service NISSAN PATROL 2002 Electronic Repair Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2002, Model line: PATROL, Model: NISSAN PATROL 2002Pages: 311, PDF Size: 12.08 MB

Page 2 of 311

FOREWORD

This manual contains maintenance and repair procedures for NISSAN

PATROL GR,modelY61 series.

In order to assure your safety and the efficient functioning of the vehicle,

this manual should be read thoroughly. It is especially important that the

PRECAUTIONS in the GI section be completely understood before starting

any repair task.

All information in this manual is based on the latest product information

at the time of publication. The right is reserved to make changes in speci-

®cations and methods at any time without notice.

IMPORTANT SAFETY NOTICE

The proper performance of service is essential for both the safety of the

technician and the efficient functioning of the vehicle.

The service methods in this Service Manual are described in such a man-

ner that the service may be performed safely and accurately.

Service varies with the procedures used, the skills of the technician and the

tools and parts available. Accordingly, anyone using service procedures,

tools or parts which are not speci®cally recommended by NISSAN must

®rst completely satisfy himself that neither his safety nor the vehicle's

safety will be jeopardized by the service method selected.

NISSAN EUROPE S.A.S.

Service Engineering SectionParis, France

Page 4 of 311

Supplemental Restraint System (SRS) ªAIR

BAGº and ªSEAT BELT PRE-TENSIONERº

The Supplemental Restraint System such as ªAIR BAGº and ªSEAT BELT PRE-TENSIONERº used along

with a seat belt, helps to reduce the risk or severity of injury to the driver and front passenger for certain

types of collision. The SRS system composition which is available to NISSAN MODEL Y61 is as follows (The

composition varies according to the destination and optional equipment.):

+For a frontal collision

The Supplemental Restraint System consists of driver air bag module (located in the center of the

steering wheel), front passenger air bag module (located on the instrument panel on passenger side),

seat belt pre-tensioners, a diagnosis sensor unit, warning lamp, wiring harness and spiral cable.

+For a side collision

The Supplemental Restraint System consists of front side air bag module (located in the outer side of

front seat), satellite sensor, diagnosis sensor unit (one of components of air bags for a frontal collision),

wiring harness, warning lamp (one of components of air bags for a frontal collision).

Information necessary to service the system safely is included in theRS sectionof this Service Manual.

WARNING:

+To avoid rendering the SRS inoperative, which could increase the risk of personal injury or death

in the event of a collision which would result in air bag inflation, all maintenance should be per-

formed by an authorized NISSAN dealer.

+Improper maintenance, including incorrect removal and installation of the SRS, can lead to per-

sonal injury caused by unintentional activation of the system. For removal of Spiral Cable and

Air Bag Module, see the RS section.

+Do not use electrical test equipment on any circuit related to the SRS unless instructed to in this

Service Manual. SRS wiring harnesses can be identified by yellow harness connector.

PRECAUTIONS

AT-3002

Page 15 of 311

BRAKE SYSTEM

SECTION

BR

MODIFICATION NOTICE:

+Front disc brake and rear disc brake have been changed.

+Parking brake has been changed.

+Wiring Diagrams have been changed.

+Service data and specification (SDS) have been changed.

CONTENTS

FRONT DISC BRAKE......................................... 3002

REAR DISC BRAKE............................................ 3003

PARKING BRAKE CONTROL............................ 3004

TROUBLE DIAGNOSES..................................... 3005

Schematic ........................................................ 3005Wiring Diagram Ð ABS Ð .............................. 3006

SERVICE DATA AND SPECIFICATIONS

(SDS).................................................................... 3011

General Specifications ..................................... 3011

BR

Page 25 of 311

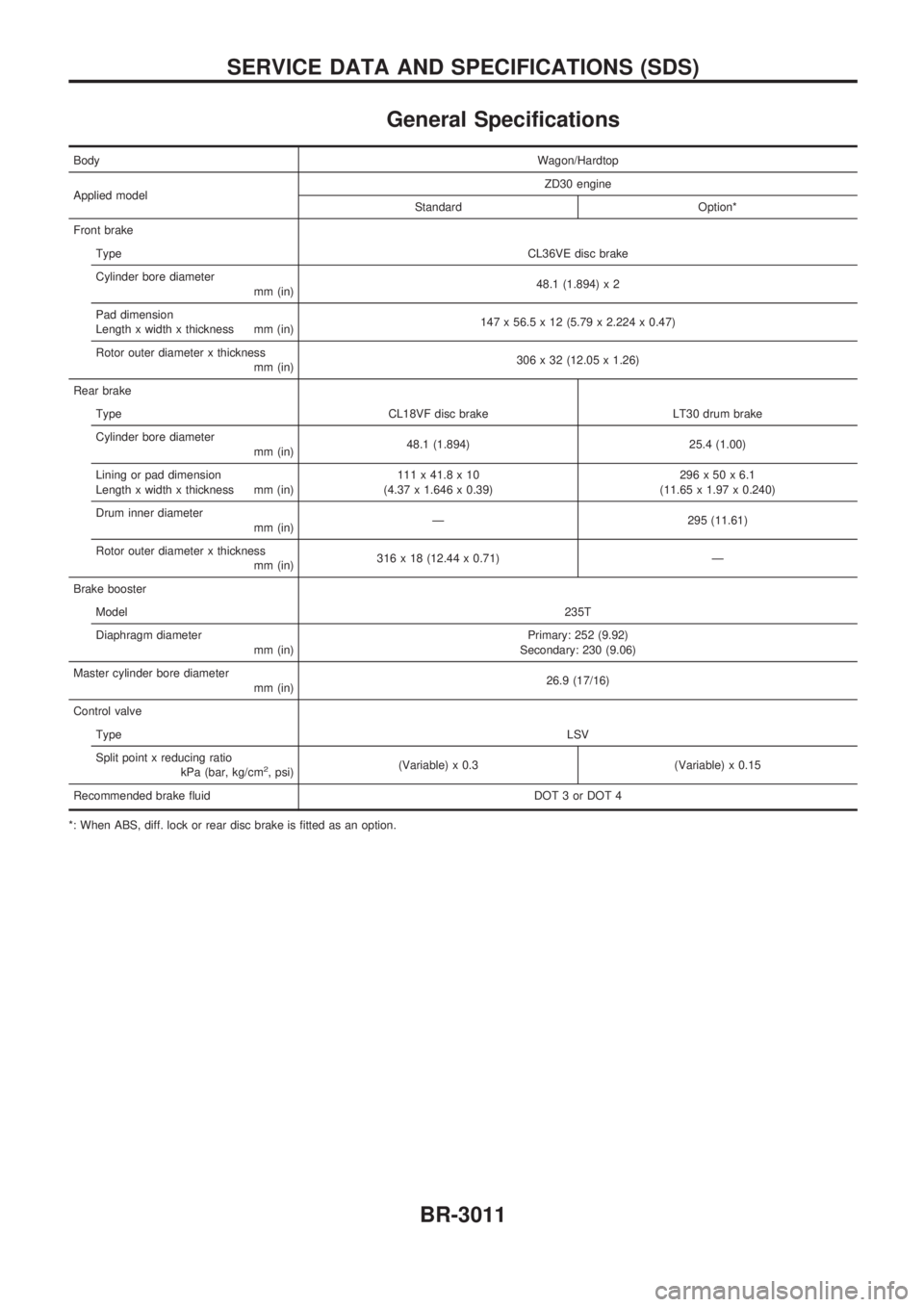

General Specifications

BodyWagon/Hardtop

Applied modelZD30 engine

Standard Option*

Front brake

TypeCL36VE disc brake

Cylinder bore diameter

mm (in)48.1 (1.894) x 2

Pad dimension

Length x width x thickness mm (in)147 x 56.5 x 12 (5.79 x 2.224 x 0.47)

Rotor outer diameter x thickness

mm (in)306 x 32 (12.05 x 1.26)

Rear brake

Type CL18VF disc brake LT30 drum brake

Cylinder bore diameter

mm (in)48.1 (1.894) 25.4 (1.00)

Lining or pad dimension

Length x width x thickness mm (in)111 x 41.8 x 10

(4.37 x 1.646 x 0.39)296x50x6.1

(11.65 x 1.97 x 0.240)

Drum inner diameter

mm (in)Ð 295 (11.61)

Rotor outer diameter x thickness

mm (in)316 x 18 (12.44 x 0.71) Ð

Brake booster

Model235T

Diaphragm diameter

mm (in)Primary: 252 (9.92)

Secondary: 230 (9.06)

Master cylinder bore diameter

mm (in)26.9 (17/16)

Control valve

TypeLSV

Split point x reducing ratio

kPa (bar, kg/cm

2, psi)(Variable) x 0.3 (Variable) x 0.15

Recommended brake fluid DOT 3 or DOT 4

*: When ABS, diff. lock or rear disc brake is fitted as an option.

SERVICE DATA AND SPECIFICATIONS (SDS)

BR-3011

Page 26 of 311

SERVICE DATA AND SPECIFICATIONS (SDS)

General Specifications (Cont'd)

BR-3012

Page 47 of 311

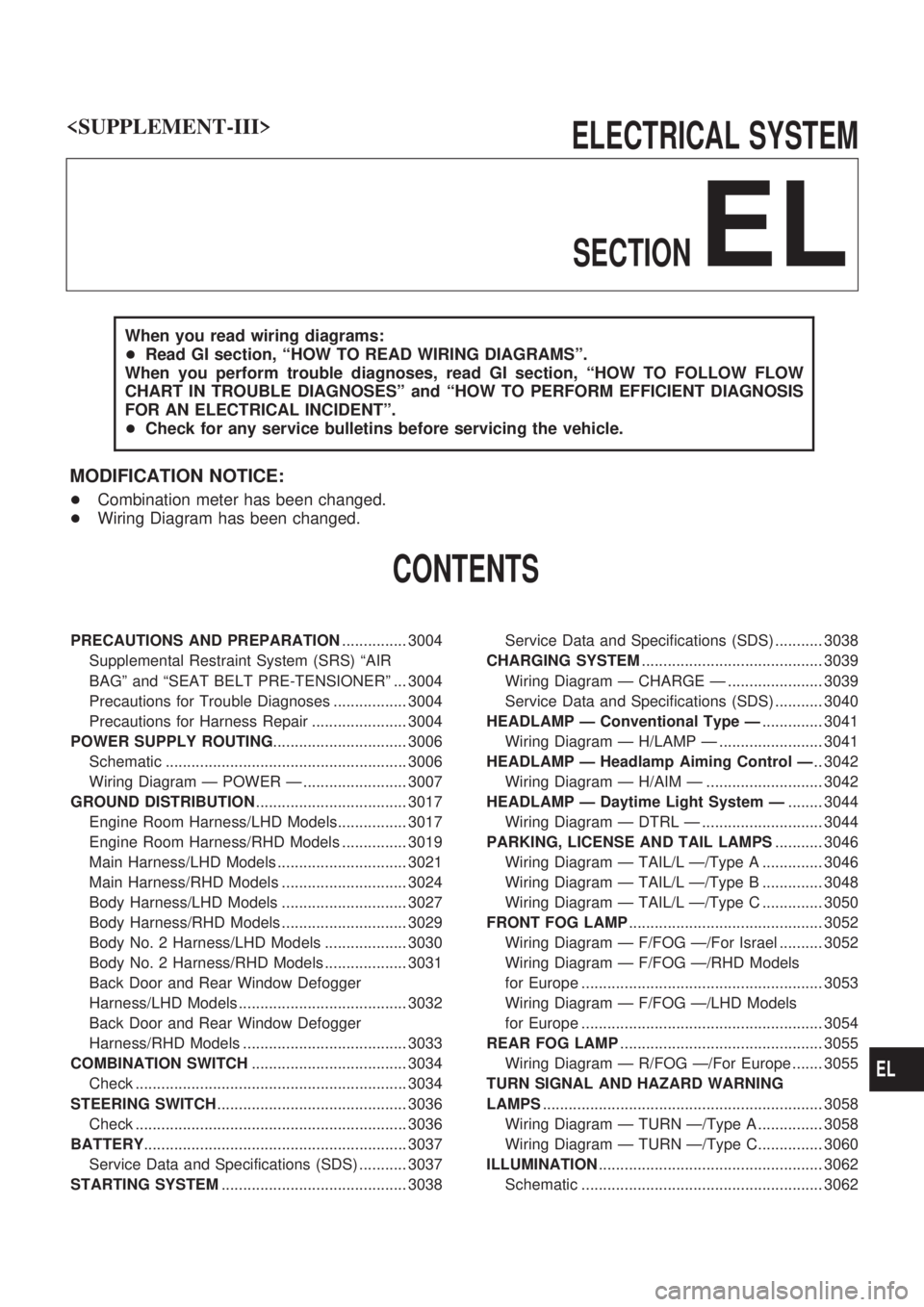

ELECTRICAL SYSTEM

SECTION

EL

When you read wiring diagrams:

+Read GI section, ªHOW TO READ WIRING DIAGRAMSº.

When you perform trouble diagnoses, read GI section, ªHOW TO FOLLOW FLOW

CHART IN TROUBLE DIAGNOSESº and ªHOW TO PERFORM EFFICIENT DIAGNOSIS

FOR AN ELECTRICAL INCIDENTº.

+Check for any service bulletins before servicing the vehicle.

MODIFICATION NOTICE:

+Combination meter has been changed.

+Wiring Diagram has been changed.

CONTENTS

PRECAUTIONS AND PREPARATION............... 3004

Supplemental Restraint System (SRS) ªAIR

BAGº and ªSEAT BELT PRE-TENSIONERº ... 3004

Precautions for Trouble Diagnoses ................. 3004

Precautions for Harness Repair ...................... 3004

POWER SUPPLY ROUTING............................... 3006

Schematic ........................................................ 3006

Wiring Diagram Ð POWER Ð ........................ 3007

GROUND DISTRIBUTION................................... 3017

Engine Room Harness/LHD Models................ 3017

Engine Room Harness/RHD Models ............... 3019

Main Harness/LHD Models .............................. 3021

Main Harness/RHD Models ............................. 3024

Body Harness/LHD Models ............................. 3027

Body Harness/RHD Models ............................. 3029

Body No. 2 Harness/LHD Models ................... 3030

Body No. 2 Harness/RHD Models ................... 3031

Back Door and Rear Window Defogger

Harness/LHD Models ....................................... 3032

Back Door and Rear Window Defogger

Harness/RHD Models ...................................... 3033

COMBINATION SWITCH.................................... 3034

Check ............................................................... 3034

STEERING SWITCH............................................ 3036

Check ............................................................... 3036

BATTERY............................................................. 3037

Service Data and Specifications (SDS) ........... 3037

STARTING SYSTEM........................................... 3038Service Data and Specifications (SDS) ........... 3038

CHARGING SYSTEM.......................................... 3039

Wiring Diagram Ð CHARGE Ð ...................... 3039

Service Data and Specifications (SDS) ........... 3040

HEADLAMP Ð Conventional Type Ð.............. 3041

Wiring Diagram Ð H/LAMP Ð ........................ 3041

HEADLAMP Ð Headlamp Aiming Control Ð.. 3042

Wiring Diagram Ð H/AIM Ð ........................... 3042

HEADLAMP Ð Daytime Light System Ð........ 3044

Wiring Diagram Ð DTRL Ð ............................ 3044

PARKING, LICENSE AND TAIL LAMPS........... 3046

Wiring Diagram Ð TAIL/L Ð/Type A .............. 3046

Wiring Diagram Ð TAIL/L Ð/Type B .............. 3048

Wiring Diagram Ð TAIL/L Ð/Type C .............. 3050

FRONT FOG LAMP............................................. 3052

Wiring Diagram Ð F/FOG Ð/For Israel .......... 3052

Wiring Diagram Ð F/FOG Ð/RHD Models

for Europe ........................................................ 3053

Wiring Diagram Ð F/FOG Ð/LHD Models

for Europe ........................................................ 3054

REAR FOG LAMP............................................... 3055

Wiring Diagram Ð R/FOG Ð/For Europe ....... 3055

TURN SIGNAL AND HAZARD WARNING

LAMPS................................................................. 3058

Wiring Diagram Ð TURN Ð/Type A ............... 3058

Wiring Diagram Ð TURN Ð/Type C............... 3060

ILLUMINATION.................................................... 3062

Schematic ........................................................ 3062

EL

Page 50 of 311

Supplemental Restraint System (SRS) ªAIR

BAGº and ªSEAT BELT PRE-TENSIONERº

The Supplemental Restraint System such as ªAIR BAGº and ªSEAT BELT PRE-TENSIONERº used along

with a seat belt, helps to reduce the risk or severity of injury to the driver and front passenger for certain

types of collision. The SRS system composition which is available to NISSAN MODEL Y61 is as follows (The

composition varies according to the destination and optional equipment.):

+For a frontal collision

The Supplemental Restraint System consists of driver air bag module (located in the center of the

steering wheel), front passenger air bag module (located on the instrument panel on passenger side),

seat belt pre-tensioners, a diagnosis sensor unit, warning lamp, wiring harness and spiral cable.

+For a side collision

The Supplemental Restraint System consists of front side air bag module (located in the outer side of

front seat), satellite sensor, diagnosis sensor unit (one of components of air bags for a frontal collision),

wiring harness, warning lamp (one of components of air bags for a frontal collision).

Information necessary to service the system safely is included in theRS sectionof this Service Manual.

WARNING:

+To avoid rendering the SRS inoperative, which could increase the risk of personal injury or death

in the event of a collision which would result in air bag inflation, all maintenance should be per-

formed by an authorized NISSAN dealer.

+Improper maintenance, including incorrect removal and installation of the SRS, can lead to per-

sonal injury caused by unintentional activation of the system. For removal of Spiral Cable and

Air Bag Module, see the RS section.

+Do not use electrical test equipment on any circuit related to the SRS unless instructed to in this

Service Manual. SRS wiring harnesses can be identified by yellow harness connector.

Precautions for Trouble Diagnoses

CAN SYSTEM

+Do not apply voltage of 7.0V or higher to the measure-

ment terminals.

+Use the tester with its open terminal voltage being 7.0V

or less.

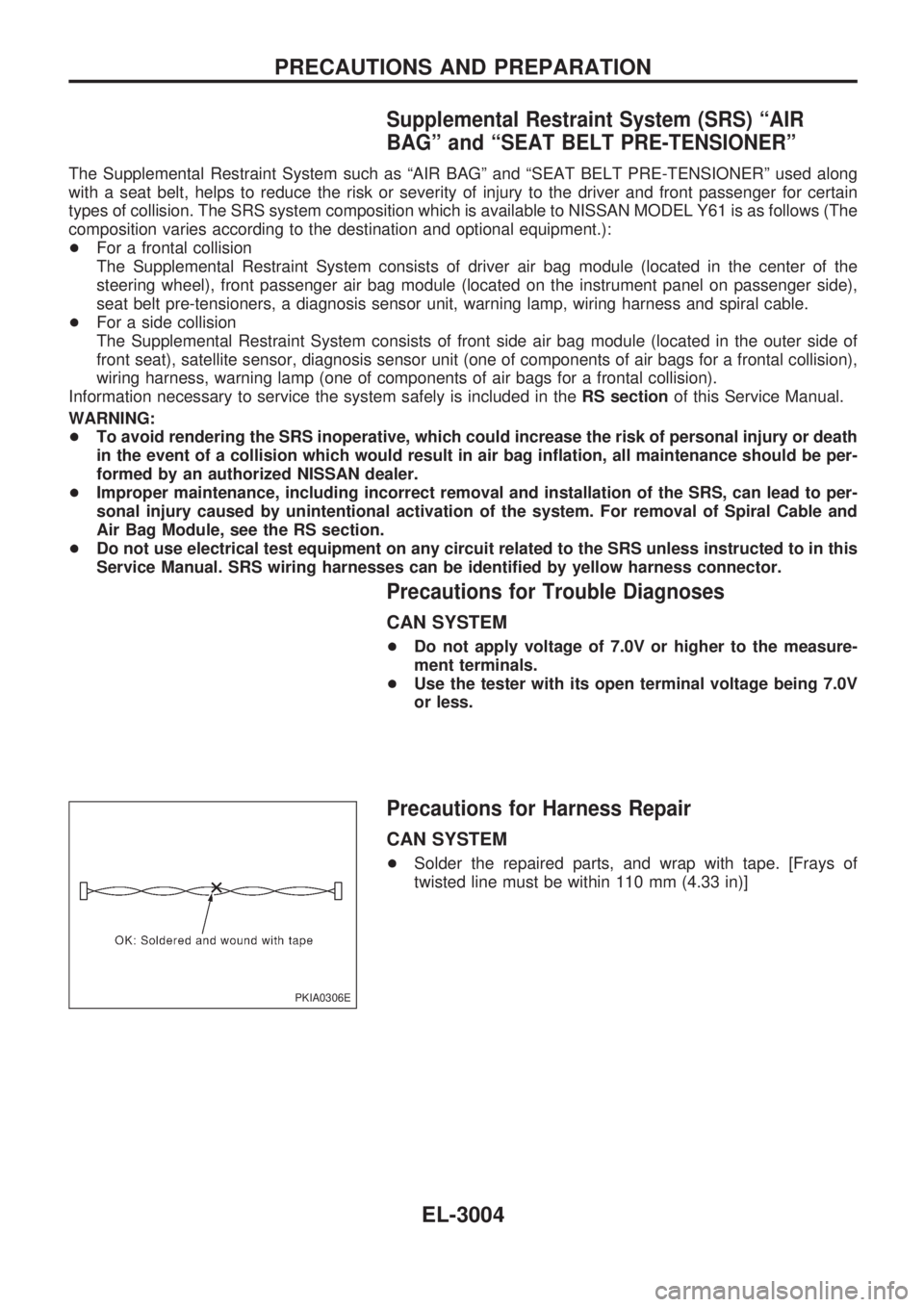

Precautions for Harness Repair

CAN SYSTEM

+Solder the repaired parts, and wrap with tape. [Frays of

twisted line must be within 110 mm (4.33 in)]

PKIA0306E

PRECAUTIONS AND PREPARATION

EL-3004

Page 83 of 311

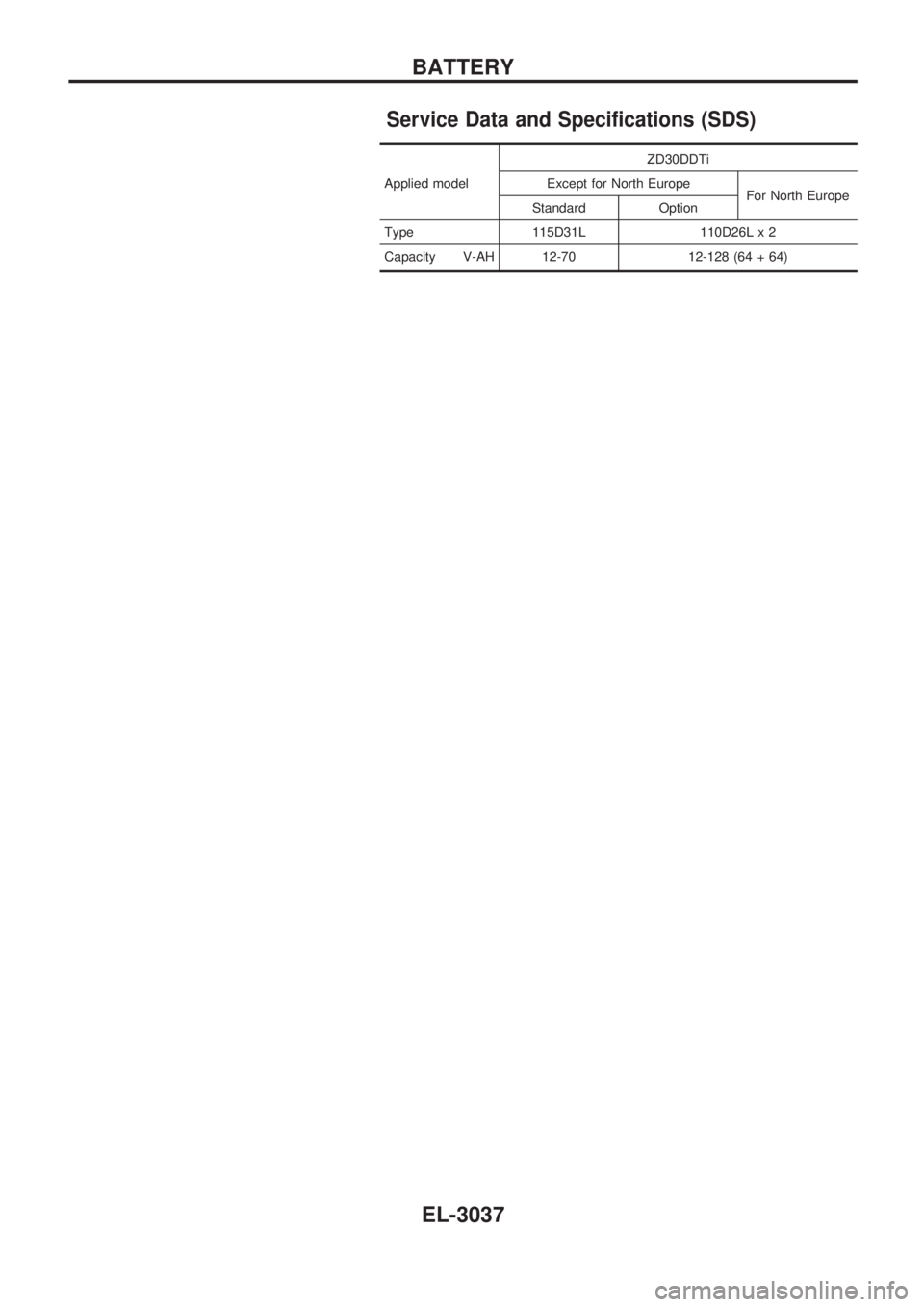

Service Data and Specifications (SDS)

Applied modelZD30DDTi

Except for North Europe

For North Europe

Standard Option

Type 115D31L 110D26L x 2

Capacity V-AH 12-70 12-128 (64 + 64)

BATTERY

EL-3037

Page 84 of 311

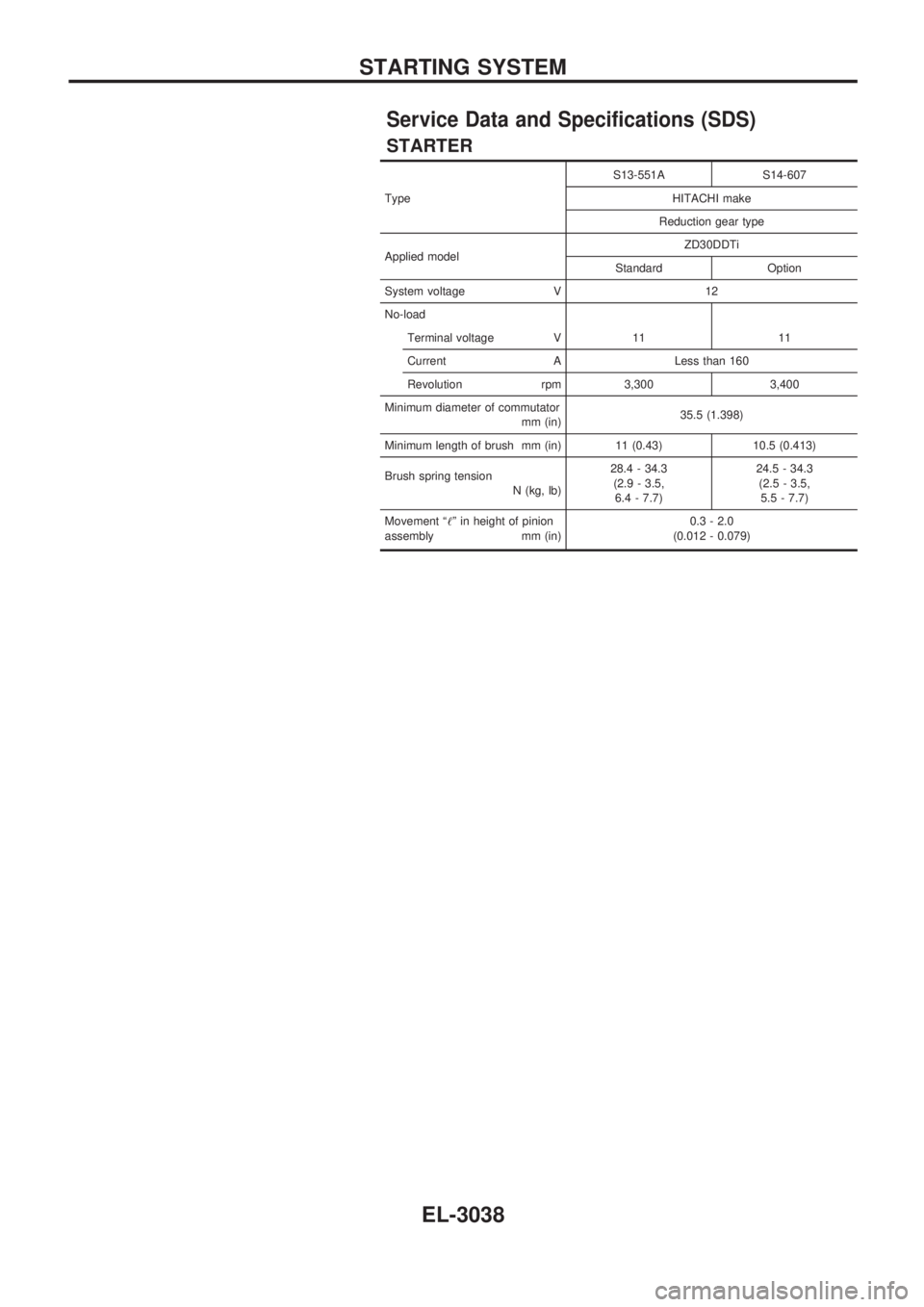

Service Data and Specifications (SDS)

STARTER

TypeS13-551A S14-607

HITACHI make

Reduction gear type

Applied modelZD30DDTi

Standard Option

System voltage V 12

No-load

Terminal voltage V 11 11

Current A Less than 160

Revolution rpm 3,300 3,400

Minimum diameter of commutator

mm (in)35.5 (1.398)

Minimum length of brush mm (in) 11 (0.43) 10.5 (0.413)

Brush spring tension

N (kg, lb)28.4 - 34.3

(2.9 - 3.5,

6.4 - 7.7)24.5 - 34.3

(2.5 - 3.5,

5.5 - 7.7)

Movement ª!º in height of pinion

assembly mm (in)0.3 - 2.0

(0.012 - 0.079)

STARTING SYSTEM

EL-3038

Page 86 of 311

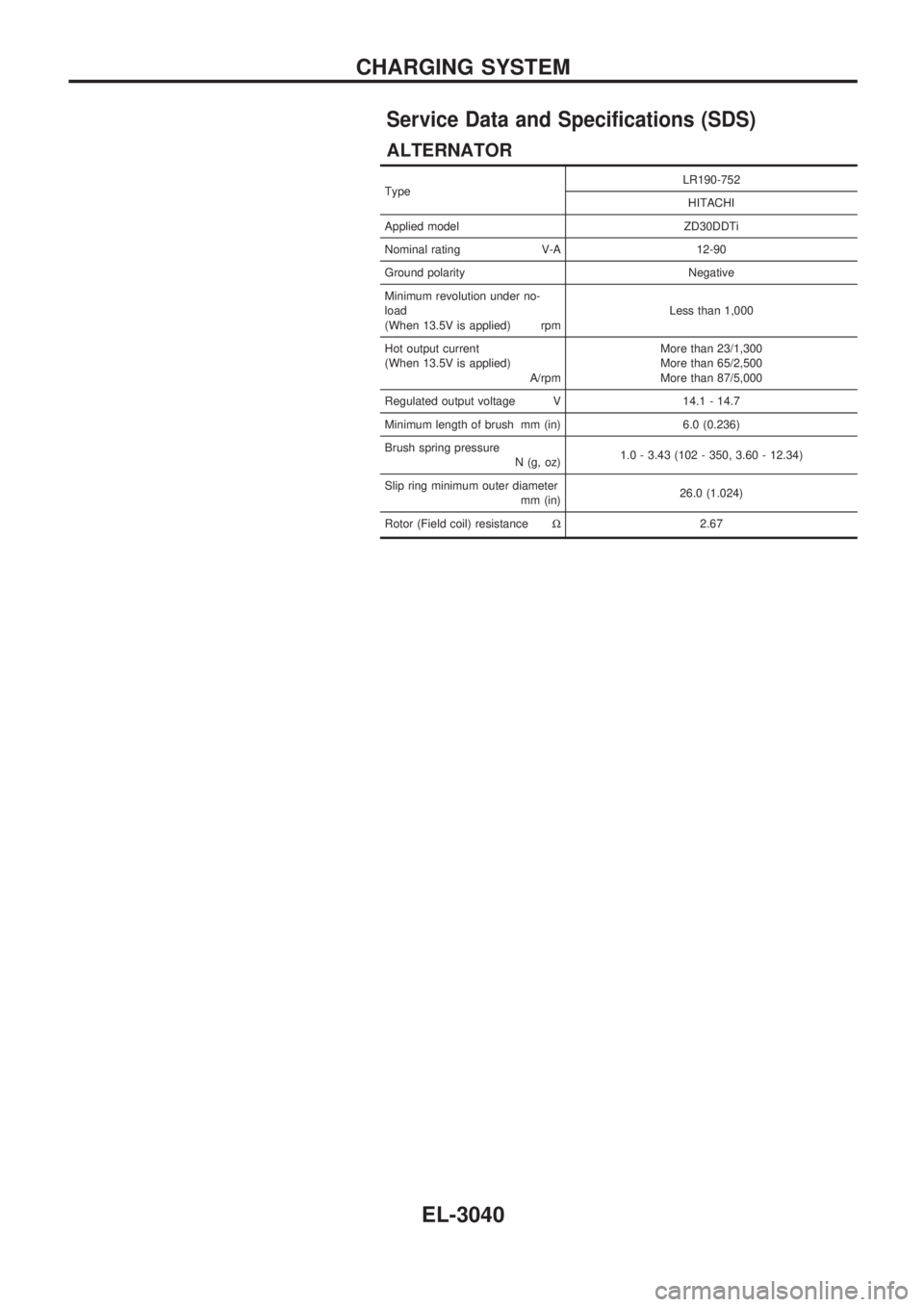

Service Data and Specifications (SDS)

ALTERNATOR

TypeLR190-752

HITACHI

Applied model ZD30DDTi

Nominal rating V-A 12-90

Ground polarity Negative

Minimum revolution under no-

load

(When 13.5V is applied) rpmLess than 1,000

Hot output current

(When 13.5V is applied)

A/rpmMore than 23/1,300

More than 65/2,500

More than 87/5,000

Regulated output voltage V 14.1 - 14.7

Minimum length of brush mm (in) 6.0 (0.236)

Brush spring pressure

N (g, oz)1.0 - 3.43 (102 - 350, 3.60 - 12.34)

Slip ring minimum outer diameter

mm (in)26.0 (1.024)

Rotor (Field coil) resistanceW2.67

CHARGING SYSTEM

EL-3040