engine NISSAN PATROL 2000 Electronic Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2000, Model line: PATROL, Model: NISSAN PATROL 2000Pages: 1033, PDF Size: 30.71 MB

Page 349 of 1033

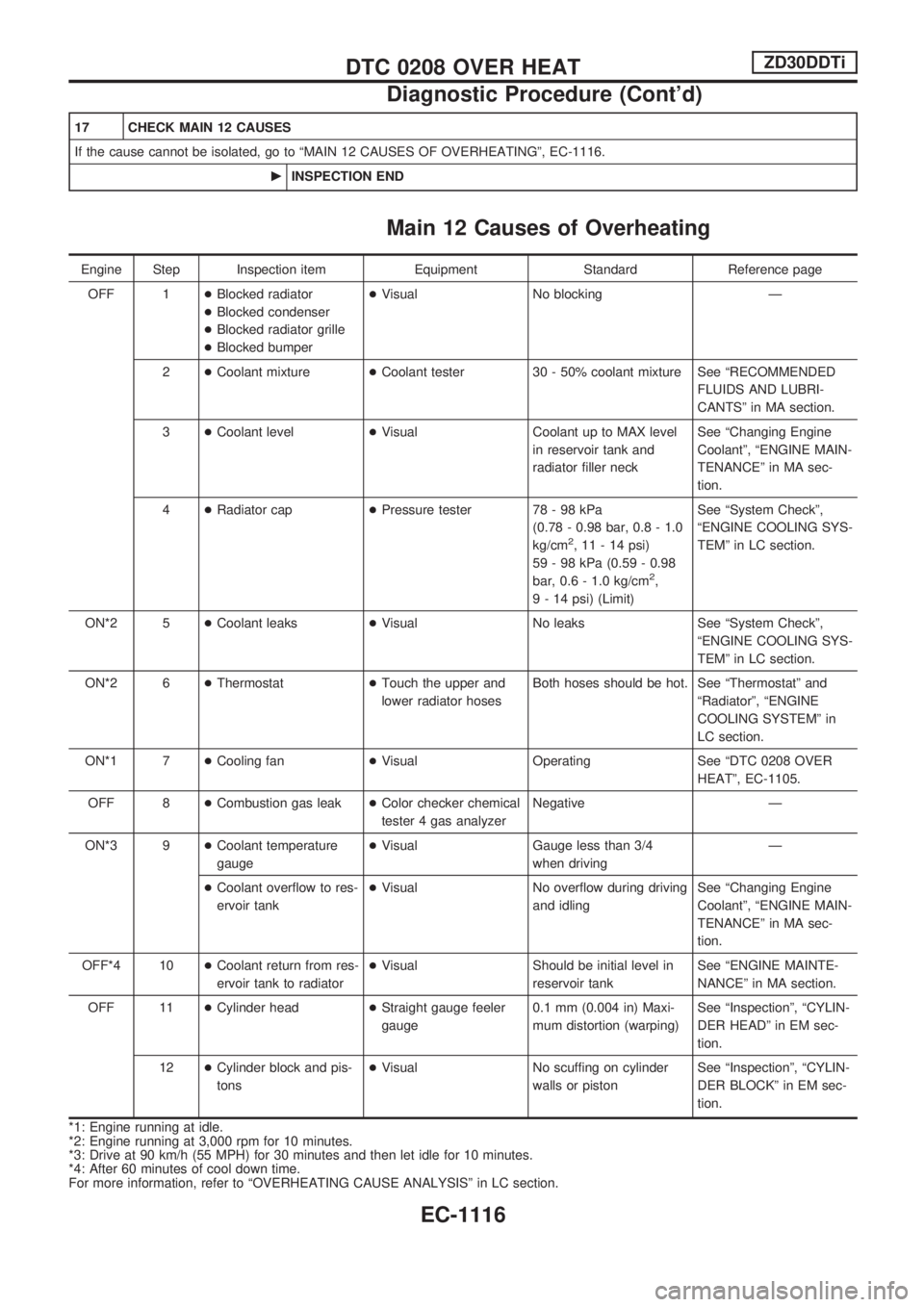

17 CHECK MAIN 12 CAUSES

If the cause cannot be isolated, go to ªMAIN 12 CAUSES OF OVERHEATINGº, EC-1116.

cINSPECTION END

Main 12 Causes of Overheating

Engine Step Inspection item Equipment Standard Reference page

OFF 1+Blocked radiator

+Blocked condenser

+Blocked radiator grille

+Blocked bumper+Visual No blocking Ð

2+Coolant mixture+Coolant tester 30 - 50% coolant mixture See ªRECOMMENDED

FLUIDS AND LUBRI-

CANTSº in MA section.

3+Coolant level+Visual Coolant up to MAX level

in reservoir tank and

radiator filler neckSee ªChanging Engine

Coolantº, ªENGINE MAIN-

TENANCEº in MA sec-

tion.

4+Radiator cap+Pressure tester 78 - 98 kPa

(0.78 - 0.98 bar, 0.8 - 1.0

kg/cm

2, 11 - 14 psi)

59 - 98 kPa (0.59 - 0.98

bar, 0.6 - 1.0 kg/cm

2,

9 - 14 psi) (Limit)See ªSystem Checkº,

ªENGINE COOLING SYS-

TEMº in LC section.

ON*2 5+Coolant leaks+Visual No leaks See ªSystem Checkº,

ªENGINE COOLING SYS-

TEMº in LC section.

ON*2 6+Thermostat+Touch the upper and

lower radiator hosesBoth hoses should be hot. See ªThermostatº and

ªRadiatorº, ªENGINE

COOLING SYSTEMº in

LC section.

ON*1 7+Cooling fan+Visual Operating See ªDTC 0208 OVER

HEATº, EC-1105.

OFF 8+Combustion gas leak+Color checker chemical

tester 4 gas analyzerNegative Ð

ON*3 9+Coolant temperature

gauge+Visual Gauge less than 3/4

when drivingÐ

+Coolant overflow to res-

ervoir tank+Visual No overflow during driving

and idlingSee ªChanging Engine

Coolantº, ªENGINE MAIN-

TENANCEº in MA sec-

tion.

OFF*4 10+Coolant return from res-

ervoir tank to radiator+Visual Should be initial level in

reservoir tankSee ªENGINE MAINTE-

NANCEº in MA section.

OFF 11+Cylinder head+Straight gauge feeler

gauge0.1 mm (0.004 in) Maxi-

mum distortion (warping)See ªInspectionº, ªCYLIN-

DER HEADº in EM sec-

tion.

12+Cylinder block and pis-

tons+Visual No scuffing on cylinder

walls or pistonSee ªInspectionº, ªCYLIN-

DER BLOCKº in EM sec-

tion.

*1: Engine running at idle.

*2: Engine running at 3,000 rpm for 10 minutes.

*3: Drive at 90 km/h (55 MPH) for 30 minutes and then let idle for 10 minutes.

*4: After 60 minutes of cool down time.

For more information, refer to ªOVERHEATING CAUSE ANALYSISº in LC section.

DTC 0208 OVER HEATZD30DDTi

Diagnostic Procedure (Cont'd)

EC-1116

Page 350 of 1033

Description

The ECM consists of a microcomputer and connectors for signal

input and output and for power supply. The unit controls the

engine.

On Board Diagnosis Logic

Malfunction is detected when ... Check Items (Possible Cause)

+ECM calculation function is malfunctioning.+ECM

(ECCS-D control module)

DTC Confirmation Procedure

WITH CONSULT-II

1) Turn ignition switch ªONº.

2) Select ªDATA MONITORº mode with CONSULT-II.

3) Start engine and wait at least 2 seconds.

4) If DTC is detected, go to ªDiagnostic Procedureº, EC-1118.

WITHOUT CONSULT-II

1) Turn ignition switch ªONº and wait at least 2 seconds.

2) Start engine and wait at least 2 seconds.

3) Turn ignition switch ªOFFº, wait at least 5 seconds and then

turn ªONº.

4) Perform ªDiagnostic Test Mode II (Self-diagnostic results)º

with ECM.

5) If DTC is detected, go to ªDiagnostic Procedureº, EC-1118.

SEC220B

SEF817Y

DTC 0301 ECM 2, DTC 0901 ECM 12ZD30DDTi

EC-1117

Page 352 of 1033

Description

SYSTEM DESCRIPTION

The ECM and the electronic control fuel injection pump control

unit (abbreviated as the injection pump control unit) perform the

real time communication (signal exchange).

The ECM transmits the signals of the target fuel injection

amount, target fuel injection timing, and engine speed, etc., and

receives the signals of the pump speed and fuel temperature,

etc. from the injection pump control unit.

By those signals, the injection pump controls the optimum fuel

injection amount and injection timing of the spill valve and tim-

ing control valve.

Injection pump control unit has an on board diagnostic system,

which detects malfunctions related to sensors or actuators built-

into electronic control fuel injection pump. These malfunction

information are transferred through the line (circuit) from injection

pump control unit to ECM.

FUEL INJECTION AMOUNT CONTROL

In accordance with the target fuel injection amount signal from

the ECM, the injection amount is controlled by controlling the spill

valve in the injection pump and by changing the needle opening

time.

FUEL INJECTION TIMING CONTROL

Based on the target fuel injection timing signal from the ECM, the

injection timing is controlled in accordance with the timer spring

by performing the duty control of the timing control valve in the

injection pump and by adjusting the pressure of the timer piston

high pressure chamber.

FUEL TEMPERATURE SENSOR

The sensor detects the fuel temperature in the injection pump

and calibrates the injection amount change by the fuel tempera-

ture.

CAM RING POSITION SENSOR

The sensor detects the passing of the protrusion on the sensor

wheel in the injection pump by the semiconductor magnetic

resistance element sensor. The cam ring position sensor syn-

chronizes with the cam ring, and detects the actual advance

amount. The injection pump control unit measures the injection

pump revolution by the signal of the cam ring position sensor.

SEF437Y

DTC 0402 P9zFUEL TEMP SENZD30DDTi

EC-1119

Page 353 of 1033

CONSULT-II Reference Value in Data Monitor

Mode

Remarks: Specification data are reference values.

MONITOR ITEM CONDITION SPECIFICATION

FUEL TEMP SEN+Engine: After warming up More than 40ÉC (104ÉF)

SPILL/V+Engine: After warming up Approx. 13ÉCA

INJ TIMG C/V+Engine: After warming up,

idle the engine.Approx. 50 - 70%

DECELER F/CUT+Engine: After warm-

ing upIdle OFF

BARO SEN+Ignition switch: ONAltitude

Approx.0m(0ft): Approx. 100.62 kPa (1.0062 bar, 1.026 kg/cm

2, 14.59

psi)

Approx. 1,000 m (3,281 ft): Approx. 88.95 kPa (0.8895 bar, 0.907 kg/cm

2,

12.90 psi)

Approx. 1,500 m (4,992 ft): Approx. 83.16 kPa (0.8316 bar, 0.848 kg/cm

2,

12.06 psi)

Approx. 2,000 m (6,562 ft): Approx. 78.36 kPa (0.7836 bar, 0.799 kg/cm

2,

11.36 psi)

ECM Terminals and Reference Value

Specification data are reference values and are measured between each terminal and ground.

CAUTION:

Do not use ECM ground terminals when measuring input/output voltage. Doing so may damage the

ECM's transistor. Use a ground other than ECM terminals, such as the ground.

TER-

MINAL

NO.WIRE

COLORITEM CONDITION DATA (DC Voltage)

33 G/YElectronic control fuel

injection pumpEngine is running.

Warm-up condition

Idle speedApproximately 2.5V

40 R/BElectronic control fuel

injection pumpEngine is running.

Warm-up condition

Idle speedApproximately 2.5V

52 L/BElectronic control fuel

injection pumpEngine is running.

Idle speedApproximately 0.1V

53 L/RElectronic control fuel

injection pumpEngine is running.

Idle speedApproximately 0.35V

On Board Diagnosis Logic

Malfunction is detected when .... Check Items (Possible cause)

+An improper voltage signal from fuel temperature sensor

(Built-into electronic control fuel injection pump) is sent to

injection pump control unit.+Harness or connectors

(Electronic control fuel injection pump circuit is open or

shorted.)

+Electronic control fuel injection pump

DTC 0402 P9zFUEL TEMP SENZD30DDTi

EC-1120

Page 354 of 1033

DTC Confirmation Procedure

WITH CONSULT-II

1) Turn ignition switch ªONº and wait at least 2 seconds.

2) Select ªDATA MONITORº mode with CONSULT-II.

3) Start engine and run it for at least 2 seconds at idle speed.

(If engine does not run, turn ignition switch to ªSTARTº for at

least 2 seconds.)

4) If DTC is detected, go to ªDiagnostic Procedureº, EC-1123.

WITHOUT CONSULT-II

1) Turn ignition switch ªONº and wait at least 2 seconds.

2) Start engine and run it for at least 2 seconds at idle speed.

(If engine does not run, turn ignition switch to ªSTARTº for at

least 2 seconds.)

3) Turn ignition switch ªOFFº, wait at least 5 seconds and then

turn ªONº.

4) Perform ªDiagnostic Test Mode II (Self-diagnostic results)º

with ECM.

5) If DTC is detected, go to ªDiagnostic Procedureº, EC-1123.

SEF817Y

DTC 0402 P9zFUEL TEMP SENZD30DDTi

EC-1121

Page 357 of 1033

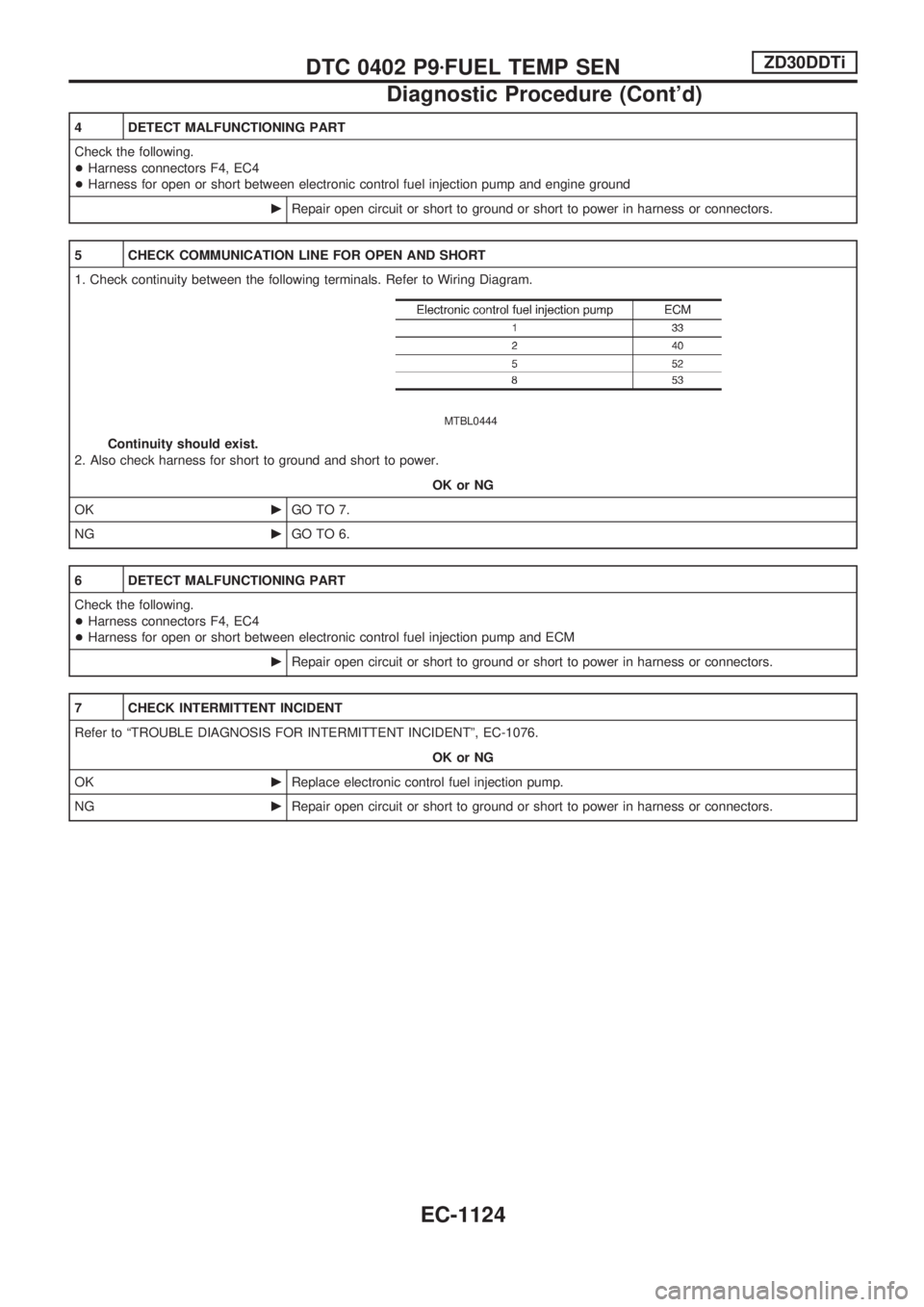

4 DETECT MALFUNCTIONING PART

Check the following.

+Harness connectors F4, EC4

+Harness for open or short between electronic control fuel injection pump and engine ground

cRepair open circuit or short to ground or short to power in harness or connectors.

5 CHECK COMMUNICATION LINE FOR OPEN AND SHORT

1. Check continuity between the following terminals. Refer to Wiring Diagram.

MTBL0444

Continuity should exist.

2. Also check harness for short to ground and short to power.

OK or NG

OKcGO TO 7.

NGcGO TO 6.

6 DETECT MALFUNCTIONING PART

Check the following.

+Harness connectors F4, EC4

+Harness for open or short between electronic control fuel injection pump and ECM

cRepair open circuit or short to ground or short to power in harness or connectors.

7 CHECK INTERMITTENT INCIDENT

Refer to ªTROUBLE DIAGNOSIS FOR INTERMITTENT INCIDENTº, EC-1076.

OK or NG

OKcReplace electronic control fuel injection pump.

NGcRepair open circuit or short to ground or short to power in harness or connectors.

DTC 0402 P9zFUEL TEMP SENZD30DDTi

Diagnostic Procedure (Cont'd)

EC-1124

Page 358 of 1033

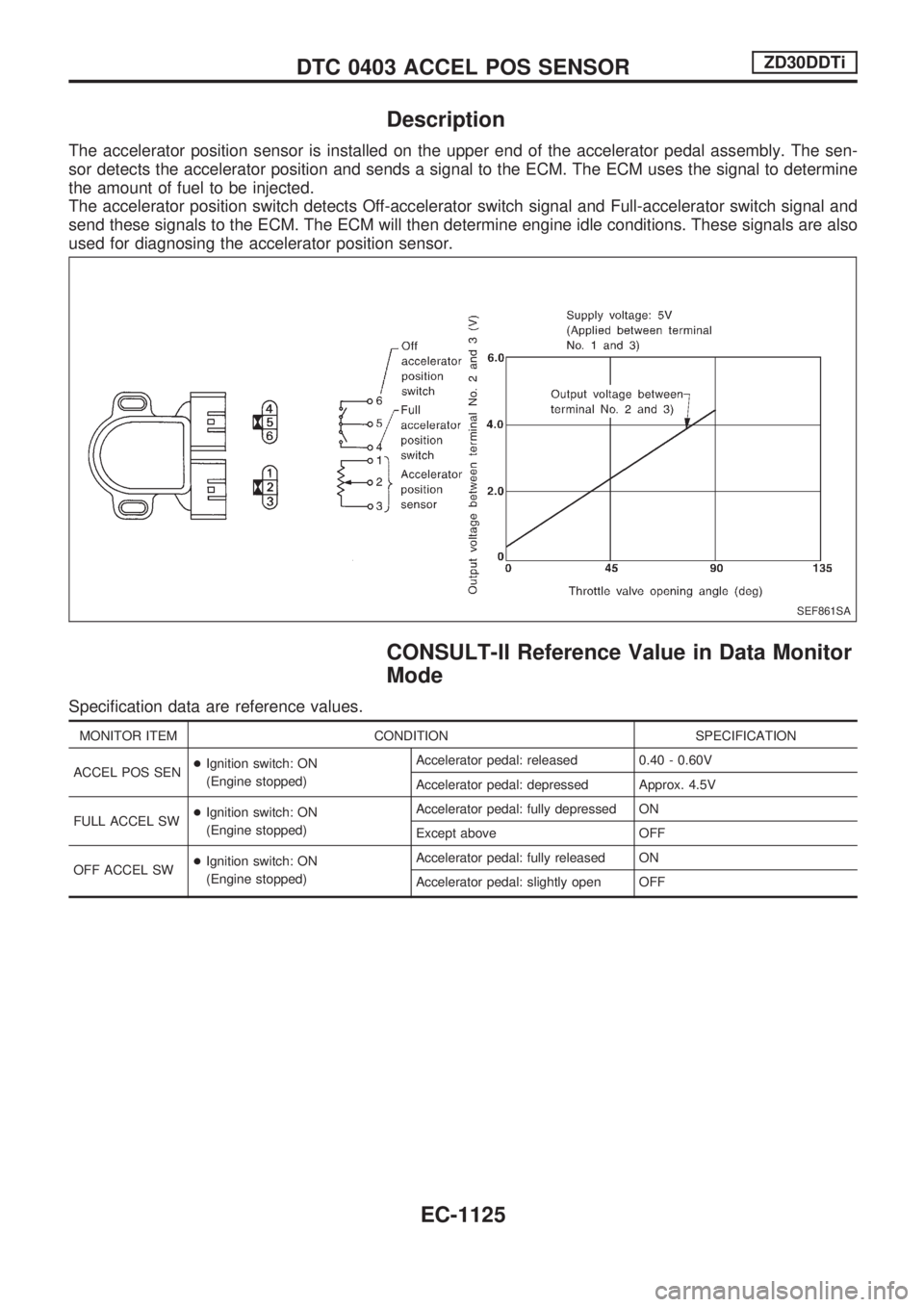

Description

The accelerator position sensor is installed on the upper end of the accelerator pedal assembly. The sen-

sor detects the accelerator position and sends a signal to the ECM. The ECM uses the signal to determine

the amount of fuel to be injected.

The accelerator position switch detects Off-accelerator switch signal and Full-accelerator switch signal and

send these signals to the ECM. The ECM will then determine engine idle conditions. These signals are also

used for diagnosing the accelerator position sensor.

CONSULT-II Reference Value in Data Monitor

Mode

Specification data are reference values.

MONITOR ITEM CONDITION SPECIFICATION

ACCEL POS SEN+Ignition switch: ON

(Engine stopped)Accelerator pedal: released 0.40 - 0.60V

Accelerator pedal: depressed Approx. 4.5V

FULL ACCEL SW+Ignition switch: ON

(Engine stopped)Accelerator pedal: fully depressed ON

Except above OFF

OFF ACCEL SW+Ignition switch: ON

(Engine stopped)Accelerator pedal: fully released ON

Accelerator pedal: slightly open OFF

SEF861SA

DTC 0403 ACCEL POS SENSORZD30DDTi

EC-1125

Page 359 of 1033

ECM Terminals and Reference Value

Specification data are reference values and are measured between each terminal and ground.

CAUTION:

Do not use ECM ground terminals when measuring input/output voltage. Doing so may damage the

ECM's transistor. Use a ground other than ECM terminals, such as the ground.

TER-

MINAL

NO.WIRE

COLORITEM CONDITION DATA (DC Voltage)

23 WAccelerator position sen-

sorIgnition switch ªONº

Accelerator pedal fully released0.4 - 0.6V

Ignition switch ªONº

Accelerator pedal fully depressedApproximately 4.5V

31 R/LAccelerator position switch

(Idle)Ignition switch ªONº

Accelerator pedal fully releasedBATTERY VOLTAGE

(11 - 14V)

Ignition switch ªONº

Accelerator pedal depressedApproximately 0V

32 W/GAccelerator position switch

(Full)Ignition switch ªONº

Accelerator pedal releasedApproximately 0V

Ignition switch ªONº

Accelerator pedal fully depressedBATTERY VOLTAGE

(11 - 14V)

48 G/RAccelerator position sen-

sor power supplyIgnition switch ªONº

Approximately 5V

51 L/WAccelerator position sen-

sor groundEngine is running.

Warm-up condition

Idle speedApproximately 0V

On Board Diagnosis Logic

Malfunction is detected when ... Check Items (Possible Cause)

+The relation between sensor and switch signal is not in the

normal range during the specified accelerator position.+Harness or connectors

(The sensor circuit is open or shorted.)

+Accelerator position sensor

+Accelerator position switch

+Accelerator switch (F/C)

DTC 0403 ACCEL POS SENSORZD30DDTi

EC-1126

Page 366 of 1033

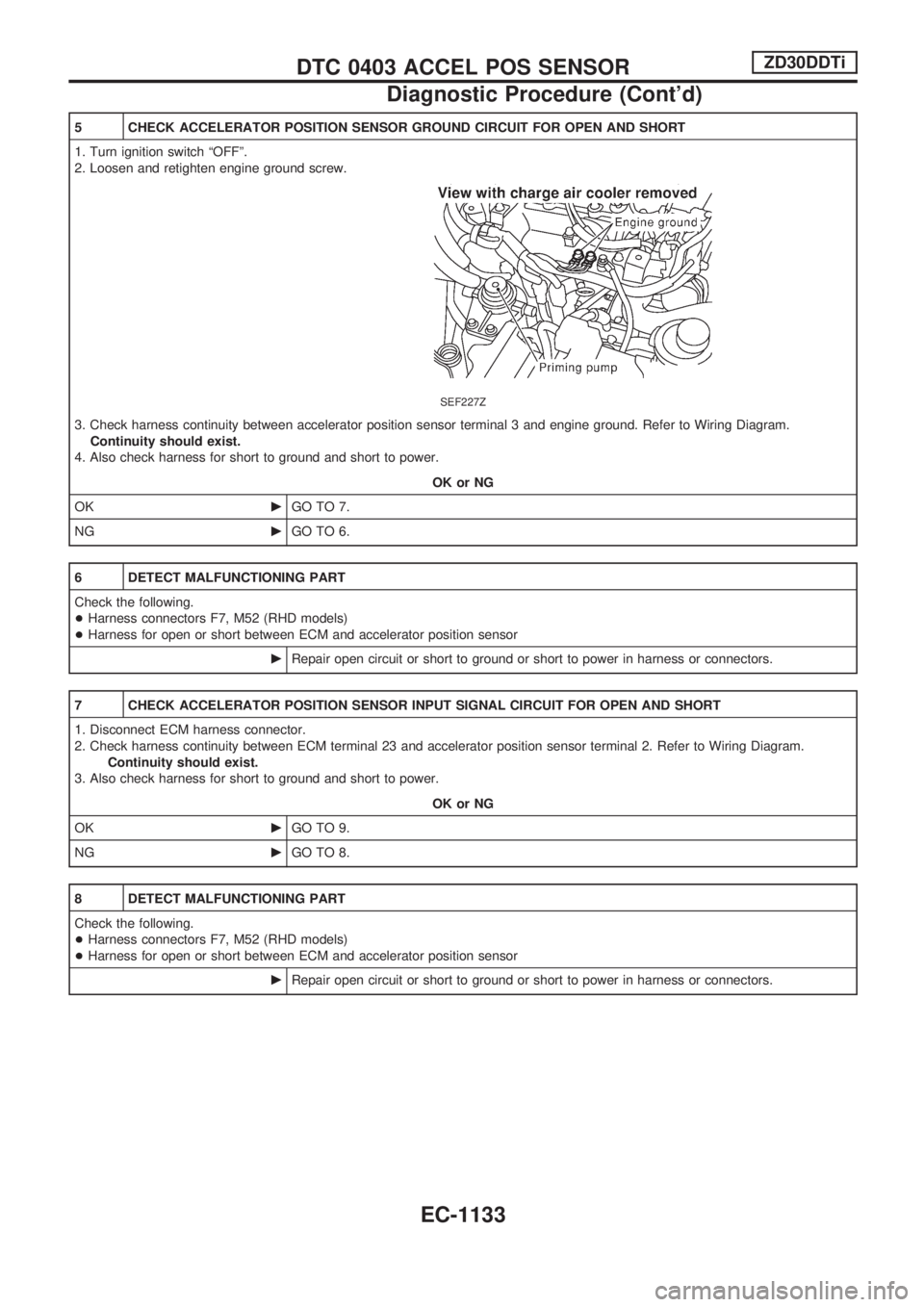

5 CHECK ACCELERATOR POSITION SENSOR GROUND CIRCUIT FOR OPEN AND SHORT

1. Turn ignition switch ªOFFº.

2. Loosen and retighten engine ground screw.

SEF227Z

3. Check harness continuity between accelerator position sensor terminal 3 and engine ground. Refer to Wiring Diagram.

Continuity should exist.

4. Also check harness for short to ground and short to power.

OK or NG

OKcGO TO 7.

NGcGO TO 6.

6 DETECT MALFUNCTIONING PART

Check the following.

+Harness connectors F7, M52 (RHD models)

+Harness for open or short between ECM and accelerator position sensor

cRepair open circuit or short to ground or short to power in harness or connectors.

7 CHECK ACCELERATOR POSITION SENSOR INPUT SIGNAL CIRCUIT FOR OPEN AND SHORT

1. Disconnect ECM harness connector.

2. Check harness continuity between ECM terminal 23 and accelerator position sensor terminal 2. Refer to Wiring Diagram.

Continuity should exist.

3. Also check harness for short to ground and short to power.

OK or NG

OKcGO TO 9.

NGcGO TO 8.

8 DETECT MALFUNCTIONING PART

Check the following.

+Harness connectors F7, M52 (RHD models)

+Harness for open or short between ECM and accelerator position sensor

cRepair open circuit or short to ground or short to power in harness or connectors.

DTC 0403 ACCEL POS SENSORZD30DDTi

Diagnostic Procedure (Cont'd)

EC-1133

Page 368 of 1033

12 RESET ACCELERATOR POSITION SENSOR IDLE POSITION MEMORY

Without CONSULT-II

1. Start engine and warm it up to normal operating temperature.

2. Let engine idle for 10 minutes.

cGO TO 13.

13 CHECK INTERMITTENT INCIDENT

Refer to ªTROUBLE DIAGNOSIS FOR INTERMITTENT INCIDENTº, EC-1076.

cINSPECTION END

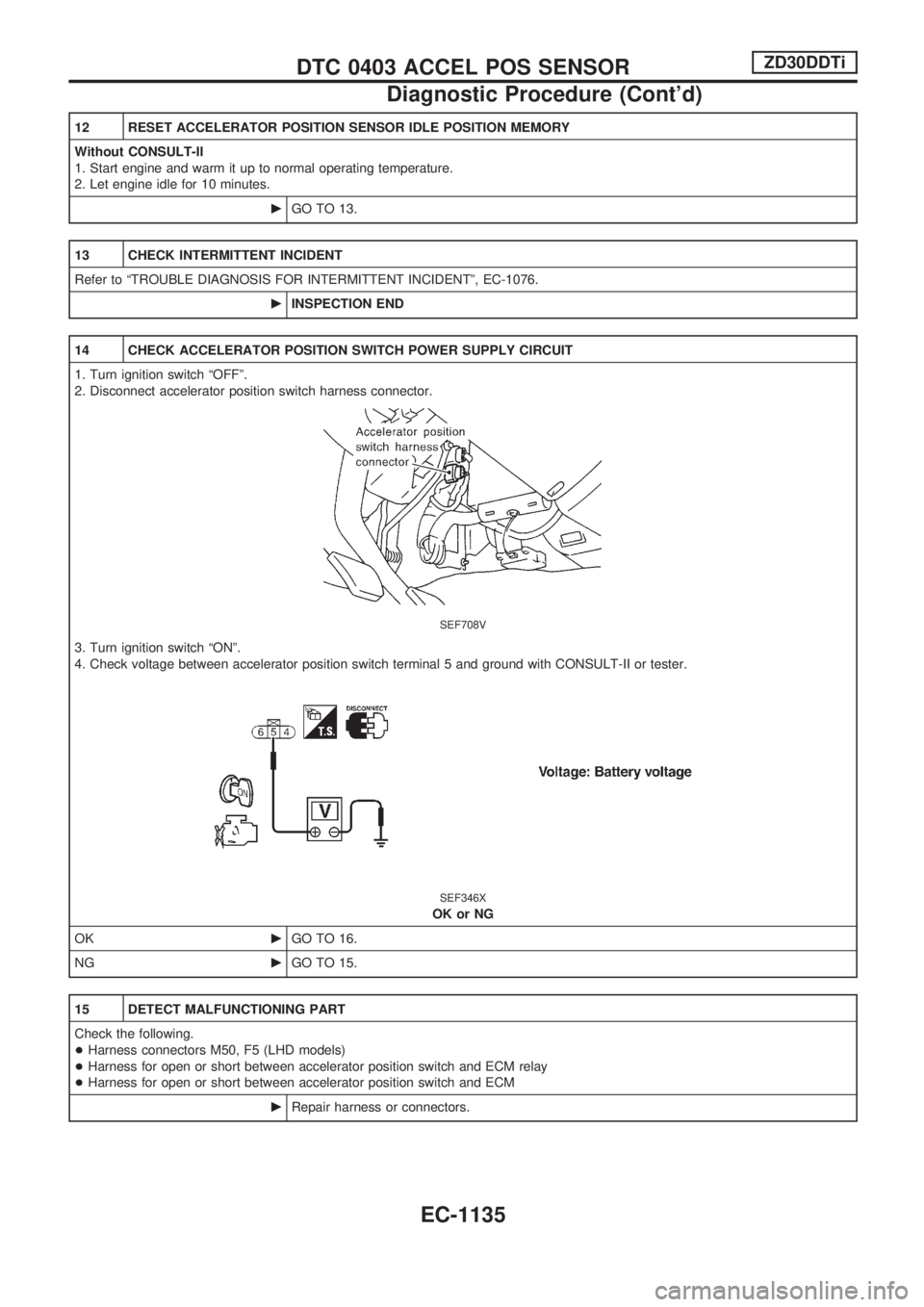

14 CHECK ACCELERATOR POSITION SWITCH POWER SUPPLY CIRCUIT

1. Turn ignition switch ªOFFº.

2. Disconnect accelerator position switch harness connector.

SEF708V

3. Turn ignition switch ªONº.

4. Check voltage between accelerator position switch terminal 5 and ground with CONSULT-II or tester.

SEF346X

OK or NG

OKcGO TO 16.

NGcGO TO 15.

15 DETECT MALFUNCTIONING PART

Check the following.

+Harness connectors M50, F5 (LHD models)

+Harness for open or short between accelerator position switch and ECM relay

+Harness for open or short between accelerator position switch and ECM

cRepair harness or connectors.

DTC 0403 ACCEL POS SENSORZD30DDTi

Diagnostic Procedure (Cont'd)

EC-1135