check engine NISSAN PATROL 2004 Electronic Owner's Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2004, Model line: PATROL, Model: NISSAN PATROL 2004Pages: 579, PDF Size: 26.61 MB

Page 506 of 579

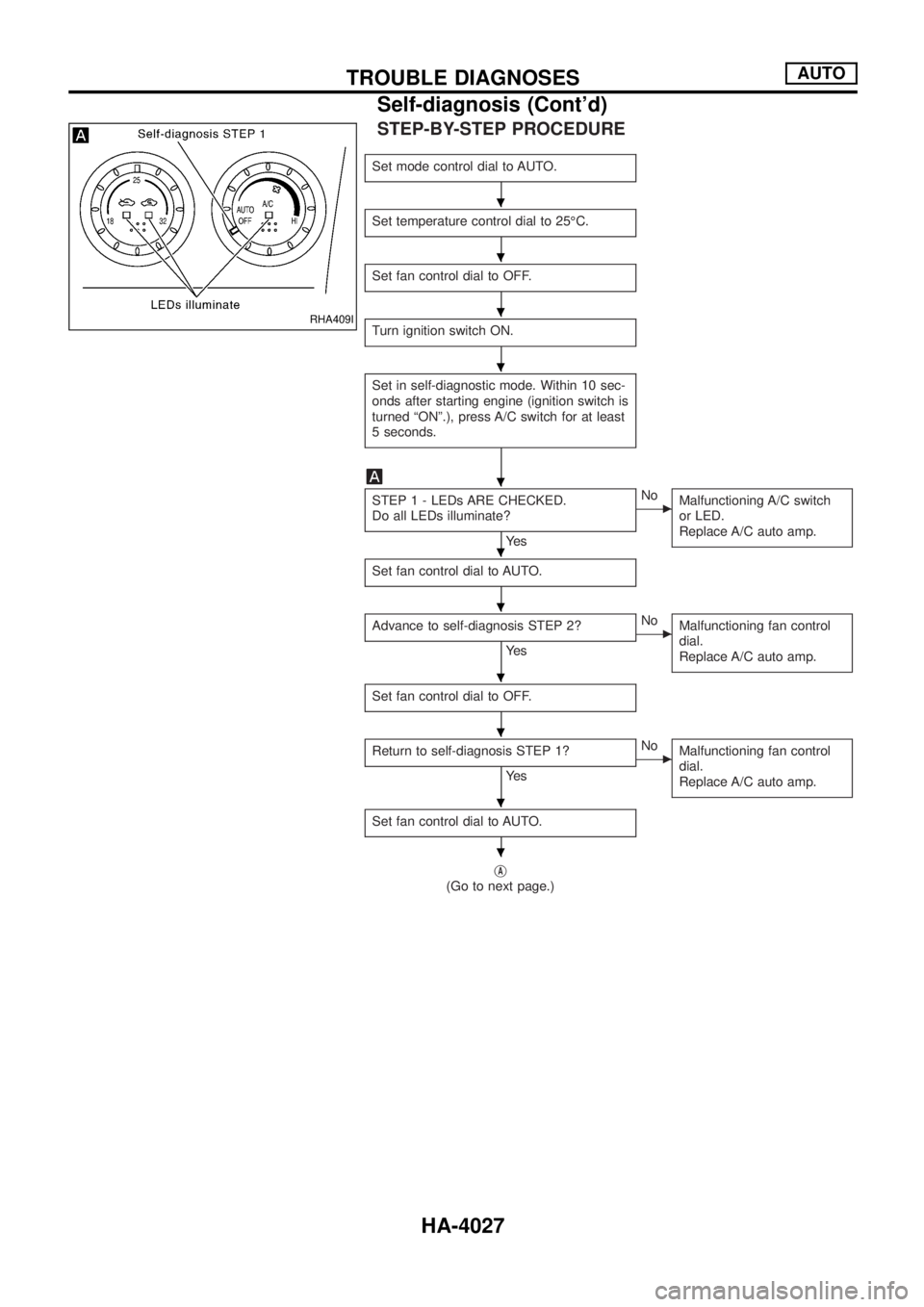

STEP-BY-STEP PROCEDURE

Set mode control dial to AUTO.

Set temperature control dial to 25ÉC.

Set fan control dial to OFF.

Turn ignition switch ON.

Set in self-diagnostic mode. Within 10 sec-

onds after starting engine (ignition switch is

turned ªONº.), press A/C switch for at least

5 seconds.

STEP 1 - LEDs ARE CHECKED.

Do all LEDs illuminate?

Ye s

cNo

Malfunctioning A/C switch

or LED.

Replace A/C auto amp.

Set fan control dial to AUTO.

Advance to self-diagnosis STEP 2?

Ye s

cNo

Malfunctioning fan control

dial.

Replace A/C auto amp.

Set fan control dial to OFF.

Return to self-diagnosis STEP 1?

Ye s

cNo

Malfunctioning fan control

dial.

Replace A/C auto amp.

Set fan control dial to AUTO.

jA

(Go to next page.)

RHA409I

.

.

.

.

.

.

.

.

.

.

.

TROUBLE DIAGNOSESAUTO

Self-diagnosis (Cont'd)

HA-4027

Page 509 of 579

jC

STEP 4 - OPERATION OF EACH ACTUA-

TOR IS CHECKED.

Engine running.

Refer to the following chart and con®rm

discharge air ¯ow, air temperature, blower

motor voltage and compressor operation.

Checks must be made visually, by lis-

tening to any noise, or by touching air

outlets with your hand, etc. for

improper operation.

OK

cNG

+Air outlet does not

change.

Go to HA-4035.

+Intake door does not

change.

Go to HA-4037.

+Discharge air tempera-

ture does not change.

Go to HA-4036.

+Magnet clutch does not

engage.

Go to HA-4039.

+Blower motor operation is

malfunctioning.

Go to HA-4038.

Turn ignition switch OFF or press intake

switch.

END

Mode

control

dial

positionActuator test pattern

Mode doorIntake

doorAir mix

doorBlower

motorCom-

pressor

AUTOVENT

RECFull

Cold4-5V ON

VENTVENT

RECFull

Cold9 - 11V ON

B/LB/L

RECFull

Cold7-9V OFF

FOOTFOOT

FREFull

Hot7-9V OFF

D/FD/F

FREFull

Hot7-9V ON

DEFDEF

FREFull

Hot10 -

12VON

RHA654FF

.

.

.

.

TROUBLE DIAGNOSESAUTO

Self-diagnosis (Cont'd)

HA-4030

Page 511 of 579

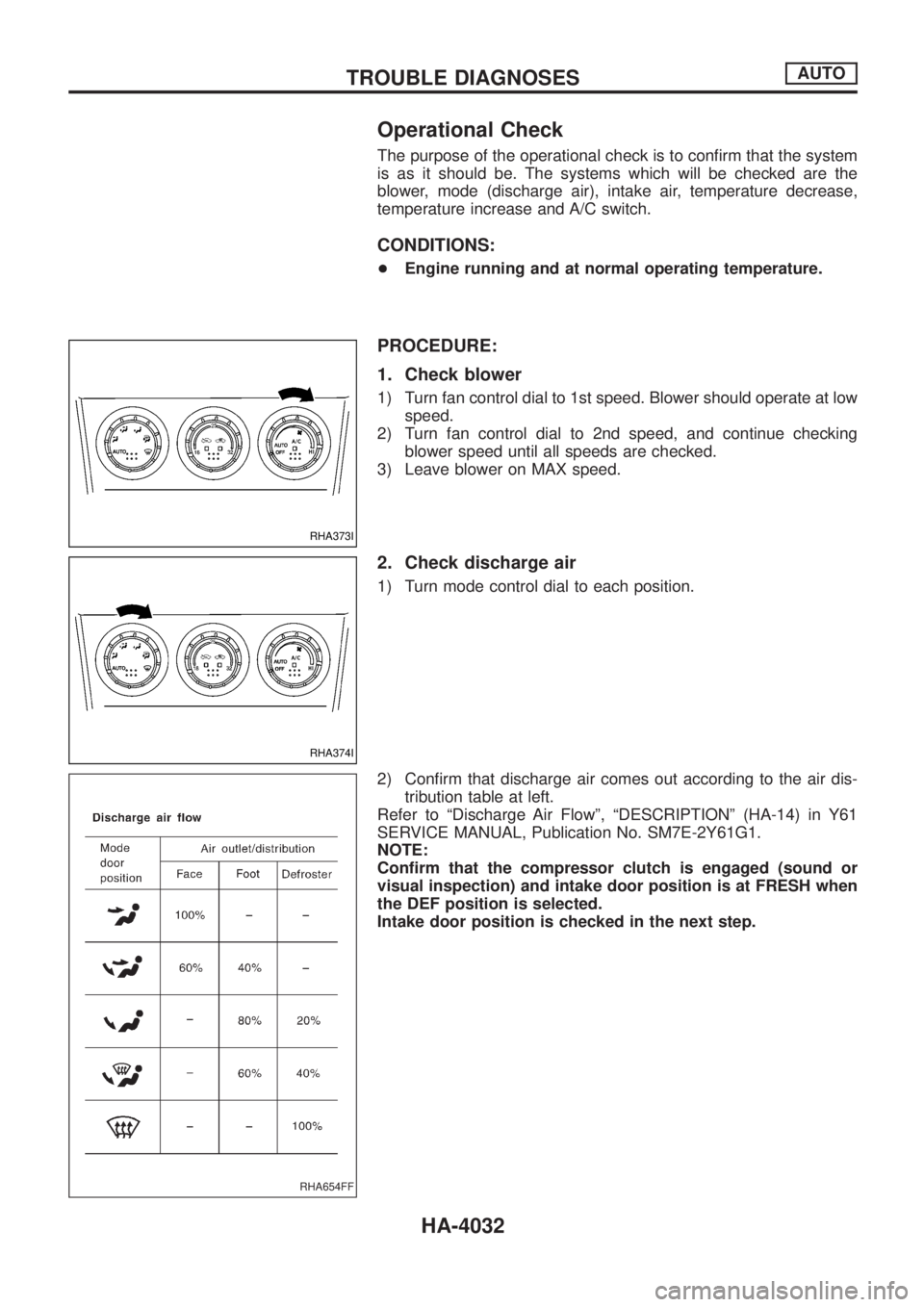

Operational Check

The purpose of the operational check is to con®rm that the system

is as it should be. The systems which will be checked are the

blower, mode (discharge air), intake air, temperature decrease,

temperature increase and A/C switch.

CONDITIONS:

+Engine running and at normal operating temperature.

PROCEDURE:

1. Check blower

1) Turn fan control dial to 1st speed. Blower should operate at low

speed.

2) Turn fan control dial to 2nd speed, and continue checking

blower speed until all speeds are checked.

3) Leave blower on MAX speed.

2. Check discharge air

1) Turn mode control dial to each position.

2) Con®rm that discharge air comes out according to the air dis-

tribution table at left.

Refer to ªDischarge Air Flowº, ªDESCRIPTIONº (HA-14) in Y61

SERVICE MANUAL, Publication No. SM7E-2Y61G1.

NOTE:

Con®rm that the compressor clutch is engaged (sound or

visual inspection) and intake door position is at FRESH when

the DEF position is selected.

Intake door position is checked in the next step.

RHA373I

RHA374I

RHA654FF

TROUBLE DIAGNOSESAUTO

HA-4032

Page 519 of 579

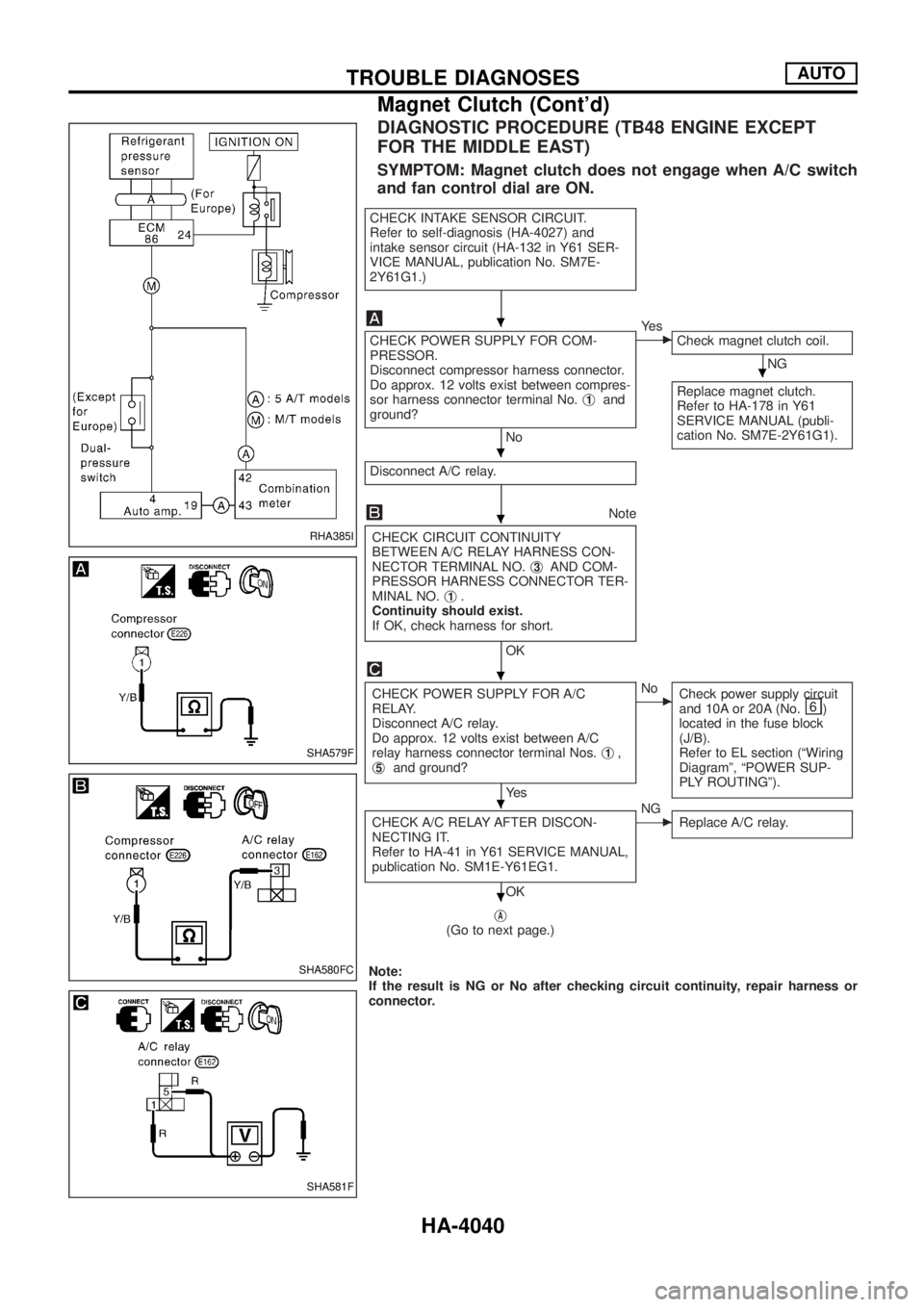

DIAGNOSTIC PROCEDURE (TB48 ENGINE EXCEPT

FOR THE MIDDLE EAST)

SYMPTOM: Magnet clutch does not engage when A/C switch

and fan control dial are ON.

CHECK INTAKE SENSOR CIRCUIT.

Refer to self-diagnosis (HA-4027) and

intake sensor circuit (HA-132 in Y61 SER-

VICE MANUAL, publication No. SM7E-

2Y61G1.)

CHECK POWER SUPPLY FOR COM-

PRESSOR.

Disconnect compressor harness connector.

Do approx. 12 volts exist between compres-

sor harness connector terminal No.j

1and

ground?

No

cYe s

Check magnet clutch coil.

NG

Replace magnet clutch.

Refer to HA-178 in Y61

SERVICE MANUAL (publi-

cation No. SM7E-2Y61G1).

Disconnect A/C relay.

Note

CHECK CIRCUIT CONTINUITY

BETWEEN A/C RELAY HARNESS CON-

NECTOR TERMINAL NO.j

3AND COM-

PRESSOR HARNESS CONNECTOR TER-

MINAL NO.j

1.

Continuity should exist.

If OK, check harness for short.

OK

CHECK POWER SUPPLY FOR A/C

RELAY.

Disconnect A/C relay.

Do approx. 12 volts exist between A/C

relay harness connector terminal Nos.j

1,

j5and ground?

Ye s

cNo

Check power supply circuit

and 10A or 20A (No.

)

located in the fuse block

(J/B).

Refer to EL section (ªWiring

Diagramº, ªPOWER SUP-

PLY ROUTINGº).

CHECK A/C RELAY AFTER DISCON-

NECTING IT.

Refer to HA-41 in Y61 SERVICE MANUAL,

publication No. SM1E-Y61EG1.

OK

cNG

Replace A/C relay.

jA(Go to next page.)

Note:

If the result is NG or No after checking circuit continuity, repair harness or

connector.

RHA385I

SHA579F

SHA580FC

SHA581F

.

.

.

.

.

.

.

TROUBLE DIAGNOSESAUTO

Magnet Clutch (Cont'd)

HA-4040

Page 522 of 579

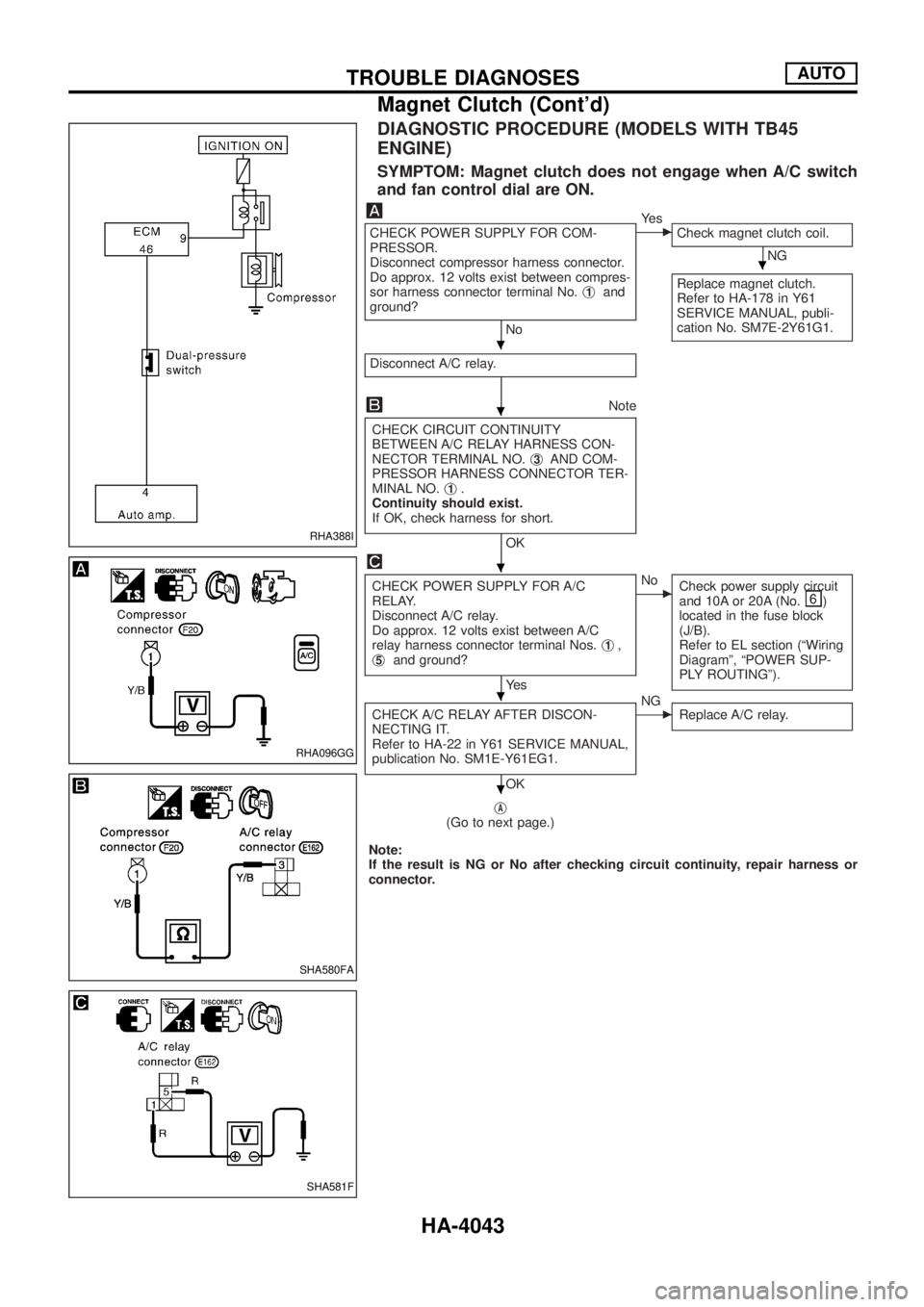

DIAGNOSTIC PROCEDURE (MODELS WITH TB45

ENGINE)

SYMPTOM: Magnet clutch does not engage when A/C switch

and fan control dial are ON.

CHECK POWER SUPPLY FOR COM-

PRESSOR.

Disconnect compressor harness connector.

Do approx. 12 volts exist between compres-

sor harness connector terminal No.j

1and

ground?

No

cYe s

Check magnet clutch coil.

NG

Replace magnet clutch.

Refer to HA-178 in Y61

SERVICE MANUAL, publi-

cation No. SM7E-2Y61G1.

Disconnect A/C relay.

Note

CHECK CIRCUIT CONTINUITY

BETWEEN A/C RELAY HARNESS CON-

NECTOR TERMINAL NO.j

3AND COM-

PRESSOR HARNESS CONNECTOR TER-

MINAL NO.j

1.

Continuity should exist.

If OK, check harness for short.

OK

CHECK POWER SUPPLY FOR A/C

RELAY.

Disconnect A/C relay.

Do approx. 12 volts exist between A/C

relay harness connector terminal Nos.j

1,

j5and ground?

Ye s

cNo

Check power supply circuit

and 10A or 20A (No.

)

located in the fuse block

(J/B).

Refer to EL section (ªWiring

Diagramº, ªPOWER SUP-

PLY ROUTINGº).

CHECK A/C RELAY AFTER DISCON-

NECTING IT.

Refer to HA-22 in Y61 SERVICE MANUAL,

publication No. SM1E-Y61EG1.

OK

cNG

Replace A/C relay.

jA(Go to next page.)

Note:

If the result is NG or No after checking circuit continuity, repair harness or

connector.

RHA388I

RHA096GG

SHA580FA

SHA581F

.

.

.

.

.

.

TROUBLE DIAGNOSESAUTO

Magnet Clutch (Cont'd)

HA-4043

Page 525 of 579

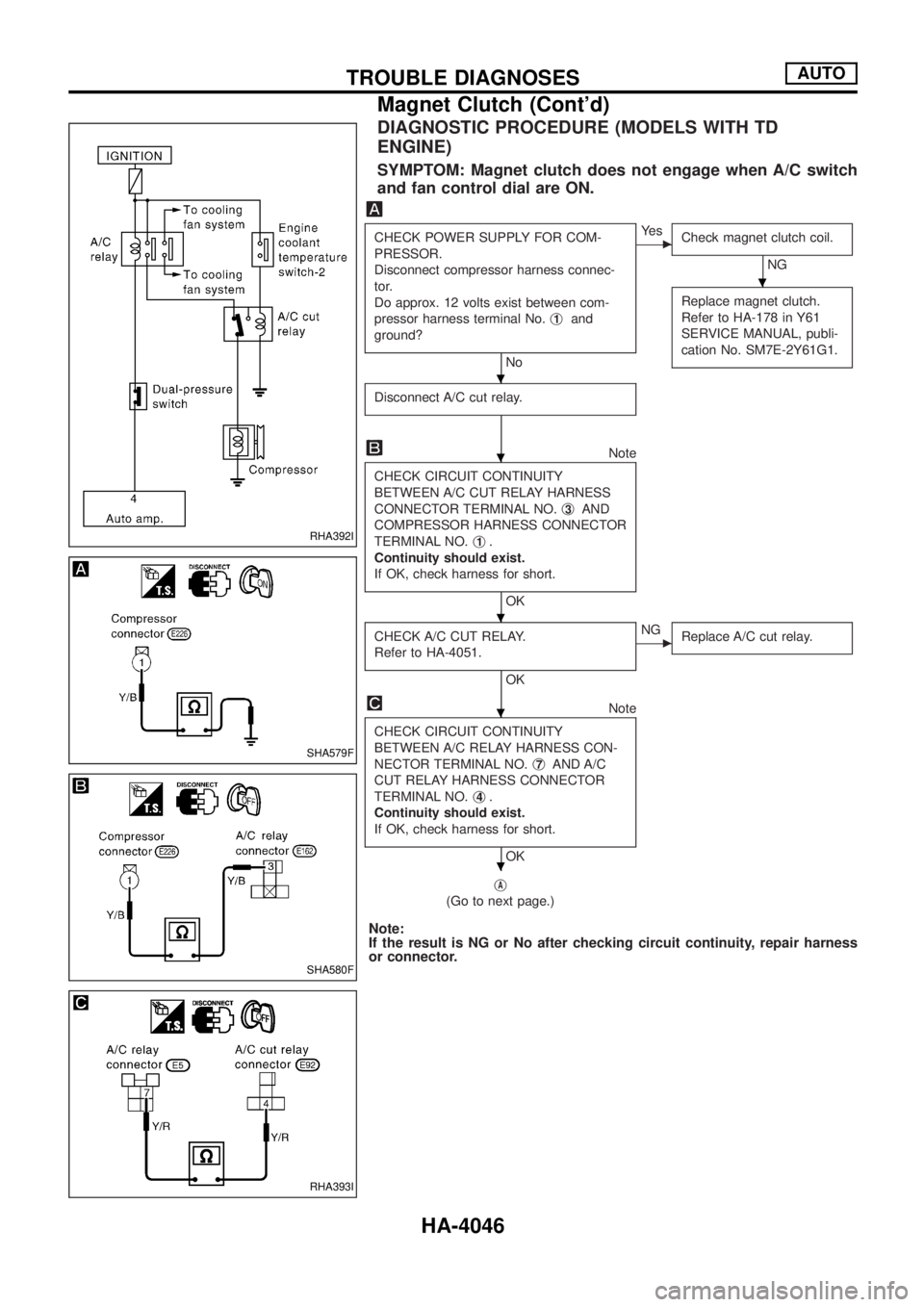

DIAGNOSTIC PROCEDURE (MODELS WITH TD

ENGINE)

SYMPTOM: Magnet clutch does not engage when A/C switch

and fan control dial are ON.

CHECK POWER SUPPLY FOR COM-

PRESSOR.

Disconnect compressor harness connec-

tor.

Do approx. 12 volts exist between com-

pressor harness terminal No.j

1and

ground?

No

cYe s

Check magnet clutch coil.

NG

Replace magnet clutch.

Refer to HA-178 in Y61

SERVICE MANUAL, publi-

cation No. SM7E-2Y61G1.

Disconnect A/C cut relay.

Note

CHECK CIRCUIT CONTINUITY

BETWEEN A/C CUT RELAY HARNESS

CONNECTOR TERMINAL NO.j

3AND

COMPRESSOR HARNESS CONNECTOR

TERMINAL NO.j

1.

Continuity should exist.

If OK, check harness for short.

OK

CHECK A/C CUT RELAY.

Refer to HA-4051.

OK

cNG

Replace A/C cut relay.

Note

CHECK CIRCUIT CONTINUITY

BETWEEN A/C RELAY HARNESS CON-

NECTOR TERMINAL NO.j

7AND A/C

CUT RELAY HARNESS CONNECTOR

TERMINAL NO.j

4.

Continuity should exist.

If OK, check harness for short.

OK

j

A

(Go to next page.)

Note:

If the result is NG or No after checking circuit continuity, repair harness

or connector.

RHA392I

SHA579F

SHA580F

RHA393I

.

.

.

.

.

.

TROUBLE DIAGNOSESAUTO

Magnet Clutch (Cont'd)

HA-4046

Page 526 of 579

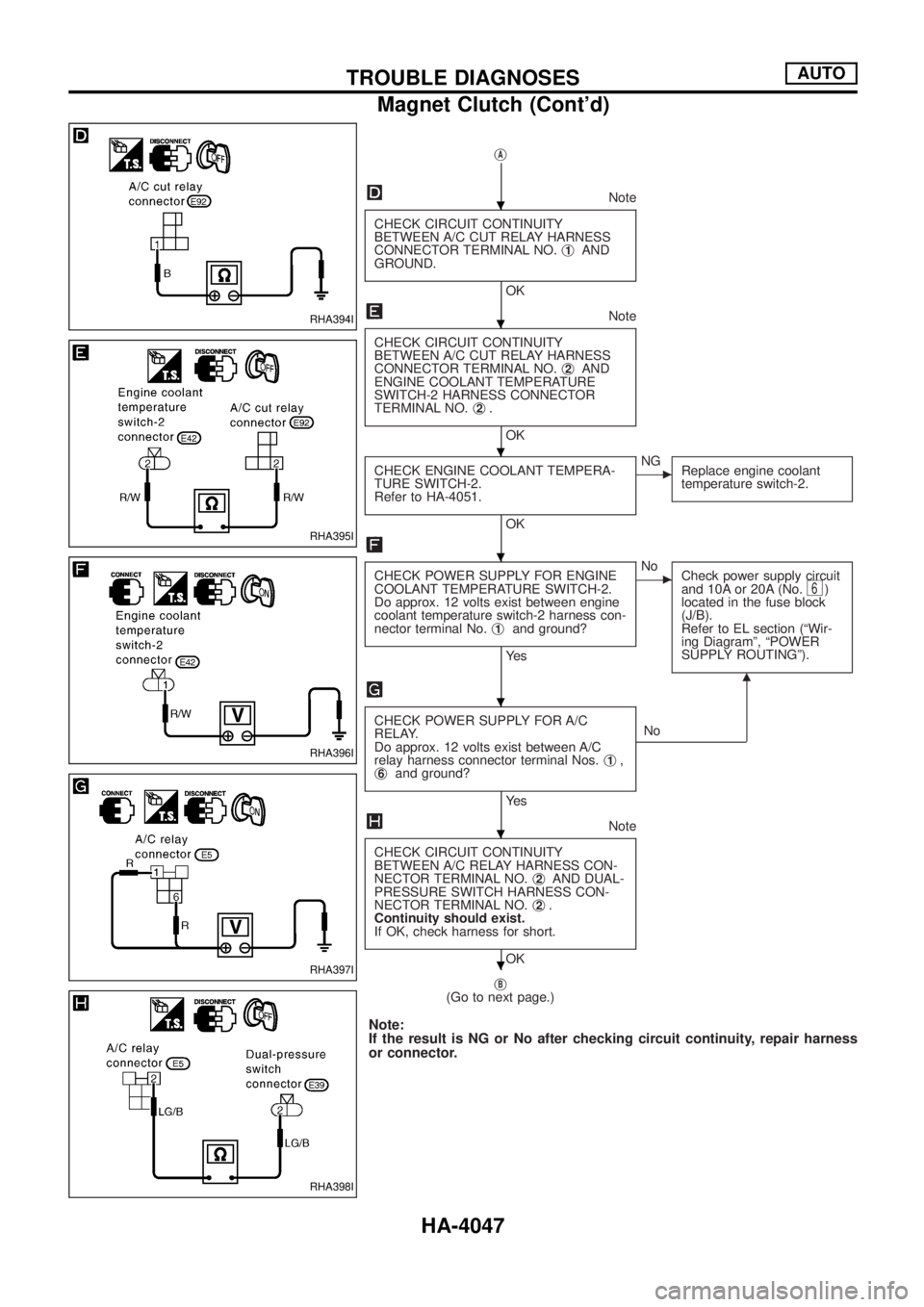

jA

Note

CHECK CIRCUIT CONTINUITY

BETWEEN A/C CUT RELAY HARNESS

CONNECTOR TERMINAL NO.j

1AND

GROUND.

OK

Note

CHECK CIRCUIT CONTINUITY

BETWEEN A/C CUT RELAY HARNESS

CONNECTOR TERMINAL NO.j

2AND

ENGINE COOLANT TEMPERATURE

SWITCH-2 HARNESS CONNECTOR

TERMINAL NO.j

2.

OK

CHECK ENGINE COOLANT TEMPERA-

TURE SWITCH-2.

Refer to HA-4051.

OK

cNG

Replace engine coolant

temperature switch-2.

CHECK POWER SUPPLY FOR ENGINE

COOLANT TEMPERATURE SWITCH-2.

Do approx. 12 volts exist between engine

coolant temperature switch-2 harness con-

nector terminal No.j

1and ground?

Ye s

cNo

Check power supply circuit

and 10A or 20A (No.

6)

located in the fuse block

(J/B).

Refer to EL section (ªWir-

ing Diagramº, ªPOWER

SUPPLY ROUTINGº).

CHECK POWER SUPPLY FOR A/C

RELAY.

Do approx. 12 volts exist between A/C

relay harness connector terminal Nos.j

1,

j6and ground?

Ye sNo

m

Note

CHECK CIRCUIT CONTINUITY

BETWEEN A/C RELAY HARNESS CON-

NECTOR TERMINAL NO.j

2AND DUAL-

PRESSURE SWITCH HARNESS CON-

NECTOR TERMINAL NO.j

2.

Continuity should exist.

If OK, check harness for short.

OK

j

B(Go to next page.)

Note:

If the result is NG or No after checking circuit continuity, repair harness

or connector.

RHA394I

RHA395I

RHA396I

RHA397I

RHA398I

.

.

.

.

.

.

.

TROUBLE DIAGNOSESAUTO

Magnet Clutch (Cont'd)

HA-4047

Page 528 of 579

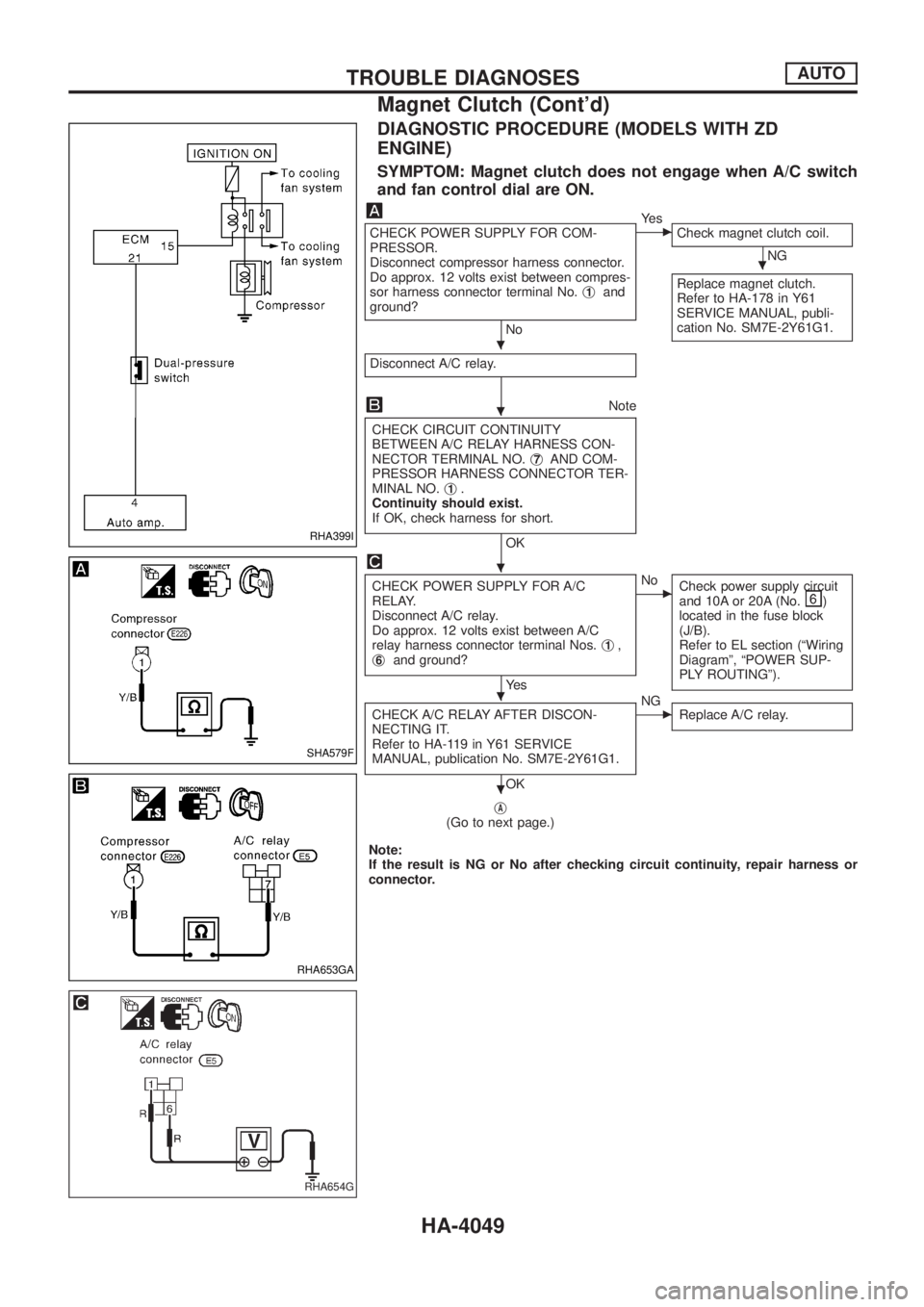

DIAGNOSTIC PROCEDURE (MODELS WITH ZD

ENGINE)

SYMPTOM: Magnet clutch does not engage when A/C switch

and fan control dial are ON.

CHECK POWER SUPPLY FOR COM-

PRESSOR.

Disconnect compressor harness connector.

Do approx. 12 volts exist between compres-

sor harness connector terminal No.j

1and

ground?

No

cYe s

Check magnet clutch coil.

NG

Replace magnet clutch.

Refer to HA-178 in Y61

SERVICE MANUAL, publi-

cation No. SM7E-2Y61G1.

Disconnect A/C relay.

Note

CHECK CIRCUIT CONTINUITY

BETWEEN A/C RELAY HARNESS CON-

NECTOR TERMINAL NO.j

7AND COM-

PRESSOR HARNESS CONNECTOR TER-

MINAL NO.j

1.

Continuity should exist.

If OK, check harness for short.

OK

CHECK POWER SUPPLY FOR A/C

RELAY.

Disconnect A/C relay.

Do approx. 12 volts exist between A/C

relay harness connector terminal Nos.j

1,

j6and ground?

Ye s

cNo

Check power supply circuit

and 10A or 20A (No.

)

located in the fuse block

(J/B).

Refer to EL section (ªWiring

Diagramº, ªPOWER SUP-

PLY ROUTINGº).

CHECK A/C RELAY AFTER DISCON-

NECTING IT.

Refer to HA-119 in Y61 SERVICE

MANUAL, publication No. SM7E-2Y61G1.

OK

cNG

Replace A/C relay.

jA(Go to next page.)

Note:

If the result is NG or No after checking circuit continuity, repair harness or

connector.

RHA399I

SHA579F

RHA653GA

RHA654G

.

.

.

.

.

.

TROUBLE DIAGNOSESAUTO

Magnet Clutch (Cont'd)

HA-4049

Page 530 of 579

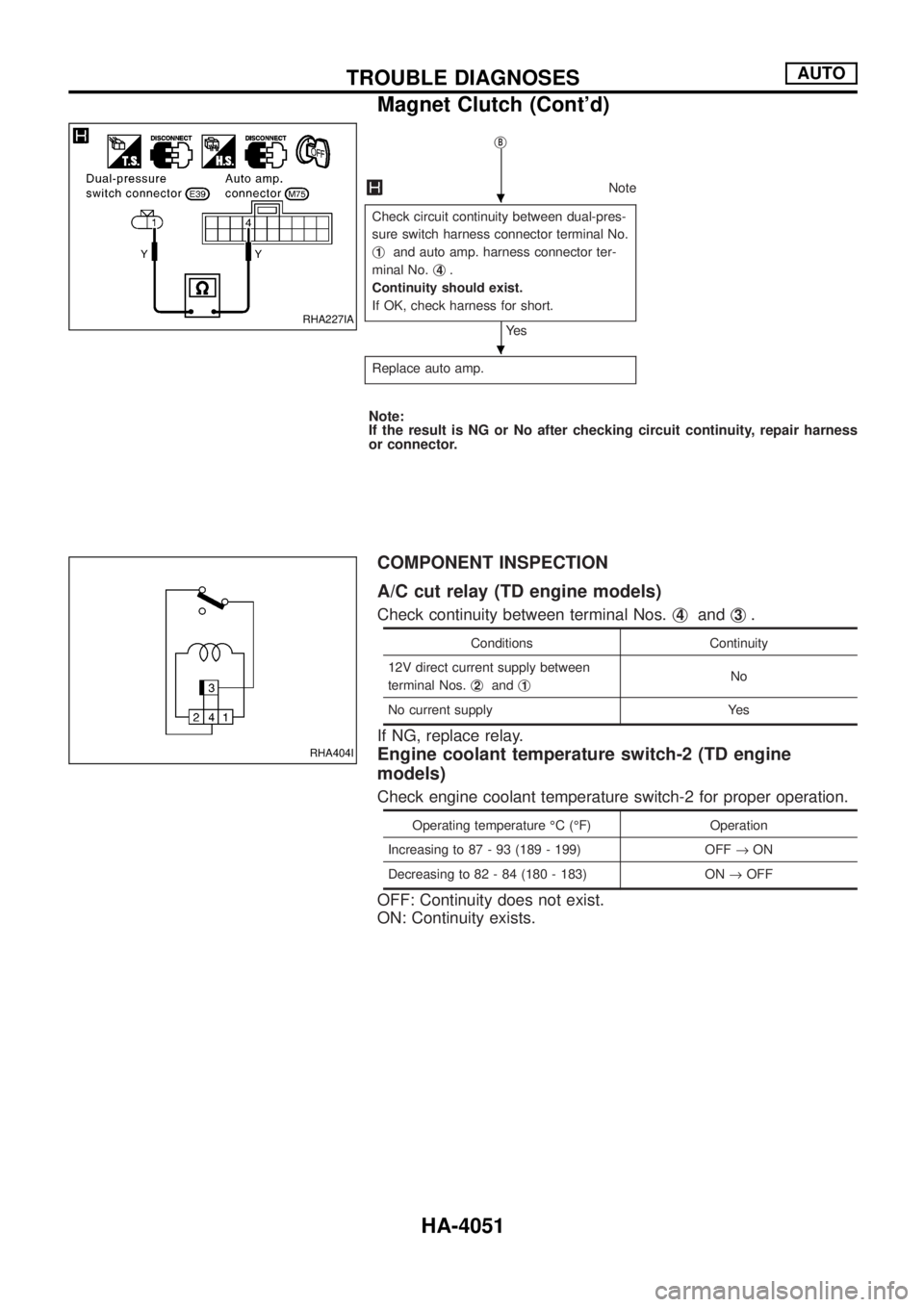

jB

Note

Check circuit continuity between dual-pres-

sure switch harness connector terminal No.

j

1and auto amp. harness connector ter-

minal No.j

4.

Continuity should exist.

If OK, check harness for short.

Ye s

Replace auto amp.

Note:

If the result is NG or No after checking circuit continuity, repair harness

or connector.

COMPONENT INSPECTION

A/C cut relay (TD engine models)

Check continuity between terminal Nos.j4andj3.

Conditions Continuity

12V direct current supply between

terminal Nos.j

2andj1No

No current supply Yes

If NG, replace relay.

Engine coolant temperature switch-2 (TD engine

models)

Check engine coolant temperature switch-2 for proper operation.

Operating temperature ÉC (ÉF) Operation

Increasing to 87 - 93 (189 - 199) OFF®ON

Decreasing to 82 - 84 (180 - 183) ON®OFF

OFF: Continuity does not exist.

ON: Continuity exists.

RHA227IA

RHA404I

.

.

TROUBLE DIAGNOSESAUTO

Magnet Clutch (Cont'd)

HA-4051

Page 547 of 579

A

A/C operational check ................................HA-4032

A/C self-diagnoses (auto A/C)....................HA-4025

A/C, A - Wiring diagram .............................HA-4009

A/CCUT - Wiring diagram ..........................EC-4058

Air cleaner ®lter replacement .....................MA-4003

Air ¯ow meter - See Mass air ¯ow

sensor .....................................................EC-4047

Air mix. door motor.....................................HA-4036

Antenna .......................................................EL-4164

ASCD (automatic speed control

device) .....................................................EL-4233

ASCD - Wiring diagram ..............................EL-4234

A/T - Wiring diagram ...................................AT-4003

A/T trouble diagnoses .................................AT-4011

A/T Wiring diagram AT - NONDTC .............AT-4012

Audio ...........................................................EL-4136

AUDIO - Wiring diagram .............................EL-4137

Audio and A/C control removal and

installation - See Instrument panel .........BT-4006

Auto air conditioner - Wiring diagram ........HA-4009

Automatic speed control system - See

ASCD ......................................................EL-4233

AV and NAVI control unit ............................EL-4164

B

Back-up lamp ..............................................EL-4055

BACK/L - Wiring diagram............................EL-4055

Blower motor ..............................................HA-4038

Bumper, front ..............................................BT-4002

Bumper, rear ...............................................BT-4005

C

Camshaft ....................................................EM-4003

CHIME - Wiring diagram .............................EL-4113

Combination meter......................................EL-4095

Combination meter removal and instal-

lation - See Instrument panel..................BT-4006

Combination switch .....................................EL-4034

COMPAS - Wiring diagram .........................EL-4099

Console box - See Instrument panel ..........BT-4006

CONSULT-II general information.................GI-4002

Cruise control - See ASCD .........................EL-4233

Cylinder head .............................................EM-4016

D

Daytime light system...................................EL-4047

DEF - Wiring diagram .................................EL-4126

DEICER - Wiring diagram...........................EL-4125

Dimensions ..................................................GI-4008

D/LOCK - Wiring diagram ...........................EL-4245Dome light - See Interior lamp ...................EL-4088

DTRL - Wiring diagram ...............................EL-4047

E

ECM input/output signal .............................EC-4040

Electrical load signal circuit ...EC-4008, 4016, 4025

Electrical units location ...............................EL-4300

Engine control circuit

diagram .............................EC-4003, 4005, 4013,

4022, 4037, 4059

Exhaust system ..........................................FE-4008

Exterior ........................................................BT-4009

F

F/FOG - Wiring diagram .............................EL-4061

FICD - Wiring diagram ...............................EC-4036

Fog lamp, front............................................EL-4061

Fog lamp, rear ............................................EL-4064

Front bumper ..............................................BT-4002

Front fog lamp.............................................EL-4061

Front washer ...............................................EL-4117

Front wiper ..................................................EL-4117

Fuel gauge ..................................................EL-4095

Fuse ..............................................................Foldout

Fusible link....................................................Foldout

G

Gauges........................................................EL-4095

GLOW - Wiring diagram.............................EC-4033

GPS antenna ..............................................EL-4164

Ground distribution......................................EL-4016

H

Harness layout ..................................EL-4307, 4308

Headlamp ....................................................EL-4040

Headlamp washer .......................................EL-4122

Heat up switch............................................EC-4054

Heated seat.................................................EL-4231

HEATUP - Wiring diagram .........................EC-4054

Height (Dimensions) ....................................GI-4008

H/LAMP - Wiring diagram ...........................EL-4040

HLC - Wiring diagram .................................EL-4122

Hood............................................................BT-4002

Horn ............................................................EL-4124

HORN - Wiring diagram..............................EL-4124

HSEAT - Wiring diagram.............................EL-4231

I

ILL - Wiring diagram ...................................EL-4080

ALPHABETICAL INDEX

IDX-4002