differential NISSAN PATHFINDER 2000 R50 / 2.G Owners Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2000, Model line: PATHFINDER, Model: NISSAN PATHFINDER 2000 R50 / 2.GPages: 265, PDF Size: 2.2 MB

Page 219 of 265

headlight aim and bumper height.

Some of these effects may lead to

accidents and could result in serious

personal injury.

IIf the wheels are changed for any

reason, always replace with wheels

which have the same offset dimen-

sion. Wheels of a different offset

could cause early tire wear, possibly

degraded vehicle handling character-

istics and/or interference with the

brake discs. Such interference can

lead to decreased braking efficiency

and/or early brake pad wear.

IDo not install a deformed wheel or

tire even if it has been repaired. Such

wheels or tires could have structural

damage and could fail without warn-

ing.

IThe use of retread tire is not rec-

ommended.

Four wheel drive models

CAUTION

Always use tires of the same size, brand,

construction (bias, bias-belted or ra-

dial), and tread pattern on all four

wheels. Failure to do so may result in a

circumference difference between tires

on the front and rear axles which will

cause excessive tire wear and may dam-

age the transmission, transfer case and

differential gears.

If excessive tire wear is found, it is recom-

mended that all four tires be replaced with tires

of the same size, brand, construction and

tread pattern. The tire pressure and wheel

alignment should also be checked and cor-

rected as necessary. Contact your NISSAN

dealer.Wheel balanceUnbalanced wheels may affect vehicle han-

dling and tire life. Even with regular use,

wheels can get out of balance. Therefore, they

should be balanced as required.

Wheel balance service should be performedwith the wheels off the vehicle. Spin balancing

the rear wheels on the vehicle could lead to

transmission damage.

Care of wheelsIWash the wheels when washing the vehicle

to maintain their appearance.

IClean the inner side of the wheels when the

wheel is changed or the underside of the

vehicle is washed.

IDo not use abrasive cleaners when wash-

ing the wheels.

IInspect wheel rims regularly for dents or

corrosion. This may cause loss of pressure

or damage the tire bead.

INISSAN recommends that the road wheels

be waxed to protect against road salt in

areas where it is used during winter.Small size spare tire (if so equipped)U.S. only. Canadian vehicles are equipped

with a full size spare tire.

Observe the following precautions if the small

size spare tire must be used, otherwise your

vehicle could be damaged or involved in an

accident.

8-32

Do-it-yourself

Z

00.1.17/R50-D/V5

X

Page 228 of 265

![NISSAN PATHFINDER 2000 R50 / 2.G Owners Manual Schedule 1Abbreviations: R = Replace I = Inspect. Correct or replace if necessary. L = Lubricate [ ]: At the mileage intervals onlyMAINTENANCE OPERATIONMAINTENANCE INTERVAL

Perform at number of miles, NISSAN PATHFINDER 2000 R50 / 2.G Owners Manual Schedule 1Abbreviations: R = Replace I = Inspect. Correct or replace if necessary. L = Lubricate [ ]: At the mileage intervals onlyMAINTENANCE OPERATIONMAINTENANCE INTERVAL

Perform at number of miles,](/img/5/640/w960_640-227.png)

Schedule 1Abbreviations: R = Replace I = Inspect. Correct or replace if necessary. L = Lubricate [ ]: At the mileage intervals onlyMAINTENANCE OPERATIONMAINTENANCE INTERVAL

Perform at number of miles, kilometers

or months, whichever comes first.Miles´1,000 3.75 7.5 11.25 15 18.75 22.5 26.25 30 33.75 37.5 41.25 45 48.75 52.5 56.25 60

(km´1,000) (6) (12) (18) (24) (30) (36) (42) (48) (54) (60) (66) (72) (78) (84) (90) (96)

Months 3 6 9 12 15 18 21 24 27 30 33 36 39 42 45 48

Chassis and body maintenance

Brake lines & cablesIIII

Brake pads, rotors, drums & liningsIIIIIIII

Automatic transmission & transfer fluid,

manual transmission & differential gear oil

(exc. LSD)See NOTE (1)IIII

Limited-slip differential (LSD) gear oil See NOTE (1)IRIR

Steering gear, linkage & transfer gear, axle & suspension partsIIIIIIII

Tire rotation See NOTE (2)

Drive shaft boots (

) IIIIIIII

Propeller shaft See NOTE (3)LLLLLLLL

Front wheel bearing grease (4x2)II

Front wheel bearing grease (

) See NOTE (4)IRIR

Exhaust systemIIIIIIII

Supplemental air bag system and supple-

mental side air bag systems (if so

equipped)See NOTE (5)

Automatic Speed Control Device (ASCD) vacuum hosesIIII

NOTE: (1) If towing a trailer, using a camper or a car-top carrier, or driving on rough or muddy roads, change (not just inspect) oil at every 30,000 miles(48,000 km)

or 24 months except for LSD. Change LSD gear oil every 15,000 miles (24,000 km) or 12 months.

(2) Refer to ªTire rotationº under the ªGeneral maintenanceº heading earlier in this section.

(3) The propeller shaft should be re-greased after being immersed in water.

(4) If operating frequently in water, replace grease every 3,750 miles (6,000 km) or 3 months.

(5) Inspect the supplemental air bag system 10 years after the date of manufacture noted on the F.M.V.S.S. certification label.

Maintenance

9-7

Z

00.1.17/R50-D/V5

X

Page 230 of 265

![NISSAN PATHFINDER 2000 R50 / 2.G Owners Manual Schedule 2Abbreviations: R = Replace I = Inspect. Correct or replace if necessary. L = Lubricate [ ]: At the mileage intervals onlyMAINTENANCE OPERATIONMAINTENANCE INTERVAL

Perform at number of miles, NISSAN PATHFINDER 2000 R50 / 2.G Owners Manual Schedule 2Abbreviations: R = Replace I = Inspect. Correct or replace if necessary. L = Lubricate [ ]: At the mileage intervals onlyMAINTENANCE OPERATIONMAINTENANCE INTERVAL

Perform at number of miles,](/img/5/640/w960_640-229.png)

Schedule 2Abbreviations: R = Replace I = Inspect. Correct or replace if necessary. L = Lubricate [ ]: At the mileage intervals onlyMAINTENANCE OPERATIONMAINTENANCE INTERVAL

Perform at number of miles, kilometers or

months, whichever comes first.Miles´1,000 7.5 15 22.5 30 37.5 45 52.5 60

(km´1,000) (12) (24) (36) (48) (60) (72) (84) (96)

Months 6 12 18 24 30 36 42 48

Chassis and body maintenance

Brake lines & cablesIIII

Brake pads, rotors, discs, drums & liningsIIII

Automatic transmission & transfer fluid, manual transmission & dif-

ferential gear oil (exc. LSD)IIII

Limited-slip differential (LSD) gear oilIRIR

Steering gear, linkage & transfer gear, axle & suspension parts I I

Tire rotation See NOTE (1)

Drive shaft boots (

) IIII

Propeller shaft See NOTE (2)LLLL

Front wheel bearing grease (4x2)II

Front wheel bearing grease (

) IRIR

Exhaust systemII

Supplemental air bag system and supplemental

side air bag systems (if so equipped)See NOTE (3)

Automatic Speed Control Device (ASCD) vacuum hosesIIII

NOTE: (1) Refer to ªTire rotationº under the ªGeneral maintenanceº heading earlier in this section.

(2) The propeller shaft should be re-greased after being immersed in water.

(3) Inspect the supplemental air bag system 10 years after the date of manufacture noted on the F.M.V.S.S. certification label.

Maintenance

9-9

Z

00.1.17/R50-D/V5

X

Page 231 of 265

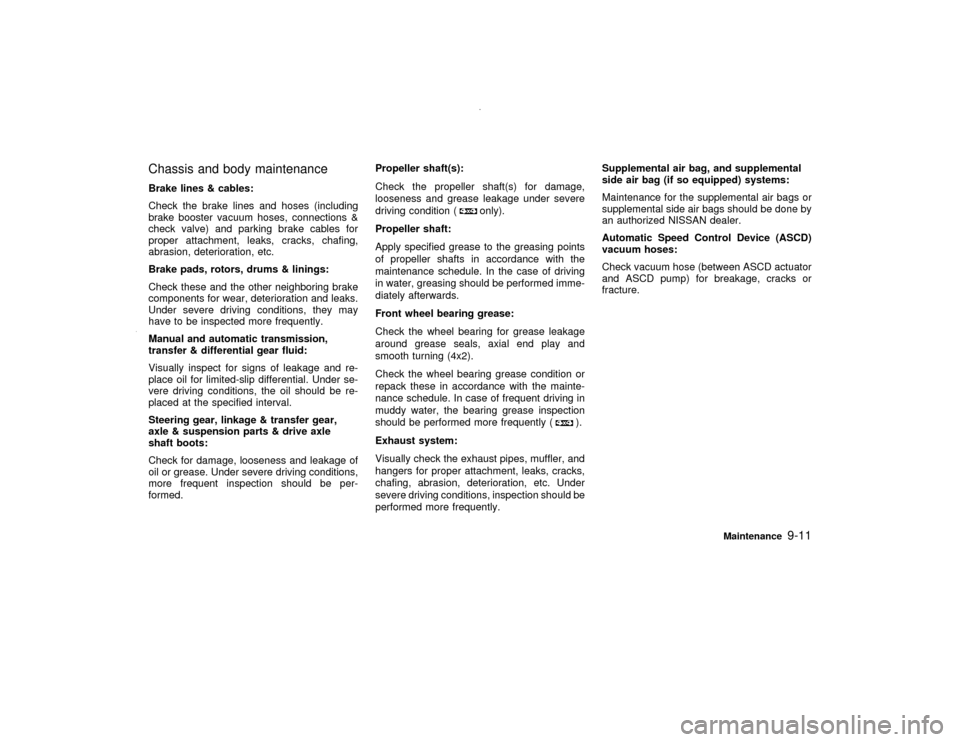

Maintenance for offroad driving

(

only)

Whenever you drive offroad through sand,

mud or water as deep as the wheel hub, more

frequent maintenance may be required of the

following items:G

Brake pads and discs

G

Brake lining and drums

G

Brake lines and hoses

G

Wheel bearing grease

G

Differential, transmission and transfer oil

G

Steering linkage

G

Propeller shafts and front drive shafts

G

Air cleaner filter

G

Clutch housing (See ªClutch housing drainº

in the ª8. Do-it-yourselfº section for check-

ing water entry.)

These items should be checked frequently to

assure safe and proper operation of your ve-

hicle.

EXPLANATION OF MAINTENANCE

ITEMS

Emission control system

maintenanceAdditional information on the following

items with * is found in the ª8. Do-it-

yourselfº section.

Drive belts*:

Check drive belts for wear, fraying or cracking

and also for proper tension. Replace the drive

belts if found damaged.

Air filter:

Under normal driving conditions, the air

cleaner filter should be replaced in accordance

with the maintenance schedule. However,

driving the vehicle in dusty areas may cause

more rapid clogging of the element. Conse-

quently, the element may have to be replaced

more frequently.

EVAP vapor lines:

Check vapor lines and connections for failure

or looseness. If leaks are found, replace the

lines.

Fuel lines:

Check the fuel hoses, piping and connectionsfor leaks, looseness or deterioration. Replace

any parts if they are damaged.

Fuel filter:

If the vehicle is operated under extremely

adverse weather conditions or in areas where

ambient temperatures are either extremely low

or extremely high, the filter might become

clogged. In such an event, replace the filter

immediately.

Engine coolant*:

Flush and refill the cooling system.

Engine oil & oil filter*:

Under normal driving conditions, the engine oil

and oil filter should be replaced in accordance

with the maintenance schedule. However, un-

der severe driving conditions, they may have

to be replaced more frequently.

Spark plugs*:

Replace with new plugs having the correct

heat range.

Timing belt:

Replace the timing belt for driving the cam-

shafts.

9-10

Maintenance

Z

00.1.17/R50-D/V5

X

Page 232 of 265

Chassis and body maintenanceBrake lines & cables:

Check the brake lines and hoses (including

brake booster vacuum hoses, connections &

check valve) and parking brake cables for

proper attachment, leaks, cracks, chafing,

abrasion, deterioration, etc.

Brake pads, rotors, drums & linings:

Check these and the other neighboring brake

components for wear, deterioration and leaks.

Under severe driving conditions, they may

have to be inspected more frequently.

Manual and automatic transmission,

transfer & differential gear fluid:

Visually inspect for signs of leakage and re-

place oil for limited-slip differential. Under se-

vere driving conditions, the oil should be re-

placed at the specified interval.

Steering gear, linkage & transfer gear,

axle & suspension parts & drive axle

shaft boots:

Check for damage, looseness and leakage of

oil or grease. Under severe driving conditions,

more frequent inspection should be per-

formed.Propeller shaft(s):

Check the propeller shaft(s) for damage,

looseness and grease leakage under severe

driving condition (

only).

Propeller shaft:

Apply specified grease to the greasing points

of propeller shafts in accordance with the

maintenance schedule. In the case of driving

in water, greasing should be performed imme-

diately afterwards.

Front wheel bearing grease:

Check the wheel bearing for grease leakage

around grease seals, axial end play and

smooth turning (4x2).

Check the wheel bearing grease condition or

repack these in accordance with the mainte-

nance schedule. In case of frequent driving in

muddy water, the bearing grease inspection

should be performed more frequently (

).

Exhaust system:

Visually check the exhaust pipes, muffler, and

hangers for proper attachment, leaks, cracks,

chafing, abrasion, deterioration, etc. Under

severe driving conditions, inspection should be

performed more frequently.Supplemental air bag, and supplemental

side air bag (if so equipped) systems:

Maintenance for the supplemental air bags or

supplemental side air bags should be done by

an authorized NISSAN dealer.

Automatic Speed Control Device (ASCD)

vacuum hoses:

Check vacuum hose (between ASCD actuator

and ASCD pump) for breakage, cracks or

fracture.

Maintenance

9-11

Z

00.1.17/R50-D/V5

X

Page 236 of 265

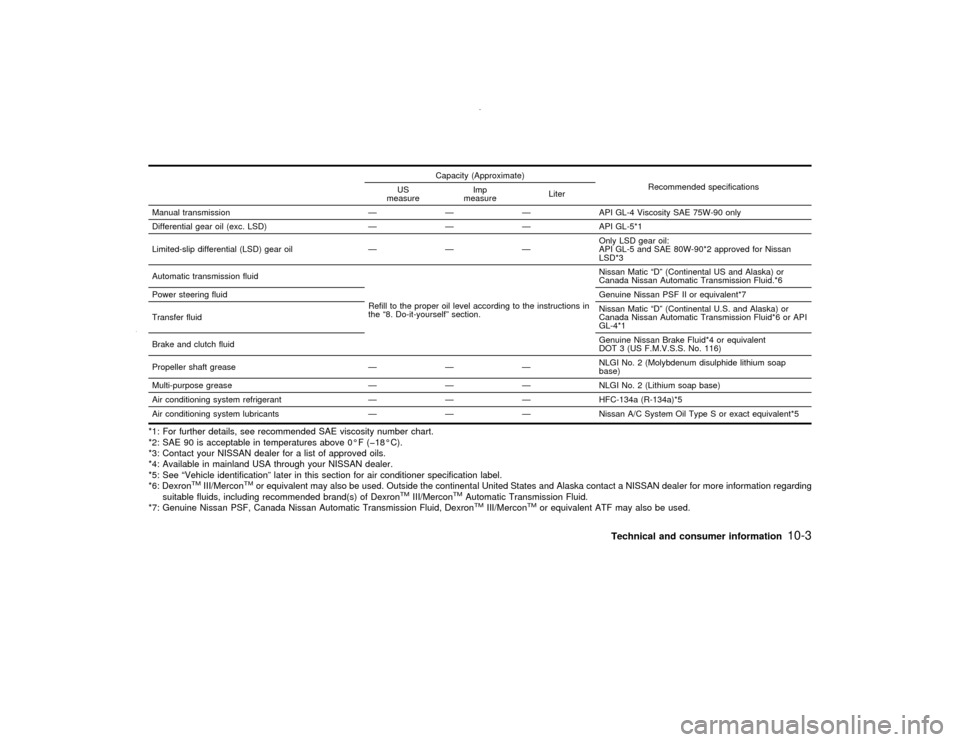

Capacity (Approximate)

Recommended specifications

US

measureImp

measureLiter

Manual transmissionÐ Ð Ð API GL-4 Viscosity SAE 75W-90 only

Differential gear oil (exc. LSD)Ð Ð Ð API GL-5*1

Limited-slip differential (LSD) gear oil Ð Ð ÐOnly LSD gear oil:

API GL-5 and SAE 80W-90*2 approved for Nissan

LSD*3

Automatic transmission fluid

Refill to the proper oil level according to the instructions in

the ª8. Do-it-yourselfº section.Nissan Matic ªDº (Continental US and Alaska) or

Canada Nissan Automatic Transmission Fluid.*6

Power steering fluidGenuine Nissan PSF II or equivalent*7

Transfer fluidNissan Matic ªDº (Continental U.S. and Alaska) or

Canada Nissan Automatic Transmission Fluid*6 or API

GL-4*1

Brake and clutch fluidGenuine Nissan Brake Fluid*4 or equivalent

DOT 3 (US F.M.V.S.S. No. 116)

Propeller shaft grease Ð Ð ÐNLGI No. 2 (Molybdenum disulphide lithium soap

base)

Multi-purpose greaseÐ Ð Ð NLGI No. 2 (Lithium soap base)

Air conditioning system refrigerantÐ Ð Ð HFC-134a (R-134a)*5

Air conditioning system lubricantsÐ Ð Ð Nissan A/C System Oil Type S or exact equivalent*5

*1: For further details, see recommended SAE viscosity number chart.

*2: SAE 90 is acceptable in temperatures above 0ÉF (þ18ÉC).

*3: Contact your NISSAN dealer for a list of approved oils.

*4: Available in mainland USA through your NISSAN dealer.

*5: See ªVehicle identificationº later in this section for air conditioner specification label.

*6: Dexron

TM

III/Mercon

TM

or equivalent may also be used. Outside the continental United States and Alaska contact a NISSAN dealer for more information regarding

suitable fluids, including recommended brand(s) of Dexron

TM

III/Mercon

TM

Automatic Transmission Fluid.

*7: Genuine Nissan PSF, Canada Nissan Automatic Transmission Fluid, DexronTM

III/Mercon

TM

or equivalent ATF may also be used.

Technical and consumer information

10-3

Z

00.1.17/R50-D/V5

X