning the

vehicle, etc.

Lights*Make sure that the headlights, stop

lights, tail lights, turn signal lights, and other

lights are all operating properly and installed

securely. Also check headlight aim.

Warning lights and buzzers/chimesMake

sure that all warning lights and buzzers/chimes

are operating properly.

Windshield wiper and washer*Check that

the wipers and washer operate properly and

that the wipers do not streak.

Windshield defrosterCheck that the air

comes out of the defroster outlets properly and

in sufficient quantity when operating the heater

or air conditioner.

Steering wheelCheck for changes in the

steering conditions, such as excessive free-

play, hard steering or strange noises.

SeatsCheck seat position controls such as

seat adjusters, seatback recliner, etc. to en-

sure they operate smoothly and that all latches

lock securely in every position. Check that the

head restraints move up and down smoothlyand that the locks (if so equipped) hold se-

curely in all latched positions.

Seat beltsCheck that all parts of the seat belt

system (e.g. buckles, anchors, adjusters and

retractors) operate properly and smoothly, and

are installed securely. Check the belt webbing

for cuts, fraying, wear or damage.

Accelerator pedalCheck the pedal for

smooth operation and make sure the pedal

does not catch or require uneven effort. Keep

the floor mats away from the pedal.

Clutch pedal*Make sure the pedal operates

smoothly and check that it has the proper free

travel.

BrakesCheck that the brakes do not pull the

vehicle to one side when applied.

Brake pedal and booster*Check the pedal

for smooth operation and make sure it has the

proper distance under it when depressed fully.

Check the brake booster function. Be certain

to keep floormats away from the pedal.

Parking brake*Check that the lever has the

proper travel and confirm that your vehicle is

held securely on a fairly steep hill with only the

parking brake applied.

Automatic transmission ªPark positionº

mechanismOn a fairly steep hill check that

8-3

Z01.2.1/R50-DX

Page 187 of 223

your vehicle is held securely with the selector

lever in the ªPº position without applying any

brakes.

UNDER THE HOOD AND VEHICLE

The maintenance items listed here should be

checked periodically e.g. each time you check

the engine oil or refuel.

Windshield washer fluid*Check that there is

adequate fluid in the tank.

Engine coolant level*Check the coolant level

when the engine is cold.

Radiator and hosesCheck the front of the

radiator and clean off any dirt, insects, leaves,

etc., that may have accumulated. Make sure

the hoses have no cracks, deformation, rot or

loose connections.

Brake and clutch fluid levels*Make sure that

the brake and clutch fluid level is between the

ªMAXº and ªMINº lines on the reservoir.

Battery*Check the fluid level in each cell. It

should be between the ªMAXº and ªMINº lines.

Engine drive belts*Make sure that no belt is

frayed, worn, cracked or oily.

Engine oil level*Check the level after parking

the vehicle on a level spot and turning off the

engine. (Be sure to wait a few minutes to allowthe oil to drain back into the sump.)

Power steering fluid level* and linesCheck

the level when the fluid is cold and the engine

is turned off. Check the lines for proper attach-

ment, leaks, cracks, etc.

Automatic transmission fluid level*Check

the level after putting the selector lever in ªPº

with the engine idling.

Exhaust systemMake sure there are no

loose supports, cracks or holes. If the sound of

the exhaust seems unusual or there is a smell

of exhaust fumes, immediately locate the

trouble and correct it. (See the carbon monox-

ide warning in the ªStarting and drivingº sec-

tion)

UnderbodyThe underbody is frequently ex-

posed to corrosive substances such as those

used on icy roads or to control dust. It is very

important to remove these substances, other-

wise rust will form on the floor pan, frame, fuel

lines and around the exhaust system. At the

end of winter, the underbody should be thor-

oughly flushed with plain water, being careful

to clean those areas where mud and dirt may

accumulate. See the ªAppearance and Interior

Careº section for additional information.

Fluid leaksCheck under the vehicle for fuel,

oil, water or other fluid leaks after the vehiclehas been parked for a while. Water dripping

from the air conditioner after use is normal. If

you should notice any leaks or if gasoline

fumes are evident, check for the cause and

have it corrected immediately.

8-4

Z01.2.1/R50-DX

Page 193 of 223

EXPLANATION OF MAINTENANCE

ITEMS

Additional information on the following

items with ª*º is found in the ªDo-it-

yourself operationsº section.

Emission control system

maintenance

Drive belts*Check drive belts for wear, fray-

ing or cracking and also for proper tension.

Replace the drive belts if found damaged.

Air cleaner filterUnder normal driving condi-

tions, the air cleaner filter should be replaced

in accordance with the maintenance schedule.

However, driving the vehicle in dusty areas

may cause more rapid clogging of the element.

Consequently, the element may have to be

replaced more frequently.

Vapor linesCheck vapor lines and connec-

tions for failure or looseness. If leaks are

found, replace the lines.

Fuel linesCheck the fuel hoses, piping and

connections for leaks, looseness or deteriora-

tion. Replace any parts if they are damaged.

Fuel filterIf the vehicle is operated under

extremely adverse weather conditions or in

areas where ambient temperatures are either

extremely low or extremely high, the filtermight become clogged. In such an event,

replace the filter immediately.

Engine coolant*Flush and refill the cooling

system.

Engine oil & oil filter*Under normal driving

conditions, the engine oil and oil filter should

be replaced in accordance with the mainte-

nance schedule. However, under severe driv-

ing conditions, they may have to be replaced

more frequently.

Spark plugs*Replace with new plugs having

the correct heat range.

Timing belt

Replace the timing belt for driving the cam-

shafts.

Chassis and body maintenance

Brake lines & cablesCheck the brake lines

and hoses (including brake booster vacuum

hoses, connections & check valve) and park-

ing brake cables for proper attachment, leaks,

cracks, chafing, abrasion, deterioration, etc.

Brake pads, discs, drums & liningsCheck

these and the other neighboring brake compo-

nents for wear, deterioration and leaks. Under

severe driving conditions, they may have to be

inspected more frequently.Manual and automatic transmission, trans-

fer & differential gear oilVisually inspect for

signs of leakage and replace oil for limited-slip

differential. Under severe driving conditions,

the oil should be replaced at the specified

interval.

Steering gear & linkage, axle & suspension

parts & drive axle shaft bootsCheck for

damage, looseness and leakage of oil or

grease. Under severe driving conditions, more

frequent inspection should be performed.

Steering linkage ball joints & front suspen-

sion ball jointsCheck the ball joints for dam-

age, looseness and grease leakage. Under

severe driving conditions, more frequent in-

spection should be performed.

Propeller shaft(s)Check the propeller

shaft(s) for damage, looseness and grease

leakage under severe driving condition

(only).

Propeller shaft greaseApply specified

grease to the greasing points of propeller

shafts in accordance with the maintenance

schedule. In the case of driving in water,

greasing should be performed immediately

afterwards.

8-10

Z01.2.1/R50-DX

Page 200 of 223

Using unleaded gasoline with an octane

rating lower than stated above can cause

persistent, heavy ªspark knockº. (ªSpark

knockº is a metallic rapping noise.) If se-

vere, this can lead to engine damage. If you

detect a persistent heavy spark knock even

when using gasoline of the stated octane

rating, or if you hear steady spark knock

while holding a steady speed on level

roads, have your dealer correct the condi-

tion. Failure to correct the condition is

misuse of the vehicle, for which NISSAN is

not responsible.

Incorrect ignition timing will result in knocking,

after-run or overheating. This in turn may

cause excessive fuel consumption or damage

to the engine. If any of the above symptoms

are encountered, have your vehicle checked at

a NISSAN dealer or other competent service

facility.

However, now and then you may notice

light spark knock for a short time while

accelerating or driving up hills. This is no

cause for concern, because you get the

greatest fuel benefit when there is light

spark knock for a short time.

9-5

Z01.2.1/R50-DX