engine NISSAN PATROL 2000 Electronic Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2000, Model line: PATROL, Model: NISSAN PATROL 2000Pages: 1033, PDF Size: 30.71 MB

Page 370 of 1033

21 RESET ACCELERATOR POSITION SENSOR IDLE POSITION MEMORY

With CONSULT-II

1. Turn ignition switch ªONº.

2. Select ªOFF ACCEL PO SIGº in ªACTIVE TESTº mode with CONSULT-II.

3. Touch ªCLEARº.

cGO TO 23.

22 RESET ACCELERATOR POSITION SENSOR IDLE POSITION MEMORY

Without CONSULT-II

1. Start engine and warm it up to normal operating temperature.

2. Let engine idle for 10 minutes.

cGO TO 23.

23 CHECK INTERMITTENT INCIDENT

Refer to ªTROUBLE DIAGNOSIS FOR INTERMITTENT INCIDENTº, EC-1076.

cINSPECTION END

DTC 0403 ACCEL POS SENSORZD30DDTi

Diagnostic Procedure (Cont'd)

EC-1137

Page 371 of 1033

On Board Diagnosis Logic

Malfunction is detected when ... Check Items (Possible Cause)

+An excessively high voltage from the mass air flow sensor is

sent to ECM when engine is running.+Air duct

+Charge air cooler

+Variable nozzle turbocharger control system

+Variable nozzle turbocharger

+Mass air flow sensor

+Harness or connectors

(The mass air flow sensor circuit is shorted.)

DTC Confirmation Procedure

NOTE:

If DTC 0406 ªINT AIR VOLº displayed with DTC 0102 ªMASS

AIR FLOW SENº, perform trouble diagnosis for DTC 0102

ªMASS AIR FLOW SENº first. (See EC-1086.)

WITH CONSULT-II

1) Turn ignition switch ªONº.

2) Select ªDATA MONITORº mode with CONSULT-II.

3) Start engine and warm it up to normal operating temperature.

4) Drive vehicle.

5) Maintain the engine speed more than 4,000 rpm for at least

10 seconds.

6) If DTC is detected, go to ªDiagnostic Procedureº, EC-1139.

WITHOUT CONSULT-II

1) Start engine and warm it up to normal operating temperature.

2) Drive vehicle.

3) Maintain the engine speed more than 4,000 rpm for at least

10 seconds.

4) Stop vehicle.

5) Turn ignition switch ªOFFº, wait at least 5 seconds and then

turn ªONº.

6) Perform ªDiagnostic Test Mode II (Self-diagnostic results)º

with ECM.

7) If DTC is detected, go to ªDiagnostic Procedureº, EC-1139.SEF817Y

DTC 0406 INT AIR VOLZD30DDTi

EC-1138

Page 372 of 1033

Diagnostic Procedure

1 CHECK INTAKE AIR LEAK

Listen for an intake air leak after the mass air flow sensor.

OK or NG

OKcGO TO 2.

NGcRepair or replace.

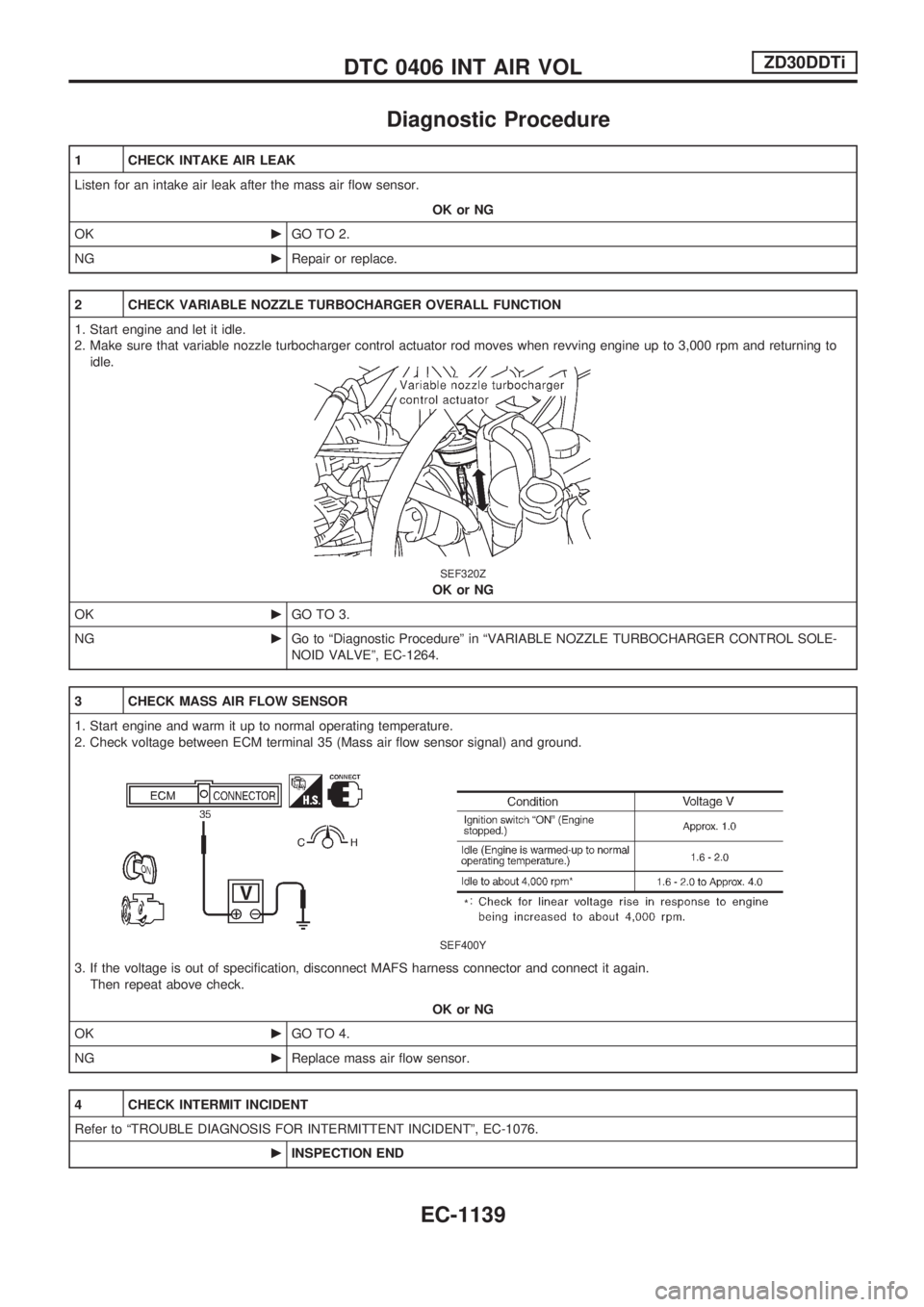

2 CHECK VARIABLE NOZZLE TURBOCHARGER OVERALL FUNCTION

1. Start engine and let it idle.

2. Make sure that variable nozzle turbocharger control actuator rod moves when revving engine up to 3,000 rpm and returning to

idle.

SEF320Z

OK or NG

OKcGO TO 3.

NGcGo to ªDiagnostic Procedureº in ªVARIABLE NOZZLE TURBOCHARGER CONTROL SOLE-

NOID VALVEº, EC-1264.

3 CHECK MASS AIR FLOW SENSOR

1. Start engine and warm it up to normal operating temperature.

2. Check voltage between ECM terminal 35 (Mass air flow sensor signal) and ground.

SEF400Y

3. If the voltage is out of specification, disconnect MAFS harness connector and connect it again.

Then repeat above check.

OK or NG

OKcGO TO 4.

NGcReplace mass air flow sensor.

4 CHECK INTERMIT INCIDENT

Refer to ªTROUBLE DIAGNOSIS FOR INTERMITTENT INCIDENTº, EC-1076.

cINSPECTION END

DTC 0406 INT AIR VOLZD30DDTi

EC-1139

Page 373 of 1033

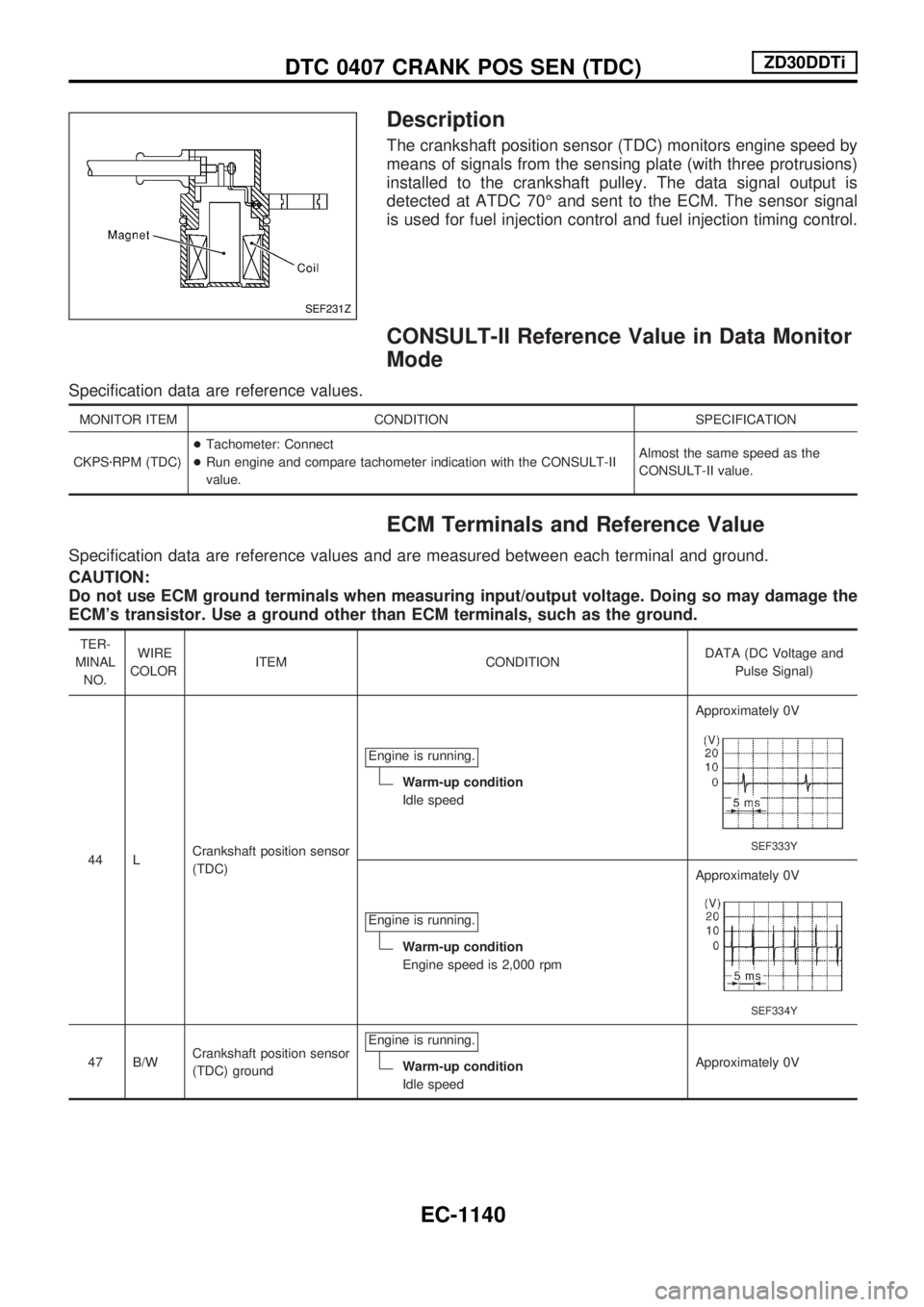

Description

The crankshaft position sensor (TDC) monitors engine speed by

means of signals from the sensing plate (with three protrusions)

installed to the crankshaft pulley. The data signal output is

detected at ATDC 70É and sent to the ECM. The sensor signal

is used for fuel injection control and fuel injection timing control.

CONSULT-II Reference Value in Data Monitor

Mode

Specification data are reference values.

MONITOR ITEM CONDITION SPECIFICATION

CKPSzRPM (TDC)+Tachometer: Connect

+Run engine and compare tachometer indication with the CONSULT-II

value.Almost the same speed as the

CONSULT-II value.

ECM Terminals and Reference Value

Specification data are reference values and are measured between each terminal and ground.

CAUTION:

Do not use ECM ground terminals when measuring input/output voltage. Doing so may damage the

ECM's transistor. Use a ground other than ECM terminals, such as the ground.

TER-

MINAL

NO.WIRE

COLORITEM CONDITIONDATA (DC Voltage and

Pulse Signal)

44 LCrankshaft position sensor

(TDC)Engine is running.

Warm-up condition

Idle speedApproximately 0V

SEF333Y

Engine is running.

Warm-up condition

Engine speed is 2,000 rpmApproximately 0V

SEF334Y

47 B/WCrankshaft position sensor

(TDC) groundEngine is running.Warm-up condition

Idle speedApproximately 0V

SEF231Z

DTC 0407 CRANK POS SEN (TDC)ZD30DDTi

EC-1140

Page 374 of 1033

On Board Diagnosis Logic

Malfunction is detected when ... Check Items (Possible Cause)

+An improper signal from the sensor is sent to ECM during

engine running and cranking.+Harness or connectors

(The sensor circuit is open.)

+Crankshaft position sensor (TDC)

DTC Confirmation Procedure

Before performing the following procedure, confirm that

battery voltage is more than 10V.

WITH CONSULT-II

1) Turn ignition switch ªONº and select ªDATA MONITORº

mode with CONSULT-II.

2) Crank engine for at least 1 second.

3) Start engine and run it for at least 2 seconds at idle speed.

4) If DTC is detected, go to ªDiagnostic Procedureº, EC-1143.

WITHOUT CONSULT-II

1) Crank engine for at least 1 second.

2) Start engine and run it for at least 2 seconds at idle speed.

3) Turn ignition switch ªOFFº, wait at least 5 seconds and then

turn ªONº.

4) Perform ªDiagnostic Test Mode II (Self-diagnostic results)º

with ECM.

5) If DTC is detected, go to ªDiagnostic Procedureº, EC-1143.

SEF817Y

DTC 0407 CRANK POS SEN (TDC)ZD30DDTi

EC-1141

Page 376 of 1033

Diagnostic Procedure

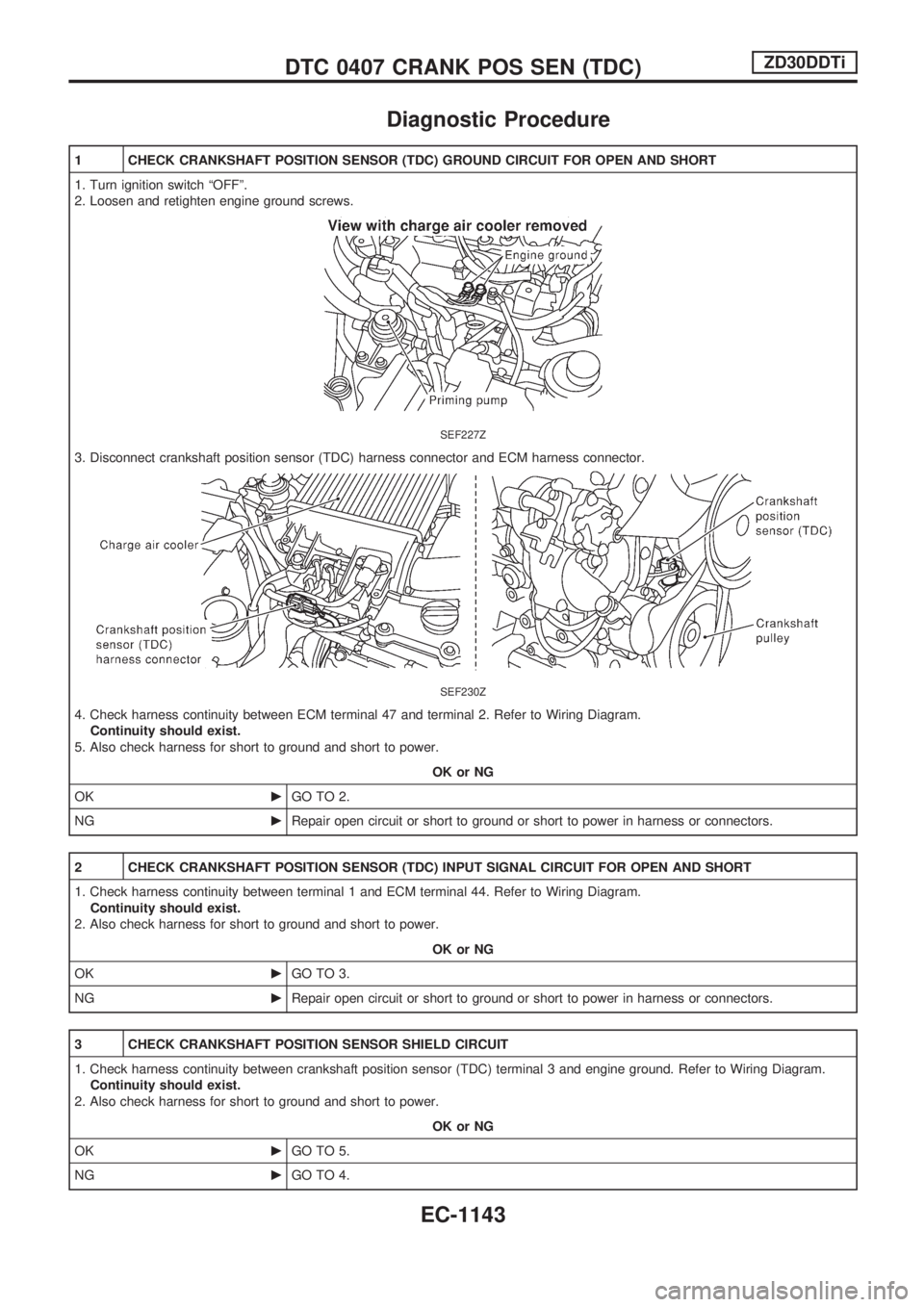

1 CHECK CRANKSHAFT POSITION SENSOR (TDC) GROUND CIRCUIT FOR OPEN AND SHORT

1. Turn ignition switch ªOFFº.

2. Loosen and retighten engine ground screws.

SEF227Z

3. Disconnect crankshaft position sensor (TDC) harness connector and ECM harness connector.

SEF230Z

4. Check harness continuity between ECM terminal 47 and terminal 2. Refer to Wiring Diagram.

Continuity should exist.

5. Also check harness for short to ground and short to power.

OK or NG

OKcGO TO 2.

NGcRepair open circuit or short to ground or short to power in harness or connectors.

2 CHECK CRANKSHAFT POSITION SENSOR (TDC) INPUT SIGNAL CIRCUIT FOR OPEN AND SHORT

1. Check harness continuity between terminal 1 and ECM terminal 44. Refer to Wiring Diagram.

Continuity should exist.

2. Also check harness for short to ground and short to power.

OK or NG

OKcGO TO 3.

NGcRepair open circuit or short to ground or short to power in harness or connectors.

3 CHECK CRANKSHAFT POSITION SENSOR SHIELD CIRCUIT

1. Check harness continuity between crankshaft position sensor (TDC) terminal 3 and engine ground. Refer to Wiring Diagram.

Continuity should exist.

2. Also check harness for short to ground and short to power.

OK or NG

OKcGO TO 5.

NGcGO TO 4.

DTC 0407 CRANK POS SEN (TDC)ZD30DDTi

EC-1143

Page 377 of 1033

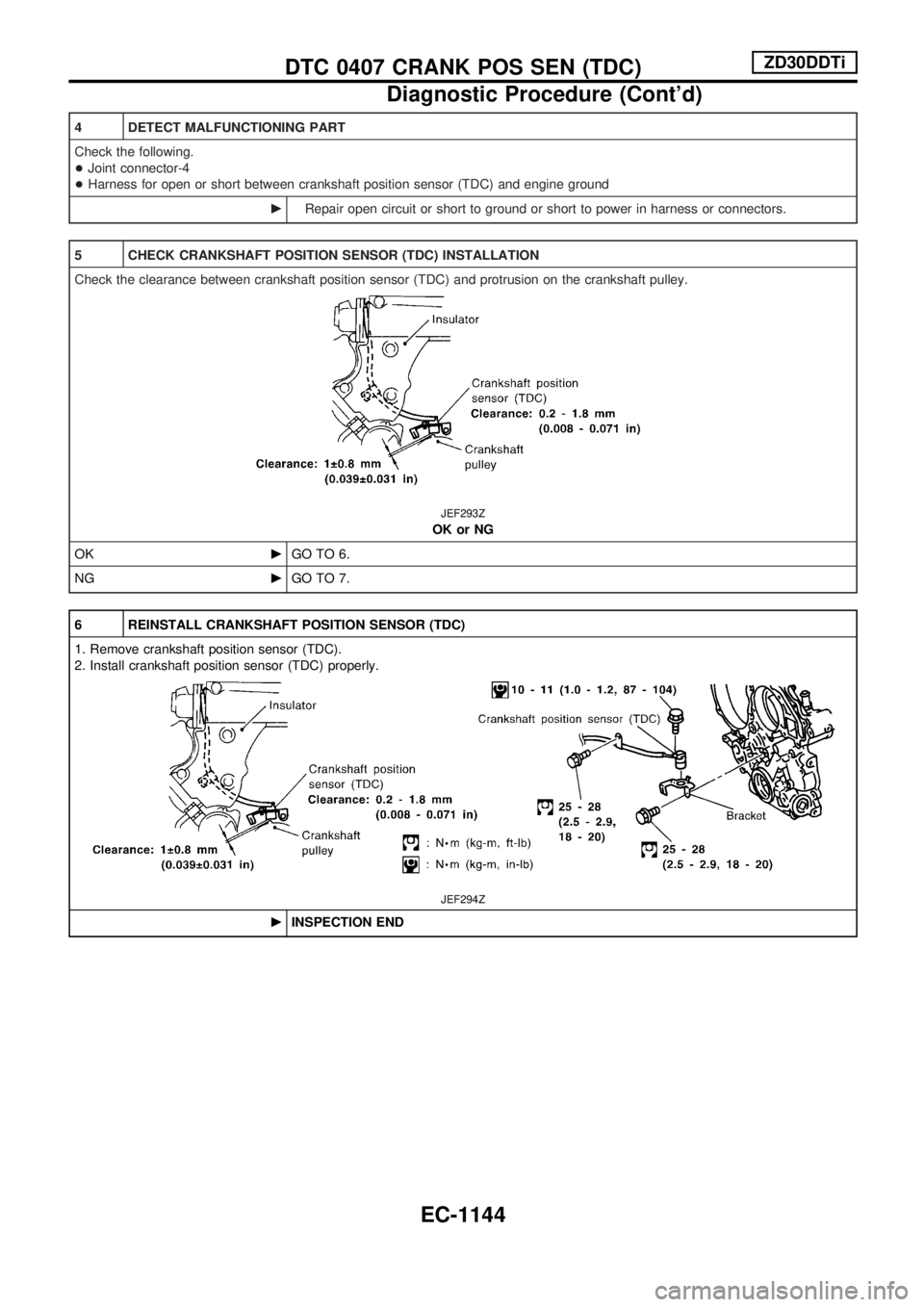

4 DETECT MALFUNCTIONING PART

Check the following.

+Joint connector-4

+Harness for open or short between crankshaft position sensor (TDC) and engine ground

cRepair open circuit or short to ground or short to power in harness or connectors.

5 CHECK CRANKSHAFT POSITION SENSOR (TDC) INSTALLATION

Check the clearance between crankshaft position sensor (TDC) and protrusion on the crankshaft pulley.

JEF293Z

OK or NG

OKcGO TO 6.

NGcGO TO 7.

6 REINSTALL CRANKSHAFT POSITION SENSOR (TDC)

1. Remove crankshaft position sensor (TDC).

2. Install crankshaft position sensor (TDC) properly.

JEF294Z

cINSPECTION END

DTC 0407 CRANK POS SEN (TDC)ZD30DDTi

Diagnostic Procedure (Cont'd)

EC-1144

Page 379 of 1033

On Board Diagnosis Logic

The ECM checks if battery voltage is within the tolerance range for the engine control system.

Malfunction is detected when ... Check Items (Possible Cause)

+ An abnormally high voltage from the battery is sent to ECM. +Incorrect jump starting

+ Battery

+ Alternator

+ ECM

DTC Confirmation Procedure

With CONSULT-II

1) Checkthefollowing.

+ Jumper cables are connected for jump starting.

+ Battery or alternator has been replaced.

If the result is ªYesº for one item or more, skip the following steps and go to ªDiagnostic Procedureº,

EC-1146.

2) Check that the positive battery terminal is connected to battery properly. If NG, reconnect it properly.

3) Check that the alternator functions properly. Refer to EL section (ªCHARGING SYSTEMº).

4) Turn ignition switch ªONº and select ªDATA MONITORº mode with CONSULT-II.

5) Wait one minute.

6) If DTC is detected, go to ªDiagnostic Procedureº, EC-1146. If DTC is not detected, go to next step.

7) Start engine and wait one minute at idle.

8) If DTC is detected, go to ªDiagnostic Procedureº, EC-1146.

Without CONSULT-II

1) Checkthefollowing.

+ Jumper cables are connected for jump starting.

+ Battery or alternator has been replaced.

If the result is ªYesº for one item or more, skip the following steps and go to ªDiagnostic Procedureº,

EC-1146.

2) Check that the positive battery terminal is connected to battery properly. If NG, reconnect it properly.

3) Check that the alternator functions properly. Refer to EL section (ªCHARGING SYSTEMº).

4) Turn ignition switch ªONº and wait one minute.

5) Turn ignition switch ªOFFº, wait 5 seconds and then turn ªONº.

6) Perform ªDiagnostic Test Mode II (Self-diagnostic result)º with ECM.

7) If DTC is detected, go to ªDiagnostic Procedureº, EC-1146. If DTC is not detected, go to next step.

8) Start engine and wait one minute at idle.

9) Turn ignition switch ªOFFº, wait 5 seconds and then turn ªONº.

10) Perform ªDiagnostic Test Mode II (Self-diagnostic result)º with ECM.

11) If DTC is detected, go to ªDiagnostic Procedureº, EC-1146.

Diagnostic Procedure

1 INSPECTION START

Are jumper cables connected for the jump starting?

Yes or No

Yes cGO TO 3.

No cGO TO 2.

DTC 0502 BATTERY VOLTAGEZD30DDTi

EC-1146

Page 381 of 1033

System Description

These circuit lines are used to control the smooth shifting up and down of A/T during the hard acceleration/

deceleration.

Voltage signals are exchanged between ECM and TCM (Transmission control module).

ECM Terminals and Reference Value

Specification data are reference values and are measured between each terminal and ground.

CAUTION:

Do not use ECM ground terminals when measuring input/output voltage. Doing so may damage the

ECM's transistor. Use a ground other than ECM terminals, such as the ground.

TER-

MINAL

NO.WIRE

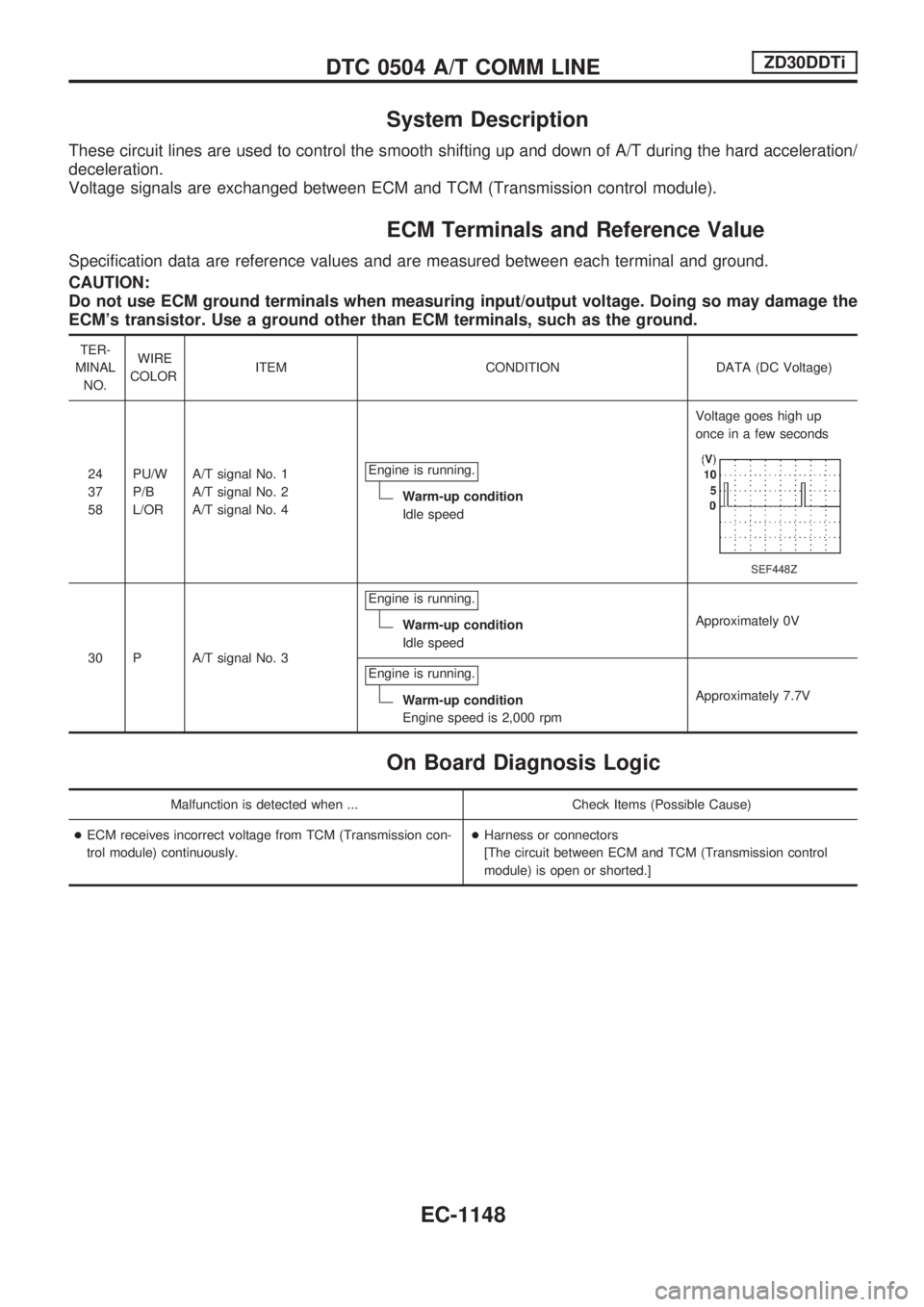

COLORITEM CONDITION DATA (DC Voltage)

24

37

58PU/W

P/B

L/ORA/T signal No. 1

A/T signal No. 2

A/T signal No. 4Engine is running.

Warm-up condition

Idle speedVoltage goes high up

once in a few seconds

SEF448Z

30 P A/T signal No. 3Engine is running.

Warm-up condition

Idle speedApproximately 0V

Engine is running.

Warm-up condition

Engine speed is 2,000 rpmApproximately 7.7V

On Board Diagnosis Logic

Malfunction is detected when ... Check Items (Possible Cause)

+ECM receives incorrect voltage from TCM (Transmission con-

trol module) continuously.+Harness or connectors

[The circuit between ECM and TCM (Transmission control

module) is open or shorted.]

DTC 0504 A/T COMM LINEZD30DDTi

EC-1148

Page 382 of 1033

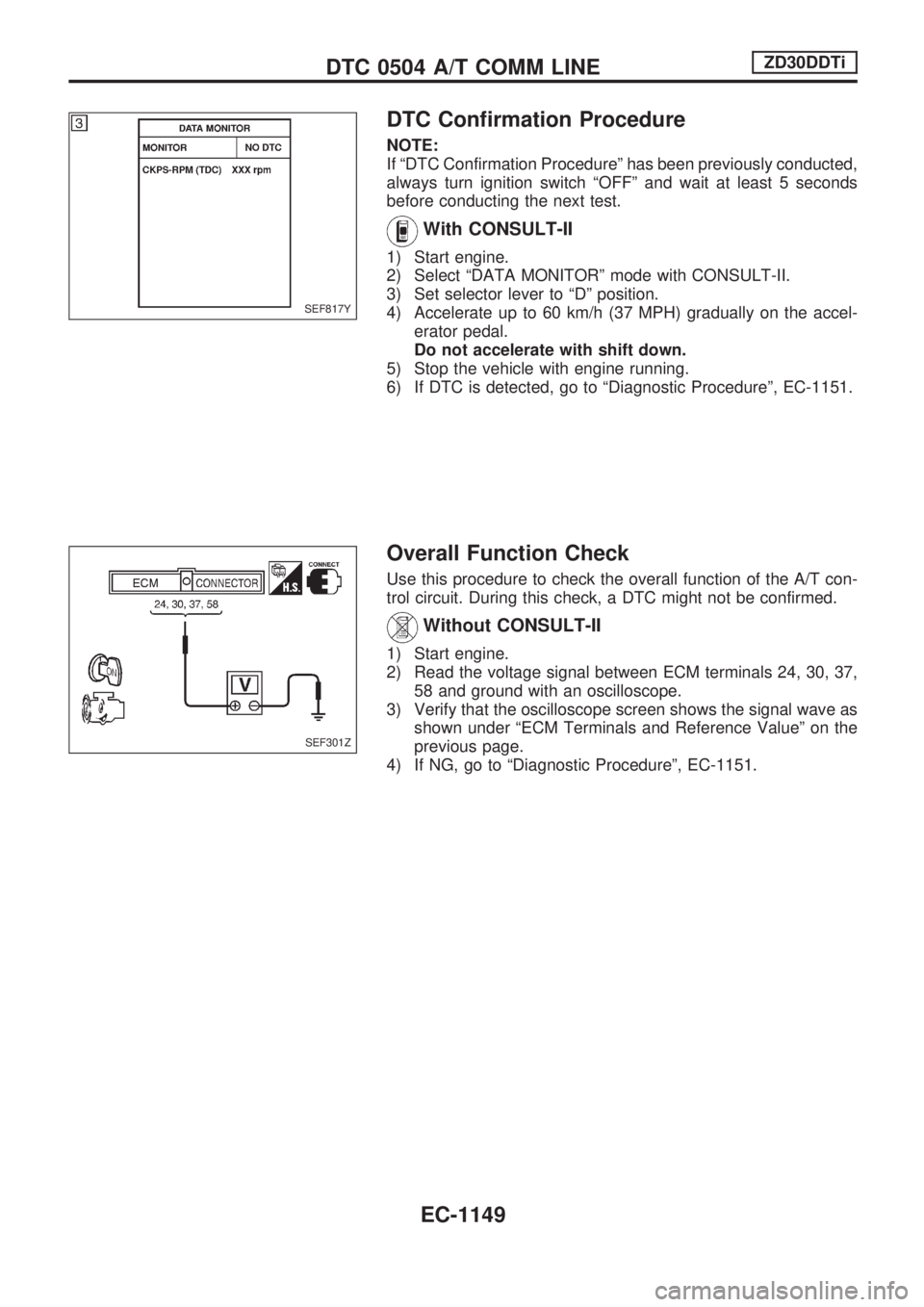

DTC Confirmation Procedure

NOTE:

If ªDTC Confirmation Procedureº has been previously conducted,

always turn ignition switch ªOFFº and wait at least 5 seconds

before conducting the next test.

With CONSULT-II

1) Start engine.

2) Select ªDATA MONITORº mode with CONSULT-II.

3) Set selector lever to ªDº position.

4) Accelerate up to 60 km/h (37 MPH) gradually on the accel-

erator pedal.

Do not accelerate with shift down.

5) Stop the vehicle with engine running.

6) If DTC is detected, go to ªDiagnostic Procedureº, EC-1151.

Overall Function Check

Use this procedure to check the overall function of the A/T con-

trol circuit. During this check, a DTC might not be confirmed.

Without CONSULT-II

1) Start engine.

2) Read the voltage signal between ECM terminals 24, 30, 37,

58 and ground with an oscilloscope.

3) Verify that the oscilloscope screen shows the signal wave as

shown under ªECM Terminals and Reference Valueº on the

previous page.

4) If NG, go to ªDiagnostic Procedureº, EC-1151.

SEF817Y

SEF301Z

DTC 0504 A/T COMM LINEZD30DDTi

EC-1149