sensor NISSAN PATROL 2000 Electronic Owner's Guide

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2000, Model line: PATROL, Model: NISSAN PATROL 2000Pages: 1033, PDF Size: 30.71 MB

Page 82 of 1033

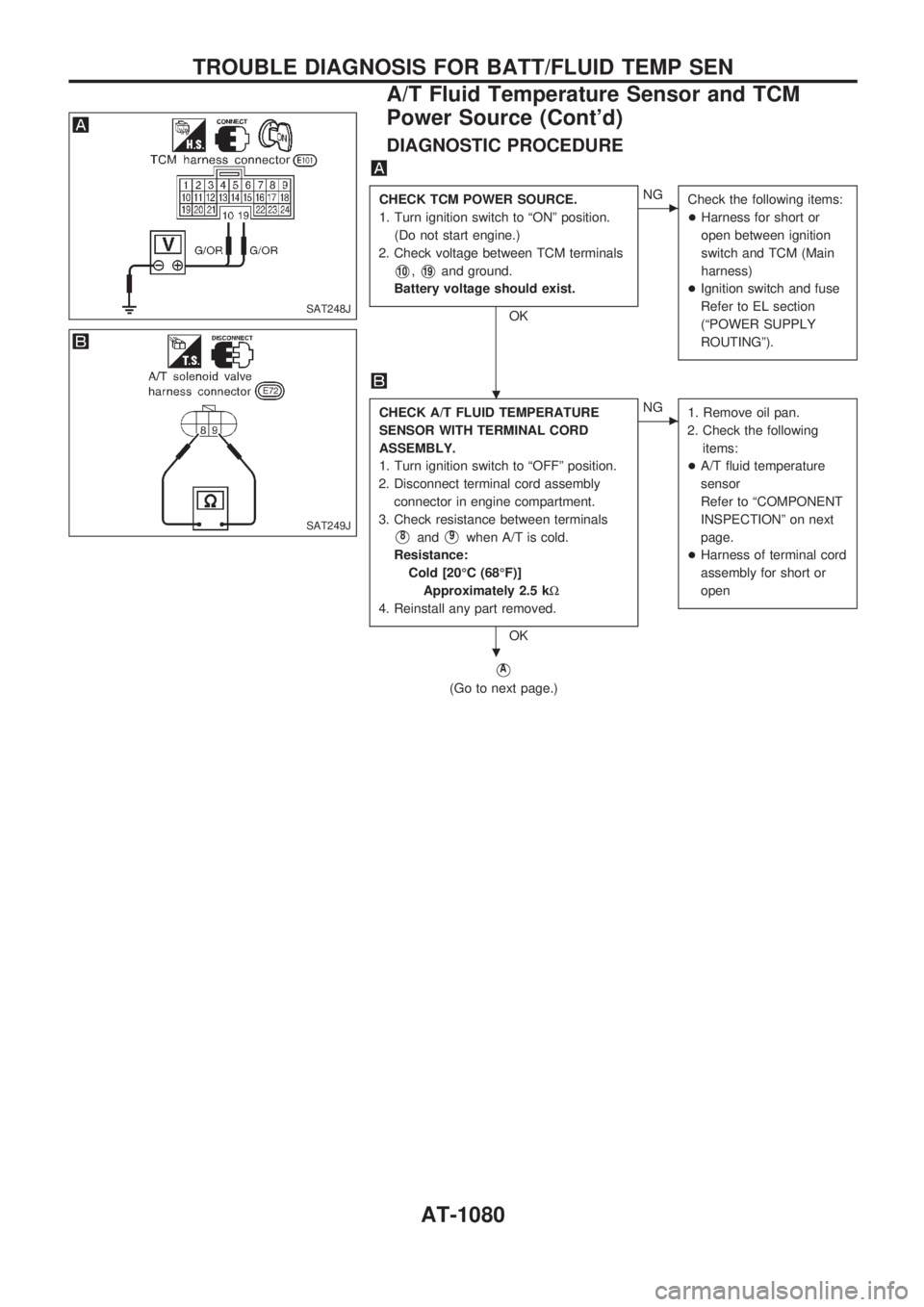

DIAGNOSTIC PROCEDURE

CHECK TCM POWER SOURCE.

1. Turn ignition switch to ªONº position.

(Do not start engine.)

2. Check voltage between TCM terminals

V10,V19and ground.

Battery voltage should exist.

OK

cNG

Check the following items:

+Harness for short or

open between ignition

switch and TCM (Main

harness)

+Ignition switch and fuse

Refer to EL section

(ªPOWER SUPPLY

ROUTINGº).

CHECK A/T FLUID TEMPERATURE

SENSOR WITH TERMINAL CORD

ASSEMBLY.

1. Turn ignition switch to ªOFFº position.

2. Disconnect terminal cord assembly

connector in engine compartment.

3. Check resistance between terminals

V8andV9when A/T is cold.

Resistance:

Cold [20ÉC (68ÉF)]

Approximately 2.5 kW

4. Reinstall any part removed.

OK

cNG

1. Remove oil pan.

2. Check the following

items:

+A/T fluid temperature

sensor

Refer to ªCOMPONENT

INSPECTIONº on next

page.

+Harness of terminal cord

assembly for short or

open

VA

(Go to next page.)

SAT248J

SAT249J

.

.

TROUBLE DIAGNOSIS FOR BATT/FLUID TEMP SEN

A/T Fluid Temperature Sensor and TCM

Power Source (Cont'd)

AT-1080

Page 83 of 1033

![NISSAN PATROL 2000 Electronic Owners Guide VA

CHECK INPUT SIGNAL OF A/T FLUID

TEMPERATURE SENSOR.

1. Start engine.

2. Select ªTCM INPUT SIGNALSº

in Data Monitor.

3. Read out the value of ªFLUID

TEMP SEº.

Voltage:

Cold [20ÉC (68ÉF)]®

Hot NISSAN PATROL 2000 Electronic Owners Guide VA

CHECK INPUT SIGNAL OF A/T FLUID

TEMPERATURE SENSOR.

1. Start engine.

2. Select ªTCM INPUT SIGNALSº

in Data Monitor.

3. Read out the value of ªFLUID

TEMP SEº.

Voltage:

Cold [20ÉC (68ÉF)]®

Hot](/img/5/57367/w960_57367-82.png)

VA

CHECK INPUT SIGNAL OF A/T FLUID

TEMPERATURE SENSOR.

1. Start engine.

2. Select ªTCM INPUT SIGNALSº

in Data Monitor.

3. Read out the value of ªFLUID

TEMP SEº.

Voltage:

Cold [20ÉC (68ÉF)]®

Hot [80ÉC (176ÉF)]:

Approximately

1.5V®0.5V

------------------------------------------------------------------------------------------------------------------------------------OR------------------------------------------------------------------------------------------------------------------------------------

1. Start engine.

2. Check voltage between TCM

terminal

V47and ground while

warming up A/T.

Voltage:

Cold [20ÉC (68ÉF)]®

Hot [80ÉC (176ÉF)]:

Approximately

1.5V®0.5V

OK

cNG

Check the following item:

+Harness for short or

open between TCM and

terminal cord assembly

(Main harness)

Perform ªSELF-DIAGNOSIS CODE CON-

FIRMATION PROCEDUREº, AT-1079.

OK

cNG

1. Perform TCM input/

output signal inspection.

2. If NG, recheck TCM pin

terminals for damage or

loose connection with

harness connector.

INSPECTION END

COMPONENT INSPECTION

A/T fluid temperature sensor

+For removal, refer to AT-1124.

+Check resistance between terminals

V8andV9while chang-

ing temperature as shown at left.

Temperature ÉC (ÉF) Resistance

20 (68) Approximately 2.5 kW

80 (176) Approximately 0.3 kW

SAT738J

SAT250J

SAT252J

.

.

.

TROUBLE DIAGNOSIS FOR BATT/FLUID TEMP SEN

A/T Fluid Temperature Sensor and TCM

Power Source (Cont'd)

AT-1081

Page 84 of 1033

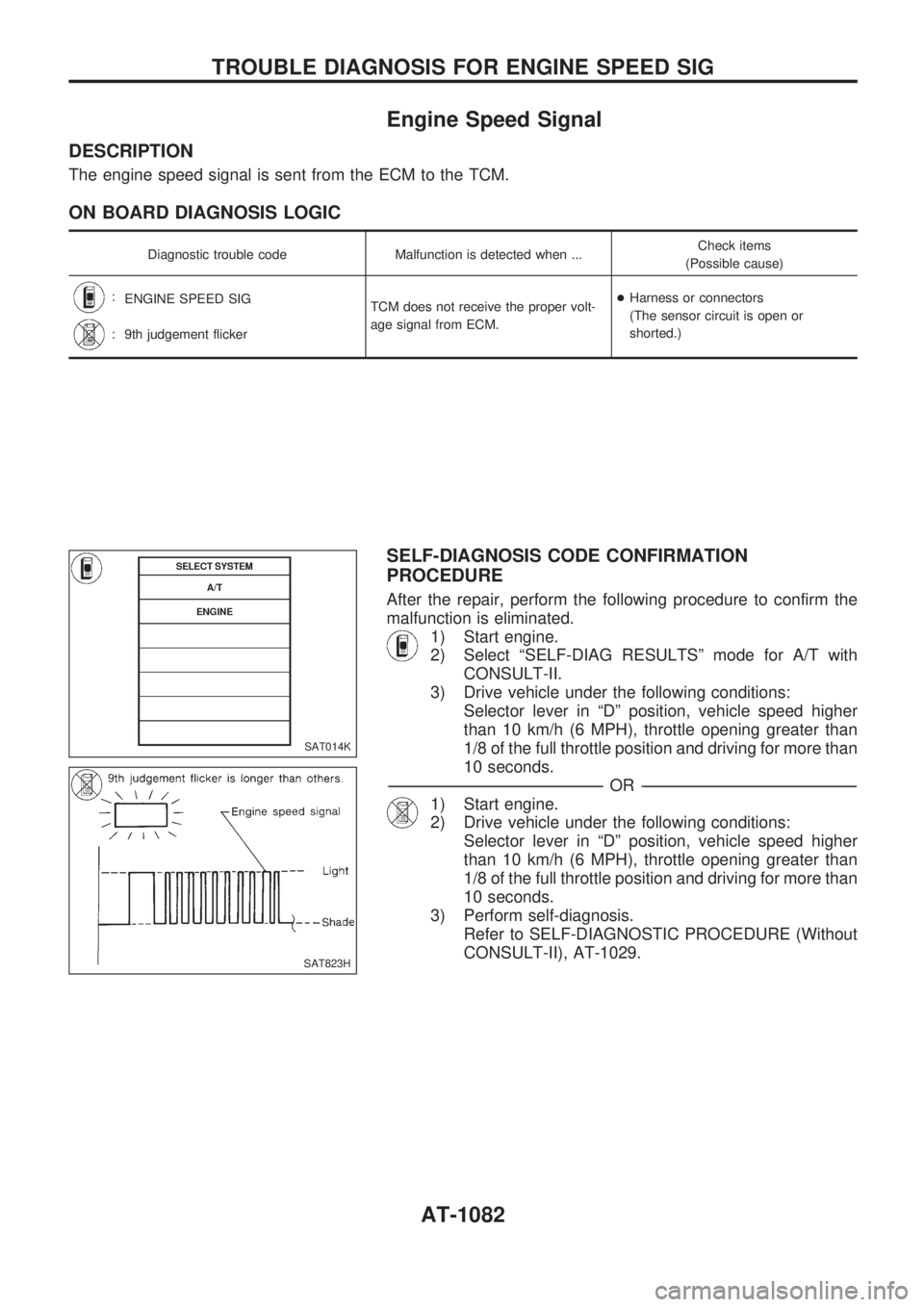

Engine Speed Signal

DESCRIPTION

The engine speed signal is sent from the ECM to the TCM.

ON BOARD DIAGNOSIS LOGIC

Diagnostic trouble code Malfunction is detected when ...Check items

(Possible cause)

:

ENGINE SPEED SIG

TCM does not receive the proper volt-

age signal from ECM.+Harness or connectors

(The sensor circuit is open or

shorted.)

:

9th judgement flicker

SELF-DIAGNOSIS CODE CONFIRMATION

PROCEDURE

After the repair, perform the following procedure to confirm the

malfunction is eliminated.

1) Start engine.

2) Select ªSELF-DIAG RESULTSº mode for A/T with

CONSULT-II.

3) Drive vehicle under the following conditions:

Selector lever in ªDº position, vehicle speed higher

than 10 km/h (6 MPH), throttle opening greater than

1/8 of the full throttle position and driving for more than

10 seconds.

-------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------OR-------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------

1) Start engine.

2) Drive vehicle under the following conditions:

Selector lever in ªDº position, vehicle speed higher

than 10 km/h (6 MPH), throttle opening greater than

1/8 of the full throttle position and driving for more than

10 seconds.

3) Perform self-diagnosis.

Refer to SELF-DIAGNOSTIC PROCEDURE (Without

CONSULT-II), AT-1029.

SAT014K

SAT823H

TROUBLE DIAGNOSIS FOR ENGINE SPEED SIG

AT-1082

Page 101 of 1033

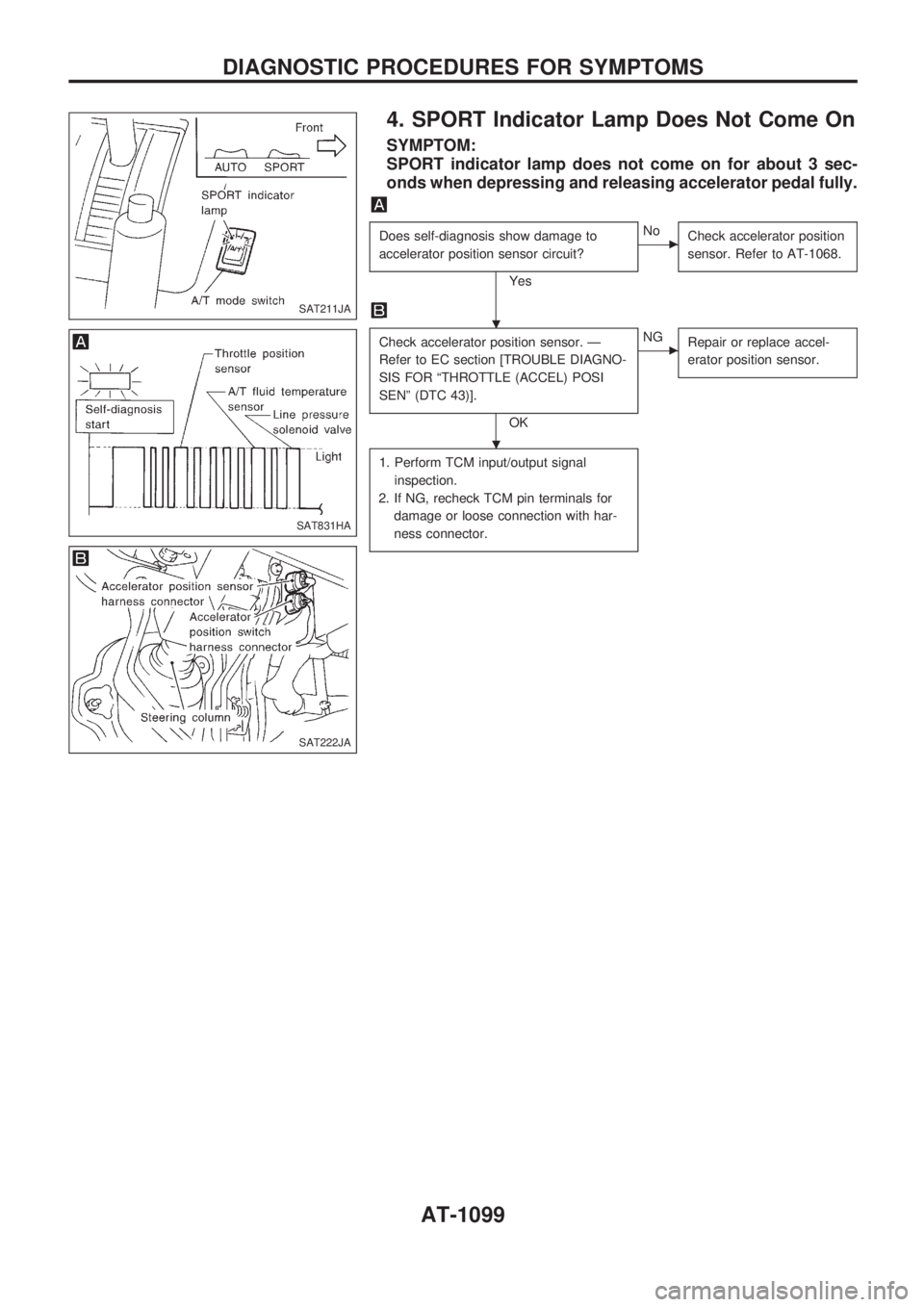

4. SPORT Indicator Lamp Does Not Come On

SYMPTOM:

SPORT indicator lamp does not come on for about 3 sec-

onds when depressing and releasing accelerator pedal fully.

Does self-diagnosis show damage to

accelerator position sensor circuit?

Yes

cNo

Check accelerator position

sensor. Refer to AT-1068.

Check accelerator position sensor. Ð

Refer to EC section [TROUBLE DIAGNO-

SIS FOR ªTHROTTLE (ACCEL) POSI

SENº (DTC 43)].

OK

cNG

Repair or replace accel-

erator position sensor.

1. Perform TCM input/output signal

inspection.

2. If NG, recheck TCM pin terminals for

damage or loose connection with har-

ness connector.

SAT211JA

SAT831HA

SAT222JA

.

.

DIAGNOSTIC PROCEDURES FOR SYMPTOMS

AT-1099

Page 104 of 1033

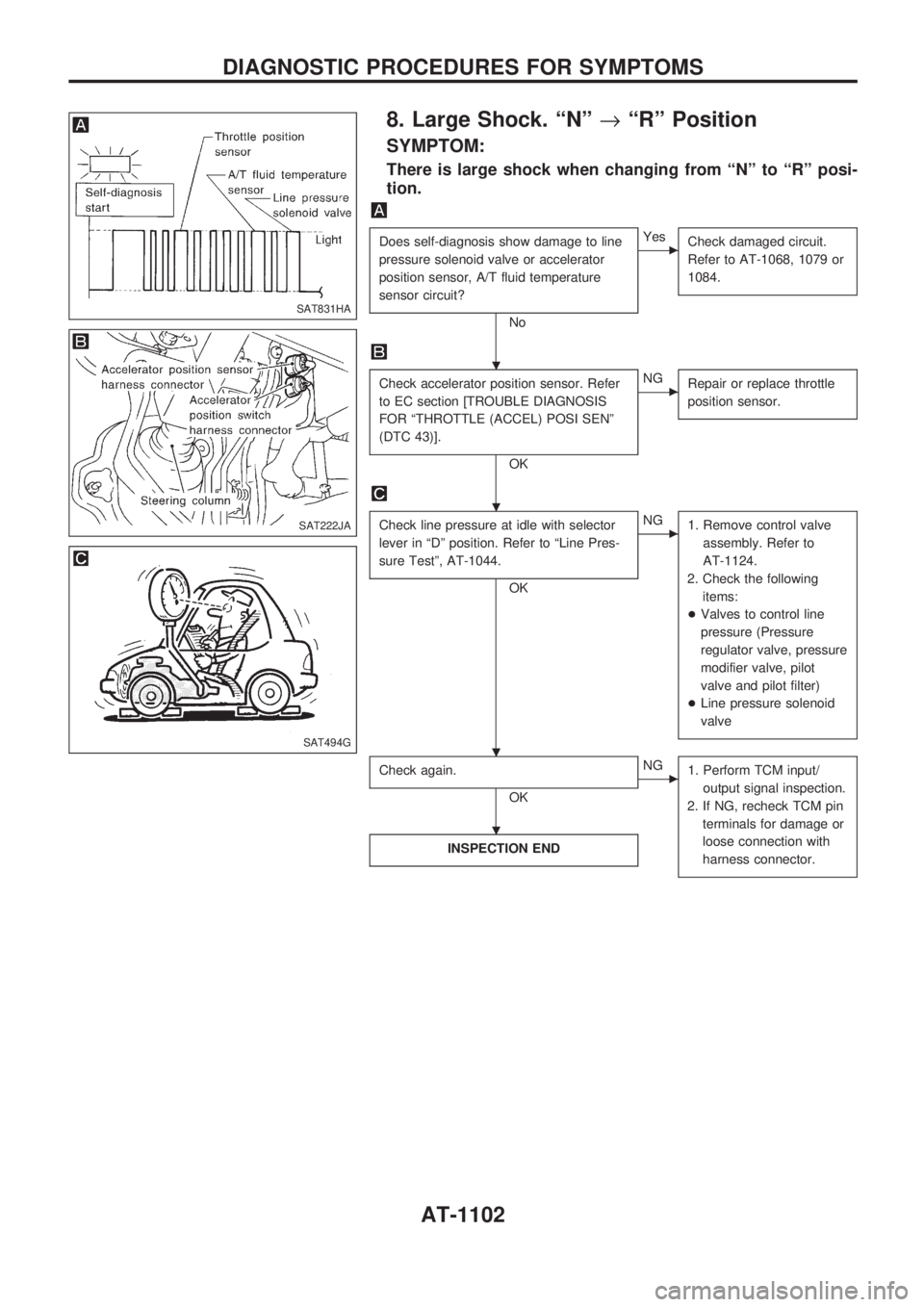

8. Large Shock. ªNº®ªRº Position

SYMPTOM:

There is large shock when changing from ªNº to ªRº posi-

tion.

Does self-diagnosis show damage to line

pressure solenoid valve or accelerator

position sensor, A/T fluid temperature

sensor circuit?

No

cYes

Check damaged circuit.

Refer to AT-1068, 1079 or

1084.

Check accelerator position sensor. Refer

to EC section [TROUBLE DIAGNOSIS

FOR ªTHROTTLE (ACCEL) POSI SENº

(DTC 43)].

OK

cNG

Repair or replace throttle

position sensor.

Check line pressure at idle with selector

lever in ªDº position. Refer to ªLine Pres-

sure Testº, AT-1044.

OK

cNG

1. Remove control valve

assembly. Refer to

AT-1124.

2. Check the following

items:

+Valves to control line

pressure (Pressure

regulator valve, pressure

modifier valve, pilot

valve and pilot filter)

+Line pressure solenoid

valve

Check again.

OK

cNG

1. Perform TCM input/

output signal inspection.

2. If NG, recheck TCM pin

terminals for damage or

loose connection with

harness connector.

INSPECTION END

SAT831HA

SAT222JA

SAT494G

.

.

. .

.

DIAGNOSTIC PROCEDURES FOR SYMPTOMS

AT-1102

Page 107 of 1033

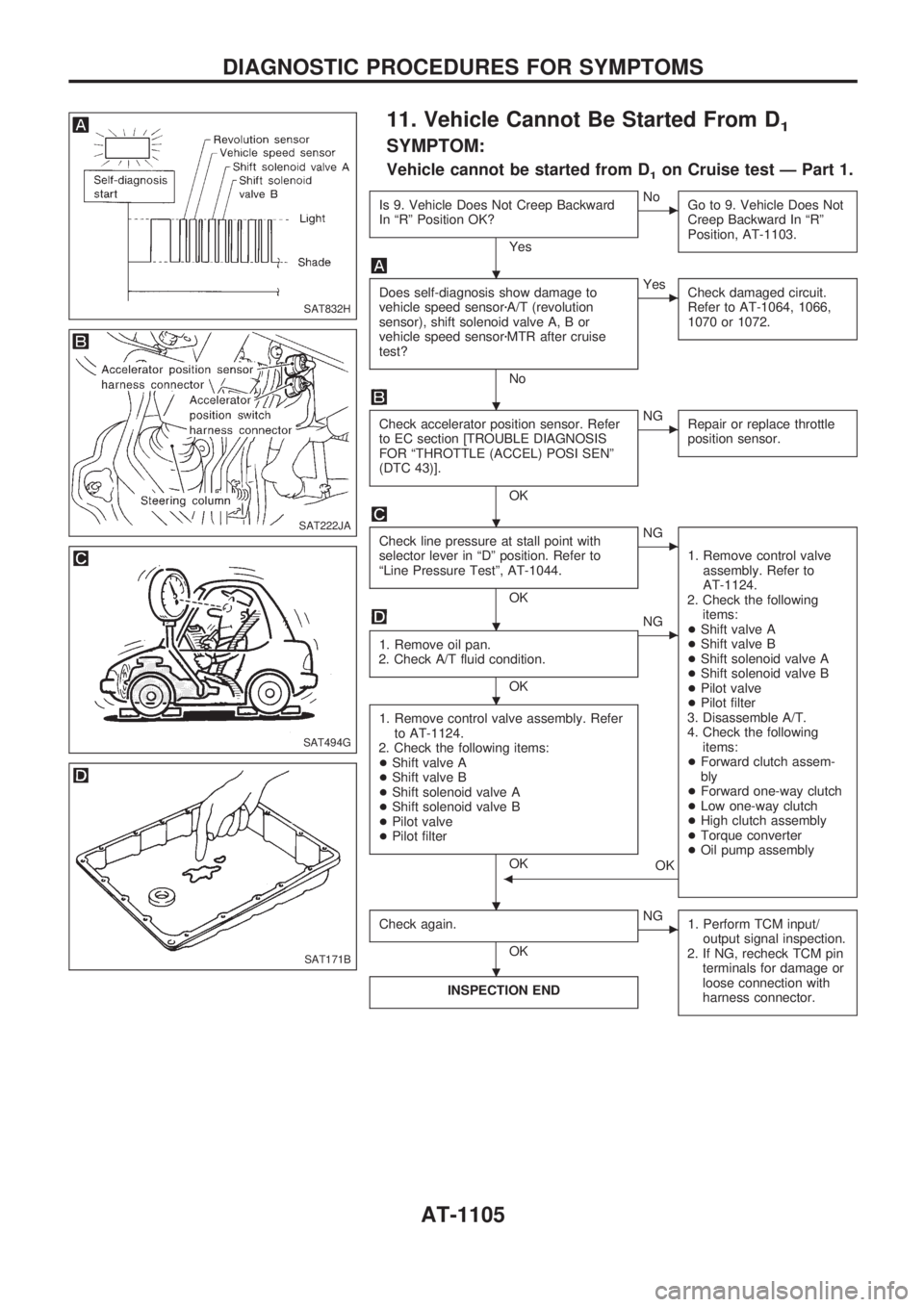

11. Vehicle Cannot Be Started From D1

SYMPTOM:

Vehicle cannot be started from D1on Cruise test Ð Part 1.

Is 9. Vehicle Does Not Creep Backward

In ªRº Position OK?

Yes

cNo

Go to 9. Vehicle Does Not

Creep Backward In ªRº

Position, AT-1103.

Does self-diagnosis show damage to

vehicle speed sensorzA/T (revolution

sensor), shift solenoid valve A, B or

vehicle speed sensorzMTR after cruise

test?

No

cYes

Check damaged circuit.

Refer to AT-1064, 1066,

1070 or 1072.

Check accelerator position sensor. Refer

to EC section [TROUBLE DIAGNOSIS

FOR ªTHROTTLE (ACCEL) POSI SENº

(DTC 43)].

OK

cNG

Repair or replace throttle

position sensor.

Check line pressure at stall point with

selector lever in ªDº position. Refer to

ªLine Pressure Testº, AT-1044.

OK

cNG

1. Remove control valve

assembly. Refer to

AT-1124.

2. Check the following

items:

+Shift valve A

+Shift valve B

+Shift solenoid valve A

+Shift solenoid valve B

+Pilot valve

+Pilot filter

3. Disassemble A/T.

4. Check the following

items:

+Forward clutch assem-

bly

+Forward one-way clutch

+Low one-way clutch

+High clutch assembly

+Torque converter

+Oil pump assembly

1. Remove oil pan.

2. Check A/T fluid condition.

OK

cNG

1. Remove control valve assembly. Refer

to AT-1124.

2. Check the following items:

+Shift valve A

+Shift valve B

+Shift solenoid valve A

+Shift solenoid valve B

+Pilot valve

+Pilot filter

OK

OKb

Check again.

OK

cNG

1. Perform TCM input/

output signal inspection.

2. If NG, recheck TCM pin

terminals for damage or

loose connection with

harness connector.

INSPECTION END

SAT832H

SAT222JA

SAT494G

SAT171B

.

.

.

.

.

. .

.

DIAGNOSTIC PROCEDURES FOR SYMPTOMS

AT-1105

Page 108 of 1033

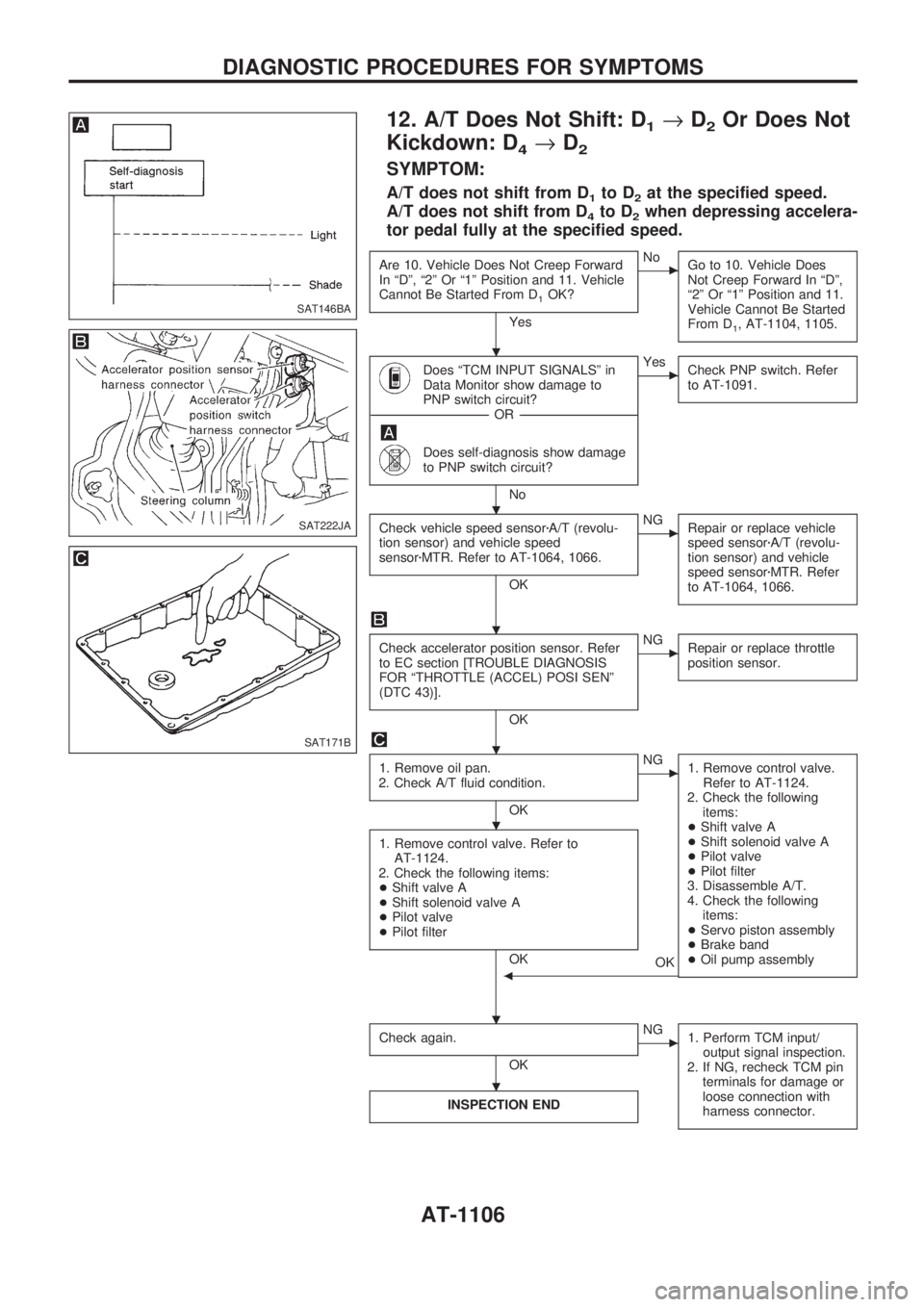

12. A/T Does Not Shift: D1®D2Or Does Not

Kickdown: D

4®D2

SYMPTOM:

A/T does not shift from D1to D2at the specified speed.

A/T does not shift from D

4to D2when depressing accelera-

tor pedal fully at the specified speed.

Are 10. Vehicle Does Not Creep Forward

In ªDº, ª2º Or ª1º Position and 11. Vehicle

Cannot Be Started From D

1OK?

Yes

cNo

Go to 10. Vehicle Does

Not Creep Forward In ªDº,

ª2º Or ª1º Position and 11.

Vehicle Cannot Be Started

From D

1, AT-1104, 1105.

Does ªTCM INPUT SIGNALSº in

Data Monitor show damage to

PNP switch circuit?

------------------------------------------------------------------------------------------------------------------------------------OR------------------------------------------------------------------------------------------------------------------------------------

Does self-diagnosis show damage

to PNP switch circuit?

No

cYes

Check PNP switch. Refer

to AT-1091.

Check vehicle speed sensorzA/T (revolu-

tion sensor) and vehicle speed

sensorzMTR. Refer to AT-1064, 1066.

OK

cNG

Repair or replace vehicle

speed sensorzA/T (revolu-

tion sensor) and vehicle

speed sensorzMTR. Refer

to AT-1064, 1066.

Check accelerator position sensor. Refer

to EC section [TROUBLE DIAGNOSIS

FOR ªTHROTTLE (ACCEL) POSI SENº

(DTC 43)].

OK

cNG

Repair or replace throttle

position sensor.

1. Remove oil pan.

2. Check A/T fluid condition.

OK

cNG

1. Remove control valve.

Refer to AT-1124.

2. Check the following

items:

+Shift valve A

+Shift solenoid valve A

+Pilot valve

+Pilot filter

3. Disassemble A/T.

4. Check the following

items:

+Servo piston assembly

+Brake band

+Oil pump assembly

1. Remove control valve. Refer to

AT-1124.

2. Check the following items:

+Shift valve A

+Shift solenoid valve A

+Pilot valve

+Pilot filter

OK

OK

b

Check again.

OK

cNG

1. Perform TCM input/

output signal inspection.

2. If NG, recheck TCM pin

terminals for damage or

loose connection with

harness connector.

INSPECTION END

SAT146BA

SAT222JA

SAT171B

.

.

.

.

.

. .

.

DIAGNOSTIC PROCEDURES FOR SYMPTOMS

AT-1106

Page 109 of 1033

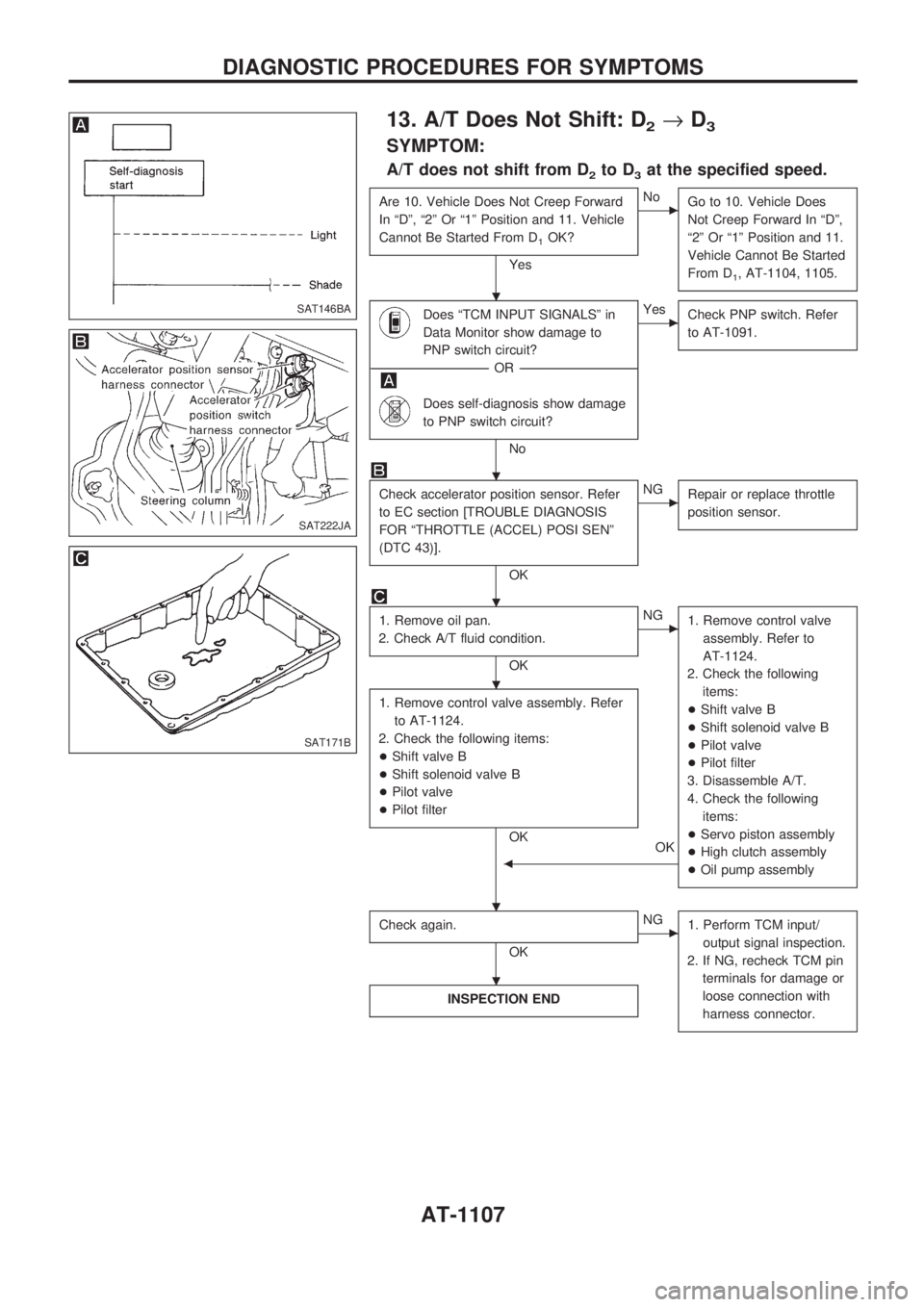

13. A/T Does Not Shift: D2®D3

SYMPTOM:

A/T does not shift from D2to D3at the specified speed.

Are 10. Vehicle Does Not Creep Forward

In ªDº, ª2º Or ª1º Position and 11. Vehicle

Cannot Be Started From D

1OK?

Yes

cNo

Go to 10. Vehicle Does

Not Creep Forward In ªDº,

ª2º Or ª1º Position and 11.

Vehicle Cannot Be Started

From D

1, AT-1104, 1105.

Does ªTCM INPUT SIGNALSº in

Data Monitor show damage to

PNP switch circuit?

------------------------------------------------------------------------------------------------------------------------------------OR------------------------------------------------------------------------------------------------------------------------------------

Does self-diagnosis show damage

to PNP switch circuit?

No

cYes

Check PNP switch. Refer

to AT-1091.

Check accelerator position sensor. Refer

to EC section [TROUBLE DIAGNOSIS

FOR ªTHROTTLE (ACCEL) POSI SENº

(DTC 43)].

OK

cNG

Repair or replace throttle

position sensor.

1. Remove oil pan.

2. Check A/T fluid condition.

OK

cNG

1. Remove control valve

assembly. Refer to

AT-1124.

2. Check the following

items:

+Shift valve B

+Shift solenoid valve B

+Pilot valve

+Pilot filter

3. Disassemble A/T.

4. Check the following

items:

+Servo piston assembly

+High clutch assembly

+Oil pump assembly

1. Remove control valve assembly. Refer

to AT-1124.

2. Check the following items:

+Shift valve B

+Shift solenoid valve B

+Pilot valve

+Pilot filter

OK

OK

b

Check again.

OK

cNG

1. Perform TCM input/

output signal inspection.

2. If NG, recheck TCM pin

terminals for damage or

loose connection with

harness connector.

INSPECTION END

SAT146BA

SAT222JA

SAT171B

.

.

.

.

. .

.

DIAGNOSTIC PROCEDURES FOR SYMPTOMS

AT-1107

Page 110 of 1033

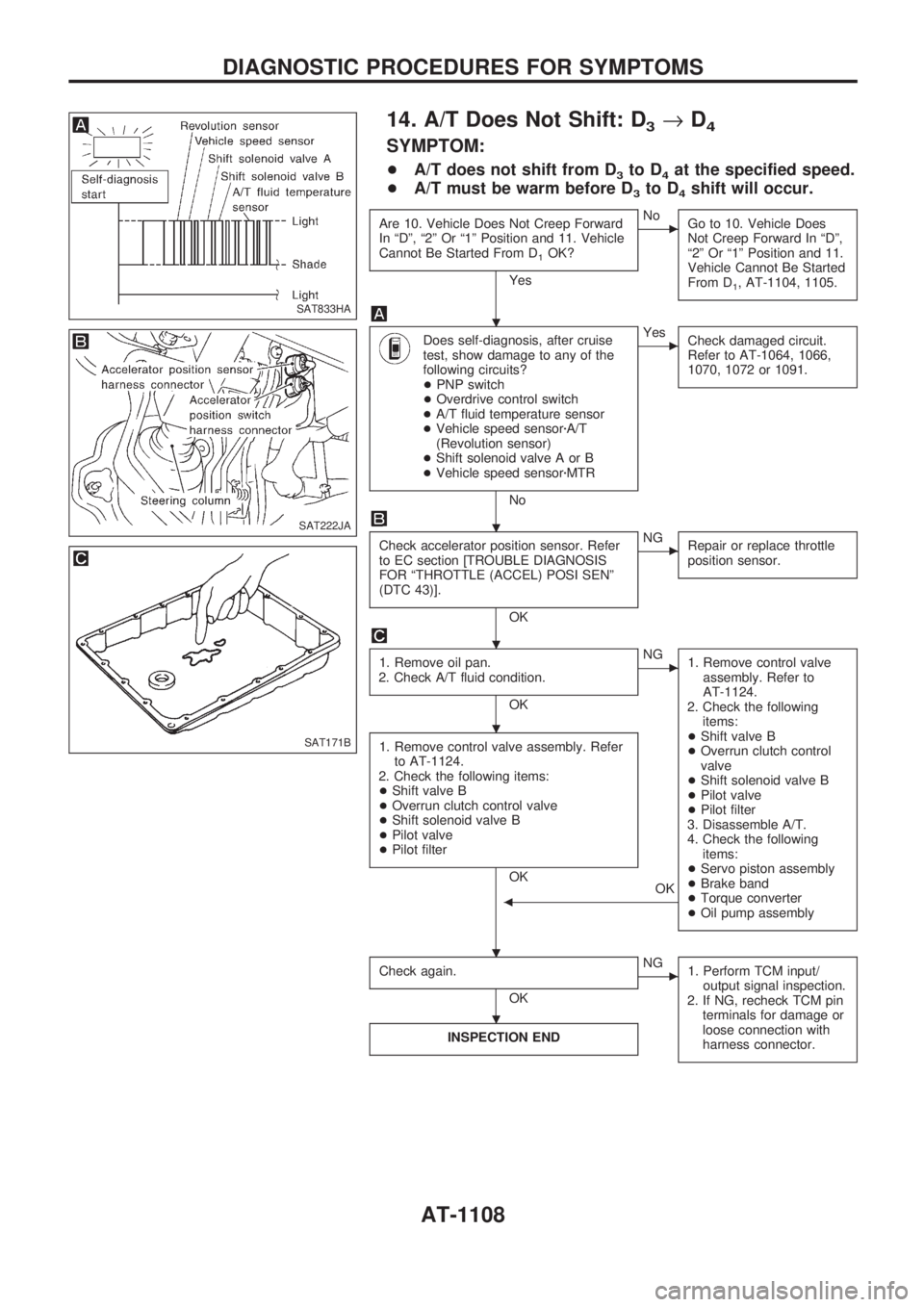

14. A/T Does Not Shift: D3®D4

SYMPTOM:

+A/T does not shift from D3to D4at the specified speed.

+A/T must be warm before D

3to D4shift will occur.

Are 10. Vehicle Does Not Creep Forward

In ªDº, ª2º Or ª1º Position and 11. Vehicle

Cannot Be Started From D

1OK?

Yes

cNo

Go to 10. Vehicle Does

Not Creep Forward In ªDº,

ª2º Or ª1º Position and 11.

Vehicle Cannot Be Started

From D

1, AT-1104, 1105.

Does self-diagnosis, after cruise

test, show damage to any of the

following circuits?

+PNP switch

+Overdrive control switch

+A/T fluid temperature sensor

+Vehicle speed sensorzA/T

(Revolution sensor)

+Shift solenoid valve A or B

+Vehicle speed sensorzMTR

No

cYes

Check damaged circuit.

Refer to AT-1064, 1066,

1070, 1072 or 1091.

Check accelerator position sensor. Refer

to EC section [TROUBLE DIAGNOSIS

FOR ªTHROTTLE (ACCEL) POSI SENº

(DTC 43)].

OK

cNG

Repair or replace throttle

position sensor.

1. Remove oil pan.

2. Check A/T fluid condition.

OK

cNG

1. Remove control valve

assembly. Refer to

AT-1124.

2. Check the following

items:

+Shift valve B

+Overrun clutch control

valve

+Shift solenoid valve B

+Pilot valve

+Pilot filter

3. Disassemble A/T.

4. Check the following

items:

+Servo piston assembly

+Brake band

+Torque converter

+Oil pump assembly

1. Remove control valve assembly. Refer

to AT-1124.

2. Check the following items:

+Shift valve B

+Overrun clutch control valve

+Shift solenoid valve B

+Pilot valve

+Pilot filter

OK

OK

b

Check again.

OK

cNG

1. Perform TCM input/

output signal inspection.

2. If NG, recheck TCM pin

terminals for damage or

loose connection with

harness connector.

INSPECTION END

SAT833HA

SAT222JA

SAT171B

.

.

.

.

. .

.

DIAGNOSTIC PROCEDURES FOR SYMPTOMS

AT-1108

Page 111 of 1033

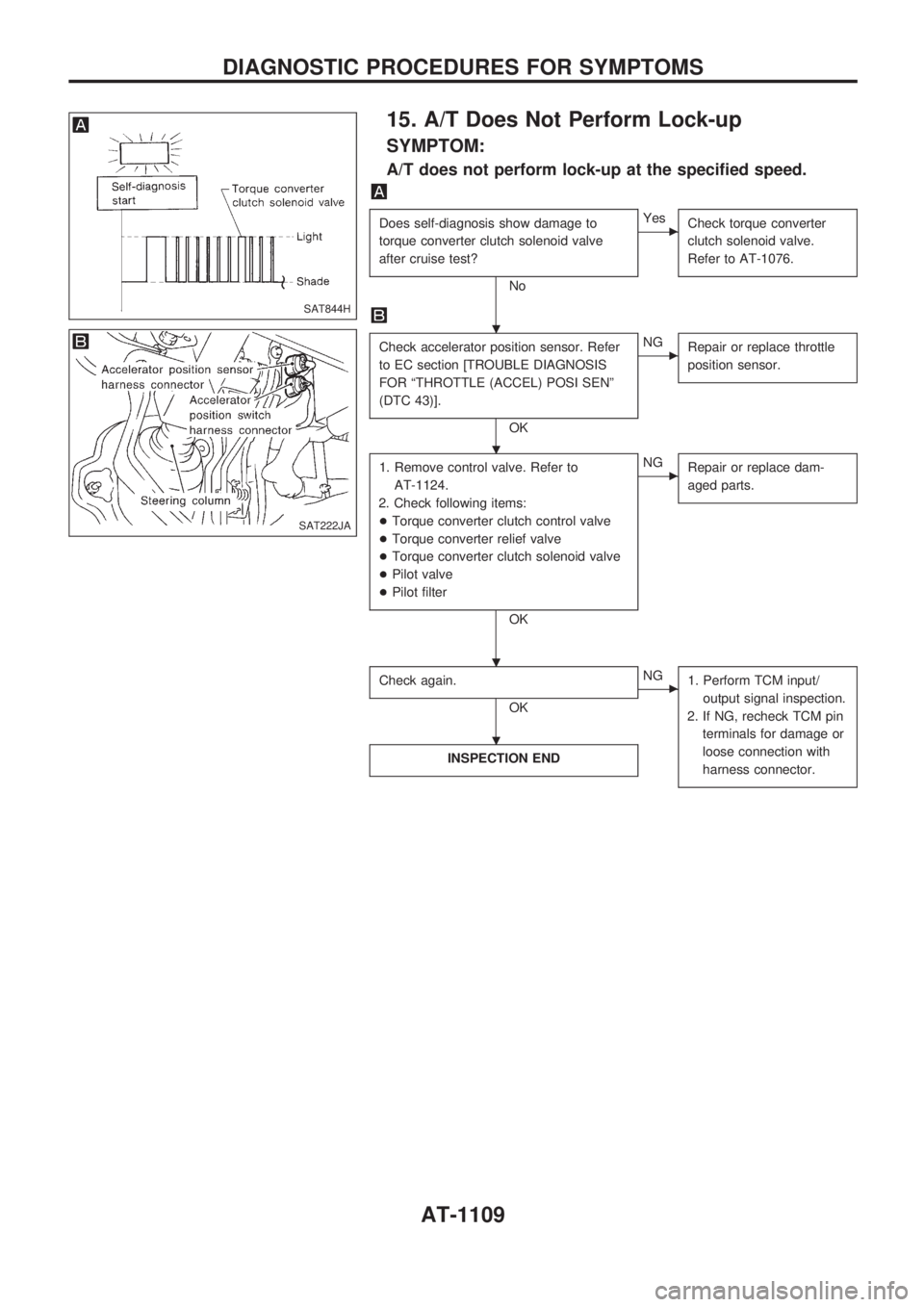

15. A/T Does Not Perform Lock-up

SYMPTOM:

A/T does not perform lock-up at the specified speed.

Does self-diagnosis show damage to

torque converter clutch solenoid valve

after cruise test?

No

cYes

Check torque converter

clutch solenoid valve.

Refer to AT-1076.

Check accelerator position sensor. Refer

to EC section [TROUBLE DIAGNOSIS

FOR ªTHROTTLE (ACCEL) POSI SENº

(DTC 43)].

OK

cNG

Repair or replace throttle

position sensor.

1. Remove control valve. Refer to

AT-1124.

2. Check following items:

+Torque converter clutch control valve

+Torque converter relief valve

+Torque converter clutch solenoid valve

+Pilot valve

+Pilot filter

OK

cNG

Repair or replace dam-

aged parts.

Check again.

OK

cNG

1. Perform TCM input/

output signal inspection.

2. If NG, recheck TCM pin

terminals for damage or

loose connection with

harness connector.

INSPECTION END

SAT844H

SAT222JA

.

.

. .

.

DIAGNOSTIC PROCEDURES FOR SYMPTOMS

AT-1109