instrument panel NISSAN PATROL 2000 Electronic Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2000, Model line: PATROL, Model: NISSAN PATROL 2000Pages: 1033, PDF Size: 30.71 MB

Page 6 of 1033

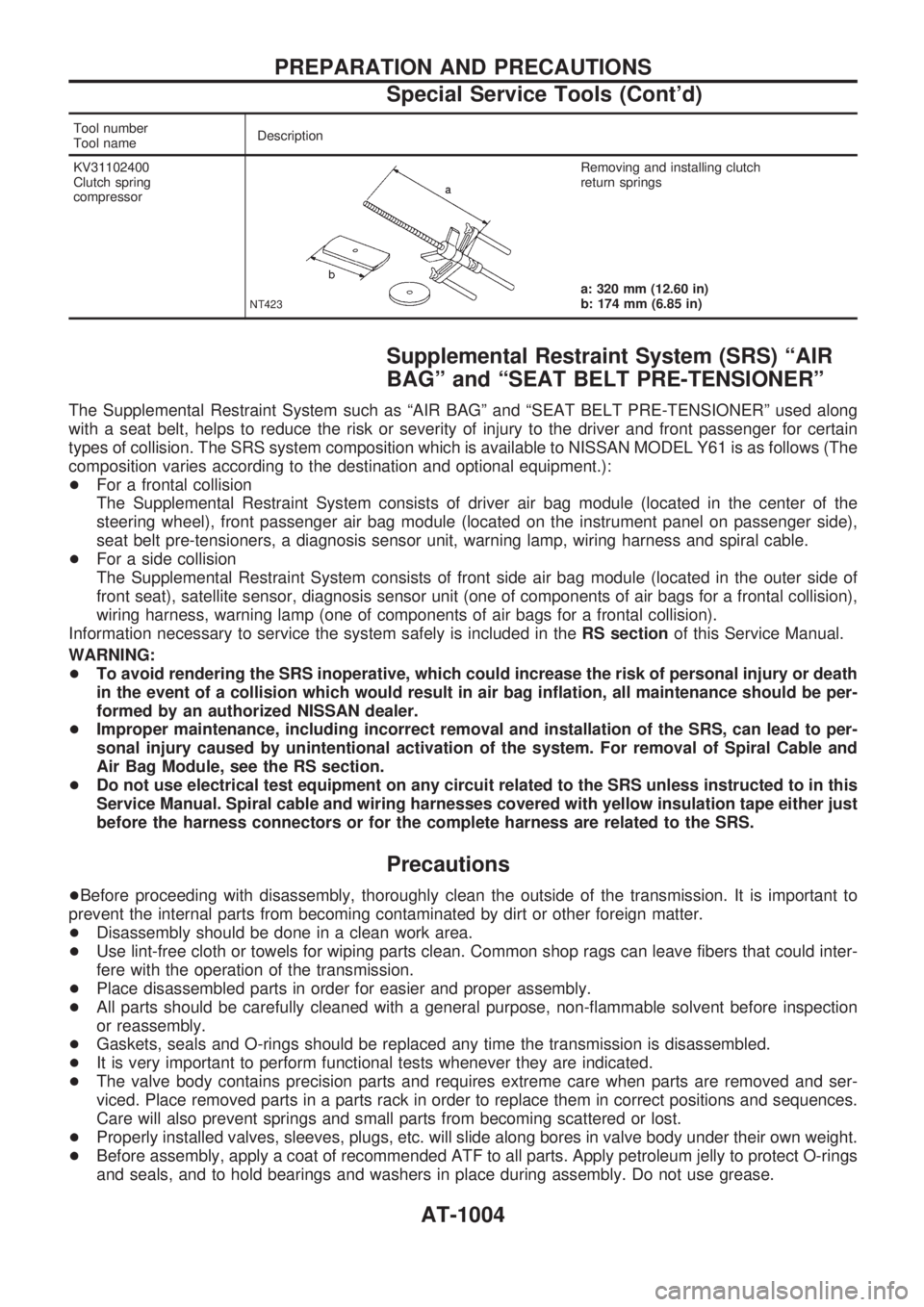

Tool number

Tool nameDescription

KV31102400

Clutch spring

compressor

NT423

Removing and installing clutch

return springs

a: 320 mm (12.60 in)

b: 174 mm (6.85 in)

Supplemental Restraint System (SRS) ªAIR

BAGº and ªSEAT BELT PRE-TENSIONERº

The Supplemental Restraint System such as ªAIR BAGº and ªSEAT BELT PRE-TENSIONERº used along

with a seat belt, helps to reduce the risk or severity of injury to the driver and front passenger for certain

types of collision. The SRS system composition which is available to NISSAN MODEL Y61 is as follows (The

composition varies according to the destination and optional equipment.):

+For a frontal collision

The Supplemental Restraint System consists of driver air bag module (located in the center of the

steering wheel), front passenger air bag module (located on the instrument panel on passenger side),

seat belt pre-tensioners, a diagnosis sensor unit, warning lamp, wiring harness and spiral cable.

+For a side collision

The Supplemental Restraint System consists of front side air bag module (located in the outer side of

front seat), satellite sensor, diagnosis sensor unit (one of components of air bags for a frontal collision),

wiring harness, warning lamp (one of components of air bags for a frontal collision).

Information necessary to service the system safely is included in theRS sectionof this Service Manual.

WARNING:

+To avoid rendering the SRS inoperative, which could increase the risk of personal injury or death

in the event of a collision which would result in air bag inflation, all maintenance should be per-

formed by an authorized NISSAN dealer.

+Improper maintenance, including incorrect removal and installation of the SRS, can lead to per-

sonal injury caused by unintentional activation of the system. For removal of Spiral Cable and

Air Bag Module, see the RS section.

+Do not use electrical test equipment on any circuit related to the SRS unless instructed to in this

Service Manual. Spiral cable and wiring harnesses covered with yellow insulation tape either just

before the harness connectors or for the complete harness are related to the SRS.

Precautions

+Before proceeding with disassembly, thoroughly clean the outside of the transmission. It is important to

prevent the internal parts from becoming contaminated by dirt or other foreign matter.

+Disassembly should be done in a clean work area.

+Use lint-free cloth or towels for wiping parts clean. Common shop rags can leave fibers that could inter-

fere with the operation of the transmission.

+Place disassembled parts in order for easier and proper assembly.

+All parts should be carefully cleaned with a general purpose, non-flammable solvent before inspection

or reassembly.

+Gaskets, seals and O-rings should be replaced any time the transmission is disassembled.

+It is very important to perform functional tests whenever they are indicated.

+The valve body contains precision parts and requires extreme care when parts are removed and ser-

viced. Place removed parts in a parts rack in order to replace them in correct positions and sequences.

Care will also prevent springs and small parts from becoming scattered or lost.

+Properly installed valves, sleeves, plugs, etc. will slide along bores in valve body under their own weight.

+Before assembly, apply a coat of recommended ATF to all parts. Apply petroleum jelly to protect O-rings

and seals, and to hold bearings and washers in place during assembly. Do not use grease.

PREPARATION AND PRECAUTIONS

Special Service Tools (Cont'd)

AT-1004

Page 52 of 1033

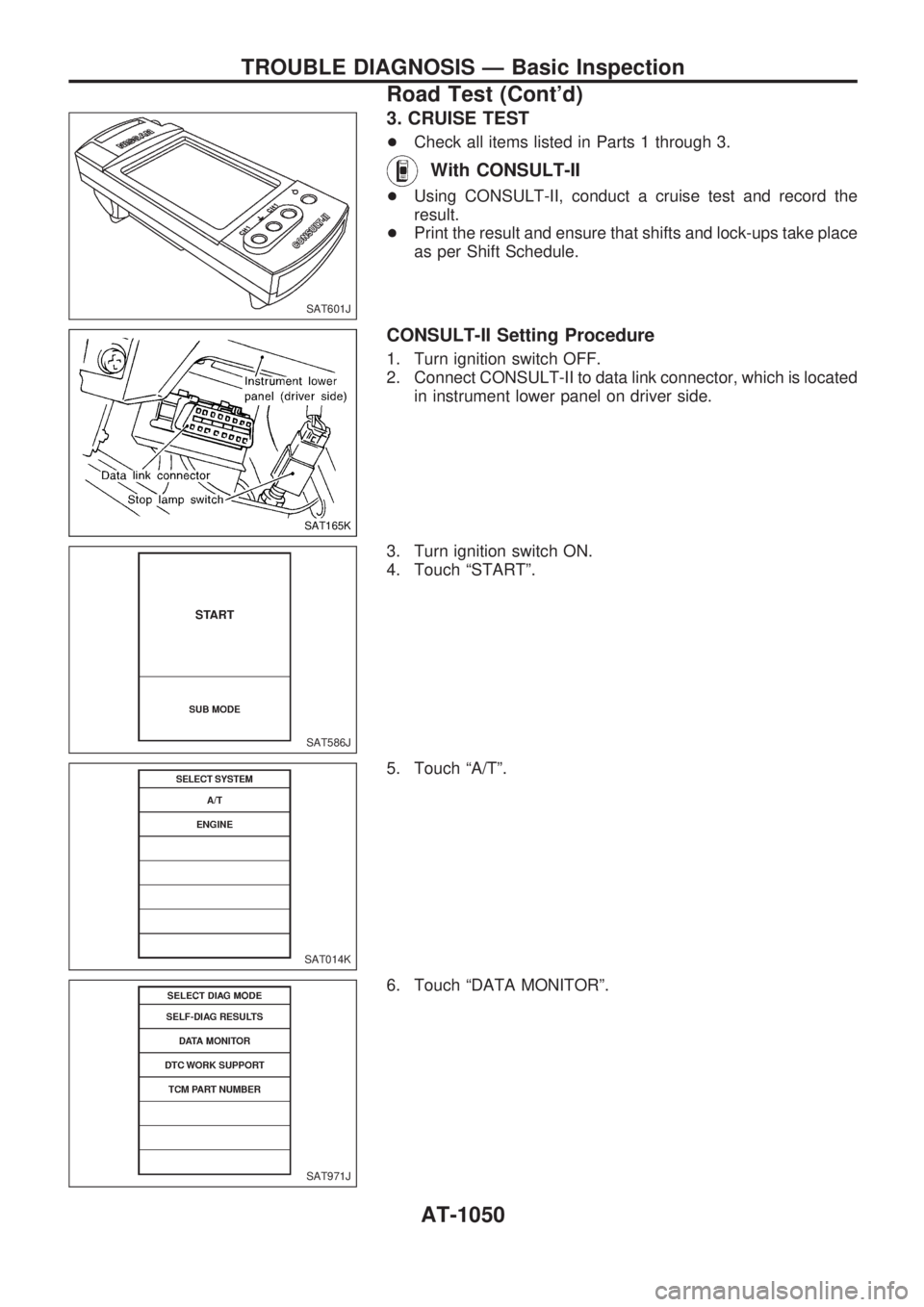

3. CRUISE TEST

+Check all items listed in Parts 1 through 3.

With CONSULT-II

+Using CONSULT-II, conduct a cruise test and record the

result.

+Print the result and ensure that shifts and lock-ups take place

as per Shift Schedule.

CONSULT-II Setting Procedure

1. Turn ignition switch OFF.

2. Connect CONSULT-II to data link connector, which is located

in instrument lower panel on driver side.

3. Turn ignition switch ON.

4. Touch ªSTARTº.

5. Touch ªA/Tº.

6. Touch ªDATA MONITORº.

SAT601J

SAT165K

SAT586J

SAT014K

SAT971J

TROUBLE DIAGNOSIS Ð Basic Inspection

Road Test (Cont'd)

AT-1050

Page 220 of 1033

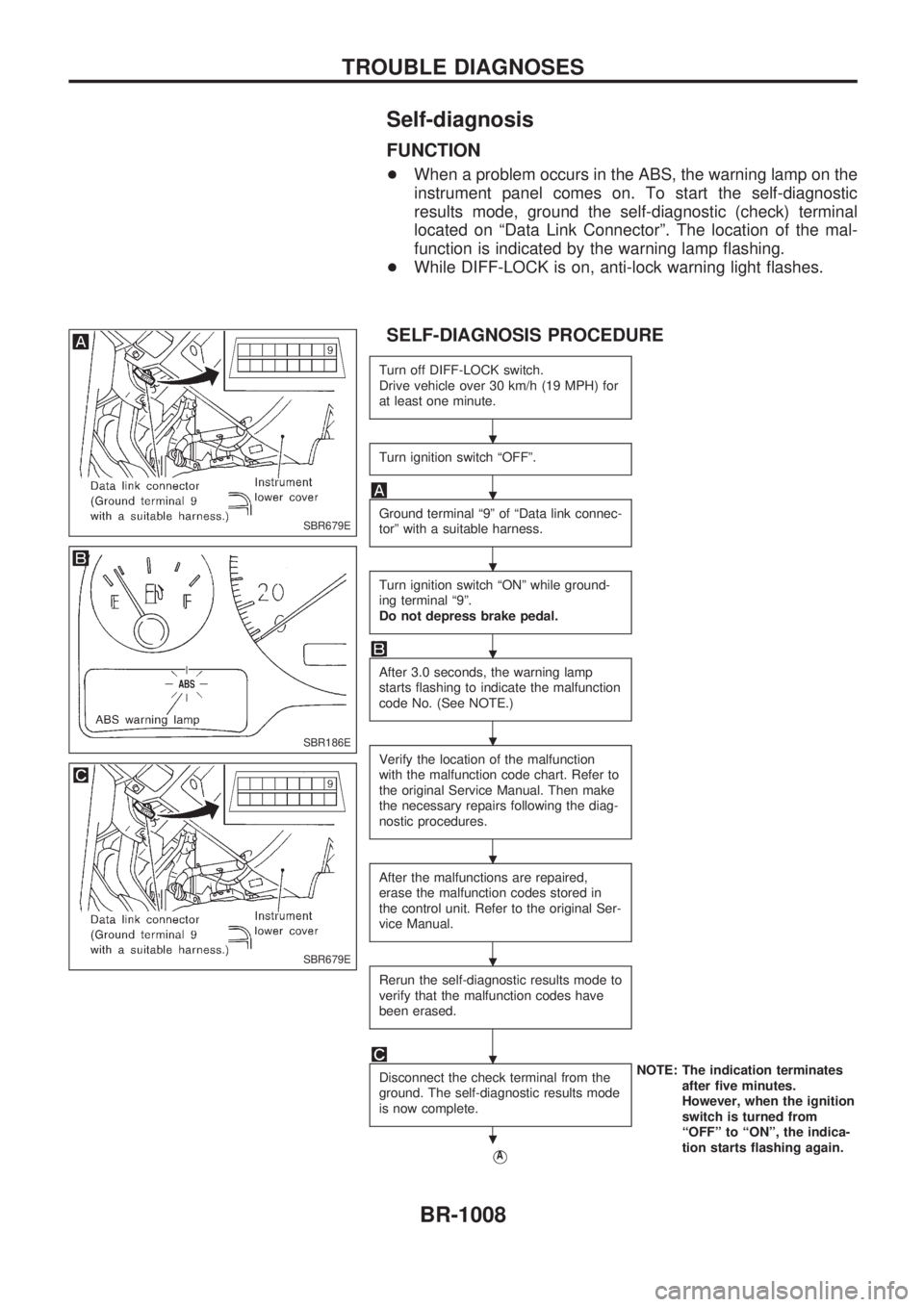

Self-diagnosis

FUNCTION

+When a problem occurs in the ABS, the warning lamp on the

instrument panel comes on. To start the self-diagnostic

results mode, ground the self-diagnostic (check) terminal

located on ªData Link Connectorº. The location of the mal-

function is indicated by the warning lamp flashing.

+While DIFF-LOCK is on, anti-lock warning light flashes.

SELF-DIAGNOSIS PROCEDURE

Turn off DIFF-LOCK switch.

Drive vehicle over 30 km/h (19 MPH) for

at least one minute.

Turn ignition switch ªOFFº.

Ground terminal ª9º of ªData link connec-

torº with a suitable harness.

Turn ignition switch ªONº while ground-

ing terminal ª9º.

Do not depress brake pedal.

After 3.0 seconds, the warning lamp

starts flashing to indicate the malfunction

code No. (See NOTE.)

Verify the location of the malfunction

with the malfunction code chart. Refer to

the original Service Manual. Then make

the necessary repairs following the diag-

nostic procedures.

After the malfunctions are repaired,

erase the malfunction codes stored in

the control unit. Refer to the original Ser-

vice Manual.

Rerun the self-diagnostic results mode to

verify that the malfunction codes have

been erased.

Disconnect the check terminal from the

ground. The self-diagnostic results mode

is now complete.NOTE: The indication terminates

after five minutes.

However, when the ignition

switch is turned from

ªOFFº to ªONº, the indica-

tion starts flashing again.

VA

SBR679E

SBR186E

SBR679E

.

.

.

.

.

.

.

.

.

TROUBLE DIAGNOSES

BR-1008

Page 224 of 1033

Supplemental Restraint System (SRS) ªAIR

BAGº and ªSEAT BELT PRE-TENSIONERº

The Supplemental Restraint System such as ªAIR BAGº and ªSEAT BELT PRE-TENSIONERº used along

with a seat belt, helps to reduce the risk or severity of injury to the driver and front passenger for certain

types of collision. The SRS system composition which is available to NISSAN MODEL Y61 is as follows (The

composition varies according to the destination and optional equipment.):

+For a frontal collision

The Supplemental Restraint System consists of driver air bag module (located in the center of the

steering wheel), front passenger air bag module (located on the instrument panel on passenger side),

seat belt pre-tensioners, a diagnosis sensor unit, warning lamp, wiring harness and spiral cable.

+ For a side collision

The Supplemental Restraint System consists of front side air bag module (located in the outer side of

front seat), satellite sensor, diagnosis sensor unit (one of components of air bags for a frontal collision),

wiring harness, warning lamp (one of components of air bags for a frontal collision).

Information necessary to service the system safely is included in the RS sectionof this Service Manual.

WARNING:

+ To avoid rendering the SRS inoperative, which could increase the risk of personal injury or death

in the event of a collision which would result in air bag inflation, all maintenance should be per-

formed by an authorized NISSAN dealer.

+ Improper maintenance, including incorrect removal and installation of the SRS, can lead to per-

sonal injury caused by intentional activation of the system. For removal of Spiral Cable and Air

Bag Module, see the RS section.

+ Do not use electrical test equipment on any circuit related to the SRS unless instructed to in this

Service Manual. Spiral cable and wiring harnesses covered with yellow insulation tape either just

before the harness connectors or for the complete harness are related to the SRS.

PRECAUTIONS

BT-1002

Page 238 of 1033

Special Service Tool

Tool number

Tool nameDescription

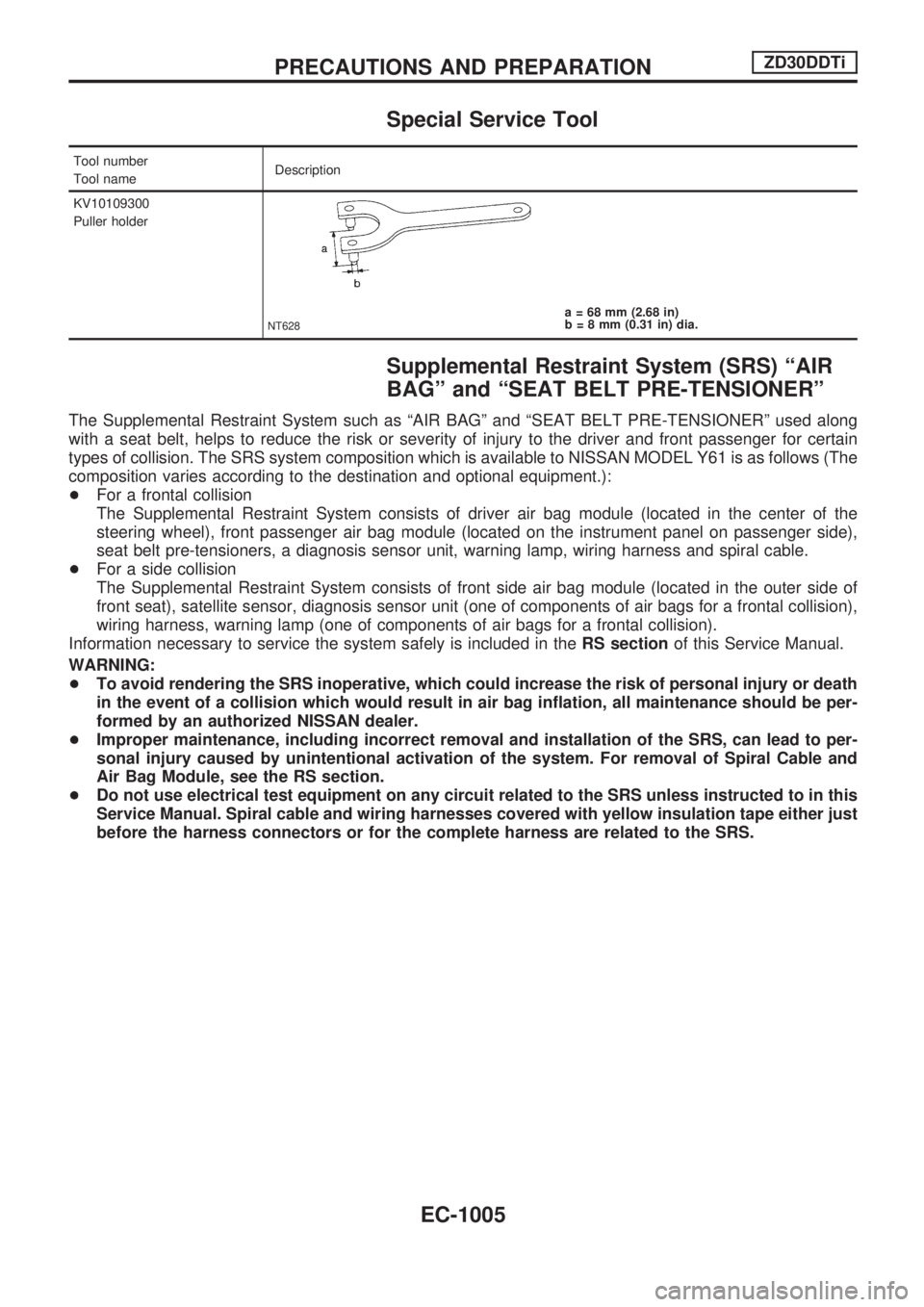

KV10109300

Puller holder

NT628a = 68 mm (2.68 in)

b = 8 mm (0.31 in) dia.

Supplemental Restraint System (SRS) ªAIR

BAGº and ªSEAT BELT PRE-TENSIONERº

The Supplemental Restraint System such as ªAIR BAGº and ªSEAT BELT PRE-TENSIONERº used along

with a seat belt, helps to reduce the risk or severity of injury to the driver and front passenger for certain

types of collision. The SRS system composition which is available to NISSAN MODEL Y61 is as follows (The

composition varies according to the destination and optional equipment.):

+For a frontal collision

The Supplemental Restraint System consists of driver air bag module (located in the center of the

steering wheel), front passenger air bag module (located on the instrument panel on passenger side),

seat belt pre-tensioners, a diagnosis sensor unit, warning lamp, wiring harness and spiral cable.

+For a side collision

The Supplemental Restraint System consists of front side air bag module (located in the outer side of

front seat), satellite sensor, diagnosis sensor unit (one of components of air bags for a frontal collision),

wiring harness, warning lamp (one of components of air bags for a frontal collision).

Information necessary to service the system safely is included in theRS sectionof this Service Manual.

WARNING:

+To avoid rendering the SRS inoperative, which could increase the risk of personal injury or death

in the event of a collision which would result in air bag inflation, all maintenance should be per-

formed by an authorized NISSAN dealer.

+Improper maintenance, including incorrect removal and installation of the SRS, can lead to per-

sonal injury caused by unintentional activation of the system. For removal of Spiral Cable and

Air Bag Module, see the RS section.

+Do not use electrical test equipment on any circuit related to the SRS unless instructed to in this

Service Manual. Spiral cable and wiring harnesses covered with yellow insulation tape either just

before the harness connectors or for the complete harness are related to the SRS.

PRECAUTIONS AND PREPARATIONZD30DDTi

EC-1005

Page 251 of 1033

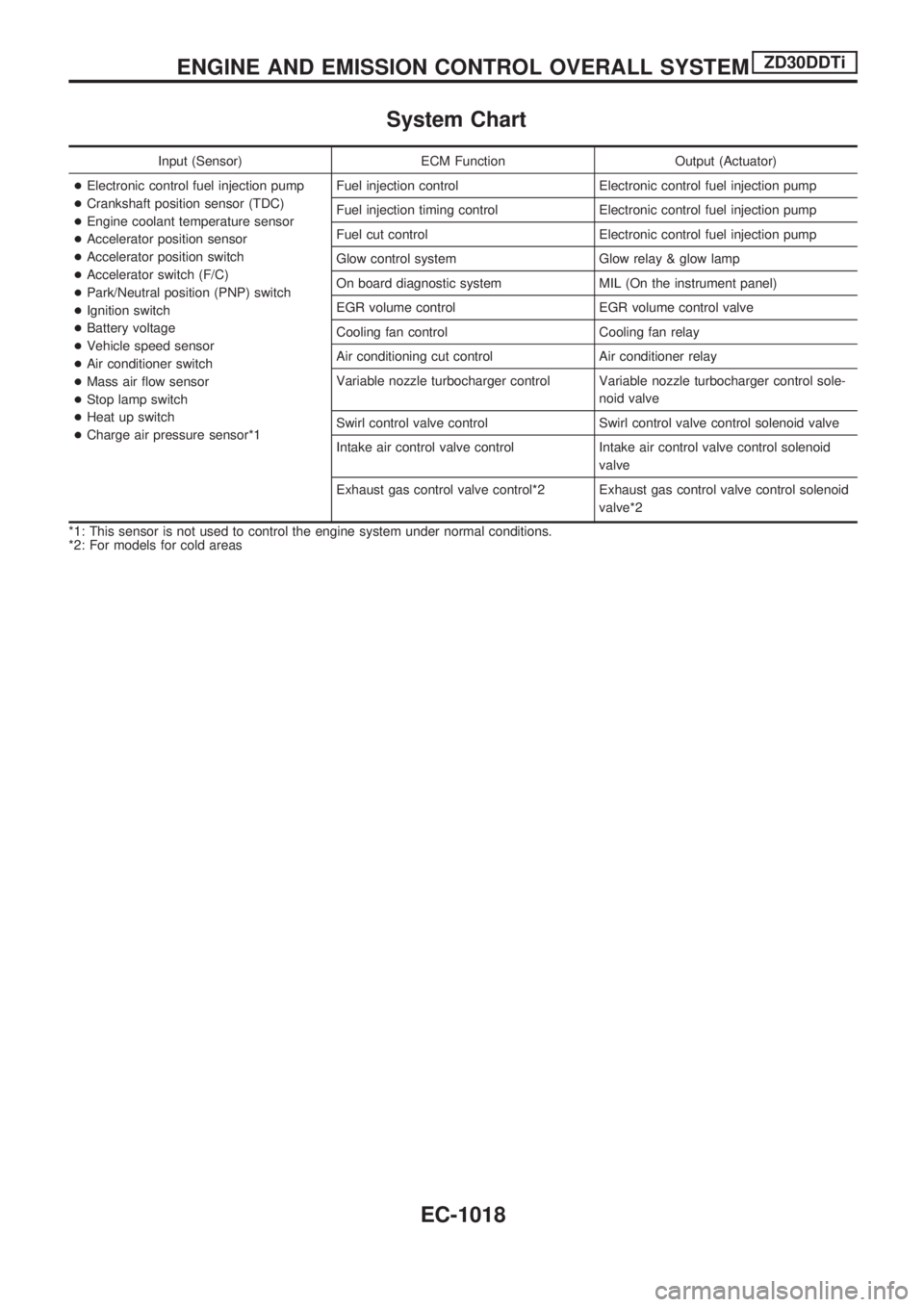

System Chart

Input (Sensor) ECM Function Output (Actuator)

+Electronic control fuel injection pump

+Crankshaft position sensor (TDC)

+Engine coolant temperature sensor

+Accelerator position sensor

+Accelerator position switch

+Accelerator switch (F/C)

+Park/Neutral position (PNP) switch

+Ignition switch

+Battery voltage

+Vehicle speed sensor

+Air conditioner switch

+Mass air flow sensor

+Stop lamp switch

+Heat up switch

+Charge air pressure sensor*1Fuel injection control Electronic control fuel injection pump

Fuel injection timing control Electronic control fuel injection pump

Fuel cut control Electronic control fuel injection pump

Glow control system Glow relay & glow lamp

On board diagnostic system MIL (On the instrument panel)

EGR volume control EGR volume control valve

Cooling fan control Cooling fan relay

Air conditioning cut control Air conditioner relay

Variable nozzle turbocharger control Variable nozzle turbocharger control sole-

noid valve

Swirl control valve control Swirl control valve control solenoid valve

Intake air control valve control Intake air control valve control solenoid

valve

Exhaust gas control valve control*2 Exhaust gas control valve control solenoid

valve*2

*1: This sensor is not used to control the engine system under normal conditions.

*2: For models for cold areas

ENGINE AND EMISSION CONTROL OVERALL SYSTEMZD30DDTi

EC-1018

Page 266 of 1033

2. Change the diagnostic test mode from Mode II to Mode I by using the data link connector. (See

EC-1035.)

The emission related diagnostic information in the ECM can be erased by changing the diagnostic test mode.

+If the battery is disconnected, the emission-related diagnostic information will be lost after

approx. 24 hours.

+Erasing the emission-related diagnostic information using CONSULT-II is easier and quicker than

switching the diagnostic test mode using the data link connector.

NATS (Nissan Anti-Theft System)

+If the security indicator lights up with the ignition switch

in the ªONº position or ªNATS MALFUNCTIONº is dis-

played on ªSELF-DIAG RESULTSº screen, perform self-

diagnostic results mode with CONSULT-II using NATS

program card. Refer to ªNATS (Nissan Anti-Theft Sys-

tem)º in EL section.

+Confirm no self-diagnostic results of NATS is displayed

before touching ªERASEº in ªSELF-DIAG RESULTSº

mode with CONSULT-II.

+When replacing ECM, initialization of NATS system and

registration of all NATS ignition key IDs must be carried

out with CONSULT-II using NATS program card.

Therefore, be sure to receive all keys from vehicle

owner. Regarding the procedures of NATS initialization

and NATS ignition key ID registration, refer to CON-

SULT-II operation manual, NATS.

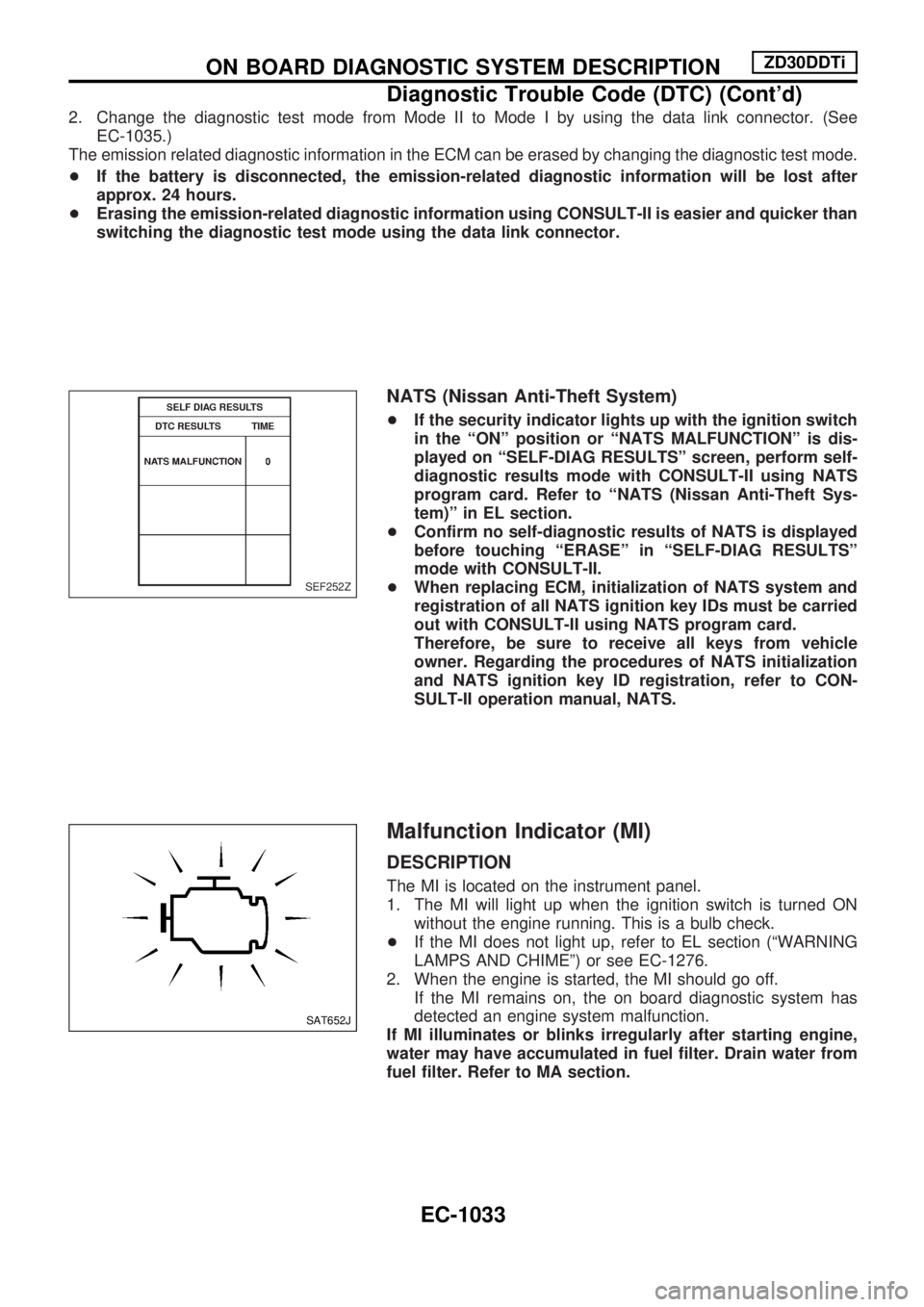

Malfunction Indicator (MI)

DESCRIPTION

The MI is located on the instrument panel.

1. The MI will light up when the ignition switch is turned ON

without the engine running. This is a bulb check.

+If the MI does not light up, refer to EL section (ªWARNING

LAMPS AND CHIMEº) or see EC-1276.

2. When the engine is started, the MI should go off.

If the MI remains on, the on board diagnostic system has

detected an engine system malfunction.

If MI illuminates or blinks irregularly after starting engine,

water may have accumulated in fuel filter. Drain water from

fuel filter. Refer to MA section.

SEF252Z

SAT652J

ON BOARD DIAGNOSTIC SYSTEM DESCRIPTIONZD30DDTi

Diagnostic Trouble Code (DTC) (Cont'd)

EC-1033

Page 269 of 1033

Diagnostic test mode I Ð Bulb check

In this mode, the MI on the instrument panel should stay ON. If it remains OFF, check the bulb. Refer to EL

section, ªWARNING LAMPS AND CHIMEº or see EC-1276.

Diagnostic test mode I Ð Malfunction warning

MI Condition

ON When the malfunction is detected or the ECM's CPU is malfunctioning.

OFF No malfunction.

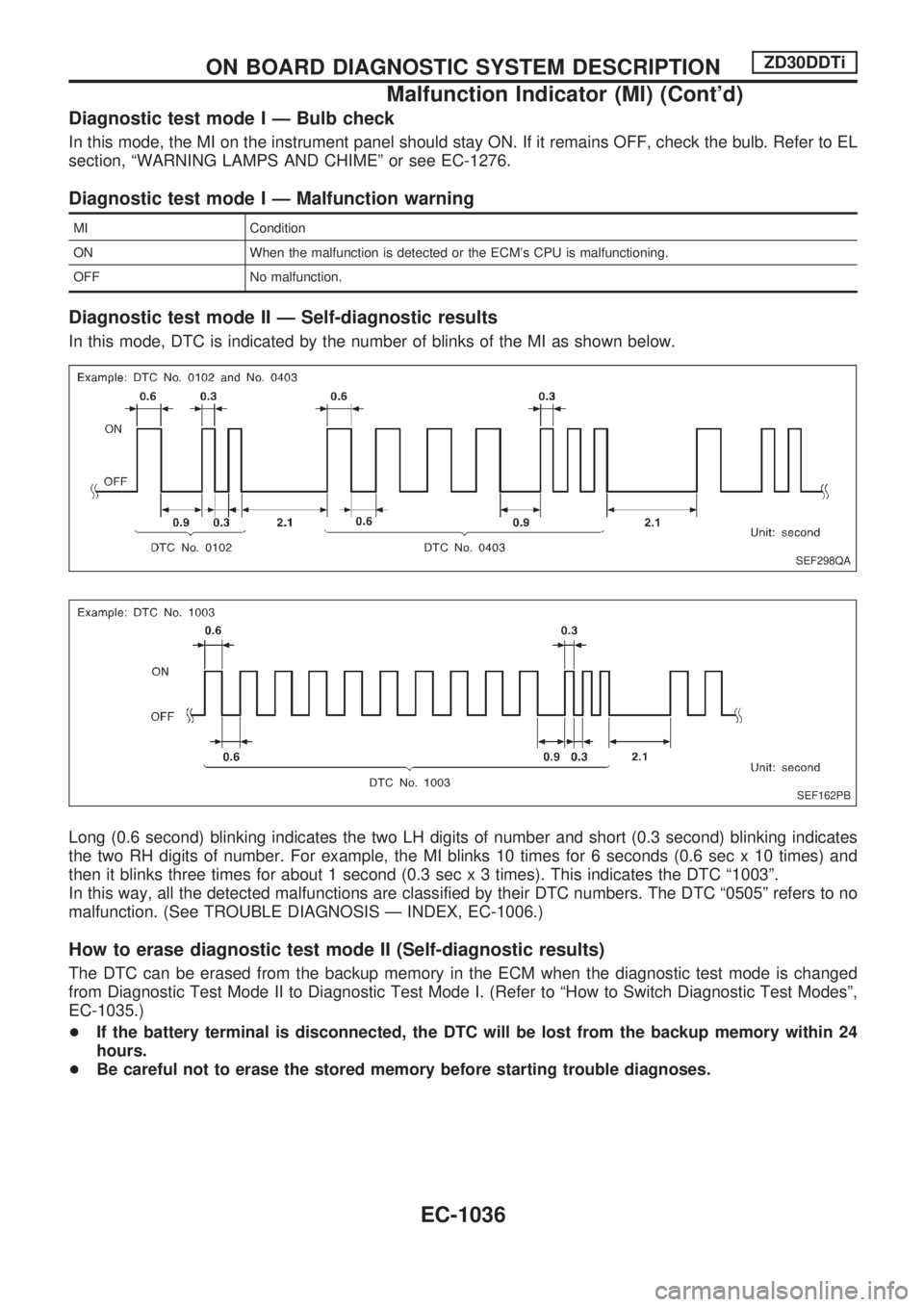

Diagnostic test mode II Ð Self-diagnostic results

In this mode, DTC is indicated by the number of blinks of the MI as shown below.

Long (0.6 second) blinking indicates the two LH digits of number and short (0.3 second) blinking indicates

the two RH digits of number. For example, the MI blinks 10 times for 6 seconds (0.6 sec x 10 times) and

then it blinks three times for about 1 second (0.3 sec x 3 times). This indicates the DTC ª1003º.

In this way, all the detected malfunctions are classified by their DTC numbers. The DTC ª0505º refers to no

malfunction. (See TROUBLE DIAGNOSIS Ð INDEX, EC-1006.)

How to erase diagnostic test mode II (Self-diagnostic results)

The DTC can be erased from the backup memory in the ECM when the diagnostic test mode is changed

from Diagnostic Test Mode II to Diagnostic Test Mode I. (Refer to ªHow to Switch Diagnostic Test Modesº,

EC-1035.)

+If the battery terminal is disconnected, the DTC will be lost from the backup memory within 24

hours.

+Be careful not to erase the stored memory before starting trouble diagnoses.

SEF298QA

SEF162PB

ON BOARD DIAGNOSTIC SYSTEM DESCRIPTIONZD30DDTi

Malfunction Indicator (MI) (Cont'd)

EC-1036

Page 301 of 1033

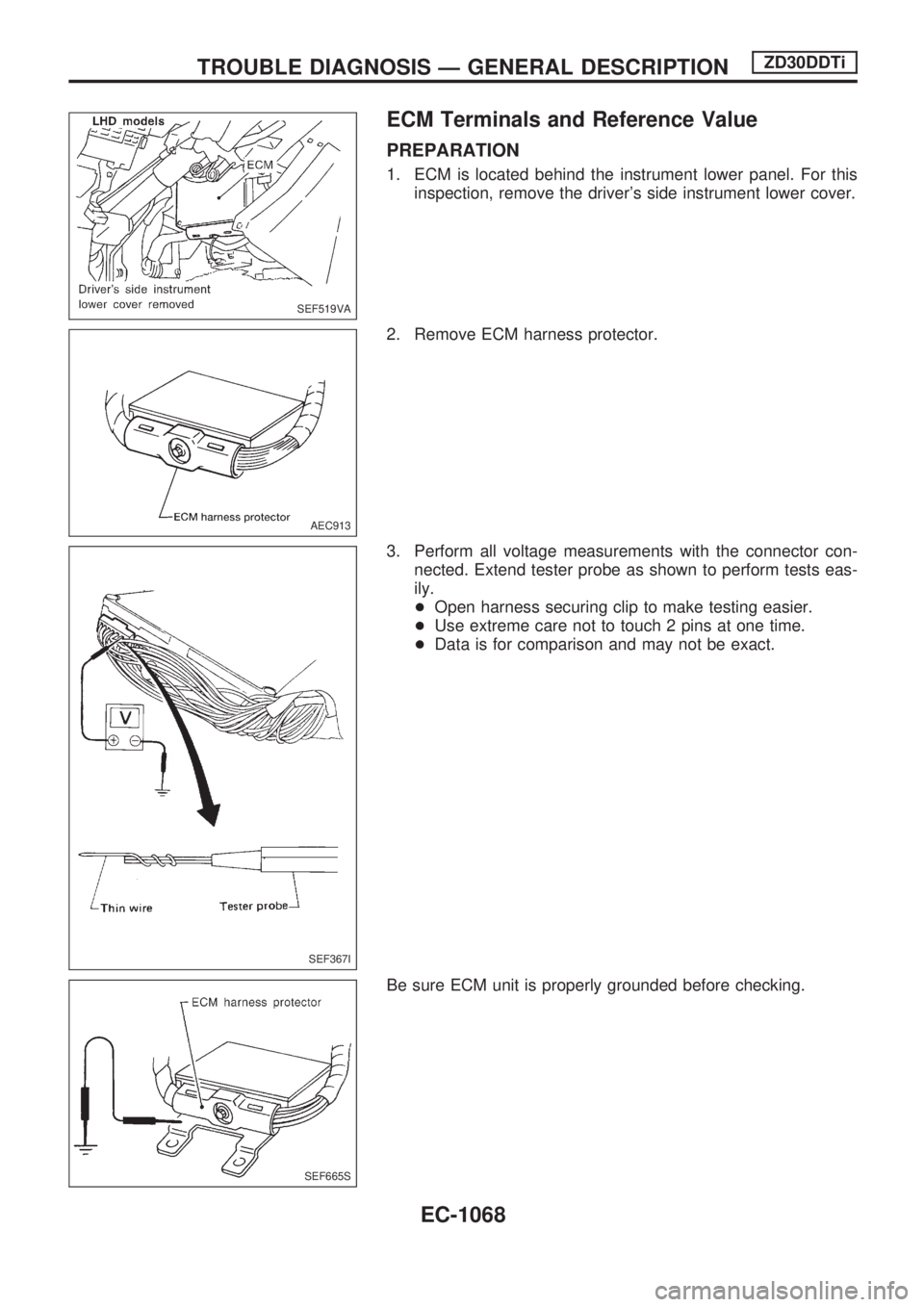

ECM Terminals and Reference Value

PREPARATION

1. ECM is located behind the instrument lower panel. For this

inspection, remove the driver's side instrument lower cover.

2. Remove ECM harness protector.

3. Perform all voltage measurements with the connector con-

nected. Extend tester probe as shown to perform tests eas-

ily.

+Open harness securing clip to make testing easier.

+Use extreme care not to touch 2 pins at one time.

+Data is for comparison and may not be exact.

Be sure ECM unit is properly grounded before checking.

SEF519VA

AEC913

SEF367I

SEF665S

TROUBLE DIAGNOSIS Ð GENERAL DESCRIPTIONZD30DDTi

EC-1068

Page 474 of 1033

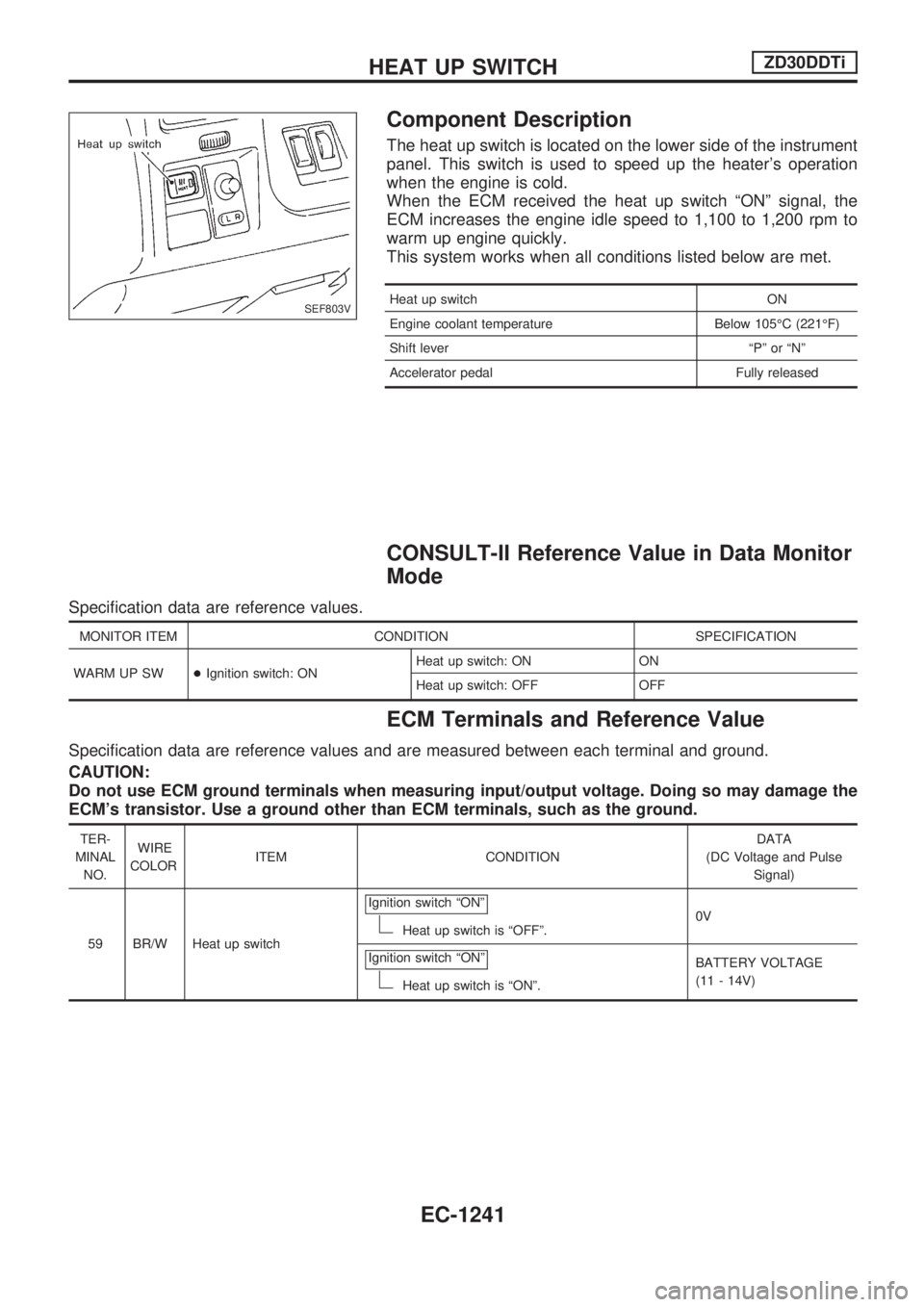

Component Description

The heat up switch is located on the lower side of the instrument

panel. This switch is used to speed up the heater's operation

when the engine is cold.

When the ECM received the heat up switch ªONº signal, the

ECM increases the engine idle speed to 1,100 to 1,200 rpm to

warm up engine quickly.

This system works when all conditions listed below are met.

Heat up switch ON

Engine coolant temperature Below 105ÉC (221ÉF)

Shift lever ªPº or ªNº

Accelerator pedal Fully released

CONSULT-II Reference Value in Data Monitor

Mode

Specification data are reference values.

MONITOR ITEM CONDITION SPECIFICATION

WARM UP SW+Ignition switch: ONHeat up switch: ON ON

Heat up switch: OFF OFF

ECM Terminals and Reference Value

Specification data are reference values and are measured between each terminal and ground.

CAUTION:

Do not use ECM ground terminals when measuring input/output voltage. Doing so may damage the

ECM's transistor. Use a ground other than ECM terminals, such as the ground.

TER-

MINAL

NO.WIRE

COLORITEM CONDITIONDATA

(DC Voltage and Pulse

Signal)

59 BR/W Heat up switchIgnition switch ªONº

Heat up switch is ªOFFº.0V

Ignition switch ªONº

Heat up switch is ªONº.BATTERY VOLTAGE

(11 - 14V)

SEF803V

HEAT UP SWITCHZD30DDTi

EC-1241