sensor NISSAN PATROL 2000 Electronic Service Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2000, Model line: PATROL, Model: NISSAN PATROL 2000Pages: 1033, PDF Size: 30.71 MB

Page 113 of 1033

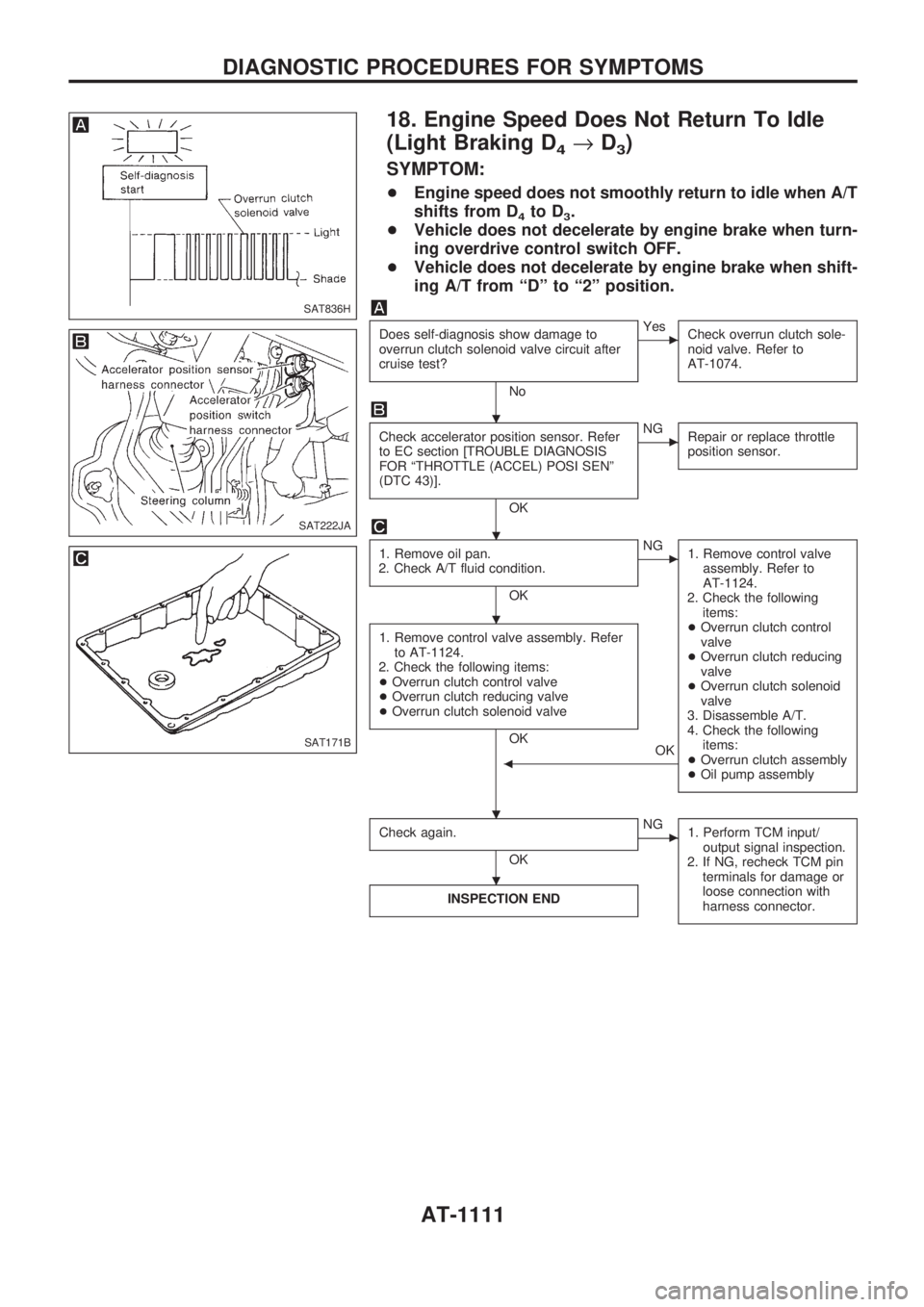

18. Engine Speed Does Not Return To Idle

(Light Braking D

4®D3)

SYMPTOM:

+Engine speed does not smoothly return to idle when A/T

shifts from D

4to D3.

+Vehicle does not decelerate by engine brake when turn-

ing overdrive control switch OFF.

+Vehicle does not decelerate by engine brake when shift-

ing A/T from ªDº to ª2º position.

Does self-diagnosis show damage to

overrun clutch solenoid valve circuit after

cruise test?

No

cYes

Check overrun clutch sole-

noid valve. Refer to

AT-1074.

Check accelerator position sensor. Refer

to EC section [TROUBLE DIAGNOSIS

FOR ªTHROTTLE (ACCEL) POSI SENº

(DTC 43)].

OK

cNG

Repair or replace throttle

position sensor.

1. Remove oil pan.

2. Check A/T fluid condition.

OK

cNG

1. Remove control valve

assembly. Refer to

AT-1124.

2. Check the following

items:

+Overrun clutch control

valve

+Overrun clutch reducing

valve

+Overrun clutch solenoid

valve

3. Disassemble A/T.

4. Check the following

items:

+Overrun clutch assembly

+Oil pump assembly

1. Remove control valve assembly. Refer

to AT-1124.

2. Check the following items:

+Overrun clutch control valve

+Overrun clutch reducing valve

+Overrun clutch solenoid valve

OK

OK

b

Check again.

OK

cNG

1. Perform TCM input/

output signal inspection.

2. If NG, recheck TCM pin

terminals for damage or

loose connection with

harness connector.

INSPECTION END

SAT836H

SAT222JA

SAT171B

.

.

.

. .

.

DIAGNOSTIC PROCEDURES FOR SYMPTOMS

AT-1111

Page 114 of 1033

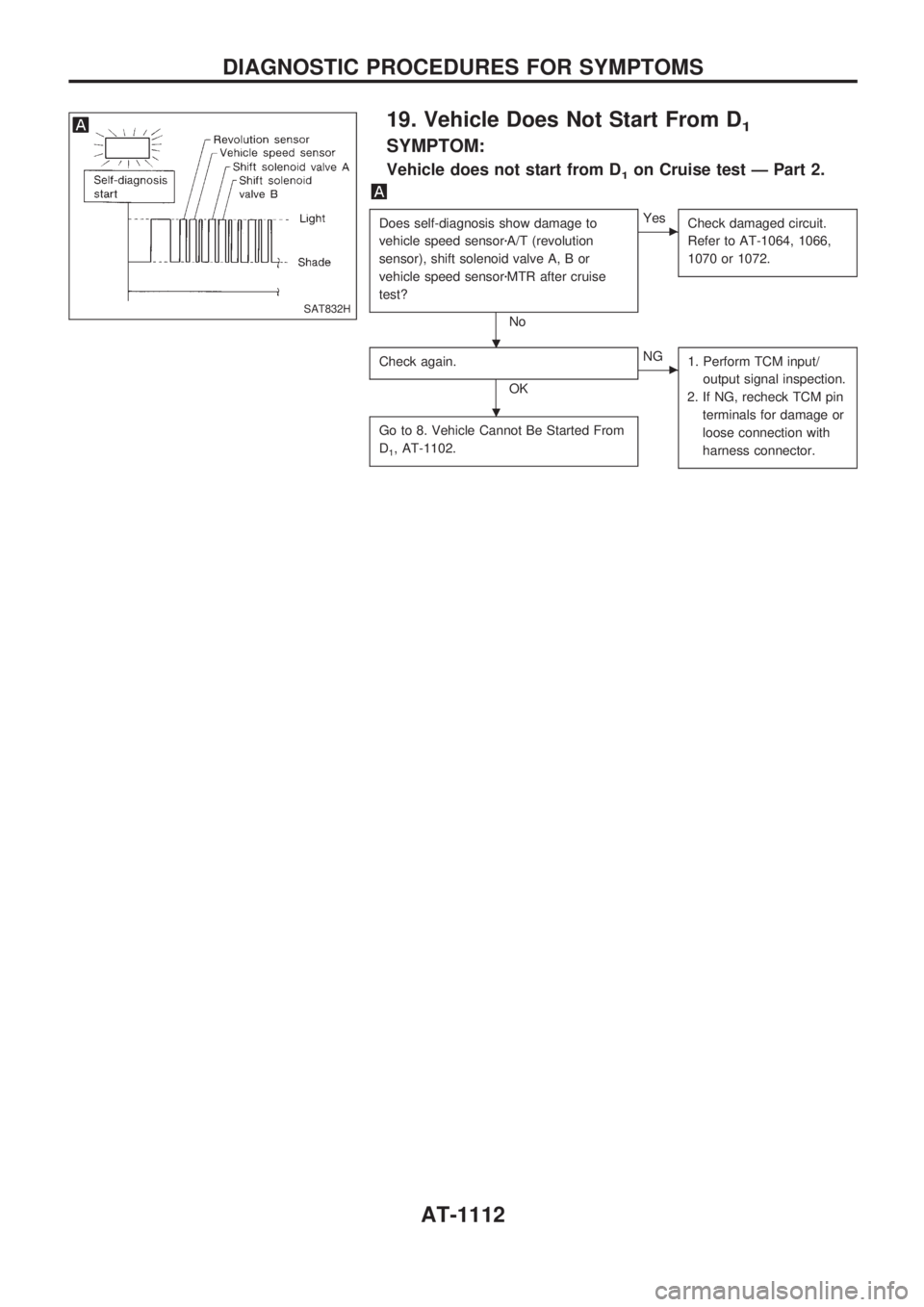

19. Vehicle Does Not Start From D1

SYMPTOM:

Vehicle does not start from D1on Cruise test Ð Part 2.

Does self-diagnosis show damage to

vehicle speed sensorzA/T (revolution

sensor), shift solenoid valve A, B or

vehicle speed sensorzMTR after cruise

test?

No

cYes

Check damaged circuit.

Refer to AT-1064, 1066,

1070 or 1072.

Check again.

OK

cNG

1. Perform TCM input/

output signal inspection.

2. If NG, recheck TCM pin

terminals for damage or

loose connection with

harness connector.

Go to 8. Vehicle Cannot Be Started From

D

1, AT-1102.

SAT832H

. .

.

DIAGNOSTIC PROCEDURES FOR SYMPTOMS

AT-1112

Page 115 of 1033

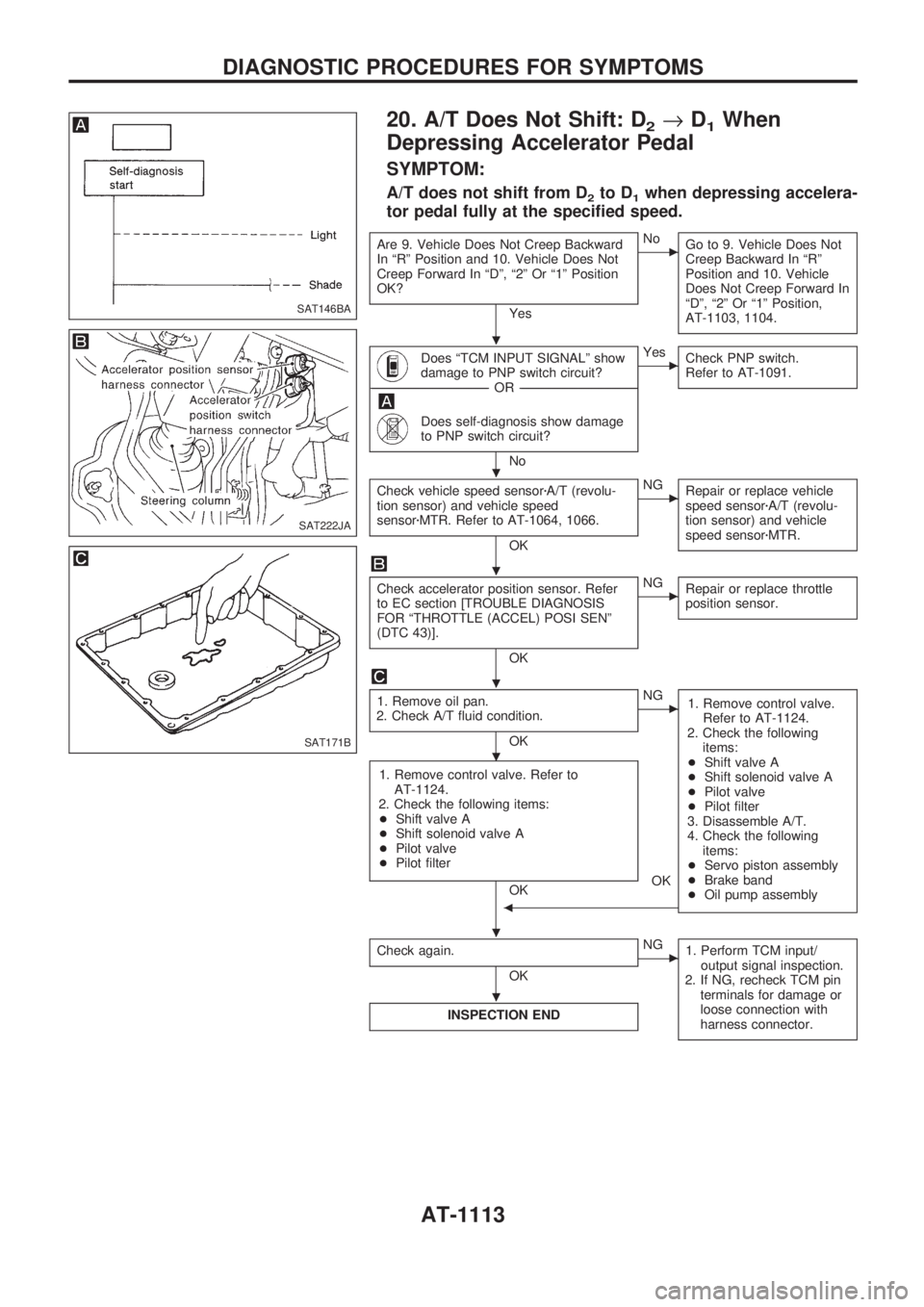

20. A/T Does Not Shift: D2®D1When

Depressing Accelerator Pedal

SYMPTOM:

A/T does not shift from D2to D1when depressing accelera-

tor pedal fully at the specified speed.

Are 9. Vehicle Does Not Creep Backward

In ªRº Position and 10. Vehicle Does Not

Creep Forward In ªDº, ª2º Or ª1º Position

OK?

Yes

cNo

Go to 9. Vehicle Does Not

Creep Backward In ªRº

Position and 10. Vehicle

Does Not Creep Forward In

ªDº, ª2º Or ª1º Position,

AT-1103, 1104.

Does ªTCM INPUT SIGNALº show

damage to PNP switch circuit?

------------------------------------------------------------------------------------------------------------------------------------OR------------------------------------------------------------------------------------------------------------------------------------

Does self-diagnosis show damage

to PNP switch circuit?

No

cYes

Check PNP switch.

Refer to AT-1091.

Check vehicle speed sensorzA/T (revolu-

tion sensor) and vehicle speed

sensorzMTR. Refer to AT-1064, 1066.

OK

cNG

Repair or replace vehicle

speed sensorzA/T (revolu-

tion sensor) and vehicle

speed sensorzMTR.

Check accelerator position sensor. Refer

to EC section [TROUBLE DIAGNOSIS

FOR ªTHROTTLE (ACCEL) POSI SENº

(DTC 43)].

OK

cNG

Repair or replace throttle

position sensor.

1. Remove oil pan.

2. Check A/T fluid condition.

OK

cNG

1. Remove control valve.

Refer to AT-1124.

2. Check the following

items:

+Shift valve A

+Shift solenoid valve A

+Pilot valve

+Pilot filter

3. Disassemble A/T.

4. Check the following

items:

+Servo piston assembly

+Brake band

+Oil pump assembly

1. Remove control valve. Refer to

AT-1124.

2. Check the following items:

+Shift valve A

+Shift solenoid valve A

+Pilot valve

+Pilot filter

OK

b

OK

Check again.

OK

cNG

1. Perform TCM input/

output signal inspection.

2. If NG, recheck TCM pin

terminals for damage or

loose connection with

harness connector.

INSPECTION END

SAT146BA

SAT222JA

SAT171B

.

.

.

.

.

.

.

DIAGNOSTIC PROCEDURES FOR SYMPTOMS

AT-1113

Page 126 of 1033

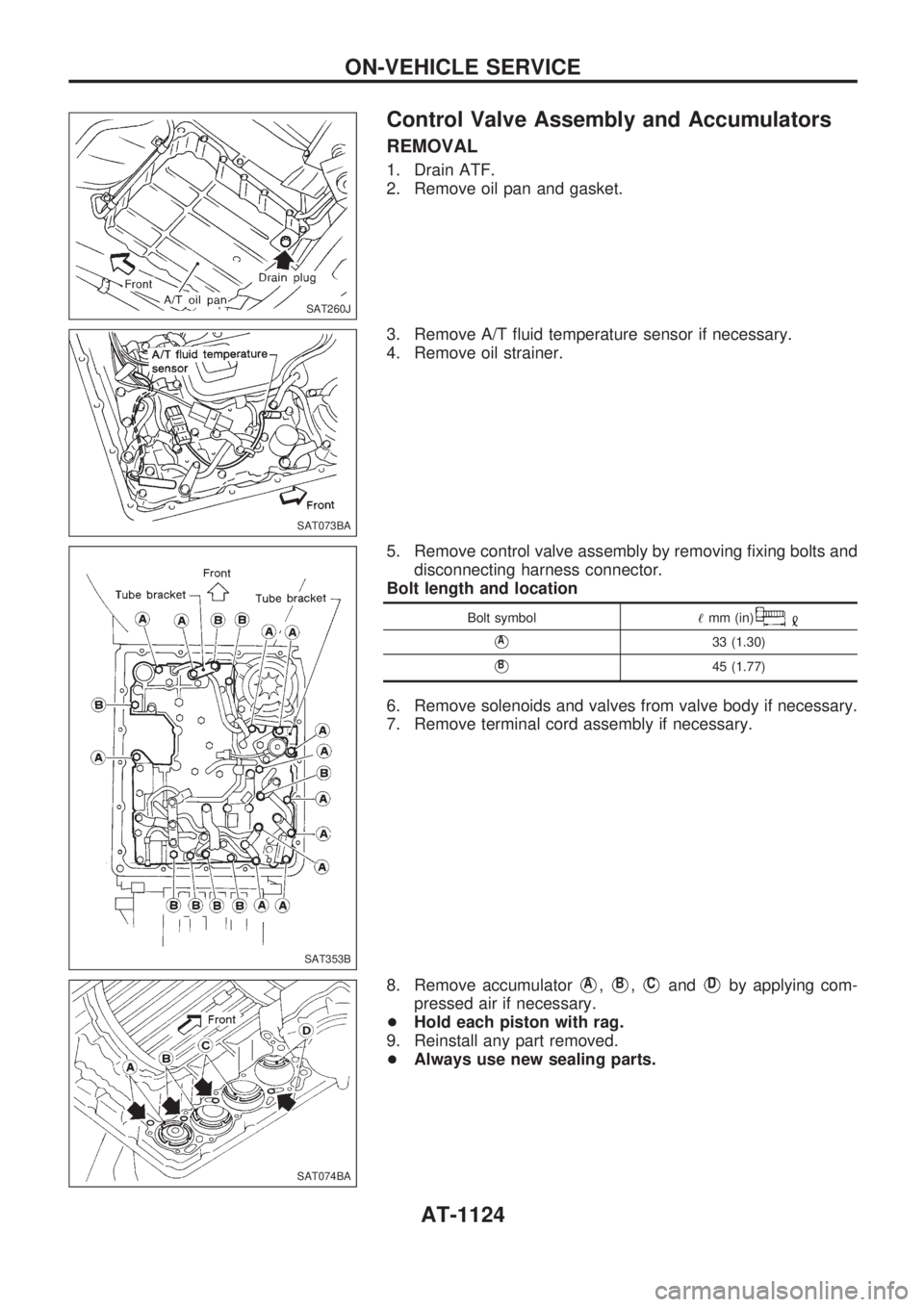

Control Valve Assembly and Accumulators

REMOVAL

1. Drain ATF.

2. Remove oil pan and gasket.

3. Remove A/T fluid temperature sensor if necessary.

4. Remove oil strainer.

5. Remove control valve assembly by removing fixing bolts and

disconnecting harness connector.

Bolt length and location

Bolt symbol!mm (in)

VA33 (1.30)

VB45 (1.77)

6. Remove solenoids and valves from valve body if necessary.

7. Remove terminal cord assembly if necessary.

8. Remove accumulator

VA,VB,VCandVDby applying com-

pressed air if necessary.

+Hold each piston with rag.

9. Reinstall any part removed.

+Always use new sealing parts.

SAT260J

SAT073BA

SAT353B

SAT074BA

ON-VEHICLE SERVICE

AT-1124

Page 127 of 1033

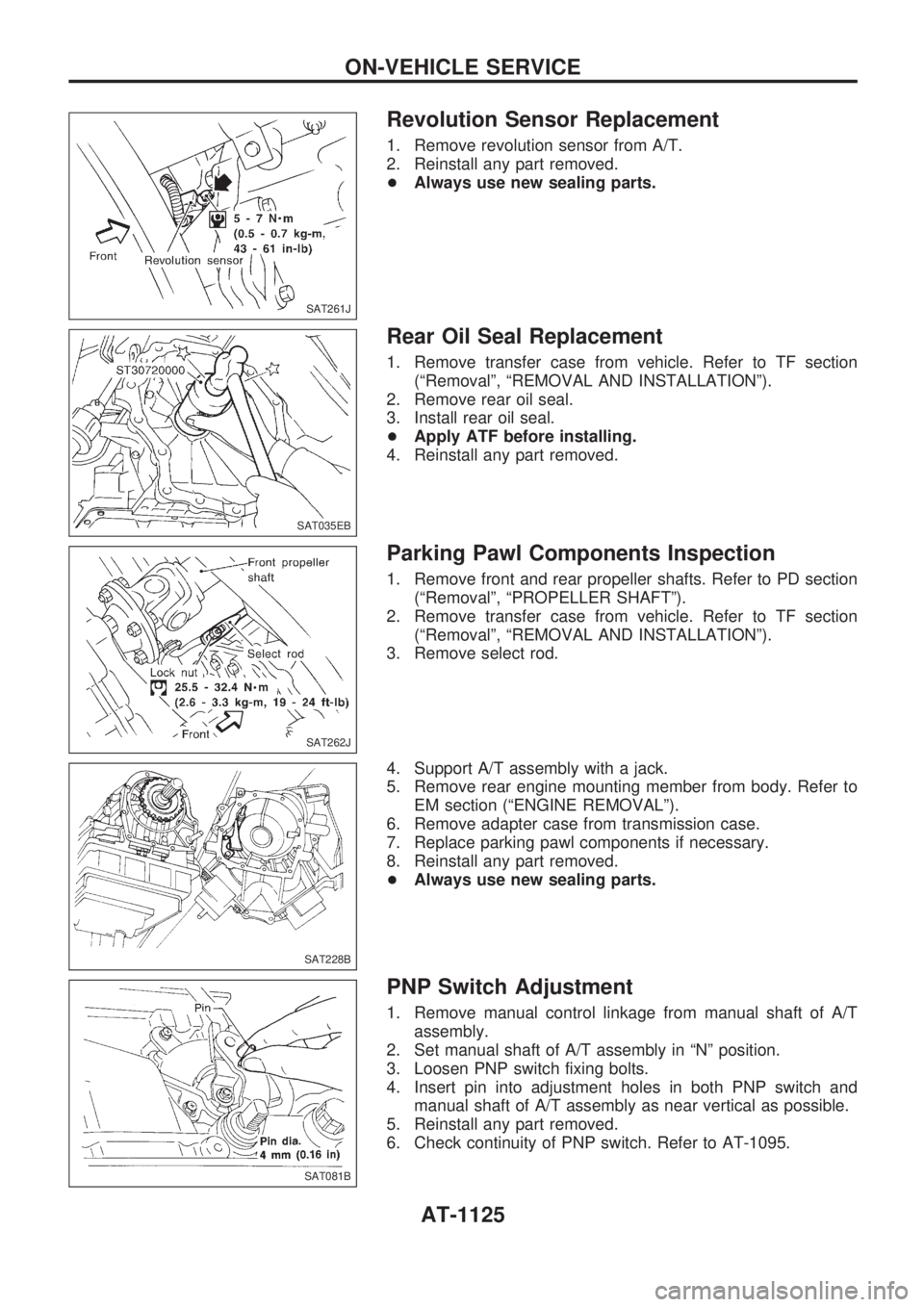

Revolution Sensor Replacement

1. Remove revolution sensor from A/T.

2. Reinstall any part removed.

+Always use new sealing parts.

Rear Oil Seal Replacement

1. Remove transfer case from vehicle. Refer to TF section

(ªRemovalº, ªREMOVAL AND INSTALLATIONº).

2. Remove rear oil seal.

3. Install rear oil seal.

+Apply ATF before installing.

4. Reinstall any part removed.

Parking Pawl Components Inspection

1. Remove front and rear propeller shafts. Refer to PD section

(ªRemovalº, ªPROPELLER SHAFTº).

2. Remove transfer case from vehicle. Refer to TF section

(ªRemovalº, ªREMOVAL AND INSTALLATIONº).

3. Remove select rod.

4. Support A/T assembly with a jack.

5. Remove rear engine mounting member from body. Refer to

EM section (ªENGINE REMOVALº).

6. Remove adapter case from transmission case.

7. Replace parking pawl components if necessary.

8. Reinstall any part removed.

+Always use new sealing parts.

PNP Switch Adjustment

1. Remove manual control linkage from manual shaft of A/T

assembly.

2. Set manual shaft of A/T assembly in ªNº position.

3. Loosen PNP switch fixing bolts.

4. Insert pin into adjustment holes in both PNP switch and

manual shaft of A/T assembly as near vertical as possible.

5. Reinstall any part removed.

6. Check continuity of PNP switch. Refer to AT-1095.

SAT261J

SAT035EB

SAT262J

SAT228B

SAT081B

ON-VEHICLE SERVICE

AT-1125

Page 129 of 1033

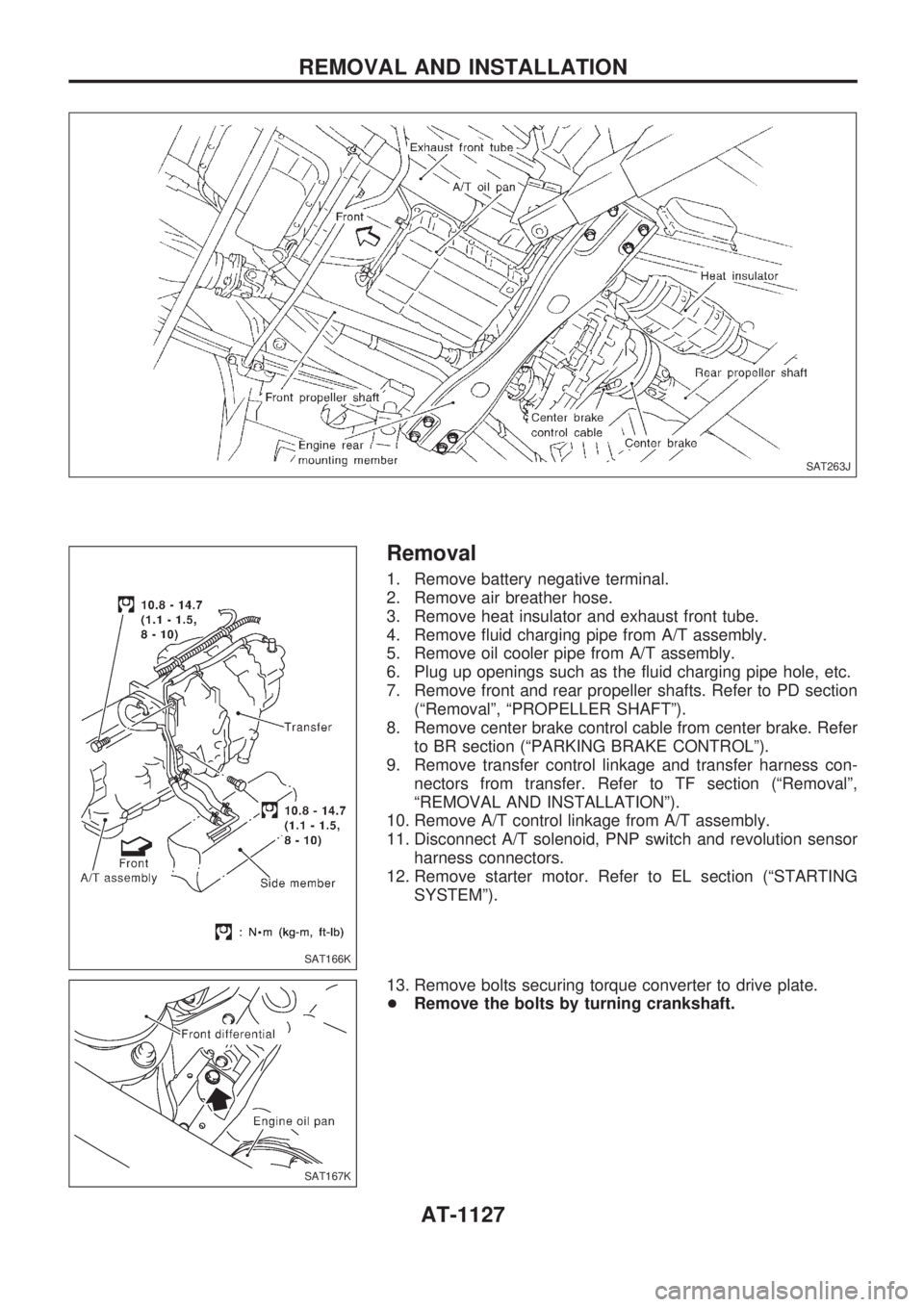

Removal

1. Remove battery negative terminal.

2. Remove air breather hose.

3. Remove heat insulator and exhaust front tube.

4. Remove fluid charging pipe from A/T assembly.

5. Remove oil cooler pipe from A/T assembly.

6. Plug up openings such as the fluid charging pipe hole, etc.

7. Remove front and rear propeller shafts. Refer to PD section

(ªRemovalº, ªPROPELLER SHAFTº).

8. Remove center brake control cable from center brake. Refer

to BR section (ªPARKING BRAKE CONTROLº).

9. Remove transfer control linkage and transfer harness con-

nectors from transfer. Refer to TF section (ªRemovalº,

ªREMOVAL AND INSTALLATIONº).

10. Remove A/T control linkage from A/T assembly.

11. Disconnect A/T solenoid, PNP switch and revolution sensor

harness connectors.

12. Remove starter motor. Refer to EL section (ªSTARTING

SYSTEMº).

13. Remove bolts securing torque converter to drive plate.

+Remove the bolts by turning crankshaft.

SAT263J

SAT166K

SAT167K

REMOVAL AND INSTALLATION

AT-1127

Page 136 of 1033

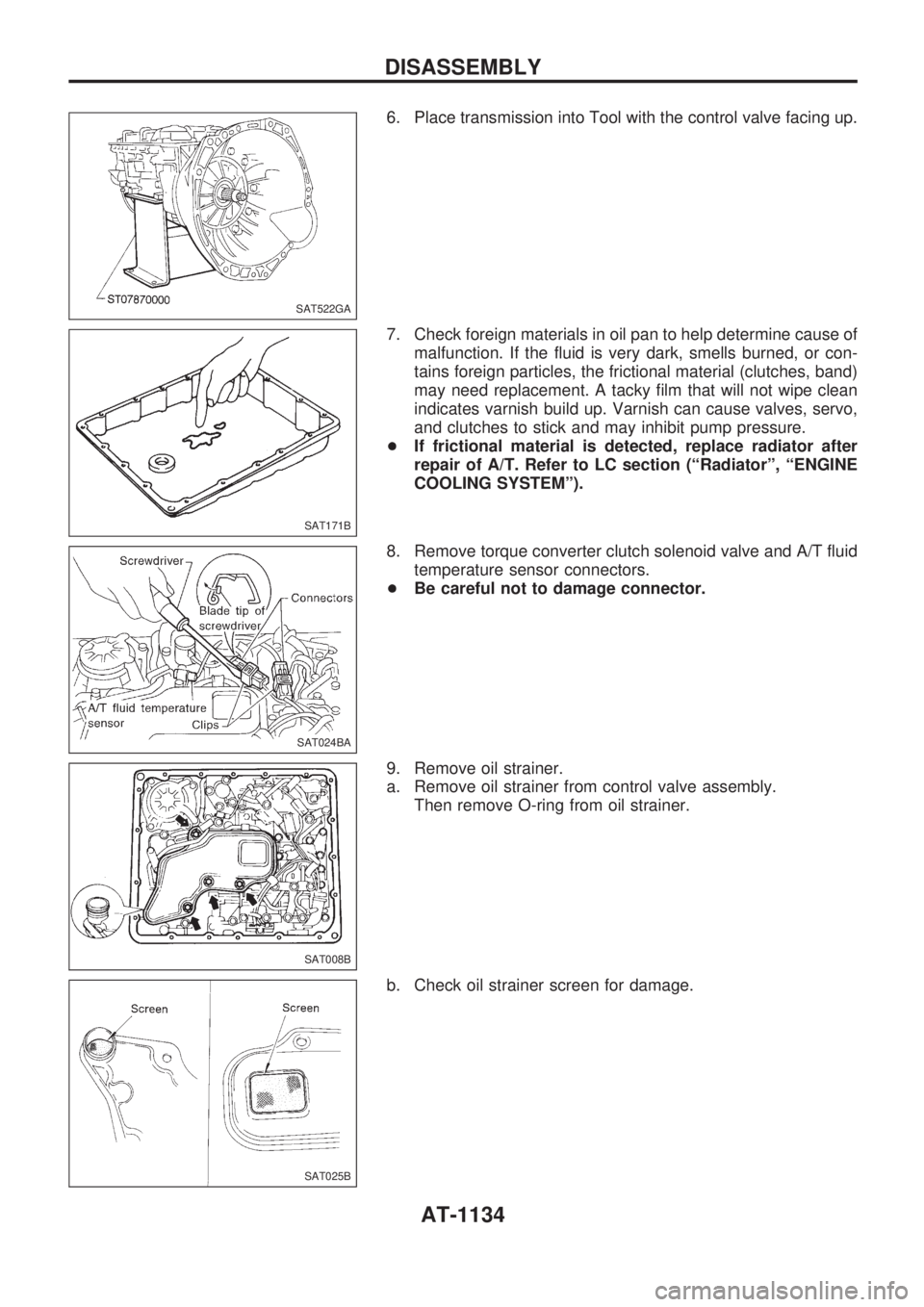

6. Place transmission into Tool with the control valve facing up.

7. Check foreign materials in oil pan to help determine cause of

malfunction. If the fluid is very dark, smells burned, or con-

tains foreign particles, the frictional material (clutches, band)

may need replacement. A tacky film that will not wipe clean

indicates varnish build up. Varnish can cause valves, servo,

and clutches to stick and may inhibit pump pressure.

+If frictional material is detected, replace radiator after

repair of A/T. Refer to LC section (ªRadiatorº, ªENGINE

COOLING SYSTEMº).

8. Remove torque converter clutch solenoid valve and A/T fluid

temperature sensor connectors.

+Be careful not to damage connector.

9. Remove oil strainer.

a. Remove oil strainer from control valve assembly.

Then remove O-ring from oil strainer.

b. Check oil strainer screen for damage.

SAT522GA

SAT171B

SAT024BA

SAT008B

SAT025B

DISASSEMBLY

AT-1134

Page 141 of 1033

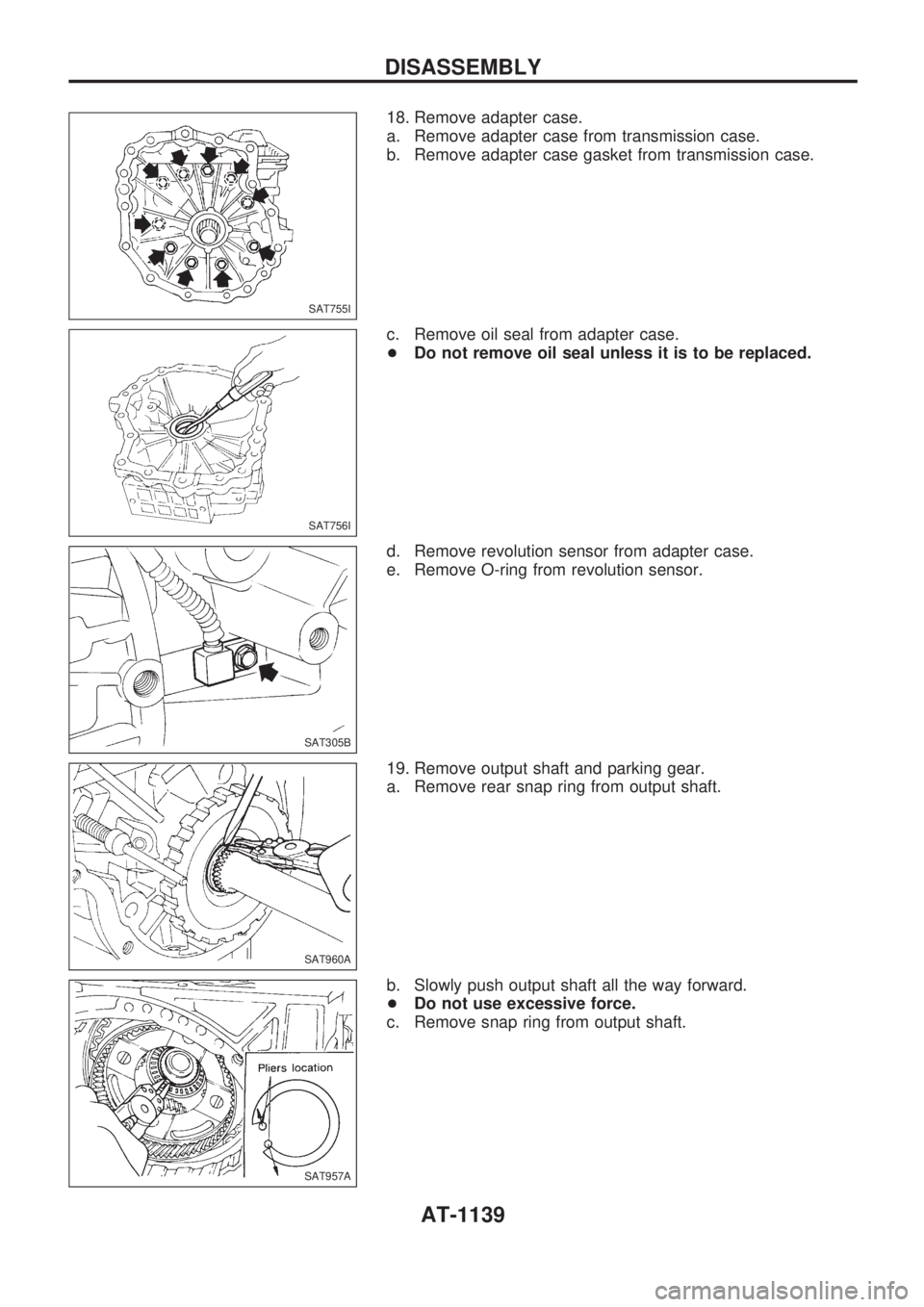

18. Remove adapter case.

a. Remove adapter case from transmission case.

b. Remove adapter case gasket from transmission case.

c. Remove oil seal from adapter case.

+Do not remove oil seal unless it is to be replaced.

d. Remove revolution sensor from adapter case.

e. Remove O-ring from revolution sensor.

19. Remove output shaft and parking gear.

a. Remove rear snap ring from output shaft.

b. Slowly push output shaft all the way forward.

+Do not use excessive force.

c. Remove snap ring from output shaft.

SAT755I

SAT756I

SAT305B

SAT960A

SAT957A

DISASSEMBLY

AT-1139

Page 153 of 1033

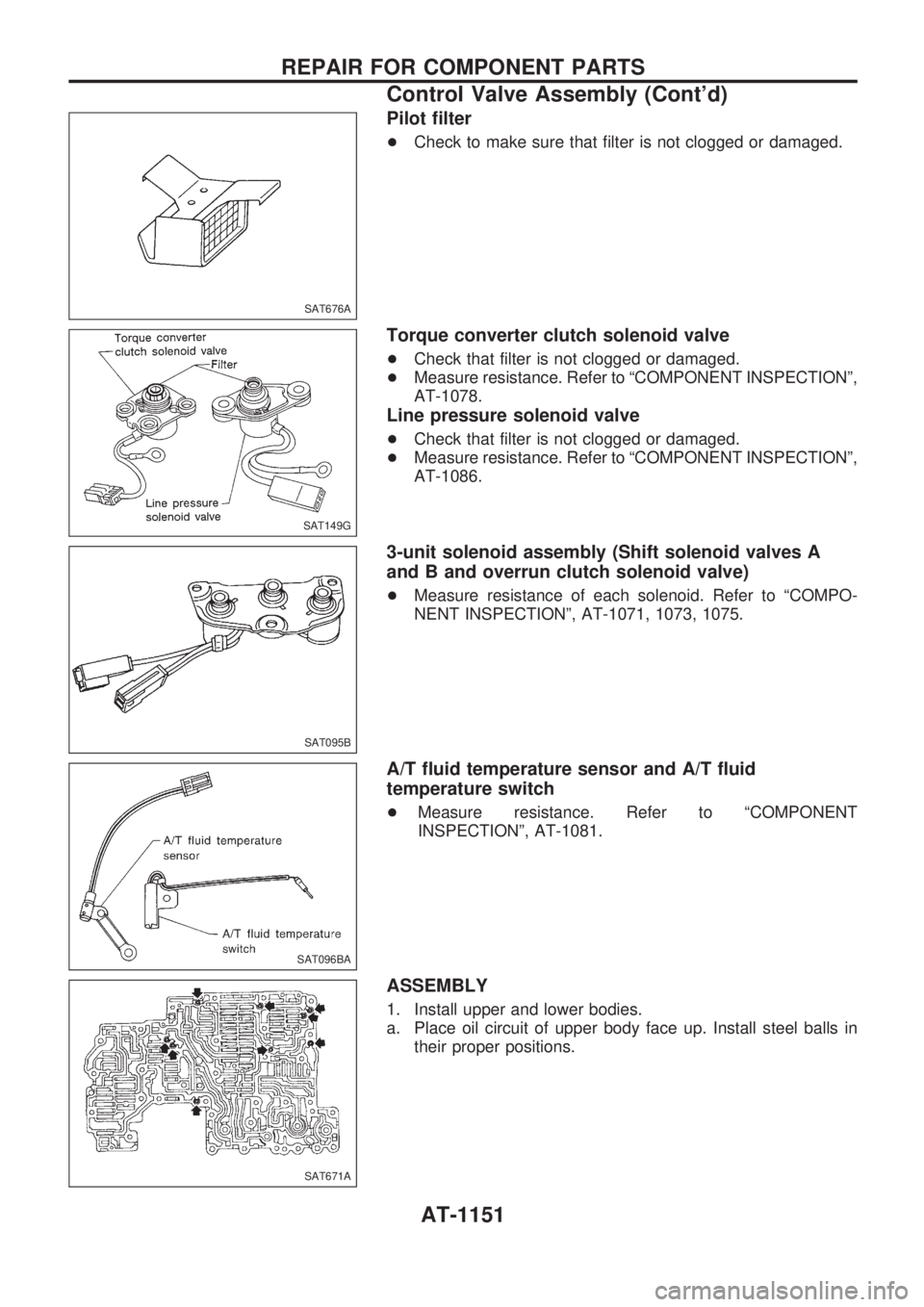

Pilot filter

+Check to make sure that filter is not clogged or damaged.

Torque converter clutch solenoid valve

+Check that filter is not clogged or damaged.

+Measure resistance. Refer to ªCOMPONENT INSPECTIONº,

AT-1078.

Line pressure solenoid valve

+Check that filter is not clogged or damaged.

+Measure resistance. Refer to ªCOMPONENT INSPECTIONº,

AT-1086.

3-unit solenoid assembly (Shift solenoid valves A

and B and overrun clutch solenoid valve)

+Measure resistance of each solenoid. Refer to ªCOMPO-

NENT INSPECTIONº, AT-1071, 1073, 1075.

A/T fluid temperature sensor and A/T fluid

temperature switch

+Measure resistance. Refer to ªCOMPONENT

INSPECTIONº, AT-1081.

ASSEMBLY

1. Install upper and lower bodies.

a. Place oil circuit of upper body face up. Install steel balls in

their proper positions.

SAT676A

SAT149G

SAT095B

SAT096BA

SAT671A

REPAIR FOR COMPONENT PARTS

Control Valve Assembly (Cont'd)

AT-1151

Page 154 of 1033

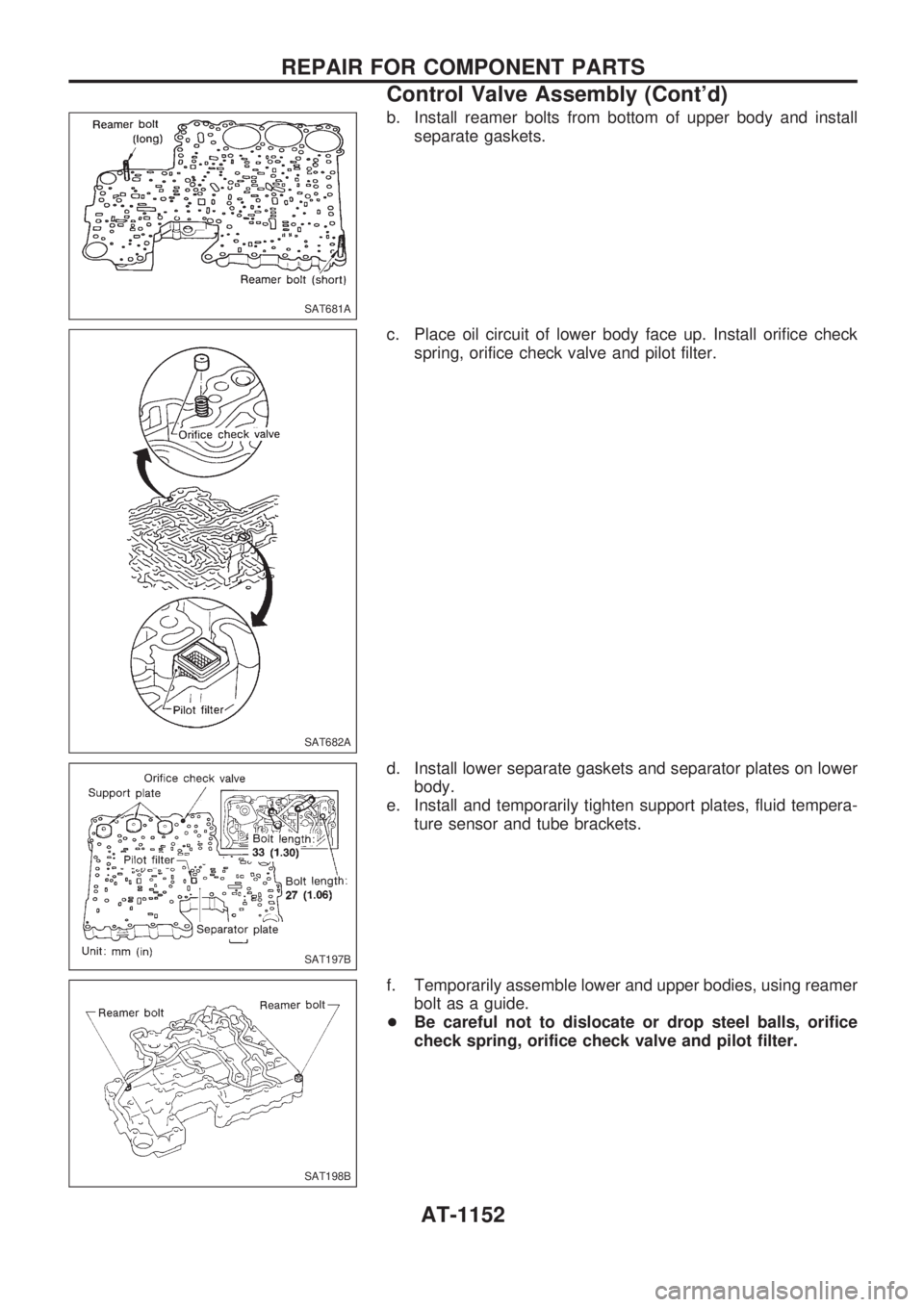

b. Install reamer bolts from bottom of upper body and install

separate gaskets.

c. Place oil circuit of lower body face up. Install orifice check

spring, orifice check valve and pilot filter.

d. Install lower separate gaskets and separator plates on lower

body.

e. Install and temporarily tighten support plates, fluid tempera-

ture sensor and tube brackets.

f. Temporarily assemble lower and upper bodies, using reamer

bolt as a guide.

+Be careful not to dislocate or drop steel balls, orifice

check spring, orifice check valve and pilot filter.

SAT681A

SAT682A

SAT197B

SAT198B

REPAIR FOR COMPONENT PARTS

Control Valve Assembly (Cont'd)

AT-1152