light NISSAN PATROL 2000 Electronic Owner's Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2000, Model line: PATROL, Model: NISSAN PATROL 2000Pages: 1033, PDF Size: 30.71 MB

Page 267 of 1033

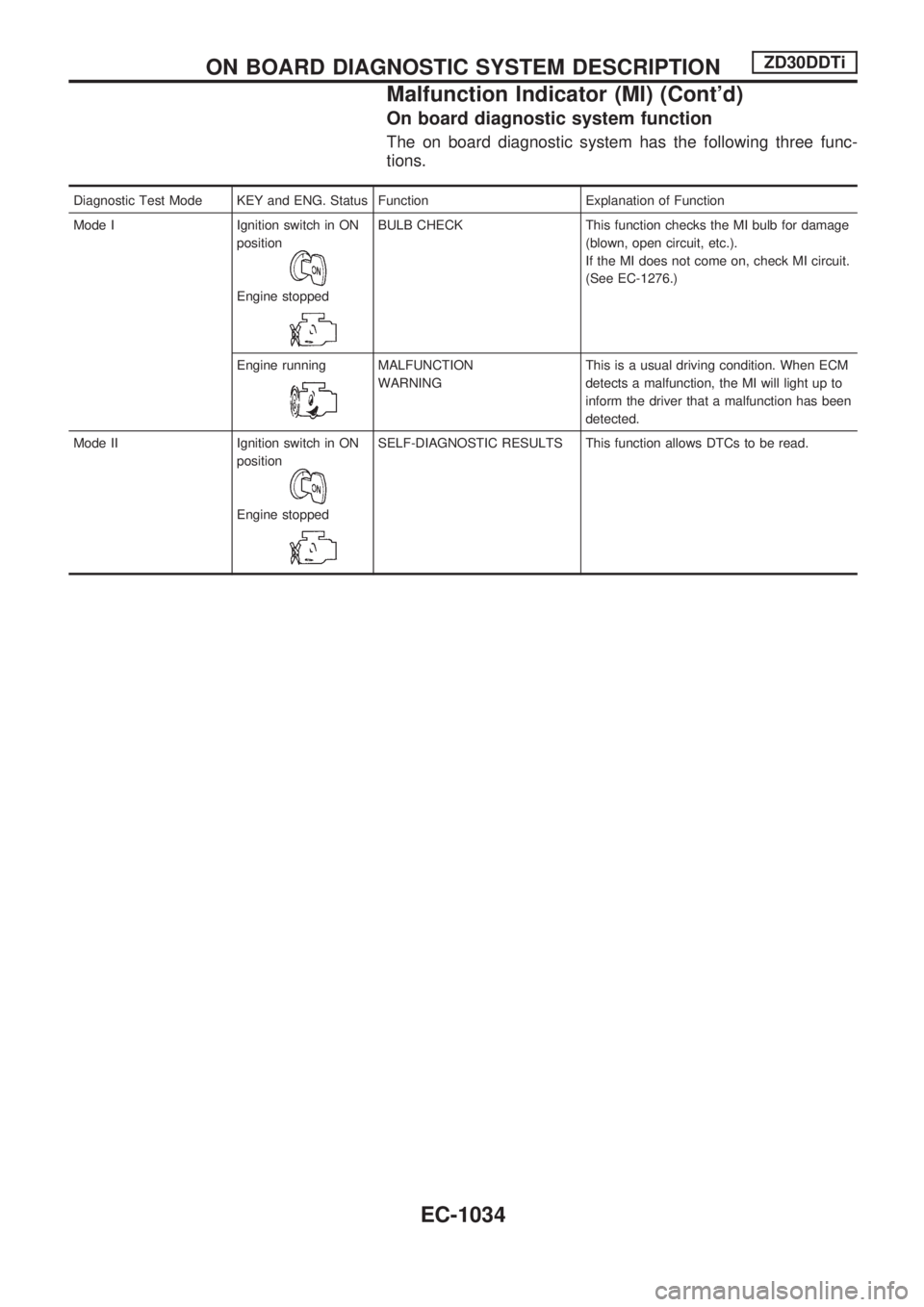

On board diagnostic system function

The on board diagnostic system has the following three func-

tions.

Diagnostic Test Mode KEY and ENG. Status Function Explanation of Function

Mode I Ignition switch in ON

position

Engine stopped

BULB CHECK This function checks the MI bulb for damage

(blown, open circuit, etc.).

If the MI does not come on, check MI circuit.

(See EC-1276.)

Engine running

MALFUNCTION

WARNINGThis is a usual driving condition. When ECM

detects a malfunction, the MI will light up to

inform the driver that a malfunction has been

detected.

Mode II Ignition switch in ON

position

Engine stopped

SELF-DIAGNOSTIC RESULTS This function allows DTCs to be read.

ON BOARD DIAGNOSTIC SYSTEM DESCRIPTIONZD30DDTi

Malfunction Indicator (MI) (Cont'd)

EC-1034

Page 270 of 1033

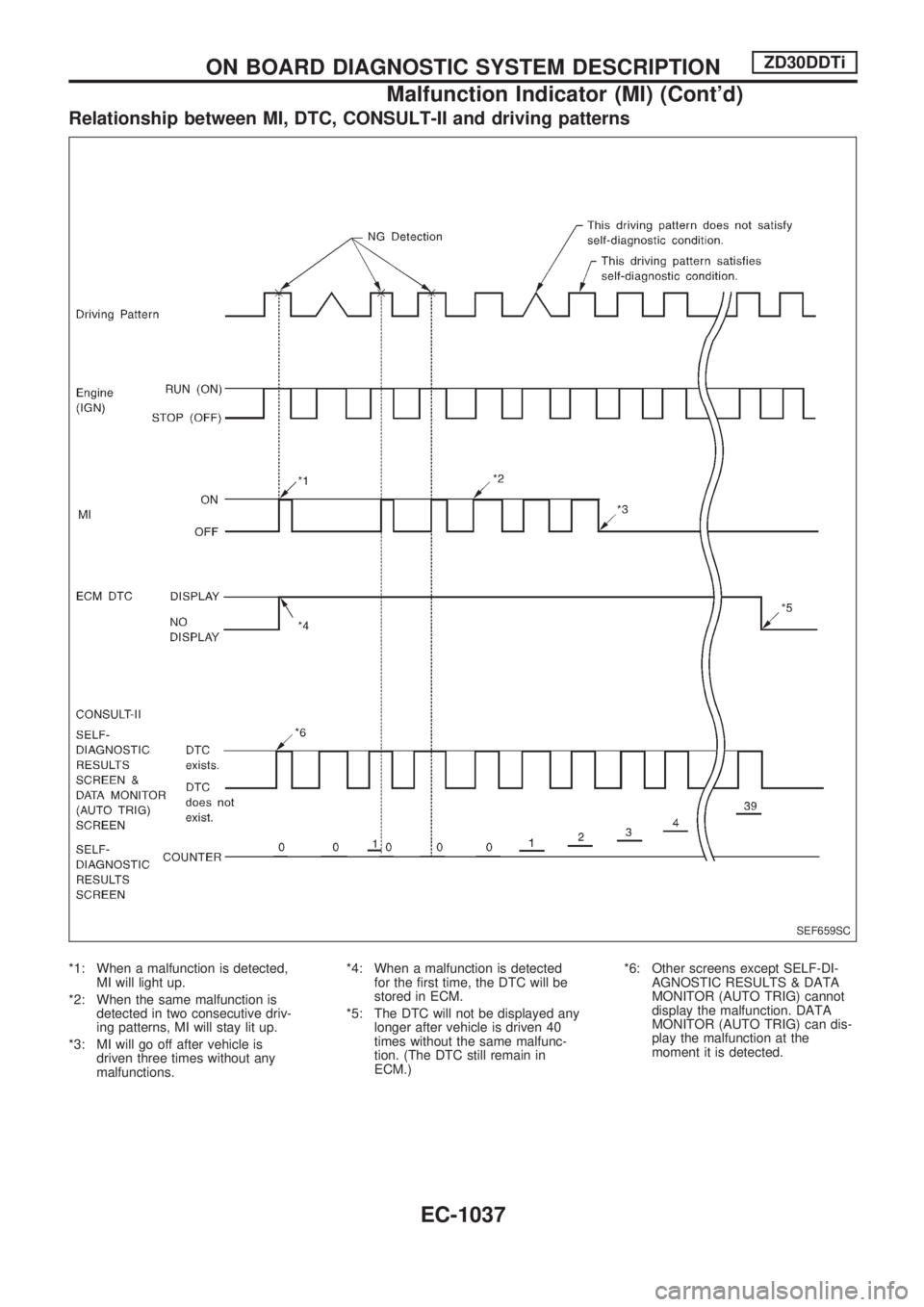

Relationship between MI, DTC, CONSULT-II and driving patterns

*1: When a malfunction is detected,

MI will light up.

*2: When the same malfunction is

detected in two consecutive driv-

ing patterns, MI will stay lit up.

*3: MI will go off after vehicle is

driven three times without any

malfunctions.*4: When a malfunction is detected

for the first time, the DTC will be

stored in ECM.

*5: The DTC will not be displayed any

longer after vehicle is driven 40

times without the same malfunc-

tion. (The DTC still remain in

ECM.)*6: Other screens except SELF-DI-

AGNOSTIC RESULTS & DATA

MONITOR (AUTO TRIG) cannot

display the malfunction. DATA

MONITOR (AUTO TRIG) can dis-

play the malfunction at the

moment it is detected.

SEF659SC

ON BOARD DIAGNOSTIC SYSTEM DESCRIPTIONZD30DDTi

Malfunction Indicator (MI) (Cont'd)

EC-1037

Page 298 of 1033

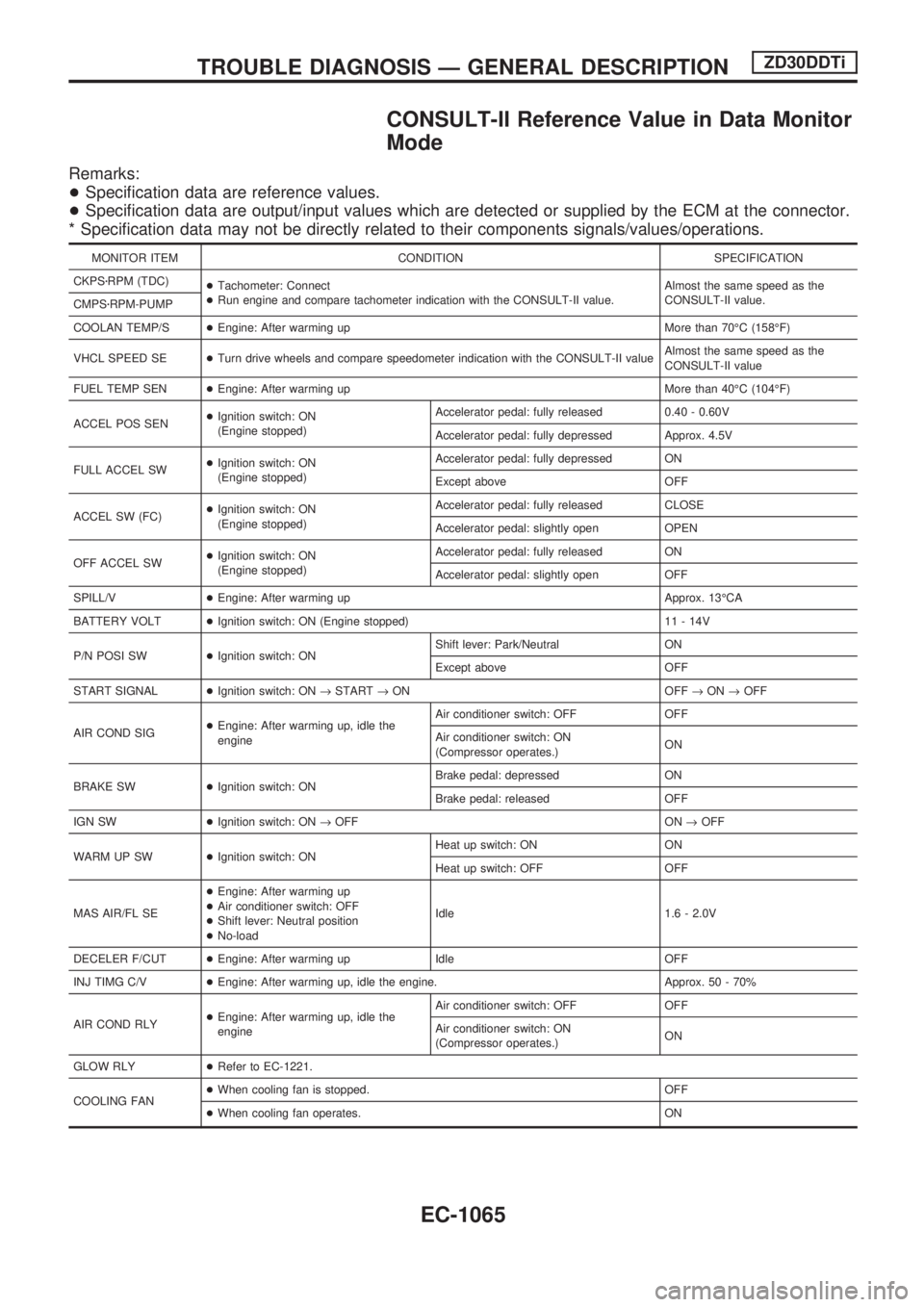

CONSULT-II Reference Value in Data Monitor

Mode

Remarks:

+Specification data are reference values.

+Specification data are output/input values which are detected or supplied by the ECM at the connector.

* Specification data may not be directly related to their components signals/values/operations.

MONITOR ITEM CONDITION SPECIFICATION

CKPSzRPM (TDC)

+Tachometer: Connect

+Run engine and compare tachometer indication with the CONSULT-II value.Almost the same speed as the

CONSULT-II value.

CMPSzRPM-PUMP

COOLAN TEMP/S+Engine: After warming up More than 70ÉC (158ÉF)

VHCL SPEED SE+Turn drive wheels and compare speedometer indication with the CONSULT-II valueAlmost the same speed as the

CONSULT-II value

FUEL TEMP SEN+Engine: After warming up More than 40ÉC (104ÉF)

ACCEL POS SEN+Ignition switch: ON

(Engine stopped)Accelerator pedal: fully released 0.40 - 0.60V

Accelerator pedal: fully depressed Approx. 4.5V

FULL ACCEL SW+Ignition switch: ON

(Engine stopped)Accelerator pedal: fully depressed ON

Except above OFF

ACCEL SW (FC)+Ignition switch: ON

(Engine stopped)Accelerator pedal: fully released CLOSE

Accelerator pedal: slightly open OPEN

OFF ACCEL SW+Ignition switch: ON

(Engine stopped)Accelerator pedal: fully released ON

Accelerator pedal: slightly open OFF

SPILL/V+Engine: After warming up Approx. 13ÉCA

BATTERY VOLT+Ignition switch: ON (Engine stopped) 11 - 14V

P/N POSI SW+Ignition switch: ONShift lever: Park/Neutral ON

Except above OFF

START SIGNAL+Ignition switch: ON®START®ON OFF®ON®OFF

AIR COND SIG+Engine: After warming up, idle the

engineAir conditioner switch: OFF OFF

Air conditioner switch: ON

(Compressor operates.)ON

BRAKE SW+Ignition switch: ONBrake pedal: depressed ON

Brake pedal: released OFF

IGN SW+Ignition switch: ON®OFF ON®OFF

WARM UP SW+Ignition switch: ONHeat up switch: ON ON

Heat up switch: OFF OFF

MAS AIR/FL SE+Engine: After warming up

+Air conditioner switch: OFF

+Shift lever: Neutral position

+No-loadIdle 1.6 - 2.0V

DECELER F/CUT+Engine: After warming up Idle OFF

INJ TIMG C/V+Engine: After warming up, idle the engine. Approx. 50 - 70%

AIR COND RLY+Engine: After warming up, idle the

engineAir conditioner switch: OFF OFF

Air conditioner switch: ON

(Compressor operates.)ON

GLOW RLY+Refer to EC-1221.

COOLING FAN+When cooling fan is stopped. OFF

+When cooling fan operates. ON

TROUBLE DIAGNOSIS Ð GENERAL DESCRIPTIONZD30DDTi

EC-1065

Page 333 of 1033

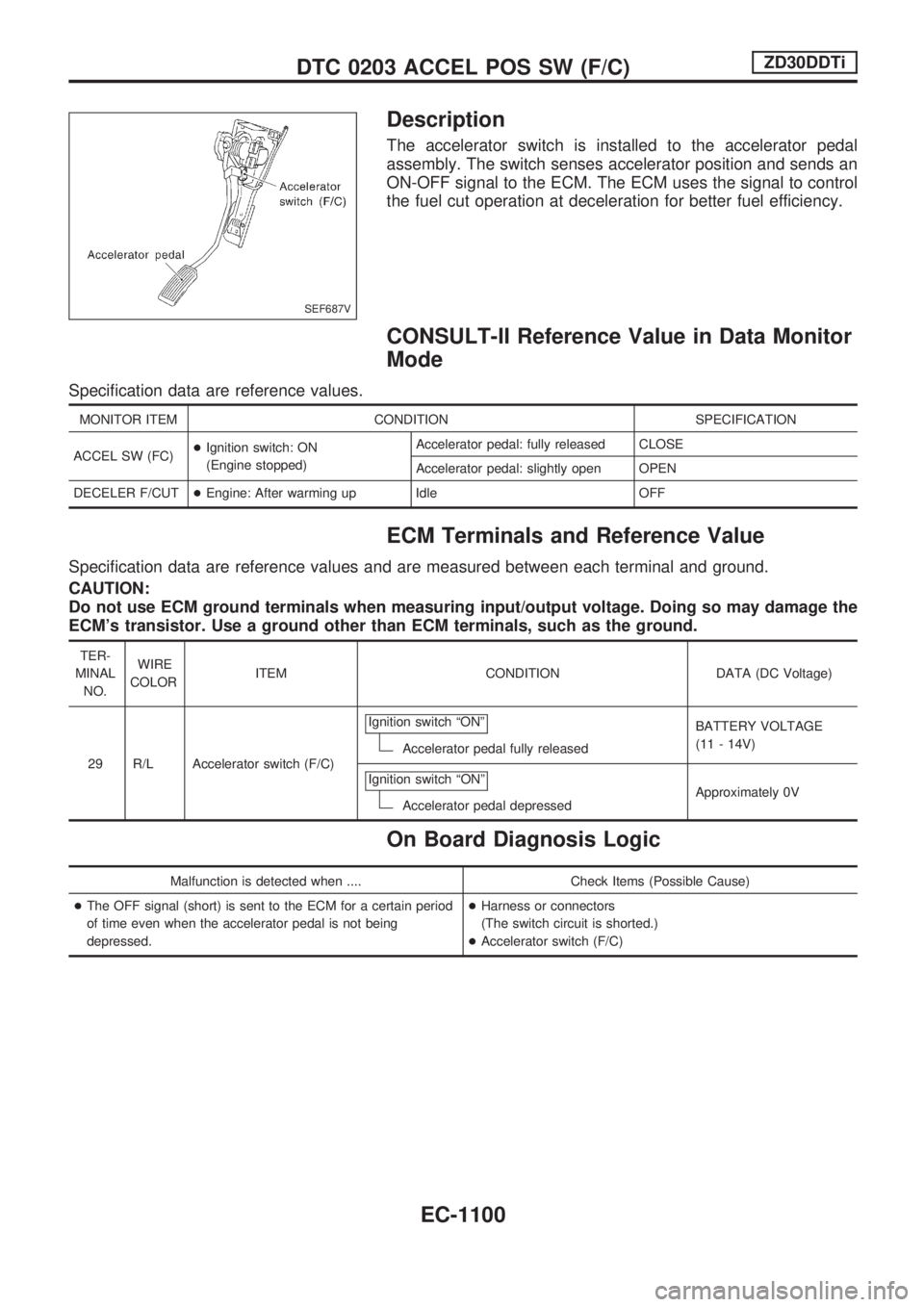

Description

The accelerator switch is installed to the accelerator pedal

assembly. The switch senses accelerator position and sends an

ON-OFF signal to the ECM. The ECM uses the signal to control

the fuel cut operation at deceleration for better fuel efficiency.

CONSULT-II Reference Value in Data Monitor

Mode

Specification data are reference values.

MONITOR ITEM CONDITION SPECIFICATION

ACCEL SW (FC)+Ignition switch: ON

(Engine stopped)Accelerator pedal: fully released CLOSE

Accelerator pedal: slightly open OPEN

DECELER F/CUT+Engine: After warming up Idle OFF

ECM Terminals and Reference Value

Specification data are reference values and are measured between each terminal and ground.

CAUTION:

Do not use ECM ground terminals when measuring input/output voltage. Doing so may damage the

ECM's transistor. Use a ground other than ECM terminals, such as the ground.

TER-

MINAL

NO.WIRE

COLORITEM CONDITION DATA (DC Voltage)

29 R/L Accelerator switch (F/C)Ignition switch ªONº

Accelerator pedal fully releasedBATTERY VOLTAGE

(11 - 14V)

Ignition switch ªONº

Accelerator pedal depressedApproximately 0V

On Board Diagnosis Logic

Malfunction is detected when .... Check Items (Possible Cause)

+The OFF signal (short) is sent to the ECM for a certain period

of time even when the accelerator pedal is not being

depressed.+Harness or connectors

(The switch circuit is shorted.)

+Accelerator switch (F/C)

SEF687V

DTC 0203 ACCEL POS SW (F/C)ZD30DDTi

EC-1100

Page 358 of 1033

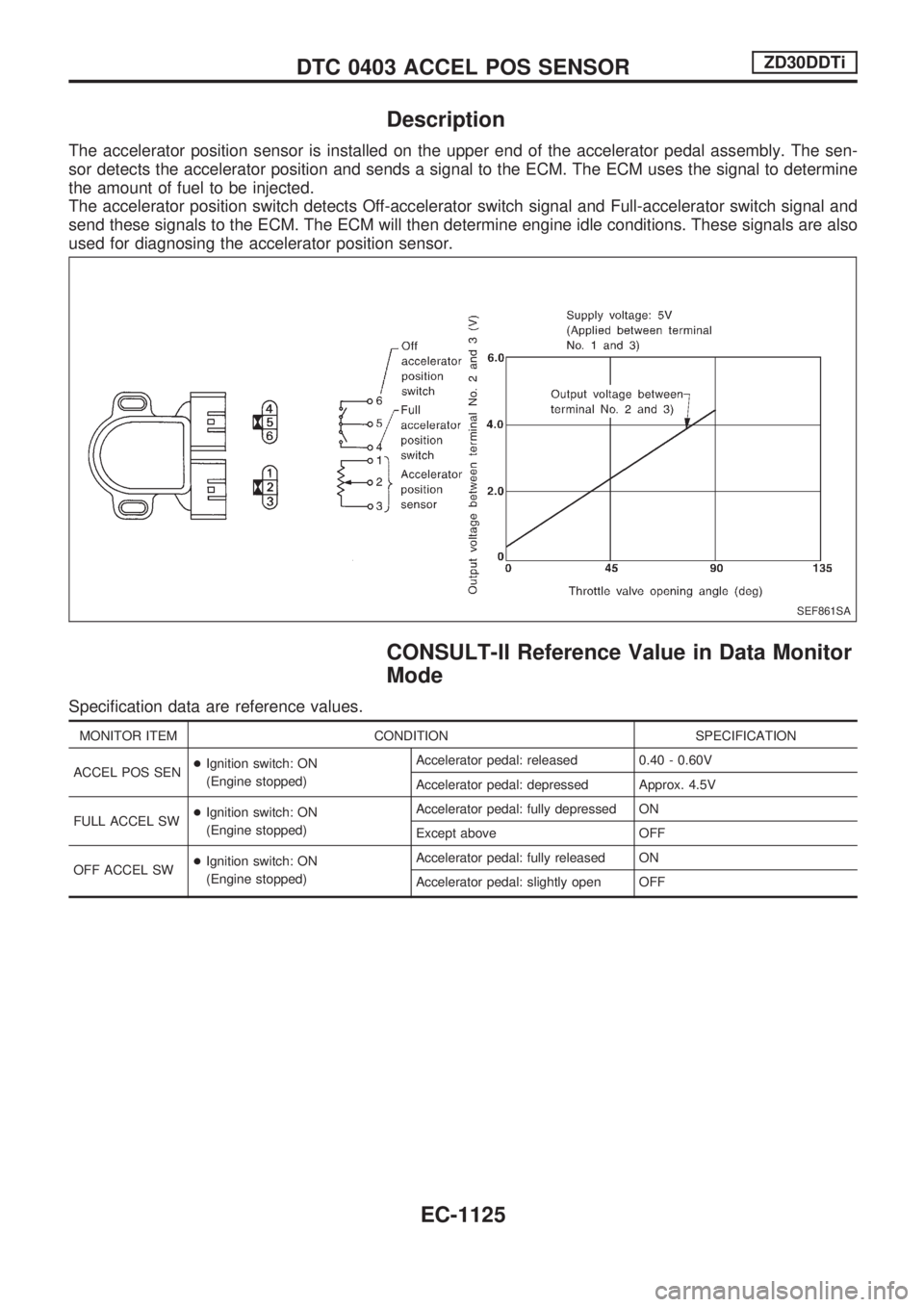

Description

The accelerator position sensor is installed on the upper end of the accelerator pedal assembly. The sen-

sor detects the accelerator position and sends a signal to the ECM. The ECM uses the signal to determine

the amount of fuel to be injected.

The accelerator position switch detects Off-accelerator switch signal and Full-accelerator switch signal and

send these signals to the ECM. The ECM will then determine engine idle conditions. These signals are also

used for diagnosing the accelerator position sensor.

CONSULT-II Reference Value in Data Monitor

Mode

Specification data are reference values.

MONITOR ITEM CONDITION SPECIFICATION

ACCEL POS SEN+Ignition switch: ON

(Engine stopped)Accelerator pedal: released 0.40 - 0.60V

Accelerator pedal: depressed Approx. 4.5V

FULL ACCEL SW+Ignition switch: ON

(Engine stopped)Accelerator pedal: fully depressed ON

Except above OFF

OFF ACCEL SW+Ignition switch: ON

(Engine stopped)Accelerator pedal: fully released ON

Accelerator pedal: slightly open OFF

SEF861SA

DTC 0403 ACCEL POS SENSORZD30DDTi

EC-1125

Page 511 of 1033

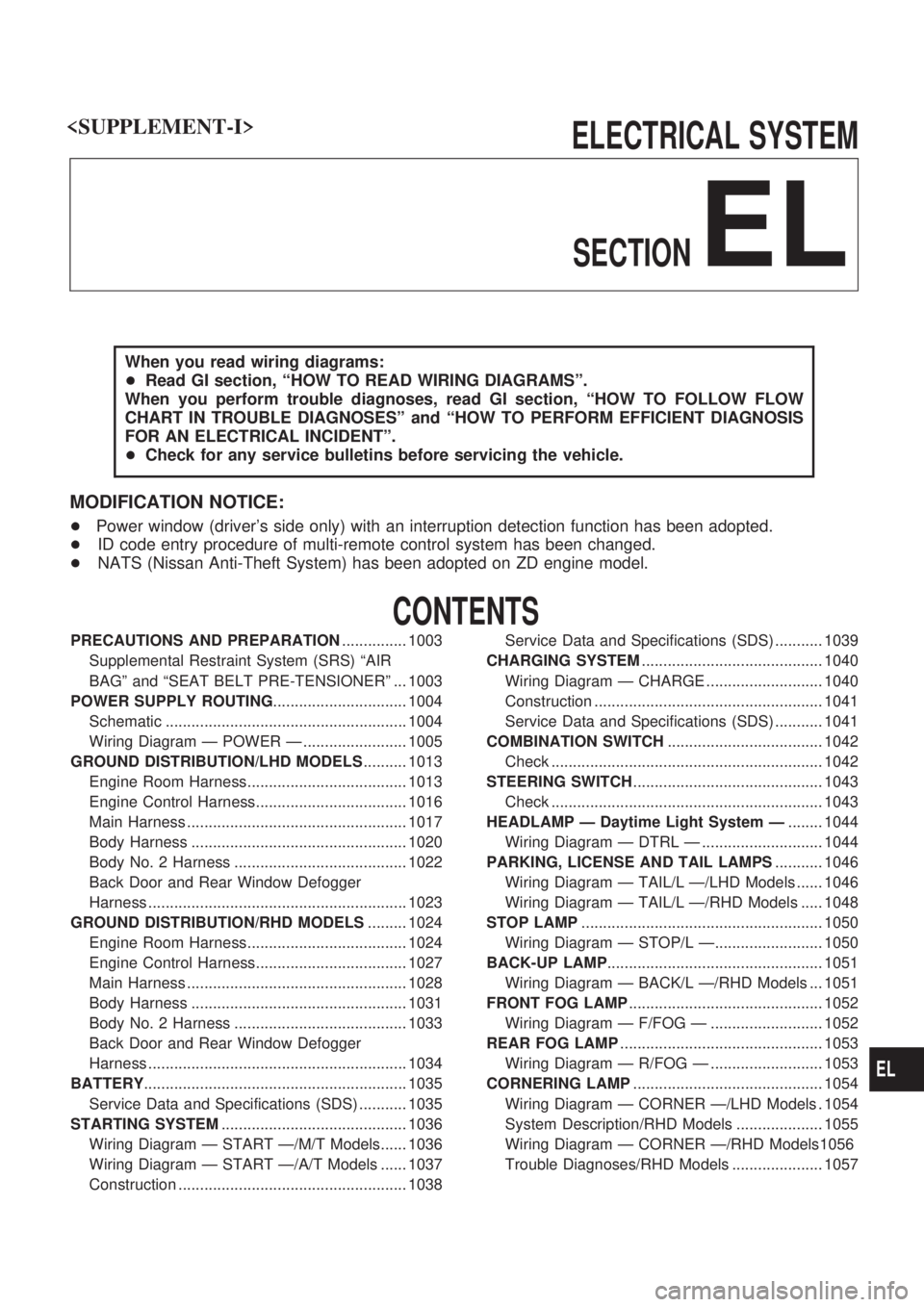

ELECTRICAL SYSTEM

SECTION

EL

When you read wiring diagrams:

+Read GI section, ªHOW TO READ WIRING DIAGRAMSº.

When you perform trouble diagnoses, read GI section, ªHOW TO FOLLOW FLOW

CHART IN TROUBLE DIAGNOSESº and ªHOW TO PERFORM EFFICIENT DIAGNOSIS

FOR AN ELECTRICAL INCIDENTº.

+Check for any service bulletins before servicing the vehicle.

MODIFICATION NOTICE:

+Power window (driver's side only) with an interruption detection function has been adopted.

+ID code entry procedure of multi-remote control system has been changed.

+NATS (Nissan Anti-Theft System) has been adopted on ZD engine model.

CONTENTS

PRECAUTIONS AND PREPARATION............... 1003

Supplemental Restraint System (SRS) ªAIR

BAGº and ªSEAT BELT PRE-TENSIONERº ... 1003

POWER SUPPLY ROUTING............................... 1004

Schematic ........................................................ 1004

Wiring Diagram Ð POWER Ð ........................ 1005

GROUND DISTRIBUTION/LHD MODELS.......... 1013

Engine Room Harness..................................... 1013

Engine Control Harness................................... 1016

Main Harness ................................................... 1017

Body Harness .................................................. 1020

Body No. 2 Harness ........................................ 1022

Back Door and Rear Window Defogger

Harness ............................................................ 1023

GROUND DISTRIBUTION/RHD MODELS......... 1024

Engine Room Harness..................................... 1024

Engine Control Harness................................... 1027

Main Harness ................................................... 1028

Body Harness .................................................. 1031

Body No. 2 Harness ........................................ 1033

Back Door and Rear Window Defogger

Harness ............................................................ 1034

BATTERY............................................................. 1035

Service Data and Specifications (SDS) ........... 1035

STARTING SYSTEM........................................... 1036

Wiring Diagram Ð START Ð/M/T Models...... 1036

Wiring Diagram Ð START Ð/A/T Models ...... 1037

Construction ..................................................... 1038Service Data and Specifications (SDS) ........... 1039

CHARGING SYSTEM.......................................... 1040

Wiring Diagram Ð CHARGE ........................... 1040

Construction ..................................................... 1041

Service Data and Specifications (SDS) ........... 1041

COMBINATION SWITCH.................................... 1042

Check ............................................................... 1042

STEERING SWITCH............................................ 1043

Check ............................................................... 1043

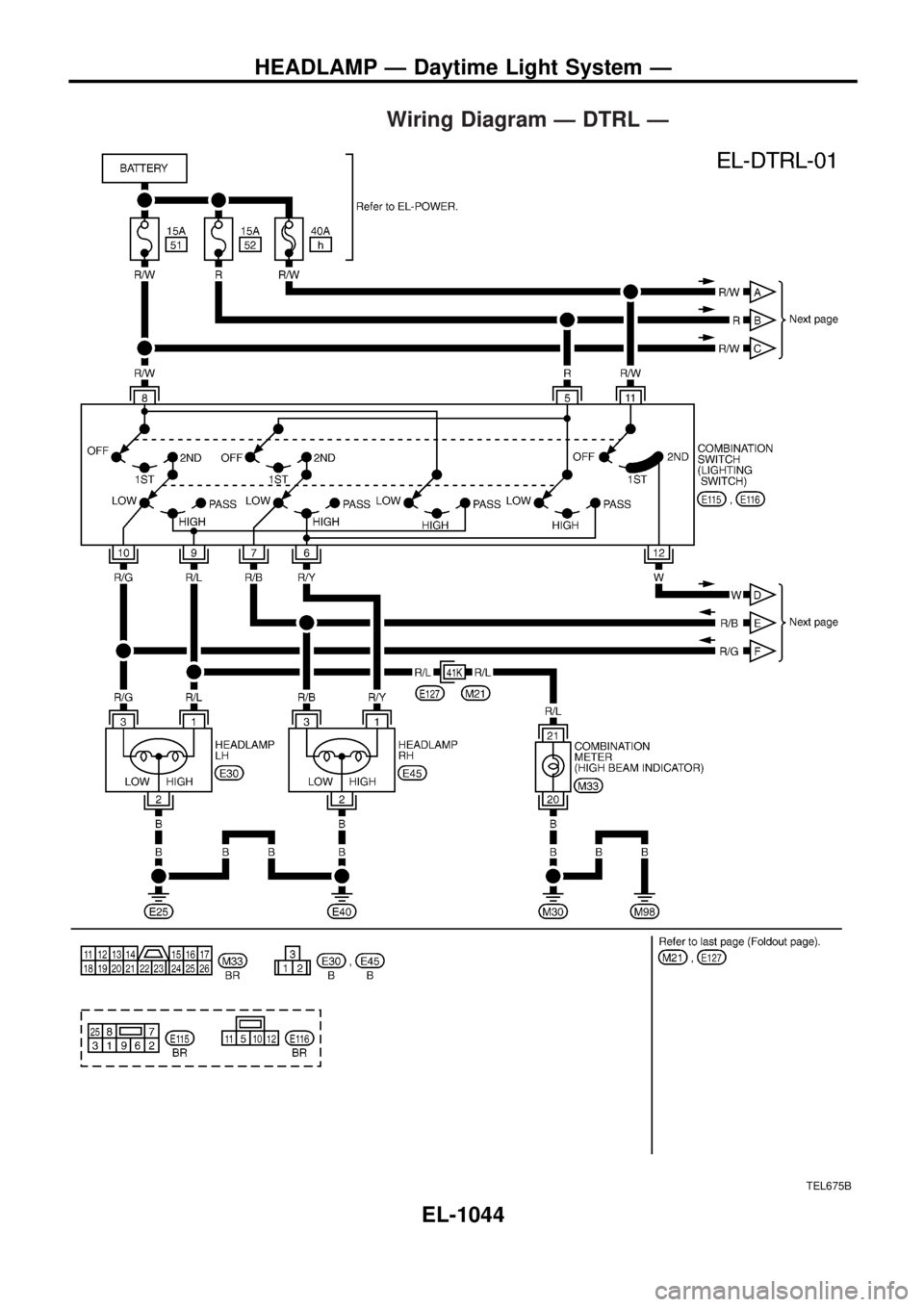

HEADLAMP Ð Daytime Light System Ð........ 1044

Wiring Diagram Ð DTRL Ð ............................ 1044

PARKING, LICENSE AND TAIL LAMPS........... 1046

Wiring Diagram Ð TAIL/L Ð/LHD Models ...... 1046

Wiring Diagram Ð TAIL/L Ð/RHD Models ..... 1048

STOP LAMP........................................................ 1050

Wiring Diagram Ð STOP/L Ð......................... 1050

BACK-UP LAMP.................................................. 1051

Wiring Diagram Ð BACK/L Ð/RHD Models ... 1051

FRONT FOG LAMP............................................. 1052

Wiring Diagram Ð F/FOG Ð .......................... 1052

REAR FOG LAMP............................................... 1053

Wiring Diagram Ð R/FOG Ð .......................... 1053

CORNERING LAMP............................................ 1054

Wiring Diagram Ð CORNER Ð/LHD Models . 1054

System Description/RHD Models .................... 1055

Wiring Diagram Ð CORNER Ð/RHD Models1056

Trouble Diagnoses/RHD Models ..................... 1057

EL

Page 554 of 1033

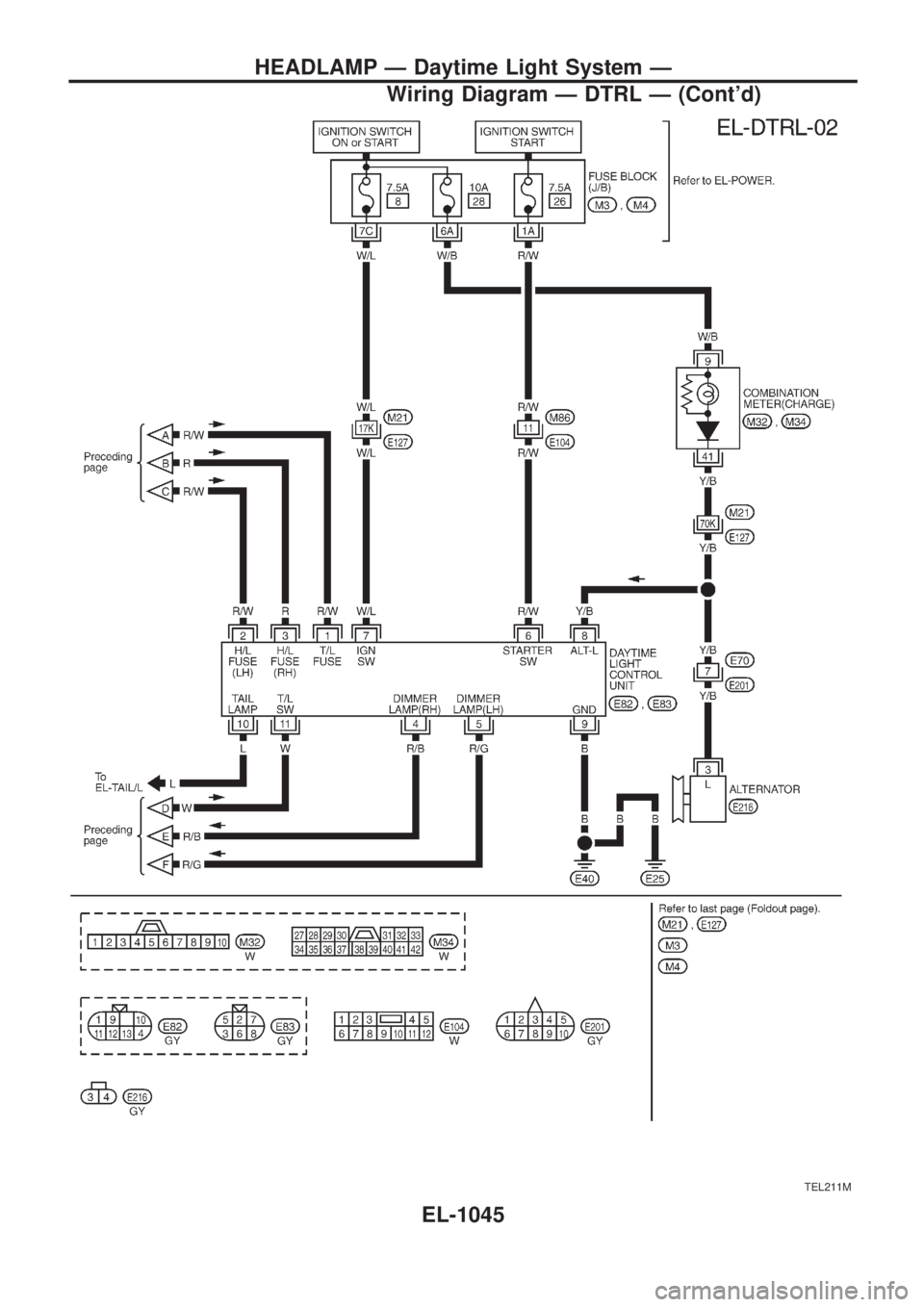

Wiring Diagram Ð DTRL Ð

TEL675B

HEADLAMP Ð Daytime Light System Ð

EL-1044

Page 555 of 1033

TEL211M

HEADLAMP Ð Daytime Light System Ð

Wiring Diagram Ð DTRL Ð (Cont'd)

EL-1045

Page 565 of 1033

System Description/RHD Models

The cornering lamp operation is controlled by the lighting switch which is built into the combination switch

and cornering lamp relay unit.

Power is supplied at all times

+to lighting switch terminal

V11

+through 10A fuse [No.15, located in the fuse block (J/B)].

Lighting operation by lighting switch

When lighting switch is in 1ST (or 2ND) position, power is supplied

+to cornering lamp relay unit terminal

V3

+through lighting switch terminalV12.

With the ignition switch in the ON or START position, power is supplied to cornering lamp relay unit termi-

nal

V2

+through 7.5A fuse [No.11, located in the fuse block (J/B)].

RH turn

When the turn signal lever is moved to the RH position, ground is supplied

+to cornering lamp relay unit terminal

V6

+through turn signal lamp switch terminalsV2andV1

+through body groundsE25andE40.

Power is supplied

+from terminal

V5of the cornering lamp relay unit

+to front combination lamp RH terminal

V3.

Ground is supplied to terminal

V4of front combination lamp RH through body groundsE25andE40.

The RH cornering lamp illuminates until the turn signal lever returns to NEUTRAL position.

LH turn

When the turn signal lever is moved to the LH position, ground is supplied

+to cornering lamp relay unit terminal

V8

+through turn signal lamp switch terminalsV3andV1

+through body groundsE25andE40.

Power is supplied

+from terminal

V10of the cornering lamp relay unit

+to front combination lamp LH terminal

V3.

Ground is supplied to terminal

V4of front combination lamp LH through body groundsE25andE40.

The LH cornering lamp illuminates until the turn signal lever returns to NEUTRAL position.

CORNERING LAMP

EL-1055

Page 567 of 1033

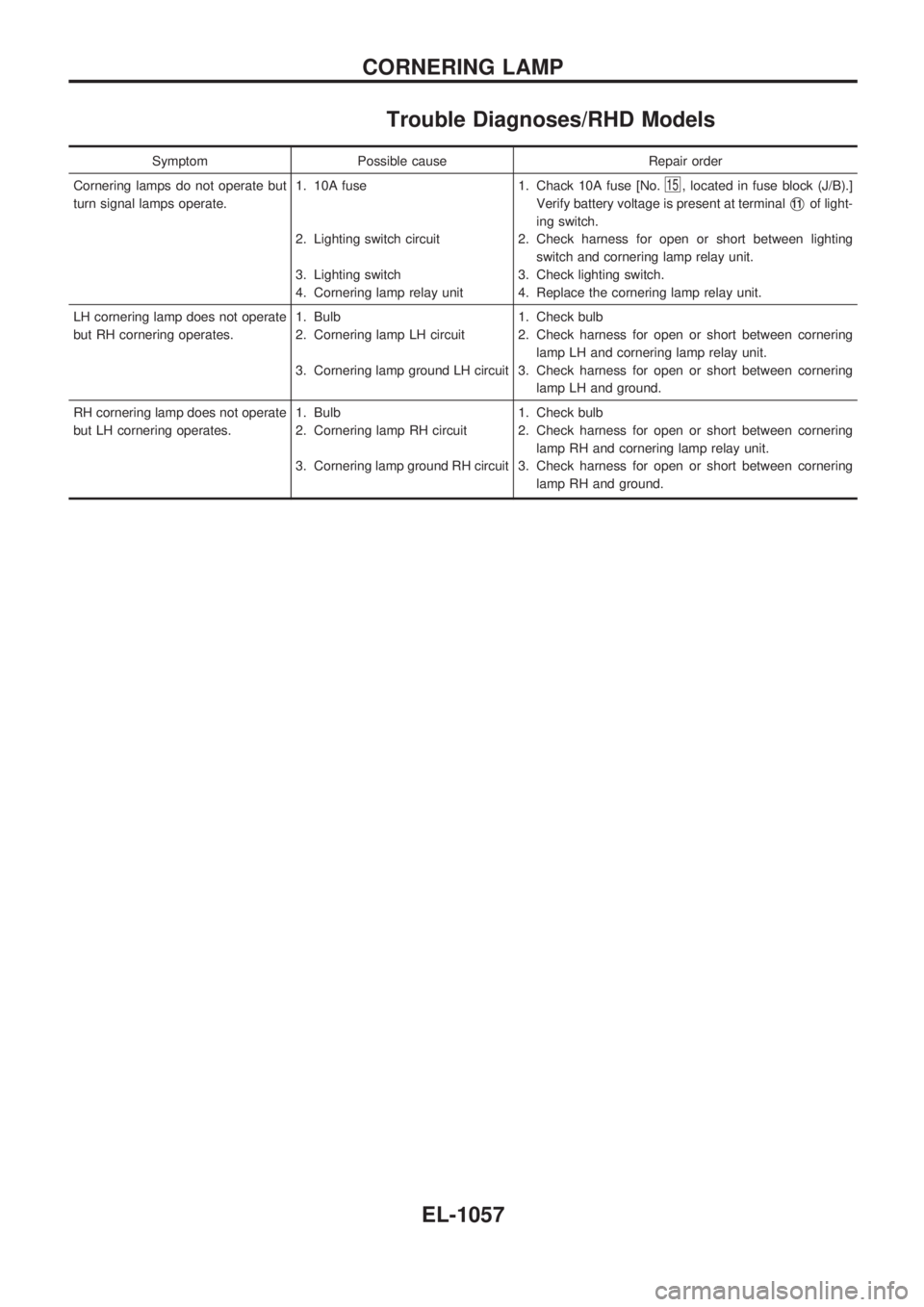

Trouble Diagnoses/RHD Models

Symptom Possible cause Repair order

Cornering lamps do not operate but

turn signal lamps operate.1. 10A fuse

2. Lighting switch circuit

3. Lighting switch

4. Cornering lamp relay unit1. Chack 10A fuse [No.

15, located in fuse block (J/B).]

Verify battery voltage is present at terminal

V11of light-

ing switch.

2. Check harness for open or short between lighting

switch and cornering lamp relay unit.

3. Check lighting switch.

4. Replace the cornering lamp relay unit.

LH cornering lamp does not operate

but RH cornering operates.1. Bulb

2. Cornering lamp LH circuit

3. Cornering lamp ground LH circuit1. Check bulb

2. Check harness for open or short between cornering

lamp LH and cornering lamp relay unit.

3. Check harness for open or short between cornering

lamp LH and ground.

RH cornering lamp does not operate

but LH cornering operates.1. Bulb

2. Cornering lamp RH circuit

3. Cornering lamp ground RH circuit1. Check bulb

2. Check harness for open or short between cornering

lamp RH and cornering lamp relay unit.

3. Check harness for open or short between cornering

lamp RH and ground.

CORNERING LAMP

EL-1057