engine NISSAN PATROL 2000 Electronic Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2000, Model line: PATROL, Model: NISSAN PATROL 2000Pages: 1033, PDF Size: 30.71 MB

Page 918 of 1033

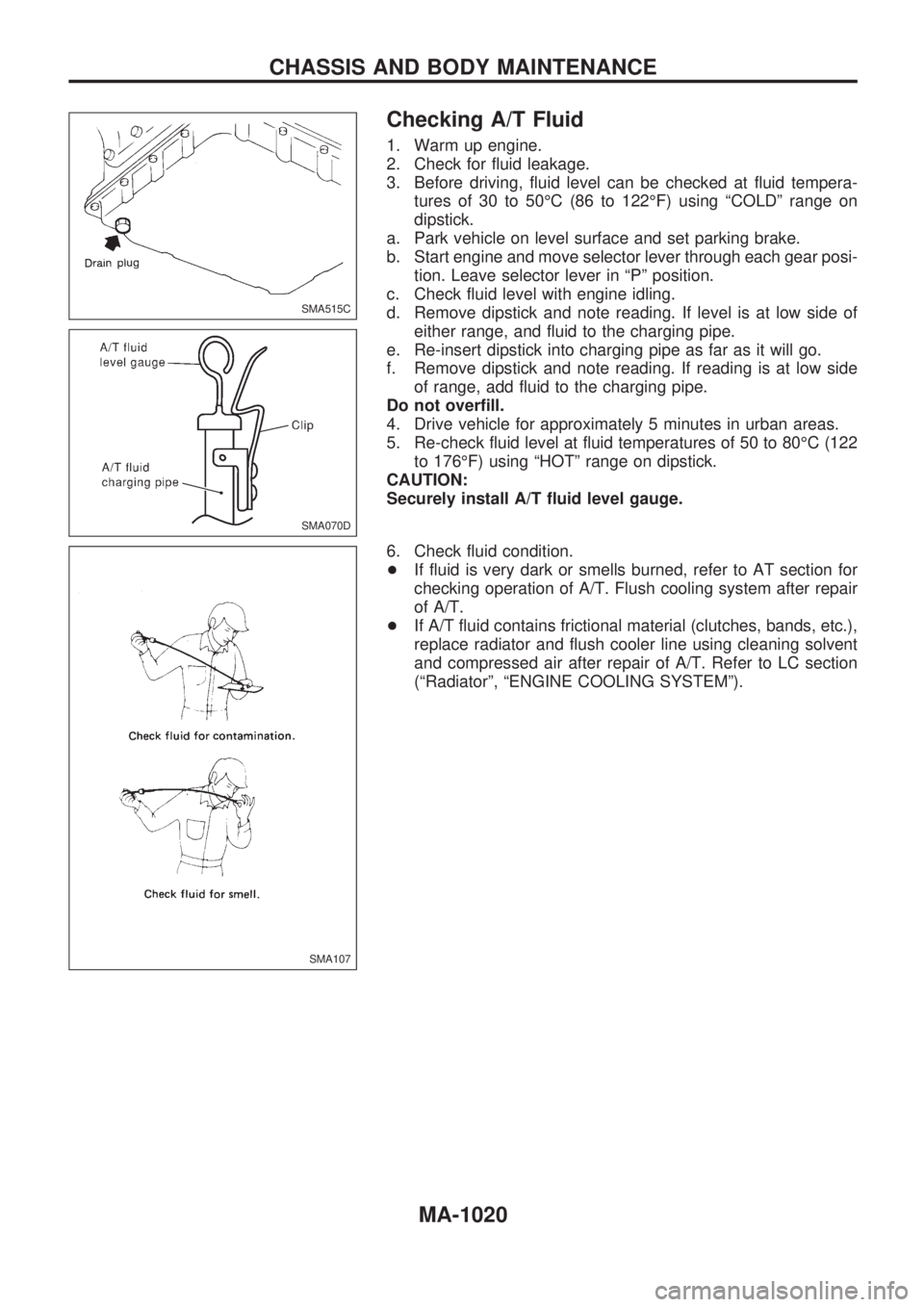

Checking A/T Fluid

1. Warm up engine.

2. Check for fluid leakage.

3. Before driving, fluid level can be checked at fluid tempera-

tures of 30 to 50ÉC (86 to 122ÉF) using ªCOLDº range on

dipstick.

a. Park vehicle on level surface and set parking brake.

b. Start engine and move selector lever through each gear posi-

tion. Leave selector lever in ªPº position.

c. Check fluid level with engine idling.

d. Remove dipstick and note reading. If level is at low side of

either range, and fluid to the charging pipe.

e. Re-insert dipstick into charging pipe as far as it will go.

f. Remove dipstick and note reading. If reading is at low side

of range, add fluid to the charging pipe.

Do not overfill.

4. Drive vehicle for approximately 5 minutes in urban areas.

5. Re-check fluid level at fluid temperatures of 50 to 80ÉC (122

to 176ÉF) using ªHOTº range on dipstick.

CAUTION:

Securely install A/T fluid level gauge.

6. Check fluid condition.

+If fluid is very dark or smells burned, refer to AT section for

checking operation of A/T. Flush cooling system after repair

of A/T.

+If A/T fluid contains frictional material (clutches, bands, etc.),

replace radiator and flush cooler line using cleaning solvent

and compressed air after repair of A/T. Refer to LC section

(ªRadiatorº, ªENGINE COOLING SYSTEMº).

SMA515C

SMA070D

SMA107

CHASSIS AND BODY MAINTENANCE

MA-1020

Page 919 of 1033

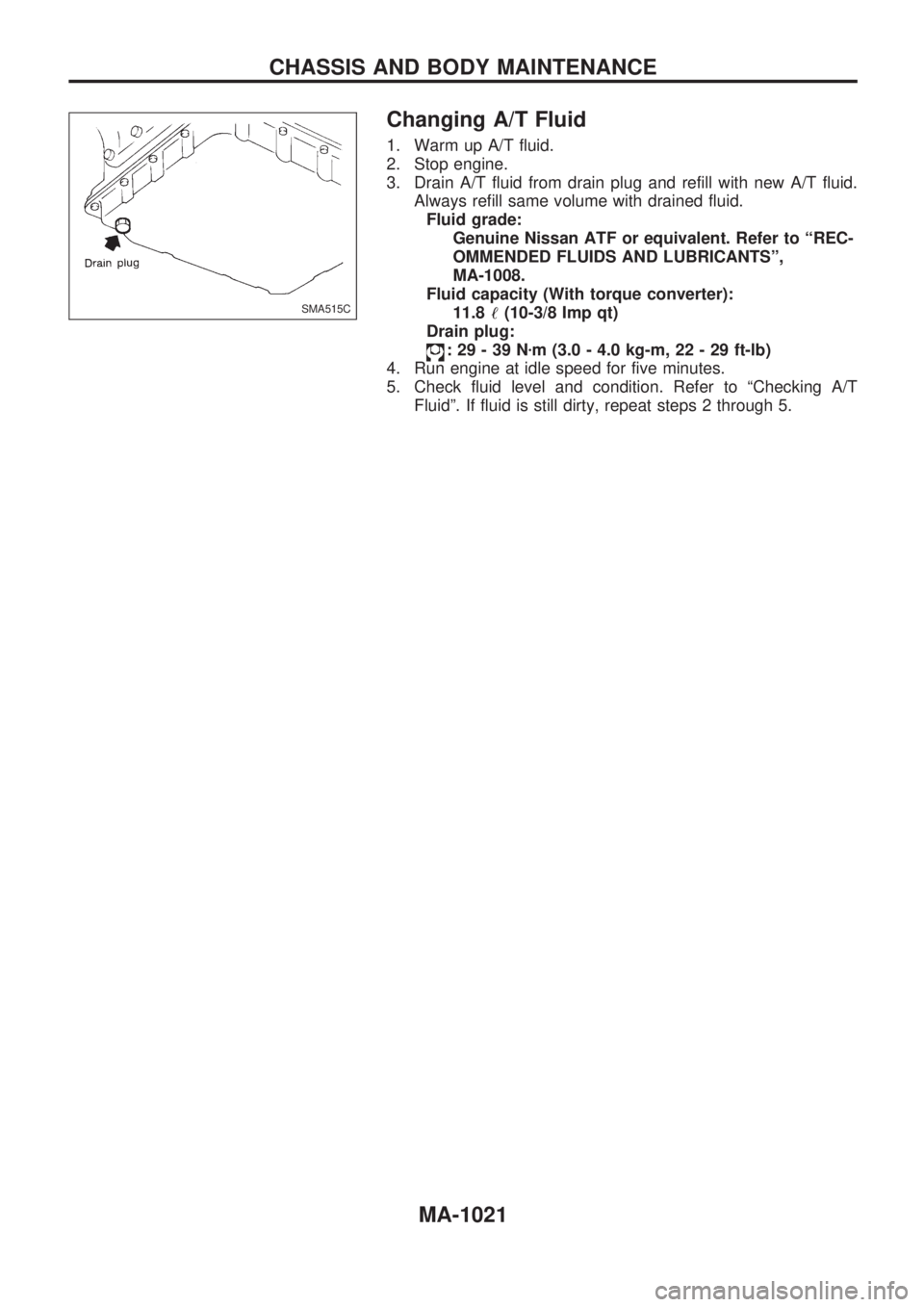

Changing A/T Fluid

1. Warm up A/T fluid.

2. Stop engine.

3. Drain A/T fluid from drain plug and refill with new A/T fluid.

Always refill same volume with drained fluid.

Fluid grade:

Genuine Nissan ATF or equivalent. Refer to ªREC-

OMMENDED FLUIDS AND LUBRICANTSº,

MA-1008.

Fluid capacity (With torque converter):

11.8!(10-3/8 Imp qt)

Drain plug:

:29-39Nzm (3.0 - 4.0 kg-m, 22 - 29 ft-lb)

4. Run engine at idle speed for five minutes.

5. Check fluid level and condition. Refer to ªChecking A/T

Fluidº. If fluid is still dirty, repeat steps 2 through 5.

SMA515C

CHASSIS AND BODY MAINTENANCE

MA-1021

Page 920 of 1033

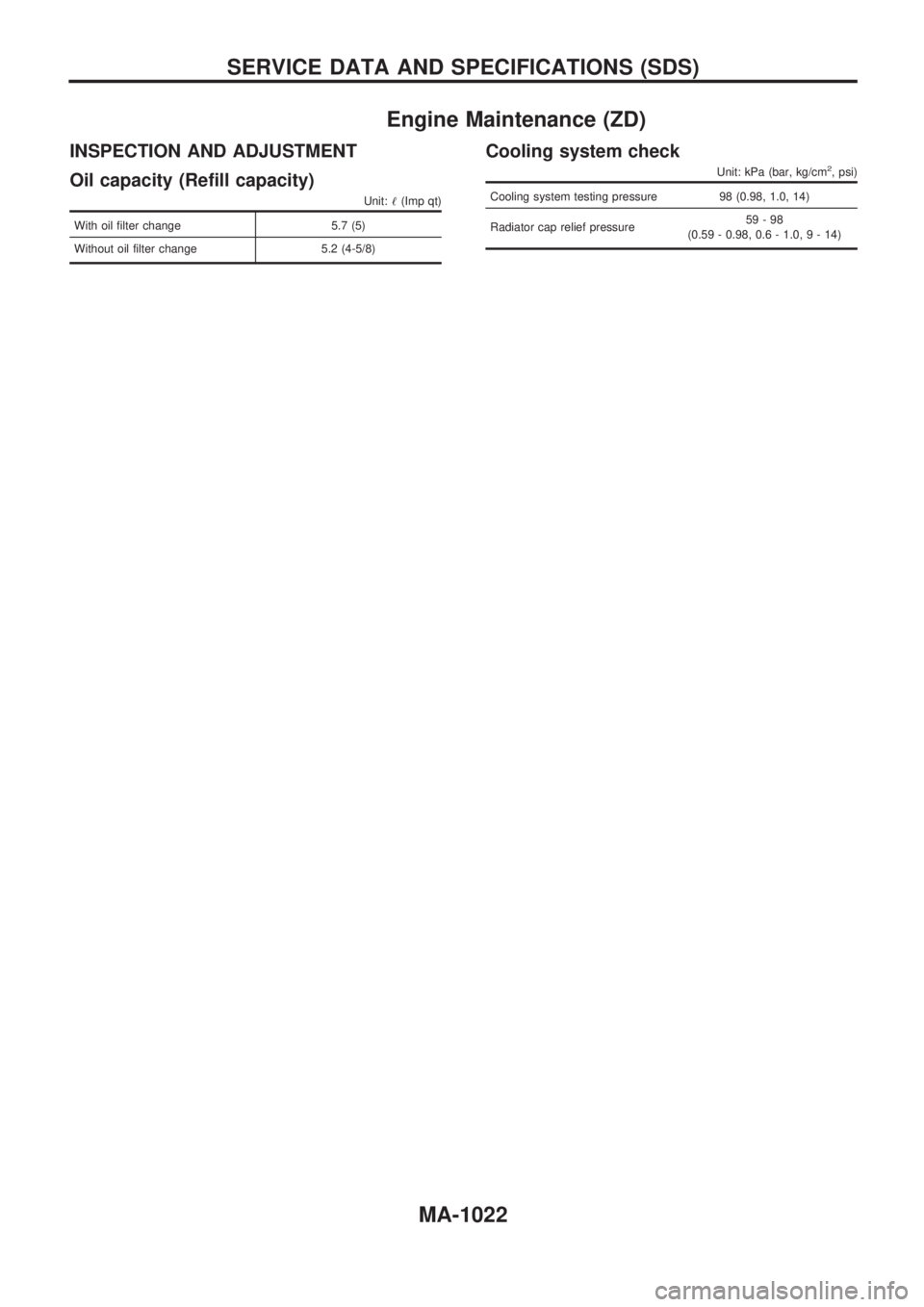

Engine Maintenance (ZD)

INSPECTION AND ADJUSTMENT

Oil capacity (Refill capacity)

Unit:!(Imp qt)

With oil filter change 5.7 (5)

Without oil filter change 5.2 (4-5/8)

Cooling system check

Unit: kPa (bar, kg/cm2, psi)

Cooling system testing pressure 98 (0.98, 1.0, 14)

Radiator cap relief pressure59-98

(0.59 - 0.98, 0.6 - 1.0,9-14)

SERVICE DATA AND SPECIFICATIONS (SDS)

MA-1022

Page 927 of 1033

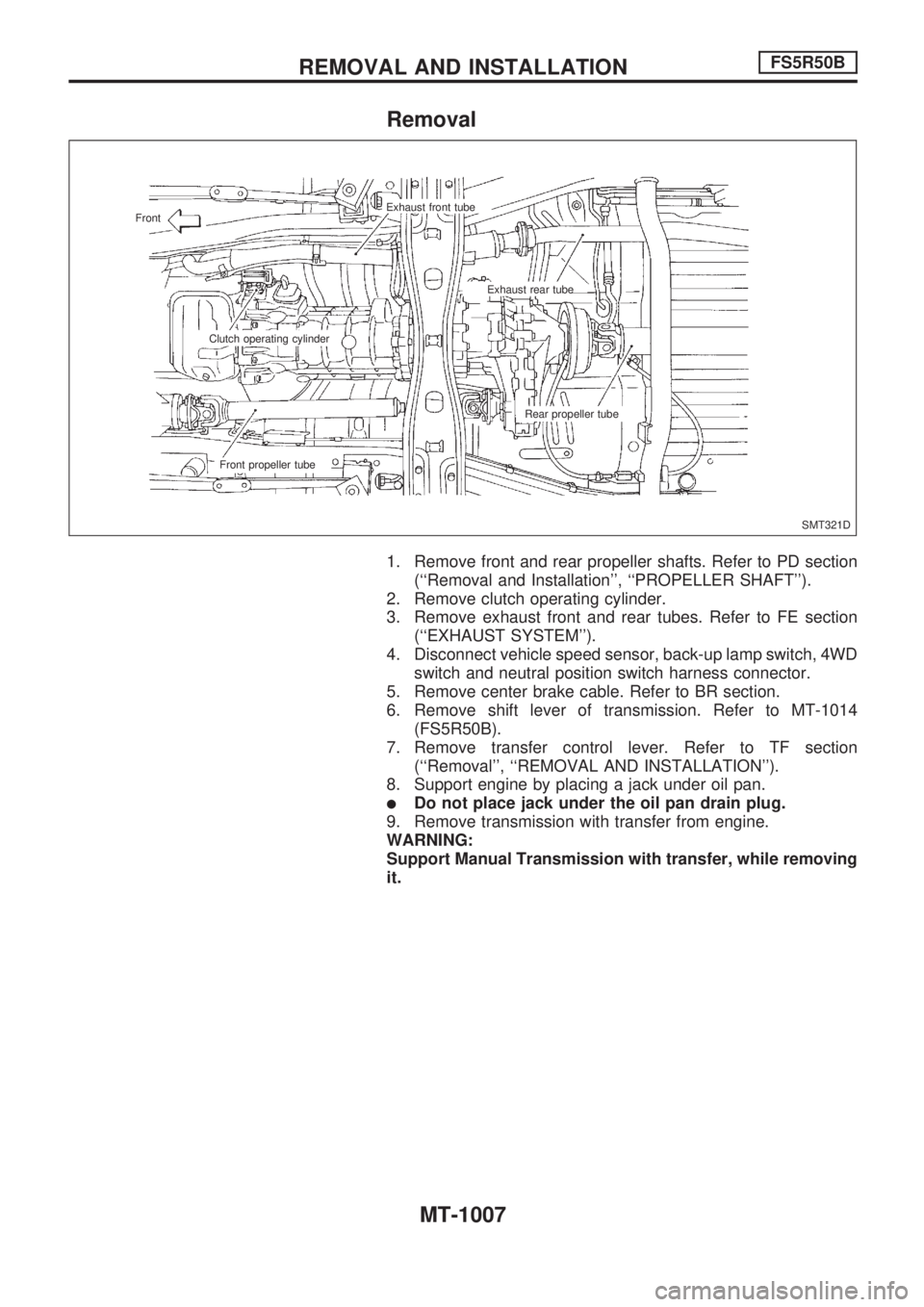

Removal

1. Remove front and rear propeller shafts. Refer to PD section

(``Removal and Installation'', ``PROPELLER SHAFT'').

2. Remove clutch operating cylinder.

3. Remove exhaust front and rear tubes. Refer to FE section

(``EXHAUST SYSTEM'').

4. Disconnect vehicle speed sensor, back-up lamp switch, 4WD

switch and neutral position switch harness connector.

5. Remove center brake cable. Refer to BR section.

6. Remove shift lever of transmission. Refer to MT-1014

(FS5R50B).

7. Remove transfer control lever. Refer to TF section

(``Removal'', ``REMOVAL AND INSTALLATION'').

8. Support engine by placing a jack under oil pan.

lDo not place jack under the oil pan drain plug.

9. Remove transmission with transfer from engine.

WARNING:

Support Manual Transmission with transfer, while removing

it.

SMT321D Exhaust front tube

Front

Exhaust rear tube

Clutch operating cylinder

Rear propeller tube

Front propeller tube

REMOVAL AND INSTALLATIONFS5R50B

MT-1007

Page 928 of 1033

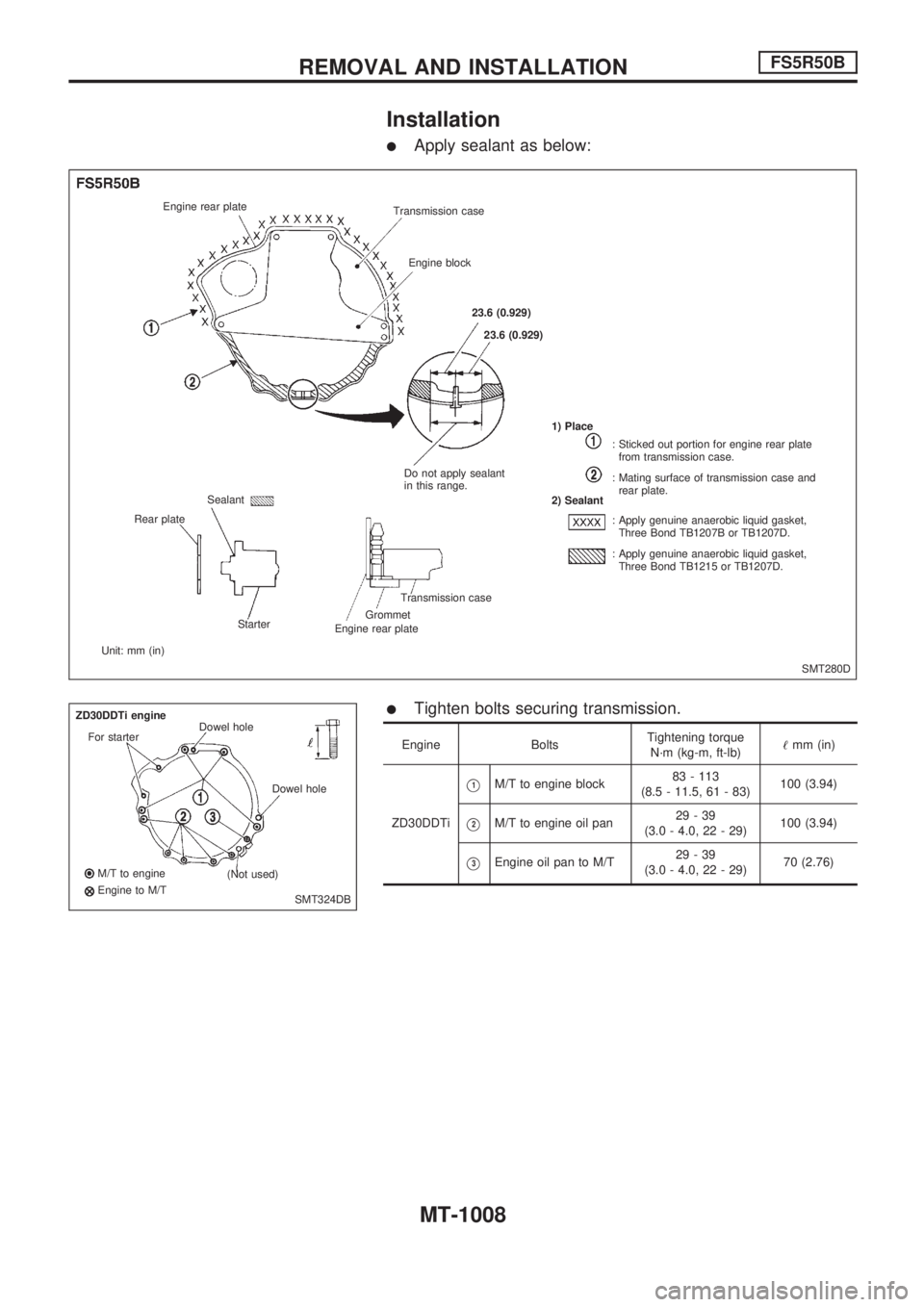

Installation

lApply sealant as below:

lTighten bolts securing transmission.

Engine BoltsTightening torque

N´m (kg-m, ft-lb)!mm (in)

ZD30DDTi

V1M/T to engine block83 - 113

(8.5 - 11.5, 61 - 83)100 (3.94)

V2M/T to engine oil pan29-39

(3.0 - 4.0, 22 - 29)100 (3.94)

V3Engine oil pan to M/T29-39

(3.0 - 4.0, 22 - 29)70 (2.76)

SMT280D Engine rear plate

Transmission case

Engine block

23.6 (0.929)

23.6 (0.929)

Do not apply sealant

in this range.1) Place

2) Sealant

: Sticked out portion for engine rear plate

from transmission case.

: Mating surface of transmission case and

rear plate.

: Apply genuine anaerobic liquid gasket,

Three Bond TB1207B or TB1207D.

: Apply genuine anaerobic liquid gasket,

Three Bond TB1215 or TB1207D.

Transmission case

Grommet

Engine rear plate Starter Sealant

Rear plate

Unit: mm (in)

SMT324DB ZD30DDTi engine

For starterDowel hole

Dowel hole

(Not used) M/T to engine

Engine to M/T

REMOVAL AND INSTALLATIONFS5R50B

MT-1008

Page 931 of 1033

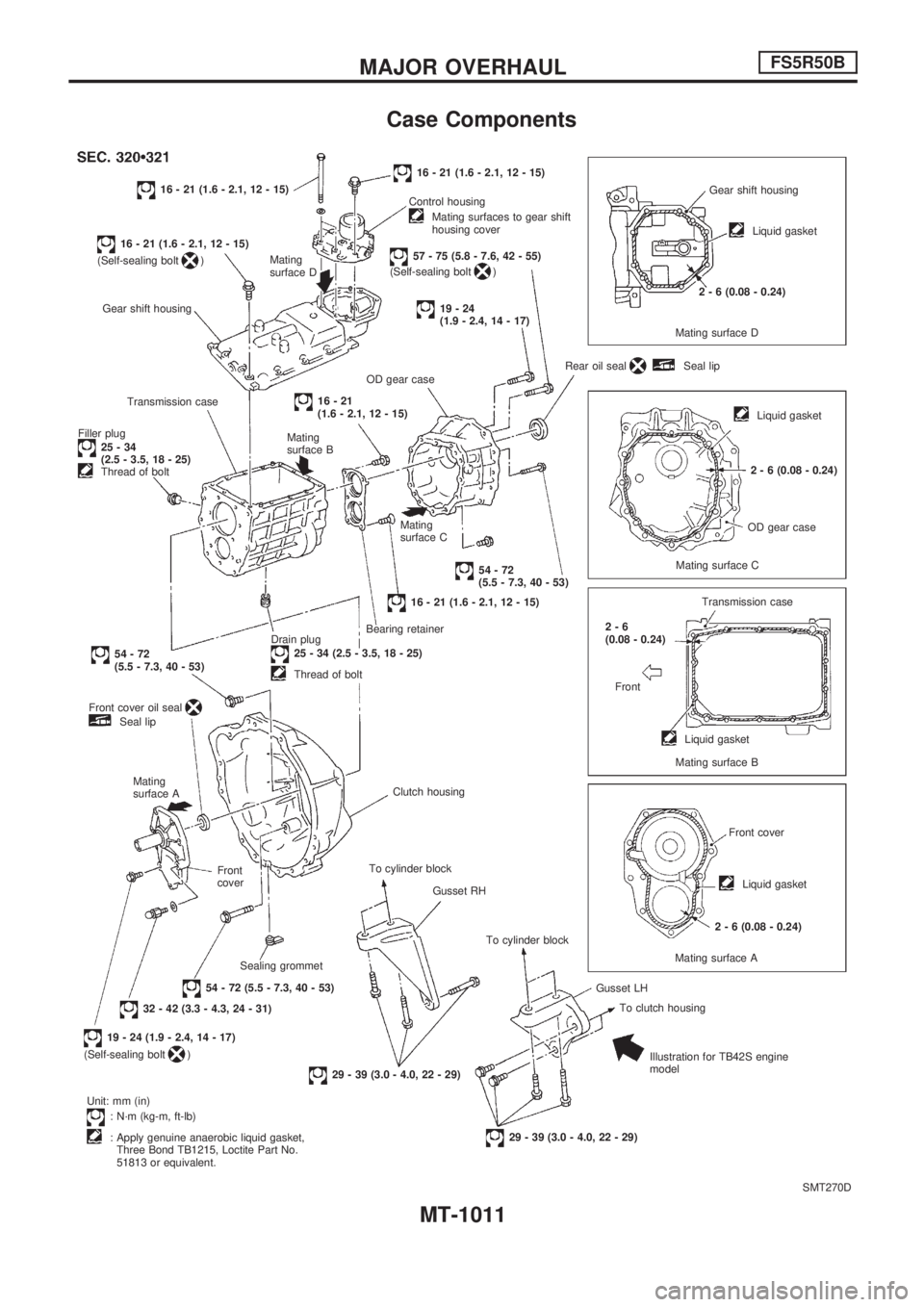

Case Components

SMT270D

16 - 21 (1.6 - 2.1, 12 - 15)

16 - 21 (1.6 - 2.1, 12 - 15)

(Self-sealing bolt

)Mating

surface D

Gear shift housing

Transmission case

Filler plug

25-34

(2.5 - 3.5, 18 - 25)

Thread of bolt

54-72

(5.5 - 7.3, 40 - 53)

Front cover oil seal

Seal lip

Mating

surface A

Front

cover

Sealing grommet

54 - 72 (5.5 - 7.3, 40 - 53)

32 - 42 (3.3 - 4.3, 24 - 31)

19 - 24 (1.9 - 2.4, 14 - 17)

(Self-sealing bolt

)

Unit: mm (in)

: N´m (kg-m, ft-lb)

: Apply genuine anaerobic liquid gasket,

Three Bond TB1215, Loctite Part No.

51813 or equivalent.

29 - 39 (3.0 - 4.0, 22 - 29)

29 - 39 (3.0 - 4.0, 22 - 29)Illustration for TB42S engine

model To clutch housing Gusset LH To cylinder block Gusset RH To cylinder blockClutch housing Drain plug

25 - 34 (2.5 - 3.5, 18 - 25)

Thread of boltBearing retainer

16 - 21 (1.6 - 2.1, 12 - 15)

54-72

(5.5 - 7.3, 40 - 53) Mating

surface C Mating

surface B

16-21

(1.6 - 2.1, 12 - 15)OD gear caseRear oil seal

Seal lip

19-24

(1.9 - 2.4, 14 - 17)

57 - 75 (5.8 - 7.6, 42 - 55)

(Self-sealing bolt) Control housing

Mating surfaces to gear shift

housing cover

16 - 21 (1.6 - 2.1, 12 - 15)

Gear shift housing

Liquid gasket

2 - 6 (0.08 - 0.24)

Mating surface D

Liquid gasket

2 - 6 (0.08 - 0.24)

OD gear case

Mating surface C

Transmission case

2-6

(0.08 - 0.24)

Front

Liquid gasket

Mating surface B

Front cover

Liquid gasket

2 - 6 (0.08 - 0.24)

Mating surface A

MAJOR OVERHAULFS5R50B

MT-1011

Page 959 of 1033

PROPELLER SHAFT &

DIFFERENTIAL CARRIER

SECTION

PD

MODIFICATION NOTICE:

+ ZD30ETi engine has been adopted.

CONTENTS

PROPELLER SHAFT .......................................... 1002

On-vehicle Service ........................................... 1003

FRONT FINAL DRIVE ......................................... 1004

REAR FINAL DRIVE ........................................... 1005

DIFFERENTIAL LOCK ........................................ 1006

Wiring Diagram Ð DIFF/L Ð/LHD Models ..... 1006 Wiring Diagram Ð DIFF/L Ð/RHD Models ..... 1008

SERVICE DATA AND SPECIFICATIONS

(SDS) .................................................................... 1010

Propeller Shaft ................................................. 1010

Final Drive ........................................................ 1011

PD

Page 968 of 1033

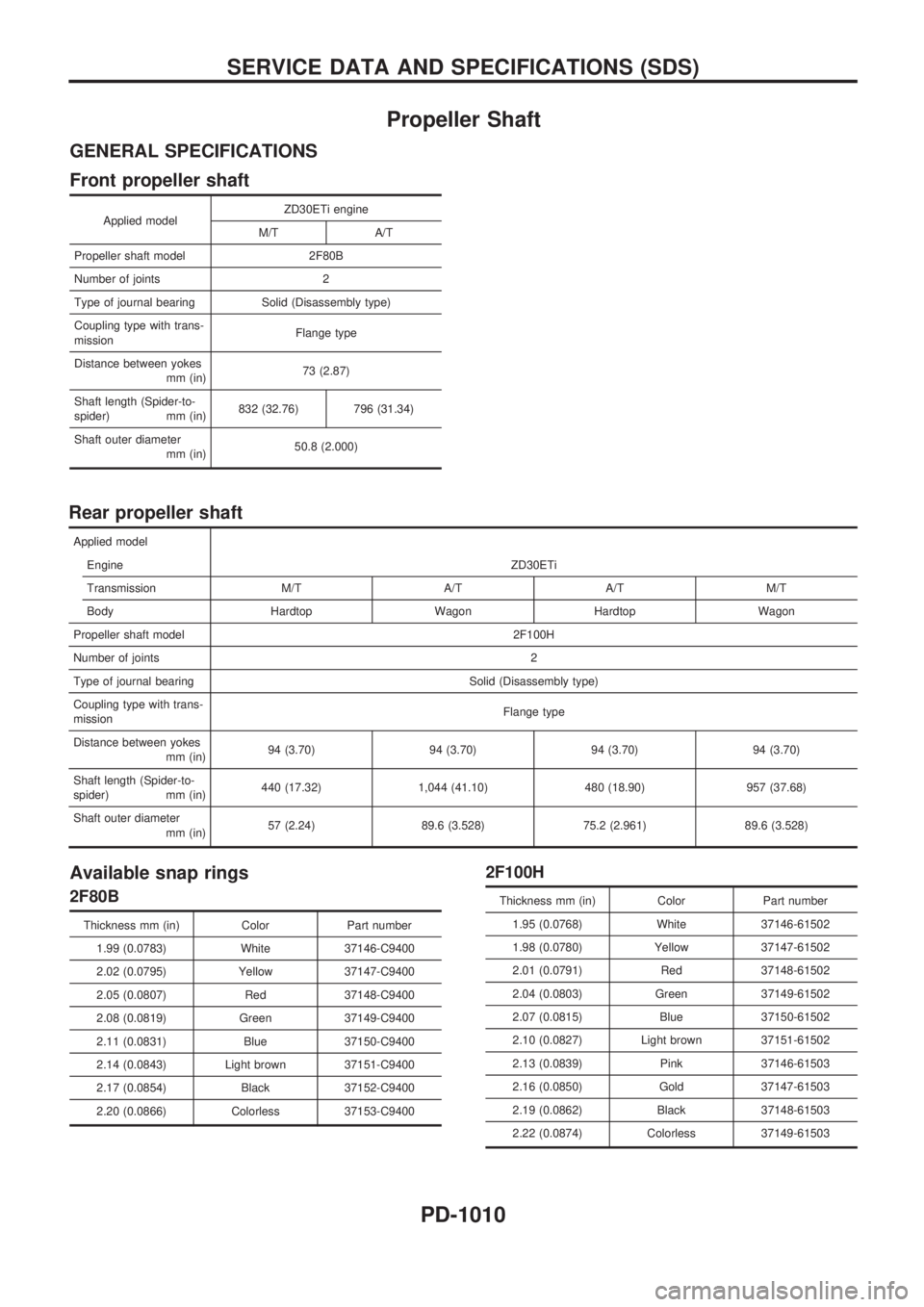

Propeller Shaft

GENERAL SPECIFICATIONS

Front propeller shaft

Applied modelZD30ETi engine

M/T A/T

Propeller shaft model 2F80B

Number of joints 2

Type of journal bearing Solid (Disassembly type)

Coupling type with trans-

mission Flange type

Distance between yokes mm (in) 73 (2.87)

Shaft length (Spider-to-

spider) mm (in) 832 (32.76) 796 (31.34)

Shaft outer diameter mm (in) 50.8 (2.000)

Rear propeller shaft

Applied model

Engine ZD30ETi

Transmission M/T A/T A/T M/T

Body Hardtop Wagon Hardtop Wagon

Propeller shaft model 2F100H

Number of joints 2

Type of journal bearing Solid (Disassembly type)

Coupling type with trans-

mission Flange type

Distance between yokes mm (in) 94 (3.70) 94 (3.70) 94 (3.70) 94 (3.70)

Shaft length (Spider-to-

spider) mm (in) 440 (17.32) 1,044 (41.10) 480 (18.90) 957 (37.68)

Shaft outer diameter mm (in) 57 (2.24) 89.6 (3.528) 75.2 (2.961) 89.6 (3.528)

Available snap rings

2F80B

Thickness mm (in) Color Part number

1.99 (0.0783) White 37146-C9400

2.02 (0.0795) Yellow 37147-C9400

2.05 (0.0807) Red 37148-C9400

2.08 (0.0819) Green 37149-C9400

2.11 (0.0831) Blue 37150-C9400

2.14 (0.0843) Light brown 37151-C9400

2.17 (0.0854) Black 37152-C9400

2.20 (0.0866) Colorless 37153-C9400

2F100H

Thickness mm (in) Color Part number1.95 (0.0768) White 37146-61502

1.98 (0.0780) Yellow 37147-61502

2.01 (0.0791) Red 37148-61502

2.04 (0.0803) Green 37149-61502

2.07 (0.0815) Blue 37150-61502

2.10 (0.0827) Light brown 37151-61502

2.13 (0.0839) Pink 37146-61503

2.16 (0.0850) Gold 37147-61503

2.19 (0.0862) Black 37148-61503

2.22 (0.0874) Colorless 37149-61503

SERVICE DATA AND SPECIFICATIONS (SDS)

PD-1010

Page 998 of 1033

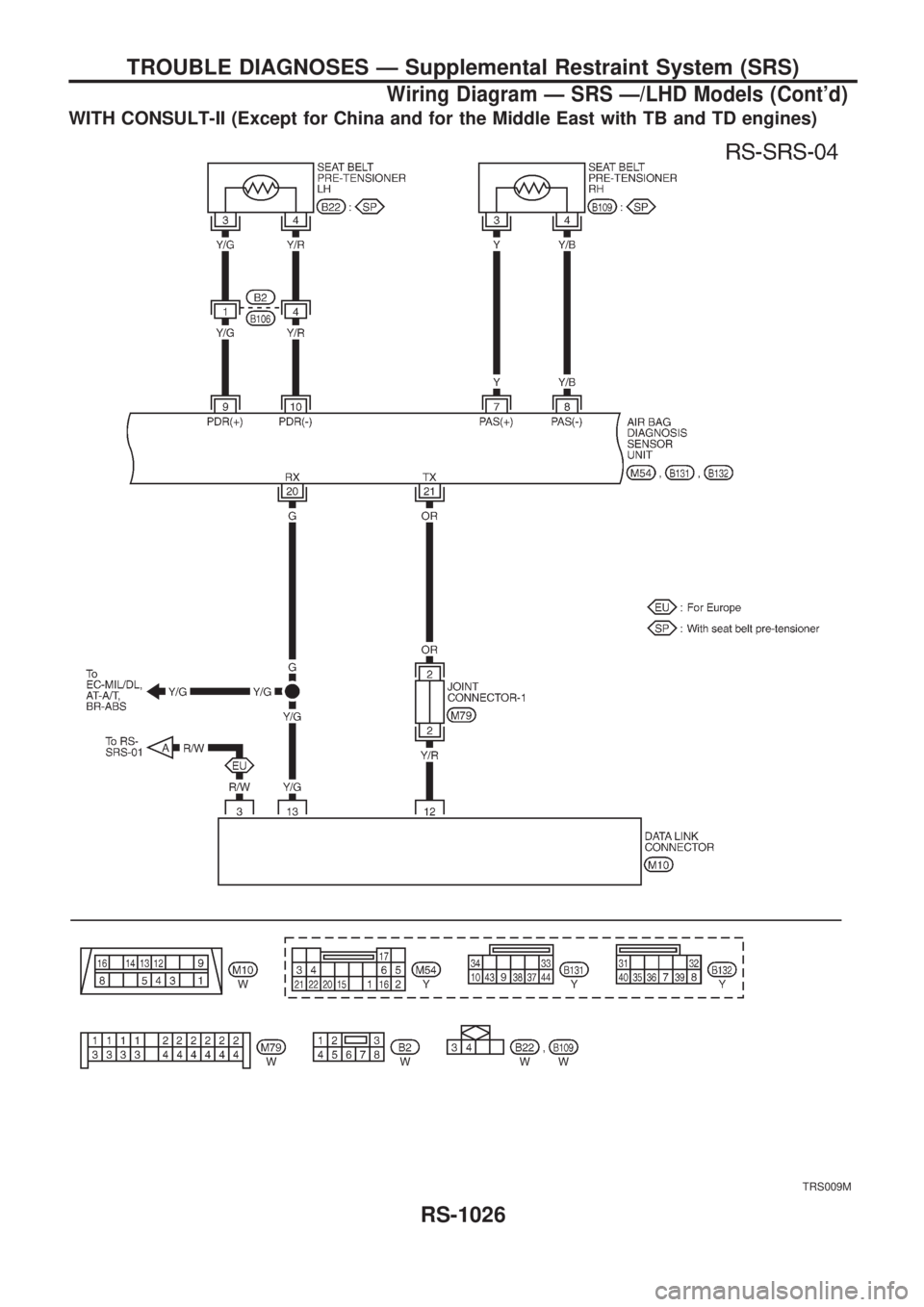

WITH CONSULT-II (Except for China and for the Middle East with TB and TD engines)

TRS009M

TROUBLE DIAGNOSES Ð Supplemental Restraint System (SRS)

Wiring Diagram Ð SRS Ð/LHD Models (Cont'd)

RS-1026

Page 1002 of 1033

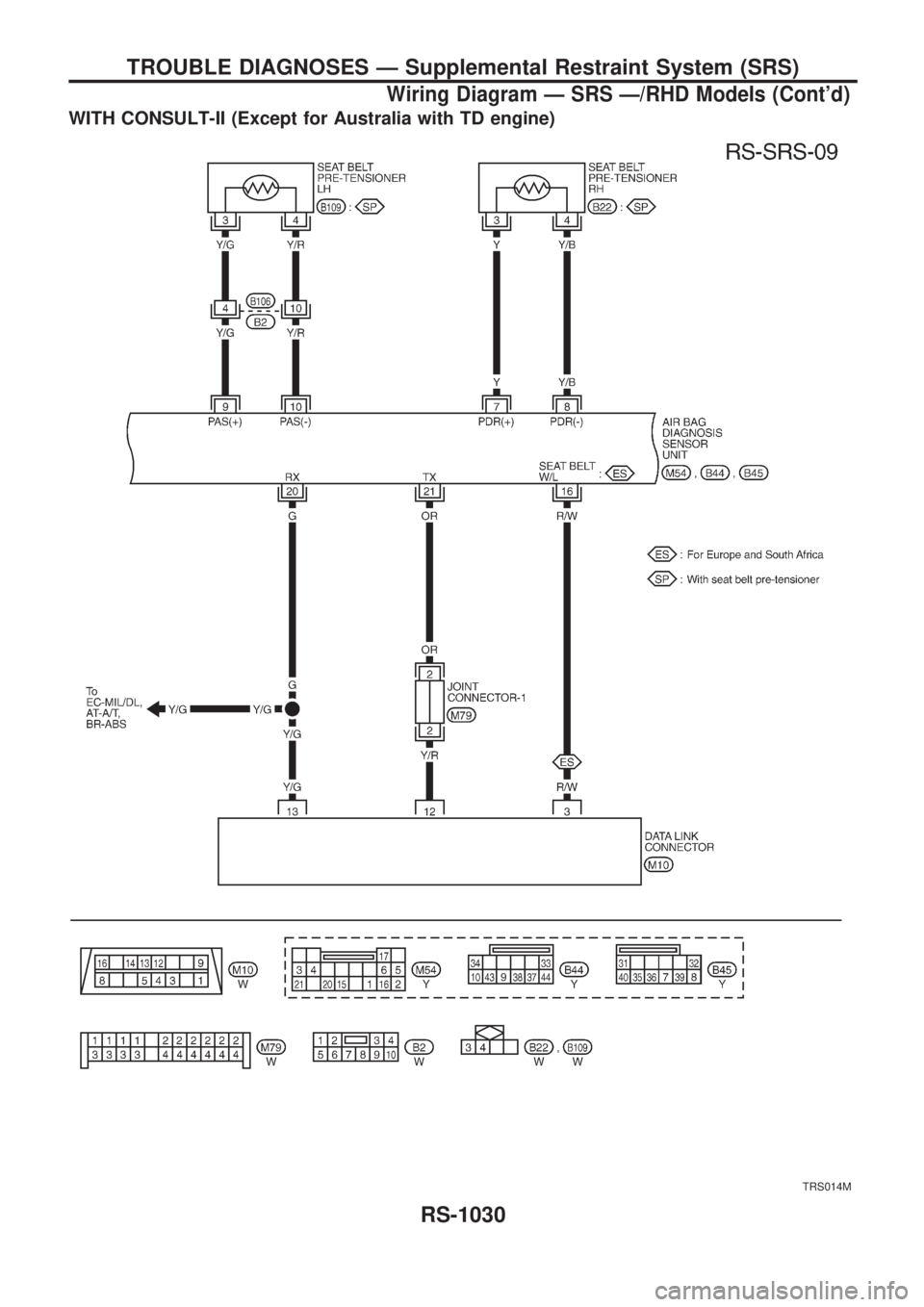

WITH CONSULT-II (Except for Australia with TD engine)

TRS014M

TROUBLE DIAGNOSES Ð Supplemental Restraint System (SRS)

Wiring Diagram Ð SRS Ð/RHD Models (Cont'd)

RS-1030