engine NISSAN PATROL 2006 User Guide

[x] Cancel search | Manufacturer: NISSAN, Model Year: 2006, Model line: PATROL, Model: NISSAN PATROL 2006Pages: 1226, PDF Size: 37.18 MB

Page 44 of 1226

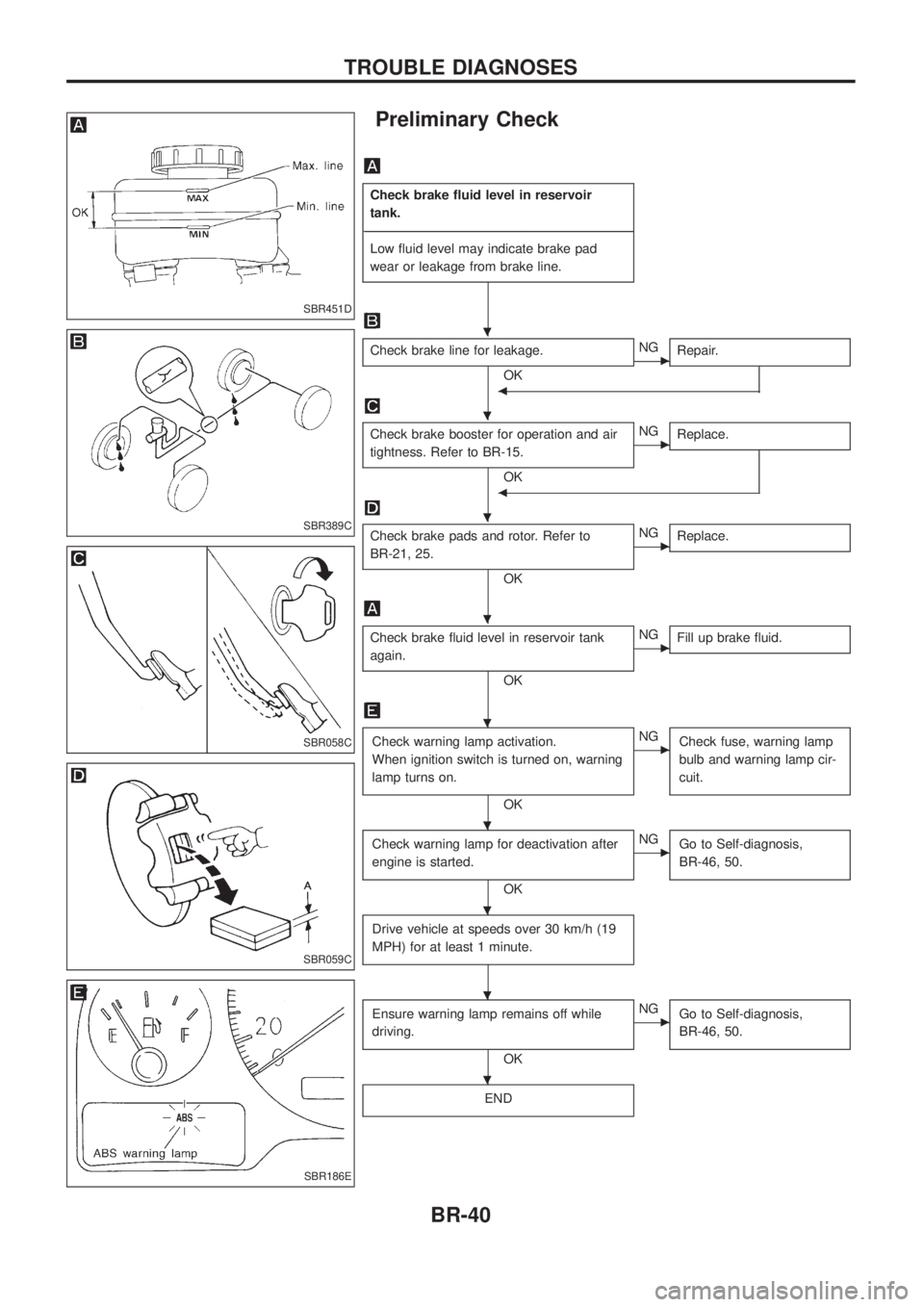

Preliminary Check

Check brake ¯uid level in reservoir

tank.

- ---------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------

Low ¯uid level may indicate brake pad

wear or leakage from brake line.

Check brake line for leakage.

OKcNG Repair.

b

Check brake booster for operation and air

tightness. Refer to BR-15.

OK

cNGReplace.

b

Check brake pads and rotor. Refer to

BR-21, 25.

OK

cNGReplace.

Check brake ¯uid level in reservoir tank

again.

OK

cNGFill up brake ¯uid.

Check warning lamp activation.

When ignition switch is turned on, warning

lamp turns on.

OK

cNG

Check fuse, warning lamp

bulb and warning lamp cir-

cuit.

Check warning lamp for deactivation after

engine is started.

OK

cNGGo to Self-diagnosis,

BR-46, 50.

Drive vehicle at speeds over 30 km/h (19

MPH) for at least 1 minute.

Ensure warning lamp remains off while

driving.

OK

cNGGo to Self-diagnosis,

BR-46, 50.

END

SBR451D

SBR389C

SBR058C

SBR059C

SBR186E

.

.

.

.

.

.

.

.

.

TROUBLE DIAGNOSES

BR-40

Page 55 of 1226

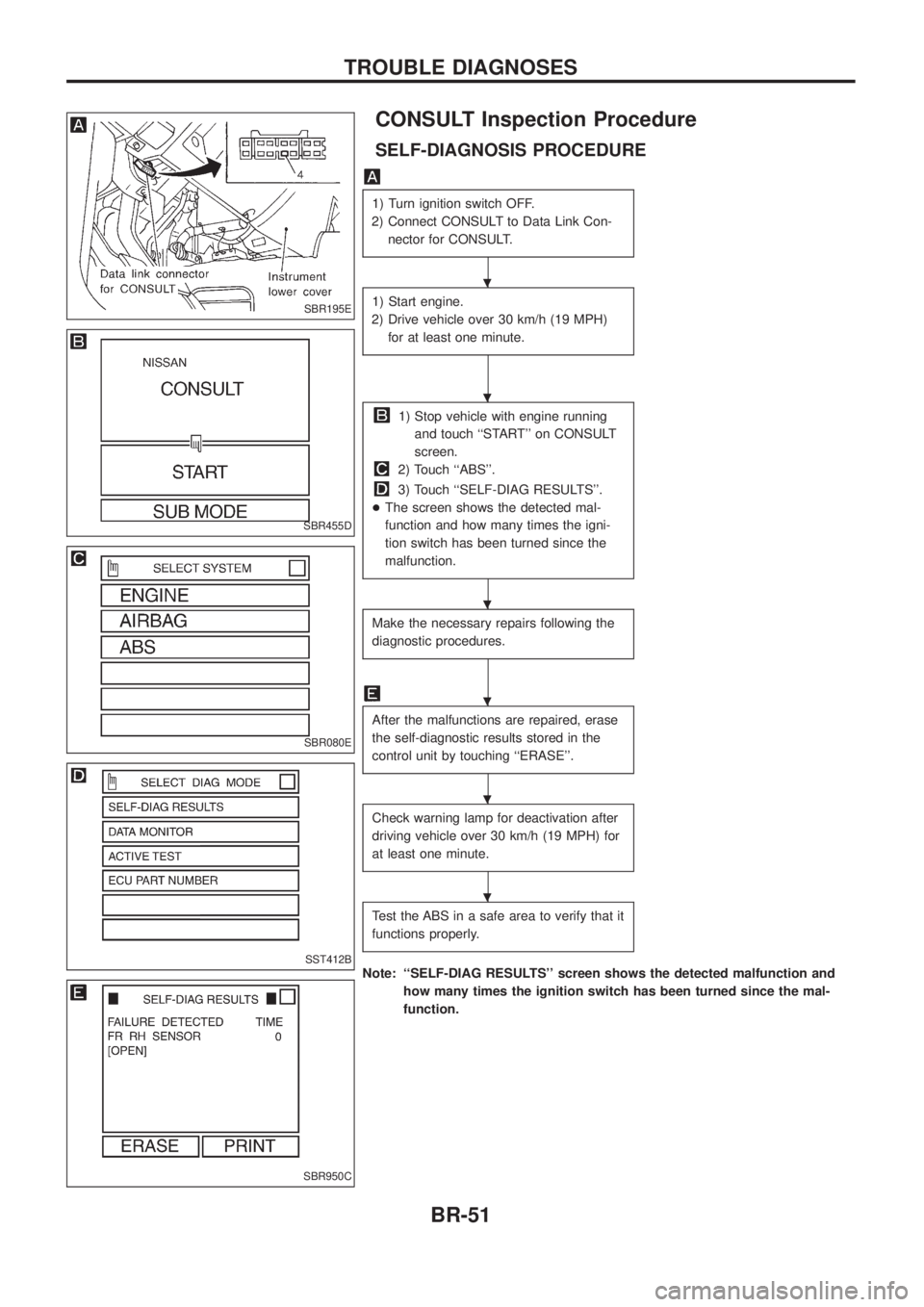

CONSULT Inspection Procedure

SELF-DIAGNOSIS PROCEDURE

1) Turn ignition switch OFF.

2) Connect CONSULT to Data Link Con- nector for CONSULT.

1) Start engine.

2) Drive vehicle over 30 km/h (19 MPH) for at least one minute.

1) Stop vehicle with engine runningand touch ``START'' on CONSULT

screen.

2) Touch ``ABS''.

3) Touch ``SELF-DIAG RESULTS''.

+ The screen shows the detected mal-

function and how many times the igni-

tion switch has been turned since the

malfunction.

Make the necessary repairs following the

diagnostic procedures.

After the malfunctions are repaired, erase

the self-diagnostic results stored in the

control unit by touching ``ERASE''.

Check warning lamp for deactivation after

driving vehicle over 30 km/h (19 MPH) for

at least one minute.

Test the ABS in a safe area to verify that it

functions properly.

Note: ``SELF-DIAG RESULTS'' screen shows the detected malfunction and how many times the ignition switch has been turned since the mal-

function.

SBR195E

SBR455D

SBR080E

SST412B

SBR950C

.

.

.

.

.

.

TROUBLE DIAGNOSES

BR-51

Page 58 of 1226

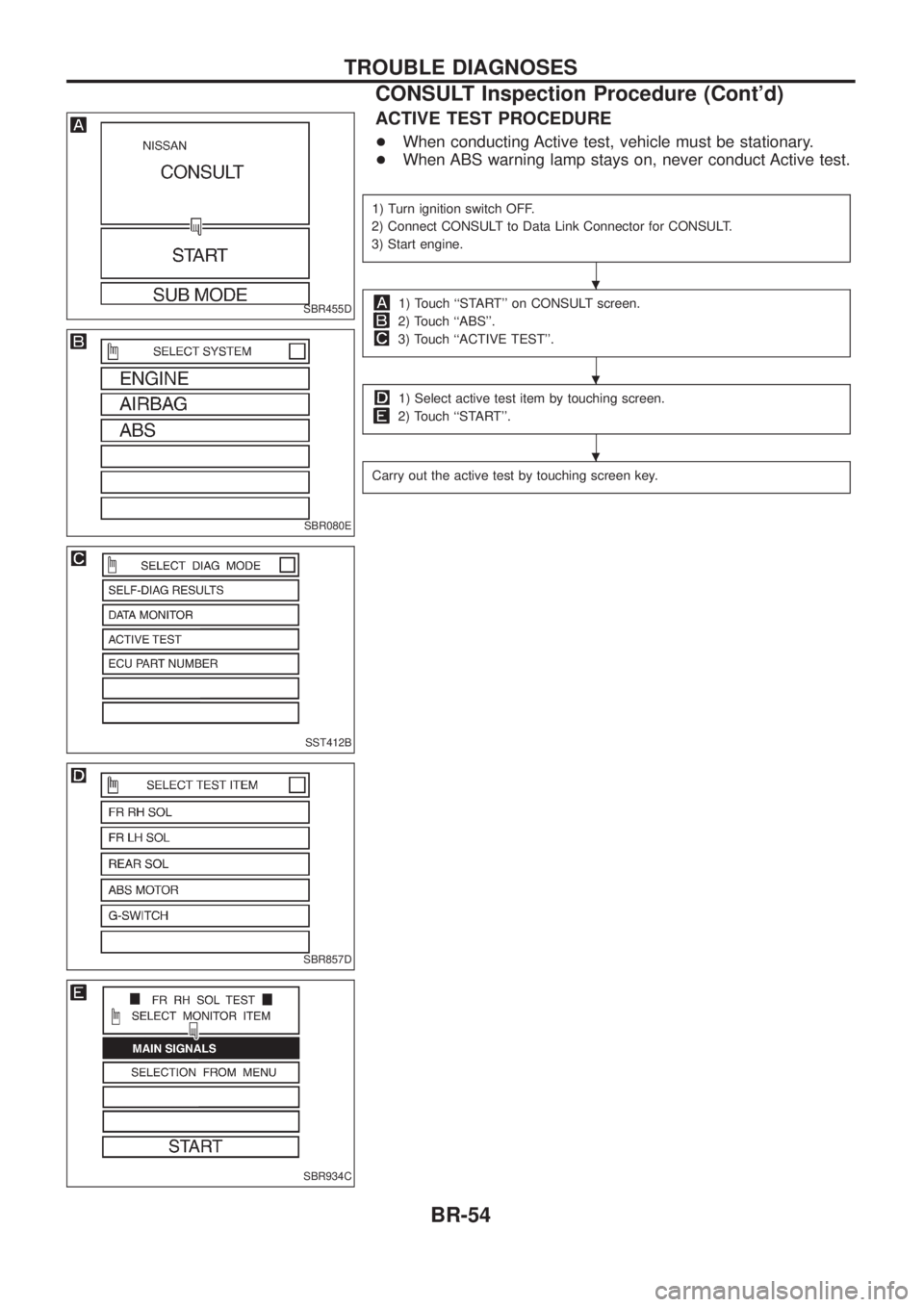

ACTIVE TEST PROCEDURE

+When conducting Active test, vehicle must be stationary.

+ When ABS warning lamp stays on, never conduct Active test.

1) Turn ignition switch OFF.

2) Connect CONSULT to Data Link Connector for CONSULT.

3) Start engine.

1) Touch ``START'' on CONSULT screen.

2) Touch ``ABS''.

3) Touch ``ACTIVE TEST''.

1) Select active test item by touching screen.

2) Touch ``START''.

Carry out the active test by touching screen key.

SBR455D

SBR080E

SST412B

SBR857D

SBR934C

.

.

.

TROUBLE DIAGNOSES

CONSULT Inspection Procedure (Cont'd)

BR-54

Page 59 of 1226

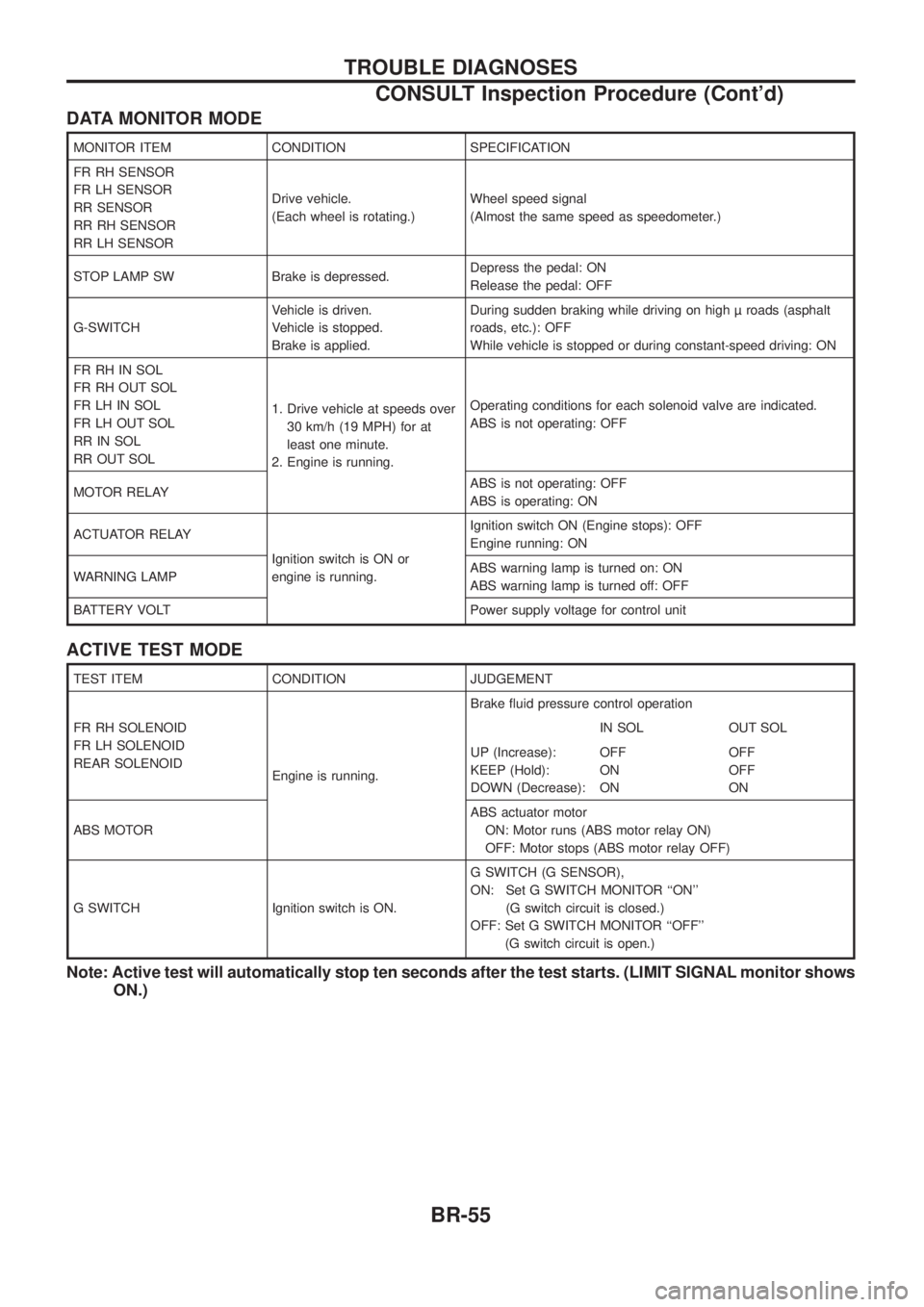

DATA MONITOR MODE

MONITOR ITEM CONDITION SPECIFICATION

FR RH SENSOR

FR LH SENSOR

RR SENSOR

RR RH SENSOR

RR LH SENSORDrive vehicle.

(Each wheel is rotating.)

Wheel speed signal

(Almost the same speed as speedometer.)

STOP LAMP SW Brake is depressed. Depress the pedal: ON

Release the pedal: OFF

G-SWITCH Vehicle is driven.

Vehicle is stopped.

Brake is applied.During sudden braking while driving on high roads (asphalt

roads, etc.): OFF

While vehicle is stopped or during constant-speed driving: ON

FR RH IN SOL

FR RH OUT SOL

FR LH IN SOL

FR LH OUT SOL

RR IN SOL

RR OUT SOL 1. Drive vehicle at speeds over

30 km/h (19 MPH) for at

least one minute.

2. Engine is running. Operating conditions for each solenoid valve are indicated.

ABS is not operating: OFF

MOTOR RELAY ABS is not operating: OFF

ABS is operating: ON

ACTUATOR RELAY Ignition switch is ON or

engine is running.Ignition switch ON (Engine stops): OFF

Engine running: ON

WARNING LAMP ABS warning lamp is turned on: ON

ABS warning lamp is turned off: OFF

BATTERY VOLT Power supply voltage for control unit

ACTIVE TEST MODE

TEST ITEM CONDITION JUDGEMENT

FR RH SOLENOID

FR LH SOLENOID

REAR SOLENOID Engine is running.Brake ¯uid pressure control operation

IN SOL OUT SOL

UP (Increase):

KEEP (Hold):

DOWN (Decrease): OFF

ON

ONOFF

OFF

ON

ABS MOTOR ABS actuator motor

ON: Motor runs (ABS motor relay ON)

OFF: Motor stops (ABS motor relay OFF)

G SWITCH Ignition switch is ON. G SWITCH (G SENSOR),

ON: Set G SWITCH MONITOR ``ON''

(G switch circuit is closed.)

OFF: Set G SWITCH MONITOR ``OFF'' (G switch circuit is open.)

Note: Active test will automatically stop ten seconds after the test starts. (LIMIT SIGNAL monitor shows ON.)

TROUBLE DIAGNOSES

CONSULT Inspection Procedure (Cont'd)

BR-55

Page 72 of 1226

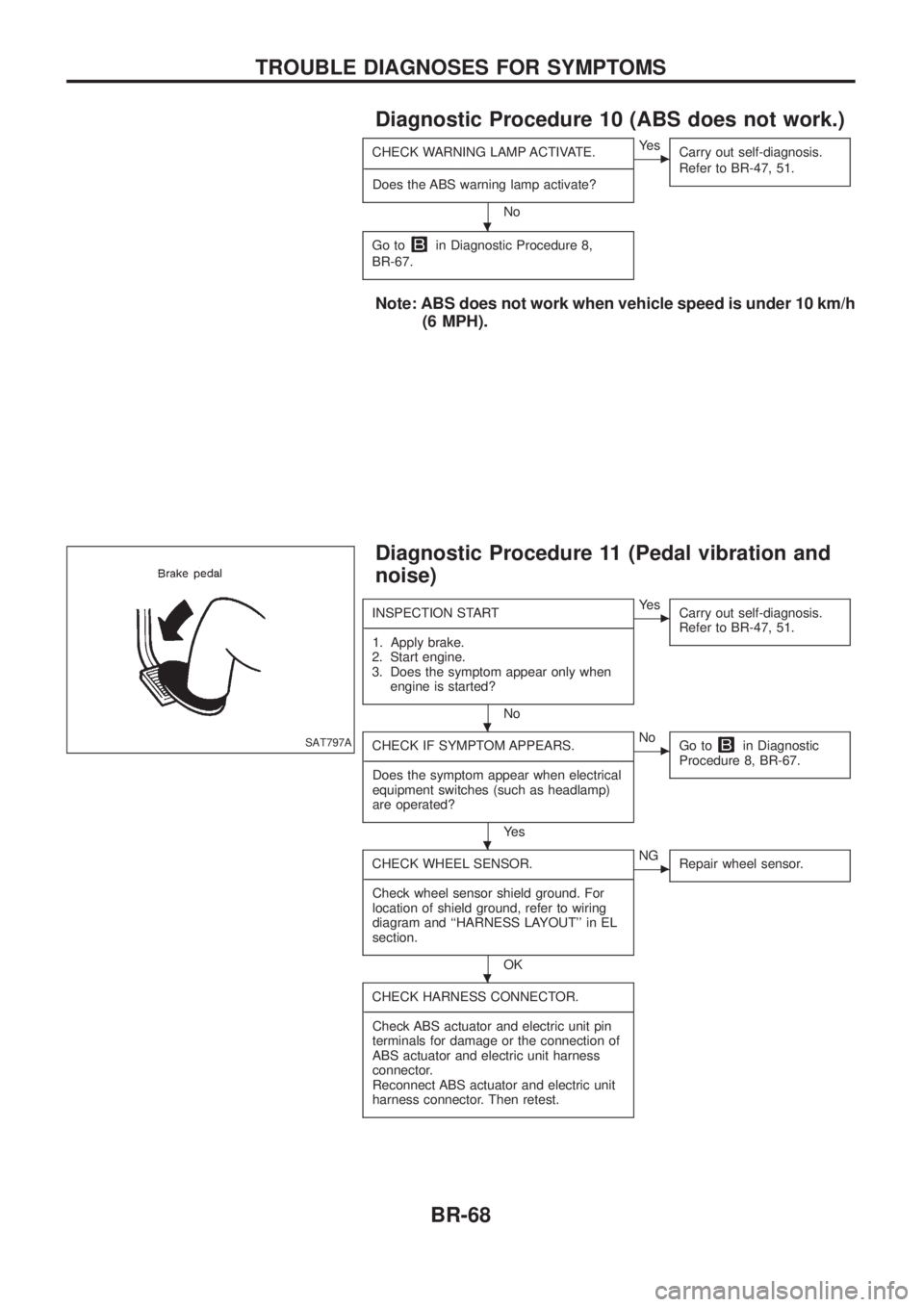

Diagnostic Procedure 10 (ABS does not work.)

CHECK WARNING LAMP ACTIVATE.

- ---------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------

Does the ABS warning lamp activate?

No

cYe s Carry out self-diagnosis.

Refer to BR-47, 51.

Go toin Diagnostic Procedure 8,

BR-67.

Note: ABS does not work when vehicle speed is under 10 km/h (6 MPH).

Diagnostic Procedure 11 (Pedal vibration and

noise)

INSPECTION START

- ---------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------

1. Apply brake.

2. Start engine.

3. Does the symptom appear only when engine is started?

No

cYe s Carry out self-diagnosis.

Refer to BR-47, 51.

CHECK IF SYMPTOM APPEARS.

- ---------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------

Does the symptom appear when electrical

equipment switches (such as headlamp)

are operated?

Ye s

cNo Go toin Diagnostic

Procedure 8, BR-67.

CHECK WHEEL SENSOR.

- ---------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------

Check wheel sensor shield ground. For

location of shield ground, refer to wiring

diagram and ``HARNESS LAYOUT'' in EL

section.

OK

cNG Repair wheel sensor.

CHECK HARNESS CONNECTOR.

- ---------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------

Check ABS actuator and electric unit pin

terminals for damage or the connection of

ABS actuator and electric unit harness

connector.

Reconnect ABS actuator and electric unit

harness connector. Then retest.

SAT797A

.

.

.

.

TROUBLE DIAGNOSES FOR SYMPTOMS

BR-68

Page 73 of 1226

Note: ABS may operate and cause vibration under any of thefollowing conditions.

+ Applying brake gradually when shifting or operating

clutch.

+ Low friction (slippery) road.

+ High speed cornering.

+ Driving over bumps and pot holes.

+ Engine speed is over 5,000 rpm with vehicle stopped.

Diagnostic Procedure 12 (Warning lamp does

not come on when ignition switch is turned

ON.)

CHECK FUSE.

- ---------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------

Check 10A fuse

28. For fuse layout, refer

to POWER SUPPLY ROUTING in EL sec-

tion.

OK

cNG Replace fuse.

CHECK WARNING LAMP ACTIVATE.

- ---------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------

Disconnect ABS actuator and electric unit

connector.

Does the warning lamp activate?

No

cYe s jA(Go to next page.)

CHECK HARNESS FOR SHORT.

- ---------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------

1. Disconnect ABS actuator and electric unit connector.

2. Check voltage between ABS actuator and electric unit connector

E18(body

side) terminal j

21and ground.

Battery voltage should not exist.

OK

cNG Repair harness or connec-

tor.

CHECK COMBINATION METER.

- ---------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------------

Check combination meter. Refer to

WARNING LAMPS in EL section.

SBR205E

SBR186E

SBR144EB

.

.

.

TROUBLE DIAGNOSES FOR SYMPTOMS

Diagnostic Procedure 11 (Pedal vibration and

noise) (Cont'd)

BR-69

Page 77 of 1226

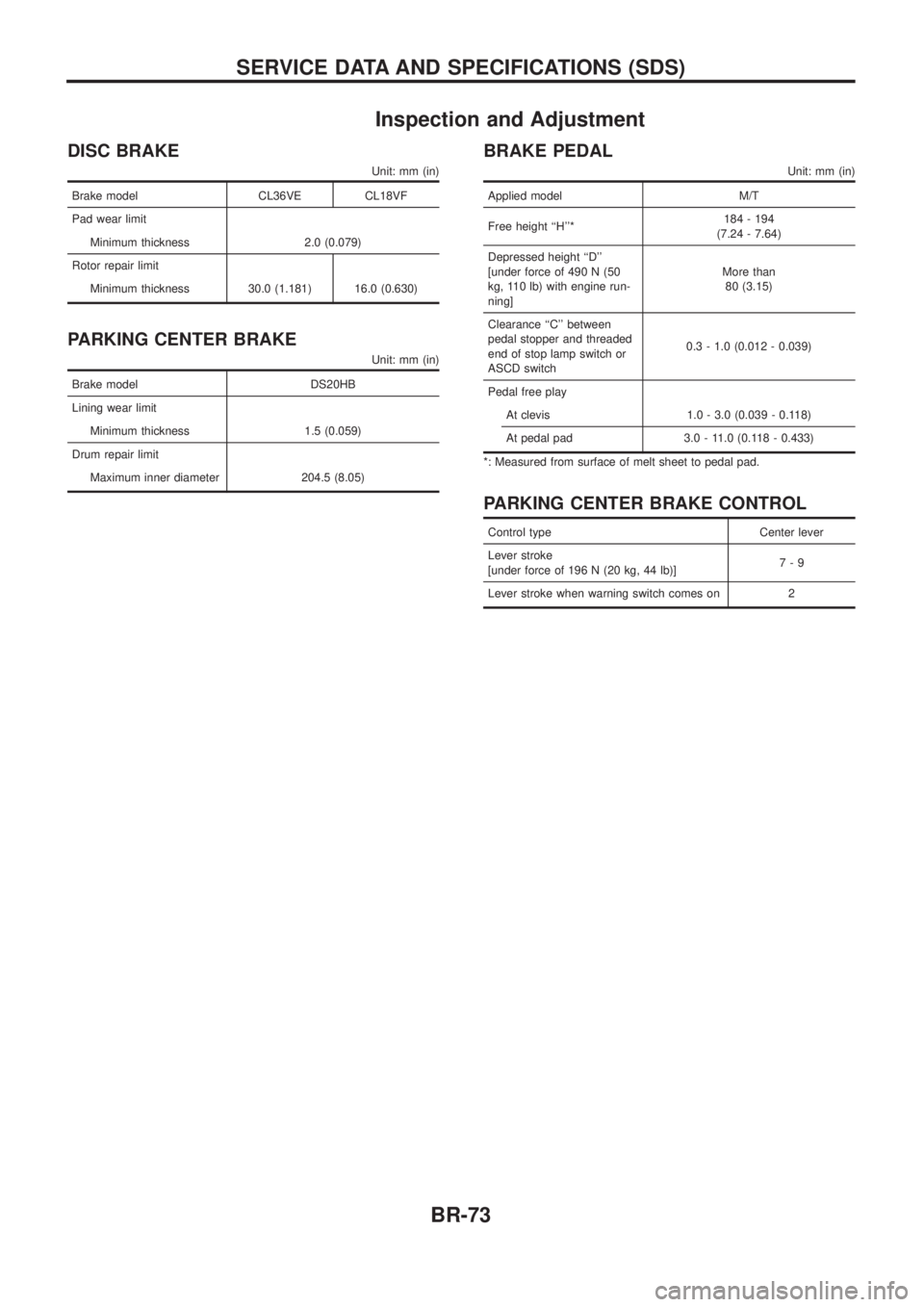

Inspection and Adjustment

DISC BRAKE

Unit: mm (in)

Brake model CL36VE CL18VF

Pad wear limit

Minimum thickness 2.0 (0.079)

Rotor repair limit

Minimum thickness 30.0 (1.181) 16.0 (0.630)

PARKING CENTER BRAKE

Unit: mm (in)

Brake model DS20HB

Lining wear limit

Minimum thickness 1.5 (0.059)

Drum repair limit

Maximum inner diameter 204.5 (8.05)

BRAKE PEDAL

Unit: mm (in)

Applied model M/T

Free height ``H''*184 - 194

(7.24 - 7.64)

Depressed height ``D''

[under force of 490 N (50

kg, 110 lb) with engine run-

ning]More than

80 (3.15)

Clearance ``C'' between

pedal stopper and threaded

end of stop lamp switch or

ASCD switch0.3 - 1.0 (0.012 - 0.039)

Pedal free play

At clevis 1.0 - 3.0 (0.039 - 0.118)

At pedal pad 3.0 - 11.0 (0.118 - 0.433)

*: Measured from surface of melt sheet to pedal pad.

PARKING CENTER BRAKE CONTROL

Control type Center lever

Lever stroke

[under force of 196 N (20 kg, 44 lb)]7-9

Lever stroke when warning switch comes on 2

SERVICE DATA AND SPECIFICATIONS (SDS)

BR-73

Page 78 of 1226

BODY & TRIM

SECTION

BT

CONTENTS

PRECAUTIONS ...............................................................1

Service Notice..............................................................1

Supplemental Restraint System (SRS) ``AIR

BAG''and``SEATBELTPRE-TENSIONER''...............1

GENERAL SERVICING ...................................................2

Clip and Fastener ........................................................2

BODY END ......................................................................4

Body Front End............................................................4

Body Rear End and Opener ........................................6

DOOR ........................................................................\

.......9

Front Door....................................................................9

Rear Door ..................................................................10

INSTRUMENT PANEL ................................................... 11

INTERIOR TRIM ............................................................14

Side and Floor Trim ...................................................14

Door Trim ...................................................................18

Roof Trim ...................................................................20

Back Door Trim ..........................................................24 EXTERIOR

.....................................................................26

SEAT ........................................................................\

......32

Front Seat ..................................................................32

Heated Seat ...............................................................34

Rear Seat...................................................................35

3rd Seat .....................................................................37

SUNROOF ......................................................................39

WINDSHIELD AND WINDOWS ....................................42

Windshield .................................................................43

Rear Side Window .....................................................44

Back Door Window ....................................................45

MIRROR ........................................................................\

.46

Door Mirror.................................................................46

CAB BODY ....................................................................47

Body Mounting ...........................................................48

BODY ALIGNMENT .......................................................49

Engine Compartment .................................................49

Underbody .................................................................51

. For seat belt, refer to MA and RS section.

. For wiring diagrams of body electrical systems, refer to EL section.

BT

Page 82 of 1226

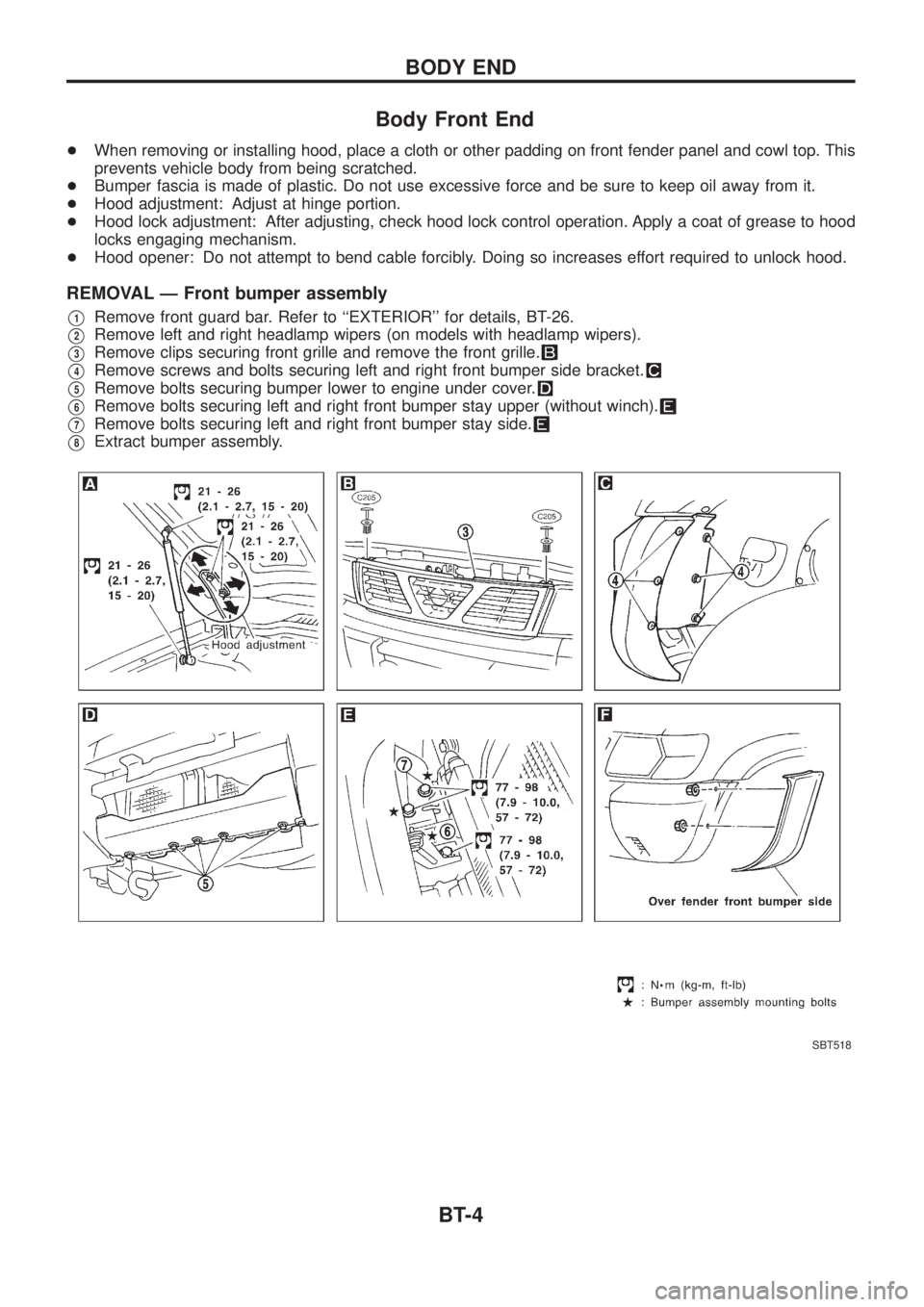

Body Front End

+When removing or installing hood, place a cloth or other padding on front fender panel and cowl top. This

prevents vehicle body from being scratched.

+Bumper fascia is made of plastic. Do not use excessive force and be sure to keep oil away from it.

+Hood adjustment: Adjust at hinge portion.

+Hood lock adjustment: After adjusting, check hood lock control operation. Apply a coat of grease to hood

locks engaging mechanism.

+Hood opener: Do not attempt to bend cable forcibly. Doing so increases effort required to unlock hood.

REMOVAL Ð Front bumper assembly

V1Remove front guard bar. Refer to ``EXTERIOR'' for details, BT-26.

V2Remove left and right headlamp wipers (on models with headlamp wipers).

V3Remove clips securing front grille and remove the front grille.

V4Remove screws and bolts securing left and right front bumper side bracket.

V5Remove bolts securing bumper lower to engine under cover.

V6Remove bolts securing left and right front bumper stay upper (without winch).

V7Remove bolts securing left and right front bumper stay side.

V8Extract bumper assembly.

SBT518

BODY END

BT-4

Page 125 of 1226

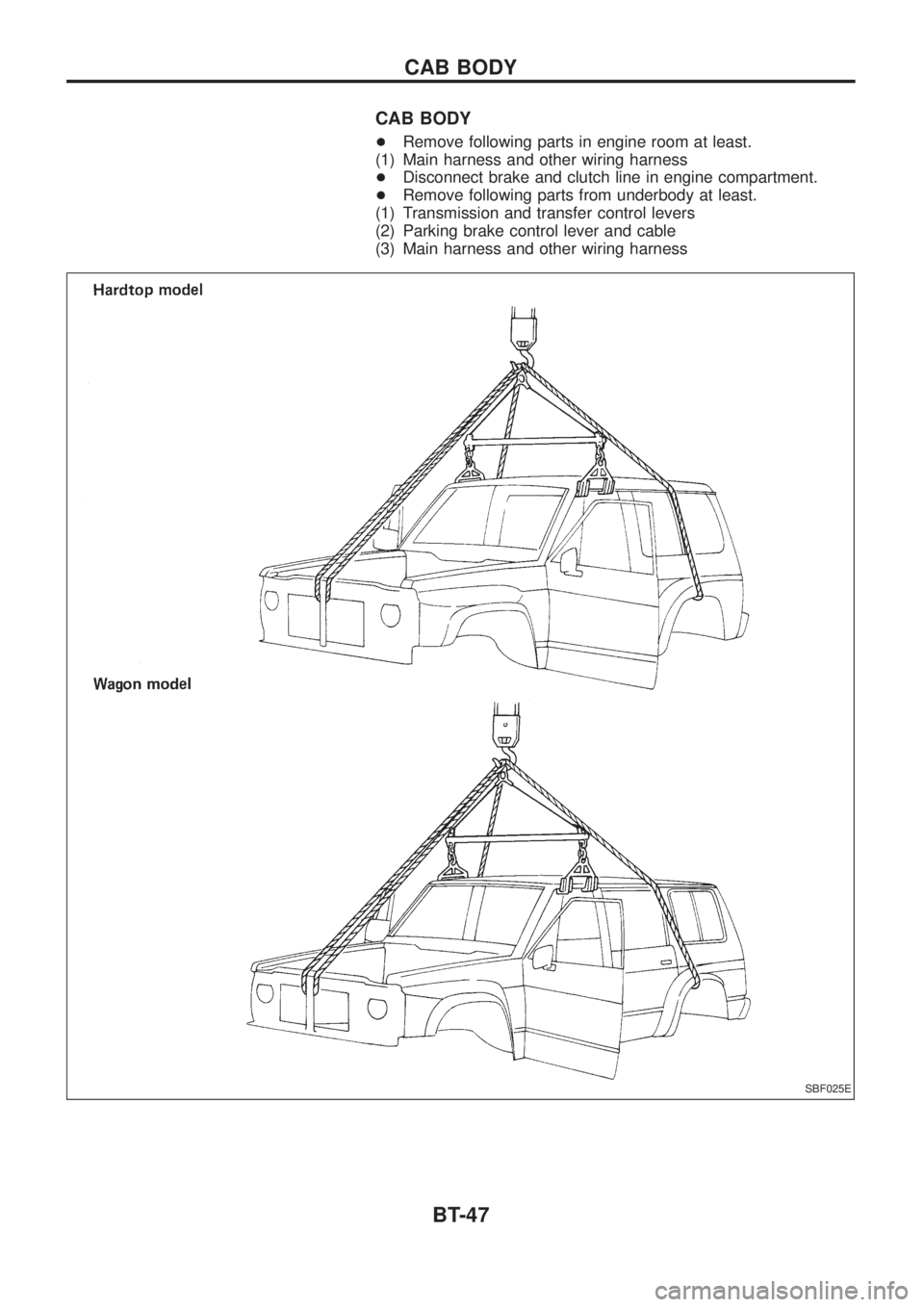

CAB BODY

+Remove following parts in engine room at least.

(1) Main harness and other wiring harness

+Disconnect brake and clutch line in engine compartment.

+Remove following parts from underbody at least.

(1) Transmission and transfer control levers

(2) Parking brake control lever and cable

(3) Main harness and other wiring harness

SBF025E

CAB BODY

BT-47