ECU NISSAN PATHFINDER 2010 Owner´s Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2010, Model line: PATHFINDER, Model: NISSAN PATHFINDER 2010Pages: 463, PDF Size: 5.69 MB

Page 395 of 463

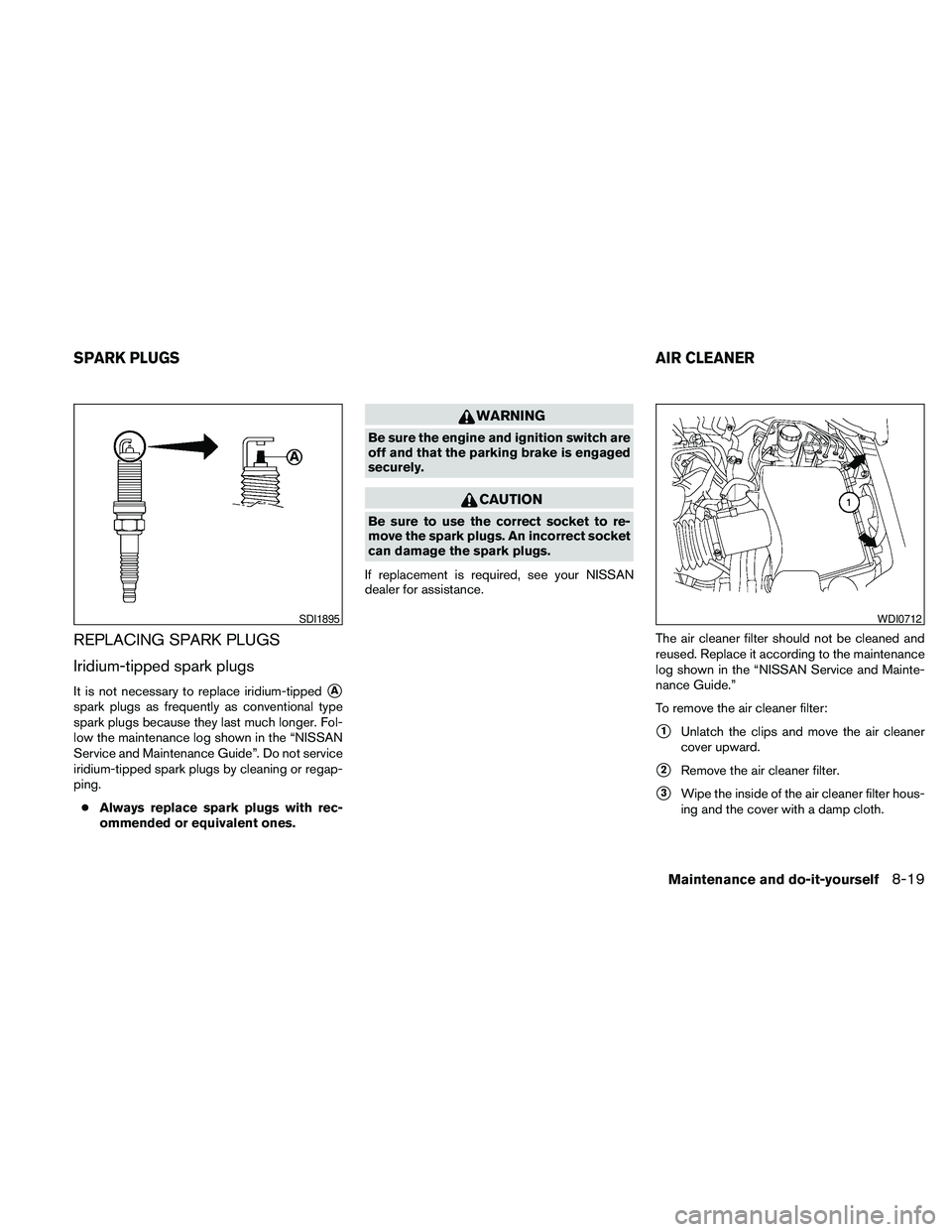

REPLACING SPARK PLUGS

Iridium-tipped spark plugs

It is not necessary to replace iridium-tippedsA

spark plugs as frequently as conventional type

spark plugs because they last much longer. Fol-

low the maintenance log shown in the “NISSAN

Service and Maintenance Guide”. Do not service

iridium-tipped spark plugs by cleaning or regap-

ping.

cAlways replace spark plugs with rec-

ommended or equivalent ones.

WARNING

Be sure the engine and ignition switch are

off and that the parking brake is engaged

securely.

CAUTION

Be sure to use the correct socket to re-

move the spark plugs. An incorrect socket

can damage the spark plugs.

If replacement is required, see your NISSAN

dealer for assistance.

The air cleaner filter should not be cleaned and

reused. Replace it according to the maintenance

log shown in the “NISSAN Service and Mainte-

nance Guide.”

To remove the air cleaner filter:

s1Unlatch the clips and move the air cleaner

cover upward.

s2Remove the air cleaner filter.

s3Wipe the inside of the air cleaner filter hous-

ing and the cover with a damp cloth.

SDI1895WDI0712

SPARK PLUGSAIR CLEANER

Maintenance and do-it-yourself8-19

Page 401 of 463

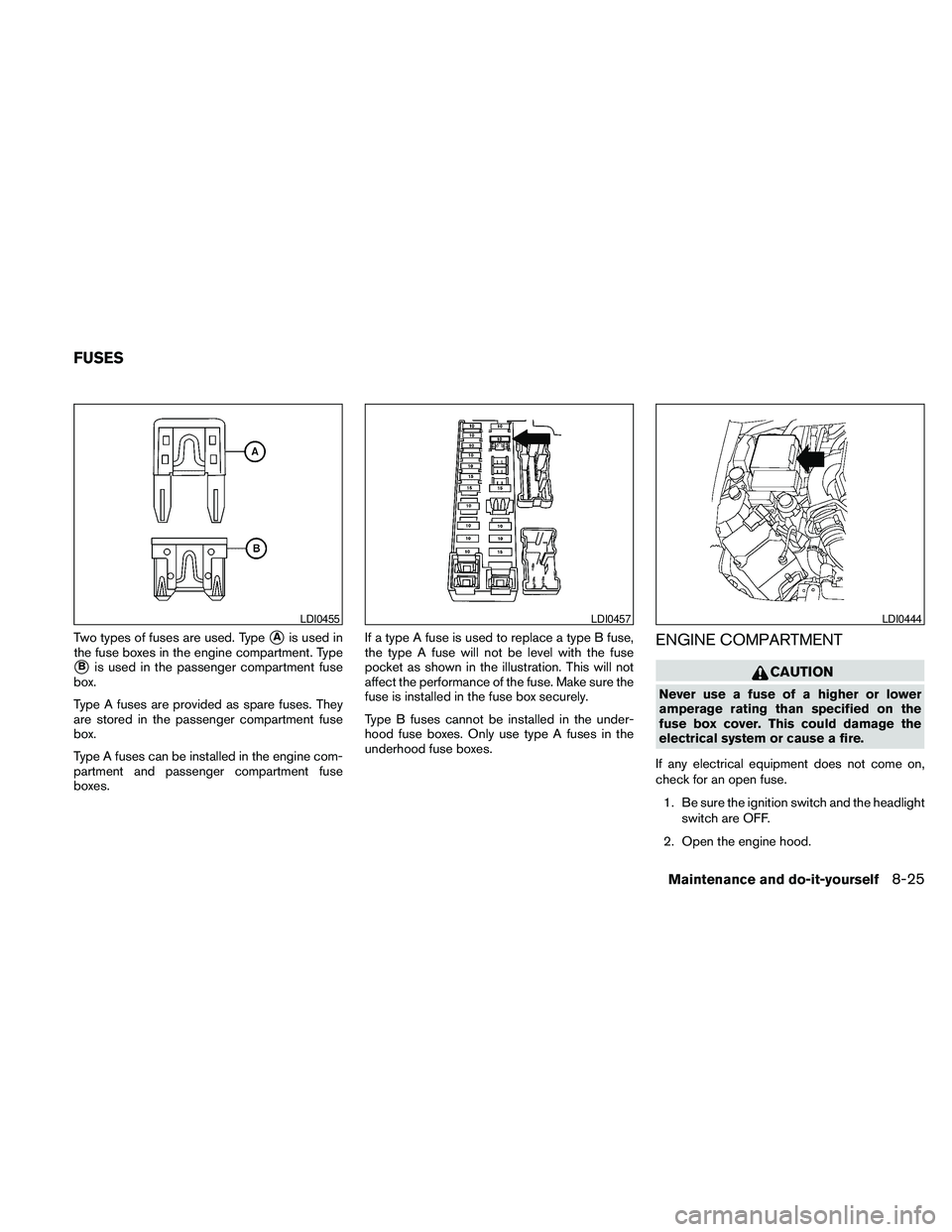

Two types of fuses are used. TypesAis used in

the fuse boxes in the engine compartment. Type

sBis used in the passenger compartment fuse

box.

Type A fuses are provided as spare fuses. They

are stored in the passenger compartment fuse

box.

Type A fuses can be installed in the engine com-

partment and passenger compartment fuse

boxes.If a type A fuse is used to replace a type B fuse,

the type A fuse will not be level with the fuse

pocket as shown in the illustration. This will not

affect the performance of the fuse. Make sure the

fuse is installed in the fuse box securely.

Type B fuses cannot be installed in the under-

hood fuse boxes. Only use type A fuses in the

underhood fuse boxes.

ENGINE COMPARTMENT

CAUTION

Never use a fuse of a higher or lower

amperage rating than specified on the

fuse box cover. This could damage the

electrical system or cause a fire.

If any electrical equipment does not come on,

check for an open fuse.

1. Be sure the ignition switch and the headlight

switch are OFF.

2. Open the engine hood.

LDI0455LDI0457LDI0444

FUSES

Maintenance and do-it-yourself8-25

Page 404 of 463

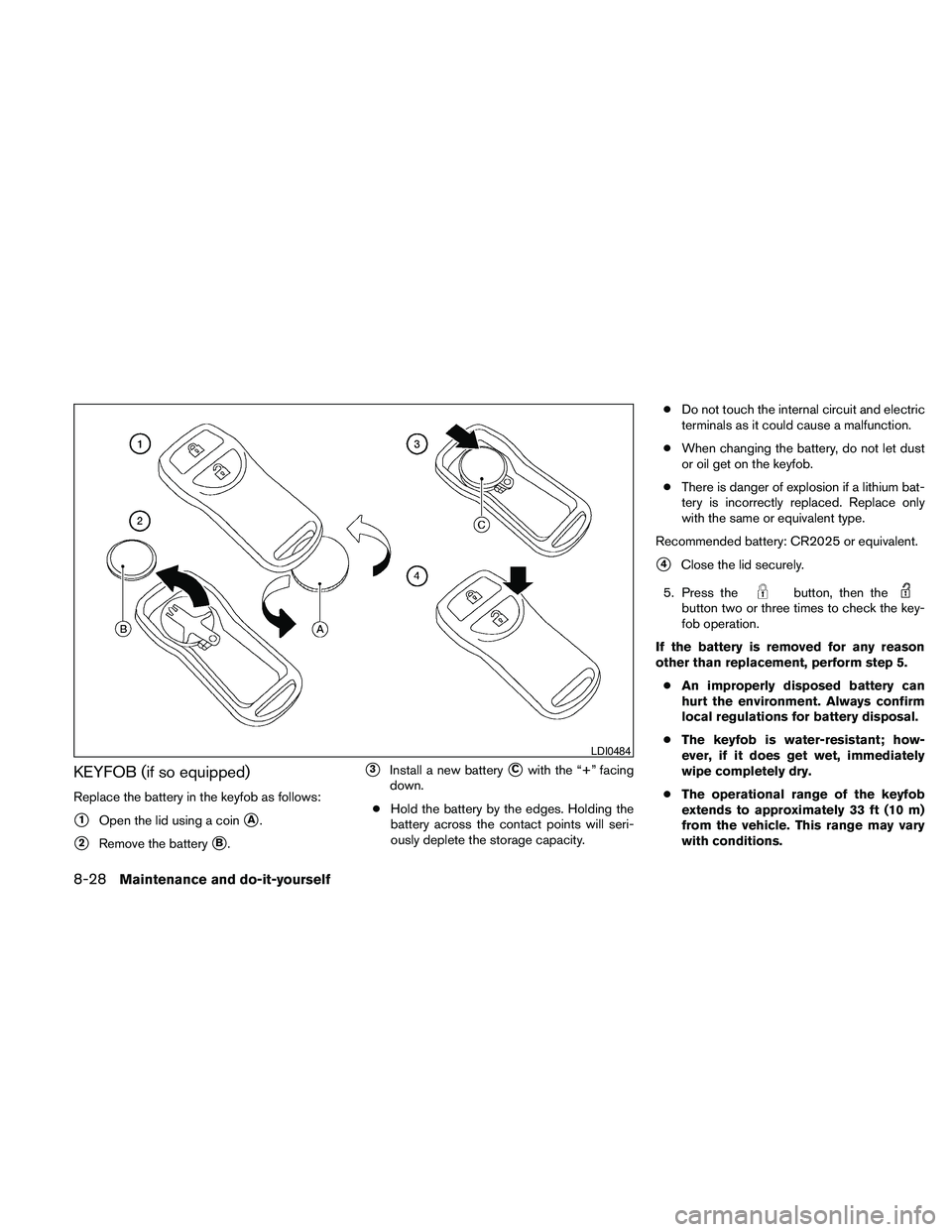

KEYFOB (if so equipped)

Replace the battery in the keyfob as follows:

s1Open the lid using a coinsA.

s2Remove the batterysB.

s3Install a new batterysCwith the “+” facing

down.

cHold the battery by the edges. Holding the

battery across the contact points will seri-

ously deplete the storage capacity.cDo not touch the internal circuit and electric

terminals as it could cause a malfunction.

cWhen changing the battery, do not let dust

or oil get on the keyfob.

cThere is danger of explosion if a lithium bat-

tery is incorrectly replaced. Replace only

with the same or equivalent type.

Recommended battery: CR2025 or equivalent.

s4Close the lid securely.

5. Press the

button, then thebutton two or three times to check the key-

fob operation.

If the battery is removed for any reason

other than replacement, perform step 5.

cAn improperly disposed battery can

hurt the environment. Always confirm

local regulations for battery disposal.

cThe keyfob is water-resistant; how-

ever, if it does get wet, immediately

wipe completely dry.

cThe operational range of the keyfob

extends to approximately 33 ft (10 m)

from the vehicle. This range may vary

with conditions.

LDI0484

8-28Maintenance and do-it-yourself

Page 406 of 463

4. Close the lid securely as illustratedsCsD.

5. Operate the buttons to check the operation.

See a NISSAN dealer if you need assistance for

replacement.

FCC Notice:

Changes or modifications not expressly ap-

proved by the party responsible for compli-

ance could void the user’s authority to op-

erate the equipment.

This device complies with Part 15 of the

FCC Rules and RSS-210 of Industry

Canada.Operation is subject to the following two

conditions: (1) This device may not cause

harmful interference, and (2) this device

must accept any interference received, in-

cluding interference that may cause undes-

ired operation of the device.

HEADLIGHTS

The headlight is a semi-sealed beam type which

uses a replaceable headlight (halogen) bulb. A

bulb can be replaced from inside the engine

compartment without removing the headlight as-

sembly.

CAUTION

cHigh pressure halogen gas is sealed

inside the halogen bulb. The bulb may

break if the glass envelope is scratched

or the bulb is dropped.

cWhen handling the bulb, do not touch

the glass envelope.

cDO NOT TOUCH THE BULB WITH BARE

HANDS.

cUse the same number and wattage as

shown in the chart.

cDo not leave the bulb out of the head-

light reflector for a long period of time

as dust, moisture and smoke may enter

the headlight body and affect the per-

formance of the headlight.

cAiming is not necessary after replacing

the bulb. When aiming adjustment is

necessary, contact a NISSAN dealer.

WDI0535

LIGHTS

8-30Maintenance and do-it-yourself

Page 418 of 463

studded tires. Skid and traction capabilities of

studded snow tires on wet or dry surfaces may be

poorer than that of non-studded snow tires.

TIRE CHAINS

Use of tire chains may be prohibited according to

location. Check the local laws before installing

tire chains. When installing tire chains, make sure

they are the proper size for the tires on your

vehicle and are installed according to the chain

manufacturer’s suggestions.Use only SAE

class “S” chains.Class “S” chains are used on

vehicles with restricted tire to vehicle clearance.

Vehicles that can use Class “S” chains are de-

signed to meet the minimum clearances between

the tire and the closest vehicle suspension or

body component required to accommodate the

use of a winter traction device (tire chains or

cables) . The minimum clearances are determined

using the factory equipped tire size. Other types

may damage your vehicle. Use chain tensioners

when recommended by the tire chain manufac-

turer to ensure a tight fit. Loose end links of the

tire chain must be secured or removed to prevent

the possibility of whipping action damage to the

fenders or underbody. If possible, avoid fully load-

ing your vehicle when using tire chains. In addi-

tion, drive at a reduced speed. Otherwise, your

vehicle may be damaged and/or vehicle handling

and performance may be adversely affected.Tire chains must be installed only on the

rear wheels and not on the front wheels.

Do not use tire chains on dry roads. Driving with

chains in such conditions can cause damage to

the various mechanisms of the vehicle due to

some overstress.

Use only the 2WD range when driving on clear

paved roads.

CHANGING WHEELS AND TIRES

Tire rotation

NISSAN recommends rotating the tires

every 7,500 miles (12,000 km) .

See “Flat tire” in the “In case of emer-

gency” section in this manual for tire re-

placing procedures.

As soon as possible, tighten the

wheel nuts to the specified torque

with a torque wrench.

WDI0258

8-42Maintenance and do-it-yourself

Page 423 of 463

9 Technical and consumer information

Capacities and recommended fuel/lubricants.........9-2

Fuel recommendation...........................9-3

Engine oil and oil filter recommendations..........9-5

Air conditioner system refrigerant and oil

recommendations..............................9-6

Specifications.....................................9-7

Engine........................................9-7

Wheels and tires...............................9-8

Dimensions and weights........................9-8

When traveling or registering your vehicle in

another country...................................9-9

Vehicle identification...............................9-9

Vehicle identification number (VIN) plate..........9-9

Vehicle identification number

(chassis number)...............................9-9

Engine serial number...........................9-10

F.M.V.S.S./C.M.V.S.S. certification label..........9-10

Emission control information label...............9-11

Tire and loading information label................9-11

Air conditioner specification label................9-11Installing front license plate........................9-12

Vehicle loading information........................9-12

Terms........................................9-12

Vehicle load capacity..........................9-13

Securing the load..............................9-15

Loading tips..................................9-16

Measurement of weights.......................9-16

Towing a trailer...................................9-17

Maximum load limits...........................9-17

Towing load/specification.......................9-20

Towing safety.................................9-20

Flat towing....................................9-26

Uniform tire quality grading........................9-27

Emission control system warranty..................9-28

Reporting safety defects (US only).................9-28

Readiness for inspection/maintenance (I/M) test.....9-28

Event Data Recorders (EDR).......................9-29

Owner’s Manual/Service Manual order information . . . 9-30

In the event of a collision.......................9-30

Page 437 of 463

5. Determine the combined weight of

luggage and cargo being loaded on

the vehicle. That weight may not

safely exceed the available cargo and

luggage load capacity calculated in

Step 4.

6. If your vehicle will be towing a trailer,

load from your trailer will be trans-

ferred to your vehicle. Consult this

manual to determine how this re-

duces the available cargo and lug-

gage load capacity of your vehicle.

Before driving a loaded vehicle, confirm

that you do not exceed the Gross Vehicle

Weight Rating (GVWR) or the Gross Axle

Weight Rating (GAWR) for your vehicle.

See “Measurement of Weights” later in

this section.

Also check tires for proper inflation pres-

sures. See the Tire and Loading Informa-

tion label.

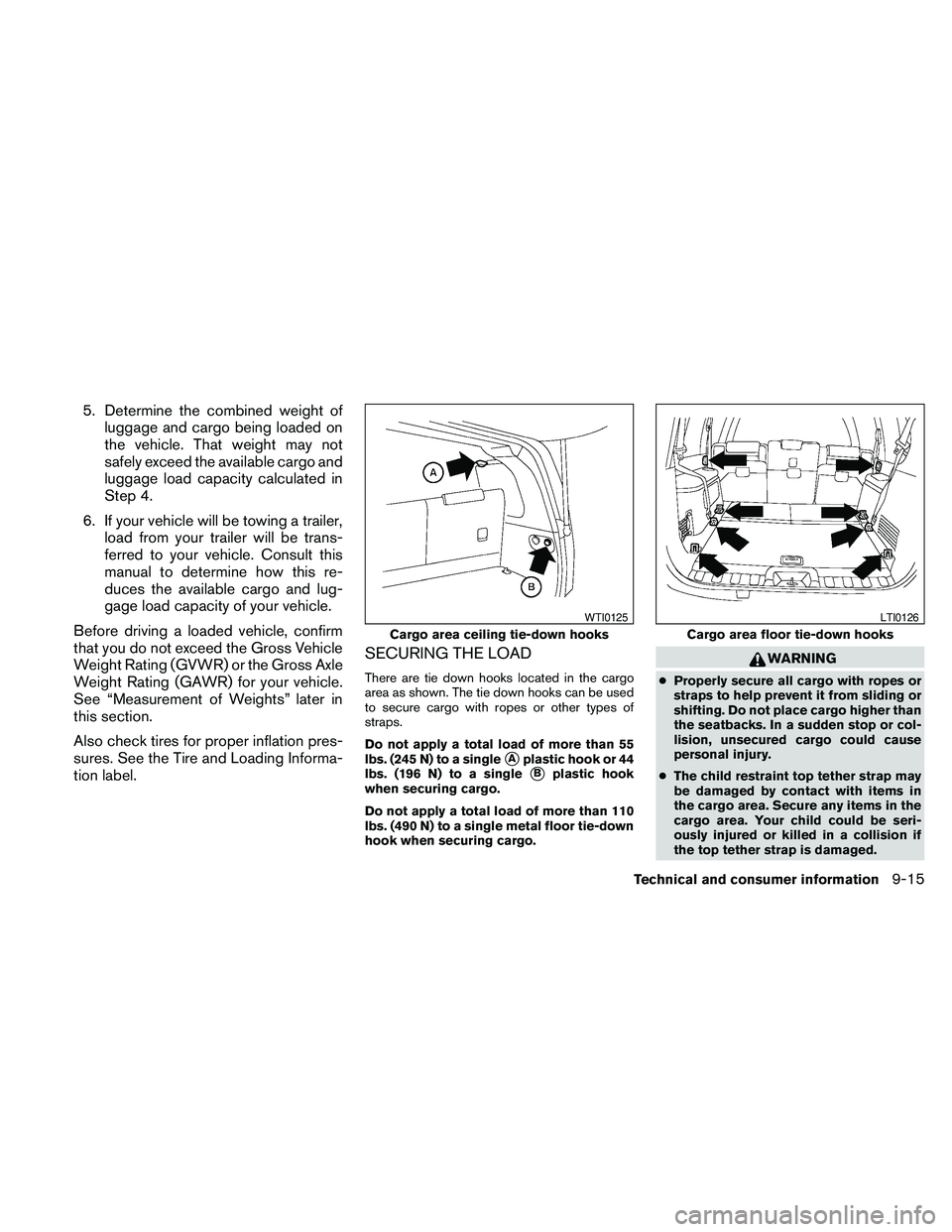

SECURING THE LOAD

There are tie down hooks located in the cargo

area as shown. The tie down hooks can be used

to secure cargo with ropes or other types of

straps.

Do not apply a total load of more than 55

lbs. (245 N) to a single

sAplastic hook or 44

lbs. (196 N) to a single

sBplastic hook

when securing cargo.

Do not apply a total load of more than 110

lbs. (490 N) to a single metal floor tie-down

hook when securing cargo.

WARNING

cProperly secure all cargo with ropes or

straps to help prevent it from sliding or

shifting. Do not place cargo higher than

the seatbacks. In a sudden stop or col-

lision, unsecured cargo could cause

personal injury.

cThe child restraint top tether strap may

be damaged by contact with items in

the cargo area. Secure any items in the

cargo area. Your child could be seri-

ously injured or killed in a collision if

the top tether strap is damaged.

Cargo area ceiling tie-down hooks

WTI0125

Cargo area floor tie-down hooks

LTI0126

Technical and consumer information9-15

Page 438 of 463

cDo not load your vehicle any heavier

than the GVWR or the maximum front

and rear GAWRs. If you do, parts of your

vehicle can break, tire damage could

occur, or it can change the way your

vehicle handles. This could result in

loss of control and cause personal

injury.

LOADING TIPS

cThe GVW must not exceed GVWR

or GAWR as specified on the

F.M.V.S.S./C.M.V.S.S. certification

label.

cDo not load the front and rear axle to

the GAWR. Doing so will exceed the

GVWR.

WARNING

cProperly secure all cargo with

ropes or straps to help prevent it

from sliding or shifting. Do not

place cargo higher than the seat-

backs. In a sudden stop or colli-

sion, unsecured cargo could

cause personal injury.cDo not load your vehicle any

heavier than the GVWR or the

maximum front and rear GAWRs.

If you do, parts of your vehicle

can break, tire damage could oc-

cur, or it can change the way your

vehicle handles. This could result

in loss of control and cause per-

sonal injury.

cOverloading not only can shorten

the life of your vehicle and the

tire, but can also cause unsafe

vehicle handling and longer brak-

ing distances. This may cause a

premature tire failure which

could result in a serious accident

and personal injury. Failures

caused by overloading are not

covered by the vehicle’s

warranty.

MEASUREMENT OF WEIGHTS

Secure loose items to prevent weight

shifts that could affect the balance of your

vehicle. When the vehicle is loaded, drive

to a scale and weigh the front and the rear

wheels separately to determine axle

loads. Individual axle loads should not ex-

ceed either of the gross axle weight rat-

ings (GAWR) . The total of the axle loads

should not exceed the gross vehicle

weight rating (GVWR) . These ratings are

given on the vehicle certification label. If

weight ratings are exceeded, move or re-

move items to bring all weights below the

ratings.

9-16

Technical and consumer information

Page 442 of 463

Remember to keep trailer tongue weight be-

tween 10 - 15% of the trailer weight or within the

trailer tongue load specification recommended

by the trailer manufacturer. If the tongue load

becomes excessive, rearrange the cargo to ob-

tain the proper tongue load. Do not exceed the

maximum tongue weight specification shown in

the “Towing load/specification” chart even if the

calculated available tongue weight is greater

than 15%. If the calculated tongue weight is less

than 10% , reduce the total trailer weight to

match the available tongue weight.

Always verify that available capacities are within

the required ratings.

Trailer frontal area

CAUTION

Exceeding the maximum trailer frontal

area specification may exceed the towing

capacity of the vehicle. This may affect the

towing performance and lead to vehicle

damage.

The trailer frontal area affects the towing load of a

trailer. The frontal area is the total area of the

vehicle and trailer that is affected by air resis-

tance while towing. Do not exceed the maximum

trailer frontal area specification shown in the

9Towing Load/Specification” chart. The frontal

area can be determined by multiplying the widthof the trailer by the height of the trailer. For

example, a trailer that is 8 feet wide by 6 feet tall

has a trailer frontal area of 48 square feet.

TOWING LOAD/SPECIFICATION

US & CAN

V6 V8

Maximum

Towing

Capacity*1, *26,000 lb.

(2722 kg)7,000 lb.

(3,175 kg)

Maximum

Tongue Load600 lb.

(272 kg)700 lb.

(318 kg)

Maximum

Gross Com-

bined Weight

Rating11,133 lb.

(5,050 kg)12,566 lb.

(5,700 kg)

Maximum trailer

frontal area60 sq ft (5.52 sq meters)

*1: The towing capacity values are calculated

assuming a base vehicle with driver and any

options required to achieve the rating. Additional

passengers, cargo and/or optional equipment

will add weight to the vehicle and reduce your

vehicle’s maximum towing capacity.

*2: Use of a weight-distributing hitch system is

recommended when towing over 5,000 lbs.

TOWING SAFETY

Trailer hitch

Your vehicle may be equipped with an optional

trailer tow package. The trailer tow package in-

cludes a receiver-type frame mounted hitch. This

hitch is rated for the maximum towing capacity of

this vehicle when the proper towing equipment is

used. Choose a proper ball mount and hitch ball

that is rated for the trailer to be towed. Genuine

NISSAN ball mounts and hitch balls are available

from your NISSAN dealer.

If your vehicle is not equipped with the optional

trailer tow package, check the towing capacity of

your receiver-type frame mounted hitch. Choose

a proper hitch for your vehicle and trailer. A

genuine NISSAN trailer hitch is available from

your NISSAN dealer. Make sure the trailer hitch is

securely attached to the vehicle to help avoid

personal injury or property damage due to sway

caused by crosswinds, rough road surfaces or

passing trucks.

9-20Technical and consumer information

Page 443 of 463

WARNING

Trailer hitch components have specific

weight ratings. Your vehicle may be capable

of towing a trailer heavier than the weight

rating of the hitch components. Never ex-

ceed the weight rating of the hitch compo-

nents. Doing so can cause serious personal

injury or property damage.

Hitch ball

Choose a hitch ball of the proper size and weight

rating for your trailer:

cThe required hitch ball size is stamped on

most trailer couplers. Most hitch balls also

have the size printed on the top of the ball.

cChoose the proper class hitch ball based on

the trailer weight.

cThe diameter of the threaded shank of the

hitch ball must be matched to the ball mount

hole diameter. The hitch ball shank should

be no more than 1/16” smaller than the hole

in the ball mount.

cThe threaded shank of the hitch ball must be

long enough to be properly secured to the

ball mount. There should be at least 2

threads showing beyond the lock washer

and nut.

Ball mount

The hitch ball is attached to the ball mount and

the ball mount is inserted into the hitch receiver.

Choose a proper class ball mount based on the

trailer weight. Additionally, the ball mount should

be chosen to keep the trailer tongue level with the

ground.

Weight carrying hitches

A weight carrying or “dead weight” ball mount is

one that is designed to carry the whole amount of

tongue weight and gross weight directly on the

ball mount and on the receiver.

Weight distribution hitch

This type of hitch is also called a “load-leveling” or

“equalizing” hitch. A set of bars attach to the ball

mount and to the trailer to distribute the tongue

weight (hitch weight) of your trailer. Many vehicles

can’t carry the full tongue weight of a given trailer,

and need some of the tongue weight transferred

through the frame and pushing down on the front

wheels. This gives stability to the tow vehicle.

A weight-distributing hitch system (Class IV) is

recommended if you plan to tow trailers with a

maximum weight over 5,000 lbs. Check with the

trailer and towing equipment manufacturers to

determine if they recommend the use of a weight-

distributing hitch system.NOTE:

A weight-distributing hitch system may af-

fect the operation of trailer surge brakes. If

you are considering use of a weight-

distributing hitch system with a surge

brake-equipped trailer, check with the

surge brake, hitch or trailer manufacturer

to determine if and how this can be done.

Follow the instructions provided by the manufac-

turer for installing and using the weight-

distributing hitch system.

General set-up instructions are as follows:

1. Park unloaded vehicle on a level surface.

With the ignition on and the doors closed,

allow the vehicle to stand for several minutes

so that it can level.

2. Measure the height of a reference point on

the front and rear bumpers at the center of

the vehicle.

3. Attach the trailer to the vehicle and adjust

the hitch equalizers so that the front bumper

height is within0-.5inches (0 – 13 mm) of

the reference height measured in step 2. The

rear bumper should be no higher than the

reference height measured in step 2.

Technical and consumer information9-21