brakes NISSAN PATHFINDER 2019 Owner´s Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2019, Model line: PATHFINDER, Model: NISSAN PATHFINDER 2019Pages: 476, PDF Size: 5.61 MB

Page 327 of 476

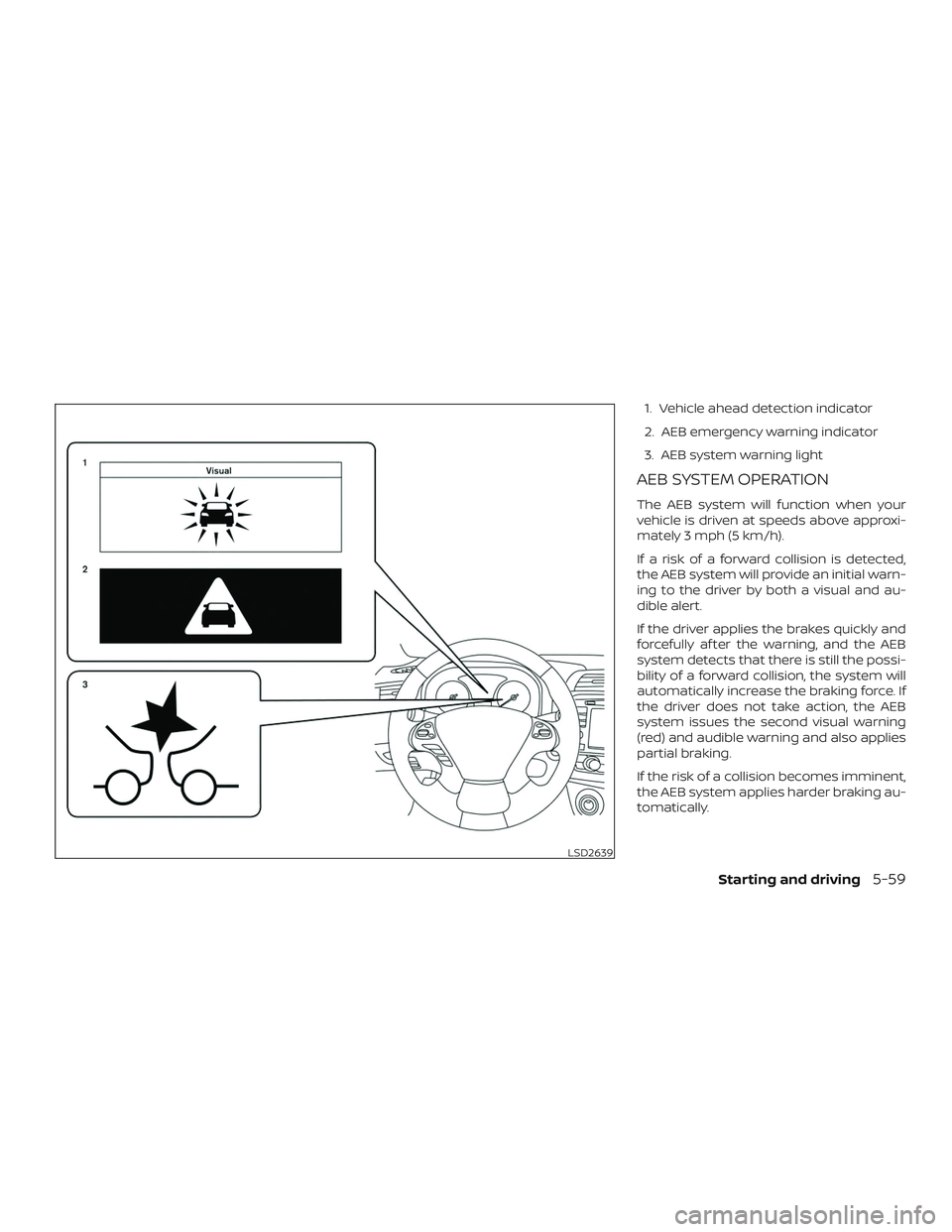

1. Vehicle ahead detection indicator

2. AEB emergency warning indicator

3. AEB system warning light

AEB SYSTEM OPERATION

The AEB system will function when your

vehicle is driven at speeds above approxi-

mately 3 mph (5 km/h).

If a risk of a forward collision is detected,

the AEB system will provide an initial warn-

ing to the driver by both a visual and au-

dible alert.

If the driver applies the brakes quickly and

forcefully af ter the warning, and the AEB

system detects that there is still the possi-

bility of a forward collision, the system will

automatically increase the braking force. If

the driver does not take action, the AEB

system issues the second visual warning

(red) and audible warning and also applies

partial braking.

If the risk of a collision becomes imminent,

the AEB system applies harder braking au-

tomatically.

LSD2639

Starting and driving5-59

Page 328 of 476

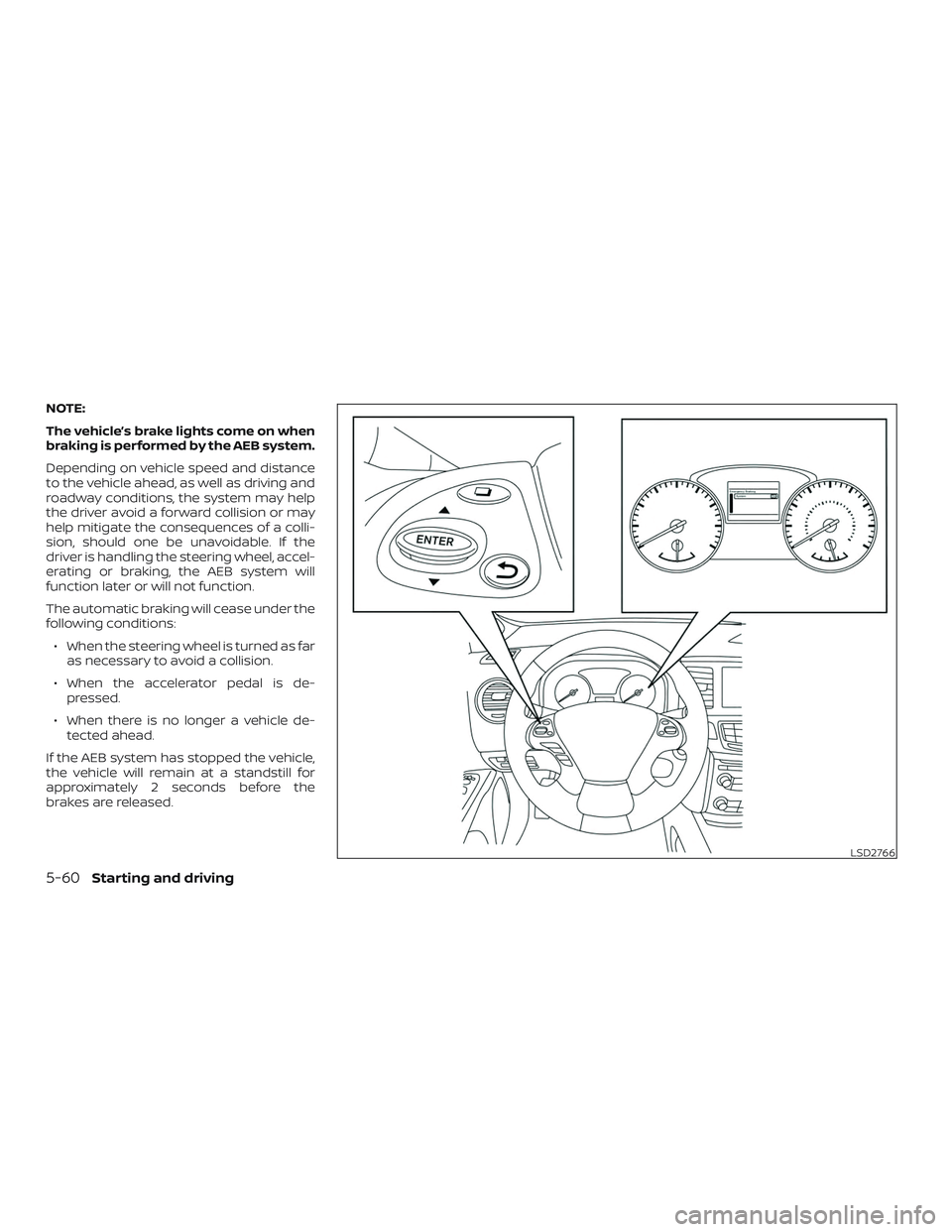

NOTE:

The vehicle’s brake lights come on when

braking is performed by the AEB system.

Depending on vehicle speed and distance

to the vehicle ahead, as well as driving and

roadway conditions, the system may help

the driver avoid a forward collision or may

help mitigate the consequences of a colli-

sion, should one be unavoidable. If the

driver is handling the steering wheel, accel-

erating or braking, the AEB system will

function later or will not function.

The automatic braking will cease under the

following conditions:∙ When the steering wheel is turned as far as necessary to avoid a collision.

∙ When the accelerator pedal is de- pressed.

∙ When there is no longer a vehicle de- tected ahead.

If the AEB system has stopped the vehicle,

the vehicle will remain at a standstill for

approximately 2 seconds before the

brakes are released.

LSD2766

5-60Starting and driving

Page 341 of 476

The brake system has two separate hy-

draulic circuits. If one circuit malfunctions,

you will still have braking at two wheels.

BRAKE PRECAUTIONS

Vacuum assisted brakes

The brake booster aids braking by using

engine vacuum. If the engine stops, you

can stop the vehicle by depressing the

brake pedal. However, greater foot pres-

sure on the brake pedal will be required to

stop the vehicle and stopping distance will

be longer.

Using the brakes

Avoid resting your foot on the brake pedal

while driving. This will overheat the brakes,

wear out the brake pads faster, and reduce

gas mileage.

To help reduce brake wear and to prevent

the brakes from overheating, reduce speed

and downshif t to a lower gear before going

down a slope or long grade. Overheated

brakes may reduce braking performance

and could result in loss of vehicle control.

WARNING

∙ While driving on a slippery surface, becareful when braking, accelerating or

downshif ting. Abrupt braking or ac-

celerating could cause the wheels to

skid and result in an accident.

∙ If the engine is not running or is turned off while driving, the power as-

sist for the brakes will not work. Brak-

ing will be harder.

Wet brakes

When the vehicle is washed or driven

through water, the brakes may get wet. As

a result, your braking distance will be lon-

ger and the vehicle may pull to one side

during braking.

To dry the brakes, drive the vehicle at a safe

speed while lightly pressing the brake

pedal to heat up the brakes. Do this until

the brakes return to normal. Avoid driving

the vehicle at high speeds until the brakes

function correctly.

Parking brake break-in

Break in the parking brake shoes whenever

the stopping effect of the parking brake is

weakened or whenever the parking brake shoes and/or drums/rotors are replaced,

in order to assure the best braking perfor-

mance.

This procedure is described in the vehicle

service manual. It is recommended that

you visit a NISSAN dealer for this service.

ANTI-LOCK BRAKING SYSTEM (ABS)

WARNING

∙ The ABS is a sophisticated device, but

it cannot prevent accidents resulting

from careless or dangerous driving

techniques. It can help maintain ve-

hicle control during braking on slip-

pery surfaces. Remember that stop-

ping distances on slippery surfaces

will be longer than on normal sur-

faces even with ABS. Stopping dis-

tances may also be longer on rough,

gravel or snow covered roads, or if you

are using tire chains. Always maintain

a safe distance from the vehicle in

front of you. Ultimately, the driver is

responsible for safety.

∙ Tire type and condition may also af- fect braking effectiveness.

BRAKE SYSTEM

Starting and driving5-73

Page 342 of 476

– When replacing tires, install thespecified size of tires on all four

wheels.

– When installing a spare tire, make sure that it is the proper size and

type as specified on the Tire and

Loading Information label. For ad-

ditional information, refer to “Tire

and Loading Information label” in

the “Technical and consumer infor-

mation” section of this manual.

– For additional information, refer to “Wheels and tires” in the “Do-it-

yourself ” section of this manual.

The ABS controls the brakes so the wheels

do not lock during hard braking or when

braking on slippery surfaces. The system

detects the rotation speed at each wheel

and varies the brake fluid pressure to pre-

vent each wheel from locking and sliding.

By preventing each wheel from locking, the

system helps the driver maintain steering

control and helps to minimize swerving

and spinning on slippery surfaces.

Using the system

Depress the brake pedal and hold it down.

Depress the brake pedal with firm steady

pressure, but do not pump the brakes. The Anti-lock Braking System will operate to

prevent the wheels from locking up. Steer

the vehicle to avoid obstacles.

WARNING

Do not pump the brake pedal. Doing so

may result in increased stopping

distances.

Self-test feature

The Anti-lock Braking System (ABS) in-

cludes electronic sensors, electric pumps,

hydraulic solenoids and a computer. The

computer has a built-in diagnostic feature

that tests the system each time you start

the engine and move the vehicle at a low

speed in forward or reverse. When the self-

test occurs, you may hear a “clunk” noise

and/or feel a pulsation in the brake pedal.

This is normal and does not indicate a mal-

function. If the computer senses a mal-

function, it switches the ABS off and illumi-

nates the ABS warning light on the

instrument panel. The brake system then

operates normally, but without anti-lock

assistance.

If the ABS warning light illuminates during

the self-test or while driving, have the ve-

hicle checked. It is recommended that you

visit a NISSAN dealer for this service.

Normal operation

The Anti-lock Braking System (ABS) oper-

ates at speeds abov

e3-6mph(5-

10 km/h). The speed varies according to

road conditions.

When the ABS senses that one or more

wheels are close to locking up, the actuator

rapidly applies and releases hydraulic pres-

sure. This action is similar to pumping the

brakes very quickly. You may feel a pulsa-

tion in the brake pedal and hear a noise

from under the hood or feel a vibration

from the actuator when it is operating. This

is normal and indicates that the ABS is op-

erating properly. However, the pulsation

may indicate that road conditions are haz-

ardous and extra care is required while

driving.

BRAKE ASSIST

When the force applied to the brake pedal

exceeds a certain level, the Brake Assist is

activated generating greater braking force

than a conventional brake booster even

with light pedal force.

5-74Starting and driving

Page 346 of 476

WARNING

∙ Never rely solely on the hill descentcontrol system to control vehicle

speed when driving on steep downhill

grades. Always drive carefully and at-

tentively when using the hill descent

control system and decelerate the ve-

hicle speed by depressing the brake

pedal if necessary. Be especially care-

ful when driving on frozen, muddy or

extremely steep downhill roads. Fail-

ure to control vehicle speed may re-

sult in a loss of control of the vehicle

and possible serious injury or death.

∙ The hill descent control may not con- trol the vehicle speed on a hill under

all load or road conditions. Always be

prepared to depress the brake pedal

to control vehicle speed. Failure to do

so may result in a collision or serious

personal injury.

The hill descent control system can only be

activated when the 4WD LOCK mode is en-

gaged.

The hill descent control system helps

maintain vehicle speed when driving under

15 mph (25 km/h) on steeper downhill

grades. Hill descent control is useful when engine braking alone cannot control ve-

hicle speed. Hill descent control applies the

vehicle brakes to control vehicle speed al-

lowing the driver to concentrate on steer-

ing while reducing the burden of brake and

accelerator operation.

If the hill descent control light is blinking,

the hill descent control is engaged; how-

ever, the hill descent control will not control

the vehicle speed.

∙ Once the system is activated, the indi- cator light will remain on in the instru-

ment panel. For additional information,

refer to “Hill descent control system ON

indicator light” in the “Instruments and

controls” section of this manual.

If the accelerator or brake pedal is de-

pressed while the hill descent control sys-

tem is on, the system will stop operating

temporarily. As soon as the accelerator or

brake pedal is released, the hill descent

control system begins to function again if

the hill descent control operating condi-

tions are fulfilled.

For the best results, when descending

steep downhill grades, the hill descent con-

trol switch should be on and the shif t lever

in L (Low gear) for engine braking.

WARNING

∙ Never rely solely on the hill start assist system to prevent the vehicle from

moving backward on a hill. Always

drive carefully and attentively. De-

press the brake pedal when the ve-

hicle is stopped on a steep hill. Be es-

pecially careful when stopped on a hill

on frozen or muddy roads. Failure to

prevent the vehicle from rolling back-

wards may result in a loss of control of

the vehicle and possible serious injury

or death.

∙ The hill start assist system is not de- signed to hold the vehicle at a stand-

still on a hill. Depress the brake pedal

when the vehicle is stopped on a

steep hill. Failure to do so may cause

the vehicle to roll backwards and may

result in a collision or serious personal

injury.

∙ The hill start assist may not prevent the vehicle from rolling backwards on

a hill under all load or road conditions.

Always be prepared to depress the

brake pedal to prevent the vehicle

from rolling backwards. Failure to do

so may result in a collision or serious

personal injury.

HILL DESCENT CONTROL SYSTEM (if

so equipped) HILL START ASSIST SYSTEM

5-78Starting and driving

Page 347 of 476

The hill start assist system automatically

keeps the brakes applied to help prevent

the vehicle from rolling backward in the

time it takes the driver to release the brake

pedal and apply the accelerator when the

vehicle is stopped on a hill.

Hill start assist will operate automatically

under the following conditions:∙ The shif t lever is moved to a forward or reverse gear.

∙ The vehicle is stopped completely on a hill by applying the brake.

The maximum holding time is 2 seconds.

Af ter 2 seconds the vehicle will begin to roll

back and hill start assist will stop operating

completely.

Hill start assist will not operate when the

shif t lever is moved to N (Neutral) or P (Park)

or on a flat and level road.

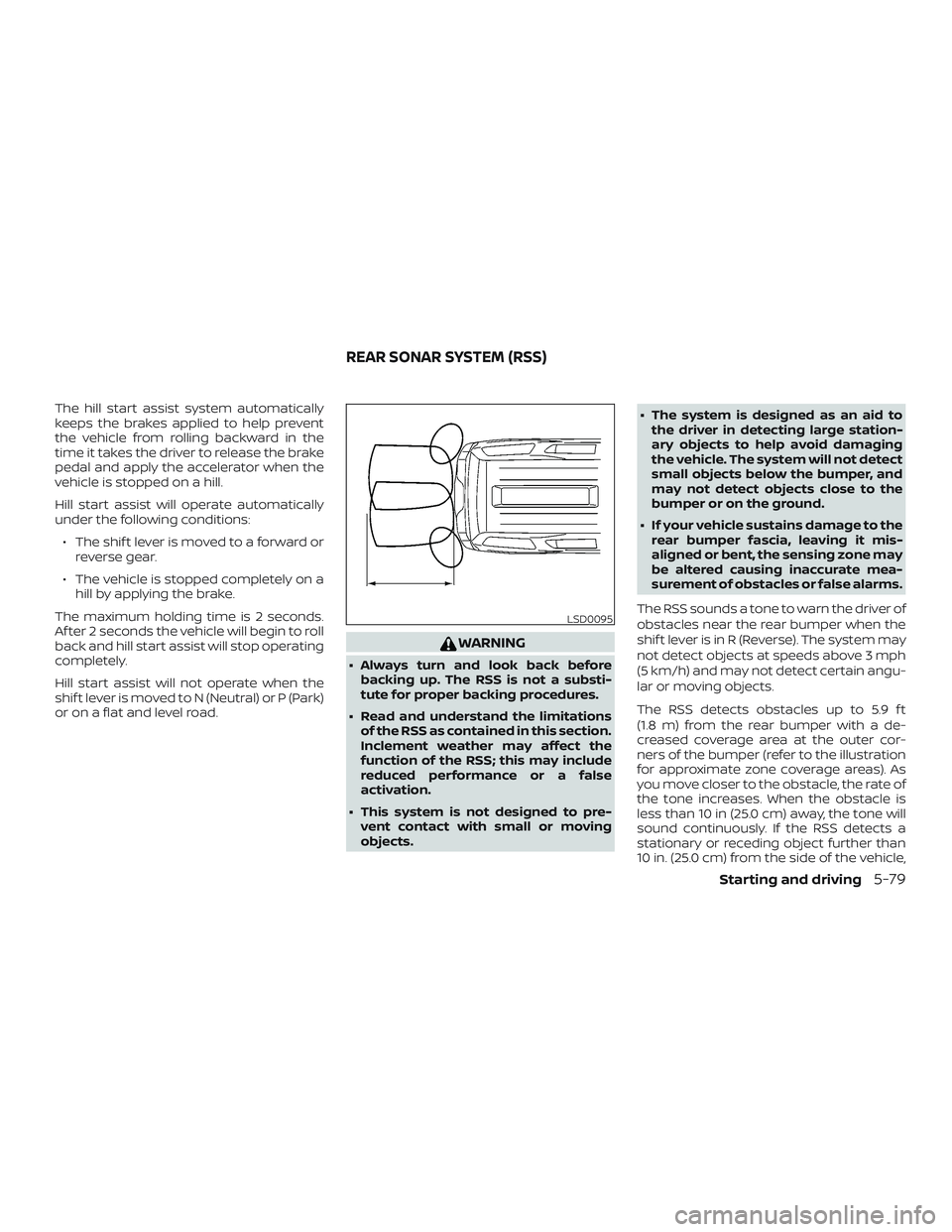

WARNING

∙ Always turn and look back before backing up. The RSS is not a substi-

tute for proper backing procedures.

∙ Read and understand the limitations of the RSS as contained in this section.

Inclement weather may affect the

function of the RSS; this may include

reduced performance or a false

activation.

∙ This system is not designed to pre- vent contact with small or moving

objects. ∙ The system is designed as an aid to

the driver in detecting large station-

ary objects to help avoid damaging

the vehicle. The system will not detect

small objects below the bumper, and

may not detect objects close to the

bumper or on the ground.

∙ If your vehicle sustains damage to the rear bumper fascia, leaving it mis-

aligned or bent, the sensing zone may

be altered causing inaccurate mea-

surement of obstacles or false alarms.

The RSS sounds a tone to warn the driver of

obstacles near the rear bumper when the

shif t lever is in R (Reverse). The system may

not detect objects at speeds above 3 mph

(5 km/h) and may not detect certain angu-

lar or moving objects.

The RSS detects obstacles up to 5.9 f t

(1.8 m) from the rear bumper with a de-

creased coverage area at the outer cor-

ners of the bumper (refer to the illustration

for approximate zone coverage areas). As

you move closer to the obstacle, the rate of

the tone increases. When the obstacle is

less than 10 in (25.0 cm) away, the tone will

sound continuously. If the RSS detects a

stationary or receding object further than

10 in. (25.0 cm) from the side of the vehicle,

LSD0095

REAR SONAR SYSTEM (RSS)

Starting and driving5-79

Page 375 of 476

8 Do-it-yourself

Maintenance precautions.......................8-2

Engine compartment check locations ...........8-3

Engine cooling system ..........................8-4

Checking engine coolant level ................8-5

Changing engine coolant .....................8-5

Engine oil ........................................8-6

Checking engine oil level .....................8-6

Changing engine oil and oil filter ..............8-6

Continuously Variable Transmission (CVT)

fluid ............................................ 8-10

Power Steering Fluid (PSF) ......................8-10

Brake fluid ....................................... 8-11

Windshield-washer fluid .........................8-11

Windshield-washer fluid reservoir .............8-11

Battery......................................... 8-13

Jump starting ............................... 8-14

Drive belt ....................................... 8-15

Spark plugs .................................... 8-15

Replacing spark plugs ....................... 8-15

Air cleaner ...................................... 8-16In-cabin microfilter

.......................... 8-16

Windshield wiper blades ........................8-17

Cleaning .................................... 8-17

Replacing ................................... 8-17

Brakes.......................................... 8-19

Fuses ........................................... 8-19

Engine compartment .......................8-20

Passenger compartment ....................8-21

Battery replacement ........................... 8-22

NISSAN Intelligent Key® ......................8-22

Lights .......................................... 8-24

Headlights ................................... 8-24

Fog lights (if so equipped) ...................8-24

Exterior and interior lights ...................8-25

Wheels and tires ................................ 8-27

Tire pressure ................................ 8-27

Tire labeling ................................. 8-31

Types of tires ................................ 8-33

Tir

e chains .................................. 8-34

Changing wheels and tires ..................8-35

Page 393 of 476

If the brakes do not operate properly have

the brakes checked. It is recommended

that you visit a NISSAN dealer for this ser-

vice.

Self-adjusting brakes

Your vehicle is equipped with self-adjusting

brakes.

The front and rear disc-type brakes self-

adjust every time the brake pedal is ap-

plied.

WARNING

Have your brake system checked if the

brake pedal height does not return to

normal. It is recommended that you

visit a NISSAN dealer for this service.

Brake pad wear indicators

The disc brake pads on your vehicle have

audible wear indicators. When a brake pad

requires replacement, a high pitched

scraping or screeching sound will be heard

when the vehicle is in motion. The noise will

be heard whether or not the brake pedal is

depressed. Have the brakes checked as

soon as possible if the wear indicator

sound is heard.Under some driving or climate conditions,

occasional brake squeak, squeal or other

noise may be heard. Occasional brake

noise during light to moderate stops is nor-

mal and does not affect the function or

performance of the brake system.

Proper brake inspection intervals should

be followed.

For additional information re-

garding brake inspections, refer to the ap-

propriate maintenance schedule informa-

tion in the "Maintenance and schedules"

section of this manual.

If any electrical equipment does not oper-

ate, check for an open fuse.

Fuses are used in the passenger and en-

gine compartment. Spare fuses are pro-

vided and can be found in the passenger

compartment fuse box.

When installing a fuse make sure the fuse is

installed in the fuse box securely.

LDI2385

BRAKES FUSES

Do-it-yourself8-19

Page 418 of 476

Inside the vehicle

The maintenance items listed here should

be checked on a regular basis, such as

when performing scheduled maintenance,

cleaning the vehicle, etc.

Accelerator pedal:Check the pedal for

smooth operation and make sure the

pedal does not catch or require uneven

effort. Keep the floor mat away from the

pedal.

Brake pedal: Check the pedal for smooth

operation. If the brake pedal suddenly goes

down further than normal, the pedal feels

spongy or the vehicle seems to take longer

to stop, have your vehicle checked imme-

diately. It is recommended that you visit a

NISSAN dealer for this service. Keep the

floor mat away from the pedal.

Brakes: Check that the brakes do not pull

the vehicle to one side when applied.

Continuously Variable Transmission

(CVT) P (Park) position mechanism: On a

fairly steep hill check that the vehicle is held

securely with the shif t lever in the P (Park)

position without applying any brakes.

Parking brake: Check the parking brake

operation regularly. The vehicle should be

securely held on a fairly steep hill with only the parking brake applied. If the parking

brake needs adjustment, it is recom-

mended that you visit a NISSAN dealer for

this service.

Seats:

Check seat position controls such

as seat adjusters, seatback recliner, etc., to

ensure they operate smoothly and all

latches lock securely in every position.

Check that the head restraints/headrests

move up and down smoothly and the locks

(if so equipped) hold securely in all latched

positions.

Seat belts: Check that all parts of the seat

belt system (for example, buckles, anchors,

adjusters and retractors) operate properly

and smoothly, and are installed securely.

Check the belt webbing for cuts, fraying,

wear or damage.

Steering wheel: Check for changes in the

steering system, such as excessive free

play, hard steering or strange noises.

Warning lights and chimes: Make sure all

warning lights and chimes are operating

properly.

Windshield defroster: Check that the air

comes out of the defroster outlets properly

and in sufficient quantity when operating

the heater or air conditioner. Windshield wiper and washer*:

Check

that the wipers and washer operate prop-

erly and that the wipers do not streak.

Under the hood and vehicle

The maintenance items listed here should

be checked periodically (for example, each

time you check the engine oil or refuel).

Battery* (for maintenance free batter-

ies): This vehicle is equipped with a sealed

maintenance free battery. It is recom-

mended that you visit a NISSAN dealer for

service.

NOTE:

Care should be taken to avoid situations

that can lead to potential battery dis-

charge and potential no-start conditions

such as:

1. Installation or extended use of elec-

tronic accessories that consume bat-

tery power when the engine is not

running (Phone chargers, GPS, DVD

players, etc.).

2. Vehicle is not driven regularly and/or

only driven short distances.

In these cases, the battery may need to

be charged to maintain battery health.

9-4Maintenance and schedules

Page 453 of 476

WARNING

Trailer hitch components have specific

weight ratings. Your vehicle may be ca-

pable of towing a trailer heavier than

the weight rating of the hitch compo-

nents. Never exceed the weight rating

of the hitch components. Doing so can

cause serious personal injury or prop-

erty damage.

Hitch ball

Choose a hitch ball of the proper size and

weight rating for your trailer:∙ The required hitch ball size is stamped on most trailer couplers. Most hitch

balls also have the size printed on the

top of the ball.

∙ Choose the proper class hitch ball based on the trailer weight.

∙ The diameter of the threaded shank of the hitch ball must be matched to the

ball mount hole diameter. The hitch ball

shank should be no more than 1/16”

smaller than the hole in the ball mount. ∙ The threaded shank of the hitch ball

must be long enough to be properly

secured to the ball mount. There should

be at least 2 threads showing beyond

the lock washer and nut.

Ball mount

The hitch ball is attached to the ball mount

and the ball mount is inserted into the

hitch receiver. Choose a proper class ball

mount based on the trailer weight. Addi-

tionally, the ball mount should be chosen to

keep the trailer tongue level with the

ground.

Weight carrying hitches

A weight carrying or “dead weight” ball

mount is one that is designed to carry the

whole amount of tongue weight and gross

weight directly on the ball mount and on

the receiver.

Weight distribution hitch

This type of hitch is also called a “load-

leveling” or “equalizing” hitch. A set of bars

attach to the ball mount and to the trailer

to distribute the tongue weight (hitch

weight) of your trailer. Many vehicles can’t

carry the full tongue weight of a given

trailer, and need some of the tongue weight transferred through the frame and

pushing down on the front wheels. This

gives stability to the tow vehicle.

A weight-distributing hitch system (Class

IV) is recommended if you plan to tow trail-

ers with a maximum weight over 5,000 lbs.

(2,268 kg). Check with the trailer and towing

equipment manufacturers to determine if

they recommend the use of a weight-

distributing hitch system.

NOTE:

A weight-distributing hitch system may

affect the operation of trailer surge

brakes. If you are considering use of a

weight-distributing hitch system with a

surge brake-equipped trailer, check with

the surge brake, hitch or trailer manufac-

turer to determine if and how this can be

done.

Follow the instructions provided by the

manufacturer for installing and using the

weight-distributing hitch system.

General set-up instructions are as follows:

1. Park unloaded vehicle on a level sur- face. With the ignition on and the doors

closed, allow the vehicle to stand for

several minutes so that it can level.

Technical and consumer information10-23