light NISSAN PATROL 2000 Electronic Service Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2000, Model line: PATROL, Model: NISSAN PATROL 2000Pages: 1033, PDF Size: 30.71 MB

Page 763 of 1033

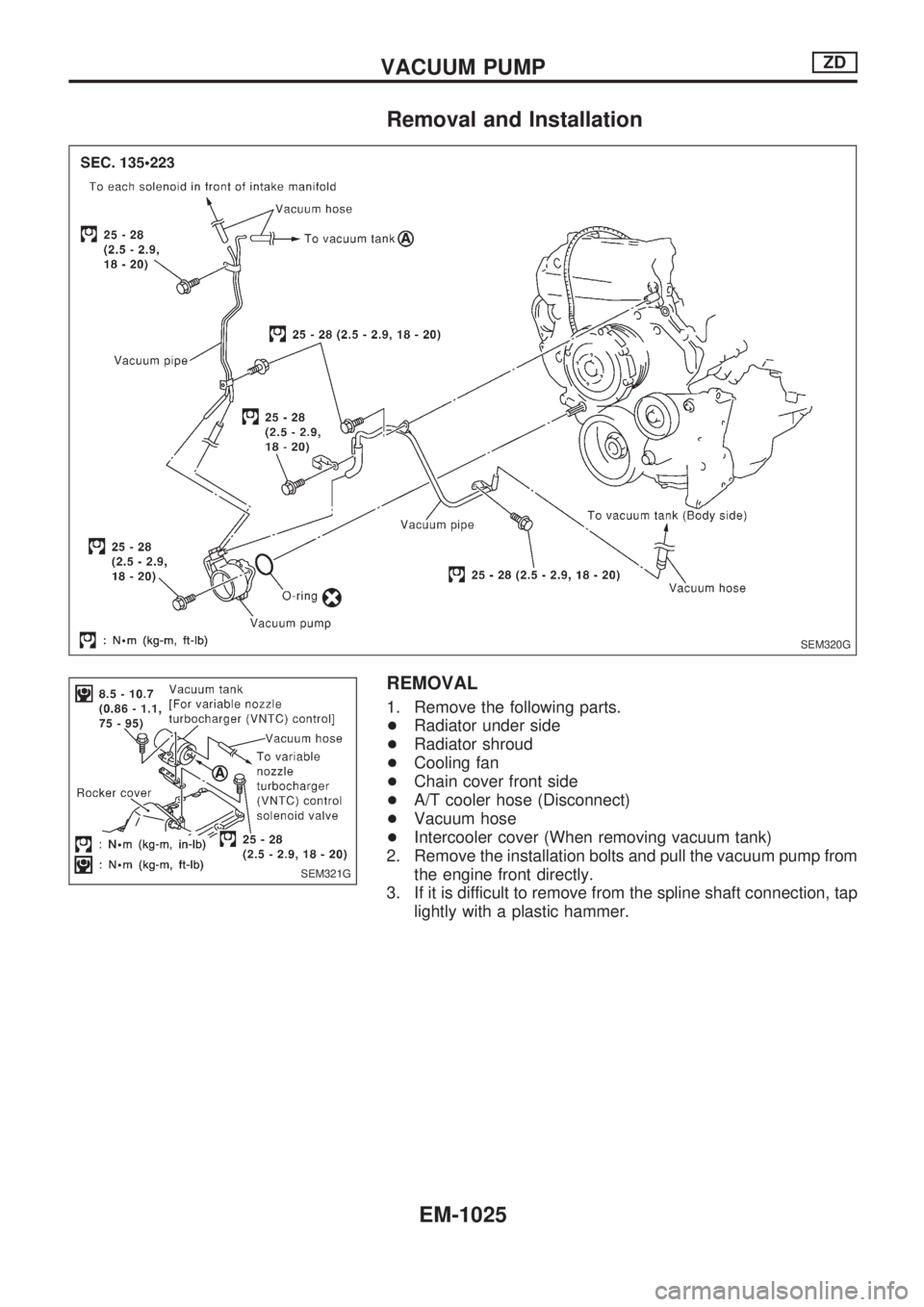

Removal and Installation

REMOVAL

1. Remove the following parts.

+Radiator under side

+Radiator shroud

+Cooling fan

+Chain cover front side

+A/T cooler hose (Disconnect)

+Vacuum hose

+Intercooler cover (When removing vacuum tank)

2. Remove the installation bolts and pull the vacuum pump from

the engine front directly.

3. If it is difficult to remove from the spline shaft connection, tap

lightly with a plastic hammer.

SEM320G

SEM321G

VACUUM PUMPZD

EM-1025

Page 785 of 1033

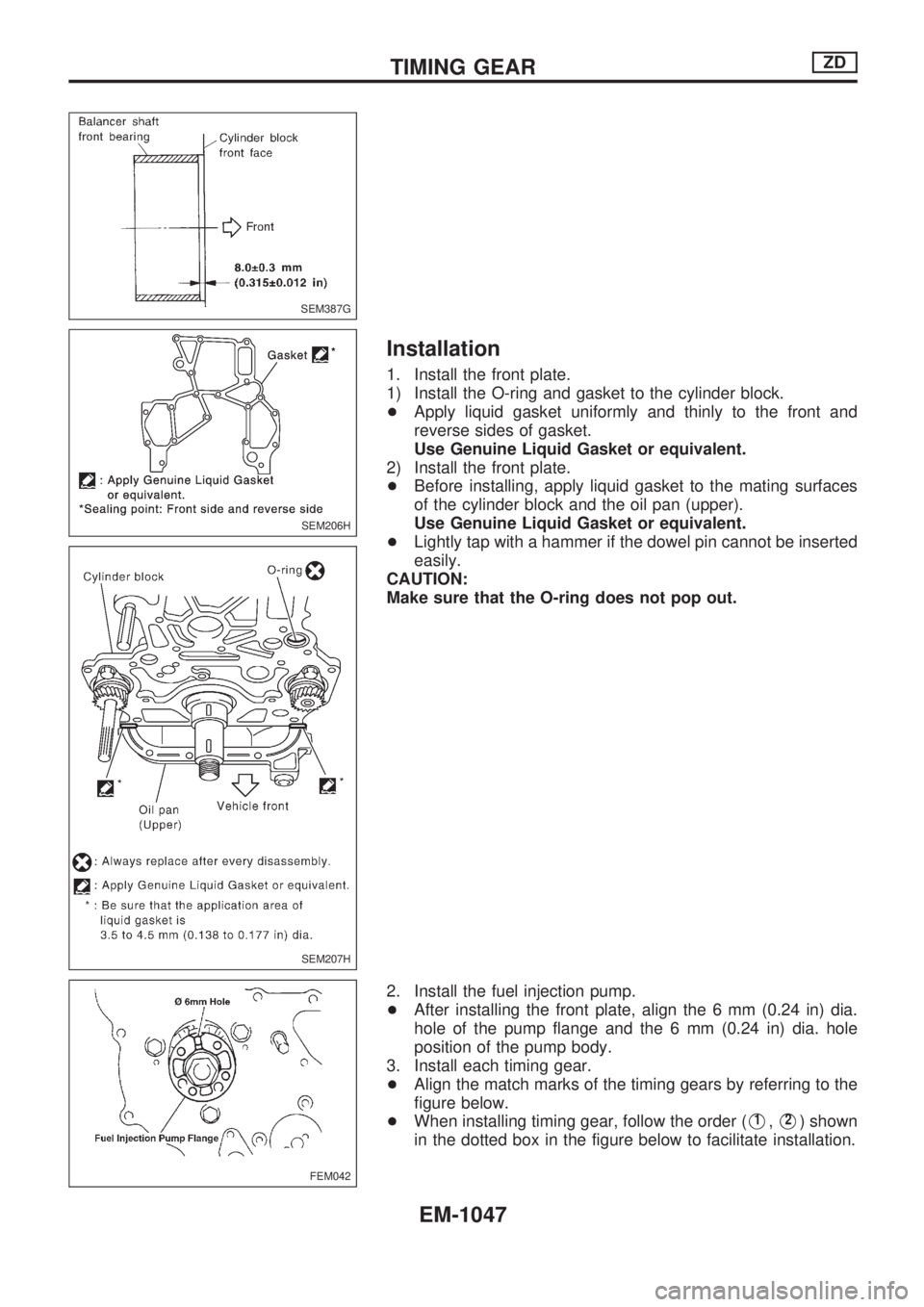

Installation

1. Install the front plate.

1) Install the O-ring and gasket to the cylinder block.

+Apply liquid gasket uniformly and thinly to the front and

reverse sides of gasket.

Use Genuine Liquid Gasket or equivalent.

2) Install the front plate.

+Before installing, apply liquid gasket to the mating surfaces

of the cylinder block and the oil pan (upper).

Use Genuine Liquid Gasket or equivalent.

+Lightly tap with a hammer if the dowel pin cannot be inserted

easily.

CAUTION:

Make sure that the O-ring does not pop out.

2. Install the fuel injection pump.

+After installing the front plate, align the 6 mm (0.24 in) dia.

hole of the pump flange and the 6 mm (0.24 in) dia. hole

position of the pump body.

3. Install each timing gear.

+Align the match marks of the timing gears by referring to the

figure below.

+When installing timing gear, follow the order (

V1,V2) shown

in the dotted box in the figure below to facilitate installation.

FEM042

SEM387G

SEM206H

SEM207H

TIMING GEARZD

EM-1047

Page 816 of 1033

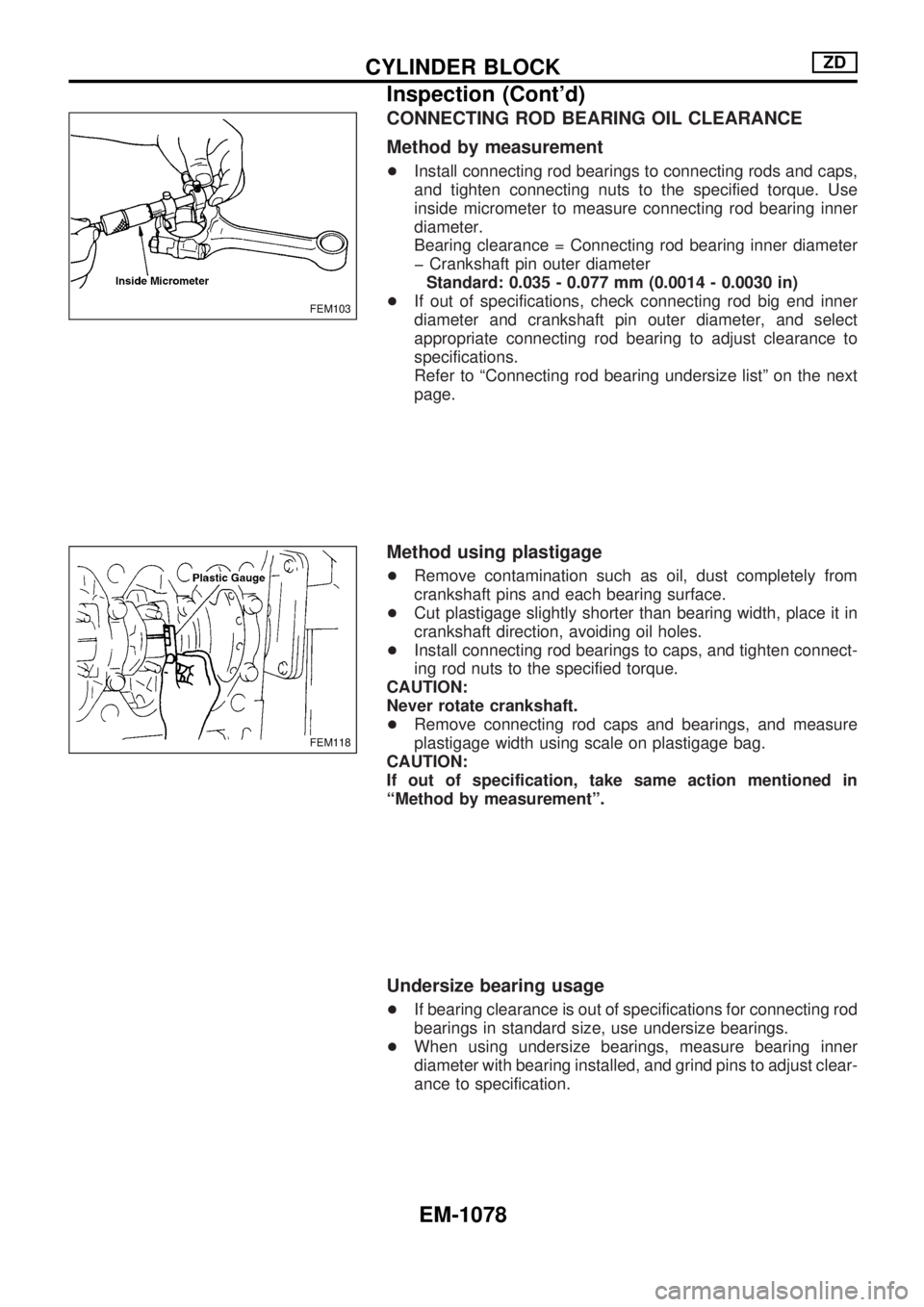

CONNECTING ROD BEARING OIL CLEARANCE

Method by measurement

+Install connecting rod bearings to connecting rods and caps,

and tighten connecting nuts to the specified torque. Use

inside micrometer to measure connecting rod bearing inner

diameter.

Bearing clearance = Connecting rod bearing inner diameter

þ Crankshaft pin outer diameter

Standard: 0.035 - 0.077 mm (0.0014 - 0.0030 in)

+If out of specifications, check connecting rod big end inner

diameter and crankshaft pin outer diameter, and select

appropriate connecting rod bearing to adjust clearance to

specifications.

Refer to ªConnecting rod bearing undersize listº on the next

page.

Method using plastigage

+Remove contamination such as oil, dust completely from

crankshaft pins and each bearing surface.

+Cut plastigage slightly shorter than bearing width, place it in

crankshaft direction, avoiding oil holes.

+Install connecting rod bearings to caps, and tighten connect-

ing rod nuts to the specified torque.

CAUTION:

Never rotate crankshaft.

+Remove connecting rod caps and bearings, and measure

plastigage width using scale on plastigage bag.

CAUTION:

If out of specification, take same action mentioned in

ªMethod by measurementº.

Undersize bearing usage

+If bearing clearance is out of specifications for connecting rod

bearings in standard size, use undersize bearings.

+When using undersize bearings, measure bearing inner

diameter with bearing installed, and grind pins to adjust clear-

ance to specification.

FEM103

FEM118

CYLINDER BLOCKZD

Inspection (Cont'd)

EM-1078

Page 817 of 1033

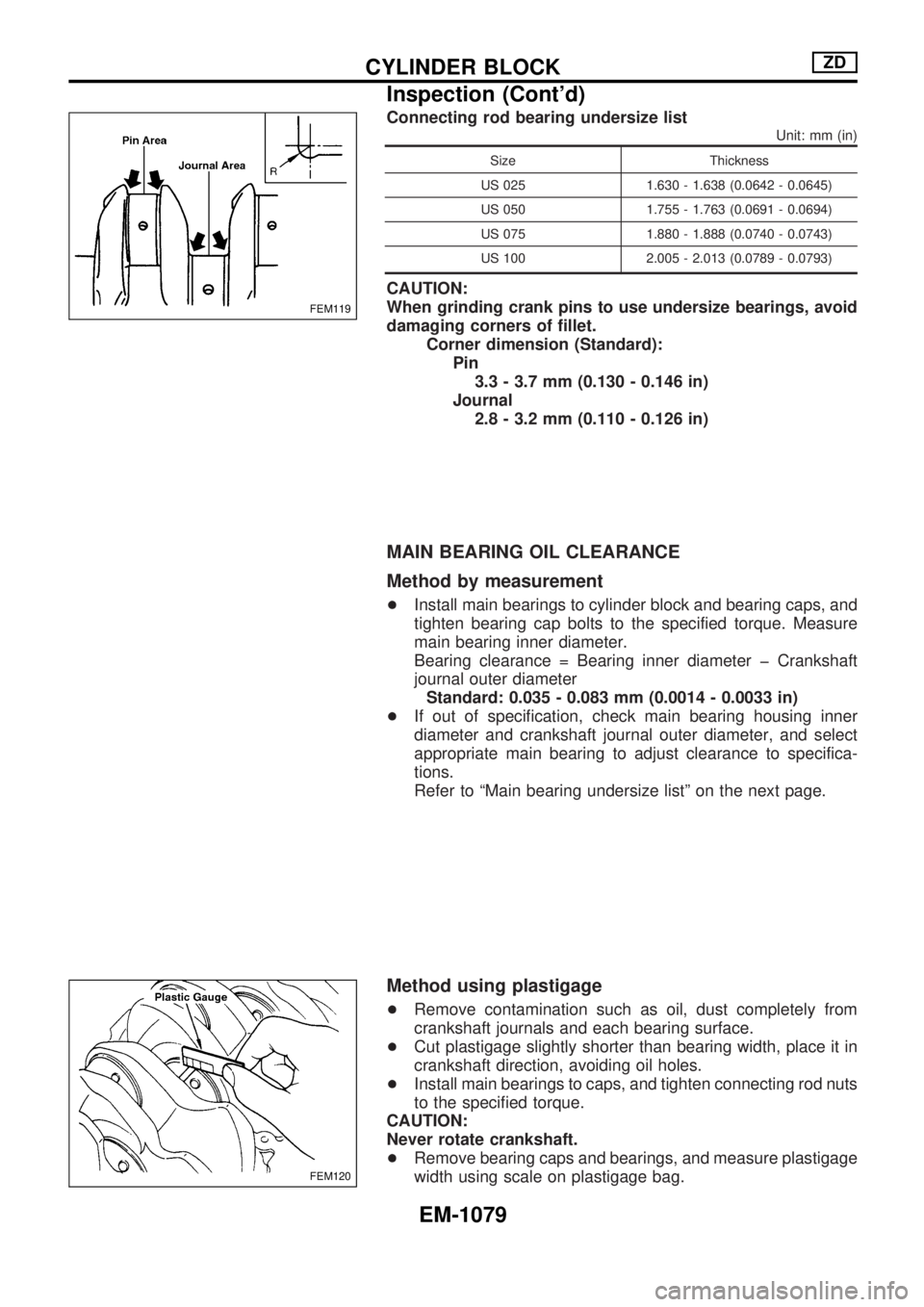

Connecting rod bearing undersize list

Unit: mm (in)

Size Thickness

US 025 1.630 - 1.638 (0.0642 - 0.0645)

US 050 1.755 - 1.763 (0.0691 - 0.0694)

US 075 1.880 - 1.888 (0.0740 - 0.0743)

US 100 2.005 - 2.013 (0.0789 - 0.0793)

CAUTION:

When grinding crank pins to use undersize bearings, avoid

damaging corners of fillet.

Corner dimension (Standard):

Pin

3.3 - 3.7 mm (0.130 - 0.146 in)

Journal

2.8 - 3.2 mm (0.110 - 0.126 in)

MAIN BEARING OIL CLEARANCE

Method by measurement

+Install main bearings to cylinder block and bearing caps, and

tighten bearing cap bolts to the specified torque. Measure

main bearing inner diameter.

Bearing clearance = Bearing inner diameter þ Crankshaft

journal outer diameter

Standard: 0.035 - 0.083 mm (0.0014 - 0.0033 in)

+If out of specification, check main bearing housing inner

diameter and crankshaft journal outer diameter, and select

appropriate main bearing to adjust clearance to specifica-

tions.

Refer to ªMain bearing undersize listº on the next page.

Method using plastigage

+Remove contamination such as oil, dust completely from

crankshaft journals and each bearing surface.

+Cut plastigage slightly shorter than bearing width, place it in

crankshaft direction, avoiding oil holes.

+Install main bearings to caps, and tighten connecting rod nuts

to the specified torque.

CAUTION:

Never rotate crankshaft.

+Remove bearing caps and bearings, and measure plastigage

width using scale on plastigage bag.

FEM119

FEM120

CYLINDER BLOCKZD

Inspection (Cont'd)

EM-1079

Page 880 of 1033

A

A/T - Wiring diagram ............................. AT-1009

A/T control ............................................. EC-1148

A/T fluid temperature sensor ................. AT-1081

A/T mode switch .................................... AT-1095

A/T self-diagnoses ................................. AT-1028

A/T shift lock system - Wiring

diagram .............................................. AT-1117

A/T shift lock system ............................. AT-1116

A/T trouble diagnoses ........................... AT-1036

APS - Wiring diagram ........................... EC-1125

ASCD (automatic speed control

device) ............................................... EL-1110

ASCD - Wiring diagram ......................... EL-1111

AT/C - Wiring diagram .......................... EC-1150

Accelerator control system .................... FE-1007

Accelerator position sensor .................. EC-1125

Air bag disposal .................................... RS-1015

Air bag precautions ................................ GI-1002

Air bag ................................................... RS-1003

Air cleaner filter replacement ............... MA-1019

Air conditioner cut control ..................... EC-1021

Air flow meter - See Mass air flow

sensor ................................................ EC-1086

Alternator ............................................... EL-1041

Angular tightening application .............. EM-1003

Anti-lock brake system - Wiring

diagram ............................................. BR-1002

Audio ...................................................... EL-1108

Automatic speed control system - See

ASCD ................................................. EL-1110

Automatic transmission fluid

replacement ...................................... MA-1021

B

BACK/L - Wiring diagram ...................... EL-1051

BOOST - Wiring diagram ...................... EC-1204

Back-up lamp ......................................... EL-1051

Basic inspection .................................... EC-1049

Battery ................................................... EL-1035

Boring/horning cylinder block ............... EM-1075

C

CHARGE - Wiring diagram ................... EL-1040

CKPS - Wiring diagram ........................ EC-1140

CONSULT for engine ............................ EC-1038

CONSULT general information .............. GI-1003

COOL/F - Wiring diagram ..................... EC-1105

CORNER - Wiring diagram ................... EL-1054

Camshaft inspection ............................. EM-1032

Charging system .................................... EL-1040

Chassis and body maintenance ........... MA-1020

Clutch operating cylinder ....................... CL-1003

Collision diagnosis ................................ RS-1052

Combination meter ................................ EL-1073Combination switch ............................... EL-1042

Compression pressure ......................... EM-1010

Compressor mounting ........................... HA-1023

Connecting rod bearing clearance ....... EM-1078

Connecting rod bushing clearance ....... EM-1074

Connecting rod ..................................... EM-1074

Control valve (A/T) ................................ AT-1148

Converter housing installation ............... AT-1128

Coolant mixture ratio ............................ MA-1010

Coolant replacement ............................ MA-1014

Cooling fan control ................................ EC-1105

Cornering lamp ...................................... EL-1054

Crankcase emission control system -

See Positive crankcase ventilation ... EC-1022

Crankcase ventilation system - See

Positive crankcase ventilation ........... EC-1022

Crankshaft position sensor (TDC) ........ EC-1140

Crankshaft ............................................ EM-1077

Cruise control - See ASCD ................... EL-1110

Cylinder block boring ............................ EM-1020

Cylinder block ....................................... EM-1067

Cylinder head bolt tightening ................ EM-1034

Cylinder head ....................................... EM-1053

D

DEF - Wiring diagram ............................ EL-1102

DTRL - Wiring diagram ......................... EL-1044

Data link connector for Consult ............ EC-1038

Daytime light system ............................. EL-1044

Diagnosis sensor unit ........................... RS-1008

Diagnostic trouble code (DTC) for

OBD system ...................................... EC-1032

Dome light - See Interior lamp .............. EL-1067

Door mirror ............................................ BT-1007

Door trim ................................................ BT-1004

Drive belt inspection ............................. MA-1011

Drive plate runout ................................. EM-1095

Dropping resistor (A/T) .......................... AT-1086

E

ECCS-D control module .. EC-1068, 1117, 1189,

1191, 1196, 1200

ECM input/output signal ........................ EC-1068

ECTS - Wiring diagram ......................... EC-1092

EGR - Wiring diagram .......................... EC-1209

EGR volume control valve .................... EC-1207

Electrical unit ......................................... EL-1231

Electrical units location .......................... EL-1185

Electronic fuel injection pump .... EC-1119, 1153,

1159, 1165, 1171, 1177, 1180, 1215

Engine control circuit diagram .............. EC-1015

Engine control component parts

location .............................................. EC-1011

Engine control system diagram and

chart .................................................. EC-1016

ALPHABETICAL INDEX

IDX-1002

Page 916 of 1033

4. Wipe clean fuel filter mounting surface on fuel filter bracket

and smear a little fuel on rubber seal of fuel filter.

5. Screw fuel filter on until a slight resistance is felt, then tighten

an additional more than 2/3 of a turn.

6. Install fuel filter sensor to new fuel filter. (Type A)

7. Bleed air from fuel filter.

Refer to ªAir Bleedingº in EC section.

8. Start engine and check for leaks.

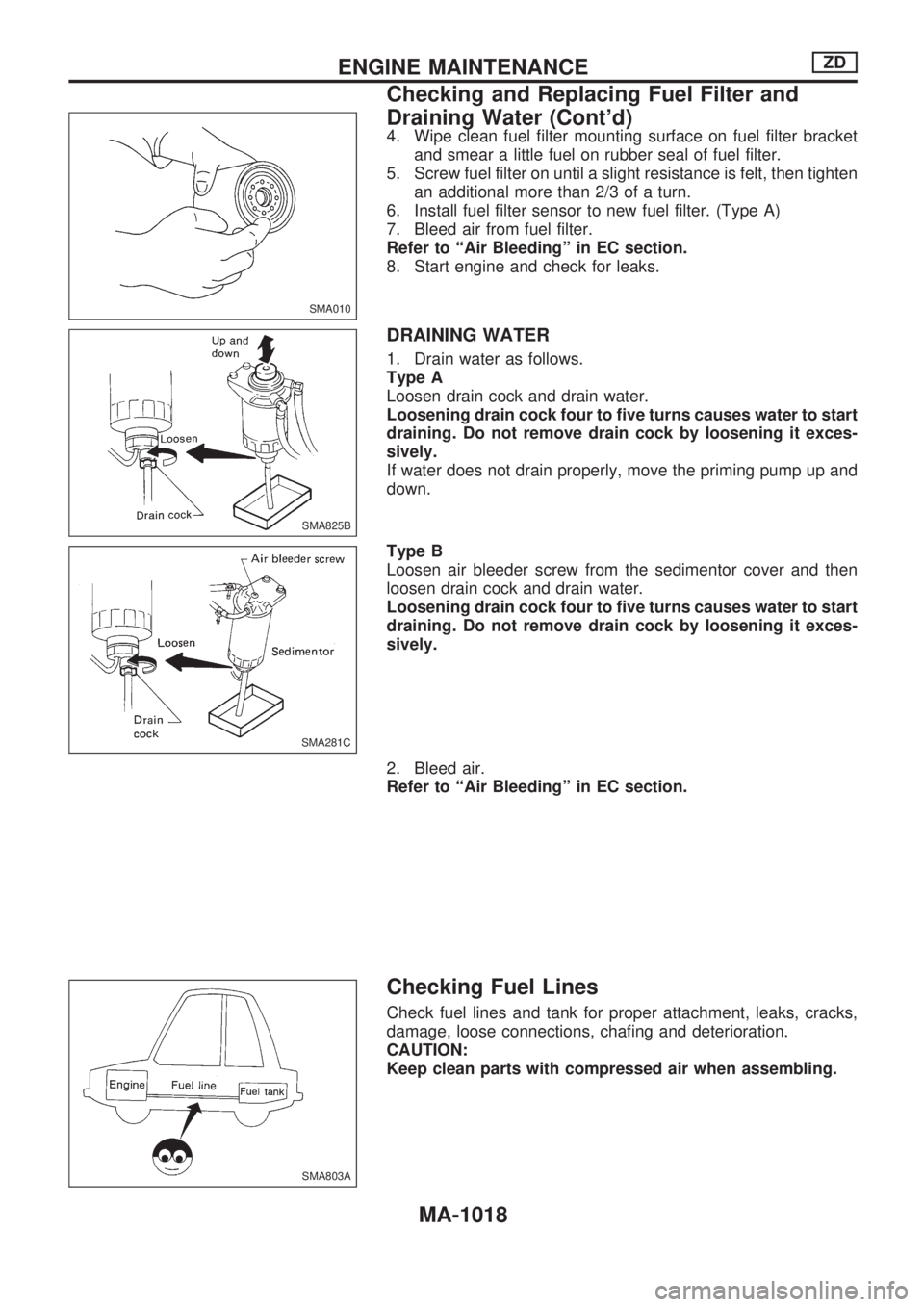

DRAINING WATER

1. Drain water as follows.

Type A

Loosen drain cock and drain water.

Loosening drain cock four to five turns causes water to start

draining. Do not remove drain cock by loosening it exces-

sively.

If water does not drain properly, move the priming pump up and

down.

Type B

Loosen air bleeder screw from the sedimentor cover and then

loosen drain cock and drain water.

Loosening drain cock four to five turns causes water to start

draining. Do not remove drain cock by loosening it exces-

sively.

2. Bleed air.

Refer to ªAir Bleedingº in EC section.

Checking Fuel Lines

Check fuel lines and tank for proper attachment, leaks, cracks,

damage, loose connections, chafing and deterioration.

CAUTION:

Keep clean parts with compressed air when assembling.

SMA010

SMA825B

SMA281C

SMA803A

ENGINE MAINTENANCEZD

Checking and Replacing Fuel Filter and

Draining Water (Cont'd)

MA-1018

Page 940 of 1033

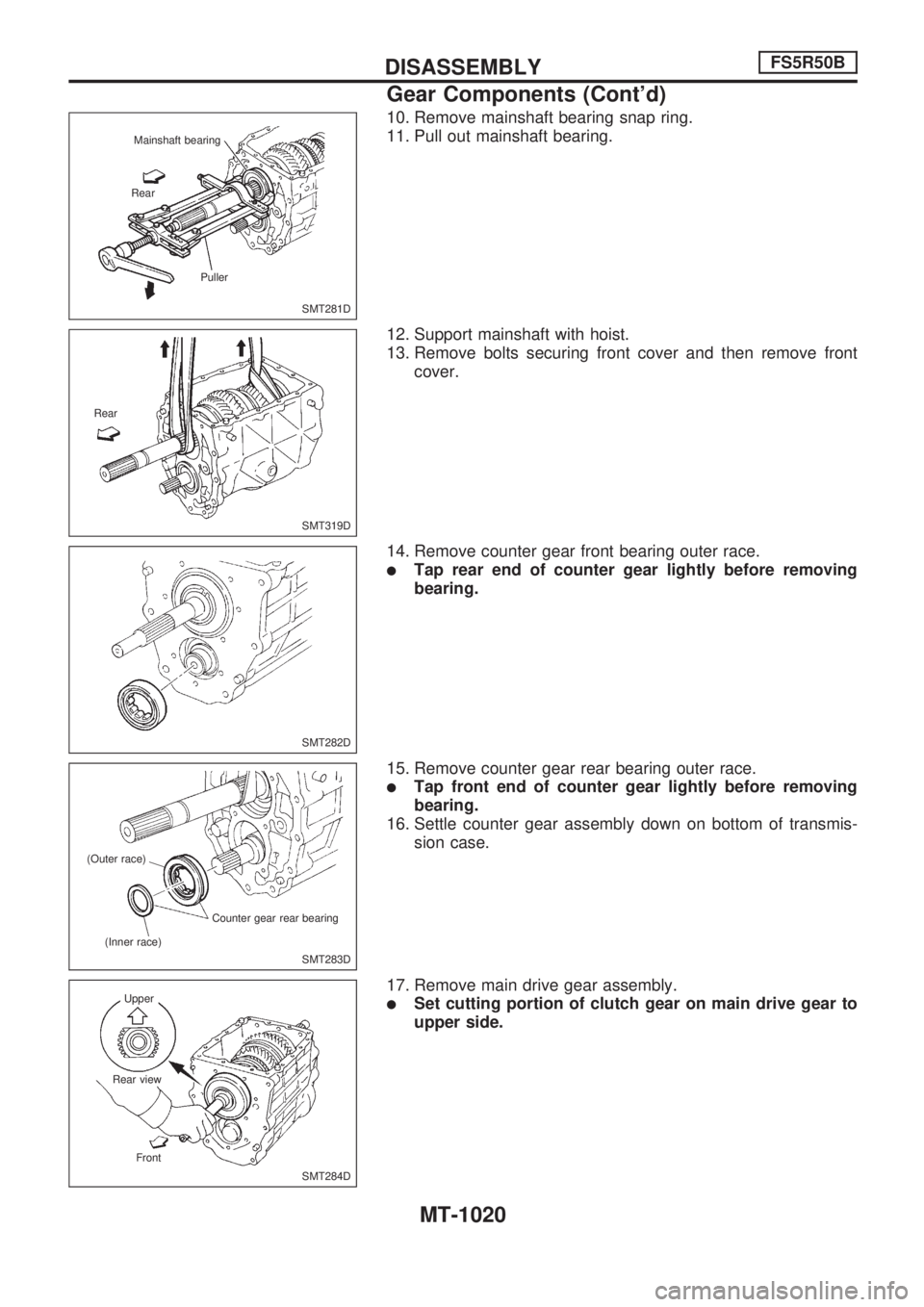

10. Remove mainshaft bearing snap ring.

11. Pull out mainshaft bearing.

12. Support mainshaft with hoist.

13. Remove bolts securing front cover and then remove front

cover.

14. Remove counter gear front bearing outer race.

lTap rear end of counter gear lightly before removing

bearing.

15. Remove counter gear rear bearing outer race.

lTap front end of counter gear lightly before removing

bearing.

16. Settle counter gear assembly down on bottom of transmis-

sion case.

17. Remove main drive gear assembly.

lSet cutting portion of clutch gear on main drive gear to

upper side.

SMT281D Mainshaft bearing

Puller Rear

SMT319D Rear

SMT282D

SMT283D (Outer race)

Counter gear rear bearing

(Inner race)

SMT284D Upper

Rear view

Front

DISASSEMBLYFS5R50B

Gear Components (Cont'd)

MT-1020

Page 948 of 1033

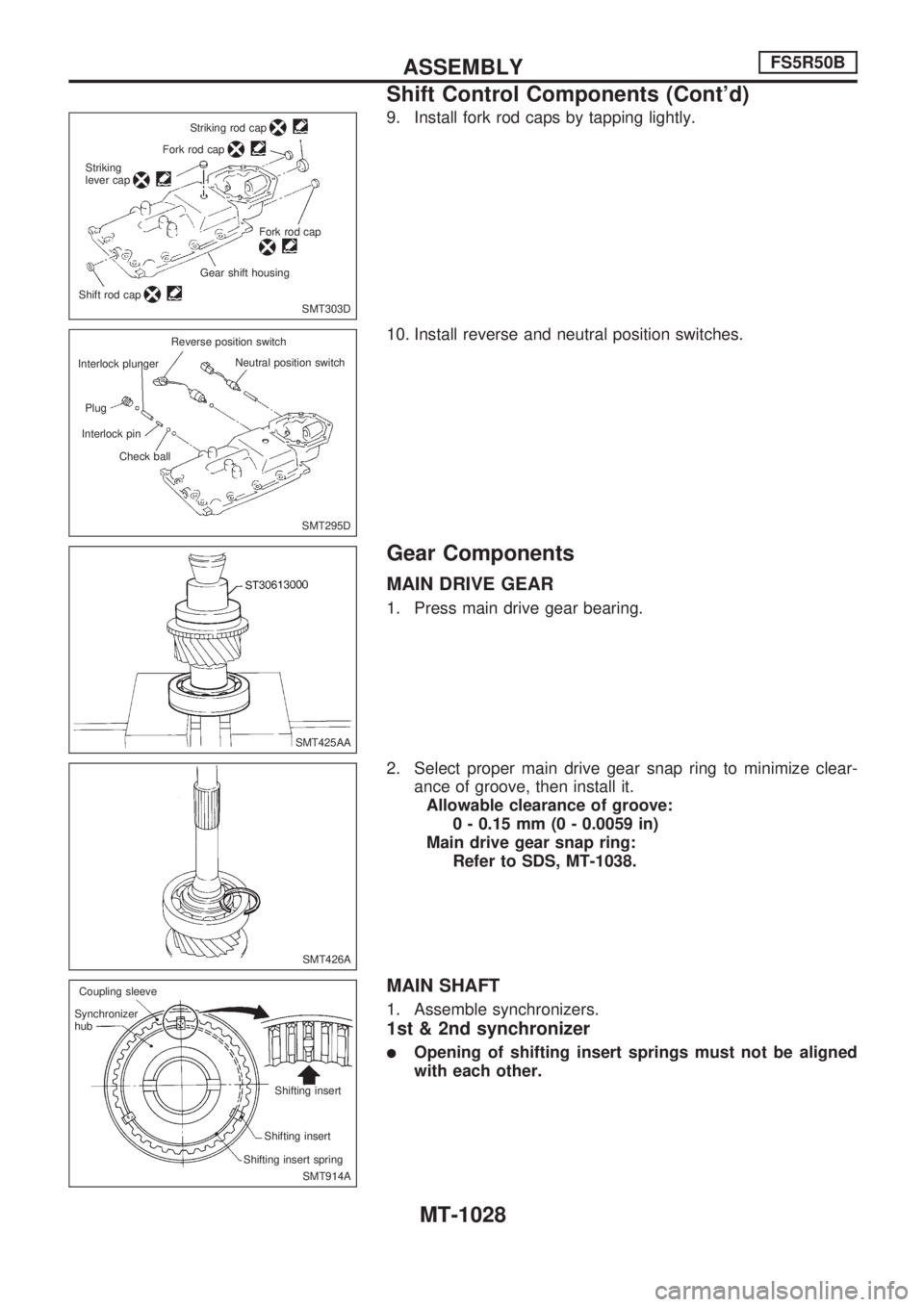

9. Install fork rod caps by tapping lightly.

10. Install reverse and neutral position switches.

Gear Components

MAIN DRIVE GEAR

1. Press main drive gear bearing.

2. Select proper main drive gear snap ring to minimize clear-

ance of groove, then install it.

Allowable clearance of groove:

0 - 0.15 mm (0 - 0.0059 in)

Main drive gear snap ring:

Refer to SDS, MT-1038.

MAIN SHAFT

1. Assemble synchronizers.

1st & 2nd synchronizer

lOpening of shifting insert springs must not be aligned

with each other.

SMT303D Striking rod cap

Fork rod cap

Striking

lever cap

Fork rod cap

Gear shift housing

Shift rod cap

SMT295D Interlock plunger

Plug

Interlock pin

Check ballNeutral position switch Reverse position switch

SMT425AA

SMT426A

SMT914A Synchronizer

hubCoupling sleeve

Shifting insert

Shifting insert

Shifting insert spring

ASSEMBLYFS5R50B

Shift Control Components (Cont'd)

MT-1028

Page 952 of 1033

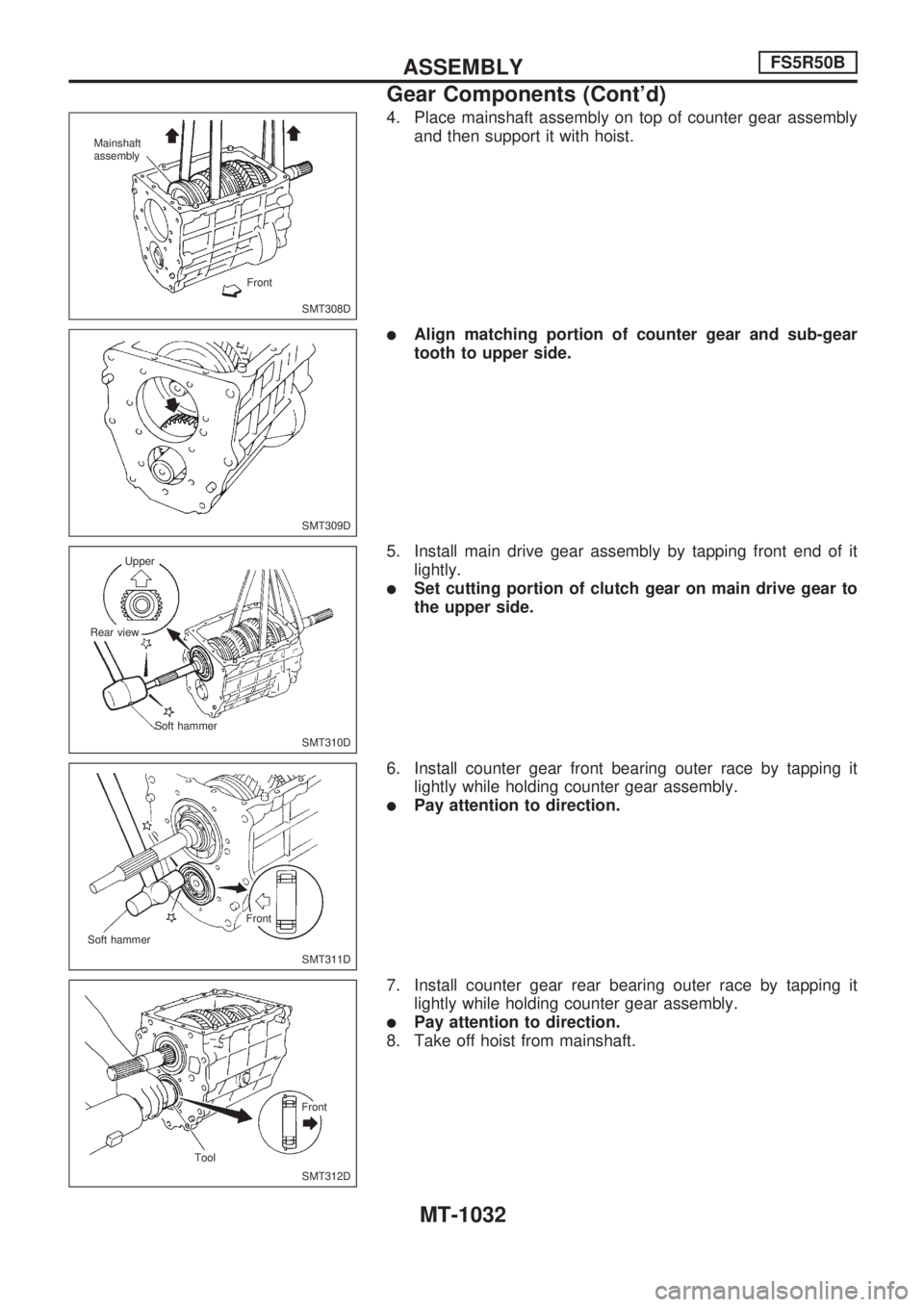

4. Place mainshaft assembly on top of counter gear assembly

and then support it with hoist.

lAlign matching portion of counter gear and sub-gear

tooth to upper side.

5. Install main drive gear assembly by tapping front end of it

lightly.

lSet cutting portion of clutch gear on main drive gear to

the upper side.

6. Install counter gear front bearing outer race by tapping it

lightly while holding counter gear assembly.

lPay attention to direction.

7. Install counter gear rear bearing outer race by tapping it

lightly while holding counter gear assembly.

lPay attention to direction.

8. Take off hoist from mainshaft.

SMT308D Mainshaft

assembly

Front

SMT309D

SMT310D Upper

Rear view

Soft hammer

SMT311D Front

Soft hammer

SMT312D Front

Tool

ASSEMBLYFS5R50B

Gear Components (Cont'd)

MT-1032

Page 968 of 1033

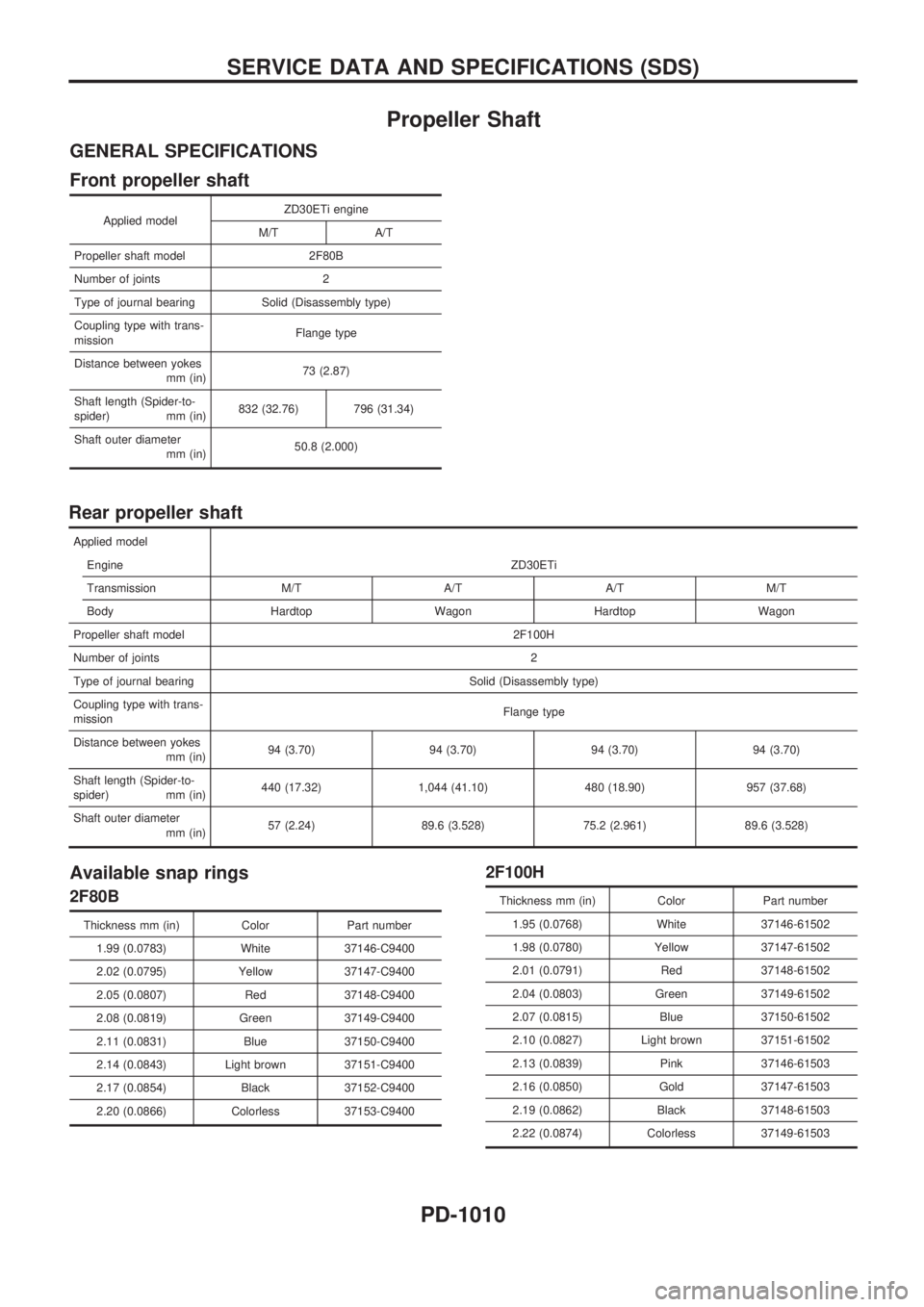

Propeller Shaft

GENERAL SPECIFICATIONS

Front propeller shaft

Applied modelZD30ETi engine

M/T A/T

Propeller shaft model 2F80B

Number of joints 2

Type of journal bearing Solid (Disassembly type)

Coupling type with trans-

mission Flange type

Distance between yokes mm (in) 73 (2.87)

Shaft length (Spider-to-

spider) mm (in) 832 (32.76) 796 (31.34)

Shaft outer diameter mm (in) 50.8 (2.000)

Rear propeller shaft

Applied model

Engine ZD30ETi

Transmission M/T A/T A/T M/T

Body Hardtop Wagon Hardtop Wagon

Propeller shaft model 2F100H

Number of joints 2

Type of journal bearing Solid (Disassembly type)

Coupling type with trans-

mission Flange type

Distance between yokes mm (in) 94 (3.70) 94 (3.70) 94 (3.70) 94 (3.70)

Shaft length (Spider-to-

spider) mm (in) 440 (17.32) 1,044 (41.10) 480 (18.90) 957 (37.68)

Shaft outer diameter mm (in) 57 (2.24) 89.6 (3.528) 75.2 (2.961) 89.6 (3.528)

Available snap rings

2F80B

Thickness mm (in) Color Part number

1.99 (0.0783) White 37146-C9400

2.02 (0.0795) Yellow 37147-C9400

2.05 (0.0807) Red 37148-C9400

2.08 (0.0819) Green 37149-C9400

2.11 (0.0831) Blue 37150-C9400

2.14 (0.0843) Light brown 37151-C9400

2.17 (0.0854) Black 37152-C9400

2.20 (0.0866) Colorless 37153-C9400

2F100H

Thickness mm (in) Color Part number1.95 (0.0768) White 37146-61502

1.98 (0.0780) Yellow 37147-61502

2.01 (0.0791) Red 37148-61502

2.04 (0.0803) Green 37149-61502

2.07 (0.0815) Blue 37150-61502

2.10 (0.0827) Light brown 37151-61502

2.13 (0.0839) Pink 37146-61503

2.16 (0.0850) Gold 37147-61503

2.19 (0.0862) Black 37148-61503

2.22 (0.0874) Colorless 37149-61503

SERVICE DATA AND SPECIFICATIONS (SDS)

PD-1010