battery NISSAN PATROL 2006 Service Manual

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2006, Model line: PATROL, Model: NISSAN PATROL 2006Pages: 1226, PDF Size: 37.18 MB

Page 959 of 1226

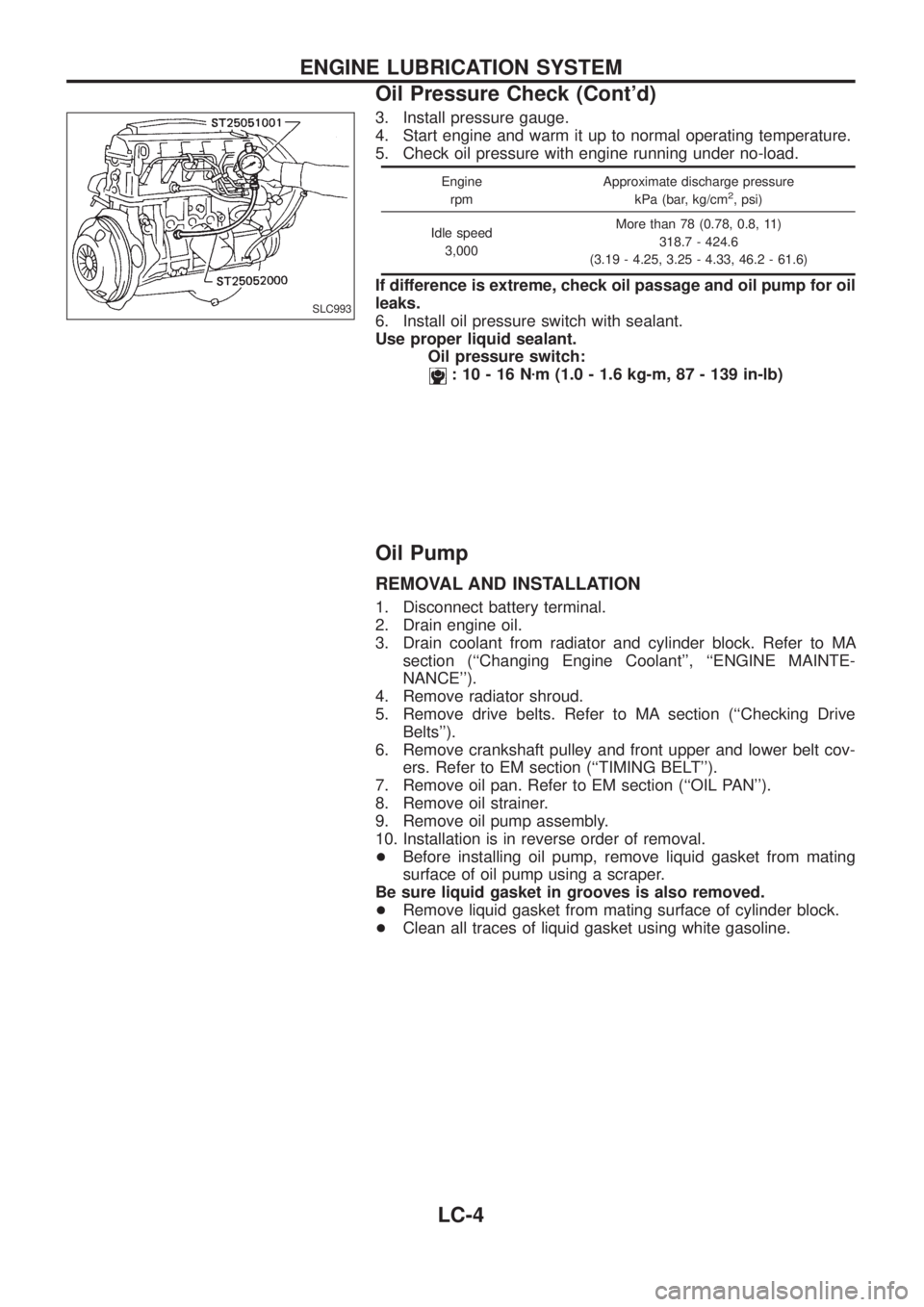

3. Install pressure gauge.

4. Start engine and warm it up to normal operating temperature.

5. Check oil pressure with engine running under no-load.

Engine

rpmApproximate discharge pressure

kPa (bar, kg/cm2, psi)

Idle speed

3,000More than 78 (0.78, 0.8, 11)

318.7 - 424.6

(3.19 - 4.25, 3.25 - 4.33, 46.2 - 61.6)

If difference is extreme, check oil passage and oil pump for oil

leaks.

6. Install oil pressure switch with sealant.

Use proper liquid sealant.

Oil pressure switch:

:10-16Nzm (1.0 - 1.6 kg-m, 87 - 139 in-lb)

Oil Pump

REMOVAL AND INSTALLATION

1. Disconnect battery terminal.

2. Drain engine oil.

3. Drain coolant from radiator and cylinder block. Refer to MA

section (``Changing Engine Coolant'', ``ENGINE MAINTE-

NANCE'').

4. Remove radiator shroud.

5. Remove drive belts. Refer to MA section (``Checking Drive

Belts'').

6. Remove crankshaft pulley and front upper and lower belt cov-

ers. Refer to EM section (``TIMING BELT'').

7. Remove oil pan. Refer to EM section (``OIL PAN'').

8. Remove oil strainer.

9. Remove oil pump assembly.

10. Installation is in reverse order of removal.

+Before installing oil pump, remove liquid gasket from mating

surface of oil pump using a scraper.

Be sure liquid gasket in grooves is also removed.

+Remove liquid gasket from mating surface of cylinder block.

+Clean all traces of liquid gasket using white gasoline.

SLC993

ENGINE LUBRICATION SYSTEM

Oil Pressure Check (Cont'd)

LC-4

Page 979 of 1226

Shown below are Pre-delivery Inspection Items required for the new vehicle. It is recommended that

necessary items other than those listed here be added, paying due regard to the conditions in each

country.

Perform applicable items on each model. Consult text of this section for speci®cations.

UNDER HOOD Ð engine off

hRadiator coolant level and coolant hose connec-

tions for leaks

hBattery ¯uid level, speci®c gravity and condi-

tions of battery terminals

hDrive belts tension

hFuel ®lter for water or dusts, and fuel lines and

connections for leaks

hEngine oil level and oil leaks

hClutch and brake reservoir ¯uid level and ¯uid

lines for leaks

hWindshield and rear window washer and head-

lamp cleaner reservoir ¯uid level

hPower steering reservoir ¯uid level and hose

connections for leaks

ON INSIDE AND OUTSIDE

hXRemove front spring/strut spacer (If applicable)

hOperation of all instruments, gauges, lights and

accessories

hOperation of horn(s), wiper and washer

hSteering lock for operation

hCheck air conditioner for gas leaks

hFront and rear seats, and seat belts for opera-

tion

hAll moldings, trims and ®ttings for ®t and align-

ment

hAll windows for operation and alignment

hHood, trunk lid, door panels for ®t and alignment

hLatches, keys and locks for operation

hWeatherstrips for adhesion and ®t

hHeadlamp aiming

hTighten wheel nuts (Inc. inner nuts if applicable)

hTire pressure (Inc. spare tire)

hCheck front wheels for toe-in

hInstall clock/voltmeter/room lamp fuse (If appli-

cable)

h

XInstall deodorizing ®lter to air puri®er (If appli-

cable)

h

XRemove wiper blade protectors (If applicable)

UNDER BODY

hManual transmission/transaxle gear oil, transfer

¯uid and differential gear oil level

hBrake and fuel lines and oil/¯uid reservoirs for

leaks

hTighten bolts and nuts of steering linkage and

gear box, suspension, propeller shafts and drive

shafts

h

XTighten rear body bolts and nuts (Models with

wooden bed only)

ROAD TEST

hClutch operation

hParking brake operation

hService brake operation

hAutomatic transmission/transaxle shift timing

and kickdown

hSteering control and returnability

hEngine performance

hSqueaks and rattles

ENGINE OPERATING AND HOT

hAdjust idle mixture and speed (and ignition tim-

ing*1)

hAutomatic transmission/transaxle ¯uid level

hEngine idling and stop knob operation (Diesel

only)

FINAL INSPECTION

hInstall necessary parts (outside mirror, wheel

covers, seat belts, mat, carpet or mud ¯aps)

hInspect for interior and exterior metal and paint

damage

hCheck for spare tire, jack, tools (wheel chock),

and literature

hWash, clean interior and exterior

*1: Not required on models with a direct ignition system

h

X: Not applicable to this model.

PRE-DELIVERY INSPECTION ITEMS

MA-2

Page 980 of 1226

General maintenance includes those items which should be checked during the normal day-to-day operation

of the vehicle. They are essential if the vehicle is to continue operating properly. The owners can perform the

checks and inspections themselves or they can have their NISSAN dealers do them.

Item Reference pages

OUTSIDE THE VEHICLE

The maintenance items listed here should be performed from time to time, unless otherwise

speci®ed.

TiresCheck the pressure with a gauge periodically when at a service station, including the

spare, and adjust to the speci®ed pressure if necessary. Check carefully for damage, cuts or

excessive wear.Ð

Windshield wiper bladesCheck for cracks or wear if they do not wipe properly. Ð

Doors and engine hoodCheck that all doors, the engine hood, the trunk lid and back door

operate properly. Also ensure that all latches lock securely. Lubricate hinges, latches, rollers and

links if necessary. Make sure that the secondary latch keeps the hood from opening when the

primary latch is released.

When driving in areas using road salt or other corrosive materials, check for lubrication fre-

quently.MA-27

Tire rotationTires should be rotated every 5,000 km (3,000 miles) for 4WD models. MA-25

INSIDE THE VEHICLE

The maintenance items listed here should be checked on a regular basis, such as when per-

forming periodic maintenance, cleaning the vehicle, etc.

LightsMake sure that the headlights, stop lights, tail lights, turn signal lights, and other lights

are all operating properly and installed securely. Also check headlight aim.Ð

Warning lights and chimesMake sure that all warning lights and chimes are operating prop-

erly.Ð

Steering wheelCheck for change in the steering conditions, such as excessive free play, hard

steering or strange noises.

Free play: Less than 35 mm (1.38 in)Ð

Seat beltsCheck that all parts of the seat belt system (e.g. buckles, anchors, adjusters and

retractors) operate properly and smoothly, and are installed securely. Check the belt webbing for

cuts, fraying, wear or damage.MA-27

UNDER THE HOOD AND VEHICLE

The maintenance items listed here should be checked periodically e.g. each time you check the

engine oil or refuel.

Windshield washer ¯uidCheck that there is adequate ¯uid in the tank. Ð

Engine coolant levelCheck the coolant level when the engine is cold. MA-14, 15

Engine oil levelCheck the level after parking the vehicle on a level spot and turning off the

engine.MA-13, 14

Brake and clutch ¯uid levelMake sure that the brake and clutch ¯uid levels are between the

``MAX'' and ``MIN'' lines on the reservoir.MA-20, 23

BatteryCheck the ¯uid level in each cell. It should be between the ``MAX'' and ``MIN'' lines. Ð

GENERAL MAINTENANCE

MA-3

Page 1116 of 1226

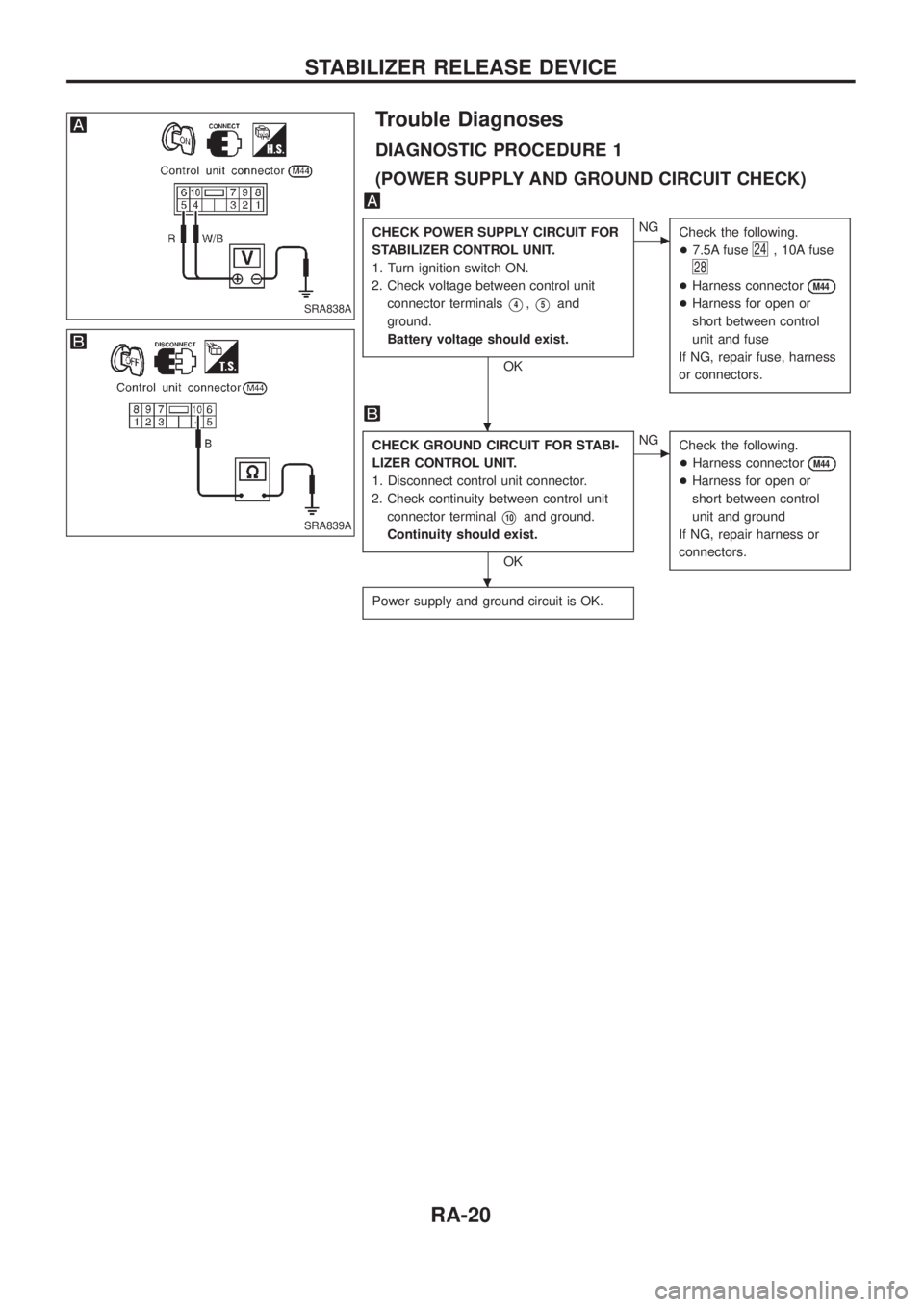

Trouble Diagnoses

DIAGNOSTIC PROCEDURE 1

(POWER SUPPLY AND GROUND CIRCUIT CHECK)

CHECK POWER SUPPLY CIRCUIT FOR

STABILIZER CONTROL UNIT.

1. Turn ignition switch ON.

2. Check voltage between control unit

connector terminals

V4,V5and

ground.

Battery voltage should exist.

OK

cNG

Check the following.

+7.5A fuse

24, 10A fuse

28

+Harness connectorM44

+Harness for open or

short between control

unit and fuse

If NG, repair fuse, harness

or connectors.

CHECK GROUND CIRCUIT FOR STABI-

LIZER CONTROL UNIT.

1. Disconnect control unit connector.

2. Check continuity between control unit

connector terminal

V10and ground.

Continuity should exist.

OK

cNG

Check the following.

+Harness connector

M44

+Harness for open or

short between control

unit and ground

If NG, repair harness or

connectors.

Power supply and ground circuit is OK.

SRA838A

SRA839A

.

.

STABILIZER RELEASE DEVICE

RA-20

Page 1118 of 1226

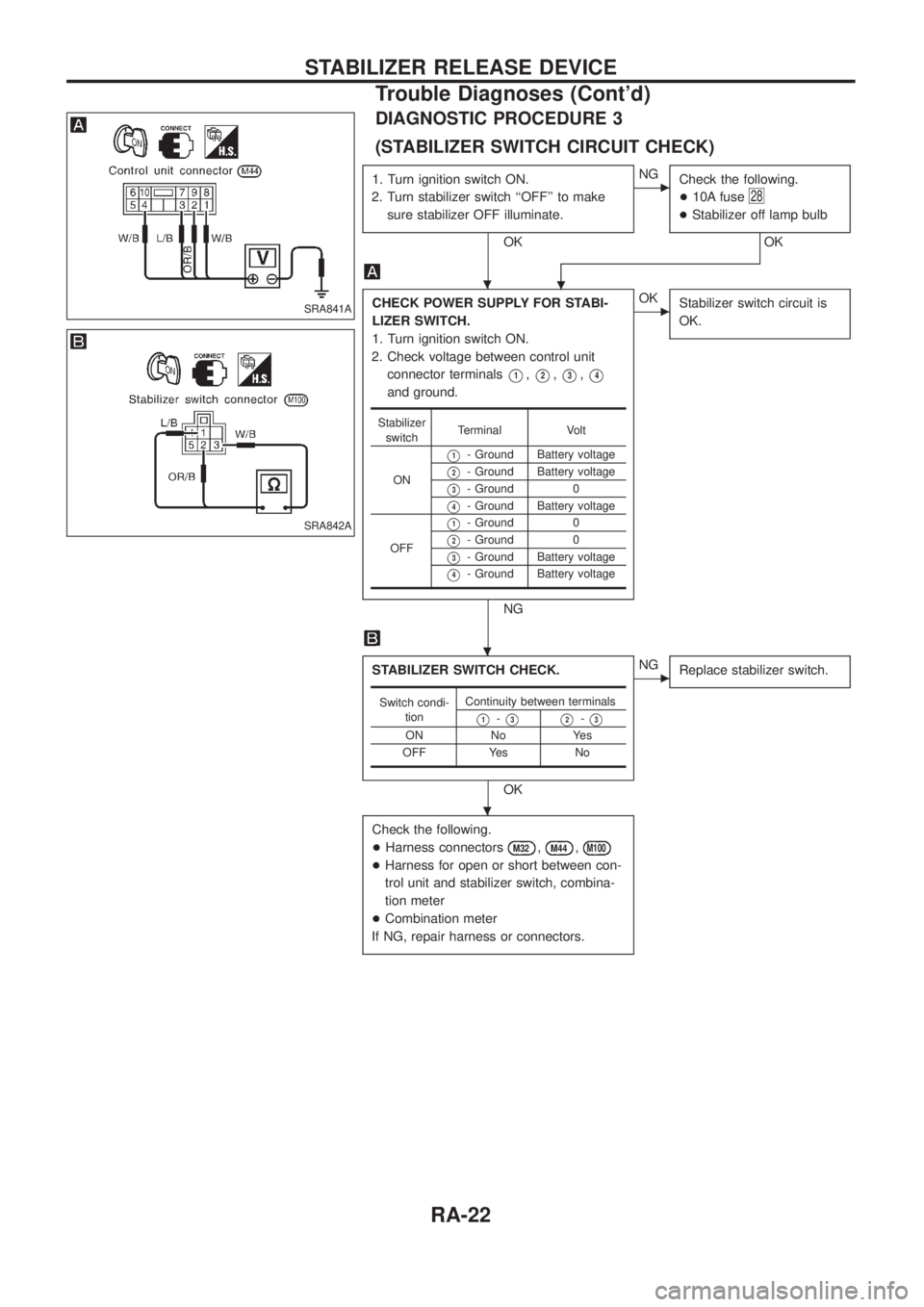

DIAGNOSTIC PROCEDURE 3

(STABILIZER SWITCH CIRCUIT CHECK)

1. Turn ignition switch ON.

2. Turn stabilizer switch ``OFF'' to make

sure stabilizer OFF illuminate.

OK

cNG

Check the following.

+10A fuse

28

+Stabilizer off lamp bulb

OK

.

CHECK POWER SUPPLY FOR STABI-

LIZER SWITCH.

1. Turn ignition switch ON.

2. Check voltage between control unit

connector terminals

V1,V2,V3,V4

and ground.

NG

cOK

Stabilizer switch circuit is

OK.

STABILIZER SWITCH CHECK.

OK

cNG

Replace stabilizer switch.

Check the following.

+Harness connectors

M32,M44,M100

+Harness for open or short between con-

trol unit and stabilizer switch, combina-

tion meter

+Combination meter

If NG, repair harness or connectors.

Stabilizer

switchTerminal Volt

ON

V1- Ground Battery voltage

V2- Ground Battery voltage

V3- Ground 0

V4- Ground Battery voltage

OFF

V1- Ground 0

V2- Ground 0

V3- Ground Battery voltage

V4- Ground Battery voltage

Switch condi-

tionContinuity between terminals

V1-V3V2-V3

ON No Yes

OFF Yes No

SRA841A

SRA842A

.

.

.

STABILIZER RELEASE DEVICE

Trouble Diagnoses (Cont'd)

RA-22

Page 1119 of 1226

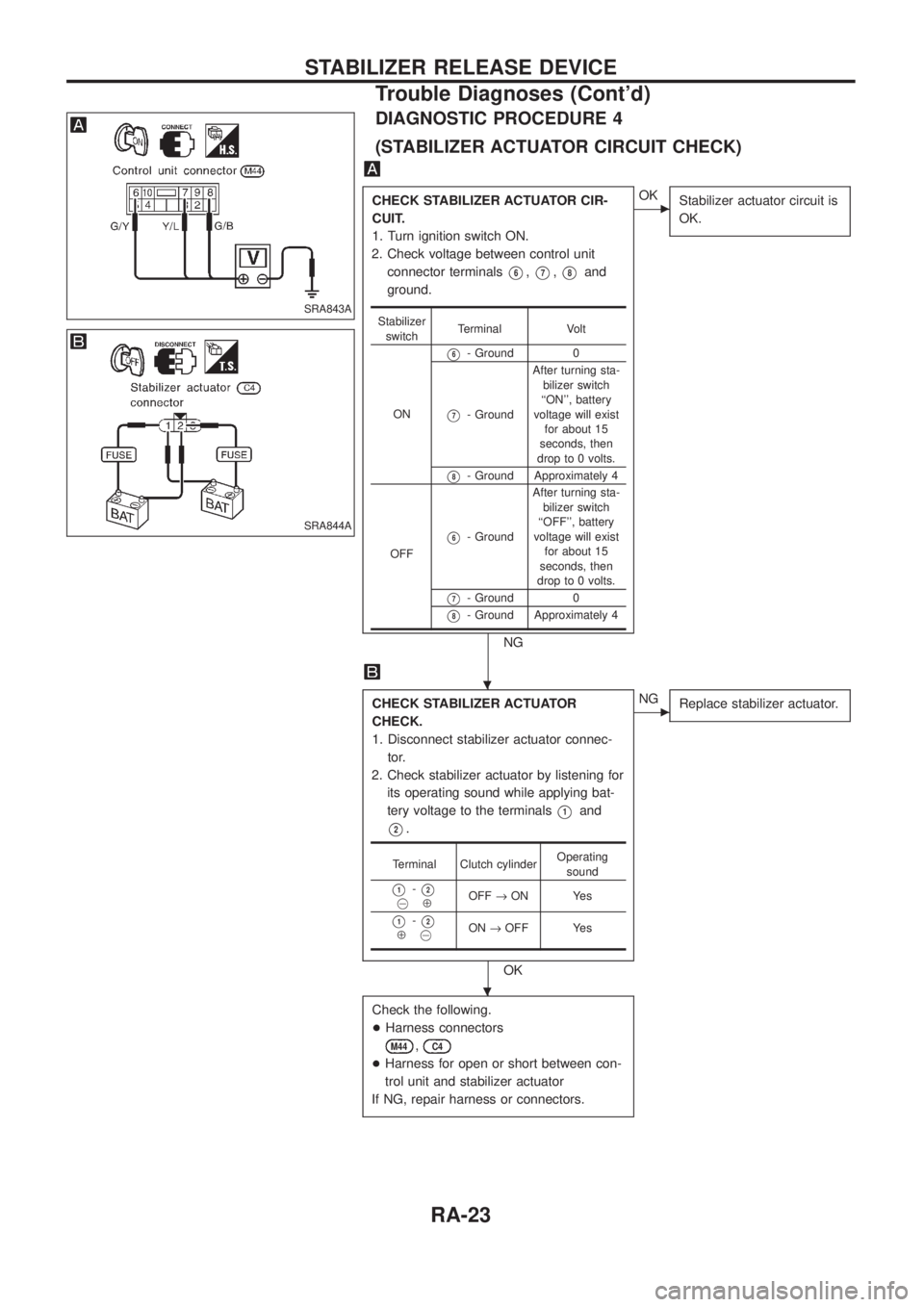

DIAGNOSTIC PROCEDURE 4

(STABILIZER ACTUATOR CIRCUIT CHECK)

CHECK STABILIZER ACTUATOR CIR-

CUIT.

1. Turn ignition switch ON.

2. Check voltage between control unit

connector terminals

V6,V7,V8and

ground.

NG

cOK

Stabilizer actuator circuit is

OK.

CHECK STABILIZER ACTUATOR

CHECK.

1. Disconnect stabilizer actuator connec-

tor.

2. Check stabilizer actuator by listening for

its operating sound while applying bat-

tery voltage to the terminals

V1and

V2.

OK

cNG

Replace stabilizer actuator.

Check the following.

+Harness connectors

M44,C4

+Harness for open or short between con-

trol unit and stabilizer actuator

If NG, repair harness or connectors.

Stabilizer

switchTerminal Volt

ON

V6- Ground 0

V7- GroundAfter turning sta-

bilizer switch

``ON'', battery

voltage will exist

for about 15

seconds, then

drop to 0 volts.

V8- Ground Approximately 4

OFF

V6- GroundAfter turning sta-

bilizer switch

``OFF'', battery

voltage will exist

for about 15

seconds, then

drop to 0 volts.

V7- Ground 0

V8- Ground Approximately 4

Terminal Clutch cylinderOperating

sound

V1-V2@ÅOFF®ON Yes

V1-V2Å@ON®OFF Yes

SRA843A

SRA844A

.

.

STABILIZER RELEASE DEVICE

Trouble Diagnoses (Cont'd)

RA-23

Page 1120 of 1226

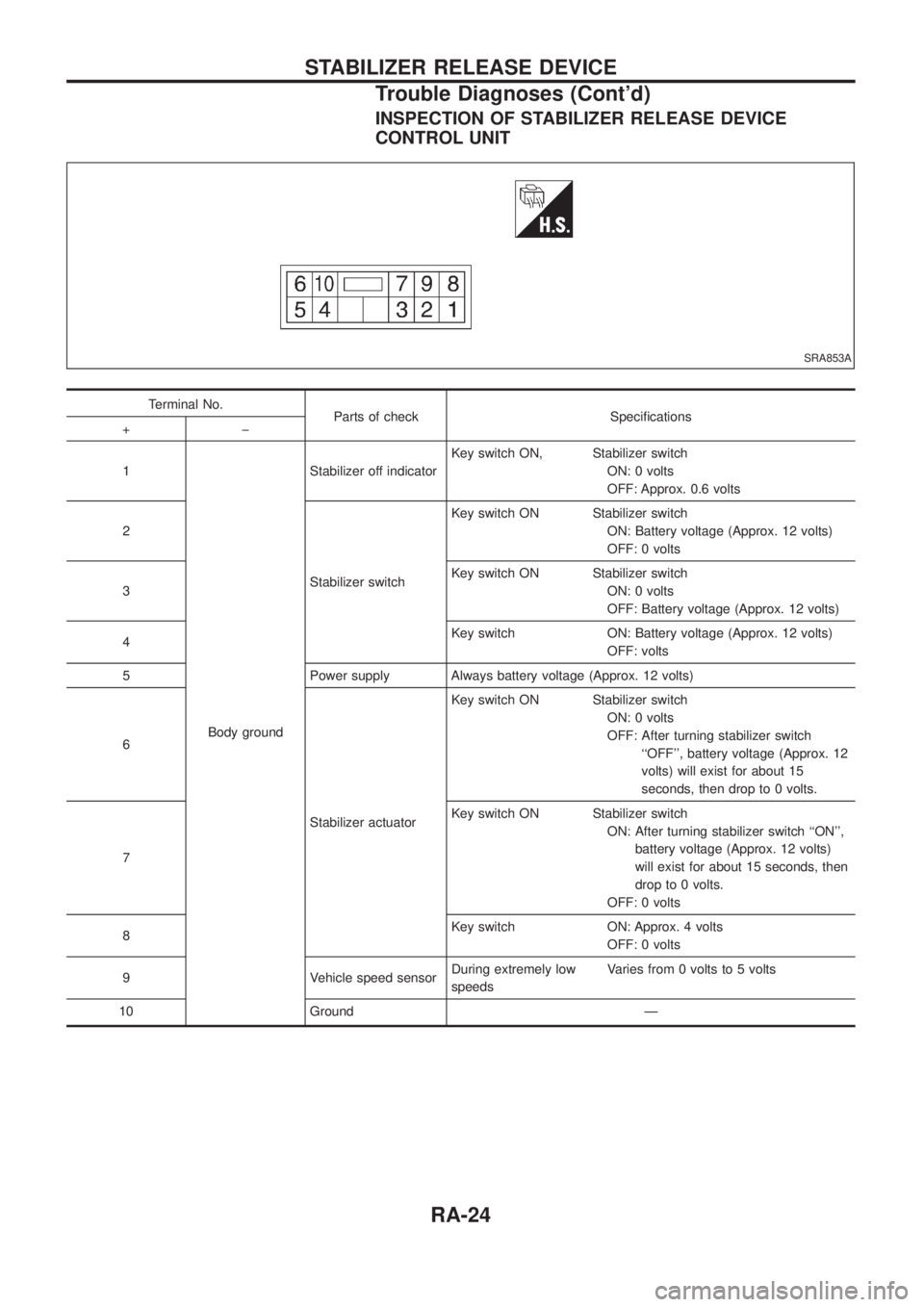

INSPECTION OF STABILIZER RELEASE DEVICE

CONTROL UNIT

Terminal No.

Parts of check Speci®cations

+þ

1

Body groundStabilizer off indicatorKey switch ON, Stabilizer switch

ON: 0 volts

OFF: Approx. 0.6 volts

2

Stabilizer switchKey switch ON Stabilizer switch

ON: Battery voltage (Approx. 12 volts)

OFF: 0 volts

3Key switch ON Stabilizer switch

ON: 0 volts

OFF: Battery voltage (Approx. 12 volts)

4Key switch ON: Battery voltage (Approx. 12 volts)

OFF: volts

5 Power supply Always battery voltage (Approx. 12 volts)

6

Stabilizer actuatorKey switch ON Stabilizer switch

ON: 0 volts

OFF: After turning stabilizer switch

``OFF'', battery voltage (Approx. 12

volts) will exist for about 15

seconds, then drop to 0 volts.

7Key switch ON Stabilizer switch

ON: After turning stabilizer switch ``ON'',

battery voltage (Approx. 12 volts)

will exist for about 15 seconds, then

drop to 0 volts.

OFF: 0 volts

8Key switch ON: Approx. 4 volts

OFF: 0 volts

9 Vehicle speed sensorDuring extremely low

speedsVaries from 0 volts to 5 volts

10 Ground Ð

SRA853A

STABILIZER RELEASE DEVICE

Trouble Diagnoses (Cont'd)

RA-24

Page 1124 of 1226

CAUTION:

+Before removing the seat belt pre-tensioner assembly (if equipped), turn the ignition switch off,

disconnect both battery cables and wait at least 3 minutes.

+After replacing or reinstalling seat belt pre-tensioner assembly, or reconnecting seat belt pre-ten-

sioner connector, check the system function. Refer to ``SRS Operation Check'' (RS-30) for details.

+Do not disassemble buckle or seat belt assembly.

+Replace anchor bolts if they are deformed or worn out.

+Never oil tongue and buckle.

+If any component of seat belt assembly is questionable, do not repair. Replace the whole seat belt

assembly.

+If webbing is cut, frayed, or damaged, replace seat belt assembly.

+When replacing seat belt assembly, use a genuine seat belt assembly.

+After any collision, inspect all seat belt assemblies, including retractors and other attached hard-

wares (i.e., guide rail set).

SEAT BELTS

RS-2

Page 1130 of 1226

Precautions for SRS ``AIR BAG'' and ``Seat Belt

Pre-tensioner'' Service

+Do not use a circuit tester to check SRS circuits unless instructed to in this Service Manual.

+Before servicing the SRS, turn ignition switch ``OFF'', disconnect both battery cables and wait for at least

3 minutes.

For approximately 3 minutes after the cables are removed, it is still possible for the air bag and seat belt

pre-tensioner to deploy. Therefore, do not work on any SRS connectors or wires until at least 3 minutes

have passed.

+Diagnosis sensor unit must always be installed with their arrow marks ``

S'' pointing towards the front of

the vehicle for proper operation. Also check diagnosis sensor unit for cracks, deformities or rust before

installation and replace as required.

+The spiral cable must be aligned with the neutral position since its rotations are limited. Do not attempt to

turn steering wheel or column after removal of steering gear.

+Handle air bag module carefully. Always place it with the pad side facing upward.

+Conduct self-diagnosis to check entire SRS for proper function after replacing any components.

+Instrument panel assembly should be replaced after air bag in¯ates if damaged.

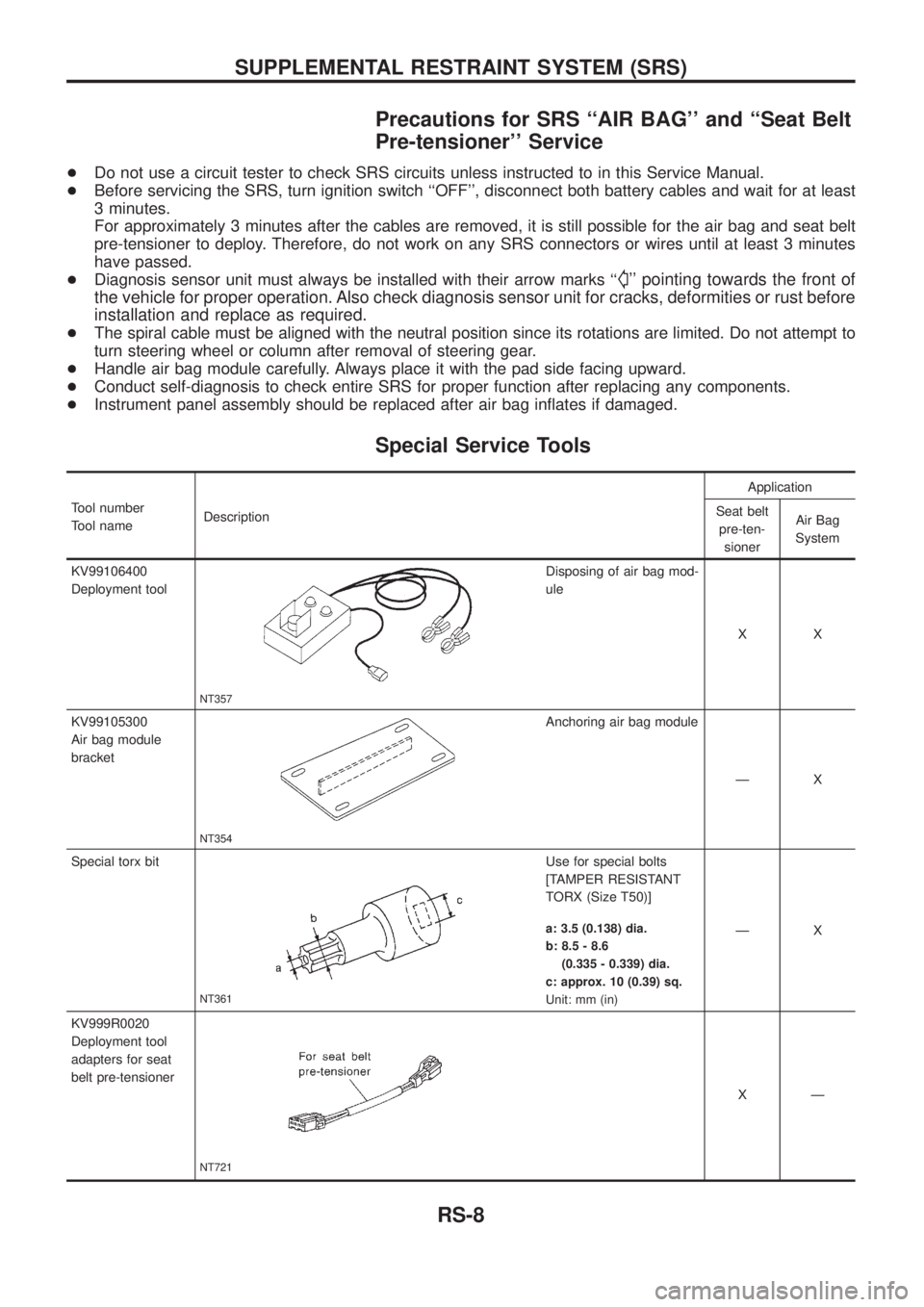

Special Service Tools

Tool number

Tool nameDescriptionApplication

Seat belt

pre-ten-

sionerAir Bag

System

KV99106400

Deployment tool

NT357

Disposing of air bag mod-

ule

XX

KV99105300

Air bag module

bracket

NT354

Anchoring air bag module

ÐX

Special torx bit

NT361

Use for special bolts

[TAMPER RESISTANT

TORX (Size T50)]

a: 3.5 (0.138) dia.

b: 8.5 - 8.6

(0.335 - 0.339) dia.

c: approx. 10 (0.39) sq.

Unit: mm (in)ÐX

KV999R0020

Deployment tool

adapters for seat

belt pre-tensioner

NT721

XÐ

SUPPLEMENTAL RESTRAINT SYSTEM (SRS)

RS-8

Page 1134 of 1226

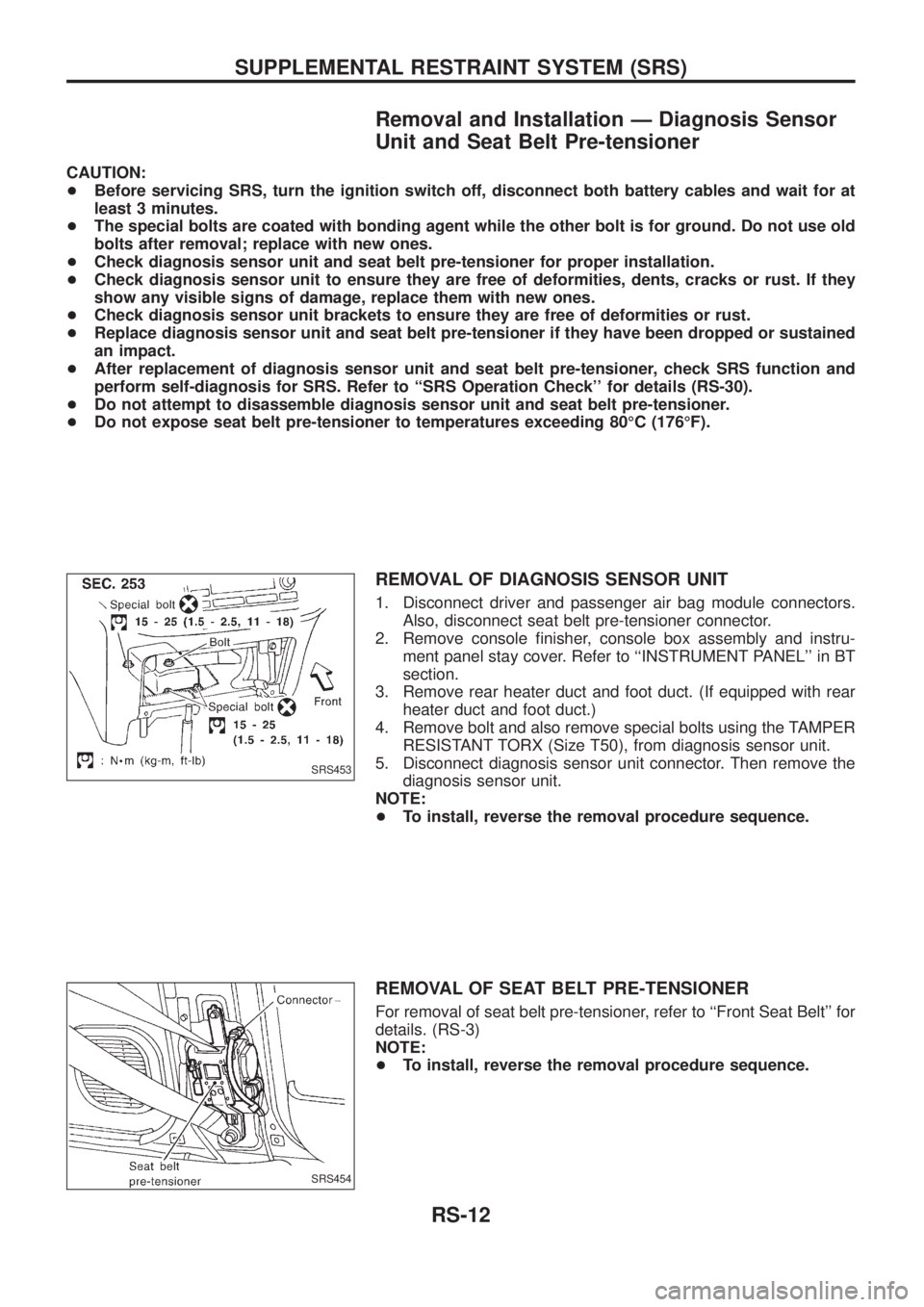

Removal and Installation Ð Diagnosis Sensor

Unit and Seat Belt Pre-tensioner

CAUTION:

+Before servicing SRS, turn the ignition switch off, disconnect both battery cables and wait for at

least 3 minutes.

+The special bolts are coated with bonding agent while the other bolt is for ground. Do not use old

bolts after removal; replace with new ones.

+Check diagnosis sensor unit and seat belt pre-tensioner for proper installation.

+Check diagnosis sensor unit to ensure they are free of deformities, dents, cracks or rust. If they

show any visible signs of damage, replace them with new ones.

+Check diagnosis sensor unit brackets to ensure they are free of deformities or rust.

+Replace diagnosis sensor unit and seat belt pre-tensioner if they have been dropped or sustained

an impact.

+After replacement of diagnosis sensor unit and seat belt pre-tensioner, check SRS function and

perform self-diagnosis for SRS. Refer to ``SRS Operation Check'' for details (RS-30).

+Do not attempt to disassemble diagnosis sensor unit and seat belt pre-tensioner.

+Do not expose seat belt pre-tensioner to temperatures exceeding 80ÉC (176ÉF).

REMOVAL OF DIAGNOSIS SENSOR UNIT

1. Disconnect driver and passenger air bag module connectors.

Also, disconnect seat belt pre-tensioner connector.

2. Remove console ®nisher, console box assembly and instru-

ment panel stay cover. Refer to ``INSTRUMENT PANEL'' in BT

section.

3. Remove rear heater duct and foot duct. (If equipped with rear

heater duct and foot duct.)

4. Remove bolt and also remove special bolts using the TAMPER

RESISTANT TORX (Size T50), from diagnosis sensor unit.

5. Disconnect diagnosis sensor unit connector. Then remove the

diagnosis sensor unit.

NOTE:

+To install, reverse the removal procedure sequence.

REMOVAL OF SEAT BELT PRE-TENSIONER

For removal of seat belt pre-tensioner, refer to ``Front Seat Belt'' for

details. (RS-3)

NOTE:

+To install, reverse the removal procedure sequence.

SRS453

SRS454

SUPPLEMENTAL RESTRAINT SYSTEM (SRS)

RS-12